GE Sensing XMO2 Data sheet

XMO2

Panametrics Smart

Oxygen Analyzer

Applications

An oxygen transmitter for use in:

•Inerting/blanketing liquid storage tanks

•Reactor feed gases

•Centrifuge gases

•Catalyst regeneration

•Solvent recovery

•Landfill gas

•Sewage wastewater digester gas

•Oxygen purity

Features

•Measurement ranges from 0.01 percent to 100 percent O2 in gases

•Explosion-proof and flameproof enclosure with weatherproof protection allows sensorto be remotelymounted at the measurement point

•Push-button, single ordual gas calibration

•Compact, rugged sensordesign with no moving parts provides long term reliability and trouble-free operation

•Dual-bridge measurement circuit compensates for variations in background gas composition

•Uniquedual-chamber,temperature-controlledcell design provides resistance to contamination and flow fluctuation

•Computer-enhanced accuracyof 1 percent of span and linearityof betterthan 0.5 percent of span

bhge.com

Smart Oxygen Transmitter

The XMO2 thermoparamagnetic oxygen transmitter is the most stable oxygen analyzeravailable on the market today. It represents the state of the art in oxygen measurement. With the XMO2 transmitter,

reliable process oxygen measurement can be as easy as temperature or pressure measurement.

Top Performance and Ease of Use

The XMO2 combines computer-enhanced, automatic oxygen signal compensation, fast-response software, real-time errordetection and automated calibration with a proven thermoparamagnetic oxygen sensorto achieve unequaled performance and ease of use.

The compact, weatherproof, explosion-proof and flameproof XMO2 is specifically designed to be field installed at the process measurement point, thus minimizing sample-conditioning requirements while ensuring the best sample and the fastest possible response.With no moving parts, it is insensitive to mounting position orvibration, and it has excellent long-term reliability.The XMO2’s dual-chamberoxygen cell design makes it resistant to contamination and flow variation.

Automatic Background Gas

Compensation

An onboard microprocessorgives the XMO2 the computing power to provide advanced online signal conditioning and digital communications via an RS232 interface and menu-driven software. Integrated signalprocessing algorithms provide improved linearity and accuracy, and automatic compensation forbackground gasvariationsand/oratmosphericpressureeffects.Afastresponse software routine provides typical response time oflessthan15seconds.Whenrecalibrationdoesbecome necessary, it can be accomplished quickly and easily through software, with no potentiometers to adjust.

Choice of Enclosures and Ranges

The XMO2 requires 24 VDC powerand provides a

4 to 20 mA output signal with fullyprogrammable zero and span settings.The output is proportional to oxygen concentrationandinternallycompensatedforbackground gas and/oratmospheric pressure variations.The weatherproof, explosion-proof and rack-mount options are available in a wide variety of measurement ranges.

XMO2 Accessories

BHGE provides a complete line of accessories for use with the XMO2.This includes sample systems customdesigned forspecific applications, a 24VDC powersupply and a four-wire color-coded cable in lengths up to

4000 ft (1200 m).The XMO2 can also be interfaced with otherBHGE displays and analyzers, such as theTMO2D, XDP and moisture.IQ analyzers.TheTMO2D and XDP displays provide microprocessor-based oxygen signal compensationformaximumaccuracy,software-enhanced response and automatic calibration of the XMO2 transmitter.

Dual-Chamber Design

Induced |

Wind Generating (Cooled) Thermistor |

|

Gas Flow |

Wind |

|

|

||

Upper |

Receiving |

|

(Warmed) |

||

Measurement |

||

Thermistor |

||

Chamber |

||

|

||

Upper |

Magnetic |

|

Flow-Through |

||

Field |

||

Chamber |

||

|

||

Sample Inlet |

Sample Outlet |

Flow schematic of the XMO2 thermoparamagnetic oxygen measuring cell. Oxygen’s paramagnetic property causes an oxygen-containing gas sample to move within the magnetic field.Thegasmovementcreatesa“magneticwind”thatissensed by the thermistor pairs. Oxygen concentration and background gas compensation are determined by the transmitter’s microprocessor.

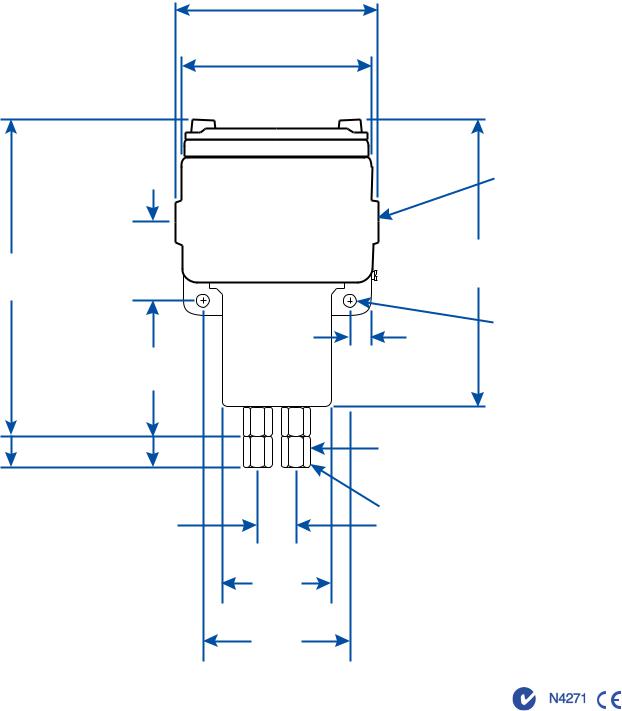

Dimensions

6 in (155 mm)

5.7 in (145 mm)

|

|

|

3/4 in NPTF |

|

|

XMO2 |

|

|

|

Transmitter |

|

9.5 in (242 mm)* |

2.7 in |

8.6 in |

|

(70 mm) |

(220 mm) |

||

10.4 in (266 mm)** |

|

|

|

|

|

0.59 in |

0.39 in (10 mm) |

|

|

diameter |

|

4 in (105 mm)* |

(15 mm) |

|

|

5 in (129 mm)** |

|

|

|

|

|

Optional flame arrestor |

|

*Weatherproof |

|

for explosion proof units only |

|

|

1/4 in NPTF |

|

|

**Explosion proof |

|

||

|

1 in |

|

|

|

(29.5 mm) |

|

|

|

|

3.2 in |

|

|

|

(83 mm) |

|

|

|

4.4 in |

|

|

|

(113.3 mm) |

|

Loading...

Loading...