GE Sensing T5 Steam & Flare Gas Transducer Operating Manual

GE |

|

Measurement & Control |

Flow |

T5 Flare Gas Transducer

(Standard and Extended Velocity Range)

Installation Guide

916-117 Rev. D

November 2014

GE

Measurement & Control

T5 Flare Gas Transducer

(Standard and Extended Velocity Range)

Installation Guide

916-117 Rev. D

November 2014

www.ge-mcs.com

©2014 General Electric Company. All rights reserved. Technical content subject to change without notice.

[no content intended for this page]

ii

Preface

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national codes, regulations, rules and laws related to safety and safe operating conditions are met for each installation.

WARNING! For installations in potentially hazardous areas, be sure to read the Certification and Safety Statements document at the end of this manual before beginning the installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards, regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As equipment can move suddenly and without warning, do not enter the work cell of this equipment during automatic operation, and do not enter the work envelope of this equipment during manual operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before you perform maintenance procedures on the equipment.

T5 Flare Gas Transducer Installation Guide |

iii |

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment. Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-back initiative, directive 2012/19/EU.

The equipment that you bought has required the extraction and use of natural resources for its production. It may contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional waste administration.

Visit http://www.ge-mcs.com/en/about-us/environmental-health-and-safety/1741-weee-req.html for take-back instructions and more information about this initiative.

iv |

T5 Flare Gas Transducer Installation Guide |

Contents

Chapter 1. Installing Pipe Nozzles

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 1.2 Bias 90° Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 1.2.1 Identifying and Checking the Nozzle Installation Kit Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 1.2.2 Selecting and Marking the Pipe for Nozzle Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 1.2.3 Installing the First Welding Boss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 1.2.4 Installing the First Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 1.2.5 Installing the Second Welding Boss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 1.2.6 Installing the Second Nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 1.2.7 Hot Tapping the Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 1.2.8 Cold Tapping the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 1.3 Tilted 45° Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 1.3.1 Identifying and Checking the Nozzle Installation Kit Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 1.3.2 Selecting and Marking the First Nozzle Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 1.3.3 Determining and Marking the Second Nozzle Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 1.3.4 Installing the First Welding Boss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 1.3.5 Installing the First Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 1.3.6 Installing the Second Welding Boss and Nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 1.3.7 Hot Tapping the Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 1.3.8 Cold Tapping the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Chapter 2. Installing the Isolation Valves

2.1 Bias 90° Installation (Standard or Extended Velocity Range). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 2.1.1 For 3 inch Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 2.1.2 For 2 inch Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 2.2 Tilted 45° Installation (Standard Velocity Range). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 2.2.1 For 3 inch Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 2.2.2 For 2 inch Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.3 Tilted 45° Installation (Extended Velocity Range) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

T5 Flare Gas Transducer Installation Guide |

v |

Contents

Chapter 3. Installing the Transducer Assemblies

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 3.2 Using the Low-Pressure Insertion Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 3.2.1 Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 3.2.2 Mounting the Insertion Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 3.3 Mounting the Bias 90 Insertion Mechanism/Transducer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.4 Inserting the Bias 90 Transducer into the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39 3.5 Aligning the Transducers (Standard Velocity Range) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 3.6 Aligning the Transducers (Extended Velocity Range). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 3.7 Mounting the Tilted 45 Insertion Mechanism/Transducer Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46 3.8 Inserting the Tilted 45 Transducer into the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52 3.9 Connecting an XAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Chapter 4. Specifications

4.1 T5 Transducer Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61 4.2 T5 Transducer Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

vi |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

Chapter 1. Installing Pipe Nozzles

1.1Introduction

Before the T5 transducers can be installed into the pipe, you will need to install pipe nozzles. Nozzles may be installed as part of a fabricated spoolpiece or by using the hot or cold tap process with a GE Sensing Nozzle Installation Kit.

IMPORTANT: This procedure only applies if you are using a Nozzle Installation Kit. If you are tapping the pipe without using a Nozzle Installation Kit, refer to the supplied drawings in your shipment. This procedure is written and illustrated for installations on horizontal pipes. However, the procedure is the same for vertical pipe installations.

This section describes how to install nozzles in the following configurations:

1.Bias 90o Installation

•Standard transducer spacings of 10” and 9”, with both transducers facing straight at each other, are for applications with gas velocities up to 100 m/s (328 ft/s). This is the standard velocity range.

•A shorter transducer spacing of 6.4”, with only the downstream transducer rotated 6° into the flow is for applications with gas velocities up to 120 m/s (394 ft/s). This is the extended velocity range.

2.Tilted 45o Installation

•Standard transducer face to face spacings, with both transducer body axes concentric and parallel to each other are for applications with gas velocities up to 100 m/s (328 ft/s). This is the standard velocity range.

•A shorter transducer face to face spacing of approximately 7.85”, with only the downstream transducer tilted 6° into the flow, is for applications with gas velocities up to 120 m/s (394 ft/s). This is the extended velocity range.

1.2Bias 90° Installation

This procedure includes the following steps:

•Identifying and checking the nozzle installation kit components

•Selecting and marking the pipe for nozzle locations

•Installing the first welding boss

•Installing the first nozzle

•Installing the second welding boss

•Installing the second nozzle

•Tapping the pipe

T5 Flare Gas Transducer Installation Guide |

1 |

Chapter 1. Installing Pipe Nozzles

1.2.1 Identifying and Checking the Nozzle Installation Kit Components

The Nozzle Installation Kit contains the materials listed below. Use Figure 1 below to help identify each component.

•

•

•

•

•

•

2 Nozzles (if purchased)

2 Welding bosses

1 Jig

1 Alignment plate (9”, 10” or 6.4” spacing)

1 Spacer flange

1 Threaded rod (1” diameter), with washer and nut

IMPORTANT: You will need eight 5/8” studs with two nuts each, or 3/4” studs with two nuts each. The 5/8” studs are needed for 2”-150#, 2”-300# and 3”-150# flanges. The 3/4” studs are needed for 3”-300# flanges.

After you are familiar with each component, verify that the welding bosses and alignment plate shipped are for the required transducer spacing and the pipe size described in the following steps.

Welding Boss

Nozzle

Jig

Spacer Flange

Threaded Rod

with Washer and Nut

Alignment

Plate

Figure 1: Components for Nozzle Installation Kit

2 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.2.1Identifying and Checking the Nozzle Installation Kit Components (cont.)

1.Check the marking on the end of the welding boss. The pipe O.D. and the bias dimension (i.e., the transducer spacing) are engraved on the boss as shown below. Typically,

•For flow velocities up to 100 m/s (328 ft/s), the 10 in. spacing is used on pipes 18 in. (450 mm) in diameter or larger, while the 9 in. spacing is used on pipes 16 in. (400 mm) in diameter or on larger pipes when attenuating gases are present.

•For flow velocities up to 120 m/s (394 ft/s), the 6.4 in. spacing is used on pipes 14 in. (356 mm) in diameter or larger.

Note: Bias dimension refers to the distance between the center of the nozzle location and the center line of the pipe.

Pipe O.D.

36 in.

5 in.

3.4 in. Bias = 6.4 in. Spacing Bias Dimension (Spacing) 4.5 in. Bias = 9 in. Spacing

5 in. Bias = 10 in. Spacing

2.Check the spacing between the holes on the alignment plate, as shown below. The dimensions should correspond to the bias/spacing dimension on the welding boss.

12.73 in.

12.73 in.

4.5 in. Bias (9 in. Spacing)  14.14 in.

14.14 in.

Bolt location shown for 150# rating.

5 in. Bias (10 in. Spacing)

9.05 in.

9.05 in.

3.2 in. Bias (6.4 in. Spacing)

T5 Flare Gas Transducer Installation Guide |

3 |

Chapter 1. Installing Pipe Nozzles

1.2.2 Selecting and Marking the Pipe for Nozzle Locations

CAUTION! Correct nozzle alignment is critical to the successful operation of the flowmeter. Therefore, all marking, positioning and welding operations must be carried out with the utmost attention to accuracy. Unless otherwise stated, dimensional positioning of the nozzles must be held to a tolerance of ±1/16 in. (±1.6 mm) relative to each other and with respect to the pipe centerline. The angular tolerance must be held to ±1O. All hole cutting in process piping must be performed using hot tapping equipment.

WARNING! Be sure to adhere to all applicable safety regulations.

1.For optimum performance, you should select a location that has at least 20 pipe diameters of straight, undisturbed flow upstream and 10 pipe diameters of straight, undisturbed flow downstream from the point of measurement. Undisturbed flow means avoiding sources of turbulence such as flanges, elbows and tees; avoiding swirl; and avoiding disturbed flow profiles. Never install the flowmeter downstream of control valves, especially butterfly valves. If you cannot find a proper location, please consult with GE Flow Application engineering.

20D |

10D |

|

D |

2.Use a center finder device to locate the center of the pipe. “EYEBALLING” IS NOT ADEQUATE FOR ACCURATE

FLOW MEASUREMENT!

3.Lightly punch two marks approximately 16 in. apart on the top of the pipe, running along the center line. The two nozzle locations will be located between these two center punch marks.

~16 in.

Top View

4 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.2.2Selecting and Marking the Pipe for Nozzle Locations (cont.)

4.Spray the area between the two punch marks on the top of the pipe with a marking dye product. Using a metal straight edge, scribe a line between the two punch marks.

Scribe Line

Top View

5.Along the new scribe line, mark off a length equal to your transducer spacing (10 in., 9 in. or 6.4 in.) and scribe two lines at least 10 in. in length and perpendicular to the scribe line on different sides of the scribe line.

10", 9" or 6.4" |

|

3", 3.5" or 4.8" |

3", 3.5" or 4.8" |

|

Top View

6.Along each of the perpendicular scribe lines, lightly punch a mark at a distance equal to half of your transducer spacing (5 in., 4.5 in. or 3.2 in.) from the center line, depending on the bias distance for your transducers. Keep in mind that the distance along the arc of the pipe (L) from the pipe centerline is slightly greater than the point-to-point distance through the pipe. These marks pinpoint the centers for the nozzles. Refer to Table 1 on page 7 for arc distances for the most commonly used pipe sizes. If your pipe size is not shown in Table 1, use the equation in the figure on page 6 to calculate the arc distance.

T5 Flare Gas Transducer Installation Guide |

5 |

Chapter 1. Installing Pipe Nozzles

1.2.2 Selecting and Marking the Pipe for Nozzle Locations (cont.)

IMPORTANT: For a 3.2 in.bias distance, the downstream port must be located on the right side of the long scribe line when viewed from the downstream end of the pipe (see the figure below). This convention is mandatory for the 6.4 in. transducer spacing and is optional (not required) for a 10 in. or 9 in. spacing.

Downstream Port Location

for 3.2 in. bias

Punch Marks

Flow

SL = Arc Length

|

|

along pipe |

Spacing |

R |

surface |

A

A

Calculate L as follows:

L = 3.142 x R x A 180

Where A = Sin -1 ( S )

R

R = Radius in inches

S = Bias in inches

End View

6 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.2.2 Selecting and Marking the Pipe for Nozzle Locations (cont.)

Table 1: Calculated Arc Distances for Common Pipe Sizes

Pipe O.D. |

|

Arc Distance |

|

|

|

|

5 in. Bias |

|

|

|

|

18 in. (450 mm) |

|

5.301 in. (134.6 mm) |

|

|

|

24 in. (600 mm) |

|

5.157 in. (131.0 mm) |

|

|

|

30 in. (750 mm) |

|

5.098 in. (129.5 mm) |

|

|

|

36 in. (900 mm) |

|

5.067 in. (128.7 mm) |

|

|

|

42 in. (1050 mm) |

|

5.048 in. (128.2 mm) |

|

|

|

|

4.5 in. Bias |

|

|

|

|

16 in. (400 mm) |

|

4.779 in. (121.4 mm) |

|

|

|

18 in. (450 mm) |

|

4.713 in. (119.7 mm) |

|

|

|

24 in. (600 mm) |

|

4.613 in. (117.2 mm) |

|

|

|

30 in. (750 mm) |

|

4.571 in. (116.1 mm) |

|

|

|

36 in. (900 mm) |

|

4.549 in. (115.5 mm) |

|

|

|

42 in. (1050 mm) |

|

4.536 in. (115.2 mm) |

|

|

|

|

3.2 in. Bias |

|

|

|

|

14 in. (350 mm) |

|

3.323 in. (84.4 mm) |

|

|

|

16 in. (400 mm) |

|

3.292 in. (83.6 mm) |

|

|

|

18 in. (450 mm) |

|

3.272 in. (83.1 mm) |

|

|

|

24 in. (600 mm) |

|

3.239 in. (82.3 mm) |

|

|

|

30 in. (750 mm) |

|

3.225 in. (81.9 mm) |

|

|

|

36 in. (900 mm) |

|

3.217 in. (81.7 mm) |

|

|

|

42 in. (1050 mm) |

|

3.213 in. (81.6 mm) |

|

|

|

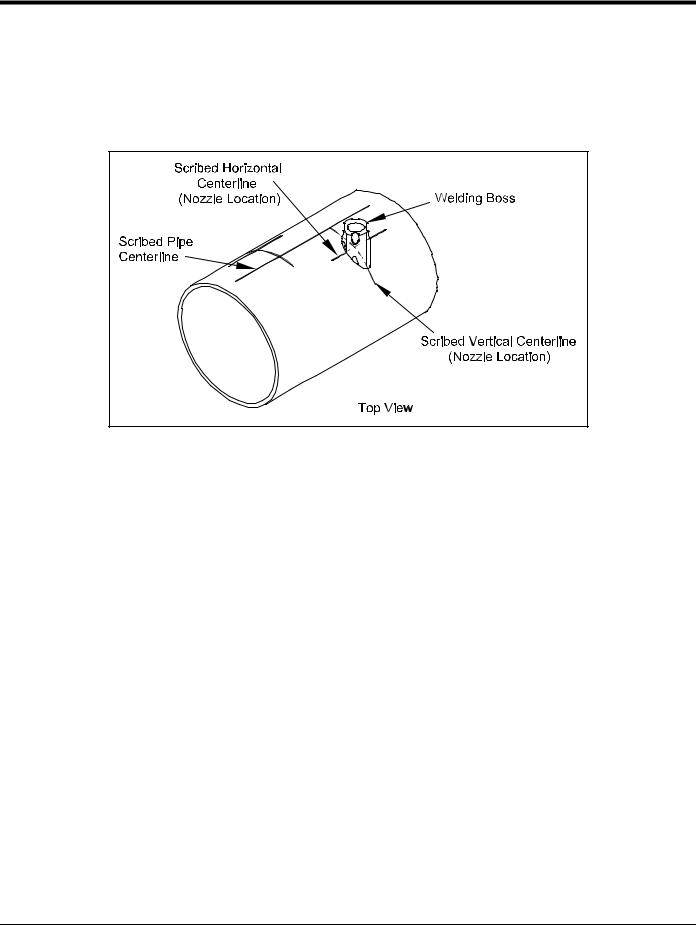

7.Scribe a 6 in. long horizontal centerline through each nozzle center location point and parallel to the original centerline.

Scribe Lines

Top View

T5 Flare Gas Transducer Installation Guide |

7 |

Chapter 1. Installing Pipe Nozzles

1.2.3Installing the First Welding Boss

1.Each welding boss has four scribe marks indicating the center of the bias.Take one welding boss and line up its scribe marks with the horizontal and perpendicular scribe marks on the pipe as shown below. Make sure you position the boss on the pipe so that the contoured end of the boss matches the pipe arc. That is, the shorter side of the boss should be closer to the original scribed pipe centerline.

2.Clamp the boss in place, using a pipe strap or equivalent, so that it cannot move during tack welding.

3.Check the boss alignment again, and then tack weld the boss in each of the four grooves between the boss scribe marks. Make sure you keep the boss contour flush with the pipe contour during the entire tack welding operation. The boss is constructed of carbon steel.

4.Check the alignment again. If the boss is misaligned by 0.02 in. (0.5 mm) or more, remove the boss, grind off the welds and reinstall the boss.

8 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.2.4 Installing the First Nozzle

CAUTION! It is essential that the nozzles are set up and fixed in position using the jig and alignment plate provided, prior to welding the nozzle.

1.Screw the threaded rod into the boss that is welded onto the pipe. If necessary, remove the washer and nut from the threaded rod.

Threaded Rod

Welding Boss

End View

2.Insert the pipe section of the jig (the key cut section) into the pipe section of the nozzle, and fasten the assembly together using four nuts and bolts.

Bolts

Jig

Nozzle

Nozzle

Side View

T5 Flare Gas Transducer Installation Guide |

9 |

Chapter 1. Installing Pipe Nozzles

1.2.4Installing the First Nozzle (cont.)

3.Slide the jig/nozzle assembly over the threaded rod, fitting the jig into the key cut end of the welding boss while aligning the contoured end of the nozzle to the pipe arc.

Threaded Rod

Threaded Rod

Jig

Nozzle

Welding Boss

Welding Boss

End View

4.Align the nozzle scribe marks with the pipe scribe marks and tighten the assembly in place using the 1-in. washer and nut provided. If slight misalignment occurs between the nozzle scribe marks and pipe scribe marks, loosen the four bolts holding the jig and nozzle assembly, and rotate the nozzle for the best alignment. After the nozzle has been accurately aligned, retighten the four bolts.

Washer and Nut

End View

5.The jig, boss, and nozzle assembly is designed to provide a 0.094 in. (2.4 mm) root gap between the beveled edge of the nozzle and the outside diameter of the pipe. If this gap is not present all the way around the nozzle, the nozzle must be removed and ground appropriately to provide the required clearance. If the root gap is larger than the 0.094 in. (2.4 mm) dimension evenly all the way around the nozzle, then suitably sized washers may be inserted between the jig and the nozzle to reduce the root gap dimension.

10 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.2.4 Installing the First Nozzle (cont.)

WARNING! Only qualified personnel should weld bosses and nozzles, using a suitable ASME IX qualified welding procedure. All applicable safety codes should be observed.

6.Tack weld the nozzle to the pipe at four diametrically opposed points, each tack being approximately 0.2 in. (5 mm) in length. Allow the weld to cool for 30 seconds between tacks.

7.Complete the root pass and subsequent filler passes as required.

8.Allow the weld to cool, and then remove the nut, washer, jig and threaded rod.

1.2.5Installing the Second Welding Boss

1.Bolt the jig to one end of the alignment plate using four bolts.

Alignment Plate

Jig

Side View

2.Screw the threaded rod into the second boss. Then, insert the bolt/boss assembly into the jig key cut grooves and secure it with a washer and nut on top.

Threaded Rod

Threaded Rod

Welding Boss

Welding Boss

Side View

Washer and Nut

to Secure

Threaded Rod

Threaded Rod

Welding Boss

Welding Boss

Side View

T5 Flare Gas Transducer Installation Guide |

11 |

Chapter 1. Installing Pipe Nozzles

1.2.5Installing the Second Welding Boss (cont.)

3.Remember to orient the boss in the jig to maintain the proper contour location to the pipe for installation.

4.Place the spacer flange on top of the welded nozzle and then mount the second end of the alignment plate on top of the spacer flange. Bolt the alignment plate into position with the remaining bolts.

Spacer

Flange

Jig

Welded

Nozzle

End View

Top View

5.The second welding boss should now be positioned over the second nozzle location scribe marks. Align the boss scribe marks with the pipe scribe marks, and then tighten all of the nuts securely.

6.Check the boss alignment again, then tack weld the boss in each of the four grooves between the boss scribe marks.

7.After tacking, check the boss alignment once more. If the boss is misaligned by 0.02 in. (0.5 mm) or more, remove the boss by grinding off the welds, and then reinstall the boss.

8.Remove the threaded rod and the jig. Leave the alignment plate bolted to the first nozzle, with the spacer flange sandwiched between them.

12 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.2.6 Installing the Second Nozzle

To install the second nozzle, complete the following steps:

1.Insert the jig into the second nozzle and position this assembly over the boss and under the alignment plate. Then, insert the threaded rod.

|

Alignment Plate |

|

Jig |

Spacer |

|

Flange |

||

|

||

Nozzle |

|

End View

2.The jig, boss, and nozzle assembly is designed to provide a 0.094 in. (2.4 mm) root gap between the beveled edge of the nozzle and the outside diameter of the pipe. If this gap is not present all the way around the nozzle, the nozzle must be removed and ground appropriately to provide the required clearance. If the root gap is larger than the 0.094 in. (2.4 mm) dimension evenly all the way around the nozzle, then suitably sized washers may be inserted between the jig and the nozzle to reduce the root gap dimension.

3.Secure the alignment plate by installing the two sets of four bolts on the alignment plate. Also, install the washer and nut on the threaded rod.

4.Line up the nozzle scribe marks with the pipe scribe marks and tighten all the nuts.

5.Make sure the nozzle is still in alignment.

WARNING! Only qualified personnel should weld bosses and nozzles, using a suitable ASME IX qualified welding procedure. All applicable safety codes should be observed.

6.Tack weld the nozzle to the pipe at four diametrically opposed points, each tack being approximately 0.2 in. (5 mm) in length. Allow the weld to cool for 30 seconds between tacks.

7.Complete the root pass and subsequent filler passes as required.

8.Allow the weld to cool, and then remove all nuts and bolts, the alignment plate, the jig, the spacer flange and the threaded rod. The completed installation should appear as shown below.

T5 Flare Gas Transducer Installation Guide |

13 |

Chapter 1. Installing Pipe Nozzles

1.2.7 Hot Tapping the Pipe

WARNING! Hot tapping should only be performed by qualified personnel. Follow all applicable code and safety practices during these procedures.

1.2.7a Hot Tapping For 3” Flanges

To hot tap the pipe for 3” flanges, complete the following steps:

1.Obtain two suitable 3 in. ANSI flanged isolation valves. The valves should be a full bore type with either 150# RF flanges and a face-to-face length of 8 in. or 300# RF flanges and a face-to-face length of 11.125 in.

2.Install one of the isolation valves, including a suitable gasket, on each of the nozzles. Secure the valves with either 5/8 in. studs and nuts for 150# flanges or 3/4 in. studs and nuts for 300# flanges.

3.Orient the isolation valve handles to minimize interference during operation of the valves.

4.Hot tap holes in the pipe using a hot tap machine equipped with a 3/4 in. (19.05 mm) drill bit.

5.Then use a coupon retaining hole saw to cut a hole with a diameter of 2.36 in. (60 mm) minimum to 2.875 in. (73 mm) maximum.

1.2.7b Hot Tapping For 2” Flanges

To hot tap the pipe for 2” flanges, complete the following steps:

1.Obtain two suitable 2 in. ANSI flanged isolation valves. The valves should be a full bore type with either 150# RF flanges and a face-to-face length of 7 in. or 300# RF flanges and a face-to-face length of 8.50 in.

2.Install one of the isolation valves, including a suitable gasket, on each of the nozzles. Secure the valves with 5/8 in. studs and nuts.

3.Orient the isolation valve handles to minimize interference during operation of the valves.

4.Hot tap holes in the pipe using a hot tap machine equipped with a 3/4 in. (19.05 mm) drill bit.

5.Then use a coupon retaining hole saw to cut a hole with a diameter of 1.81 in. (46 mm) minimum to 1.89 in. (48 mm) maximum.

1.2.8Cold Tapping the Pipe

WARNING! Cold tapping should only be performed by qualified personnel. Follow all applicable code and safety practices during these procedures.

The procedure for cold tapping a pipe is the same as the hot tapping procedure described above. However, isolation valves are not necessary during the tapping process. The hot tap machine is used directly on the nozzles. The isolation valves are added after the tapping process has been completed.

14 |

T5 Flare Gas Transducer Installation Guide |

Chapter 1. Installing Pipe Nozzles

1.3Tilted 45° Installation

This procedure includes the following steps:

•Identifying and checking the nozzle installation kit components

•Selecting and marking the pipe for nozzle locations

•Installing the first welding boss

•Installing the first nozzle

•Installing the second welding boss

•Installing the second nozzle

•Tapping the pipe

1.3.1 Identifying and Checking the Nozzle Installation Kit Components

The Nozzle Installation Kit contains the materials listed below. Use Figure 2 below to help identify each component.

•

•

•

•

2 Nozzles (if purchased)

2 Welding bosses

1 Jig

1 Threaded rod (1” diameter), with washer and nut

IMPORTANT: You will need eight 5/8” studs with two nuts each, or 3/4” studs with two nuts each. The 5/8” studs are needed for 2”-150#, 2”-300# and 3”-150# flanges. The 3/4” studs are needed for 3”-300# flanges.

Welding Boss

Nozzle

Jig

Threaded Rod with Washer and Nut

Figure 2: Components for Nozzle Installation Kit

T5 Flare Gas Transducer Installation Guide |

15 |

Loading...

Loading...