GE Sensing VeriDri OEM Operating Manual

GE

Sensing & Inspection Technologies

VeriDriTM

Moisture Transmitter

User’s Manual

GE

Sensing & Inspection Technologies

VeriDriTM

Moisture Transmitter

User’s Manual

916-095B January 2009

January 2009

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Sample System Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inserting the Transmitter in the Sample System/Process . . . . . 4

Making Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning the Transmitter Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Soaking the Sensor and Shield. . . . . . . . . . . . . . . . . . . . . . . . 11

Evaluating the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Moisture Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Warm-up Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Calibrated Accuracy @ 77°F (25°C) . . . . . . . . . . . . . . . . . . . . 14

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Moisture Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

iii

January 2009

Introduction

The GE Sensing & Inspection Technologies VeriDriTM is a lowcost, loop-powered transmitter that provides accurate dew/frost

point measurements covering an overall range of –110o to 40°C

(-166o to 104oF). It can also be provided to cover a number of moisture ranges from 0 to 10,000 PPMv.

The VeriDri is supplied with one 4 to 20 mA analog output that is factory-configured for a specified range.

The VeriDri is easy to install, operate and maintain. This manual contains the following sections:

•Sample System Guidelines

•Inserting the Transmitter in the Sample System/Process

•Making Wiring Connections

•Operating the Transmitter

•Cleaning the Transmitter Probe

•Specifications

VeriDri Moisture Transmitter |

1 |

January 2009

Sample System Guidelines

You can install the VeriDri transmitter into a sample system or directly into the process. GE recommends that the unit be installed in a sample system to protect the probe from coming into contact with damaging elements in the process.

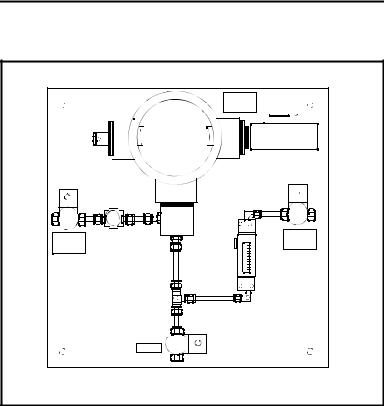

Before constructing a sample system, you should consult a GE Applications Engineer and adhere to the guidelines below. See Figure 1 on the next page for an example of a sample system.

•Consult Specifications on page 13 for dimensions and other requirements.

•Sample systems should be kept very simple.

•The transmitter should be installed so it is perpendicular to the sample inlet.

•The sample system should contain as few components as possible and all or most of those components should be located downstream of the measurement location.

•If possible, you should use stainless steel material for all wetted parts.

•Sample system components should not be made of any material that will affect measurement. Most common filters and pressure regulators are not suitable for sample systems because they have wetted parts that may absorb or release components (such as moisture) into the sample system. They may also allow ambient contamination to enter the sample system.

2 |

VeriDri Moisture Transmitter |

January 2009

Sample System Guidelines (cont.)

|

Sample |

|

|

Cell |

|

Sample |

Sample |

|

Outlet |

||

Inlet |

||

|

||

|

Vent |

Figure 1: Example of a Sample System

VeriDri Moisture Transmitter |

3 |

January 2009

Inserting the Transmitter in the Sample

System/Process

!CAUTION!

If you are mounting the VeriDri directly into the process line, you must consult the factory

for proper installation instructions and precautions before beginning the following procedure.

Use the steps below to install the VeriDri:

1.Make sure the sintered or sheet stainless-steel shield is in place. The shield protects the aluminum oxide sensor from damaging elements in the process.

Shield |

2.The probe is mounted into the process via the 3/4-16 straight male thread located on the probe. Thread the probe end of the transmitter into the process/sample system fitting. Make sure not to cross thread it.

3/4-16 UNF-2A

4 |

VeriDri Moisture Transmitter |

January 2009

Inserting the Transmitter in the Sample

System/Process (cont.)

3.Using a 1-1/8 in. wrench, tighten the probe securely into the process using the probe hex nut.

!CAUTION!

Do not apply force to the transmitter module to tighten the unit into its fitting.

Probe Hex Nut

VeriDri Moisture Transmitter |

5 |

Loading...

Loading...