Page 1

PanaFlow™ Z1G/Z2G

User’s Manual

Flow

bhge.com

910-321 Rev. A

Jun 2018

Page 2

Page 3

PanaFlow™ Z1G/Z2G

Gas Ultrasonic Volumetric Flow Meter

User’s Manual

910-321 Rev. A

Jun 2018

bhge.com

© 2017 Baker Hughes, a GE company – All rights reserved.

Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product

described at any time without notice or obligation. Contact your BHGE representative for the most current information. The

Baker Hughes logo is a trade mark of Baker Hughes, a GE company. The GE Monogram is a trademark of the General Electric

Company.

Page 4

[no content intended for this page]

Page 5

Contents

Product Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Terms and Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Auxiliary Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Environmental Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Chapter 1. General Information

1.1 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Transit-Time Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Multi-Path Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Flow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Meter Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.7 Tag Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7.1 Model Tag Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7.2 Specification Tag Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7.3 Part String and Serial Number Tag Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7.4 Transmitter Tag Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2. Installation

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Lifting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Flowcell Location Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.1 Wiring the Line Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4.2 Wiring the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.4.3 Wiring the Standard 4-20 mA Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.4.4 Wiring the Standard RS485 Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4.5 Wiring the Option Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chapter 3. Initial Setup

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2 Programming Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3 The Magnetic Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.4 Initial Power On Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.5 Entering Data in the GLOBL Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.5.1 Entering Global System Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.5.2 Selecting Volumetric Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.5.3 Selecting Totalizer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

PanaFlow™ Z1G/Z2G User’s Manual iii

Page 6

Contents

3.5.4 Selecting Mass Flow Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.6 Activating a Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.7 Entering System Data for a Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.7.1 Accessing the Channelx-System Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.7.2 Selecting Volumetric Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.7.3 Selecting Totalizer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.7.4 Selecting Mass Flow Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Chapter 4. Operation

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.2 Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.3 The PanaFlow Z1G/Z2G Process Gas Flowmeter LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.4 The Optional PanaView Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.5 Taking Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.5.1 Programming the LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.5.2 Programming the PanaView Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.5.3 Pausing Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PT Sensor Drift and Recalibration44

Chapter 5. Specifications

5.1 Operation and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

5.2 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Appendix A. CE Mark Compliance and High Noise Environments

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

A.2 EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Appendix B. Gas Process Flowmeter Service Record

B.1 Option Cards Installed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

B.2 Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

B.3 Setup Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

iv PanaFlow™ Z1G/Z2G User’s Manual

Page 7

Preface

Product Registration

Thank you for purchasing your PanaFlow™ Z1G/Z2G Process Gas FlowMeter from Baker Hughes, a GE

Company. Please register your product at www.gemeasurement.com/productregistration for product support

such as the latest software/firmware upgrades, product information and special promotions.

Services

BHGE provides customers with an experienced staff of customer support personnel ready to respond to

technical inquiries, as well as other remote and on-site support needs. To complement our broad portfolio of

industry-leading solutions, we offer several types of flexible and scalable support services including:

Training, Product Repairs, Extended Warranties, Service Agreements and more. Please visit

www.gemeasurement.com/services for more details.

Terms and Conditions

Sales Terms and Conditions for your recent purchase of a BHGE product, including the applicable product

Warranty, can be found on our website at the following link:

www.gemeasurement.com/sales-terms-and-conditions

Typographical Conventions

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper

setup of the equipment. Failure to follow these instructions carefully may cause unreliable

performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Attention European Customers! To meet CE Mark requirements for all units intended for use in

the EU, all electrical cables must be installed as described in this manual.

PanaFlow™ Z1G/Z2G Process Gas FlowMeter User’s Manual v

Page 8

Preface

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on this equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary

equipment. Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

vi PanaFlow™ Z1G/Z2G Process Gas FlowMeter User’s Manual

Page 9

Environmental Compliance

RoHS

The PanaFlow™ Z1G/Z2G Process Gas FlowMeter fully complies with RoHS regulations (Directive

2011/65/EU).

Waste Electrical and Electronic Equipment (WEEE) Directive

BHGE is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-back

initiative (Directive 2012/19/EU).

Preface

The equipment that you bought has required the extraction and use of natural resources for its production. It

may contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on

the natural resources, we encourage you to use the appropriate take-back systems. Those systems will reuse

or recycle most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or

regional waste administration.

Please visit

more information about this initiative.

http://www.gemeasurement.com/environmental-health-safety-ehs for take-back instructions and

PanaFlow™ Z1G/Z2G Process Gas FlowMeter User’s Manual vii

Page 10

Preface

[no content intended for this page]

viii PanaFlow™ Z1G/Z2G Process Gas FlowMeter User’s Manual

Page 11

Chapter 1. General Information

Chapter 1. General Information

1.1 Theory of Operation

The PanaFlow Z1G/Z2G Process Gas Flowmeter system uses ultrasonic transit-time technology. A brief

description of transit-time theory follows. For more information about the theory, and the use of BHGE

ultrasonic flow meters for measuring flow, please refer to Ultrasonic Measurements for Process Control by L.C.

Lynnworth (Academic Press, 1989).

1.1.1 Transit-Time Method

The transit time technique uses a pair of transducers, with each transducer alternately sending and

receiving coded ultrasonic signals through the fluid. When the fluid is flowing, signal transit time in the

downstream direction is shorter than in the upstream direction. The difference between these transit times

is proportional to the flow velocity. The PanaFlow Z1G/Z2G Process Gas Flowmeter measures this very small

time difference and, using various digital signal processing techniques combined with programmed pipe

parameters, determines the flow rate and direction.

1.1.2 Transducers

When in a transmit cycle, transducers convert electrical energy into ultrasonic pulses and then convert the

ultrasonic pulses back to electrical energy when in a receive cycle. In other words, they act like loudspeakers

when transmitting the signal and like microphones when receiving it. They perform the actual data

transmission and collection, thus interrogating the flow.

1.2 Multi-Path Design

Multi-path ultrasonic flow meters are designed to accommodate more than one pair of transducers to

interrogate the flow field in different locations and more accurately determine the actual flow rate. The

PanaFlow Z1G/Z2G Process Gas Flowmeter system is available in either a 1-Path or 2-Path configuration. For

the 2-Path configuration, the measurement paths are located either at Diametrical path or at Midradius

configurations. In addition to the flow transducers, the PanaFlow Z1G/Z2G Process Gas Flowmeter can be

fitted with optional temperature and pressure transducers to permit mass flow measurements.

1.3 Flow Profile

One of the main factors affecting an ultrasonic flow measurement is the flow profile. If the flow profile is

known, mathematical modeling of the flow and the relationships between the raw data of the two paths can

be made. Maintaining a constant flow-profile shape across all flow velocities, pipe sizes and upstream flow

disturbances can be difficult. For this reason, BHGE has tested the PanaFlow Z1G/Z2G Process Gas Flowmeter

under various conditions in an effort to determine its operational limits.

PanaFlow™ Z1G/Z2G User’s Manual 1

Page 12

Chapter 1. General Information

1.4 Unpacking

The PanaFlow Z1G/Z2G Process Gas Flowmeter is typically packaged in a wooden crate, the size of which will

depend on the size of product ordered. The flowcell is secured by several 2x4 wood blocks to prevent shifting

during transit. Simply remove these 2x4 braces to unpack the system. For local-mount systems the

transmitter electronics enclosure is installed directly on top of the flowcell via an adapter. For remote-mount

systems the transmitter electronics enclosure and the remote cable may ship in a separate package.

1.5 Inspection

Prior to installation, inspect all materials to be used in the installation:

• Gaskets - check for cracks, tears and over compression

• Nuts and Bolts - check for damaged threads and for debris

• RF Flange Faces - check for damage to serrations that may cause gaskets to not seal properly.

In general, check for anything that may prevent safe operation of the equipment.

IMPORTANT: If pipes are shipped pre-assembled as a single section, care should be taken to inspect and check

the bolts and gaskets.

1.6 Meter Components

Figure 1 on page 3 shows a PanaFlow Z1G/Z2G Process Gas Flowmeter system, with the items described in

Table 1 below.

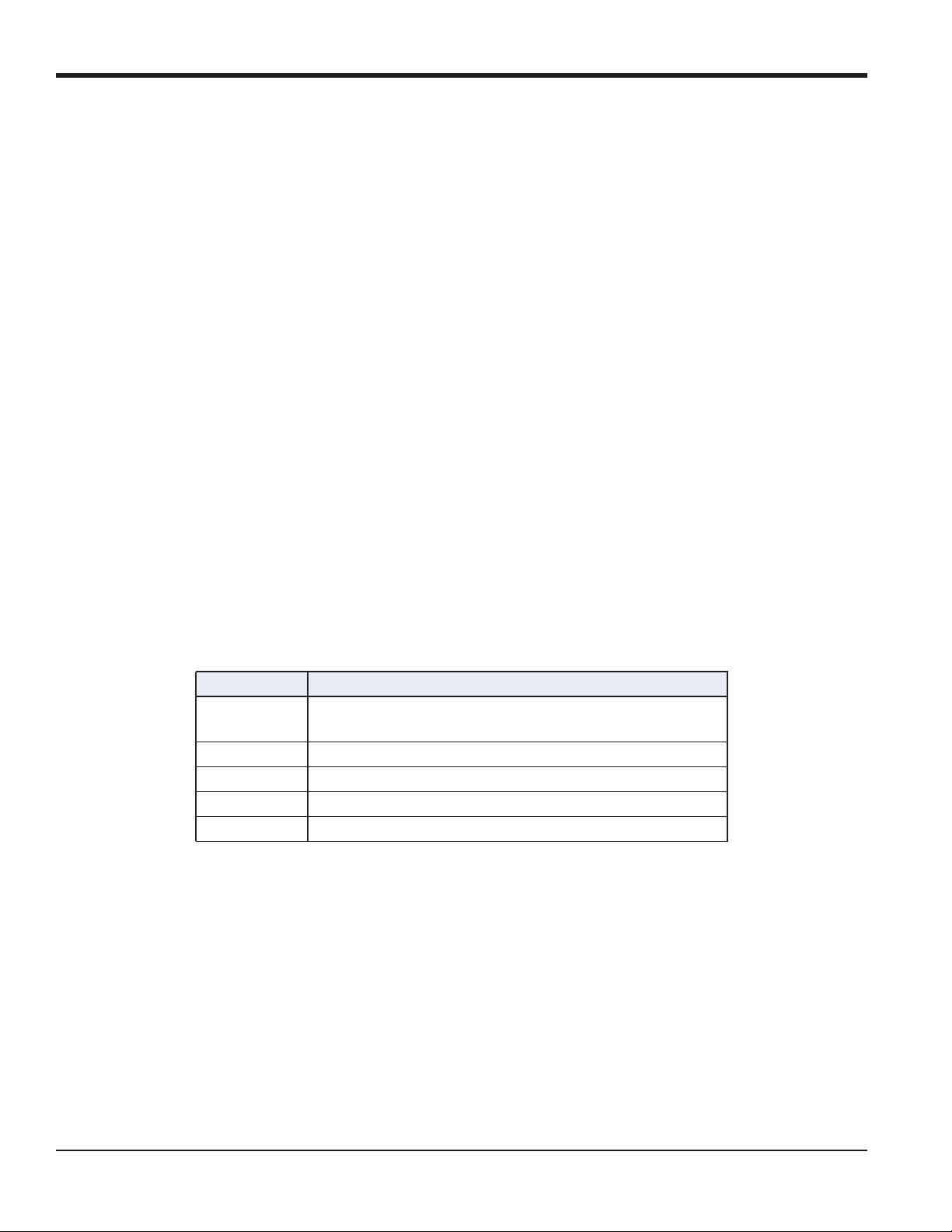

Table 1: Typical System Components

Item No. Component

1 Meter Body with Flanges (material list WCB: LCB: CF8:

CF8M: CK3MCuN: CD3MWCuN)

2 Transmitter Electronics

3 Magnetic Stylus (for Transmitter Keypad)

4 Mounting Adapter, Transmitter (for local mount only)

5 Transducers/Inserts

The meter body with Flanges together is called as Flowcell or Spool.

2 PanaFlow™ Z1G/Z2G User’s Manual

Page 13

1.6 Meter Components (cont.)

Mounting Adapter (4)

Chapter 1. General Information

Transmitter Electronics (2)

Magnetic Stylus (3)

Transducer/Insert (5)

Figure 1: Typical PanaFlow Z1G/Z2G Process Gas Flowmeter Assembly

Meter Body with Flanges (1)

Note: Design details may vary slightly with pipe size.

PanaFlow™ Z1G/Z2G User’s Manual 3

Page 14

Chapter 1. General Information

1.7 Tag Plates

The PanaFlow Z1G/Z2G Process Gas Flowmeter is marked with a variety of labels which provide valuable

information about your specific system. Examples of typical flowcell tag plates are shown in the following

sections.

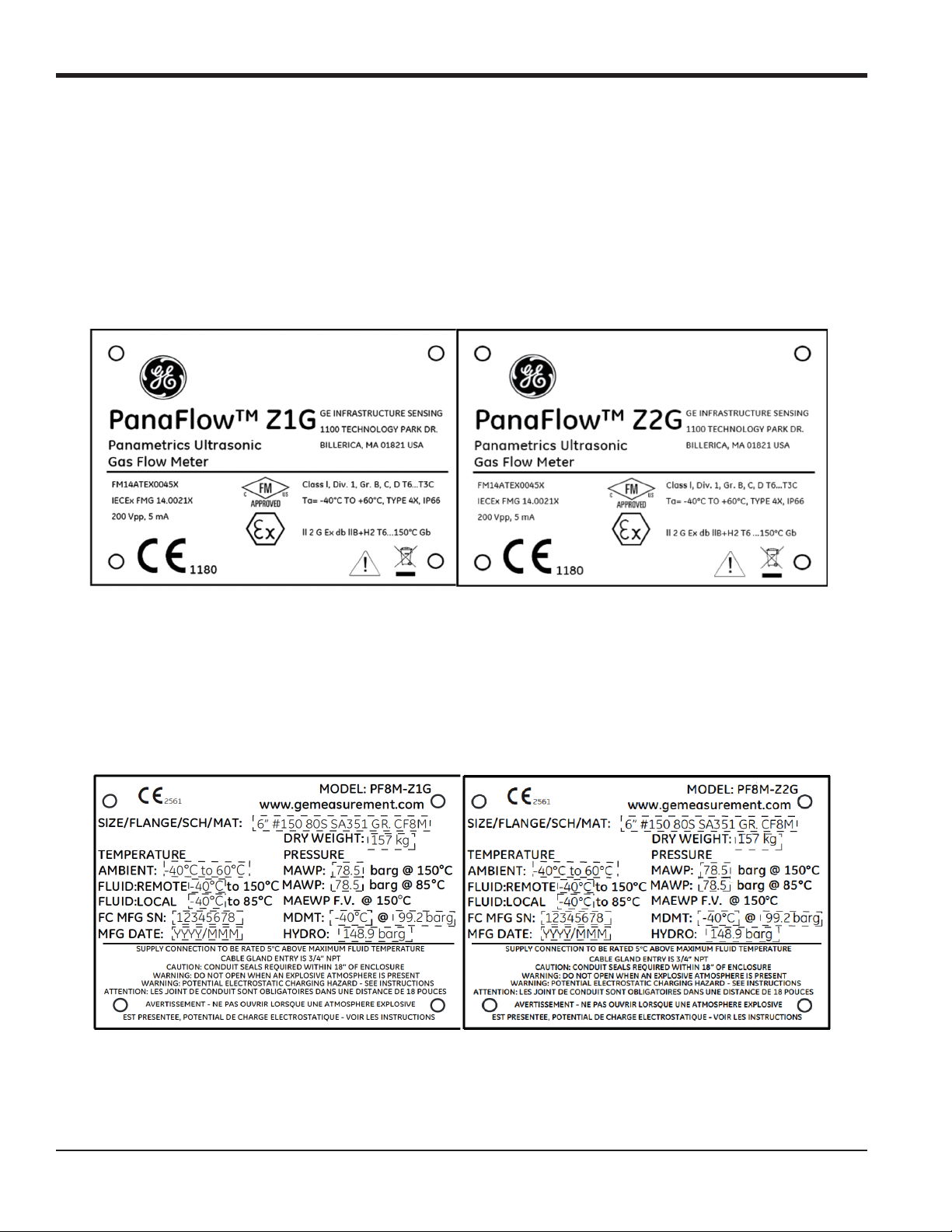

1.7.1 Model Tag Plate

The Model Tag Plate (see Figure 2 below) contains the model name and certification markings for the spool

and its hazardous area usage.

Figure 2: Model Tag Plate

1.7.2 Specification Tag Plate

The Specification Tag Plate (see Figure 3 below) contains information pertaining to the build and test of the

spool, such as spool nominal size, flange rating, wall thickness, material, dry weight (including transmitter),

vessel manufacturing serial number, ambient and fluid temperature ranges, operating pressures, hydro test

pressure and date.

Figure 3: Specification Tag Plate

4 PanaFlow™ Z1G/Z2G User’s Manual

Page 15

Chapter 1. General Information

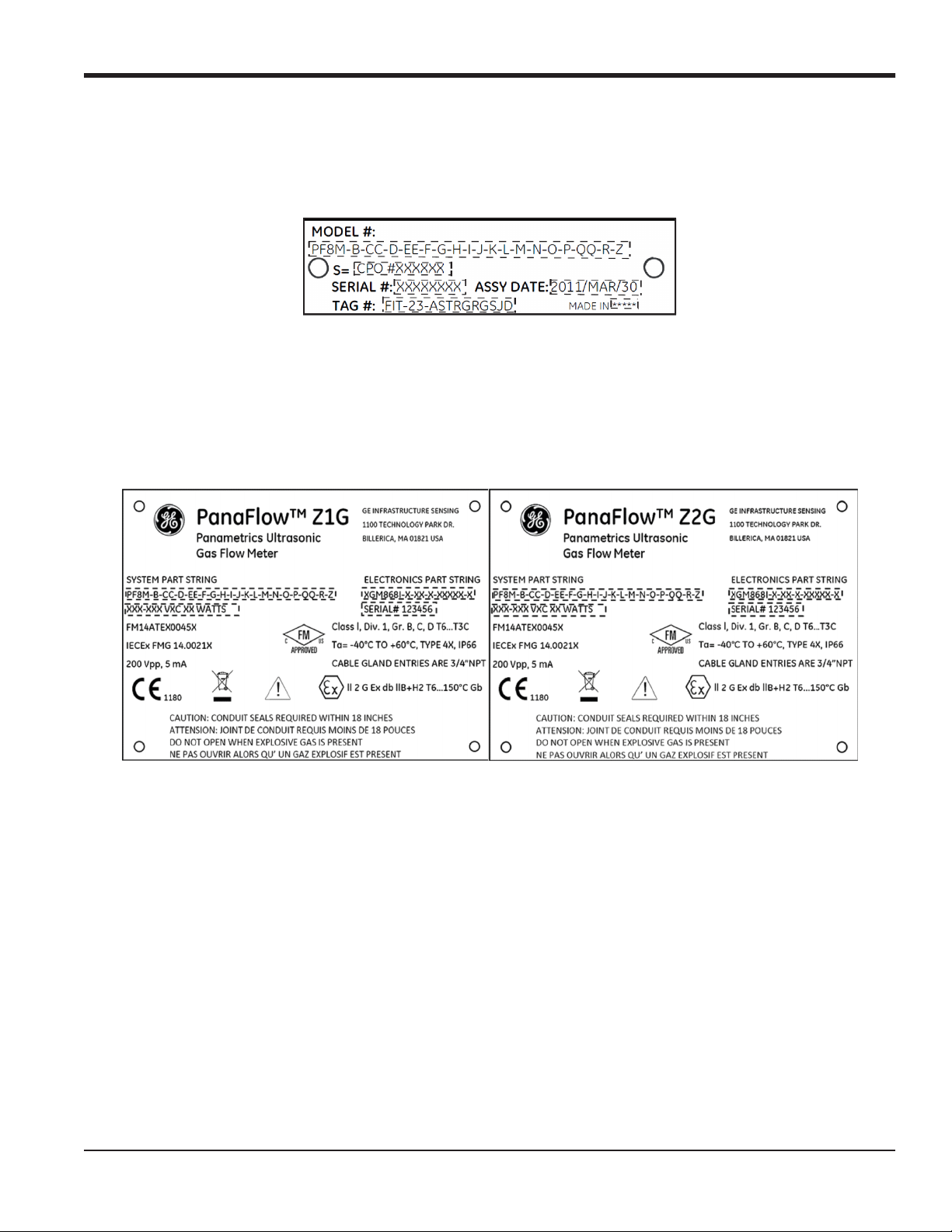

1.7.3 Part String and Serial Number Tag Plate

The Part String and Serial Number Tag (see Figure 4 below) contains the specific configuration of the spool as

well as the final assembly date, BHGE serial number and customer tag number.

Figure 4: Part String and S/N Tag Plate

1.7.4 Transmitter Tag Plate

The Flow Transmitter Tag Plate (see Figure 5 below) is affixed to the transmitter and includes the

configuration per the model information detailed on the Model Tag Plate. This tag plate also contains the

hazardous area certification information for the transmitter.

Figure 5: Flow Transmitter Tag Plate

PanaFlow™ Z1G/Z2G User’s Manual 5

Page 16

Chapter 1. General Information

[no content intended for this page]

6 PanaFlow™ Z1G/Z2G User’s Manual

Page 17

Chapter 2. Installation

Chapter 2. Installation

2.1 Introduction

To ensure safe and reliable operation of the PanaFlow Z1G/Z2G Process Gas Flowmeter, the system must be

installed in accordance with the guidelines established by BHGE engineers. Those guidelines are explained

in detail in this chapter.

WARNING! The PanaFlow Z1G/Z2G Process Gas Flowmeter can measure the flow rate of many

gases, some of which are potentially hazardous. In such cases, the importance of proper safety

practices cannot be overemphasized.

Be sure to follow all applicable local safety codes and regulations for installing electrical equipment

and working with hazardous gases or flow conditions. Consult company safety personnel or local

safety authorities to verify the safety of any procedure or practice.

Attention! To meet CE Mark requirements for all units intended for use in the EU or in high

electrical noise environments, all electrical cables must be installed as described in Appendix A, “CE

Mark Compliance and High Noise Environments”.

2.2 Lifting Instructions

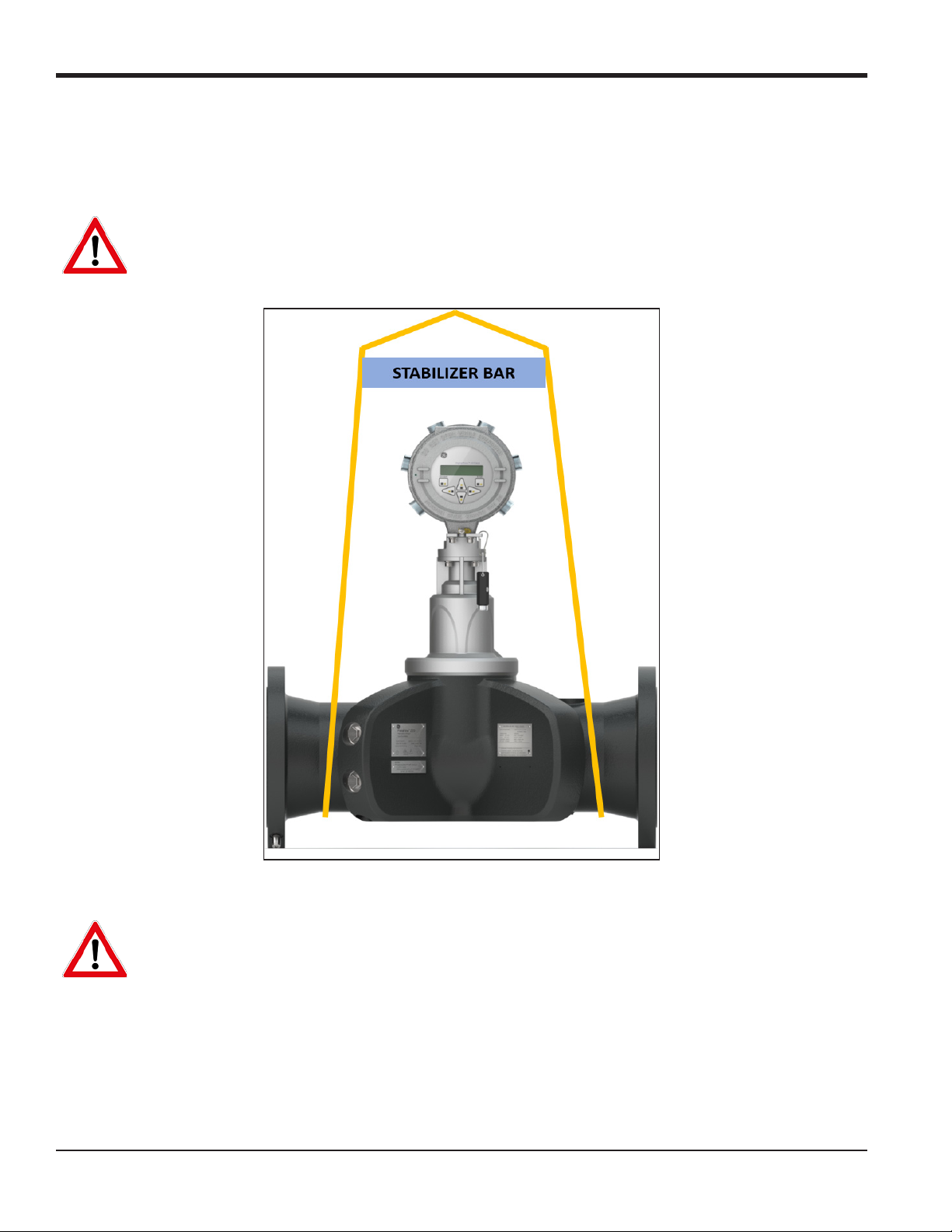

Use proper lifting techniques when moving the PanaFlow Z1G/Z2G Process Gas Flowmeter. No lifting hooks or

eyelets are provided. The recommended method for lifting the PanaFlow Z1G/Z2G Process Gas Flowmeter is

by using lifting straps on each side of the spool with a stabilizer bar between them, located above the

transmitter head. Additional care may need to be taken to prevent the transmitter from rotating, especially

on the smaller systems where the transmitter weight is a larger percentage of the total system weight. A

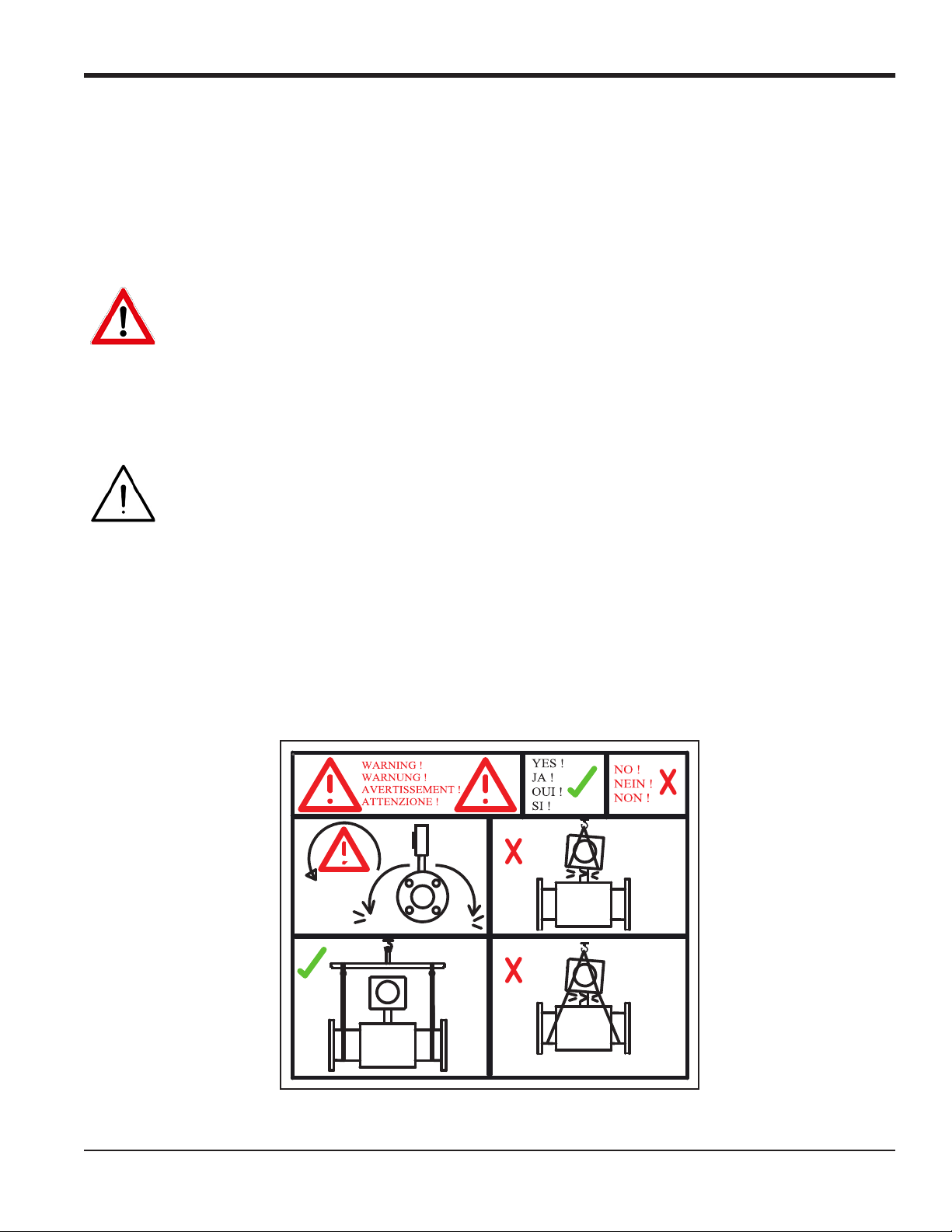

label similar to Figure 6 below, which illustrates these required precautions, is attached to the flowcell.

Figure 6: Spoolpiece Lifting Label (ref. dwg. 442-1232)

PanaFlow™ Z1G/Z2G User’s Manual 7

Page 18

Chapter 2. Installation

2.2 Lifting Instructions (cont.)

While lifting the PanaFlow Z1G/Z2G Process Gas Flowmeter, be sure to observe the warnings and figures

below:

WARNING! Never stand below any object being lifted.

Figure 7: Proper Lifting Method

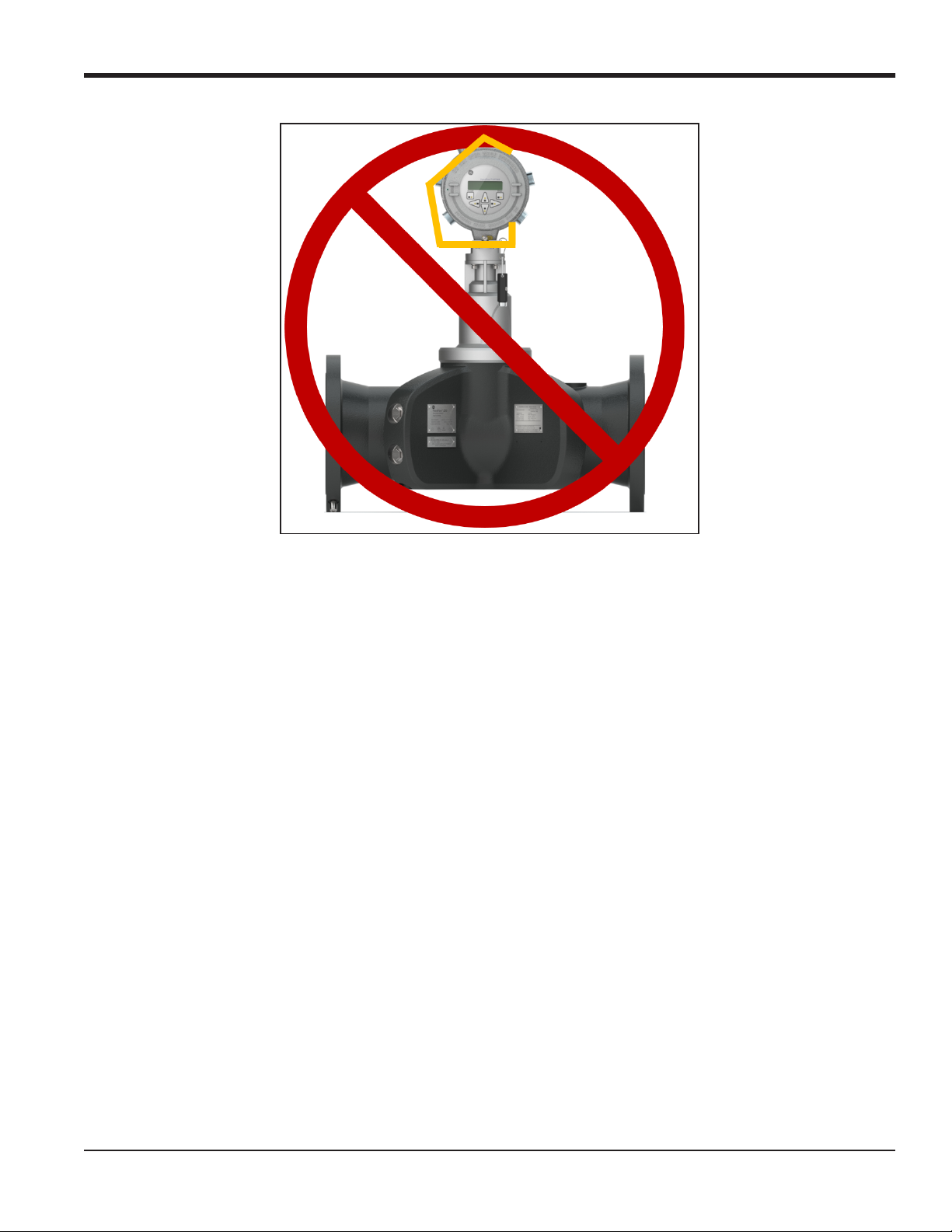

WARNING! Do not use the transmitter to support the weight of the flowcell as shown in Figure 8

below. The transmitter cannot support the weight of the Flowcell/Spool.

8 PanaFlow™ Z1G/Z2G User’s Manual

Page 19

Chapter 2. Installation

Figure 8: Improper Lifting Method

2.3 Flowcell Location Guidelines

The flowcell includes the flow transducers and, optionally, pressure and temperature transmitters. Ideally,

install the flowcell in a section of pipe with access to the flowcell, such as a long run of pipe that is above

ground. Observe the following recommendations:

• There should be at least 20 pipe diameters of straight, undisturbed flow upstream and 10 pipe

diameters of straight, undisturbed flow downstream from the measurement point. To ensure

undisturbed flow, avoid sources of disturbances in the fluid such as valves, flanges, expansions, and

elbows.

• Because condensate or sediment at the bottom of the pipe may cause attenuation of the ultrasonic

signal, always install the PanaFlow Z1G/Z2G Process Gas Flowmeter with the transmitter in a vertical

orientation on the top of the pipe. This ensures that the transducers are located on the sides of the

pipe rather than on the top or bottom.

• Only authorized personnel should perform the installation. The proper personal protection

equipment (PPE) should always be used when working with this equipment.

• The flowcell shall be installed in such a way that it can be safely operated, maintained and inspected.

Please refer to specific outline and installation drawings for proper clearances and specific distances

for each system size. In general, allow for a minimum of 12” of space on all sides of the flowcell and

flow transmitter, with an ideal clearance of 24” on all sides.

• You must provide suitable over-pressure protection at the main piping to the flowcell in order to

prevent damage to the flowcell and injury to personnel. The utilized over-pressure protection device

shall be supplied with all declarations of conformity and EC-type design certificates.

PanaFlow™ Z1G/Z2G User’s Manual 9

Page 20

Chapter 2. Installation

• Make sure the difference between the inside diameter of the pipe and that of the PanaFlow Z1G/Z2G

Process Gas Flowmeter does not exceed 0.5%, as changes in internal diameters will cause flow profile

disturbances.

• Make sure any non-symmetrical offset does not exceed 1%, as misalignment between the piping and

the meter may cause flow profile disturbances.

• Make sure the gasket is centered on the flange faces and does not protrude into the pipe, as

protrusion of the gasket into the pipe may cause flow profile disturbances.

• If pipe insulation is required, install all insulation materials and accessories in accordance with the

manufacturer's instructions and recognized industry practices. Adhere to the local code where

applicable to ensure that the safe and proper installation will serve its intended purpose.

2.4 Making the Electrical Connections

This section contains instructions for making all the necessary electrical connections to the PanaFlow

Z1G/Z2G Process Gas Flowmeter. Refer to Figure 13 on page 19 for a complete wiring diagram.

Note: Except for the power connector, all electrical connectors are stored on their terminal blocks during

shipment and may be removed from the enclosure for more convenient wiring. Simply, feed the cables

through the conduit holes on the side of the enclosure, attach the wires to the appropriate connectors,

and plug the connectors back into their terminal blocks.

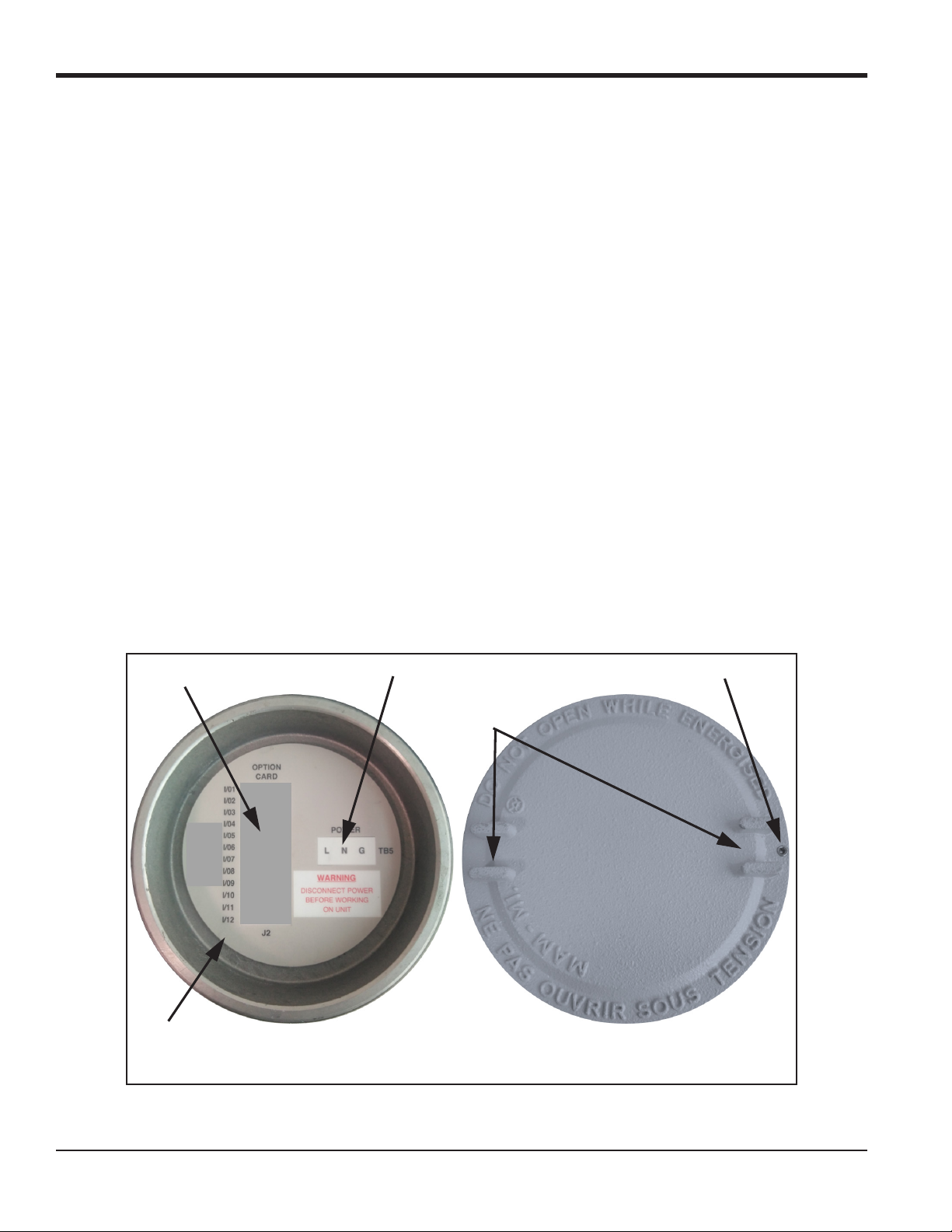

To prepare the PanaFlow Z1G/Z2G Process Gas Flowmeter for wiring, refer to Figure 9 below, and complete the

following steps:

Option Card Connections

Wiring Label

Power Connections

Slots

Set Screw

Inside View

Figure 9: Rear Cover with Connection Labels

10 PanaFlow™ Z1G/Z2G User’s Manual

Outside View

Page 21

Chapter 2. Installation

WARNING! Always disconnect the line power from the PanaFlow Z1G/Z2G Process Gas Flowmeter

electronics before removing either the front or rear cover. This is especially important in a hazardous

environment.

1. Disconnect any existing power line from its source.

2. Loosen the set screw on the rear cover.

3. Place a rod or long screwdriver across the cover in the slots provided, and rotate the cover

counterclockwise until it comes free from the enclosure.

4. Install any required cable clamps in the appropriate conduit holes around the side of the enclosure.

5. Refer to the labels inside the rear cover to assist in making the power and option card connections.

Also, Figure 14 on page 20 shows the specific connection labels for all available option cards.

2.4.1 Wiring the Line Power

The PanaFlow Z1G/Z2G Process Gas Flowmeter may be ordered for operation with power inputs of either

85-240 VAC (standard) or

12-28 VDC (optional). The tag plate on the side of the electronics enclosure lists the required line voltage and

the power rating. Be sure to connect the meter only to the specified line voltage.

WARNING! Proper grounding of the PanaFlow Z1G/Z2G Process Gas Flowmeter is required to

prevent the possibility of electric shock. See Figure 11 on page 17 for the location of the chassis

grounding screw.

WARNING! For compliance with the European Union’s Low Voltage Directive, this unit requires an

external power disconnect device such as a switch or circuit breaker. The disconnect device must be

marked as such, clearly visible, directly accessible, and located within 1.8 m (6 ft) of the meter.

WARNING! Improper connection of the line power leads or connecting the meter to the incorrect

line voltage may damage the unit. It may also result in hazardous voltages at the flowcell and

associated piping as well as within the electronics enclosure.

Refer to Figure 13 on page 19 to locate the correct terminal block, and connect the line power as follows:

1. Prepare the line power leads by trimming the line and neutral AC power leads (or the positive and

negative DC power leads) to a length 0.5 in. (1 cm) shorter than the ground lead. This ensures that the

ground lead is the last to detach if the power cable is forcibly disconnected from the meter.

2. Install a cable clamp in the conduit hole closest to the power terminal block. Avoid using the other

conduit holes for this purpose to minimize any interference in the circuitry from the AC power line.

3. Strip 1/4 in. of insulation from the end of each of the three power line leads.

4. Route the cable through the conduit hole and connect the line power leads to the terminal block,

using the pin number assignments shown in Figure 13 on page 19.

5. Leaving a bit of slack, secure the power line with the cable clamp.

PanaFlow™ Z1G/Z2G User’s Manual 11

Page 22

Chapter 2. Installation

WARNING! Make sure both covers, with their o-ring seals, are installed and the set screws

tightened before applying power in a hazardous environment.

CAUTION! The transducers must be properly wired before applying power to the meter.

(If the electronics enclosure is mounted directly on the flowcell, these connections are made at the

factory prior to shipment.)

Proceed to the next section to continue the wiring of the PanaFlow Z1G/Z2G Process Gas Flowmeter.

2.4.2 Wiring the Transducers

Attention! To meet CE Mark requirements for all units intended for use in the EU or in high

electrical noise environments, all electrical cables must be installed as described in Appendix A, “CE

Mark Compliance and High Noise Environments”.

For a PanaFlow Z1G/Z2G Process Gas Flowmeter system with the flow transmitter mounted on the flowcell,

no external transducer wiring is required. However, for a system with a remote mounted flow transmitter,

refer to the wiring diagram in Figure 12 on page 18 to connect the transducers and preamplifiers to the

transmitter.

2.4.3 Wiring the Standard 4-20 mA Analog Outputs

The standard configuration of the PanaFlow Z1G/Z2G Process Gas Flowmeter includes two isolated 4-20 mA

analog outputs (designated as outputs 1 and 2). Connections to these outputs may be made with standard

twisted-pair wiring, but the current loop impedance for these circuits must not exceed 600

Attention! To meet CE Mark requirements for all units intended for use in the EU or in high

electrical noise environments, all electrical cables must be installed as described in Appendix A, “CE

Mark Compliance and High Noise Environments”.

To wire the analog outputs, complete the following steps:

1. Disconnect the main power and remove the rear cover.

2. Install a cable clamp in the chosen conduit hole on the side of the electronics enclosure.

3. Refer to Figure 13 on page 19 to locate the correct terminal block, and wire the analog outputs as

shown. Secure the cable clamp.

Note: Analog outputs 1 and 2 in the wiring diagram correspond to analog outputs A and B in Slot 0 in the

Panaview software.

4. If wiring of the unit has been completed, reinstall the rear cover on the enclosure and tighten the set

screw.

Ω.

WARNING! Make sure both covers, with their o-ring seals, are installed and the set screws

tightened before applying power in a hazardous environment.

12 PanaFlow™ Z1G/Z2G User’s Manual

Page 23

Chapter 2. Installation

Note: Prior to use, the analog outputs must be set up and calibrated.

Proceed to the next section to continue the wiring of the PanaFlow Z1G/Z2G Process Gas Flowmeter.

2.4.4 Wiring the Standard RS485 Serial Port

The PanaFlow Z1G/Z2G Process Gas Flowmeter is equipped with a standard RS485 serial interface. This serial

port will be used to communicate with PC/DCS system. In addition, the PanaFlow Z1G/Z2G Process Gas

Flowmeter can receive and execute remote commands, using BHGE’s PanaView software.

Note: For more detailed information on serial communications refer to BHGE’s EIA-RS Serial

Communications manual (document #916-054).

Attention! To meet CE Mark requirements for all units intended for use in the EU or in high

electrical noise environments, all electrical cables must be installed as described in Appendix A, “CE

Mark Compliance and High Noise Environments”.

Refer to Figure 13 on page 19 to locate the correct terminal block, and wire the RS485 serial port as follows:

WARNING! Always disconnect the line power from the PanaFlow Z1G/Z2G Process Gas Flowmeter

electronics before removing either the front or rear cover. This is especially important in a hazardous

environment.

1. Disconnect the main power and remove the rear cover.

2. Install the required cable clamp in the chosen conduit hole on the side of the electronics enclosure.

3. Feed one end of the cable through the conduit hole, wire it to terminal block, and secure the cable

clamp. Use the information in Table 2 below to prepare a suitable cable for connecting the PanaFlow

Z1G/Z2G Process Gas Flowmeter to the external serial device.

Table 2: RS485 Cable Connections

TB Pin # Signal Description

1 RS485+

2 RS485-

3COM

4 Not Used

5 Not Used

4. If wiring of the unit has been completed, reinstall the rear cover on the enclosure and tighten the set

screw.

Proceed to the next section to continue the wiring of the PanaFlow Z1G/Z2G Process Gas Flowmeter.

2.4.5 Wiring the Option Cards

The PanaFlow Z1G/Z2G Process Gas Flowmeter can accommodate two option cards one in Slot 1 and other

option card in Slot 2. The following option card functions are available only in certain combinations.

PanaFlow™ Z1G/Z2G User’s Manual 13

Page 24

Chapter 2. Installation

• Analog Inputs (Slot 1)

• RTD Inputs (Slot 1)

• Modbus Communications (Slot 2)

• HART Communications (Slot 2)

• Foundation Fieldbus Communications (Slot 2)

Figure 14 on page 20 shows the connection labels for the available option cards. Wiring any option card

installed in Slot 1 requires completion of the following steps:

Attention! To meet CE Mark requirements for all units intended for use in the EU or in high

electrical noise environments, all electrical cables must be installed as described in Appendix A, “CE

Mark Compliance and High Noise Environments”.

1. Disconnect the main power and remove the rear cover.

2. Install a cable clamp in the chosen conduit hole on the side of the electronics enclosure and feed a

standard twisted-pair cable through this conduit hole.

3. Locate the 12-pin terminal block in Figure 13 on page 19 and wire the option card as indicated on the

label inside the rear cover (see Figure 9 on page 10). Secure the cable clamp.

IMPORTANT: If you have multiple flow transmitters, because of the attached wiring label, all rear covers

remain with their original meters!

4. If wiring of the unit has been completed, reinstall the rear cover on the enclosure and tighten the set

screw.

IMPORTANT: Prior to use, the option card must be set up and calibrated.

For more specific instructions on particular option cards, proceed to the appropriate section(s) that follow.

must

14 PanaFlow™ Z1G/Z2G User’s Manual

Page 25

Chapter 2. Installation

2.4.5.1 Wiring a 4-20 mA Analog Inputs Option Card

To calculate standard flow rates, the PanaFlow Z1G/Z2G Process Gas Flowmeter requires accurate

temperature and pressure data from the measurement site. Transmitters installed in the flowcell can provide

this information via an optional4-20 mA analog inputs option card. This option card includes two or four

isolated 4-20 mA analog inputs (designated as A, B, C and D), each of which includes a 24 VDC power supply

for loop-powered transmitters. Either input may be used to process the temperature signal, while the other

input is used to process the pressure signal.

IMPORTANT: To properly enter programming data into the meter, it is necessary to know which input is

assigned to which process parameter.

The analog inputs, which have an impedance of 118

Ω, should be connected with standard twisted-pair

wiring. Power to the transmitters may be supplied either by the integral 24 VDC power supply on the analog

input option card or by an external power supply. Figure 10 below shows typical wiring diagrams, with and

without an external power supply, for one of the analog inputs.

24 VDC

POWER SUPPLY

+–

Analog Input

INPUT +

+24V

Transmitter

+ IN

– OUT

With External Power Supply With Internal Power Supply

Sensor

Analog Input

INPUT +

+24V

Transmitter

– OUT

+ IN

Sensor

Figure 10: Typical Analog Input Wiring Diagrams

Before making any connections, complete the steps in “Making the Electrical Connections” on page 10. Then,

wire the analog inputs as shown on the label in the rear cover (see Figure 9 on page 10).

IMPORTANT: The analog inputs option card can be calibrated with the PanaFlow Z1G/Z2G Process Gas

Flowmeter’s built-in analog outputs. However, be certain that the analog outputs have been

calibrated first.

PanaFlow™ Z1G/Z2G User’s Manual 15

Page 26

Chapter 2. Installation

2.4.5.2 Wiring an RTD Inputs Option Card

The PanaFlow Z1G/Z2G Process Gas Flowmeter RTD inputs option card provides two or four direct RTD inputs

(designated as A, B, C and D). Each RTD input requires three wires, and should be connected as shown on the

label in the rear cover (see Figure 9 on page 10).

Before making any connections, complete the steps in “Making the Electrical Connections” on page 10.

2.4.5.3 Wiring a Modbus Option Card

A Modbus option card uses the RS485 standard for communication, and it must be installed in Slot 2. The

RS485 standard allows up to 32 nodes (drivers and receivers) on one multi-drop network, at distances up to

4000 ft (1200 m). BHGE recommends using 24-gauge (24 AWG) twisted-pair wire with a characteristic

impedance of 120

Note: The Modbus option card provides its own RS485 connections.

Ω and 120 Ω termination at each end of the communications line.

2.4.5.4 Wiring The HART Interface

To connect the HART interface, refer to Figure 13 on page 19 and proceed as follows:

1. Connect the HART Net (+) wire to pin #1.

2. Connect the HART Net (-) wire to pin #2.

3. Connect the optional cable shield to pin #3.

2.4.5.5 Wiring the Foundation Fieldbus Interface

To connect the Foundation Fieldbus interface, refer to Figure 13 on page 19 and proceed as follows:

1. Connect the Fieldbus Net (+) wire to pin #1.

2. Connect the Fieldbus Net (-) wire to pin #2.

3. Connect the optional cable shield to pin #3.

WARNING! Make sure both covers, with their o-ring seals, are installed and the set screws

tightened before applying power in a hazardous environment.

16 PanaFlow™ Z1G/Z2G User’s Manual

Page 27

Chapter 2. Installation

PanaFlow™ Z1G/Z2G User’s Manual 17

D

S

O

R

U

V

I

R

N

E

P

A

T

U

O

S

S

E

O

I

N

S

N

O

P

O

O

T

N

E

N

W

H

S

E

D

E

R

N

E

I

L

E

G

I

Ø6.10 (155)

8.20

2.06

51°

7 PLCS

3/4" NPTF

7 PLCS

3.86

SEE

A A

VIEW A-A

0.52 (13)

DETAIL A

3/4" NPT

1/4-20 UNC-2B

1.50

1.00

0.28 (7)

0.25 (6)

10-32 EXTERNAL GROUND SCREW

4PLCS

3/4" NPTF

7 PLCS

(52)

(98)

(208)

(38)

NOTES:

1. ALL DIMENSIONS ARE REFERENCE.

2. WEIGHT: 10 LB (4.5 KG) AL

25 LB (11.5 KG) SS

3. DIMENSIONS ARE IN INCHES (MILLIMETERS).

(25)

DETAIL A

Figure 11: Transmitter Electronics Enclosure - Outline & Dimensions (ref. dwg. 712-1318)

Page 28

Chapter 2. Installation

PanaFlow™ Z1G/Z2G User’s Manual 18

Figure 12: Remote Mount Electronics - Transducer and Preamplifier Wiring (ref. dwg. 702-731, 732)

Page 29

Chapter 2. Installation

PanaFlow™ Z1G/Z2G User’s Manual 19

COM (SHIELD)

1

3

2

TX (RS485+)

RX (RS485-)

CTS

DTR

AOUTB-

AOUTB+

AOUTA-

AOUTA+

I/O1

I/O2

I/O3

I/O4

I/O5

I/O6

I/O7

I/O8

I/O9

I/1O

I/11

I/12

CH1UP

CH1RTN

CH1RTN

CH1DN

CH2UP

CH2RTN

CH2RTN

CH2DN

OPTION CONTACT TERMINAL BLOCK

4-20 OUTPUT 1 SIG

4-20 OUTPUT 1 RTN

4-20 OUTPUT 2 SIG

4-20 OUTPUT 2 RTN

DATA TERMINAL READY

CLEAR TO SEND

COMMON

TRANSMIT

DESCRIPTION

RS232/RS485/4-20 ANALOG OUTPUT TERMINAL BLOCK

PIN

5 DTR

4 CTS

3 COM (SHLD)

7 AOUT B+

6 AOUT B-

9 AOUT A+

8 AOUT A-

2 RX (RS485 -)

1 TX (RS485 +)

RECEIVE

CH1 DOWNSTREAM TRANSDUCER ANALOG RTN (-)

CH1 UPSTREAM TRANSDUCER SIG (+)

CH1 UPSTREAM TRANSDUCER ANALOG RTN (-)

CH1 DOWNSTREAM TRANSDUCER SIG (+)

DESCRIPTION

LINE POWER CONNECTION

NEUTRAL CONNECTION

EARTH GROUND CONNECTION

CH1 TRANSDUCER CONNECTION TERMINAL BLOCK

AC WIRING SHOWN

1 CH1UP

3 CH1RTN

2 CH1RTN

4 CH1DN

PIN

1 L

PIN

3 G

2 N

DESCRIPTION

SUPPLY VOLTAGE

85V TO 250VAC

CH2 DOWNSTREAM TRANSDUCER ANALOG RTN (-)

CH2 UPSTREAM TRANSDUCER SIG (+)

CH2 UPSTREAM TRANSDUCER ANALOG RTN (-)

CH2 DOWNSTREAM TRANSDUCER SIG (+)

CH2 TRANSDUCER CONNECTION TERMINAL BLOCK

1 CH2UP

3 CH2RTN

2 CH2RTN

4 CH2DN

PIN

DESCRIPTION

OPTIONAL

N/C

MODBUS +

MODBUS -

MODBUS CONNECTION

1 +

3 N/C

2 -

PIN

DESCRIPTION

OPTIONAL

OPTIONAL SHIELD

FIELDBUS NET (+)

FIELDBUS NET (-)

FOUNDATION FIELDBUS

1 +

3 SHIELD

2 -

PIN

DESCRIPTION

OPTIONAL

DC WIRING (OPTIONAL)

OR 12 TO 28 VDC

OPTIONAL SHIELD

HART NET (+)

HART NET (-)

HART

1 +

3 SHIELD

2 -

PIN

DESCRIPTION

OPTIONAL

Figure 13: Transmitter Electronics - Wiring Diagram (ref. dwg. #702-1846)

Page 30

Chapter 2. Installation

PanaFlow™ Z1G/Z2G User’s Manual 20

-05 (CI,TI,FI)

-09 (OI)

-08 (AI,HI)

11

12

9

10

7

8

2

4

5

6

3

Pin 1

9

11

12

10

7

8

6

5

3

4

Pin 1

2

12

11

10

9

8

7

2

4

5

6

3

Pin 1

R = RTD Input

A = Standard Alarm

H = Hermetic Alarm

F = Frequency Output

T = Totalizer Output

I = Current Input

C = Current Output

O = Blank/No Connection

NOTE:

Figure 14: Labels - Option Card Connections

Page 31

Chapter 3. Initial Setup

Chapter 3. Initial Setup

3.1 Introduction

This chapter provides instructions for programming the data required to place the PanaFlow Z1G/Z2G

Process Gas Flowmeter into operation. Before the PanaFlow Z1G/Z2G Process Gas Flowmeter can begin taking

measurements and displaying valid data, the current system and pipe parameters must be entered.

Additional programming options provide access to the more advanced features of the PanaFlow Z1G/Z2G

Process Gas Flowmeter, but this information is not required to begin taking measurements.

Note: Be sure to record all programming data in Appendix B, “Gas Process Flowmeter Service Record”.

As a guide in following the programming instructions in this chapter, see Figure 16 on page 31 for the

relevant portions of the PanaFlow Z1G/Z2G Process Gas Flowmeter menu map.

3.2 Programming Methods

You can program the PanaFlow Z1G/Z2G Process Gas Flowmeter with the magnetic keypad on the electronics

enclosure, or with PanaView™, BHGE’s PC-based non-resident software program that communicates with

the PanaFlow Z1G/Z2G Process Gas Flowmeter via its serial port. PanaView provides additional programming

capabilities, such as:

• Load and save site file data

• Create and save graph and log files

• Display text output and graphs of live measurement data

• Create custom templates for displaying text, graph, and log data

• Interface with multiple BHGE instruments.

This chapter focuses on programming via the magnetic keypad. For information on programming the

PanaFlow Z1G/Z2G Process Gas Flowmeter via PanaView, refer to the PanaView User’s Manual (BHGE

document #910-211).

PanaFlow™ Z1G/Z2G User’s Manual 21

Page 32

Chapter 3. Initial Setup

3.3 The Magnetic Keypad

The glass window on the electronics enclosure includes the components shown in Figure 15 below.

Figure 15: Display and Magnetic Keypad

IMPORTANT: The PanaFlow Z1G/Z2G Process Gas Flowmeter magnetic keypad enables programming of the

instrument through the glass faceplate without removing the cover. Thus, all programming

procedures may be performed while the unit is installed in a hazardous area.

The six keys on the magnetic keypad (see Table 3 below) enable users to program the PanaFlow Z1G/Z2G

Process Gas Flowmeter.

Table 3: Keypad Keys and Functions

Key Key Name Functions

Escape Key To cancel a numeric entry change, or exit a menu or as Back key

Enter Key To accept a numeric entry or select a menu option

Left Arrow Key To navigate among menu choices or to set cursor position

Right Arrow Key To navigate among menu choices or to set cursor position

Up Arrow Key To navigate among menu choices or to Increment numeric entries

Down Arrow Key To navigate among menu choices or to Decrement numeric entries

22 PanaFlow™ Z1G/Z2G User’s Manual

Page 33

Chapter 3. Initial Setup

3.4 Initial Power On Screens

When you power On the PanaFlow Z1G/Z2G Process Gas Flowmeter, the display first shows the model name

and software version:

GE

XGM868i Y4FM.SP1

The meter then starts to display measured parameters.

Ch1 VEL

0.00 m/s

To enter the Keypad Program, press the [

successive key must be entered within 10 seconds of the prior key.

As a guide in following the programming instructions in this chapter, the relevant portions of the PanaFlow

Z1G/Z2G Process Gas Flowmeter menu map can be found in Figure 16 on page 31. Proceed to the following

sections to enter data in the Channel or GLOBL menus.

IMPORTANT: If the keypad has not been pressed for 10 minutes, the PanaFlow Z1G/Z2G Process Gas

Flowmeter exits the Keypad Program and returns to displaying measurements. The meter

retains any configuration changes that were confirmed with the [

programming had been completed.

] key, followed by the [] key, and the [] key again. Each

] key, and restarts as if the

PanaFlow™ Z1G/Z2G User’s Manual 23

Page 34

Chapter 3. Initial Setup

3.5 Entering Data in the GLOBL Menu

To begin programming your meter, you must select the system units from the GLOBL menu as discussed

below. Refer to Figure 16 on page 31 and remember to record all programming data in Appendix B, “Gas

Process Flowmeter Service Record”.

3.5.1 Entering Global System Data

The GLOBL-SYSTM submenu is used to enter several general system parameters (e.g., English or metric units).

For meters with 2 channels, this menu is also used to compute parameters such as the sum, difference or

average of the channel 1 and channel 2 signals. When calculating the SUM, DIF or AVE readouts, data from the

GLOBL-SYSTM submenu is used. Any conflicting data entered in the CHANNEL-SYSTM submenu is overridden.

Complete the following steps:

1. In the Keypad Program, scroll to PROG and press [

2. In the PROG menu, scroll to GLOBL and press [

3. In the Global PROGRAM menu, scroll to SYSTM and press [

4. Scroll to the desired System Units selection (either metric or English) and press [

parameters and measurements in the designated units.

5. Scroll to the desired Pressure Units selection (absolute or gauge) and press [

6. Do one of the following:

].

].

].

].

• If PSIa (absolute) was selected, skip this step.

• If PSIg (gauge) was selected, enter the desired atmospheric pressure and press [].

7. The program automatically returns to the Global PROGRAM menu.

] to display all

24 PanaFlow™ Z1G/Z2G User’s Manual

Page 35

Chapter 3. Initial Setup

3.5.2 Selecting Volumetric Units

1. Scroll to the desired Volumetric Units for the flow rate display and press []. Table 4 below lists the

available volumetric units.

Table 4: Available Volumetric/Totalizer Units

English Metric

ACF = Actual Cubic Feet ACM = Actual Cubic Meters

KACF = Thousands of ACF KACM = Thousands of ACM

MMACF = Millions of ACF MMACM = Millions of ACM

SCF = Standard Cubic Feet SCM = Standard Cubic Meters

KSCF = Thousands of SCF KSCM = Thousands of SCM

MMSCF = Millions of SCF MMSCM = Millions of SCM

2. Scroll to the desired unit of Volumetric Time (from seconds to days) and press [].

3. Scroll to the desired number of Vol Decimal Digits (digits to the right of the decimal point) in the

volumetric flow display and press [

].

3.5.3 Selecting Totalizer Units

4. Scroll to the desired Totalizer Units for the flow rate display and press []. Available units are listed

in Table 4 above.

5. Scroll to the desired number of Tot Decimal Digits (digits to the right of the decimal point in the

totalized flow rate display) and press [

6. Do one of the following:

].

• If MASS FLOW is ON, proceed to “Selecting Mass Flow Units” on page 26.

• If MASS FLOW is OFF, the meter returns to the Global PROGRAM window. Press [] twice and proceed

to

Chapter 4, “Operation”.

Note: The following prompts appear only if Mass Flow is activated for both channels.

PanaFlow™ Z1G/Z2G User’s Manual 25

Page 36

Chapter 3. Initial Setup

3.5.4 Selecting Mass Flow Units

1. Scroll to the desired Mass Flow units for the flow rate display and press []. The available units for

this prompt are determined by the selection made at the System Units screen. See Table 5 below for

the available units.

Table 5: Available Mass Flow Units

English Metric

LB = Pounds Kilograms

KLB = Thousands of LB Metric Tons (1000 KG)

MMLB = Millions of LB

Tons (2000 LB)

2. Scroll to the desired Mass Flow Time units for the mass flow rate display (from seconds to days) and

press [

3. Scroll to the desired number of Mdot Dec. Digits (digits to the right of the decimal point in the mass

flow rate display) and press [

].

].

4. Scroll to the desired Mass (Totalizer) units for the totalized mass flow rate display and press [

available units for this prompt are determined by the selection made at the System Units prompt.

5. Scroll to the desired number of Mass Dec. Digits (digits to the right of the decimal point in the

totalized mass flow rate display) and press [

6. After completing the above steps, the PanaFlow Z1G/Z2G Process Gas Flowmeter returns to the Global

PROGRAM window. Press [

] and scroll to CH1 or CH2 to continue the initial setup programming.

].

]. The

26 PanaFlow™ Z1G/Z2G User’s Manual

Page 37

Chapter 3. Initial Setup

3.6 Activating a Channel

The Channelx-ACTIV submenu permits selection of the desired measurement method. In addition, it is used

to activate/deactivate one or both of the channels in a 2-Channel PanaFlow Z1G/Z2G Process Gas Flowmeter.

To access the Channelx-ACTIV submenu, proceed as follows:

1. From the Keypad Program, scroll to CH1 or CH2 and press [

2. In the Channel PROGRAM menu, scroll to ACTIV and press [

3. Scroll to Burst to activate the channel/path, and press [

Note: Burst is automatically selected for a 1-Channel meter.

4. Scroll to one of the measurement methods described below and press [

].

].

].

].

• Skan Only is the preferred technique for locating the acoustic signal and for high velocity measurements. It

is more robust in a noisy environment than the Measure technique.

• Skan/Measure is the preferred technique to use for low velocity measurements.

If Skan Only is selected at the above prompt, the meter uses this technique exclusively. However, if

Skan/Measure is selected, the meter uses Skan Only to find the acoustic signal and then tries to use the

Skan/Measure technique for the actual measurement.

After completing the above step, the meter returns to the Channel PROGRAM menu. Proceed to the next

section to continue programming your meter.

PanaFlow™ Z1G/Z2G User’s Manual 27

Page 38

Chapter 3. Initial Setup

3.7 Entering System Data for a Channel

The Channelx-System submenu is used to enter system parameters for the channel.

3.7.1 Accessing the Channelx-System Submenu

1. From the Channel PROGRAM menu, scroll to SYSTM and press [].

2. The first prompt asks for the Channel Label.Use the four arrow keys to enter the desired label (in any

numeric or text combination up to five characters), and then press [

3. The next prompt asks for the Channel (Site) Message. Enter the desired text in the same manner as the

channel label with up to 15 characters, and then press [

].

3.7.2 Selecting Volumetric Units

1. Scroll to the desired Volumetric Units for the flow rate display and press []. the available units are

listed in Table 6 below.

2. Scroll to the desired Volumetric Time units for the flow rate display (from seconds to days) and press

[

].

].

3. Scroll to the desired number of Vol Decimal Digits (digits to the right of the decimal point in the

volumetric flow rate display) and press [

Table 6: Available Volumetric/Totalizer Units

English Metric

ACF = Actual Cubic Feet ACM = Actual Cubic Meters

KACF = Thousands of ACF KACM = Thousands of ACM

MMACF = Millions of ACF MMACM = Millions of ACM

SCF = Standard Cubic Feet SCM = Standard Cubic Meters

KSCF = Thousands of SCF KSCM = Thousands of SCM

MMSCF = Millions of SCF MMSCM = Millions of SCM

].

3.7.3 Selecting Totalizer Units

1. Scroll to the desired Totalizer Units for the totalized flow rate display and press []. The available

units are listed in Table 6 above.

2. Scroll to the desired number of Tot Decimal Digits (digits to the right of the decimal point in the

totalized flow rate display) and press [

3. Do one of the following:

].

• If MASS FLOW is ON, proceed to “Selecting Mass Flow Units” on page 29.

• If MASS FLOW is OFF, the meter returns to the Channel PROGRAM menu.

28 PanaFlow™ Z1G/Z2G User’s Manual

Page 39

Chapter 3. Initial Setup

3.7.4 Selecting Mass Flow Units

1. Scroll to the desired Mass Flow units for the flow rate display and press []. The available units for

this prompt are determined by the selection made at the System Units prompt (see Table 7 below).

Table 7: Available Mass Flow Units

English Metric

LB = Pounds Kilograms

KLB = Thousands of LB Metric Tons (1000 KG)

MMLB = Millions of LB

Tons (2000 LB)

2. Scroll to the desired Mass Flow Time units for the mass flow rate display and press [].

3. Scroll to the desired number of Mdot Decimal Digits (digits to the right of the decimal point in the mass

flow rate display) and press [

].

4. Scroll to the desired Mass (Totalizer) units for the totalized mass flow rate display and press [

available units for this prompt are determined by the selection made at the System Units prompt.

5. Scroll to the desired number of Mass Dec. Digits (digits to the right of the decimal point in the totalized

mass flow rate display) and press [

After completing the above steps, the PanaFlow Z1G/Z2G Process Gas Flowmeter returns to the Channel

PROGRAM menu.

].

]. The

PanaFlow™ Z1G/Z2G User’s Manual 29

Page 40

Chapter 3. Initial Setup

[no content intended for this page]

30 PanaFlow™ Z1G/Z2G User’s Manual

Page 41

Chapter 3. Initial Setup

PanaFlow™ Z1G/Z2G User’s Manual 31

[Esc][Enter][Esc]

PROG RESET CALIB

CNTRS

NO YES

Reset Totals

See Service

Manual

DARKN LITEN

STORE ABORT

CH2* GLOBLCH1

(* for 2-Channel meter only)

I/O COMMSYSTM

I/O SETUP

SYSTMACTIV

Off

Burst Burst

1-CH meter2-CH meter

Channel Status

Site Status

Skan Only

Skan/Measure

Skan/Measure Mode

Volumetric Units

Channel Label

Site/Channel Message

MetricEnglish

ACF KACF MMACF

SCF KSCF MMSCF

ACM KACM MMACM

SCM KSCM MMSCM

/SEC /MIN /HR /DAY

Volumetric Time

0

1 2

3

Vol. Dec.Digits

Totalizer Units

0

1 2

3

Tot. Dec.Digits

MetricEnglish

Mass Flow Units

Mass Flow OFFMass Flow ON

LB KLB MMLB TONS KG TONNE

MetricEnglish

/SEC

/MIN /HR /DAY

Mass Flow Time

0

1 2

3

MDOT Dec.Digits

Mass Totals

LB KLB MMLB TONS KG TONNE

0 1 2 3

Mass Dec.Digits

MetricEnglish

ACF KACF MMACF

SCF KSCF MMSCF

ACM KACM MMACM

SCM KSCM MMSCM

Volumetric Units

1-Channel Units

2-Channel Units

MetricEnglish

ACF KACF MMACF

SCF KSCF MMSCF

ACM KACM MMACM

SCM KSCM MMSCM

/SEC /MIN /HR /DAY

Volumetric Time

0

1 2

3

Vol. Dec.Digits

Totalizer Units

0

1 2

3

Totalizer Decimal Digits

MetricEnglish

ACF KACF MMACF

SCF KSCF MMSCF

ACM KACM MMACM

SCM KSCM MMSCM

MetricEnglish

Mass Flow Off

LB

KLB MMLB TONS KG TONNE

MetricEnglish

/SEC

/MIN /HR /DAY

Mass Flow Time

0

1 2

3

MDOT Dec.Digits

Mass Totals

LB KLB MMLB TONS KG TONNE

Mass Dec.Digits

English

Metric

PSia

PSig

BARa

BARg Kpaa Kpag

Meter Message

System Units

Pressure Units

Atmospheric

Pressure

ATM

Pressure

ATM

Pressure

Mass Flow On

0

1 2

3

English

Metric

Figure 16: PanaFlow Z1G/Z2G Menu Map

Page 42

Chapter 3. Initial Setup

PanaFlow™ Z1G/Z2G User’s Manual 32

[no content intended for this page]

Page 43

Chapter 4. Operation

Chapter 4. Operation

4.1 Introduction

See Chapter 2, “Installation”, and Chapter 3, “Initial Setup”, to prepare your PanaFlow Z1G/Z2G Process Gas

Flowmeter system for operation. When the meter is ready to take measurements, proceed with this chapter.

The following specific topics are discussed:

• “Powering Up” on page 34

• “The PanaFlow Z1G/Z2G Process Gas Flowmeter LCD Display” on page 35

• “The Optional PanaView Display” on page 36

• “Taking Measurements” on page 37

Note: All inputs and outputs of the PanaFlow Z1G/Z2G Process Gas Flowmeter are calibrated at the factory

prior to shipment. If it becomes necessary to recalibrate any of the inputs and/or outputs, consult the

factory for instructions.

WARNING! To ensure the safe operation of the PanaFlow Z1G/Z2G Process Gas Flowmeter, it must

be installed and operated as described in this manual. In addition, be sure to follow all applicable local

safety codes and regulations for the installation of electrical equipment.

PanaFlow™ Z1G/Z2G User’s Manual 33

Page 44

Chapter 4. Operation

4.2 Powering Up

Because the PanaFlow Z1G/Z2G Process Gas Flowmeter does not have an ON/OFF switch, it will power up as

soon as the connected power source is energized.

WARNING! For compliance with the European Union’s Low Voltage Directive, this unit requires an

external power disconnect device such as a switch or circuit breaker. The disconnect device must be

marked as such, clearly visible, directly accessible, and located within 1.8 m (6 ft) of the meter.

There are three methods for obtaining readings from the PanaFlow Z1G/Z2G Process Gas Flowmeter:

• Built-in PanaFlow Z1G/Z2G Process Gas Flowmeter LCD display

• PanaView software installed on a personal computer

• External analog device to read the PanaFlow Z1G/Z2G Process Gas Flowmeter analog output

At least one of the above display options must be installed in order to obtain flow rate readings from the

meter.

Immediately upon power up, the software version display appears. Then, the meter performs a series of

internal checks, which take about 45 seconds, prior to displaying the flow rate data (see“Initial Power On

Screens” on page 23).

Note: If the PanaFlow Z1G/Z2G Process Gas Flowmeter fails any of the internal checks, try disconnecting the

power and then re-powering the unit. If the meter continues to fail any of the internal checks, contact

the factory for assistance.

After successfully performing the internal checks, the PanaFlow Z1G/Z2G Process Gas Flowmeter begins

taking measurements and the software version display is replaced by a measurement mode display. Proceed

to the appropriate section for instructions on using the LCD display and the PanaView display option.

Note: As a minimum, the system and pipe parameters for each installed channel must be entered before the

PanaFlow Z1G/Z2G Process Gas Flowmeter can display valid data. Refer to Chapter 3, “Initial Setup”, for

specific instructions.

34 PanaFlow™ Z1G/Z2G User’s Manual

Page 45

Chapter 4. Operation

4.3 The PanaFlow Z1G/Z2G Process Gas Flowmeter LCD Display

The components of the PanaFlow Z1G/Z2G Process Gas Flowmeter LCD display are shown in Figure 17 below,

along with a typical mass flow rate readout.

ParameterChannel #

Ch1 MDOT

VEL

0.00 LB/SEC

Flow Rate

Figure 17: A Typical LCD Flow Rate Display

As shown in Figure 17 above, the PanaFlow Z1G/Z2G Process Gas Flowmeter display screen includes the

following information:

Units

• Channel Number

• Flow Parameter

• Units of Measure

• Flow Rate Value

However, the items in this list may be reprogrammed to display a variety of alternative choices (see

“Programming the LCD Display” on page 37).

Note: The LCD backlight flashes to signal errors. If the backlight is Off when an error is detected, the display is

illuminated briefly, but if the backlight is already On, the light is interrupted briefly. In addition, Error

Code messages may appear in the upper right corner of the LCD display.

PanaFlow™ Z1G/Z2G User’s Manual 35

Page 46

Chapter 4. Operation

4.4 The Optional PanaView Display

The components of the PanaView text display are shown in Figure 18 below, along with a typical flow rate

readout.

Figure 18: A Typical PanaView Text Display Pane

As shown in Figure 18 above, the PanaView text pane includes the following information:

• Channel Number

• Flow Parameter

• Units of Measure

• Flow Rate Value

However, the items in this list may be reprogrammed to display a variety of alternative choices (see

“Programming the PanaView Display” on page 40).

Note: As shown in Figure 18 above, Error Code messages may appear in the lower left corner of the PanaView

text display window.

36 PanaFlow™ Z1G/Z2G User’s Manual

Page 47

Chapter 4. Operation

4.5 Taking Measurements

The PanaFlow Z1G/Z2G Process Gas Flowmeter is capable of displaying several different variables in a variety

of formats. However, this manual discusses only the basic measurement displays using the LCD display or

the PanaView display. Refer to the PanaView User’s Manual (BHGE document #910-211) for details on using

PanaView and the PanaFlow Z1G/Z2G Process Gas Flowmeter analog outputs to obtain the flow rate data.

4.5.1 Programming the LCD Display

Note: When you first initialize the PanaFlow Z1G/Z2G Process Gas Flowmeter, the number of LCD parameters

is set to OFF. You must program the LCD to display any measured parameters.

Using the Keypad Program, you can program the LCD display to display up to four variables in sequence.

Complete the following steps to program the LCD display:

1. Power up the PanaFlow Z1G/Z2G Process Gas Flowmeter and wait until it has initialized.

2. To enter the Keypad Program, press the [

successive key must be entered within 10 seconds of the prior key.

3. In the Keypad Program window, scroll to PROG and press [

4. In the PROG menu, scroll to GLOBL and press [

5. Scroll to I/O and press [

6. Scroll to LCD and press [

7. At the # of LCD Parameters screen, scroll to the desired number (from OFF through 1-4 and KEY) and

press [

change the measurement display with the arrow keys, without accessing the Keypad Program. If you

select KEY:

]. The OFF setting switches the measurement display Off. The KEY setting enables users to

].

].

] key, followed by the [] key, and the [] key again. Each

].

].

• To view a parameter other than the one currently displayed, press the [] and [] keys to scroll through

the various available parameters.

8. Select the desired Measurement Parameter (see Table 8 on page 38 for a list of the available

parameters).

PanaFlow™ Z1G/Z2G User’s Manual 37

Page 48

Chapter 4. Operation

Table 8: Available Measurement Parameters

Option Bar Description Good Bad

VEL Displays the flow velocity. N.A. N.A.

VOLUM Displays the volumetric flow. N.A. N.A.

+TOTL Displays the forward totalized volume flow. N.A. N.A.

-TOTL Displays the reverse totalized volume flow. N.A. N.A.

TIMER Displays the total flow measurement time. N.A. N.A.

MDOT Displays the mass flow. N.A. N.A.

+MASS Displays the forward totalized mass flow. N.A. N.A.

-MASS Displays the reverse totalized mass flow. N.A. N.A.

SS up Displays the signal strength for the upstream direction. 50–75 <50 or >75

SS do Displays the signal strength for the downstream direction. 50–75 <50 or >75

SNDSP Displays the measured speed of sound in the gas. N.A. N.A.

Tup Displays the upstream ultrasonic signal transit time. N.A. N.A.

Tdown Displays the downstream ultrasonic signal transit time. N.A. N.A.

DELTA Displays the transit time difference between the upstream and

N.A. N.A.

downstream signals.

Tot K Displays the total K factor. N.A. N.A.

PEAK% Displays the percentage of peak (set to +50 by default). N.A. N.A.

Qup Displays the signal quality for the upstream direction.

Qdown Displays the signal quality for the downstream direction.

AMPup Displays the value for the signal amplitude of the upstream

>1200 –400 to +400

>1200 –400 to +400

24 ± 5 <19 or >29

direction.

AMPdn Displays the value for the signal amplitude of the downstream

24 ± 5 <19 or >29

direction.

CNTup Displays the AGC DAC count for the upstream gain setting. N.A. N.A.

CNTdn Displays the AGC DAC count for downstream gain setting. N.A. N.A.

P#up Displays signal peaks for the upstream direction. 100-2300 <100 or >2300

P#dn Displays signal peaks for the downstream direction. 100-2300 <100 or >2300

TEMP Displays the gas temperature (from 0/4-20 mA input). N.A. N.A.

PRESR Displays the gas pressure (from 0/4-20 mA input). N.A. N.A.

AcVOL Displays actual volumetric flow. N.A. N.A.

StVOL Displays standard volumetric flow. N.A. N.A.

1

Tu S

Td S

DT S

Tu M

Td M

DT M

1

1

Displays Skan transit time upstream. N.A. N.A.

Displays Skan transit time downstream. N.A. N.A.

Displays Skan Delta T. N.A. N.A.

1

Displays Measure transit time upstream. N.A. N.A.

1

Displays Measure transit time downstream. N.A. N.A.

1

Displays Measure Delta T. N.A. N.A.

Vinst Displays the instantaneous velocity. N.A. N.A.

1

available only if Burst Mode = S/M

38 PanaFlow™ Z1G/Z2G User’s Manual

Page 49

Chapter 4. Operation

4.5.1 Programming the LCD Display (cont.)

Note: The measurement units that appear in these prompts are those selected in the GLOBL-SYSTM menu.

Also, when differences in one channel's programming invalidates an output previously chosen for the

other channel, the measurement defaults to the nearest selectable item in the parameter list.

The previous two prompts repeat until all of the specified # of LCD Parameters have been set up. When all of

the display parameters have been set up, the meter returns to the Global I/O window. To leave the Keypad

Program, press [

After leaving the Keypad Program, the PanaFlow Z1G/Z2G Process Gas Flowmeter resets itself and begins to

display the parameters specified in this section. If more than one parameter was set up, each of the

parameters is displayed in sequence, with a pause of several seconds between display changes.

To use the programmed LCD display to obtain flow rate data, simply power on the PanaFlow Z1G/Z2G Process

Gas Flowmeter as described earlier in this chapter. Then, read the flow rate directly from the display (see

Figure 17 on page 35).

] three times.

PanaFlow™ Z1G/Z2G User’s Manual 39

Page 50

Chapter 4. Operation

4.5.2 Programming the PanaView Display

Launch the PanaView software on the PC and establish communications with the PanaFlow Z1G/Z2G Process

Gas Flowmeter (see the PanaView manual, BHGE document #910-211 as necessary). Then, enter the required

startup parameters, as described in Chapter 3, “Initial Setup”. Proceed as follows:

1. In PanaView, open the Output menu (see Figure 19 below) and click on the Text Display option.

Figure 19: The Output Menu

Note: The Text Display window is actually stacked on top of any previously opened PanaView windows, such

as the Meter Browser window.

2. Using the Window menu, as described in the PanaView manual, arrange the open windows in the

desired format. For this discussion, Figure 20 below shows the Text Display window in its maximized

(full-screen) size.

Figure 20: The Text Display Window

3. The left pane of the Text Display window contains the standard PanaView network tree. Expand the

branch for your PanaFlow Z1G/Z2G Process Gas Flowmeter model, and double-click on the desired

channel. On 2-channel units, you can also display the SUM, DIFF or AVG parameters.

40 PanaFlow™ Z1G/Z2G User’s Manual

Page 51

Chapter 4. Operation

4.5.2 Programming the PanaView Display (cont.)

4. From the expanded tree, double-click on the desired flow parameter to display it in the right pane of

the window.

5. Before actual data values can be displayed in the text pane, activate one of the following data

collection modes (see Figure 20 on page 40):

• Click on the [Get Once] option button at the bottom of the right pane in the Text Display window. The

current value of the selected process parameter, as specified in the PanaView network tree, is displayed in

the right pane of the Text Display window.

• Enter an Interval in the text box at the bottom of the right pane in the Text Display window, or check the

Max. Comm Rate box to collect readings as fast as the system allows (i.e., 1 sec). Then, click on the

[Continuous] option button to begin collecting data for display in the right pane of the Text Display