Page 1

User’s Manual

MANUALplus

4110

NC Software

526 488-xx

English (en)

9/2007

Page 2

MANUALplus 4110, Software and Functions

This manual describes functions that are available in

MANUALplus 4110 controls with NC software numbers

507 807-xx and 526 488-xx.

The machine manufacturer adapts the features offered by the control

to the capabilities of the specific machine tool by setting machine

parameters. Therefore, some of the functions described in this manual

may not be among the features provided by the MANUALplus on your

machine tool.

Some of the MANUALplus functions which are not available on every

machine are:

Positioning of spindle (M19) and driven tool

Machining with the C Axis

Please contact your machine manufacturer for detailed information on

the features that are supported by your machine tool.

Many machine manufacturers and HEIDENHAIN offer programming

courses for the MANUALplus controls. We recommend these courses

as an effective way of improving your programming skills and sharing

information and ideas with other MANUALplus users.

HEIDENHAIN also offers the PC software DataPilot 4110 which is

designed to simulate the functions of the MANUALplus 4110 control.

The DataPilot is suitable for both shop-floor programming as well as

off-location program creation and testing. It is also ideal for training

purposes. The DataPilot can be run on WINDOWS operating systems.

Intended place of operation

The MANUALplus 4110 complies with EN 55022, Class A, and is

intended primarily for operation in industrially zoned areas.

Page 3

Contents

Introduction and Fundamentals

1

Basics of Operation

Machine Mode of Operation

Cycle Programming

ICP Programming

DIN Programming

Tool Management Mode

Organization Mode of Operation

Examples

Tables and Overviews

2

3

4

5

6

7

8

9

10

HEIDENHAIN MANUALplus 4110 3

Page 4

Page 5

1 Introduction and Fundamentals 19

1.1 The MANUALplus ..... 20

The C axis ..... 20

1.2 Features ..... 21

1.3 MANUALplus Design ..... 22

Lathe design ..... 22

Machine operating panel ..... 24

1.4 Axis Designations and Coordinate System ..... 25

Axis designations ..... 25

Coordinate system ..... 25

Absolute coordinates ..... 26

Incremental coordinates ..... 26

Polar coordinates ..... 26

1.5 Machine Reference Points ..... 27

Machine zero point ..... 27

Workpiece zero point ..... 27

Reference points ..... 27

1.6 Tool Dimensions ..... 28

Tool length ..... 28

Tool compensation ..... 28

Tool-tip radius compensation (TRC) ..... 28

Milling cutter radius compensation (MCRC) ..... 29

HEIDENHAIN MANUALplus 4110 5

Page 6

2 Basics of Operation 31

2.1 The MANUALplus Screen ..... 32

2.2 Operation and Data Input ..... 33

Modes of operation ..... 33

Menu selection ..... 33

Soft keys ..... 33

Data input ..... 34

List operations ..... 34

Alphanumeric keyboard ..... 35

2.3 Error Messages ..... 36

Direct error messages ..... 36

Error display ..... 36

Clearing an error message ..... 37

System error, internal error ..... 37

PLC error, PLC status display ..... 37

Warnings during simulation ..... 38

2.4 Explanation of Terms ..... 39

6

Page 7

3 Machine Mode of Operation 41

3.1 Machine Mode of Operation ..... 42

3.2 Switch-On / Switch-Off ..... 43

Switch-on ..... 43

Traversing the reference marks ..... 43

Monitoring EnDat encoders ..... 44

Switch-off ..... 45

3.3 Machine Data ..... 46

Input and display of machine data ..... 46

Tool call ..... 47

Tools in different quadrants ..... 48

Feed rate ..... 48

Spindle ..... 49

3.4 Machine Setup ..... 50

Defining the workpiece zero point ..... 50

Setting the protection zone ..... 51

Defining the tool change position ..... 52

Setting C-axis values ..... 53

3.5 Setting up Tools ..... 54

Tool compensation ..... 58

Tool life monitoring ..... 59

3.6 Manual Mode ..... 60

Tool change ..... 60

Spindle ..... 60

Handwheel operation ..... 60

Jog operation (joystick) ..... 60

Cycles in Manual mode ..... 61

3.7 Teach-In Mode ..... 62

3.8 Program Run Mode ..... 63

Faulty programs ..... 63

Before executing a program ..... 63

Start block search and program execution ..... 64

Entering compensation values during program execution ..... 65

Setting compensation values with the handwheel ..... 66

Program execution in “dry run” mode ..... 67

HEIDENHAIN MANUALplus 4110 7

Page 8

3.9 Graphic Simulation ..... 68

Views ..... 70

Graphic elements ..... 71

Warnings ..... 72

Magnify / Reduce ..... 73

3.10 Time Calculation ..... 74

3.11 Program Management ..... 75

Program information ..... 75

Functions for program management ..... 76

3.12 Conversion into DIN Format ..... 77

3.13 Inch Mode ..... 78

4 Cycle Programming 79

4.1 Working with Cycles ..... 80

Starting point of cycles ..... 80

Cycle transitions ..... 80

DIN macros ..... 81

Graphical test run (simulation) ..... 81

Cycle keys ..... 81

Switching functions (M functions) ..... 82

Comments ..... 82

Cycle menu ..... 83

Soft keys in cycle programming ..... 84

4.2 Workpiece Blank Cycles ..... 85

Blank—bar/tube ..... 86

ICP workpc. blank contour ..... 87

4.3 Single Cut Cycles ..... 88

Rapid traverse positioning ..... 89

Approach the tool change position ..... 90

Linear machining, longitudinal ..... 91

Linear machining, transverse ..... 92

Linear machining at angle ..... 93

Circular machining ..... 94

Chamfer ..... 95

Rounding ..... 96

M functions ..... 97

8

Page 9

4.4 Roughing Cycles ..... 98

Roughing, longitudinal/transverse ..... 101

Roughing, longitudinal/transverse—Expanded ..... 103

Finishing cut, longitudinal/transverse ..... 105

Finishing cut, longitudinal/transverse—Expanded ..... 107

Plunge longitudinal/transverse ..... 109

Plunge, longitudinal/transverse—Expanded ..... 111

Finishing plunge, longitudinal/transverse ..... 113

Finishing plunge, longitudinal/transverse—Expanded ..... 115

ICP contour-parallel, longitudinal/transverse ..... 117

ICP contour-parallel finishing, longitudinal/transverse ..... 119

ICP roughing, longitudinal/transverse ..... 121

ICP finishing, longitudinal or transverse ..... 123

Examples of roughing cycles ..... 125

4.5 Recessing cycles ..... 129

Recessing, radial/axial ..... 131

Recessing, radial/axial—Expanded ..... 133

Recessing radial/axial, finishing ..... 135

Recessing radial/axial, finishing—Expanded ..... 137

ICP recessing cycles ..... 139

ICP recessing radial/axial, finishing ..... 141

Recess turning ..... 143

Recess turning, radial/axial ..... 144

Recess turning, radial/axial—Expanded ..... 146

Recess turning radial/axial, finishing ..... 148

Recess turning radial/axial, finishing—Expanded ..... 150

ICP recess turning, radial/axial ..... 152

ICP recess turning radial/axial, finishing ..... 154

Undercut type H ..... 156

Undercut type K ..... 157

Undercut type U ..... 158

Parting ..... 159

Examples of recessing cycles ..... 160

HEIDENHAIN MANUALplus 4110 9

Page 10

4.6 Thread and Undercut Cycles ..... 162

Thread cycle (longitudinal) ..... 165

Thread cycle (longitudinal)—Expanded ..... 166

Tapered thread ..... 168

API thread ..... 170

Recut (longitudinal) thread ..... 172

Recut (longitudinal) thread—Expanded ..... 174

Recut tapered thread ..... 176

Recut API thread ..... 178

Undercut DIN 76 ..... 180

Undercut DIN 509 E ..... 182

Undercut DIN 509 F ..... 184

Examples of thread and undercut cycles ..... 186

4.7 Drilling Cycles ..... 190

Drilling, axial/radial ..... 191

Deep-hole drilling, axial/radial ..... 193

Tapping, axial/radial ..... 195

Thread milling, axial ..... 197

Examples of drilling cycles ..... 199

4.8 Milling Cycles ..... 201

Rapid traverse positioning ..... 202

Slot, axial ..... 203

Figure, axial ..... 204

ICP contour, axial ..... 208

Face milling ..... 211

Slot, radial ..... 215

Figure, radial ..... 216

ICP contour, radial ..... 220

Helical-slot milling, radial ..... 223

Cutting direction for contour milling and pocket milling ..... 224

Examples of milling cycles ..... 226

4.9 Drilling/Milling Patterns ..... 227

Drilling/milling pattern linear, axial ..... 228

Drilling/milling pattern circular, axial ..... 230

Drilling/milling pattern linear, radial ..... 232

Drilling/milling pattern circular, radial ..... 234

Examples of pattern machining ..... 236

4.10 DIN Cycles ..... 239

10

Page 11

5 ICP Programming 241

5.1 ICP Contours ..... 242

5.2 Editing ICP Contours ..... 243

Programming and adding to ICP contours ..... 244

Absolute or incremental dimensions ..... 244

Transitions between contour elements ..... 245

Contour graphics ..... 246

Changing the ICP contour graphics ..... 247

Selection of solutions ..... 248

Contour direction ..... 249

5.3 Importing of DXF Contours ..... 250

Fundamentals ..... 250

DXF import ..... 251

Configuring the DXF import ..... 252

5.4 Programming Changes to ICP Contours ..... 254

Editing a contour element ..... 254

Adding a contour element ..... 257

Deleting a contour element ..... 257

"Splitting" a contour ..... 258

Superimposing form elements ..... 259

5.5 ICP Contour Elements, Turning Contour ..... 260

Entering lines, turning contour ..... 260

Entering circular arcs, turning contour ..... 262

Entering form elements ..... 263

Chamfer/rounding, turning contour ..... 264

Undercuts, turning contour ..... 265

5.6 ICP Contour Elements on the Face ..... 268

Entering lines on the face ..... 269

Entering circular arcs on the face ..... 270

Entering chamfers/roundings on the face ..... 271

5.7 ICP Contour Elements on the Lateral Surface ..... 272

Entering lines on the lateral surface ..... 273

Entering circular arcs on the lateral surface ..... 274

Entering chamfers/roundings on the lateral surface ..... 275

HEIDENHAIN MANUALplus 4110 11

Page 12

6 DIN Programming 277

6.1 DIN Programming ..... 278

Program and block structure ..... 279

6.2 Editing DIN Programs ..... 281

Block functions ..... 281

Word functions ..... 283

Address parameters ..... 283

Comments ..... 284

Block functions ..... 285

Menu structure ..... 286

Programming G functions ..... 287

6.3 Definition of Workpiece Blank ..... 288

Chuck part, cylinder/tube G20 ..... 288

Workpiece blank contour G21 ..... 289

6.4 Tool Positioning without Machining ..... 290

Rapid traverse G0 ..... 290

Tool change point G14 ..... 291

6.5 Simple Linear and Circular Movements ..... 292

Linear path G1 ..... 292

Circular path G2, G3—incremental center coordinates ..... 293

Circular path G12, G13—absolute center coordinates ..... 295

6.6 Feed Rate and Spindle Speed ..... 297

Speed limitation G26/G126 ..... 297

Interrupted feed G64 ..... 297

Feed per tooth G193 ..... 298

Constant feed G94 (feed per minute) ..... 298

Feed per revolution G95/G195 ..... 298

Constant cutting speed G96/G196 ..... 299

Spindle speed G97/G197 ..... 299

6.7 Tool-Tip / Milling-Cutter Radius Compensation ..... 300

Fundamentals ..... 300

G40: Switch off TRC/MCRC ..... 301

G41/G42: Switch on TRC/MCRC ..... 301

6.8 Compensation Values ..... 302

(Changing the) cutter compensation G148 ..... 302

Additive compensation G149 ..... 303

Compensation of right-hand tool nose G150

Compensation of left-hand tool nose G151 ..... 304

6.9 Zero Point Shifts ..... 305

Zero point shift G51 ..... 305

Additive zero point shift G56 ..... 306

Absolute zero point shift G59 ..... 307

12

Page 13

6.10 Oversizes ..... 308

Axis-parallel oversize G57 ..... 308

Contour-parallel oversize (equidistant) G58 ..... 309

6.11 Contour-Based Turning Cycles ..... 310

Contour definition ..... 310

End of cycle G80 ..... 310

Longitudinal contour roughing G817/G818 ..... 311

Longitudinal contour roughing with recessing G819 ..... 313

Transverse contour roughing G827/G828 ..... 314

Transverse contour roughing with recessing G829 ..... 316

Contour-parallel roughing G836 ..... 317

Contour finishing G89 ..... 318

6.12 Simple Turning Cycles ..... 319

Roughing longitudinal G81 ..... 319

Roughing transverse G82 ..... 320

Simple contour repeat cycle G83 ..... 321

Line with radius G87 ..... 322

Line with chamfer G88 ..... 323

6.13 Recessing Cycles ..... 324

Contour recessing axial G861 / radial G862 ..... 324

Contour recessing cycle, finishing, axial G863 / radial G864 ..... 326

Simple recessing cycle, axial G865 / radial G866 ..... 328

Recessing finishing, axial G867 / radial G868 ..... 329

Simple recessing cycle G86 ..... 330

6.14 Recess-Turning Cycles ..... 331

Function of recess turning cycles ..... 331

Simple recess-turning cycle, longitudinal G811 / transverse G821 ..... 332

Recess-turning cycle, longitudinal G815 / transverse G825 ..... 333

6.15 Thread Cycles ..... 335

Universal thread cycle G31 ..... 335

Single thread G32 ..... 337

Thread single path G33 ..... 338

Metric ISO thread G35 ..... 339

Simple longitudinal single-start thread G350 ..... 340

Extended longitudinal multi-start thread G351 ..... 341

Tapered API thread G352 ..... 342

Tapered thread G353 ..... 343

HEIDENHAIN MANUALplus 4110 13

Page 14

6.16 Undercut Cycles ..... 344

Undercut contour G25 ..... 344

Undercut cycle G85 ..... 345

Undercut according to DIN 509 E with cylinder machining G851 ..... 347

Undercut according to DIN 509 F with cylinder machining G852 ..... 348

Undercut according to DIN 76 with cylinder machining G853 ..... 349

Undercut type U G856 ..... 350

Undercut type H G857 ..... 351

Undercut type K G858 ..... 352

6.17 Parting Cycle ..... 353

Parting cycle G859 ..... 353

6.18 Drilling Cycles ..... 354

Drilling cycle G71 ..... 354

Deep-hole drilling cycle G74 ..... 355

Tapping G36 ..... 357

Thread milling, axial G799 ..... 358

6.19 C-Axis Commands ..... 359

Zero point shift, C axis G152 ..... 359

Standardize C axis G153 ..... 359

6.20 Face Machining ..... 360

Starting point of contour / rapid traverse G100 ..... 360

Linear segment, face G101 ..... 361

Circular arc, face G102/G103 ..... 362

Linear slot, face G791 ..... 363

Contour and figure milling cycle, face G793 ..... 364

Area milling, face G797 ..... 366

Figure definition: Full circle, face G304 ..... 368

Figure definition: Rectangle, face G305 ..... 369

Figure definition: Eccentric polygon, face G307 ..... 370

6.21 Lateral Surface Machining ..... 371

Reference diameter G120 ..... 371

Starting point of contour / rapid traverse G110 ..... 372

Linear segment, lateral surface G111 ..... 373

Circular arc, lateral surface G112/G113 ..... 374

Linear slot, lateral surface G792 ..... 376

Contour and figure milling cycle, lateral surface G794 ..... 377

Helical-slot milling G798 ..... 379

Figure definition: Full circle, lateral surface G314 ..... 380

Figure definition: Rectangle, lateral surface G315 ..... 381

Figure definition: Eccentric polygon, lateral surface G317 ..... 382

14

Page 15

6.22 Pattern Machining ..... 383

Linear pattern, face G743 ..... 383

Circular pattern, face G745 ..... 385

Linear pattern, lateral surface G744 ..... 387

Circular pattern, lateral surface G746 ..... 389

6.23 Other G Functions ..... 391

Period of dwell G4 ..... 391

Precision stop G9 ..... 391

Deactivate protection zone G60 ..... 391

Wait for moment G204 ..... 391

6.24 Set T, S, F ..... 392

Tool number, spindle speed /cutting speed and feed rate ..... 392

6.25 Data Input and Data Output ..... 393

INPUT ..... 393

WINDOW ..... 394

PRINT ..... 395

6.26 Programming Variables ..... 396

Fundamentals ..... 396

# variables ..... 397

V variables ..... 399

6.27 Program Branches, Program Repeats ..... 401

IF (...) (conditional program branch) ..... 401

WHILE (program repeat) ..... 402

6.28 Variables as Address Parameters ..... 403

6.29 Subprograms ..... 406

6.30 M Functions ..... 408

HEIDENHAIN MANUALplus 4110 15

Page 16

7 Tool Management Mode 411

7.1 Tool Management Mode of Operation ..... 412

Tool types ..... 412

Tool life management ..... 413

7.2 Tool Organization ..... 414

7.3 Tool Texts ..... 416

7.4 Tool Data ..... 418

Tool orientation ..... 418

Reference point ..... 418

Editing tool data ..... 418

Lathe tools ..... 419

Recessing and recess-turning tools ..... 421

Thread-cutting tools ..... 422

Drilling tools ..... 423

Tapping tools ..... 424

Milling tools ..... 425

7.5 Tool Data—Supplementary Parameters ..... 426

Driven tool ..... 426

Direction of rotation ..... 426

Cutting data ..... 426

Tool life management ..... 427

16

Page 17

8 Organization Mode of Operation 429

8.1 Organization Mode of Operation ..... 430

8.2 Parameters ..... 431

Current parameters ..... 432

Configuration parameters ..... 435

8.3 Transfer ..... 441

Data backup ..... 441

Data exchange with DataPilot 4110 ..... 441

Printer ..... 441

Interfaces ..... 442

Basics of data transfer ..... 442

Configuring for data transfer ..... 444

Transferring programs (files) ..... 446

8.4 Service and Diagnosis ..... 453

Access authorization ..... 453

System service ..... 455

Diagnosis ..... 455

9 Examples 457

9.1 Working with MANUALplus ..... 458

Setting up the machine ..... 459

Selecting a cycle program ..... 460

Creating a cycle program ..... 461

9.2 ICP Example "Threaded Stud" ..... 470

9.3 ICP Example "Matrix" ..... 483

9.4 ICP Example "Recessing Cycle" ..... 495

9.5 ICP Example "Milling Cycle" ..... 507

9.6 DIN Programming Example "Threaded Stud" ..... 516

9.7 DIN Programming Example "Milling Cycle" ..... 519

10 Tables and Overviews 523

10.1 Thread Pitch ..... 524

10.2 Undercut Parameters ..... 525

DIN 76—undercut parameters ..... 525

DIN 509 E, DIN 509 F—undercut parameters ..... 527

10.3 Technical Information ..... 528

10.4 Peripheral Interface ..... 532

HEIDENHAIN MANUALplus 4110 17

Page 18

Page 19

Introduction and Fundamentals

Page 20

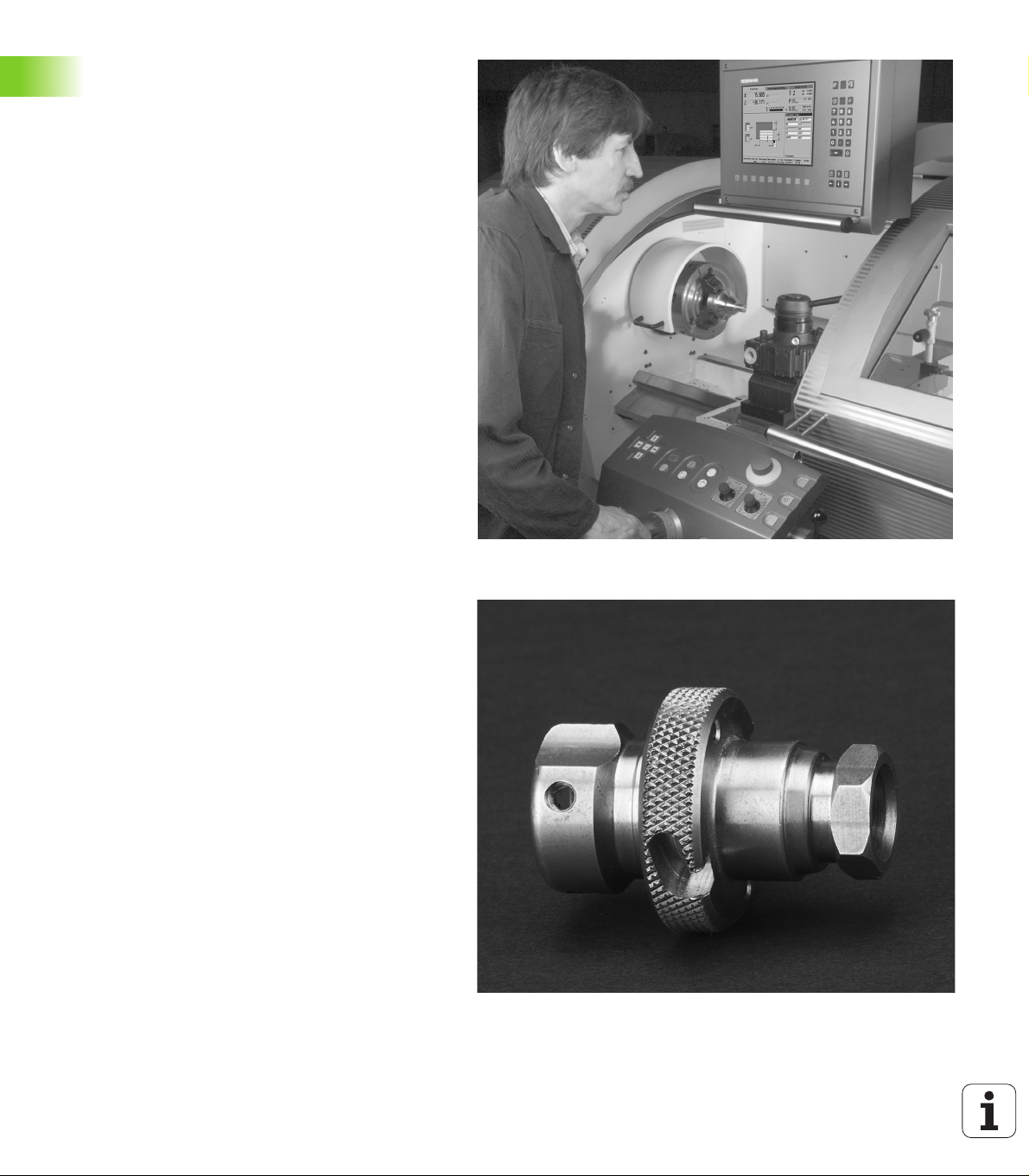

1.1 The MANUALplus

The MANUALplus control combines modern control

and drive technology with the functional features of a

hand-operated machine tool. You can run simple

machining operations, such as turning or facing, on

MANUALplus just like on any conventional lathe. The

axes are moved as usual by handwheel or joystick. For

machining difficult contours, such as tapers, radii,

chamfers, undercuts or threads, MANUALplus offers

fixed cycles. These cycles enable you to work faster

and produce a higher quality than on a conventional

lathe.

In addition, you can teach in a machining sequence

1.1 The MANUALplus

and then have MANUALplus rerun the machining

operation automatically as often as desired. Each

additional part machined saves you time.

MANUALplus offers a wide range of capabilities:

From performing simple lathe jobs through to

complex workpiece contours, including drilling and

milling operations on the face and lateral surface.

MANUALplus lets you choose between manual,

semi-automatic and automatic operation. Regardless

of whether you are machining a single part, producing

a whole batch or repairing a workpiece, MANUALplus

always gives you optimum support.

The C axis

With a C axis you can drill and mill a workpiece on its

front, back and lateral surfaces.

During use of the C axis, one axis interpolates linearly

or circularly with the spindle in the given working

plane, while the third axis interpolates linearly.

MANUALplus supports cycle and DIN programming

with the C axis.

20 1 Introduction and Fundamentals

Page 21

1.2 Features

The functions of the MANUALplus are grouped into operating modes:

Machine mode of operation

This operating mode includes all functions for machine setup,

workpiece machining, and cycle and DIN program definition.

The cycle programming functions are available in both manual

and automatic modes. You can program cycles for roughing,

recessing, thread-cutting and drilling operations.

ICP programming (Interactive Contour Programming) enables

you to describe complex and even incomplete contours. You need

to enter the values for the known elements, MANUALplus then

automatically calculates the transitions, intersections, and any

other missing data. MANUALplus graphically displays the contour

sections entered and calculated. You can usually program a

contour with the dimensions given in the workpiece drawing. ICP

contour descriptions are included in the machining cycles.

The DIN programming feature (NC programming in DIN format

according to DIN 66025 (ISO 6983)) enables you to run highly

complex, technologically sophisticated machining operations.

Apart from pure traversing commands, DIN cycles also provide

functions for roughing, drilling and milling, for programming

schematic contour geometry to calculate missing data, and for

programming variables. You can even write separate DIN

programs or integrate DIN macros in cycles.

Before executing a part program, you can run a graphic

simulation of all machining operations that were programmed

with cycles, cycle programs, or DIN programs.

Tool management mode

MANUALplus stores and manages up to 99 tool definitions.

MANUALplus stores all of the tool data required for calculating

cutting radius compensation, proportioning of cuts, plunging angle,

etc.

1.2 Features

With the tool data, MANUALplus also manages the data for tool life

monitoring as well as the cutting data, feed rate and spindle speed.

Organization mode of operation

The behavior of the MANUALplus system is controlled by

parameters. In the Organization mode, you set the parameters to

adapt the MANUALplus to your situation.

Furthermore, you can exchange and save cycles and DIN programs

with other systems over a serial data line (PC, host computer, etc).

This operating mode also provides diagnostic functions for

commissioning and checking the system.

HEIDENHAIN MANUALplus 4110 21

Page 22

1.3 MANUALplus Design

The dialog between machinist and control takes place via:

Screen

Soft keys

Data input keypad

Machine operating panel

The entered data can be displayed and checked on the screen. With

the function keys directly below the screen, you can select functions,

capture position values, confirm entries, and a lot more.

With the information key (also found beneath the screen), you can

call error and PLC information and activate the PLC diagnostic

function.

The data input keyboard (operating panel) serves for the input of

1.3 MANUALplus Design

machine data, positioning data, etc. The MANUALplus does not need

an alphanumeric keyboard. Tool descriptions, program descriptions or

comments in a DIN program are entered with an on-screen

alphanumeric keyboard.

The machine operating panel contains all necessary controls for

manual operation of the lathe.

The actual control is not accessible to the machinist. You should know,

however, that your MANUALplus has an integrated hard disk on which

all cycle programs, ICP contours and DIN programs that you enter are

stored. This allows you to save a vast number of programs.

For data exchange and data backup, you can use the serial data

interface (RS-232-C) or the Ethernet interface.

Lathe design

MANUALplus is configured by the machine manufacturer as a vertical

boring and turning mill or to machine with tools "in front of" or "behind"

the workpiece—depending on the design of the lathe or the position

of the tool carrier. The menu symbols, the graphic support windows

as well as the graphic representation during ICP and graphic

simulation all reflect the configuration of the lathe.

The representations in this User's Manual assume a lathe with tool

carrier in front of the workpiece.

22 1 Introduction and Fundamentals

Page 23

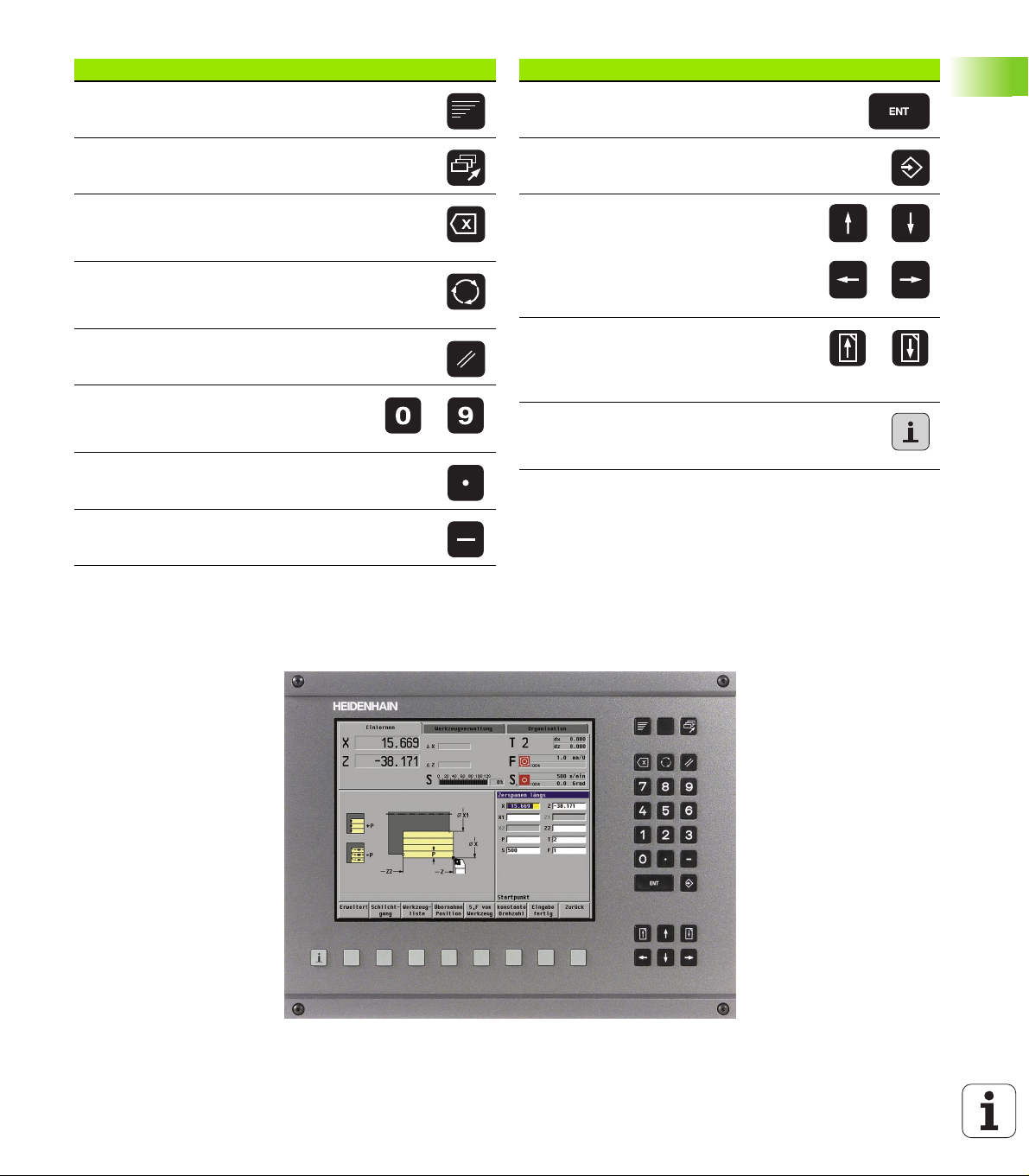

Data input keypad Symbol

Menu

Call the main menu.

Data input keypad Symbol

ENTER

Confirm the entered value.

Process

Select a new mode of operation.

Backspace

Delete the character to the left of the

cursor.

Switching key

Switch between help graphics for

internal/external machining.

Clear

Delete error messages.

Numbers (0 to 9)

For entering values and selecting soft

keys.

Decimal point

Minus

Enter the algebraic sign.

Store

Conclude data input and transfer values.

Arrow keys

Move the cursor in the indicated

direction by one position (character,

field, line, etc.).

Page up, Page down (PgUp/PgDn)

Show the information of the previous/

next screen page; toggle between two

input windows.

Info

Call the error information or PLC status

display.

1.3 MANUALplus Design

HEIDENHAIN MANUALplus 4110 23

Page 24

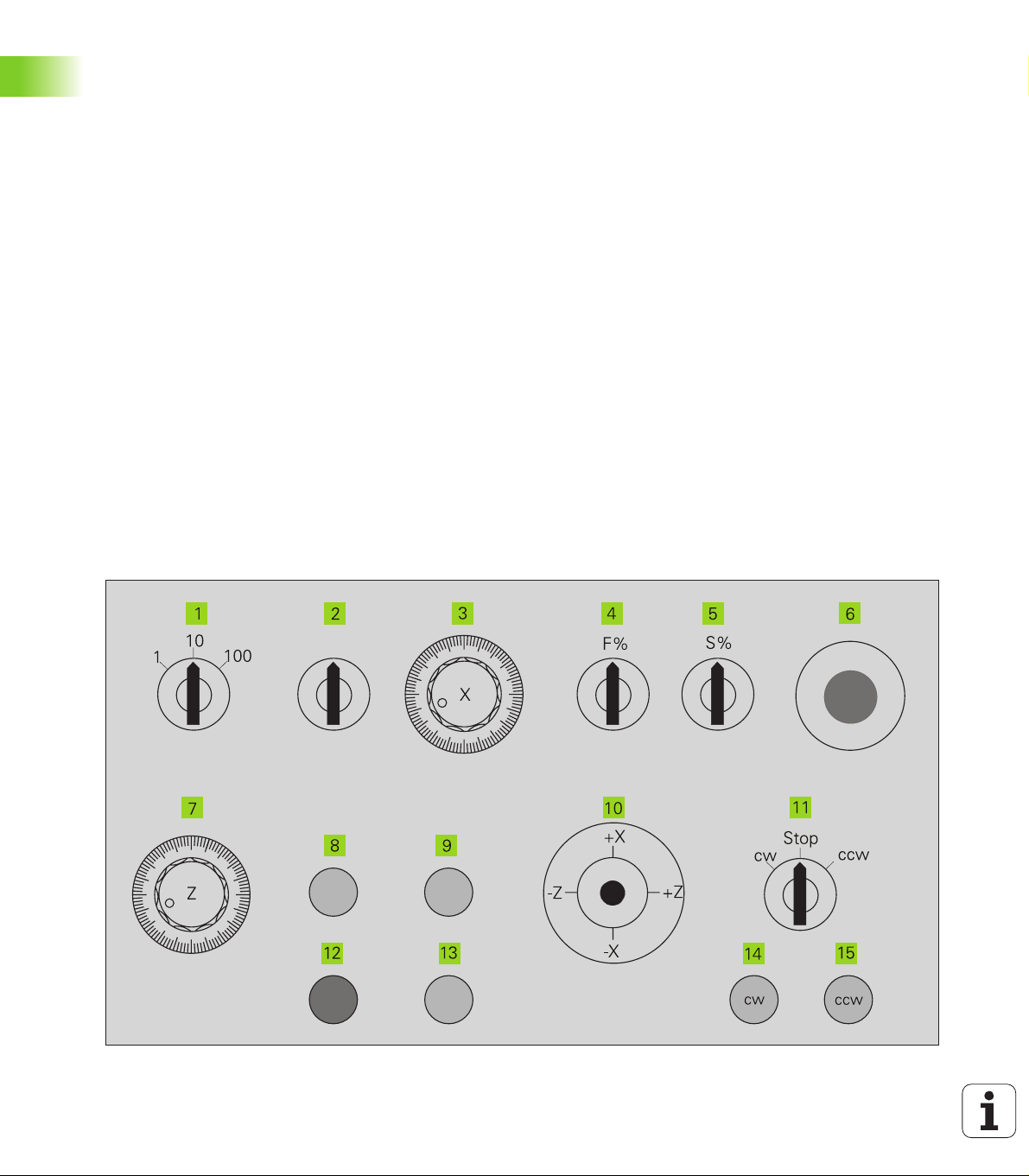

Machine operating panel

The machine operating panel is interfaced to the lathe by the

machine tool builder. The controls on your machine may

deviate slightly from those shown in the illustration. Your

machine documentation provides more detailed information.

Controls and displays

1 Handwheel resolution

Set the handwheel resolution to 1/10 mm, 1/100 mm or 1/

1000 mm per graduation mark—or to other resolutions

defined by the machine tool builder.

2 Handwheel superposition in thread cycles

Set the handwheel to "superposition for thread cycles."

3 X handwheel

Position the cross slide (cross slide axis = X axis).

4 Feed-rate override

1.3 MANUALplus Design

Change the programmed feed rate.

5 Speed override

Change the preset speed.

6 EMERGENCY STOP button

7Z handwheel

Position the saddle (saddle axis = Z axis).

8Tool change

Confirm a tool change.

9 Coolant ON/OFF

Enable/disable coolant supply.

10 Joystick

Move the slide on a linear path at feed rate or rapid

traverse; with a built-in switch for enabling rapid traverse.

11 Spindle switch

Switch spindle to clockwise rotation (cw),

counterclockwise rotation (ccw), or spindle stop (M05).

12 Cycle STOP

Stop traverse and cycle execution (the spindle remains

ON).

13 Cycle START

Start a cycle, cycle program or NC program.

14 Spindle jog cw

Slowly rotate the spindle clockwise (cw).

15 Spindle jog ccw

Slowly rotate the spindle counter-clockwise (ccw).

24 1 Introduction and Fundamentals

Page 25

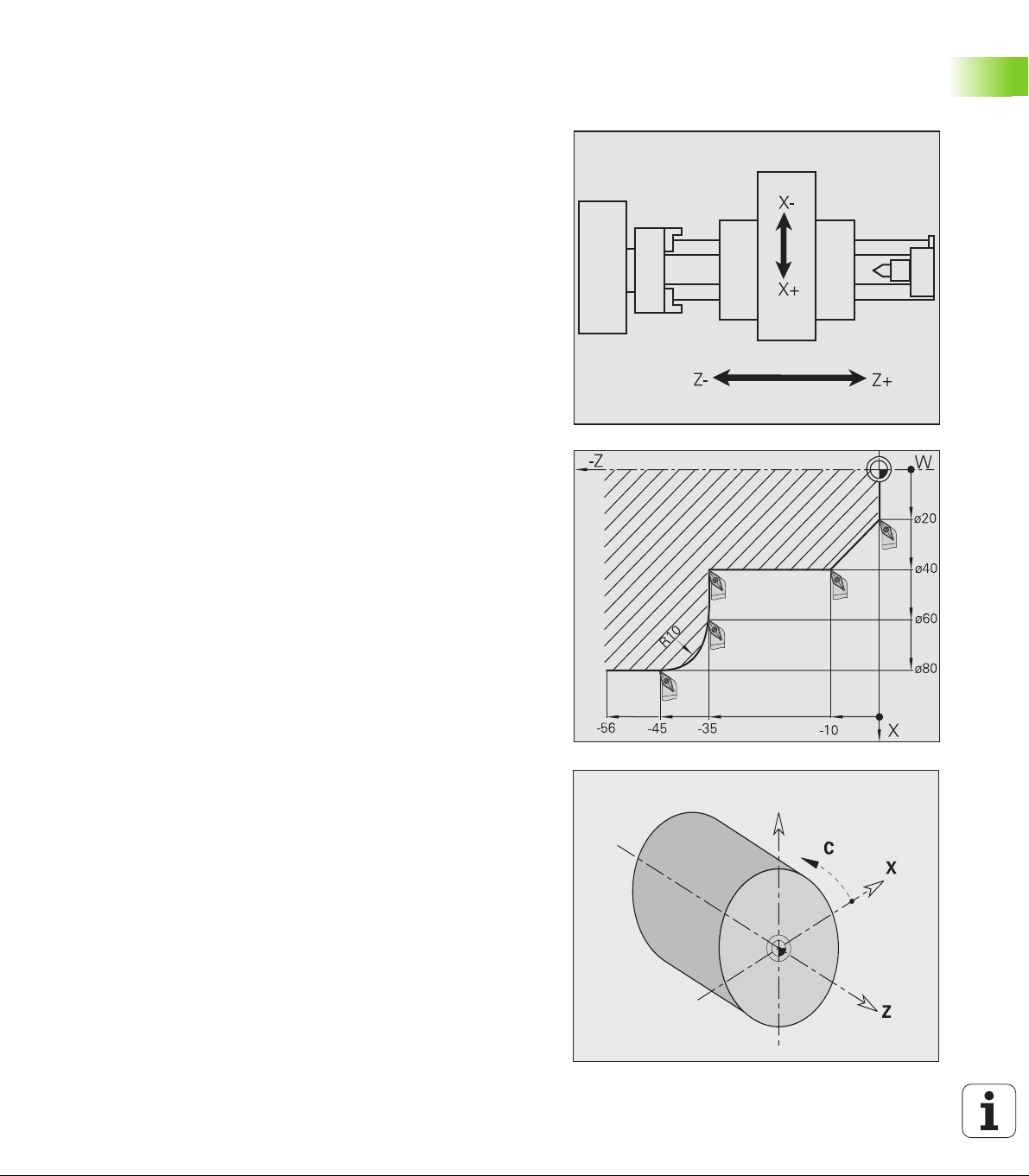

1.4 Axis Designations and

Coordinate System

Axis designations

The cross slide is referred to as the X axis and the saddle as the Z axis

(see figure at top right).

All X-axis values that are displayed or entered are regarded as

diameters.

When programming paths of traverse, remember to:

Program a positive value to depart the workpiece.

Program a negative value to approach the workpiece.

Coordinate system

The axis designations X and Z describe positions in a two-dimensional

coordinate system. As you can see from the figure to the center right,

the position of the tool tip is clearly defined by its X and Z coordinates.

MANUALplus can connect points by linear and circular paths of

traverse (interpolations). Workpiece machining is programmed by

entering the coordinates for a succession of points and connecting the

points by linear or circular paths of traverse.

Like the paths of traverse, you can also describe the complete contour

of a workpiece by defining single points through their coordinates and

connecting them by linear or circular paths of traverse.

The coordinates entered for the X axis and Z axis are referenced to

the workpiece zero point.

Angles entered for the C axis are referenced to the zero point of the

C axis (see bottom-right figure).

Positions can be programmed to an accuracy of 1 µm (0.001 mm). This

is also the accuracy with which they are displayed.

1.4 Axis Designations and Coordinate System

HEIDENHAIN MANUALplus 4110 25

Page 26

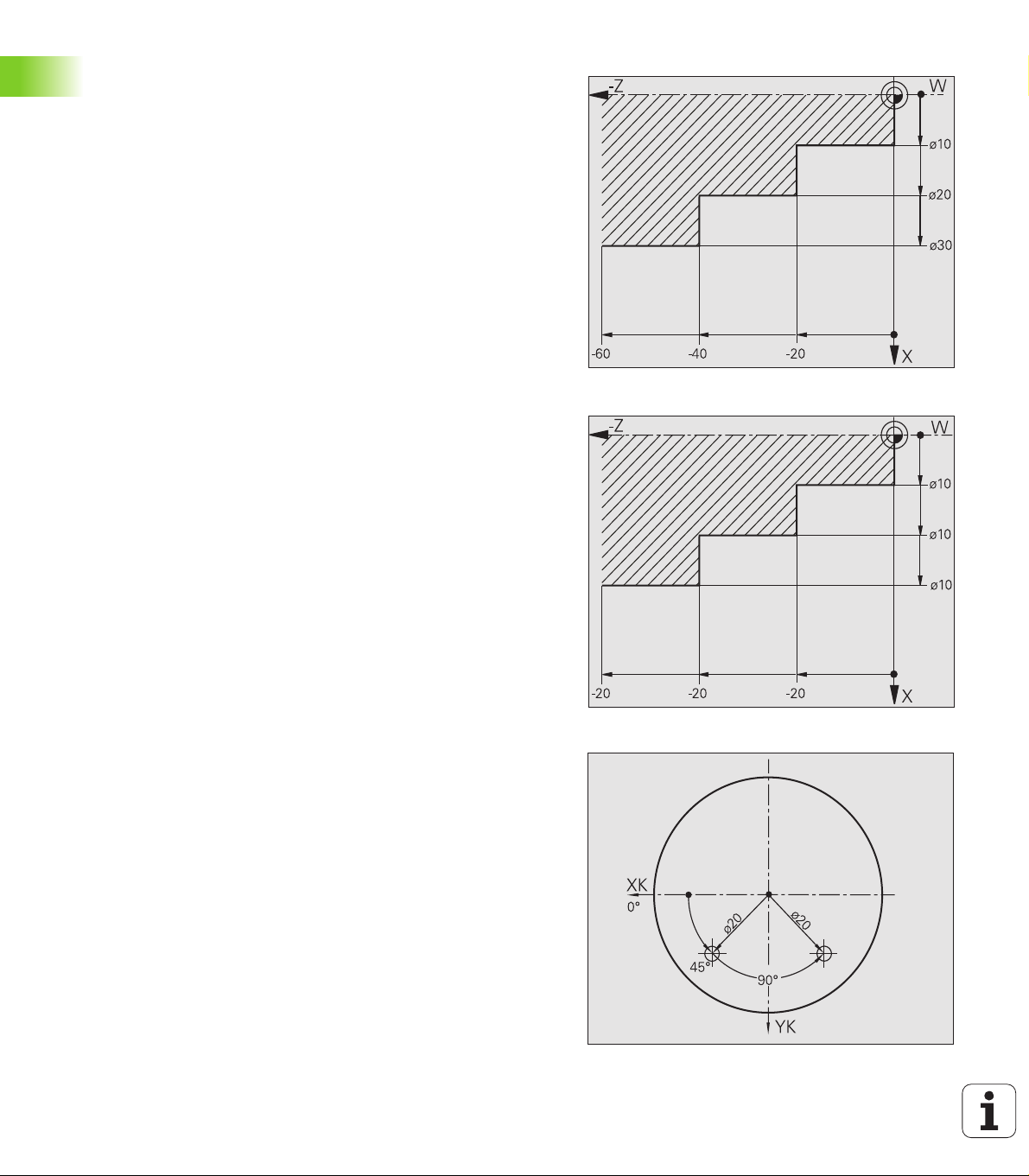

Absolute coordinates

If the coordinates of a position are referenced to the workpiece zero

point, they are referred to as absolute coordinates. Each position on a

workpiece is clearly defined by its absolute coordinates (see figure at

upper right).

Incremental coordinates

Incremental coordinates are always referenced to the last

programmed position. They specify the distance from the last active

position and the subsequent position. Each position on a workpiece is

clearly defined by its incremental coordinates (see figure at center

right).

Polar coordinates

Positions located on the face or lateral surface can either be entered

in Cartesian coordinates or polar coordinates.

When programming with polar coordinates, a position on the

workpiece is clearly defined by the entries for diameter and angle (see

figure at bottom right).

1.4 Axis Designations and Coordinate System

26 1 Introduction and Fundamentals

Page 27

1.5 Machine Reference Points

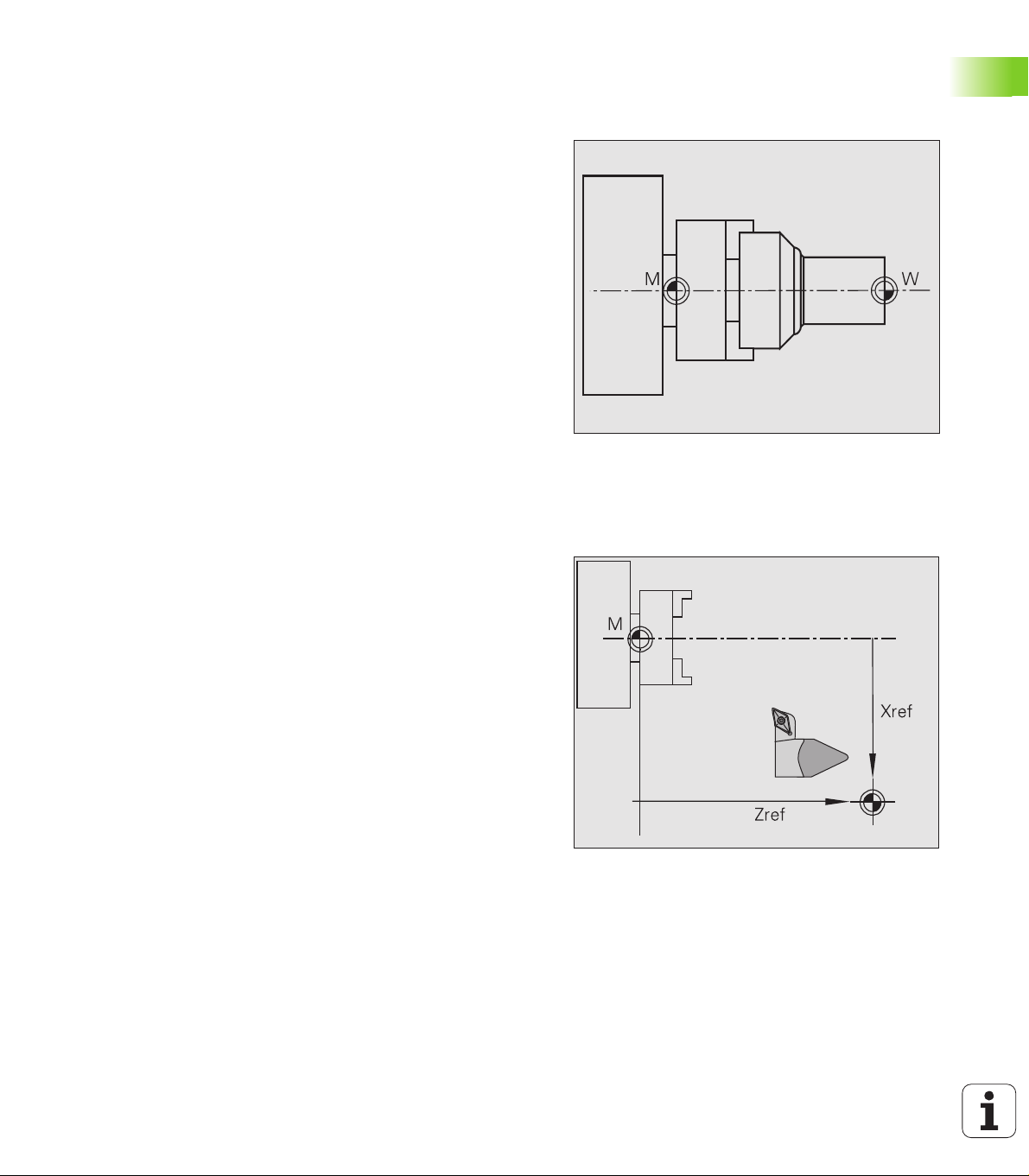

Machine zero point

The point of intersection of the X and Z axes is called the "machine

zero point." On a lathe, the machine zero point is usually the point of

intersection of the spindle axis and the spindle surface. The machine

zero point is designated with the letter "M" (see figure at upper right).

Workpiece zero point

For machining a workpiece, it is easier to reference all input data to a

zero point located on the workpiece. By programming the zero point

used in the workpiece drawing, you can take the dimensions directly

from the drawing, without further calculation. This point is the

"workpiece zero point." The workpiece zero point is designated with

the letter "W" (see figure at center right).

Reference points

Whether the control "forgets" the positions of the machine axes when

it is switched off depends on the position encoders used. If the

positions are lost, you must pass over the fixed reference points after

switching on the MANUALplus. The control knows the exact distance

between these reference marks and the machine zero point (see

figure at lower right).

1.5 Machine Reference Points

HEIDENHAIN MANUALplus 4110 27

Page 28

1.6 Tool Dimensions

MANUALplus requires data on the specific tools for a variety of tasks,

such as positioning the axes, calculating cutting radius compensation

or proportioning of cuts.

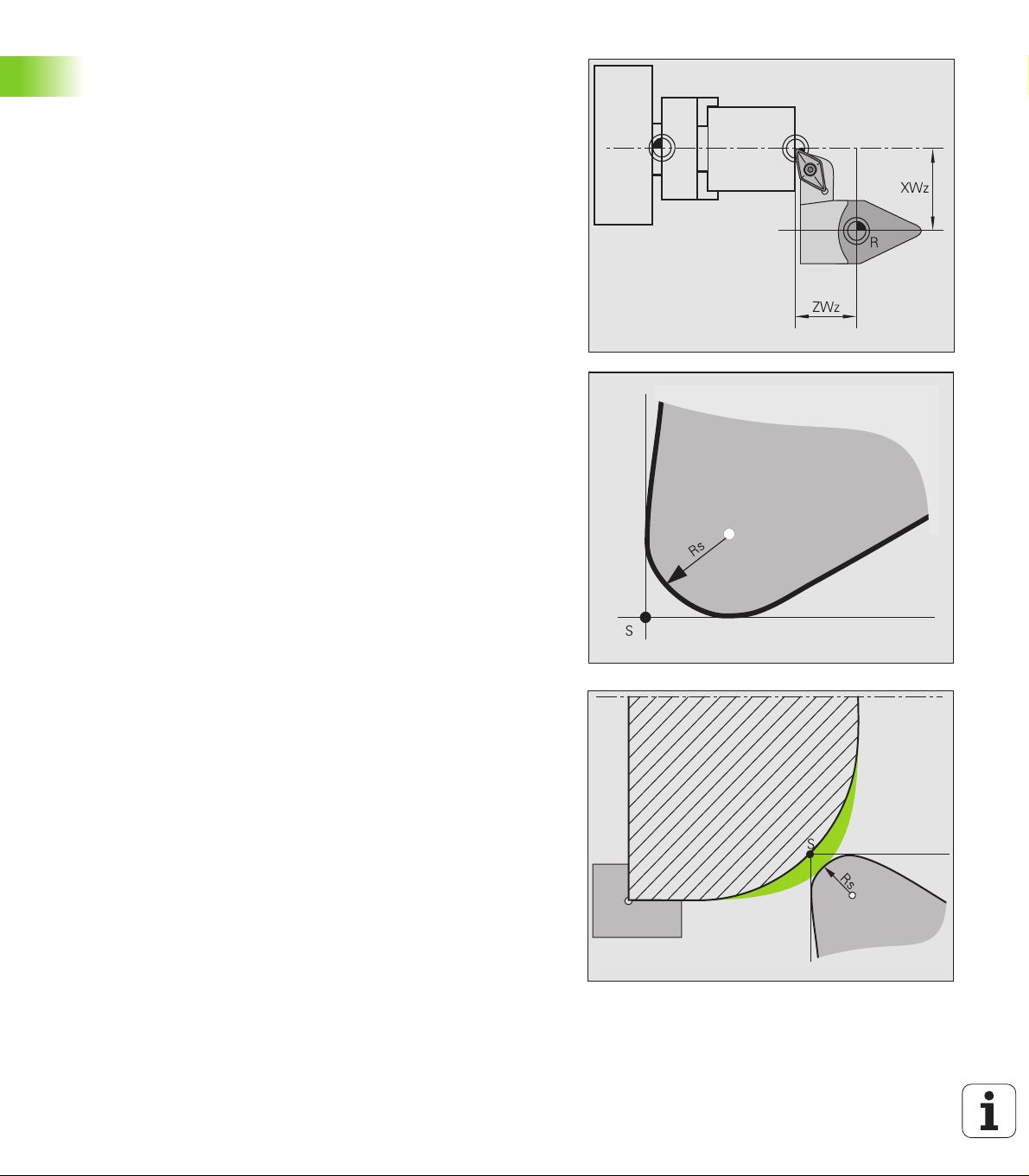

Tool length

All position values that are programmed and displayed are referenced

to the distance between the tool tip and workpiece zero point. Since

the control only knows the absolute position of the tool carrier (slide),

it needs the dimensions XWz and ZWz to calculate and display the

position of the tool tip (see figure at upper right).

1.6 Tool Dimensions

Tool compensation

The tool tip is subjected to wear during machining processes. To

compensate for this wear, MANUALplus uses compensation values

which are managed independent of the values for length. The system

automatically adds the compensation values to the values for length.

Tool-tip radius compensation (TRC)

The tip of a lathe tool has a certain radius. When machining tapers,

chamfers and radii, this results in inaccuracies which MANUALplus

compensates with its cutting radius compensation function.

Programmed paths of traverse are referenced to the theoretical tool

tip S (see figure at center right). With non-paraxial contours, this will

lead to inaccuracies during machining.

The TRC function compensates this error by calculating a new path of

traverse, the equidistant line (see figure at bottom right).

MANUALplus calculates the TRC for cycle programming. The DIN

programming feature also takes the TRC for clearance cycles into

account. During DIN programming with single paths, you can also

enable/disable TRC.

28 1 Introduction and Fundamentals

Page 29

Milling cutter radius compensation (MCRC)

In milling operations, the outside diameter of the milling cutter

determines the contour. When the MCRC function is not active, the

system defines the center of the cutter as reference point. The MCRC

function compensates for this error by calculating a new path of

traverse, the equidistant line.

1.6 Tool Dimensions

HEIDENHAIN MANUALplus 4110 29

Page 30

Page 31

Basics of Operation

Page 32

2.1 The MANUALplus

Screen

MANUALplus shows the data to be displayed in

windows. Some windows only appear when they are

needed, for example, for typing in entries.

In addition, MANUALplus shows the type of

operation and the soft-key display on the screen.

Each function that appears in a field of the soft-key

row is activated by pressing the soft key directly

below it.

Screen windows displayed

Machine window

Position display, display of machine data, machine

status, etc.

List and program window

Display of program lists, tool lists, parameter lists,

etc. To select specific elements from the list, simply

2.1 The MANUALplus Screen

move the highlight to the desired element with the

arrow keys.

Menu window

Display of menu symbols. This window only

appears on the screen when menu selection is

active.

Input box

For entering the parameters of a cycle, ICP

element, DIN command, etc. You can enter data,

check already programmed data, and edit and

delete data as required. This window is also used to

display data.

Graphic support window

Input data (such as cycle parameters, tool data, etc.)

are explained with graphics. The Circle key allows

you to switch between the help graphics for internal

and external machining.

Simulation window

The simulation window shows a graphic

representation of the contour elements and a

simulation of the tool movements. This enables you

to check cycles, entire cycle programs, and DIN

programs.

ICP contour graphics

Display of the contour during ICP programming.

DIN editing window

Display of the DIN program during DIN

programming. It is superimposed on the "machine

window."

Error window

Display of encountered errors and warnings.

32 2 Basics of Operation

Page 33

2.2 Operation and Data Input

Modes of operation

The active mode of operation is highlighted. MANUALplus

differentiates between the following operating modes:

Machine—with the submodes:

Manual mode (display: "Machine")

Teach-in

Program run

Tool administration (tool management)

Organization

You can switch between the different operating modes using the

Process key. Press the Process key once to activate the operatingmode bar. Select the desired mode of operation using the arrow keys

and press the Process key again to activate it.

The Process key can only be used when the main menu of

the current operating mode is active. You reach the main

menu with Back or with the “Menu” key.

Menu selection

The numerical keypad is used for activating a menu and for entering

data. The menu items are presented as a 9-field box. Each field of this

symbol corresponds to the numerical key that is located at the same

position on the numerical keypad. The functions, cycles, tools, etc. are

displayed as symbols. The meaning of the selected symbol / menu

item is described in the footer.

Press the corresponding numerical key, or move the highlight with the

arrow keys to the symbol on the screen and press the ENTER key.

Soft keys

With some system functions, the available functions are arranged

on several soft-key levels.

Some soft keys work like "toggle switches." A function is active

when the associated field in the soft-key row is highlighted in color.

The setting remains in effect until the function is disabled again.

With functions like Take over position you do not have to enter

values manually. The data are automatically written into the

appropriate input fields.

Data entries are not concluded until the Save or Input finished soft

key has been pressed.

The Back soft key takes you back to the previous operating level.

2.2 Operation and Data Input

HEIDENHAIN MANUALplus 4110 33

Page 34

Data input

Input windows comprise several input fields. You can move the

cursor to the desired input field with the vertical arrow keys. The

function of the selected field is shown in the bottom line of the

window.

Place the highlight on the desired input field and enter the data.

Existing data are overwritten. With the horizontal arrow keys, you can

move the cursor within the input field and place it on the position

where you want to delete, copy or add characters.

To confirm the data you entered in a field, press a vertical arrow key

or the ENTER key.

If there are more input fields than a window can show, a second input

window is used. You will recognize this through the symbol in the

bottom line of the input window. To switch back and forth between

the windows, press the PgUp/PgDn keys.

Data entry is concluded when you press Input finished or

Save.—If you press the Back soft key, entries or changes

2.2 Operation and Data Input

will be lost.

List operations

Cycle programs, DIN programs, tool lists, etc. are displayed as lists.

You can scroll through a list with the arrow keys to check data or to

highlight elements for operations like deleting, copying, editing, etc.

34 2 Basics of Operation

Page 35

Alphanumeric keyboard

Program descriptions, tool descriptions, comments,

etc. are entered with the on-screen alphanumeric

keyboard. You select the desired character with the

arrow keys and confirm the character with ENTER.

You can switch between upper and lower case letters

with the SHIFT button.

To edit existing texts, place the cursor on the desired

position: Press the Up arrow key repeatedly until the

cursor reaches the input line. Then use the horizontal

arrow keys to delete, overwrite or add to the text, as

required.

With the INS key (on the alphanumeric keyboard) you

can determine whether to insert or overwrite

characters. Which mode of the INS key is presently

active (insert mode or overwrite mode) is indicated

below the input line.

Numbers are entered with the data input keypad.

2.2 Operation and Data Input

HEIDENHAIN MANUALplus 4110 35

Page 36

2.3 Error Messages

The appearance and effect of a MANUALplus error

message depend on the current operation.

Direct error messages

The MANUALplus uses direct error messages

whenever immediate error correction is possible and

advisable, for example if the input value of a cycle

parameter exceeds the valid input range. Confirm the

message with ENTER and correct the error (see figure

2.3 Error Messages

to the upper right).

Information of direct error messages:

The error description explains the error that has

occurred.

The error number is needed whenever you contact

the machine manufacturer about a specific error

message.

The time shows you when the indicated error

occurred.

Meaning of the symbols

Warning: The program run / operation continues.

MANUALplus points out the problem.

Error: The program run/operation is stopped. You

must correct the error before being able to continue.

Error display

The control temporarily stores any errors or messages

that appear during system start, operation or program

run, and sets the error symbol in the top line. Using

the Info key, open the error window to view the

messages.

If more error messages have occurred than can be

shown in one screen page of the error window, you

can scroll through the error display with the arrow

keys and PgUp/PgDn to check all messages.

36 2 Basics of Operation

Page 37

Clearing an error message

You can cancel the error message on which the cursor is located with

the "Backspace" key, or cancel all of the error messages with the

"Clear" key.

The error symbol remains set in the top line until all of the errors have

been canceled.

You can exit the error window without clearing any error messages by

pressing Back.

Information in the error message:

The error description explains the error that has occurred.

The error number, level indication (D level, C level) and "OM no."

are needed whenever the supplier needs to be contacted.

The time shows you when the indicated error occurred.

The error class is indicated in the framed field (to the top left of the

message). A message without this field represents a warning.

Background: This message serves as information, or merely a

"small" error has occurred.

Abort: The current operation (execution of a cycle, traverse

command, etc.) was aborted. You can resume operation once the

error has been cleared.

Emergency stop: An error condition has caused all traverse to be

stopped and the abortion of cycle program and DIN program

execution. You can resume operation once the error has been

cleared.

Reset: An error condition has caused all traverse to be stopped

and the abortion of cycle program and DIN program execution.

Switch off the control for a moment, then restart. Contact your

machine manufacturer if the error occurs again.

2.3 Error Messages

System error, internal error

In the unlikely event that a system error or an internal error occurs,

write down all information on the displayed message and inform your

machine manufacturer. You cannot correct these errors. Switch off

the control and restart.

PLC error, PLC status display

Using the soft keys PLC diagnosis and CNC diagnosis, you can

switch between the error information and the PLC window.

The PLC window is used for PLC messages and the PLC diagnosis.

Please refer to your machine manual for more information.

HEIDENHAIN MANUALplus 4110 37

Page 38

Warnings during simulation

If during simulation of a cycle, an entire cycle program

or a DIN program MANUALplus detects problems, it

displays a warning in the soft key to the extreme left

(see figure to the lower right). Press the soft key to

call these messages.

2.3 Error Messages

38 2 Basics of Operation

Page 39

2.4 Explanation of Terms

Cursor: In lists, or during data input, a list item, an input field or a

character is highlighted. This "highlight" is called a cursor. Entries

and operations, like copying, deleting, inserting a new item, etc.,

refer to the current cursor position.

Arrow keys: The cursor is moved with the horizontal and vertical

arrow keys and with the PgUp/PgDn keys.

Page keys: The PgUp/PgDn keys are also called "Page keys."

Navigate: Within a list or an input box, you can move the cursor to

any position you would like to check, change, delete or add to. In

other words, you "navigate" through the list.

Active/ inactive windows, functions, menu items: Of all

windows that are displayed on the screen, only one is active. That

means, any data you type on the keyboard or keypad are entered in

the active window only. In the active window the title bar is shown

in color. In the inactive windows, the title bar appears dimmed.

Inactive function keys or menu keys also appear dimmed.

Menu, menu key: MANUALplus arranges the available functions

and function groups in a 9-field box. This box is called a menu. Each

symbol in the menu is a menu key.

Editing: Editing is changing, deleting and adding to parameters,

commands, etc. within programs, tool data or parameters.

Default value: If the parameters of cycles or DIN commands are

preassigned values, these values are referred to as default values.

These values are used if you do not enter the parameters.

Byte: The capacity of a storage disk is indicated in bytes. Since

MANUALplus features a hard disk, the individual program lengths

are expressed in bytes.

Extension: File names consist of the actual name and the

extension. The name part and the extension part are separated by

".". The extension indicates the type of file. Examples:

„*.NC“DIN programs

„*.NCS“DIN subprograms (DIN macros)

„*.MAS“Machine parameters

2.4 Explanation of Terms

HEIDENHAIN MANUALplus 4110 39

Page 40

Page 41

Machine Mode of Operation

41 3 Machine Mode of Operation

Page 42

3.1 Machine Mode of Operation

The Machine mode of operation includes all functions for machine

setup, workpiece machining, and cycle and DIN program definition.

Machine setup

For preparations like setting axis values (defining workpiece zero

point), measuring tools or setting the protection zone.

Manual operation

Machine a workpiece manually or semi-automatically.

Teach-in

"Teach-in" a new cycle program, change an existing program, or

graphically simulate cycles.

DIN programming

Creating, editing, deleting DIN programs.

Program run

Graphically simulate existing cycle programs or DIN programs and

use them for the production of parts.

With MANUALplus, you produce a part in the usual manner by moving

the axes with the handwheels and jog controls, just like on a

conventional lathe. In most cases, however, it is much more

3.1 Machine Mode of Operation

convenient to use the cycles offered by MANUALplus.

A cycle is a machining step that has already been programmed for

you. This can be any machining operation from a single cut through to

a complex machining task like thread cutting. In any case, a cycle is

always a complete machining step that is immediately executable

once you have defined a few parameters that describe the workpiece

to be machined.

In Manual mode, the cycles that you program are not stored. In

Teach-in mode, each machining step is executed with a cycle and then

stored and integrated into a complete cycle program. You can

subsequently use this cycle program in parts production by repeating

it as often as desired in the Program run mode.

In ICP programming, any contour can be defined using linear/circular

elements and transition elements (chamfers, roundings, undercuts).

The contour descriptions are included in ICP cycles (see “ICP

Contours” on page 242).

The DIN programming feature provides commands for simple

traversing movements, DIN cycles for complex machining tasks,

switching functions, mathematical operations and programming with

variables.

You can either create "independent" programs that already contain all

necessary switching and traversing commands and are executed in

the Program run mode, or program DIN macros that are integrated in

cycles. The commands that you use in a DIN macro depend on the job

at hand. DIN macros support the complete range of commands that is

available for DIN programs.

You can also convert cycle programs to DIN programs. This enables

you to make use of straightforward cycle programming, and then

convert the part program to DIN format for subsequent optimization or

completion.

42 3 Machine Mode of Operation

Page 43

3.2 Switch-On / Switch-Off

Switch-on

In the screen headline, MANUALplus displays the

individual steps that are performed during system

start. When the system has completed all tests and

initializations, it switches to the Machine mode of

operation. The tool display shows the tool that was

last used. Whether a reference run is necessary

depends on the encoders used.

If errors are encountered during system start,

MANUALplus displays the error symbol on the

screen. You can check these error messages as soon

as the system is ready (see “Error Messages” on

page 36).

After system start, MANUALplus

assumes that the tool which was last used

is still inserted in the tool holder. If this is

not the case, you must inform

MANUALplus of the tool change.

Traversing the reference marks

Reference run

Select X reference.

Select Z reference.

Press Cycle START for the control to

traverse the reference marks.

MANUALplus activates the position display and

switches the menu and the soft-key row to the main

menu.

3.2 Switch-On / Switch-Off

Whether a reference run is necessary depends on the

encoders used:

EnDat encoder: Reference run is not necessary.

Distance-coded encoders: The position of the axes

is ascertained after a short reference run.

HEIDENHAIN MANUALplus 4110 43

Page 44

Standard encoder: The axes move to known, machine-based points.

As soon as a reference mark is traversed, a signal is transmitted to

the control. The control knows the distance between the reference

mark and the machine zero point and can now establish the precise

position of the axis.

In case you traverse the reference marks separately for

the X and Z axes, you only traverse in either the X or the

Z axis.

Monitoring EnDat encoders

If EnDat encoders are used, the control saves the axis positions during

switch-off. During switch-on, the MANUALplus compares for each

axis the position during switch-on with the position saved during

switch-off.

If there is a difference, one of the following messages appears:

"Axis was moved after the machine was switched-off."

3.2 Switch-On / Switch-Off

Check the current position and confirm it if the axis was in fact

moved.

"Saved encoder position of the axis is invalid."

This message is correct if the control has been switched on for the

first time, or if the encoder or other control components involved

were exchanged.

"Parameters were changed. Saved encoder position of the axis is

invalid."

This message is correct if configuration parameters were changed.

The cause for one of the above listed messages can also be a defect

in the encoder or control. Please contact your machine supplier if the

problem recurs.

44 3 Machine Mode of Operation

Page 45

Switch-off

Proper switch-off is recorded in the error

log file.

Switch-off

Go to the main level of the Machine

mode of operation.

Press the Switch off soft key.

MANUALplus displays a confirmation request.

Press ENTER to terminate the

control.

Wait until MANUALplus requests you to switch off

the machine.

3.2 Switch-On / Switch-Off

HEIDENHAIN MANUALplus 4110 45

Page 46

3.3 Machine Data

Input and display of machine data

In Manual mode, the machine data for tool, spindle

speed and feed rate are entered in "Set T, S, F ." In

cycle programs the machine data are included in the

cycle parameters, and in DIN programs they are part

of the NC program.

In "Set T, S, F" you also define the "maximum speed"

and the "stopping angle."

3.3 Machine Data

You can store the cutting data (spindle speed, feed

rate) together with the tool data and transfer them

with the S, F from tool soft key (see “Tool Data—

Supplementary Parameters” on page 426).

Machine data display

The machine data display is configurable.

The machine data that appear on your

screen may therefore deviate from the

example shown.

Entering the machine data

Select "Set T, S, F" (only available in

Manual mode).

Define the parameters.

Conclude data input.

Elements of machine data display

Position display X, Z: Distance between tool tip and workpiece

zero point

Letter designating the axis appears in white: Axis "disabled"

Position display C: Position of the C axis

Empty box: C axis is not active

Letter designating the axis appears in white: Axis "disabled"

Distance-to-go display X, Z, C: The distance remaining from the

current position to the target position of the active traversing

command

Distance-to-go Z and protection zone status: Distance-to-go

display and display of status of protective zone monitoring

Spindle utilization: Utilization of the spindle motor relative to the

rated torque

Spindle utilization and maximum speed: Utilization of the

spindle motor and additional display of valid maximum speed

46 3 Machine Mode of Operation

Page 47

Tool call

Elements of machine data display

T display

T number of the inserted tool

Tool compensation values

"T" highlighted in color: Machining of "mirrored contour" active

S display

Symbol of spindle status

Upper field: Programmed value

Lower field: Setting of override control and actual spindle

speed—with position control (M19): spindle position

Gear range (figure beside "S")

"S" highlighted in color: Display applies to driven tool

F display

Symbol of cycle status

Upper field: Programmed value

Lower field: Setting of override control and actual feed rate

3.3 Machine Data

T is the identification letter for the tool data.

Depending on the tool carrier used, "T" is followed by

2 or 4 characters.

One tool holder (e.g. Multifix):

Call: "Tdd"

More than one tool holder (e.g. turret): Call:

„Tddpp“

dd: Position in the tool file (tool list)

pp: Position on the tool carrier (turret location)

In Manual mode, the T number is entered in "Set T, S,

F"—in Teach-in mode, "T" is a cycle parameter.

Power-driven tools

Driven tools are defined in the tool description.

If the active tool is driven, the displayed spindle data

refer to the tool.

The following input parameters refer to spindle 1

when a driven tool is active:

Spindle speed / Constant cutting speed

Maximum speed

Feed per revolution in "Set T, S, F"

Soft keys for "Set T, S, F"

See “Tool compensation” on page 58

See “Setting up Tools” on page 54

Call the tool list—Transfer of T number from the tool

list possible

Transfer of spindle speed and feed rate from the tool

data

On: Feed per minute (mm/min)

Off: Feed per revolution (mm/rev)

On: Constant speed (rpm)

Off: Constant cutting speed (m/min)

HEIDENHAIN MANUALplus 4110 47

Page 48

If a driven tool is active, the spindle speed and speed

limitation refer to the tool.

Your machine documentation provides information on

whether the driven tool can be operated with feed per

revolution.

Tools with more than one cutting edge

If you use special tools with more than one cutting edge, different tool

parameters apply (set-up dimensions, cutting radius, etc.). Enter more

3.3 Machine Data

than one tool definition to define these tools. If "T" is programmed with

four digits (Tddpp), program a new "dd" ("pp" remains the same) when

another cutting edge of the special tool is used.

Tools in different quadrants

Example: The principal tool carrier of your lathe is in front of the

workpiece (standard quadrant). An additional tool holder is behind the

workpiece.

When MANUALplus is configured, it is defined for each tool holder

whether the X dimensions and the direction of rotation of circular arcs

must be mirrored. In the above-mentioned example the additional tool

holder is assigned the attribute "Mirrored."

If this method is used, all machining operations are programmed as

usual—regardless of which tool holder executes the operation. The

simulation also shows all machining operations in the standard

quadrant.

The tools are also described and dimensioned for the standard

quadrant—even if they are inserted in the additional tool holder.

Mirroring does not become effective until the machining of the

workpiece, i.e. when the additional tool holder is executing the

machining operation.

Feed rate

"F" is the identification letter for feed data. Depending on which mode

of the Feed rate soft key is active, data is entered in:

Millimeters per spindle revolution (feed per revolution)

Millimeters per minute (feed per minute).

On the screen, you can tell the type of feed rate from the unit of

measure in the input field.

You can change the feed value with the feed compensation

controller (feed override) (range: 0% to 150%).

48 3 Machine Mode of Operation

Feed symbols (F display) Symbol

Status "Cycle ON"

Cycle or program execution is active.

Status "Cycle OFF"

Cycle or program execution is not

active.

Page 49

Spindle

"S" is the identification letter for spindle data. Depending on which

mode of the Constant speed soft key is active, data is entered in:

Revolutions per minute (constant speed)

Meters per minute (constant cutting speed).

The input range is limited by the maximum spindle speed. You define

the speed limitation in "Set T, S, F", in machine parameters 805/855,

or in DIN programming with the G26 command.

The speed limit remains in effect until a new speed limit value is

programmed.

The speed compensation controller (speed override) allows you to

change the spindle speed (range: 50% to 150%).

The subscript number after the identification letter "S" indicates the

gear range.

If you are machining with a constant cutting speed,

MANUALplus calculates the spindle speed from the

position of the tool tip. The smaller the diameter of the

tip, the higher the spindle speed. The maximum spindle

speed, however, is never exceeded.

The spindle symbols indicate the direction of spindle

rotation as seen from the point of view of the machinist.

Spindle symbols (S display) Symbol

Direction of spindle rotation M3

Direction of spindle rotation M4

Spindle stopped

3.3 Machine Data

Spindle position-controlled (M19)

HEIDENHAIN MANUALplus 4110 49

Page 50

3.4 Machine Setup

The machine always requires a few preparations, regardless of

whether you are machining a workpiece manually or automatically. In

Manual mode the following functions are subitems of the "Setup"

menu item:

Setting the axis values (defining workpiece zero point)

Setting the protection zone

Defining the tool change position

Setting C-axis values

3.4 Machine Setup

Defining the workpiece zero point

Select "Setup."

„Select "Set axis values."

Touch the workpiece zero point (end face).

Define this point as the workpiece zero point Z.

Enter the distance between the tool and the workpiece zero point as

"measuring point coordinate Z."

MANUALplus calculates the "workpiece zero point Z."

Machine zero point Z = workpiece zero point Z

(offset = 0).

Machine zero point X = workpiece zero point X

(offset = 0).

In the graphic support window, MANUALplus illustrates the distance

between the machine zero point and the workpiece zero point (also

referred to as "offset").

If the workpiece zero point is changed, the display values will be

changed accordingly.

If you want to change the workpiece zero point in X, enter

the diameter value as "Meas. pt. coordin. X." The graphic

display shows the distance "Machine zero point X to

workpiece zero point" as a radius value.

50 3 Machine Mode of Operation

Page 51

Setting the protection zone

Whenever the tool is moved, MANUALplus checks whether the

"protection zone" is violated (in the negative Z direction). If it detects

such a violation, it stops the axis movement and generates an error

message.

The graphic support window shows the current setting for the

protection zone:

Distance between machine zero point and protection zone.

"-99999.000" means: Protection zone (in the negative Z direction) is

not monitored.

Setting the protection zone/switching off the monitoring

function

Select "Setup."

Select the function for setting the protection zone.

Move the tool with the jog keys or handwheel until it reaches the

protection zone.

Define this position as protection zone.

3.4 Machine Setup

Enter the position of the protection zone relative to the workpiece zero

point (field: "Meas. pt. coordin.–Z").

Transfer the entered position as protection zone.

Switch off protective zone monitoring.

Display of the status of protective zone monitoring

Display symbol 9 of the machine display shows the current status of

protective zone monitoring (see “Configuration parameters” on

page 435 – control parameter 301).

Protective zone monitoring is not active if the input

window "Set protect. zone" is open.

In DIN programming, protective zone monitoring can be

deactivated with M417 and reactivated with M418.

HEIDENHAIN MANUALplus 4110 51

Protection zone status Symbol

Protective zone monitoring active

Protective zone monitoring not

active

Page 52

Defining the tool change position

With the cycle "Move to tool change position" or the DIN command

G14, the slide moves to the tool change point. Always program the

tool change point as far from the workpiece as possible to avoid

damage to the workpiece during tool change.

Defining the tool change position

Select "Setup."

3.4 Machine Setup

Approach the tool change position.

Move to the tool change point using the jog keys or the handwheel.

Press "Tool change point."

Define this position as tool change point.

The coordinates of the tool change position are entered

and displayed as distance between machine zero point

and tool carrier zero point. As these values are not

displayed, it is advised to approach the tool change point

and then to define the parameters using Take over

position.

52 3 Machine Mode of Operation

Page 53

Setting C-axis values

The zero point for the C axis can be defined as follows:

Defining the zero point of the C axis

Select "Setup."

Press "Set C-axis values."

Position the C axis.

Define the position as the zero point of the C axis.

Enter the zero point shift of the C axis.

Confirm entry for MANUALplus to calculate the zero

point of the C axis.

Delete zero point shift of the C axis.

3.4 Machine Setup

HEIDENHAIN MANUALplus 4110 53

Page 54

3.5 Setting up Tools

MANUALplus offers functions for measuring tools by touching the

workpiece with the tool or by using a touch probe or an optical gauge.

Set the measuring method in machine parameter 6.

If the tool dimensions are already known, you can enter the setup

dimensions directly in the "Tool management" mode of operation.

Finding the tool dimensions by touch-off with the tool

In the tool table, enter the tool you want to measure (see “Tool Data”

on page 418).

3.5 Setting up Tools

Insert the reference tool and enter the T number in

"Set T, S, F."

Turn an end face and define this coordinate as the workpiece zero

point.

Return to "Set T, S, F", insert the tool to be measured

and enter the associated T number.

Activate Measure tool.

Touch the end face with the tool. Enter the value "0" for the "measuring

point coordinate Z" (workpiece zero point).

Save the tool dimensions (the compensation value is

deleted).

Turn a measuring diameter. Enter the diameter value as "measuring

point coordinate X."

Save the tool dimensions (the compensation value is

deleted).

Enter the cutting radius.

Transfer the cutting radius to the tool table.

54 3 Machine Mode of Operation

Page 55

There are several ways to determine tool dimensions. The following

method describes how the dimensions are determined by comparing

a tool with an already measured tool.

The graphic support window shows the details of the tool

measurement process, taking the selected tool type and

tool orientation into account.

3.5 Setting up Tools

HEIDENHAIN MANUALplus 4110 55

Page 56

Finding the tool dimensions by using a touch probe

In the tool table, enter the tool you want to measure (see “Tool Data”

on page 418).

Insert the tool and enter the T number in "Set T, S, F."

Activate Measure tool.

3.5 Setting up Tools

Pre-position the tool for the first direction of measurement.

Press the soft key for this direction (e.g. Z direction).

Press Cycle START. The tool moves in the direction of

measurement. When it contacts the touch probe, the

control calculates and saves the set-up dimensions.

The compensation value is deleted.

Pre-position the tool for the second direction of measurement.

Press the soft key for this direction (e.g. X direction).

Press Cycle START. The tool moves in the direction of

measurement. When it contacts the touch probe, the

control calculates and saves the set-up dimensions.

The compensation value is deleted.

Enter the cutting radius.

Transfer the cutting radius to the tool table.

56 3 Machine Mode of Operation

Page 57

Finding the tool dimensions by using an optical gauge

In the tool table, enter the tool you want to measure (see “Tool Data”

on page 418).

Insert the tool and enter the T number in "Set T, S, F."

Activate Measure tool.

Position the tool at the cross hairs of the optical gauge by using the jog

keys or the handwheel.

Save the tool dimension in Z (the compensation value

is deleted).

Save the tool dimension in X (the compensation value

is deleted).

3.5 Setting up Tools

Enter the cutting radius.

Transfer the cutting radius to the tool table.

HEIDENHAIN MANUALplus 4110 57

Page 58

Tool compensation

The tool compensation in X and Z as well as the special compensation

for recessing tools compensate for wear of the cutting edge.

A compensation value must not exceed 99 mm.

Defining tool compensation

Select "Set T, S, F" (only available in Manual mode).

3.5 Setting up Tools

Press Tool correct.

Select X offset for tool.

The compensation values that you determine per

handwheel are now shown in the "Distance-to-go"

display.

Transfer the compensation value to the tool table.

The T display shows the new compensation value.

The distance-to-go display is cancelled.

Repeat this procedure for the tool compensation Z and the special

compensation.

Deleting tool compensation values

Select "Set T, S, F" (only available in Manual mode).

Select Tool correct.

Cancel the compensation value entered in X.

Repeat this procedure for the tool compensation Z and the special

compensation.

58 3 Machine Mode of Operation

Page 59

Tool life monitoring

If desired, you can have MANUALplus monitor tool

life or the number of parts that are produced with a

specific tool.

The tool life monitoring function adds the times a tool

is traversed at the machine feed rate and counts the

number of finished parts. The count is compared with

the entry in the tool data.

As soon as the tool life expires or the programmed

quantity is reached, MANUALplus generates an error

message and stops program execution after the end

of the program. If you are working with program

repeats (M99 in DIN programs), the system is

stopped after execution of the current repeat.

Tool life monitoring should be carried out for each tool

used.

The tool life monitoring data (type of monitoring,

maximum tool life / remaining tool life and the

maximum number of pieces / remaining number of

pieces) are managed in the tool data. The tool life

monitoring data are also edited and displayed in the

tool data (see “Tool Data— Supplementary

Parameters” on page 426).

Tool life monitoring is enabled and disabled in "Current

parameters—Setup parameters—Tool monitoring."

You must update the data on tool life and number of

pieces in the Tool management mode when you

replace the cutting edge of a tool.

3.5 Setting up Tools

HEIDENHAIN MANUALplus 4110 59

Page 60

3.6 Manual Mode

With manual workpiece machining, you move the axes with the

handwheels or jog controls. You can also use cycles for machining

complex contours (semi-automatic mode). The paths of traverse and

the cycles, however, are not stored.

After switch-on and traversing the reference marks, MANUALplus is

always in Manual mode. This mode remains active until you select

Teach-in or Program run. You can return to Manual mode with the

"Menu" key. "Machine" displayed in the header indicates that you are

in Manual mode.

3.6 Manual Mode

Define the workpiece zero point (see“Machine Setup” on page 50)

and enter the machine data (see “Machine Data” on page 46) before

you start machining.

Tool change

Enter the T number and check the tool parameters.

"T0" does not define a tool. This also means that T0 does not contain

any data on tool length, cutting radius, etc.

Spindle

The spindle speed is entered in "Set T, S, F." To start and stop spindle

rotation, press the buttons on the machine operating panel. Position

the spindle by defining the "Stopping angle A" in the "Set T, S, F"

menu.

Pay attention to the maximum speed (can be defined with

"Set T, S, F").

Handwheel operation

You set the traverse per handwheel increment with the handwheel

resolution selector switch on the machine operating panel.

Jog operation (joystick)

With the jog controls, you can move the axes at the programmed feed

rate or at rapid traverse. The feed rate is programmed in "Set T, S, F."

The rapid traverse speed is set in "Current parameters—Machine

parameters—Feeds."

60 3 Machine Mode of Operation

Page 61

Cycles in Manual mode

Set the spindle speed.

Set the feed rate

Insert tool, define T number and check tool data (T0 is not

permitted).

Approach cycle start point.

Select the cycle and enter cycle parameters.

Graphic control of cycle run.

Run the cycle.

3.6 Manual Mode

HEIDENHAIN MANUALplus 4110 61

Page 62

3.7 Teach-In Mode

In Teach-in mode (cycle mode), you machine a

workpiece step by step with the help of cycles.

MANUALplus "memorizes" how the workpiece was

machined and stores the necessary working steps in

a cycle program, which you can call up again at any

time.

The Teach-in mode can be switched on by soft key

and is displayed in the header.

Each cycle program is given a number and a short

3.7 Teach-In Mode

description. The individual cycles of a cycle program

are listed as blocks and are numbered in ascending

order. The block number has no meaning for the

program run. The cycles are run after each other.

When the cursor is located on a cycle block,

MANUALplus displays the cycle parameters.

The cycle block includes:

Block number

Tool used

Cycle designation

Number of ICP contour or of DIN macro (in [...])

Cycle programming

When creating a new cycle program, you program

each cycle in the following sequence of actions

"Enter—Simulate—Execute—Save." The individual

cycles form the cycle program.

You can change cycle programs by simply editing the

necessary cycle parameters, and delete or add cycles

as required.

When you exit the Teach-in mode or switch off the

machine, the cycle program remains as it was

programmed or edited.

When you call an ICP cycle, MANUALplus displays a

soft key for switching to the ICP contour editor (see

“Editing ICP Contours” on page 243).

DIN macros are programmed in the DIN editor and

then integrated in a DIN cycle. You can call the DIN

editor by soft key when you select the DIN cycle or

when you are in the "Main menu" (see “DIN

Programming” on page 278).

Soft keys

Switch to the "Select cycle programs" function (see

“Program Management” on page 75).

Renumber the block numbers of the cycles.

Call the alphanumeric keyboard to enter or edit the

program description.

Delete the selected cycle.

Copy the cycle parameters into a buffer memory.

When you then press "Add cycle," the data is inserted

(example: copy parameters of roughing cycle into a

finishing cycle).

Edit cycle parameters or cycle mode (the cycle type

cannot be edited).

Insert a new cycle below the highlighted block.

62 3 Machine Mode of Operation

Page 63

3.8 Program Run Mode

In Program run mode, you use cycle programs and

DIN programs for parts production. You cannot

change the programs in this mode. The "graphic

simulation" feature, however, allows you to check the

programs before you run them. MANUALplus also

offers the "Single block" mode with which you can

machine a workpiece, for example, the first of a whole

batch, step by step.

You can start a cycle or DIN program at any desired

block to resume a machining operation after an

interruption.

The program run mode can be switched on with the

soft key and is displayed in the header.

If you press Program run, MANUALplus reads in the

program that was last active in this mode or in the

editing mode. Alternately, you can select another

program with Program list (see “Program