Harman Stove Company 929 DV User Manual

Installation & Operating Manual

The Harman Clarity 929 DV

Direct Vent Gas Stove

ARM A

H

N

“Ce manuel est disponible en Français sur demande”

R5

SAFETY NOTICE

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW ROOM HEATER. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

FOR USE IN THE U.S. AND CANADA. SUITABLE FOR INSTALLATION IN MOBILE HOMES

IF THIS HARMAN STOVE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR SAFETY, FOLLOW

INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION

REQUIREMENTS IN YOUR AREA.

CONTACT YOUR LOCAL AUTHORITY (SUCH AS MUNICIPAL BUILDING DEPARTMENT, FIRE DEPARTMENT, FIRE

PREVENTION BUREAU, ETC.) TO DETERMINE THE NEED FOR A PERMIT.

CETTE GUIDE D'UTILISATION EST DISPONIBLE EN FRANCAIS. CHEZ VOTRE CONCESSIONNAIRE DE HARMAN STOVE

COMPANY.

SAVE THESE INSTRUCTIONS.

R1

1

CONTENTS

INTRODUCTION ..........................................3

INSTALLATION ............................................4

Clearances...........................................4

Venting.................................................5

Requirements for Terminating the

Venting .............................................................6

Assembly.............................................7

Connecting to a Gas Supply...............9

Connecting the Cordset.................. 10

Connecting the Thermostat............ 10

Air Shutter Adjustment ....................11

Monitoring the Gas Flame...............11

OPERATION ............................................... 12

How to Light the Fire...................... 12

How to Turn Off the Fire ................ 12

Lighting Instructions....................... 13

MAINTENANCE......................................... 14

Removing the Glass ........................ 14

Replacing the Gasket ...................... 14

Cleaning the Glass .......................... 14

Inspecting the Venting .................... 14

Cleaning the Logset and Firebox... 14

Manufactured by:

Harman Stove Co.

352 Mountain House Road

Halifax, PA 17032

2

PARTS LIST & DRAWING ................... 16-17

BURNER MODULE ...................................18

SPECIFICATIONS ......................................19

APPENDIX A: FUEL CONVERSION ....... 20

APPENDIX B: ALTITUDE DE-RATING.. 21

VENTING REFERENCE CHARTS........22-23

WARRANTY ................................................ 24

Tested by

Inchcape Testing/Warnock Hersey

8431 Murphy Drive

Middleton, WI 53562

INTRODUCTION

The Harman Clarity Direct Vent 929DV Gas Heater is a

listed gas-fired direct vent room heater tested by Inchcape

Testing/Warnock Hersey to ANSI standard Z21.88-2002,

CSA 2.33-M02, and CAN/CGA-2.17-M91.

The installation of the Clarity Direct Vent Gas Heater

must conform with local codes, or in the absence of local

codes, with National Fuel Gas Code, ANSI Z223.1 —

latest edition and CAN 1 B1-149.1 and .2 Installation

Code.

Also for use in mobile (manufactured) homes after home

is sited.

Mobile (manufactured) home installations must adhere

to the current edition of Title 24 CFR, part 3280, or CSA

Z240.4.

CAUTION: This appliance must be vented to the outside.

Installation and repair of the Clarity Direct Vent Gas

Heater should be done by a qualified service person. The

appliance should be inspected before use and at least annually by a qualified service person. More frequent cleaning may be required due to excessive lint from carpeting,

bedding material, etc. It is imperative that control compartments, burners, and circulating air passageways of the

Clarity be kept clean.

When operating your Harman Clarity Gas Heater, respect basic safety standards. Read these instructions carefully before you attempt to operate the heater. Failure to

do so may result in damage to property or personal injury

and may void the product warranty.

Consult with your local building code agency and insurance representative before you begin your installation to

ensure compliance with local codes, including the need for

permits and follow-up inspections.

Several issues must be addressed when selecting a suitable location for your Clarity Gas Heater. Observing required clearances to combustible materials, the proximity

to a safe chimney or venting system location, and the accessibility of the gas and electrical supply must all be considered. In addition, selecting a location that takes advantage of the building's natural air flow is also desirable to

maximize the heating effectiveness of the heater. In many

cases, this is a central location within the building.

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

FOR YOUR SAFETY: WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Open windows.

• Extinguish any open flame.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified gas installer, service agency,

or the gas supplier.

3

INSTALLATION

IMPORTANT NOTICE

Due to high temperatures, the Clarity Direct Vent

Gas Heater should be located out of traffic and away

from furniture and draperies.

Children and adults should be alerted to the hazards of high surface temperatures and should stay

away to avoid burns or clothing ignition.

Young children should be carefully supervised

when they are in the same room as the appliance.

Clothing or other flammable materials should not

be placed on or near the Clarity Direct Vent Gas Heater.

4" (100 mm)

4" (100 mm)

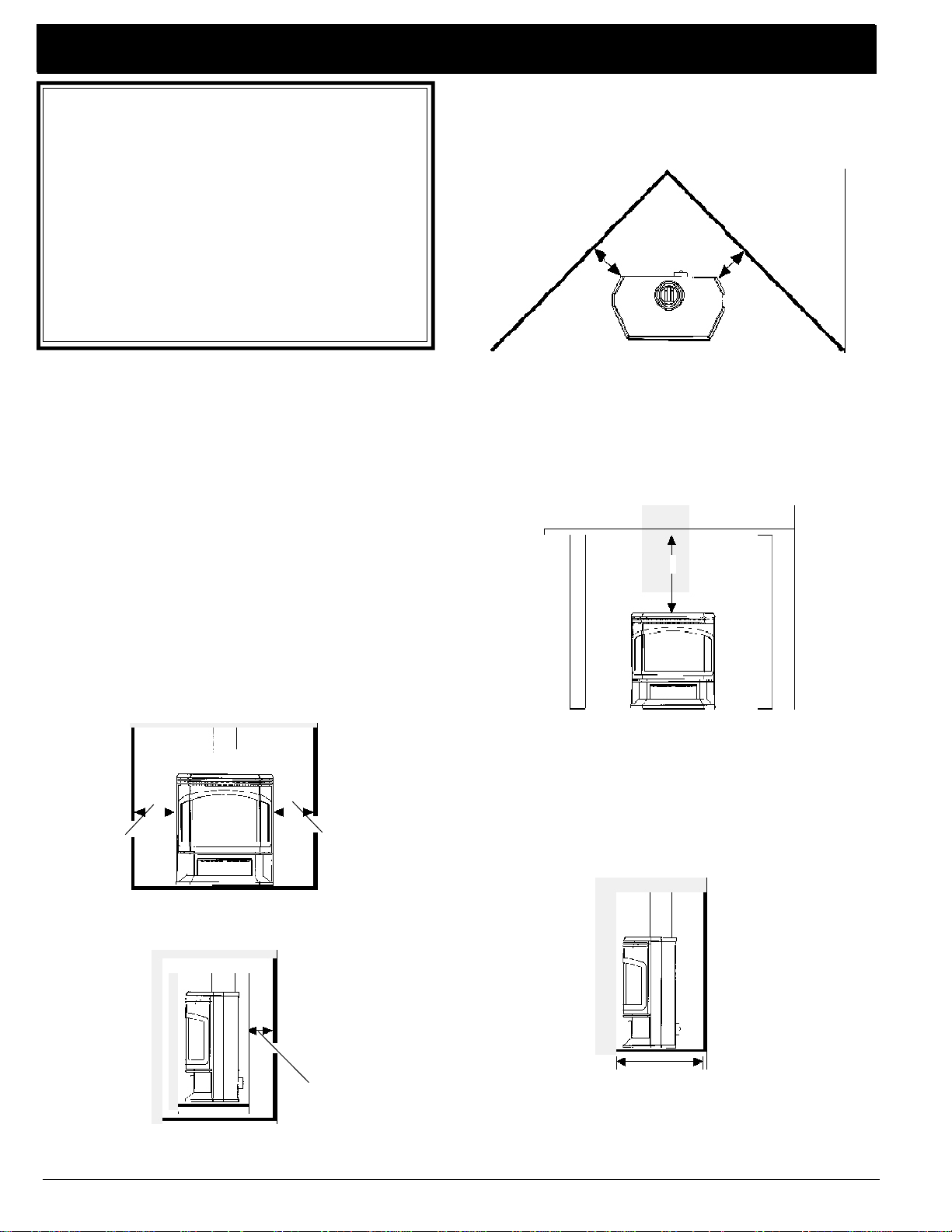

Clearances

The following clearances to combustibles must be ob-

served:

Heater to left sidewall 9" (230 mm)

Heater to right sidewall 9" (230 mm)

Heater corner to walls 4" (100 mm)

Heater to back wall 3" (75 mm)

(measured from rear of heater to wall)

Heater to alcove ceiling 18" (460 mm)

Maximum alcove depth 14" (355 mm)

In addition to the clearances mentioned previously, adequate accessibility clearance for servicing and proper operation must be maintained.

If this appliance is installed directly on carpeting, vinyl

tile, or other combustible material other than wood flooring

the appliance shall be installed on a metal or wood panel

extending at least the full width and depth of the appliance.

Clearance from corner of unit to walls.

18" (460 mm)

Clearance to alcove ceiling.

9" (230 mm) 9" (230 mm)

Sidewall clearance

3" (75 mm)

Clearance to back wall

4

14" (355 mm)

Maximum alcove depth

VENTING

Use Only Approved Venting

The Clarity Direct Vent Gas Heater has been tested

and is listed for installation with Simpson Duravent GS venting components. The Simpson Duravent GS warranty will

be voided, and serious fire, health, or other safety hazards

may result from any of the following actions:

• Installation of any damaged Duravent GS component.

• Unauthorized modification of the Duravent GS System.

• Installation of any component part not manufactured or

approved by Simpson Duravent.

• Installation other than as instructed by Simpson Duravent

and the appliance manufacturer.

Consult your local building codes before beginning the

installation, and follow the manufacturer's instructions exactly. The following Simpson Duravent GS 4" X 6 5/8" venting components are approved for use with the Clarity Direct Vent Gas Heater.

SIMPSON DURA-VENT COMPONENT NO.

Basic Termination Kit.......................................................970

Horizontal Termination Kit A...........................................971

VerticalTermination Kit A.................................................973

Horizontal Square Termination Cap.................................984

VerticalTermination Cap...................................................983

Snorkel Termination Cap, 36" Vertical Rise.....................981

Snorkel Termination Cap, 14" Vertical Rise.....................982

Vinyl Siding Standoff .......................................................950

Wall Thimble.....................................................................942

Round Ceiling Support/Wall Thimble Cover..................940

Cathedral Ceiling Support Box ........................................941

Storm Collar ......................................................................953

Firestop Spacer.................................................................963

Adjustable Roof Flashing, 0/12-6/12 pitch .....................943

Steep Roof Flashing, 7/12-12/12 pitch.......................... 943S

Wall Strap .........................................................................988

Designer Series Trim Kits ..........................3951, 3952, 3953,

3960, 3961, 3962

High Wind Vertical Termination Cap...............................991

Low Profile Termination Cap............................................980

WARNING: The flow of ventilation air must not be

obstructed.

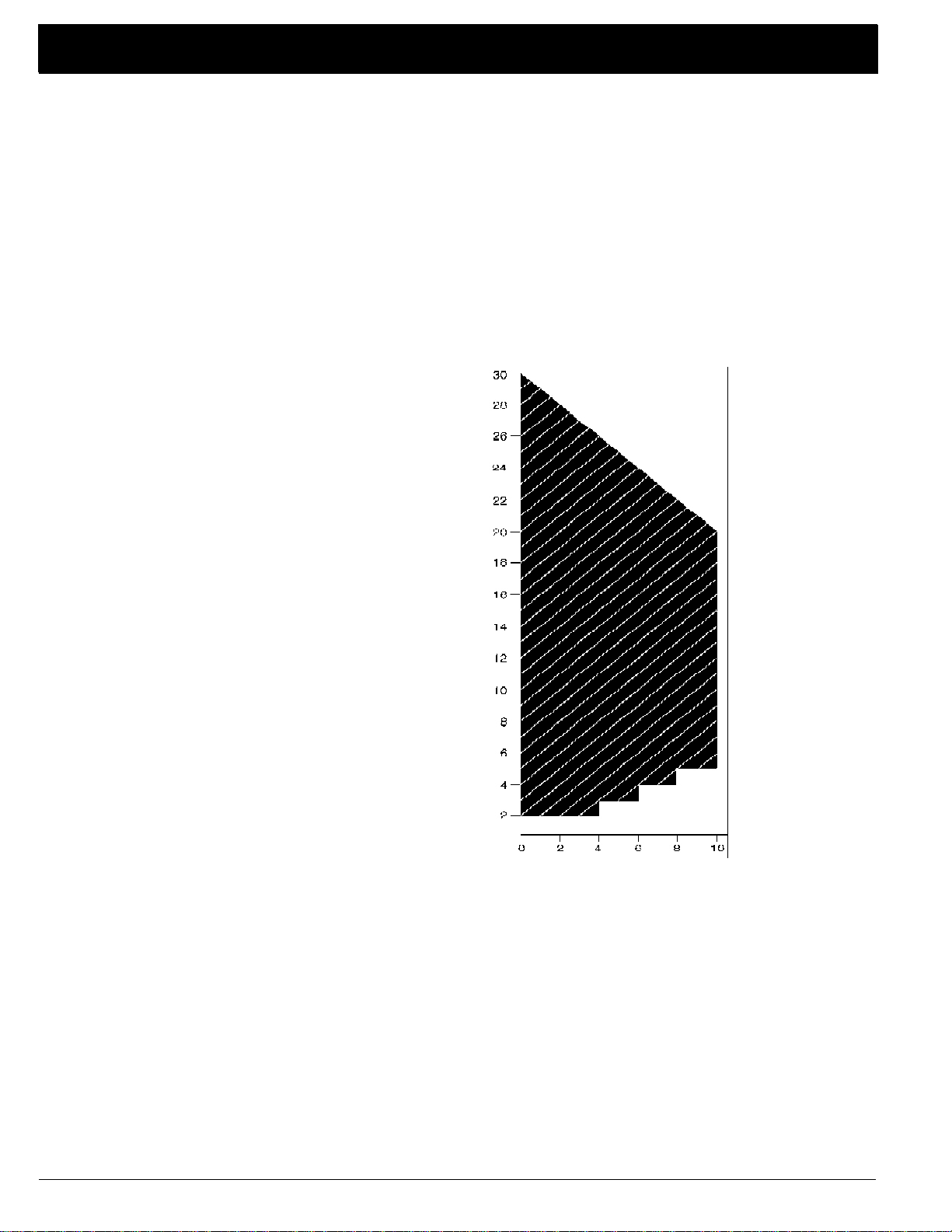

Horizontal and Vertical Venting Requirements

The maximum horizontal run allowed for the Clarity Direct Vent is 10 feet. The maximum vertical rise and maximum total vent length is 30 feet. The horizontal and vertical

lengths of venting must fall within the shaded portion of the

chart below:

Restrictor plates supplied by Harman

(Part No. G218) may be added in straight vertical installations only. For each 10' of vertical rise above the first 10',

one restrictor plate may be added. No more than two

restrictor plates may be used.

For venting systems that utilize one or two el-

bows (either 45° or 90°), restrictor plates

should not be used.

For the Clarity Direct Vent, the vent/

air intake termination clearances

above the high side of an

angled roof are as follows:

Vertical rise (feet)

DIRECT VENT PIPE LENGTHS

DURA-VENT COMPONENT NO.

GALVANIZED BLACK

6" length NA 908B

9" length NA 907B

12" length 906 906B

24" length 904 904B

36" length 903 903B

48" length 902 902B

11-14 5/8" Adjustable - 911B

45° Elbow 945 945B

90° Elbow 990 990B

The Clarity Direct Vent should be installed with no more

than 12 joints and 2 elbows. The elbows may be either 45°

or 90°.

The Clarity Direct Vent must not be connected to a chim-

ney flue serving any other appliance.

Horizontal run (feet)

Roof Pitch Feet Meters

Flat to 6/12 1 0.3

7/12 to 9/12 2 0.6

10/12 to 12/12 4 1.2

13/12 to 16/12 6 1.8

17/12 to 21/12 8 2.4

5

VENTING

Requirements for Terminating the Venting

WARNING: Venting terminals must not be recessed

into a wall or siding.

In addition, the following must be observed:

A. The clearance above grade, or a veranda, porch, deck

or balcony must be a minimum of 12" (30 cm).

B. The clearance to a window or door that may be opened

must be a minimum of 12" (30 cm).

1

C. A 12" (30 cm) clearance to a permanently closed window is recommended to prevent condensation on the window.

D. The vertical clearance to a ventilated soffit located

above the terminal within a horizontal distance of 2 feet (60

cm) from the center-line of the terminal must be a minimum of 18" (46 cm).

E. The clearance to an unventilated soffit must be a minimum of 12" (30 cm).

F. The clearance to an outside corner is 9" (23 cm).

G. The clearance to an inside corner is 12" (30 cm).

H. A vent must not be installed within 3 feet (90 cm)

above a meter/regulator assembly when measured from the

horizontal center-line of the regulator.

1

I. The clearance to service regulator vent outlet must be a

minimum of 6 feet (1.8 m).

1

J. The clearance to a non-mechanical air supply inlet to

the building or the combustion air inlet to any other appliance must be a minimum of 12 feet (30 cm).

K. The clearance to a mechanical air supply inlet must be

a minimum of 6 feet (1.8 m).

1

L. The clearance above a paved sidewalk or a paved

driveway located on public property must be a minimum of

7 feet (2.1 m).

1,2

M. The clearance under a veranda, porch, deck or balcony must be a minimum of 12 inches (30 cm).

1

1

1,3

1

As specified in CAN 1 B1-149 Installation Codes (currend

edition). Note: local codes or regulations may require different clearances.

2

A vent shall not terminate directly above a side-walk or

paved driveway which is located between two single family dwellings and serves both dwellings.

3

Only permitted if veranda, porch, deck, or balcony is fully

open on a minimum of 2 sides beneath the floor.

Connecting To An Existing Chimney

The Clarity may be connected to an existing ma-

sonry chimney by using a Simpson Dura-Vent con-

version kit #934.

With this kit and a 4" flex linner in the chimney the

flue gases exit through the 4" linner and the outside

air comes down the chimney in the space between

the chimney and the linner. This method allows you

to install the Clarity your chimney and still get the

added efficiency provided by direct venting.

The use of an existing chimney as an

air intake is not covered under the ANSI Z21.50-1996.

CGA 2.22-M96 test methods and the resulting ITS/WHI

product certfication: The code Authority Having Jurisdiction must be consulted prior to proceeding.

Inside

Corner

Det ail

G

A

A

Fixed

Closed

J

V

H

V

B

B

A

= Area where terminal is not permitted

M

V

A

K

D

E

V

B

V

L

= Vent terminal = Air supply inlet

V

C

V

Fixed

Closed

Openab le

V

F

B

A

B

V

Openable

B

V

6

ASSEMBLY

The Clarity is shipped from the factory with the log set

packed inside the firebox. To prepare the stove for installation, the log set must be unpacked, the appropriate burner

system module for either natural gas or propane installed,

and the logs installed.

Removing the Glass Front

NOTE: The glass front is heavy. Be prepared for its

weight when lifting it to avoid damage during removal.

The wing doors on each side are held closed by magnets. Push on each door to open it. Loosen the wing nut on

each of the two spring-loaded levers. Grasp each lever and

push to the rear to disengage the front. To keep the levers in

the disengaged position, tighten the wing nuts. Lift the glass

front slightly and remove it from the stove. Set the glass

aside in a safe place where it will not be damaged.

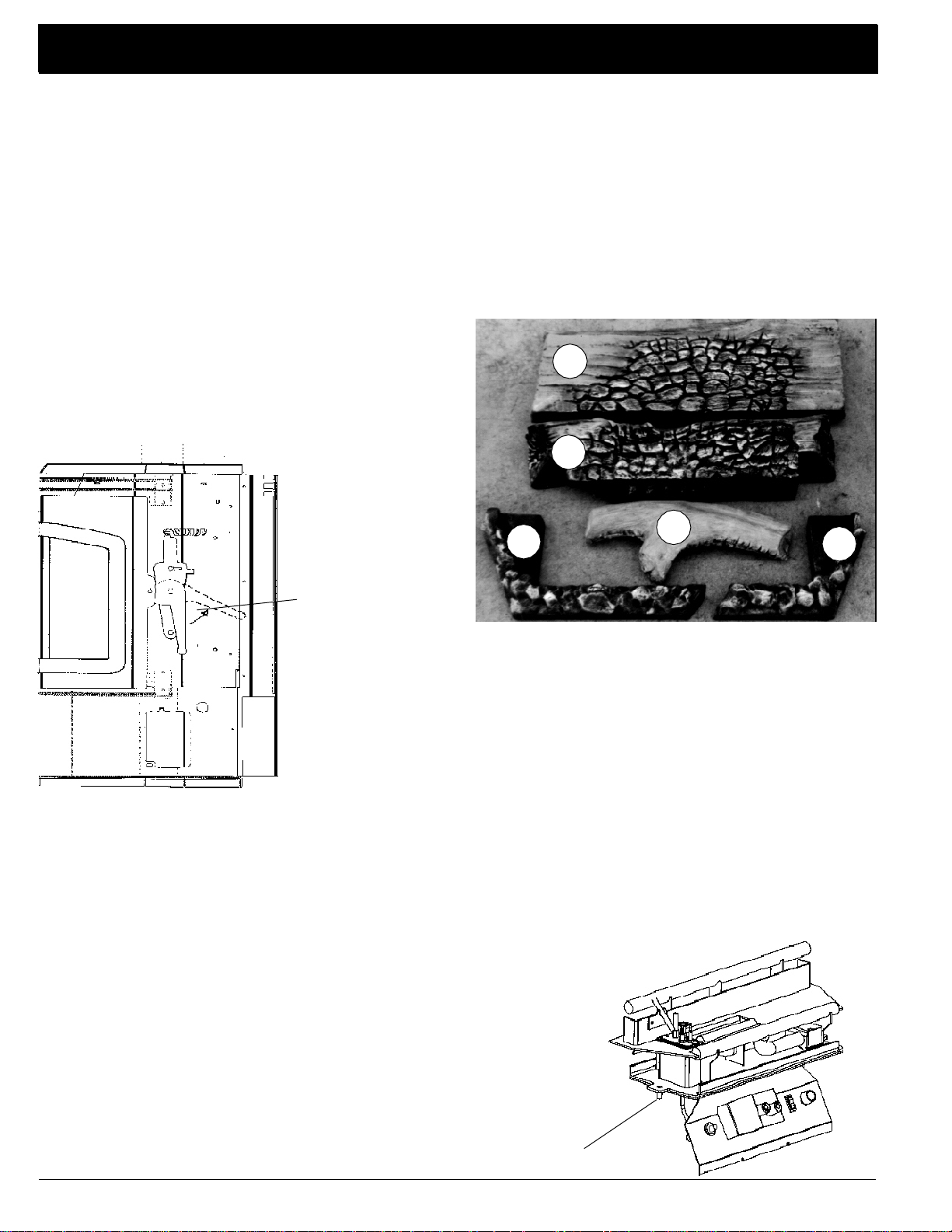

Remove and Unwrap the Log Set

As shown in the photo in the right column, the log set

consists of a back log (1), a center log that has a pilot-viewing port in the left end (2), two ember strips (3), and a branch

that rests on top (4).

In addition, there are two side brick panels and a back

brick panel.

The log set components are shipped from the factory

individually wrapped and packed inside the stove. Take them

out of the stove, then carefully remove the wrapping. Handle

the logs gently as they may be damaged easily.

1

2

4

3

3

The front is released

when spring-loaded

levers on the left

and right sides are

pushed to the rear

WARNING: Do not abuse the Clarity's glass

by striking, slamming, or similar trauma. Do not

operate the Clarity Gas Heater with the glass

panel removed, cracked or broken. Use only

glass supplied by Harman and approved for use

with this heater. Do not use substitute materials. Replacement of the panel should be done

by a licensed or qualified service person.

Installing the Burner System Module

The burner system module may be installed into the firebox as an integrated unit, and it may help to have an assistant

who can assist in guiding the components into position and in

making sure that the module does not sit on any wiring components.

Hold the module at a slight angle, then lower it through the

opening and rotate upright until it is in position.

Reach underneath and install one of the wing nuts, finger

tight. Then check to see that the module is seated correctly.

A sealing gasket affixed to the bottom of the module's base

plate will cause the log support plate to be elevated slightly

above the plane of the firebox bottom plate. When the two

wing nuts are tightened, this gasket will be compressed and a

correct fit will be indicated by the log support plate becoming

flush with the bottom of the firebox.

Install wing nut

on threaded stud

7

ASSEMBLY

With the module installed and secured, reach through

the side access ports and plug in the electrical connections.

(Two AMP Mate-N-Lok connectors).

The two electrical

connectors may be

reached through the

side access port

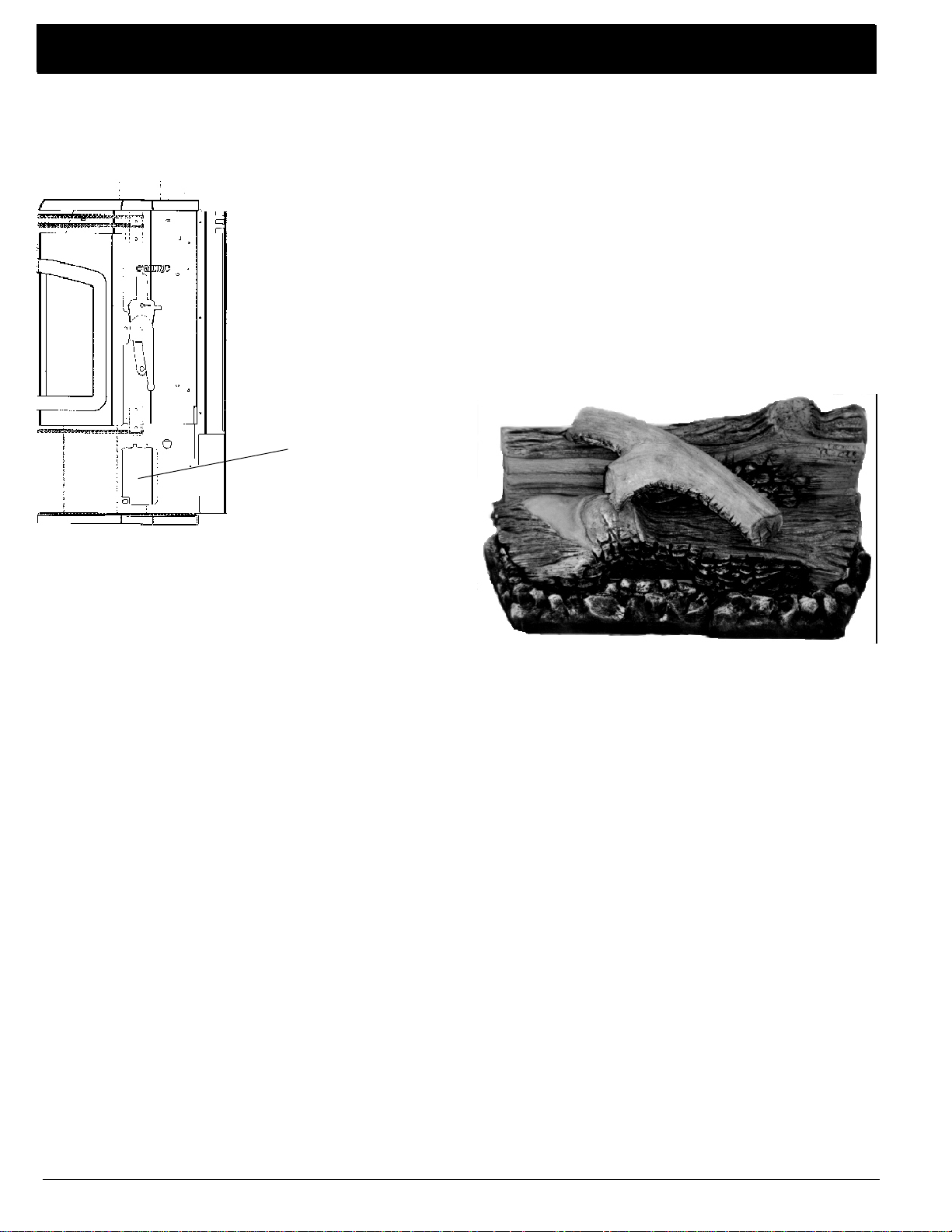

Install the Branch

Orient the branch with the forked end toward the left

rear of the stove and slip it over the two locator pins, one on

top of the back log and the other on the top of the center log.

Secure the Glass Front

NOTE: The glass front is heavy. Lift it carefully to prevent damage. Center the glass on the opening and suspend

it in place by placing the the tab hooks over the top edge of

the opening. Loosen the wing nuts that hold the spring-loaded

levers in place. Press the glass slightly against the stove to

confirm that it seats properly, then press it firmly against the

front while pulling the levers forward to engage them. Tighten

the wing nuts.

Install the Back Log and Back Brick Panel

These two components are installed as a single piece.

Rest the back brick panel on the shelf located on the back

side of the back log, and center it. Holding the two pieces as

a single unit, tilt the top forward slightly and manuever it

over the top of the rear burner—taking care that the top

corners clear the front opening. Place it snugly against the

back wall and center it.

Install the Side Brick Panels

These slide into place along each side and are held by

friction. The notch in each panel faces the back. Install one

side, and then the other.

Install the Ember Strips

The ember strips rest against the front of the firebox

and should fit snugly. Guide them toward you and to the

outside until they fit snugly. Check the air slot in the inside of

the ember strips to confirm that they do not obstruct it.

Install the Center Log

The center log goes all the way to the back and should

be centered. When properly positioned, there should be an

even gap along the front of the center burner in the cavity in

the log. A small portion of the log support frame will be

revealed.

The center log has a round viewing port in the left end

through which the pilot can be observed.

The complete log set with all logs in the correct position.

8

Loading...

Loading...