GE Sensing MIS 1 Operating Manual

Moisture Image Series 1

Hygrometer

Programming Manual

April 2004

Process Control Instruments

Moisture Image Series 1

Hygrometer

Programming Manual |

910-108PB2 |

!ATTENTION!

This manual contains instructions for Series 1 units equipped with controller card p/n 703-1250. This controller card supports the PanaCom/PanaView user interface software.

|

June 2003 |

|

|

Warranty |

Each instrument manufactured by GE Panametrics is warranted to be |

|

free from defects in material and workmanship. Liability under this |

|

warranty is limited to restoring the instrument to normal operation or |

|

replacing the instrument, at the sole discretion of GE Panametrics. Fuses |

|

and batteries are specifically excluded from any liability. This warranty |

|

is effective from the date of delivery to the original purchaser. If GE |

|

Panametrics determines that the equipment was defective, the warranty |

|

period is: |

|

• one year for general electronic failures of the instrument |

|

• one year for mechanical failures of the transducers |

|

If GE Panametrics determines that the equipment was damaged by |

|

misuse, improper installation, the use of unauthorized replacement parts, |

|

or operating conditions outside the guidelines specified by GE |

|

Panametrics, the repairs are not covered under this warranty. |

|

|

|

The warranties set forth herein are exclusive and are in lieu of |

|

all other warranties whether statutory, express or implied |

|

(including warranties or merchantability and fitness for a |

|

particular purpose, and warranties arising from course of |

|

dealing or usage or trade). |

Return Policy |

|

If a GE Panametrics instrument malfunctions within the warranty period, |

|

|

the following procedure must be completed: |

|

1. Notify GE Panametrics, giving full details of the problem, and |

|

provide the model number and serial number of the instrument. If the |

|

nature of the problem indicates the need for factory service, GE |

|

Panametrics will issue a RETURN AUTHORIZATION NUMBER |

|

(RAN), and shipping instructions for the return of the instrument to a |

|

service center will be provided. |

|

2. If GE Panametrics instructs you to send your instrument to a service |

|

center, it must be shipped prepaid to the authorized repair station |

|

indicated in the shipping instructions. |

|

3. Upon receipt, GE Panametrics will evaluate the instrument to |

|

determine the cause of the malfunction. |

|

Then, one of the following courses of action will then be taken: |

|

• If the damage is covered under the terms of the warranty, the |

|

instrument will be repaired at no cost to the owner and returned. |

|

• If GE Panametrics determines that the damage is not covered under |

|

the terms of the warranty, or if the warranty has expired, an estimate |

|

for the cost of the repairs at standard rates will be provided. Upon |

|

receipt of the owner’s approval to proceed, the instrument will be |

|

repaired and returned. |

iii

April 2004

Table of Contents

Chapter 1: Features and Capabilities

Introduction to the Moisture Image

Series 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 Electronics Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 BASEEFA Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3 CSA Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3 Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

M Series and TF Series Moisture Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4 Moisture Image Series Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6 Delta F Oxygen Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7 Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 M Series and TF Series Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 Moisture Image Series Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 Delta F Oxygen Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 RS232 Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 User Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Chapter 2: Basic Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Entering Data into the User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 Screen and Key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5 Entering the Passcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6 Getting On-Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7 Verifying and Entering Setup Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8 Activating and Changing Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9 Entering Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12 Entering High and Low Reference Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21 Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28 Setting Up the Matrix Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32 Setting Up the Line Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35 Tagging the Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37 Adjusting the Contrast of the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40 Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

v

April 2004

Table of Contents (cont.)

Chapter 3: Advanced Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Selecting Measurement Mode and Units for Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Setting the Range for Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting Up the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Selecting the Measurement Mode, Units and High/Low Values for Alarms . . . . . . . . . . . . 3-5

Entering the Setpoint and Deadband Values for Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Using Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Entering Constants and User Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Entering User Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Specifying User Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Entering User-Defined Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Entering Saturation Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Using Computer Enhanced Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting Up the Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Viewing the Data Logger Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Viewing Logged Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Removing Logged Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Entering Data Logger Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting Up the RS232 Communications Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Configuring the Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Description of a Sample Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Setting Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Procedure for Setting Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Loading New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Chapter 4: Programming with PanaView

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Changing Measurement Modes and Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Open the Meter Display Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 Change Meter Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 Changing a Matrix Display to a Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6 Changing Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7 Changing Recorder Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9 Setting Recorder Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9 Testing Recorder Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10 Programming Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11 Programming User Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12 Entering User Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14 Entering Saturation Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

vi

Chapter 1

Features and Capabilities

Introduction to the Moisture Image Series 1 . . . . . . . . . . . . . . . . .1-1

Electronics Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Introduction to the Moisture Image Series 1

Electronics Unit

June 2003

The GE Panametrics Moisture Image Series 1 is a microprocessor based multi-channel analyzer designed to measure dissolved moisture concentration in gases and non-aqueous liquids, and dissolved oxygen concentration in gases. It is a highly advanced industrial analyzer which is versatile and adaptable to many applications.

The Series 1 combines the use of hardware and software to make various measurements. The user connects the needed inputs (moisture probes, oxygen cells, pressure transducers, etc.) to the back panel of the electronics unit using several types of cables. Typically, the user installs moisture probes and oxygen cells into the process using a sample system that is specifically designed for the application. The sample system delivers a sample of the process to the probes. The probes then send a signal to the Series 1 electronics unit, which interprets the signal and converts it into a measurement.

The complete analyzer, including electronics, cables, and measurement probes, forms a “system” which is designed to monitor the process accurately and reliably. The following sections discuss each part of this “system.”

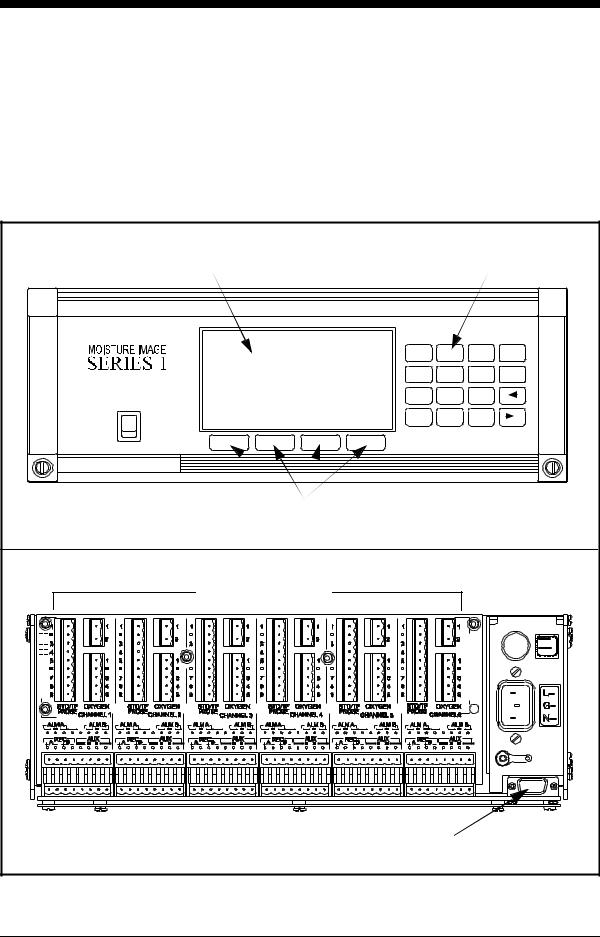

The center of the “system” is the electronics unit. The electronics unit has many components, including terminal blocks for all connections, an RS232 port, a Liquid Crystal Display (LCD), a keypad, and menu keys. See Figure 1-1.

The back panel of the electronics unit contains the terminal blocks for connecting moisture probes, oxygen cells, recorders, and optional alarms (standard or hermetically sealed) for up to six channels. The Series 1 also provides connections for two isolated outputs per channel. Input connections for the M Series, TF Series, Moisture Image Series and Delta F oxygen sensors are intrinsically safe.

As an optional feature, the Series 1 provides connections for two auxiliary inputs (not intrinsically safe) on each channel. The auxiliary inputs can accept signals from any 0/4 to 20-mA or 0 to 2-VDC device, including other GE Panametrics analyzers.

The RS232 port enables the user to connect a remote terminal, printer, or computer to the Series 1. Using an optional Personal Computer (PC) interface software package, the user can also set up and operate one or more analyzers from a remote location, transfer data for further analysis, and create data logs.

The front panel of the electronics unit has a Liquid Crystal Display (LCD) to show data.The LCD is capable of displaying data in a line graph, or a text matrix format.

Features and Capabilities |

1-1 |

April 2004

Electronics Unit (cont.) The front panel also has a 16-key keypad that is used to enter data and operate the Series 1. There are four menu keys below the LCD, as shown in Figure 1-1 below. The function of a menu key is indicated directly above it on the LCD. The menu key functions change as the user makes menu selections.

The electronics unit with all these features is available in a rack mount, bench mount, panel mount, weatherproof, or explosion-proof versions.

LCD Screen |

|

|

Keypad |

1 |

2 |

3 |

YES |

4 |

5 |

6 |

NO |

7 |

8 |

9 |

|

POWER |

0 . |

|

|

- |

|

||

Menu Keys |

|

|

|

Terminal Blocks |

|

|

|

|

|

|

12 |

|

|

|

2 50 |

|

|

|

3 |

RS232 Port |

|

|

|

Figure 1-1: The Series 1 Electronics Unit Features

1-2 |

Features and Capabilities |

|

June 2003 |

|

|

BASEEFA Certification |

Rack, bench, panel Series 1s s/n 2000 and above and WPF Series 1s |

|

s/n 2300 and above are BASEEFA certified to supply intrinsically |

|

safe levels. Installation requires that the Series 1 be mounted in a |

|

general purpose area only. M Series, TF Series, and Moisture Image |

|

Series probes and Delta F oxygen cells are intrinsically safe when |

|

connected to the Series 1, allowing for sensor installation in IEC/ |

|

CENELEC zone 0 areas. |

CSA Certification |

Newer versions of rack, bench, panel and WPF Series 1’s are |

|

CSA-NRTL certified intrinsically safe. Installation requires the |

|

Series 1 be mounted in either a NEC CL.1, Div. 2, Group B, C or D |

|

hazardous area or a general purpose area. M Series, TF Series, and |

|

Moisture Image Series probes and Delta F oxygen cells are |

|

intrinsically safe when connected to the Series 1, allowing for sensor |

|

installation in NEC CL.1, Div. 1, Groups A, B, C and D hazardous |

|

areas. |

|

Note: Refer to certification labels on your instrument and |

|

installation drawing #752-138 to determine the applicable |

|

level of certification that your meter carries. |

Features and Capabilities |

1-3 |

June 2003

Probes

M Series and TF Series

Moisture Probes

Probes are the part of the system that come into contact with the process flow. The Series 1 uses various types of probes to fit the needs of a wide range of applications.

The term “probe” includes devices such as moisture sensors, pressure transducers, and oxygen cells. Although you can supply your own probes for certain measurements, GE Panametrics provides the following standard probes to make moisture, temperature, pressure and oxygen measurements:

•Moisture (M) Series - moisture and temperature (in gases and liquids)

•Three Function (TF) Series and Moisture Image Series Probes - moisture, temperature, and pressure (in gases and liquids)

•Delta-F Cells - oxygen measurement (in gases)

The most commonly used probes are discussed in more detail below.

The M Series and the TF Series probes are very similar. Both probes use GE Panametrics aluminum oxide sensors to measure moisture, and thermistor beads to measure temperature (the thermistor is optional). The TF Series, however, also has an optional built-in strain-gage-type pressure transducer. The sensor assemblies are secured to a probe mount and are usually protected with a sintered stainless-steel shield (TF-9 probes do not have a shield). Other types of shields are available (refer to Figure 1-2 below and Figure 1-3 on page 1-5).

When using an M Series probe, a separate pressure transmitter is required if in-line pressure measurement is needed. The Series 1 can use any pressure transmitter with a 0/4 to 20 mA or 0 to 2-V output. Alternatively, the user can enter fixed values for temperature and pressure into the Series 1 memory if the process conditions are constant.

Figure 1-2: The M Series Probe

1-4 |

Features and Capabilities |

June 2003

M Series and TF Series

Moisture Probes (cont.)

Figure 1-3: The TF Series Probe

Although the M and the TF Series probes may be installed directly in the process line, more often these probes are inserted into a sample system. The sample system protects the probes and enables the user to easily remove the probes for calibrating, servicing and cleaning. Sample systems also control the flow of the process stream so that it is within the specifications of the measurement probe or cell.

The M and TF Series probes, when used with a BASEEFA-approved Series 1, are intrinsically safe (see Chapter 3, Specifications, of the Startup Guide for BASEEFA certification numbers) and designed to meet the requirements of IEC/CENELEC zone 0 areas.

When operated with a CSA-NRTL approved Series 1, the M and TF Series probes are intrinsically safe (see Chapter 3, Specifications, of the Series 1 Startup Guide for CSA-NRTL certification numbers) and designed to meet the requirements of NEC C1.1, Div. 1, Groups A, B, C and D hazardous areas.

The M and TF Series probes measure moisture content in a standard range from –110°C to 20°C (–166°F to 68°F) dew/frost point temperature and optionally from –110°C to 60°C (–166°F to 140°F). Both probes optionally measure temperature in a range of –30°C to 70°C (–22°F to 158°F). The TF probe optionally measures pressure from 30 to 300, 50 to 500, 100 to 1000, 300 to 3000, or 500 to 5000 PSIG.

Features and Capabilities |

1-5 |

June 2003

Moisture Image Series

Probe

The Moisture Image Series Probe measures moisture, temperature (optional), and pressure (optional). The Moisture Image Series Probe has its own electronics module that consists of a built-in microcontroller with 16-bit resolution (see Figure 1-4 below).

The electronics module stores the probe calibration and reference data in non-volatile memory; therefore, the user never needs to enter the data by hand. The Moisture Image Series Probe also features continuous compensation of its own analog circuitry to assure longterm electronic stability.

The Moisture Image Series Probe, when operated with a BASEEFAapproved Series 1, is intrinsically safe (see Chapter 3, Specifications, of the Startup Guide for BASEEFA certification numbers) and designed to meet the requirements of IEC/CENELEC zone 0 areas.

The Moisture Image Series Probe, when operated with a CSA-NRTL certified Series 1, is intrinsically safe (see Chapter 3, Specifications, of the Series 1 Startup Guide for CSA-NRTL certification numbers) and designed to meet the requirements of NEC C1.1, Div. 1, Groups A, B, C and D hazardous areas.

The Moisture Image Series Probe measures moisture content in a standard range from –110°C to 20°C (–166°F to 68°F) dew/frost point temperature and optionally from –110°C to 60°C (–166°F to 140°F). Additionally, the Moisture Image Series Probe can be used to measure temperature in a range of –30°C to 70°C (–22°F to 158°F) and pressure from 30 to 300, 50 to 500, 100 to 1000, 300 to 3000, or 500-5000 PSIG.

Electronics Module |

Figure 1-4: The Moisture Image Series Probe

1-6 |

Features and Capabilities |

|

June 2003 |

|

|

Delta F Oxygen Cell |

The Series 1 standard oxygen measurement probe is the Delta F Cell. |

|

Overall oxygen content range is from 0 to 25%. You may choose |

|

from seven standard oxygen ranges.The lowest standard range is 0 to |

|

1/10/100 ppm, and the highest standard range is 0 to 25% oxygen. An |

|

ultra-low range sensor that covers 0-500 ppbv and is sensitive to less |

|

than 5 ppb is also available. The Series 1 also accepts oxygen inputs |

|

from other GE Panametrics oxygen sensors. |

|

If your application has a high concentration of acid-forming |

|

components, GE Panametrics can supply a STAB-EL option for the |

|

Delta F Cell. The STAB-EL option is specially designed to |

|

effectively neutralize these components from the sample gas stream. |

|

The Delta F Cell is available in a general purpose model with both a |

|

top and bottom drain or only a top drain (see Figure 1-5 below). The |

|

Delta F Cell is usually installed in its own sample system.The Delta F |

|

Cell is available with VCR® fittings, mounted in a NEMA-4X |

|

enclosure for weatherproof/corrosion resistant applications, or |

|

mounted in a NEMA-7 enclosure for hazardous areas. |

|

The Delta F Cell, when operated with a BASEEFA-approved |

|

Series 1, is intrinsically safe (see Chapter 3, Specifications, of the |

|

Startup Guide for BASEEFA certification numbers) and designed to |

|

meet the requirements of IEC/CENELEC zone 0 areas. |

|

The Delta F Cell, when used with a CSA-NRTL certified Series 1, is |

|

intrinsically safe (see Chapter 3, Specifications, of the Series 1 |

|

Startup Guide for CSA-NRTL certification numbers) and designed to |

|

meet the requirements of NEC C1.1, Div. 1, Groups A, B, C and D |

|

hazardous areas. |

|

|

|

|

Bottom Drain |

Top Drain |

Figure 1-5: Delta F Oxygen Cells - Bottom and Top Drain

Features and Capabilities |

1-7 |

April 2004 |

|

|

|

Cabling |

Each probe requires an interconnecting cable. Cables differ |

|

depending on the probe. The various cables are discussed below |

|

under the appropriate probe type. All of these cable assemblies can be |

|

ordered from GE Panametrics. |

M Series and TF Series

Probes

The M and the TF Series probes are connected to the analyzer with a special GE Panametrics shielded cable. Probes can be located up to 600 meters (2000 feet) from the Series 1 (consult GE Panametrics for distances up to 1200 meters). To measure pressure with a TF probe, the maximum cable length is approximately 152 meters (500 feet). Small electronic offsets, especially with longer cables, are possible and should be corrected as described in Performing a MH Calibration Test/Adjustment on page 1-20 of the Service Manual.

Moisture Image Series |

The Moisture Image Series Probe can be connected to the Series 1 |

Probe |

with an unshielded, twisted-pair cable. The probe may be located up |

|

to 915 meters (3000 feet) from the analyzer using 22 AWG twisted |

|

pair cable. (Consult GE Panametrics for longer cable lengths.) |

Delta F Oxygen Cells |

The standard Delta F Cell is connected to the analyzer with a four- |

|

wire shielded cable (22 AWG). With 22-AWG cable, oxygen cells |

|

with a range from 0 to 1/10/100 ppmv or 0 to 0.5/5/50 ppmv can be |

|

located up to 90 meters (300 feet) away from the analyzer. All other |

|

oxygen cells can be located up to 15 meters (50 feet) away. For |

|

greater cable lengths, 20, 18 or 16 AWG wire is required. Consult a |

|

factory engineer when a longer length is required. |

Pressure Sensors |

The Series 1 accepts either pressure transducers or pressure |

|

transmitters. Most pressure transducers can be connected with a |

|

standard four-wire shielded cable. Most pressure transmitters are |

|

connected using either a two or four-wire non-shielded cable and can |

|

be either loop or self-powered. |

RS232 Communications

Port

A personal computer or serial printer can be connected to the Series 1 RS232 communications port using a standard serial cable. A special switch enables the user to configure the unit as Data Terminal Equipment (DTE) or Data Communications Equipment (DCE). (See

Connecting a PC or Printer in Chapter 1 of the Service Manual for details on DTE/DCE configuration.)

1-8 |

Features and Capabilities |

|

June 2003 |

|

|

User Program |

The Series 1 has a user program that is accessed and controlled by the |

|

keypad (to the right of the LCD screen) and the four menu keys |

|

(located under the LCD screen).The user program enables the user to |

|

enter the necessary probe data, set up the LCD screen, and control the |

|

other operational features. The meter stores this data in battery- |

|

backed RAM for up to five years, even if power is off. |

|

The user program consists of the following four main menus: |

|

• HELP - provides on-line help for the various menus within the user |

|

program. |

|

• SELECT - lets the user select the type of measurement and units to |

|

display. |

|

• SETTINGS - enables the user to enter probe data and set up basic |

|

functions such as recorders and alarms. |

|

• OPTIONS - enables the user to set up the Series 1 screen to display |

|

measurements in matrix or graphic format and perform advanced |

|

functions. |

|

The Settings Menu prompts the user to enter a passcode (see Entering |

|

the Passcode in Chapter 2). |

|

All the functions and features of the Series 1 program are discussed in |

|

Chapters 2 and 3, Basic Programming and Advanced Programming. |

Features and Capabilities |

1-9 |

Chapter 2

Basic Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Verifying and Entering Setup Data . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Adjusting the Contrast of the Screen. . . . . . . . . . . . . . . . . . . . . .2-40

Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

|

June 2003 |

|

|

Introduction |

The Moisture Image Series 1 is a highly advanced and versatile |

|

instrument. Because of this, operation ranges from basic to advanced |

|

functions. This section is designed to provide a step-by-step guide to |

|

basic operations. For information on other functions, refer to Chapter |

|

3, Advanced Programming. |

|

IMPORTANT: You must install a switch or circuit breaker on the |

|

input power line. For greatest safety, locate the |

|

circuit breaker or power switch near the electronics |

|

console. To comply with the Low Voltage Directive, |

|

you must install an external current protection |

|

device. |

|

The following sections cover basic programming functions: |

|

• Getting Started - describes how to power up, gives a description of |

|

the user program, and explains how to obtain on-line help. |

|

• Verifying Setup Data - describes how to verify and, if necessary, |

|

enter setup data for moisture, pressure, oxygen, and any other input |

|

devices. |

|

• Displaying Measurements - explains how to display measurements |

|

using different screen formats. |

|

• Adjusting the Contrast of the Screen - explains how to adjust the |

|

screen for optimal viewing. |

|

• Setting the Clock and Calendar - explains how to set the internal |

|

clock and calendar. |

|

Note: Because they are so essential, the instructions covered in the |

|

Getting Started, Verifying and Entering Setup Data and |

|

Displaying Measurements sections are also included in the |

|

Startup Guide. If you have read this material, you may skip |

|

those sections of this chapter. |

Basic Programming |

2-1 |

June 2003 |

|

|

|

Getting Started |

The purpose of this section is to give a brief description of the Series |

|

1 user program and explain how to use its front panel for viewing and |

|

entering data. This section includes the following: |

•

•

•

•

•

powering up the meter

entering data into the user program

screen and key functions

entering the passcode

getting on-line help

Read the following sections carefully to properly set up and operate your instrument.

|

!WARNING! |

|

TO ENSURE THE SAFE OPERATION OF THIS UNIT, |

|

YOU MUST INSTALL AND OPERATE THE SERIES 1 |

|

AS DESCRIBED IN THIS MANUAL. IN ADDITION, BE |

|

SURE TO FOLLOW ALL APPLICABLE SAFETY |

|

CODES AND REGULATIONS FOR INSTALLING |

|

ELECTRICAL EQUIPMENT IN YOUR AREA. |

Powering Up |

|

The Series 1 has a universal power supply that automatically adjusts |

|

|

to line voltages from 90 to 260 VAC. After making electrical |

|

connections (including grounding) as described in Chapter 1, |

|

Installation, of the Startup Guide, press the power switch to power up |

|

the meter. |

|

IMPORTANT: .The AC power cord is the main disconnect device. |

|

For compliance with the EU’s Low Voltage Directive |

|

(IEC 1010), this unit requires an external power |

|

disconnect device such as a switch or circuit breaker. |

|

The disconnect device must be marked as such, |

|

clearly visible, directly accessible, and located |

|

within 1.8 m (6 ft) of the unit. |

2-2 |

Basic Programming |

June 2003

|

|

Powering Up (cont.) |

|

Caution! |

|

|

Do not operate the Delta F oxygen cell for extended |

|

periods of time at oxygen concentrations that are over |

|

range. Trace and low percent range sensors may be |

|

damaged if exposed to high levels of oxygen, such as |

|

air, for long periods (>1 hour) while the Series 1 is on. If |

|

exposure is unavoidable, either disconnect the oxygen |

|

cell from the Series 1 or equip the sample system with a |

|

valve that allows the cell to be switched to purge gas. |

|

|

|

If the meter passes its self-test, the screen begins displaying |

|

measurements in a matrix format similar to the one shown in |

|

Figure 2-1 below. |

1 Dew Point |

|

4 Oxygen |

|

|

|

48.3 ppbv |

|

||

-18.0 °C |

|

|

||

2 Temperature |

|

5 Pressure |

|

|

+35.9 °C |

|

27.10 PSIg |

||

3 H2O |

|

|

X Unassigned |

|

+0.535 ppmv |

|

|

|

|

Main Menu |

11:35 01/22/2000 |

|||

|

|

|

|

pg: 1 |

HELP |

SELECT |

SETTINGS |

OPTIONS |

|

Figure 2-1: Screen Matrix Format After Power Up

Basic Programming |

2-3 |

June 2003

Entering Data into the User Program

The Series 1 has a user program that enables you to enter data to set up alarms, recorders, and probes, as well as its other features.

The user program consists of the following four main menus (refer to Figures 3-17 and 3-18, pages 3-31 and 3-32, for menu maps of the user program):

•HELP - provides on-line help for the various menus of the user program.

•SELECT - lets you select the type of measurement and units to display.

•SETTINGS - enables you to set up recorders and alarms, as well as enter probe data for basic operation. (To enter this menu you must enter the passcode. See page 2-6.)

•OPTIONS - enables you to set up the screen to display measurements in text or graphical form. It is also used to perform advanced functions.

You can use the screen, four menu keys, and the keypad to enter data into the unit (see Figure 2-2 below).

Screen |

Keypad |

|

|

|

|

1 |

2 |

3 |

YES |

|

4 |

5 |

6 |

NO |

POWER |

7 |

8 |

9 |

|

|

|

|

|

|

|

- |

0 . |

|

|

|

Menu Keys |

|

|

|

Figure 2-2: The Moisture Image Series 1 Front Panel

2-4 |

Basic Programming |

Screen and Key

Functions

June 2003

The screen displays measurements, up to four menu options, system messages, and a pointer. The pointer acts as a measurement indicator, as well as a guide during data entry.

While the unit displays measurements in the matrix format, the pointer moves sequentially from box to box to indicate measurement updates. However, while in the user program, you can use the arrow keys to move the pointer to the desired location for data entry.

The menu options appear at the bottom of the screen. Below the screen are the corresponding menu keys (refer to Figure 2-3). Each menu key corresponds to each of the menu options in the user program. Up to four new menu options appear each time you enter a menu.

The line above the menu options is the message line (see Figure 2-3 below). The message line displays the menu title, the time, and the date. The message line also displays a list of selections depending on the menu option you enter.

The page indicator is located in between the message line and the menu keys. Since the Series 1 is capable of displaying up to six pages of data, the page indicator displays the currently selected page.

Message Line |

Page Indicator |

||

Main Menu |

11:35 01/22/2000 |

||

|

|

|

pg: 1 |

HELP |

SELECT |

SETTINGS |

OPTIONS |

Menu Options |

|

|

|

|

|

Menu Keys |

|

Figure 2-3: Screen Components

Basic Programming |

2-5 |

June 2003

Screen and Key

Functions (cont.)

Entering the Passcode

The keypad to the side of the screen consists of 16 keys, including the [.] and [-] symbols, two arrow keys, and two response keys: [YES] and [NO]. The numeric keys are for numeric entry only; however, the arrow and response keys have more than one function.

The arrow keys perform two functions:

•Use either arrow key to move the screen pointer to the desired location for data entry.

•Use the left arrow key as a backspace during number entry.

The response keys perform three functions:

•Use either the [YES] or [NO] key to respond to questions.

•Use the [NO] key to erase data.

•Press [YES] to confirm a number entry or after erasing data to retrieve the previous number.

The Settings Menu is the only menu that requires a passcode. The passcode is a four-digit number that enables only authorized users to enter setup data. The Series 1 prompts you to enter the passcode when you enter the Settings Menu. See the end of this chapter for your default passcode.

2-6 |

Basic Programming |

June 2003

Getting On-Line Help The Series 1 offers on-line help screens that contain descriptions and instructions for various topics. The first menu option in most of the menus is HELP.

When you press the HELP menu key, the screen display gives a list of help topics as shown in Figure 2-4. This list enables you to get help for most subjects, regardless of the current menu. To select a topic, use the arrow keys to move the pointer to the topic you want to view, then press [YES]. Use the NEXT and PREVIOUS menu options to scroll from one page to another. The NEXT menu option brings you to the following page and the PREV menu options brings you to the previous page. Press DONE to exit and return to the current menu.

Select Topic, then press YES.

Alarms |

|

Entering Text |

|

AutoCal |

|

Error Messages |

|

Calibration |

|

Error Processing |

|

Clock/Calendar |

|

Graphs |

|

Cs Constant |

|

Henry’s Law |

|

Configuration |

|

Legends,Entering |

|

Data Logging |

|

Logger,Capacity |

|

Delta-F Tables |

|

Logger,Setting |

|

Enhanced Response |

Logger,Viewing |

||

Entering Numbers |

Main Menu |

|

|

Help Topic Index Menu |

|

|

|

ABOUT |

NEXT |

PREV |

DONE |

|

|

||

Figure 2-4: HELP Screen |

|

||

By pressing the ABOUT key, users can access the history of their particular Series 1: its serial number, PCI number, software revision number and date of manufacture. This information remains part of the HELP file and cannot be changed by the user.

Basic Programming |

2-7 |

April 2004

Verifying and Entering

Setup Data

Before the Series 1 can make measurements, it must have the proper setup data entered into its memory. GE Panametrics has entered all or most of the setup data for each probe before delivery; however, you should verify that all the data is correct and entered into your unit.

Note: If you want to switch a probe from one channel to another, you must re-enter some or all of the setup data as described in this section.

Verifying setup data consists of three steps:

•Verify that probes are properly activated in the Probe Configuration Menu as described on page 2-9.

•Verify that calibration data for all necessary probes is properly entered in the System Calibration Menu as described on page 2-12.

•Verify that applicable high and low reference values for the Series 1 measurement circuitry are properly entered into the Reference Menu as described on page 2-21.

Caution!

All high and low reference values are factory set and normally do not need adjustment. However, the factory may instruct you to adjust the high and low moisture reference values. If necessary, you should do so as described in Performing an MH Calibration/Adjustment Test on page 1-20 of the Service Manual.

Use the following sections to properly verify and enter setup data.

IMPORTANT: While you are reviewing data, you should take the time to record it on the Program Information List supplied in Appendix A of the Startup Guide, or on a separate sheet of paper.

2-8 |

Basic Programming |

April 2004

Activating and Changing

Probes

Verifying Probe

Configuration Data

Although the probes are physically connected to the back of the electronics unit, you must “tell” the electronics what type of measurements the probe is capable of making. In addition, if you want to use a constant value rather than a live input, you must “tell” the electronics that you are using a constant value.

If you do not activate probes, or if you activate them incorrectly, the unit will display No Probe or other error messages.

Once you verify and/or change configuration data, refer to Entering Calibration Data on page 2-12.

IMPORTANT: You should record this data on the Program Information List supplied in Appendix A of the Startup Guide, or on a separate sheet of paper, and keep it in a safe place.

1.Enter the Probe Configuration Menu (for a menu map, refer to Figure 3-19 on page 3-32). A screen similar to Figure 2-5 below appears.

Table 2-1: Entering the Probe Configuration Menu

Press the Main Menu key: |

To enter the: |

|

|

SETTINGS* |

Settings Menu |

|

|

SYSTEM |

System Settings Menu |

|

|

CONFIG |

Probe Configuration Menu |

|

|

* The Settings Menu will prompt for a passcode (see page 2-6).

SYSTEM CONFIGURATION |

|

|

|

||

Ch |

O2 |

HYG |

T |

P Aux1 |

Aux2 |

1 |

|

|

|

|

|

2 |

|

|

|

|

|

3 |

|

|

|

|

|

4 |

|

|

|

|

|

5 |

|

|

|

|

|

6 |

|

|

|

|

|

Probe Configuration Menu |

|

|

|||

|

HELP |

TAG |

|

ERRORS |

DONE |

Figure 2-5: Probe Configuration Menu

Basic Programming |

2-9 |

April 2004

Activating and Changing

Probes (cont.)

Verify that the correct probe types have been activated for each channel. To do this, make sure a probe is activated for each measurement it is capable of taking. For example, if a Moisture Image Series Probe with the temperature and pressure functions is connected to channel 1, “MIS” must be selected in the hygrometry, temperature, and pressure columns as shown in Figure 2-6 below.

If the optional auxiliary inputs are installed and active, you only need to select whether the input is current or voltage. If you do not select current or voltage, the Series 1 defaults to current.

Note: If you are using an auxiliary input to measure pressure, activate Au1 (or Au2 depending on which input you are using) in the pressure column for the desired channel; then activate current or voltage in the Aux 1(or Aux 2) column.

In addition, if you connect a pressure transducer to the PRESS/ OTHER terminal block, you must activate the TF probe in the pressure column for that channel.

If you need to change any data in the Probe Configuration Menu, see the following section, Entering or Changing Probe Configuration Data. If the data is correct, refer to Tagging the Inputs on page 2-37.

SYSTEM CONFIGURATION |

|

|

|

|

||

Ch |

O2 |

HYG |

T |

P |

Aux1 |

Aux2 |

1 |

|

MIS |

MIS |

MIS |

|

|

2

3

4

5

6

Probe Configuration Menu

HELP |

TAG |

ERRORS |

DONE |

Figure 2-6: MIS Probe Configuration on Channel 1

2-10 |

Basic Programming |

Entering or Changing Probe Configuration Data

April 2004

Figure 3-19 on page 3-32 for a menu map.

1.From the Probe Configuration Menu (Table 2-1 on page 2-9), move the pointer to the channel and probe you want to select. The arrow will move only to installed channels.

2.Press [YES].

3.The possible probe types appear on the message line at the bottom of the screen. Table 2-2 on page 2-12 shows the available probe types.

If you choose to enter a constant for moisture (Kh), temperature (Kt), or pressure (Kp), you must enter a constant value in the User Constant Menu. See Entering Constants and User Functions on page 3-9 for instructions.

4.Move the brackets to the correct probe type, then press [YES]. The selected probe type displays.

5.Repeat Steps 1 through 4 for each channel.

6.To exit, press the DONE menu key until Main Menu appears on the message line.

Note: You can only select probes for an installed channel.

If you are only using Moisture Image Series probes, proceed to Displaying Measurements on page 2-28. If you are using any other type of input device, proceed to Entering Calibration Data

on page 2-12.

Basic Programming |

2-11 |

April 2004

Entering or Changing Probe Configuration Data (cont.)

Entering Calibration

Data

Table 2-2: Probe Types

Measurement Mode |

|

Probe Type |

|

|

|

|

|

|

– |

(None) |

|

OXY (Oxygen) |

% |

(Percent) |

|

ppM (Parts per Million) |

|||

|

|||

|

ppB |

(Parts per Billion) |

|

|

|

|

|

|

– |

(None) |

|

|

MIS (MIS Probe) |

||

HYG (Hygrometry) |

TF |

(Three-Function Probe) |

|

|

Mxx (M Series Probe) |

||

|

Kh |

(Constant Dew Point) |

|

|

|

|

|

|

– |

(None) |

|

|

MIS (MIS probe) |

||

T (Temperature) |

TF |

(Three-Function probe) |

|

|

Mxx (M-Series probe) |

||

|

Kt |

(Constant Temperature) |

|

|

|

|

|

|

– |

(None) |

|

|

MIS (MIS probe) |

||

P (Pressure) |

TF |

(Three-Function probe) |

|

Au1 (Auxiliary 1) |

|||

|

|||

|

Au2 (Auxiliary 2) |

||

|

Kp |

(Constant Pressure) |

|

|

|

||

|

– (None) |

||

Aux1 (Auxiliary 1) |

I (Current) |

||

|

V (Voltage) |

||

|

|

||

|

– (None) |

||

Aux2 (Auxiliary 2) |

I (Current) |

||

|

V (Voltage) |

||

|

|

|

|

The Series 1 needs calibration data for moisture, oxygen, and pressure probes, as well as auxiliary inputs. GE Panametrics has already entered calibration data for probes; however, you should verify this data before startup. You will need to enter this data if you:

•sent the probes back to the factory for calibration

•use a different probe

•use a non-GE Panametrics input

To enter, verify, or change calibration data for any probe type, enter the System Calibration Menu as described in Table 2-3 below. (see Figure 3-19 on page 3-32 for a menu map.)

.

Table 2-3: Moving to the System Calibration Menu

Press the Main Menu key: |

To enter the: |

|

|

SETTINGS* |

Settings Menu |

|

|

SYSTEM |

System Settings Menu |

|

|

CALIB |

System Calibration Menu |

|

|

*The Settings Menu will prompt for a passcode (see page 2-6).

2-12 |

Basic Programming |

Loading...

Loading...