GE Sensing MMS 35 Operating Manual

GE Infrastructure

Sensing

Moisture Monitor Series 35

Single-Channel Hygrometer

User’s Manual

GE Infrastructure

Sensing

Moisture Monitor Series 35

Single-Channel Hygrometer

User’s Manual

910-140E September 2004

September 2004

Warranty

Each instrument manufactured by GE Infrastructure Sensing, Inc. is warranted to be free from defects in material and workmanship. Liability under this warranty is limited to restoring the instrument to normal operation or replacing the instrument, at the sole discretion of GE Infrastructure Sensing, Inc. Fuses and batteries are specifically excluded from any liability. This warranty is effective from the date of delivery to the original purchaser. If GE Infrastructure Sensing, Inc. determines that the equipment was defective, the warranty period is:

•one year from delivery for electronic or mechanical failures

•one year from delivery for sensor shelf life

If GE Infrastructure Sensing, Inc. determines that the equipment was damaged by misuse, improper installation, the use of unauthorized replacement parts, or operating conditions outside the guidelines specified by GE Infrastructure Sensing, Inc. , the repairs are not covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of all other warranties whether statutory, express or implied (including warranties or merchantability and fitness for a particular purpose, and warranties arising from course of dealing or usage or trade).

iii

September 2004

Return Policy

If a GE Infrastructure Sensing, Inc. instrument malfunctions within the warranty period, the following procedure must be completed:

1.Notify GE Infrastructure Sensing, Inc., giving full details of the problem, and provide the model number and serial number of the instrument. If the nature of the problem indicates the need for factory service, GE Infrastructure Sensing, Inc. will issue a RETURN AUTHORIZATION NUMBER (RAN), and shipping instructions for the return of the instrument to a service center will be provided.

2.If GE Infrastructure Sensing, Inc. instructs you to send your instrument to a service center, it must be shipped prepaid to the authorized repair station indicated in the shipping instructions.

3.Upon receipt, GE Infrastructure Sensing, Inc. will evaluate the instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

•If the damage is covered under the terms of the warranty, the instrument will be repaired at no cost to the owner and returned.

•If GE Infrastructure Sensing, Inc. determines that the damage is not covered under the terms of the warranty, or if the warranty has expired, an estimate for the cost of the repairs at standard rates will be provided. Upon receipt of the owner’s approval to proceed, the instrument will be repaired and returned.

iv

September 2004

Table of Contents

Chapter 1: Features & Capabilities

Electronics Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

User Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter 2: Installing the Series 35

Choosing a Site for Best Performance . . . . . . . . . . . . . . . . . 2-2 Precautions for Moisture Probes . . . . . . . . . . . . . . . . . . . . . . 2-4 Sample System Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6 Installing the Sample System . . . . . . . . . . . . . . . . . . . . . . . . . 2-8 Installing a Probe in the Sample System. . . . . . . . . . . . . . . 2-9 Mounting the Electronics Unit. . . . . . . . . . . . . . . . . . . . . . . . 2-11 Making Wiring Connections to the Electronics Unit. . . . 2-12

Modified or Non-GE Panametrics Cables . . . . . . . . . 2-13 Connecting the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14 Connecting the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16 Connecting a Recorder Output Device. . . . . . . . . . . . 2-18 Connecting a Recorder Output Device (cont.) . . . . . 2-19 Connecting Power to the Unit . . . . . . . . . . . . . . . . . . . . 2-21 Performing an MH Calibration/Test Adjustment . . . 2-22

v

September 2004

Table of Contents (cont.)

Chapter 3: Operating the Series 35

Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Powering Up the Series 35 . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Entering Data into the User Program . . . . . . . . . . . . . . 3-4 Verifying and Changing Factory Setup Data . . . . . . . 3-8 Changing the Measurement Display . . . . . . . . . . . . . . . . . 3-14 Setting Up the Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . . 3-15 Enabling or Disabling the Alarms. . . . . . . . . . . . . . . . . 3-17 Selecting the Measurement Mode. . . . . . . . . . . . . . . . 3-17 Selecting the Measurement Units . . . . . . . . . . . . . . . . 3-18 Configuring the Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20 Setting Up a Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21 Selecting the Output Signal . . . . . . . . . . . . . . . . . . . . . . 3-21 Selecting the Measurement Mode and Units . . . . . . 3-22 Setting the Zero and Span Values . . . . . . . . . . . . . . . . 3-23 Setting Up User-Defined Functions . . . . . . . . . . . . . . . . . . 3-24 Entering an Offset Value . . . . . . . . . . . . . . . . . . . . . . . . . 3-25 Entering a Constant Pressure . . . . . . . . . . . . . . . . . . . . 3-26 Entering an Automatic Calibration Interval . . . . . . . 3-27 Entering a Backlight-On Time Interval . . . . . . . . . . . . 3-29 Setting Up Computer Enhanced Response. . . . . . . . 3-30 Setting Up Range Error Processing . . . . . . . . . . . . . . . 3-31 Setting Up Calibration Error Processing. . . . . . . . . . . 3-33 Entering a PPMv Constant Multiplier. . . . . . . . . . . . . . 3-34

vi

September 2004

Table of Contents (cont.)

Chapter 4: Troubleshooting and Maintenance

Common Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Screen Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Replacing the User Program . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Removing the Circuit Board (Bench-Mount Only) . . . 4-8

Removing and Replacing the EPROM (All Units) . . . . 4-9

Replacing the Circuit Board (Bench-Mount Only) . . 4-10

Replacing and Recalibrating the Moisture Probes . . . . . 4-12

Testing the Alarm Relays and Recorder Output . . . . . . . 4-13

Testing the Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Testing the Recorder Output . . . . . . . . . . . . . . . . . . . . . 4-15

Adjusting the Recorder Zero/Span Values . . . . . . . . . . . . 4-16

Adjusting the Recorder Zero . . . . . . . . . . . . . . . . . . . . . 4-16

Adjusting the Recorder Span. . . . . . . . . . . . . . . . . . . . . 4-19

Chapter 5: Specifications

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Moisture Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

vii

September 2004

Table of Contents (cont.)

Appendix A: Application of the Hygrometer

Moisture Monitor Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2 Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4 Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5 Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Contaminants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7 Non-Conductive Particulates . . . . . . . . . . . . . . . . . . . . . A-7 Conductive Particulates . . . . . . . . . . . . . . . . . . . . . . . . . . A-8 Corrosive Particulates . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8 Aluminum Oxide Probe Maintenance. . . . . . . . . . . . . . . . . . A-9 Corrosive Gases And Liquids . . . . . . . . . . . . . . . . . . . . . . . . . A-11 Materials of Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12 Calculations and Useful Formulas in Gas Applications. A-13 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13 Parts per Million by Volume . . . . . . . . . . . . . . . . . . . . . . A-14 Parts per Million by Weight . . . . . . . . . . . . . . . . . . . . . . A-15 Relative Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15 Weight of Water per Unit Volume of Carrier Gas . . A-16 Weight of Water per Unit Weight of Carrier Gas. . . A-16 Comparison of PPMV Calculations . . . . . . . . . . . . . . . A-26 Liquid Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27 Moisture Content Measurement in Organic Liquids . A-

27

Empirical Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-34 Solids Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-40

Appendix B: Outline and Installation Drawings

Appendix C: Menu Maps

Appendix D: Data Information Sheet

Series 35 Data Information Sheet . . . . . . . . . . . . . . . . . . . . . D-2

Appendix E: Series 35 Hygrometer Spare Parts List

Appendix F: Older Version Circuit Boards

Replacing the User Program . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

viii

September 2004

Chapter 1

Features & Capabilities

The Series 35 is a microprocessor-based, single-channel hygrometer that measures moisture content in gases.

The Series 35 is suitable for a wide range of process conditions requiring real-time moisture measurement. It measures dew/frost points over a range of -110 to +60°C (-166 to +140°F), and comes equipped with two optional alarm relays, one fault alarm, and a single analog output.

Electronics Unit

The Series 35 is available in four configurations: rack mount, bench mount, panel mount, and NEMA-4X weatherproof.

All Series 35 configurations display measurement data on a oneline, 16-character alphanumeric LCD display screen. Users enter probe information into the unit via the programming keys on the front panel keypad (see Figure 1-1 below). The Series 35 accepts line voltages of 100, 120, 230, and 240 VAC, and can also be powered by 24VDC.

POWER |

|

|

ENTER |

P |

|

ON |

|

|

OFF |

|

|

ESC |

AUX |

|

IN |

||

|

Figure 1-1: Series 35 Front Panel

Features & Capabilities |

1-1 |

September 2004

Probes

The moisture probe is the part of the system that comes in contact with the process, and is usually installed in a sample system. The Series 35 uses any M Series probe to measure dew point temperature in °C or °F. A sensor assembly is secured to the probe mount and protected with a sintered stainless steel shield (see Figure 1-2 below). Other types of shields are available.

Figure 1-2: The M Series Probe

1-2 |

Features & Capabilities |

September 2004

Sample System

The sample system delivers a controlled sample stream at the specifications of the measurement probe. Typically, the sample system is kept very simple, with as few components as possible located upstream of the measurement probe. The sample system may include a filter to remove particulates from the sample stream and/or a pressure regulator to control the pressure of the stream. In general, stainless steel is the preferred material for all wetted parts in the sample system. The sample system is located outside of the Series 35 enclosure.

User Program

The Series 35 User Program enables you to change moisture calibration data, set up and test alarms and recorders, and select a number of user-defined program functions. The main menu programming options include: DP RANGE, CURVE,

REFERENCE, ALARMS, RECORDER, TEST, USER, and FACTORY SETUP menus.

All functions and features of the Series 35 User Program are discussed in Chapter 3, Operation.

Features & Capabilities |

1-3 |

September 2004

Chapter 2

Installing the Series 35

This chapter discusses installing the Series 35 in all of its configurations. Below is a list of procedures that you must follow to install your unit.

Depending on the type of unit you have, refer to the appropriate section(s) that follow to install your Series 35 correctly.

Installing your Series 35 consists of the following procedures:

•Choosing a Site for Best Performance

•Precautions for Moisture Probes

•Sample System Guidelines

•Installing the Sample System

•Installing the Probe into the Sample System

•Mounting the Electronics Unit

•Making Wiring Connections to the Electronics Unit.

Proceed to the following sections to install your Series 35.

Installing the Series 35 |

2-1 |

September 2004

Choosing a Site for Best Performance

Before you receive your Series 35, discuss environmental and installation factors with a GE Infrastructure Sensing applications engineer or field sales person. The equipment should be suited to the application and installation site.

Before installing the unit, read the guidelines below to verify that you have selected the best installation site.

•Choose an installation site for the probes and sample systems that is as close to the process line as possible. Avoid long lengths of connecting tubing. If long distances are unavoidable, a fast sampling by-pass loop is recommended.

•Do not install any other components, such as filters, upstream of the probe or sample system unless instructed to do so by GE Infrastructure Sensing. Many common components, such as filters and pressure regulators, are not suitable for sample systems because they have wetted parts that may absorb or release materials such as moisture into the sample stream. They may also allow ambient contamination to enter the sample stream. In general, use stainless steel for all parts in contact with the sample.

•Observe all normal safety precautions. Use the probes within their maximum pressure and temperature ratings.

•Although the Series 35 may not need to be accessed during normal operation, install the electronics unit at a convenient location for programming, testing and servicing. A control room or instrument shed are typical locations.

•Locate the electronics unit away from high temperatures, strong electrical transients, mechanical vibrations, corrosive atmospheres, and any other conditions that could damage or interfere with the Series 35 operation. See Chapter 5, Specifications, for limitations.

2-2 |

Installing the Series 35 |

September 2004

Choosing a Site for Best Performance (cont.)

•Observe the proper cable restrictions for the probes. The M Series probes require specially shielded cable. You can locate the M Series probes up to 600 meters (2,000 feet) from the Series 35.

•Protect the probe cables from excessive physical strain (bending, pulling, twisting, etc.). Do not subject the cables to temperatures above +105°C (221°F) or below -40°C (-40°F). Avoid splicing the cables.

Installing the Series 35 |

2-3 |

September 2004

Precautions for Moisture Probes

The M Series probes consist of an aluminum oxide sensor located on a connector and covered by a protective stainless-steel shield.

The probe sensor materials and housing maximize durability and insure a minimum of water absorbing surfaces in the vicinity of the aluminum oxide surface. A sintered stainless-steel shield is used to protect the sensor from high flow rates and particulate matter (other shields are available). The shield should not be removed except upon advice from GE Infrastructure Sensing.

The sensor has been designed to withstand normal shock and vibration. Make sure that the active sensor surface is never touched or allowed to come into direct contact with foreign objects, since this may adversely affect performance.

Observing these precautions will result in a long and useful probe life. GE Infrastructure Sensing recommends that probe calibration be checked routinely, at one-year intervals, or as recommended by our applications engineers for your particular application.The probe measures the water vapor pressure in its immediate vicinity; therefore, readings will be influenced by its proximity to the system walls, materials of construction, and other environmental factors. The sensor can be operated under vacuum or pressure, flowing or static conditions. Observe the following environmental precautions.

a.Temperature Range: The standard probe is operable from-110 to +70°C (-166 to 158°F).

b.Moisture Condensation: Be sure the process/ambient temperature is at least 10°C higher than the dew/frost point temperature. If this condition is not maintained, moisture condensation could occur on the sensor or in the sample system, which will cause reading errors. If this happens, refer to the Probe Cleaning Procedure in Appendix A.

2-4 |

Installing the Series 35 |

September 2004

Precautions for Moisture Probes (cont.)

c.Static or Dynamic Use: The sensor performs equally well in still air or where considerable flow occurs. Its small size makes it ideal for measuring moisture conditions within completely sealed containers or dry boxes. It also performs well at gas flow rates as high as 10,000 cm/sec, and liquid flow rates up to 10 cm/sec. Refer to Appendix A for the maximum flow rates in gases and liquids.

d.Pressure: The moisture probe always senses the existing water vapor pressure, regardless of the total ambient pressure. The moisture sensor measures water vapor under vacuum or high pressure conditions from as little as 5 microns of Hg to as high as 5,000 psi total pressure.

e.Long-Term Storage & Operational Stability: Sensors are not affected by continuous abrupt humidity changes or damaged by exposure to saturation conditions, even when stored.

f.Freedom from Interference: The sensor is completely unaffected by the presence of a wide variety of gases or organic liquids. Large concentrations of hydrocarbon gases, Freon™, carbon dioxide, carbon monoxide, and hydrogen have no effect on sensor water vapor indications. The sensor operates properly in a multitude of gaseous or non-conductive liquid environments.

g.Corrosive Materials: Avoid all materials that are corrosive or otherwise damaging to aluminum or aluminum oxide. These include strongly acidic or basic materials and primary amines.

Installing the Series 35 |

2-5 |

September 2004

Sample System Guidelines

A sample system, although not mandatory, is highly recommended for moisture measurement. The purpose of a sample system is to condition or control a sample stream to within the specifications of the probe. The application requirements determine the design of the sample system. GE Infrastructure Sensing applications engineers will make recommendations based on the following general guidelines.

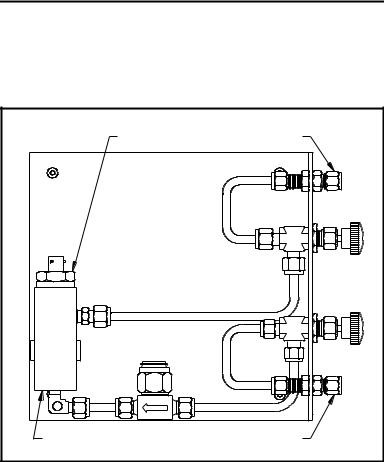

Typically, sample systems should be kept very simple.They should contain as few components as possible and all or most of those components should be located downstream of the measurement probe. Figure 2-1 on page 2-7 shows a simple sample system consisting of a general-purpose sample cell, a filter, and two shut-off valves, one at the inlet and one at the outlet.

The sample system components should not be made of any material that will affect measurements. A sample system may include a filter to remove particulates from the sample stream or a pressure regulator to reduce or control the pressure of the stream. However, most common filters and pressure regulators are not suitable for sample systems because they have wetted parts that may absorb or release components (such as moisture) into the sample stream. They may also allow ambient contamination to enter the sample stream In general, you should use stainless steel material for all wetted parts.

2-6 |

Installing the Series 35 |

September 2004

Sample System Guidelines (cont.)

Note: The actual sample system design is dependent on the application requirements.

Probe |

Outlet |

Sample Cell |

Inlet |

Figure 2-1: A Typical Moisture Sample System

Installing the Series 35 |

2-7 |

September 2004

Installing the Sample System

The sample system is usually fastened to a metal plate that has four mounting holes. GE Infrastructure Sensing also provides the sample system in an enclosure if requested. Outline and dimension drawings are included with all GE Infrastructure Sensing sample systems.

Follow the steps below to mount the external sample system and connect it to the process:

1.Mount the sample system plate or enclosure with four bolts, one in each corner.

2.Connect the process supply and return lines to the sample system inlet and outlet using the appropriate stainless steel fittings and tubing.

Caution!

Do not start flow through the sample system until the probe has been properly installed.

2-8 |

Installing the Series 35 |

September 2004

Installing a Probe in the Sample System

The sample system protects the probe from any damaging elements in the process. The probe must be inserted into the cylindrical shaped container called the sample cell that is included as part of the sample system.

M2 probes have 3/4-16 straight threads with an o-ring seal to secure the probe either into the sample system or directly into the process line. Other mounts are available for special applications.

Caution!

If mounting the probe directly into the process line, consult GE Infrastructure Sensing for proper installation instructions and precautions.

Follow the steps below to install the probe into the external sample cell.

1.Insert the probe into the sample cell so it is perpendicular to the sample inlet.

2.Screw the probe into the receptacle fitting, making sure not to cross the threads.

3.Tighten the probe securely.

Note: Do not over-tighten the probe, or the o-ring seal may be damaged.

Figure 2-2 on page 2-10 shows a typical probe installation, with the probe mounted in a sample cell.

Note: For maximum protection of the aluminum oxide moisture sensor, the protective shield should always be left in place.

Installing the Series 35 |

2-9 |

September 2004

Installing a Probe in the Sample System (cont.)

Probe

Probe

Inlet

Sample Cell

Outlet

Figure 2-2: A Typical Probe Installation

2-10 |

Installing the Series 35 |

September 2004

Mounting the Electronics Unit

The rack mount Series 35 may be mounted into a standard 19” rack, the panel mount Series 35 may be mounted into a rectangular cutout on most instrument panels, and the weatherproof Series 35 may be mounted on any vertical wall. See Appendix B, Outline and Installation Drawings, for details.

To install the panel-mount unit:

1.Remove the nuts and washers from the four mounting screws on the front panel of the unit.

2.Slide the unit into the panel cutout.

3.Install the washers and nuts on the mounting bolts, and tighten them securely.

To install the rack-mount unit:

1.Insert four mounting screws into the front panel of the unit.

2.Slide the unit into the rack.

3.From behind the rack, install the washers and nuts on the mounting screws and tighten them securely.

To install the weatherproof unit:

1.Position the unit against a flat, vertical mounting surface (i.e., a structure wall). Mark and drill appropriate size holes to accommodate the mounting bolts.

2.Insert the four mounting bolts into the four mounting holes of the weatherproof enclosure.

3.Place the enclosure against the mounting surface so that the four bolts enter the pre-drilled holes. From behind the mounting surface, install washers and nuts on the mounting bolts and tighten them securely.

Installing the Series 35 |

2-11 |

September 2004

Making Wiring Connections to the Electronics Unit

This section covers the following topics:

•precautions for modified or non-GE Infrastructure Sensing cables

•connecting the probe

•connecting the alarms

•connecting a recorder output device

•connecting an auxiliary input

•connecting power to the unit

•performing an MH/calibration test adjustment

IMPORTANT: To maintain good contact at each terminal block and to avoid damaging the pins on the connector, pull the connector straight off (not at an angle), make cable connections while the connector is away from the unit, and push the connector straight on (not at an angle) when the wiring is complete.

2-12 |

Installing the Series 35 |

September 2004

Modified or Non-GE Infrastructure Sensing Cables

Many customers must use pre-existing cables, or in some cases, modify the standard GE Infrastructure Sensing-supplied moisture cable to meet special needs. If you prefer to use your own cables or to modify our cables, observe the precautions listed below. In addition, after connecting the moisture probe, you must perform a calibration adjustment as described on 22 to compensate for any electrical offsets.

IMPORTANT: GE Infrastructure Sensing cannot guarantee operation to the specified accuracy of the Series 35 unless you use GE Infrastructure Sensingsupplied hygrometer cables.

•Use cable that matches the electrical characteristics of the GE Infrastructure Sensing cable (contact the factory for specific information on cable characteristics). The cable must have individually shielded wire pairs. A single overall shield is incorrect.

•If possible, avoid all splices. Splices impair performance. When possible, instead of splicing, coil the excess cable.

•If you must splice cables, be sure the splice introduces minimum resistive leakage or capacitive coupling between conductors.

•Carry the shield through any splice. A common mistake is to not connect the shields over the splice. If you are modifying a GE Infrastructure Sensing cable, the shield will not be accessible without cutting back the cable insulation. Also, do not ground the shield at both ends. Only ground the shield at the hygrometer end of the cable.

Installing the Series 35 |

2-13 |

September 2004

Connecting the Probe

The moisture probe must be connected to the Series 35 electronics with a continuous run of GE Infrastructure Sensing two-wire shielded cable (see Figure 2-3 below).

Red |

Shield |

Green |

Figure 2-3: Two-Wire Shielded Cable

Be sure to protect cables from excessive strain (bending, pulling, etc.) Do not subject cables to temperatures above +105°C (221°F) or below -40°C (-40°F). Standard cable assemblies (including connectors) can be ordered from GE Infrastructure Sensing in any length up to 600 meters (2,000 feet).

Follow the steps below to connect the probe to the electronics:

1.Make sure the power is disconnected from the Series 35.

2.Connect the probe cable to the terminal block on the Series 35 electronics, as shown in Table 2-4 on page 2-15 and the interconnection diagrams in Appendix B.

3.Connect the cable to the probe by inserting the bayonet-type connector onto the probe and twisting the shell clockwise until it snaps into a locked position.

2-14 |

Installing the Series 35 |

September 2004

Connecting the Probe (cont.)

IMPORTANT: To maintain good contact at each terminal block and to avoid damaging the pins on the connector, pull the connector straight off (not at an angle), make cable connections while the connector is away from the unit, and push the connector straight on (not at an angle) when the wiring is complete.

Table 2-4: Probe Connections

Connect: |

To PROBE Terminal Block: |

|

|

Red (H2) wire |

pin #1 |

|

|

Shield |

pin #2 |

|

|

Green (H1) wire |

pin #3 |

|

|

Installing the Series 35 |

2-15 |

September 2004

Connecting the Alarms

The Series 35 has one fault alarm, and two optional alarms that can be configured as high or low; that is, the contacts can be programmed to trip when the measured reading is over or under the alarm setpoint. The fault alarm, if enabled, will trip when there is a power failure, when a calibration error or a range error occurs, when there is a signal fault, or when the system is reset by the watchdog function.

Note: The Watchdog Function is a supervisory circuit that automatically resets the User Program in the event of a system error (see Setting Up Alarm Relays in Chapter 3).

Connecting the High and Low Alarms

The Series 35 has optional dual alarm relays available. Hermetically-sealed alarm relays are also optionally available. Each alarm relay is a single-pole, double throw contact set that has the following contacts:

•

•

•

Normally Open (NO)

Armature Contact (A)

Normally Closed (NC)

Make connections to Alarm relays A and B using the terminal block on the Series 35, as shown in Table 2-5 on page 2-17 and the interconnection diagrams in Appendix B.

Note: For European applications, the voltage levels at the alarm contacts must be less than 100 VRMS.

IMPORTANT: To maintain good contact at each terminal block and to avoid damaging the pins on the connector, pull the connector straight off (not at an angle), make cable connections while the connector is away from the unit, and push the connector straight on (not at an angle) when the wiring is complete.

2-16 |

Installing the Series 35 |

September 2004

Connecting the Alarms (cont.)

Table 2-5: High & Low Alarm Connections

Connect Alarm A: |

To ALARM A Terminal Block: |

|

|

NC Contact |

pin #4 |

|

|

NO Contact |

pin #5 |

|

|

A Contact |

pin #6 |

|

|

Connect Alarm B: |

To ALARM B Terminal Block: |

|

|

NC Contact |

pin #7 |

|

|

NO Contact |

pin #8 |

|

|

A Contact |

pin #9 |

|

|

Connecting the Fault Alarm

The fault alarm connections are on the “OUT” connector, pins 1, 2, and 3. Pins 1 and 3 provide a “normally closed” contact. When the Series 35 is operating in a non-fault state, the contact between pins 1 and 3 is energized (open) to remain open. When a fault occurs or power is lost, the contact between pins 1 and 3 is deenergized (closed). Pins 2 and 3 work in the opposite way. (Refer to Chapter 3, Operating the Series 35, to enable the fault alarm.)

Make connections to the fault alarm relay using the terminal block on the back of the Series 35 (or on the side of a benchmount unit), as shown in Table 2-6 below and the interconnection diagrams in Appendix B.

Table 2-6: Fault Alarm Connections

Connect Fault Alarm: |

To FAULT ALARM Terminal Block: |

|

|

NC Contact |

pin #1 |

|

|

NO Contact |

pin #2 |

|

|

A Contact |

pin #3 |

Note: For European applications, the voltage levels at the alarm contacts must be less than 100 VRMS.

Installing the Series 35 |

2-17 |

September 2004

Connecting a Recorder Output Device

IMPORTANT: The following instructions apply to Series 35 models with Output Board 703-1175. For models with Output Board 703-1180, see Appendix F.

The Series 35 has one recorder output, which is isolated. This output provides either a current or voltage signal, which is set using switch S1 on the output circuit board (see Figure 2-7 on page 2-19 for the location of S1).

Although this switch is normally set at the factory to provide a current output signal, the setting should be checked before making any recorder output connections.

Use the following sections to check or reset the S1 setting and connect an output device.

Checking or Resetting Switch S1

1.Turn off the Series 35 and disconnect power before opening the unit.

!WARNING!

YOU MUST TURN OFF AND UNPLUG THE SERIES 35 BEFORE YOU CONTINUE WITH THE FOLLOWING STEPS.

2.To access the output circuit board, remove the screws from the Series 35 enclosure and remove the cover.

3.Locate switch S1 on the output circuit board (see Figure 2-7 on page 2-19).

4.Set switch S1 to the appropriate position: “I” for current output or “V” for voltage output.

5.Replace the enclosure cover and install the screws.

2-18 |

Installing the Series 35 |

September 2004

Connecting a Recorder Output Device (cont.)

Switch S1

Figure 2-7: S1 Location on 703-1175 Output Board

Installing the Series 35 |

2-19 |

Loading...

Loading...