Page 1

PanaFlow Gas Meter

System

Panametrics Ultrasonic

Flow Meters for Gas

The PanaFlow Gas Meter System is a

complete ultrasonic flow meter offering for

gas applications with a unique combination

of accuracy, rangeability, and reliability in a

robust meter design.

The PanaFlow Gas Meter System consists of

two models—the one-path PanaFlow Z1G and

the two-path PanaFlow Z2G. Both meters offer

a high-performance, yet affordable solution

for a variety of gas flow applications.

Applications

PanaFlow gas flow meters can be used in applications

such as:

• Biogas

• Natural gas production

• Vent gas

• Waste gas

• Shale gas

• Coal-seam gas wellhead

• Vapor recovery

• Fuel gas

Features & Benefits

Features Benefits

No drifting, no

periodic calibration

required

No pressure drop

No restriction in the

pipe

No filters or

strainers

Bi-directional

measurement

No moving parts

Explosion-proof

transducer design

Full ultrasonic

product line

No loss of process control, no

downtime, no expense from

calibration, and optimization

of assets.

No wasted energy from

running a pump or need to

purchase a larger size pump

Contamination will not

affect meter’s measurement

(drifting) or cause any

damage to meter

No maintenance cost

No additional meters

required

No loss of process control, no

downtime, no expense from

calibration, and optimization

of assets.

More power to transducers

at higher voltages, less risk of

attenuation in fluid

Meets more needs with

full product portfolio; one

manufacturer for ultrasonic

flow meters

Panametrics.com

Page 2

Reliable Flow Measurement that is

Easy on Your Budget

The PanaFlow gas portfolio represents a new

generation of Panametrics ultrasonic flow meters.

Offered in one-path or two-path wetted versions,

PanaFlow gas meters bring together Panametrics

ultrasonic expertise with the benefits of ultrasonic

technology for affordable, high performance flow

measurement.

Unlike other flow measurement technologies, the

PanaFlow meters do not require maintenance since

they do not have any obstruction in the flow path to

clog the process line or moving parts to be damaged

by flowing gas. They provide years of trouble-free

operation with no adjustments, tuning or corrections.

PanaFlow gas meters provide a lower overall total

cost of ownership, superb reliability, and excellent

performance.

Designed for High Impurity Gas

Measurements

Each PanaFlow gas meter is a complete ultrasonic

flow metering system specifically designed for the

measurement of gases with high levels of impurities.

Engineered to the highest levels of reliability and

dependability, it is designed with an all-cast meter

body and high-accuracy machined surfaces. It has

no welds to adversely impact flow dynamics, making

possible high accuracy flow measurements, even at

low flow conditions.

Transit-Time Flow Measurement

In this method, two transducers serve as both ultrasonic

signal generators and receivers. They are in acoustic

communication with each other, meaning the second

transducer can receive ultrasonic signals transmitted

by the first transducer and vice versa.

In operation, each transducer functions as a

transmitter, generating a certain number of acoustic

pulses, and then as a receiver for an identical number

of pulses. The time interval between transmission and

reception of the ultrasonic signals is measured in both

directions. When the gas in the pipe is not flowing,

the transit-time downstream equals the transit-time

upstream. However, when the gas is flowing, the

transit-time downstream is less than the transit-time

upstream.

The difference between the downstream and upstream

transit times is proportional to the velocity of the flowing

gas, and its sign indicates the direction of flow.

Local or Remote Electronics

PanaFlow gas meters are offered with local or remote

electronics that are factory-installed on the meter

body or electronics that can be installed remotely

from the meter body. It is not recommended to locally

mount the electronics in applications above 185°F

(85°C). PanaFlow gas meters have robust electronics

functionality to meet your application needs.

Electronics ordered with a PanaFlow Gas Meter

System are programmed with setup information

based on your application, so the system is ready

to use as soon as the meter body is installed. When

local electronics are integrated with the system,

the transducer wiring is already complete, further

simplifying the field installation. When remote

electronics are used, transducer cabling must be run

between the flow meter system and the flow meter

electronics.

Transit time ow measurement

Page 3

Proven Technology with Improved

Sound Isolation

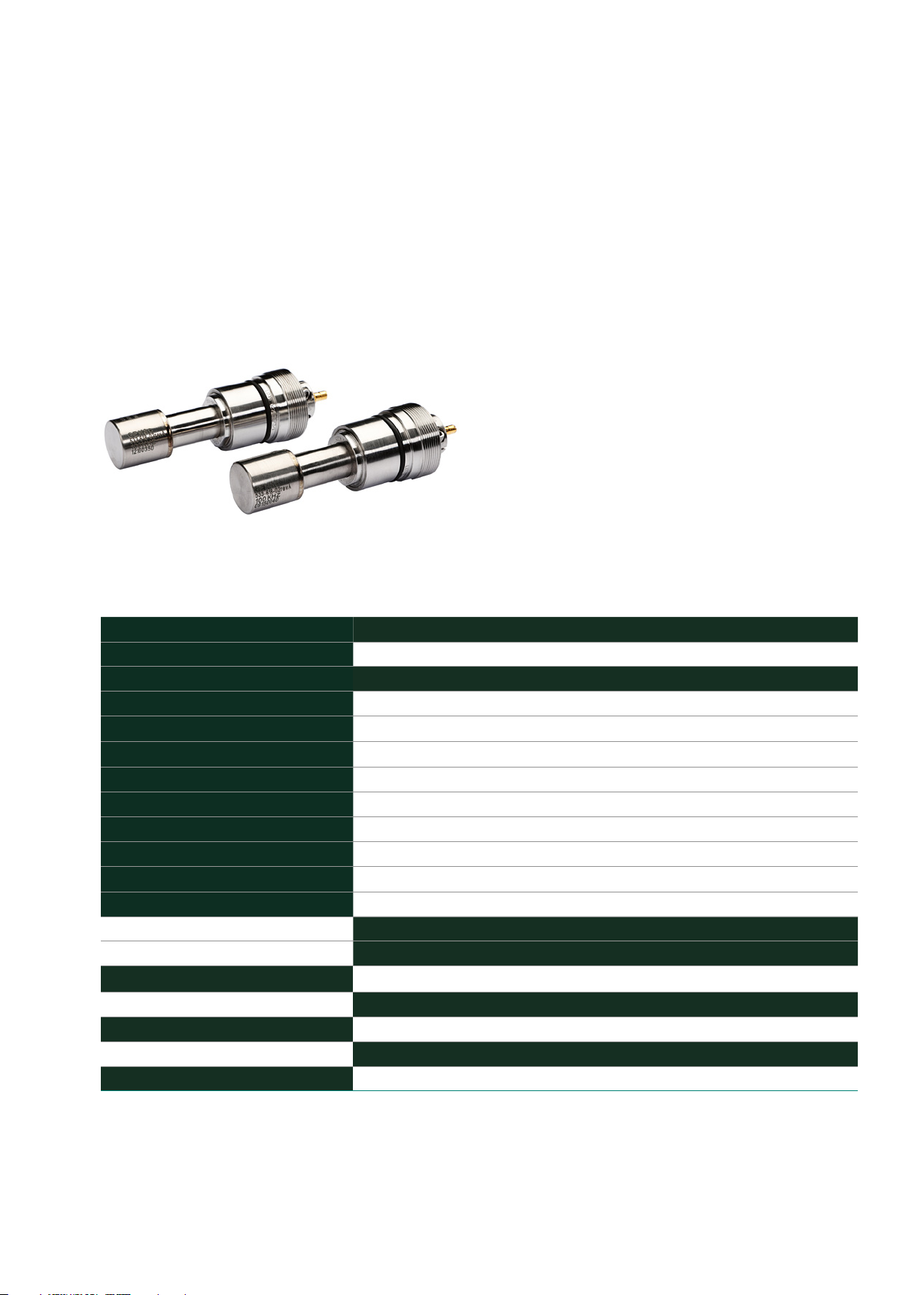

A PanaFlow Gas Meter System employs similar robust

and reliable transducer technology used in thousands

of Panametrics flare gas applications around the

world. Ultra-high power transducers with enhanced

sound isolation are designed for conditions of extreme

condensate and impurities, and for continuous

operation even under the harshest of process

conditions.

The unique design ensures the highest field reliability

for continuous flow measurements over a wide range of

conditions.

High powered T18 transducers

Fast and Easy Installation

An integrated PanaFlow Gas Meter System is fast and

easy to install as all components are already installed

in the meter body. The system is factory assembled

and tested so it meets strict quality control standards.

A PanaFlow meter body is composed of a length of

pipe with flanged ends and transducer ports rated to

the application’s pressure requirements, so all the user

needs to do is bolt the end flanges into place in the

process pipeline.

Performance Specifications

Model Z1G Z2G

Number of Paths One Path Two Path

Flow Measurement Range (+/-)

2” (50mm) 0.5 to 250 ft/s (0.15 to 76 m/s) 0.5 to 250 ft/s (0.15 to 76 m/s)

3” (80mm) 0.5 to 250 ft/s (0.15 to 76 m/s) 0.5 to 250 ft/s (0.15 to 76 m/s)

4” (100mm) 0.5 to 250 ft/s (0.15 to 76 m/s) 0.5 to 250 ft/s (0.15 to 76 m/s)

6” (150mm) 0.5 to 250 ft/s (0.15 to 76 m/s) 0.5 to 250 ft/s (0.15 to 76 m/s)

8” (200mm) 0.5 to 200 ft/s (0.15 to 60 m/s) 0.5 to 210 ft/s (0.15 to 64 m/s)

10” (250mm) 0.5 to 170 ft/s (0.15 to 51 m/s) 0.5 to 180 ft/s (0.15 to 54 m/s)

12” (300 mm) 0.5 to 130 ft/s (0.15 to 39 m/s) 0.5 to 150 ft/s (0.15 to 45 m/s)

14” (350mm) 0.5 to 100 ft/s (0.15 to 30 m/s) 0.5 to 130 ft/s (0.15 to 39 m/s)

16” (400mm) 0.5 to 80 ft/s (0.15 to 24 m/s) 0.5 to 100 ft/s (0.15 to 30 m/s)

Meter Accuracy and Sensitivity - See Accuracy Notes below

Flow Velocity Accuracy from 5 ft/s (1.5 m/s) to Qmax - Note1

2” (50mm) to 16” (400mm) +-1.5% +-1%

Flow Velocity Sensitivity from 0.5 ft/s to 5 ft/s (0.15 to 1.5 m/s) – Note 1

2” (50mm) to 16” (400mm) +/- 0.075 ft/s (+/- 0.02 m/s) +/- 0.05 ft/s (+/- 0.015 m/s)

Repeatability – Notes 1 & 2

2” (50mm) to 16” (400mm) 0.5% of reading

Note 1:

Accuracy/repeatability specifications assume a final installation with fully developed flow profile (typically 20 diameters

upstream and 10 diameters downstream of straight pipe run), Reynolds Number > 5000 and single phase fluids.

Applications with piping arrangements that induce swirl (e.g., two out-of-plane elbows) may require additional straight

run and/or flow conditioning. For shorter straight pipe runs, consult the factory for a computational flow dynamic

evaluation.

Page 4

Operation and Performance

Fluid Types

Acoustically conductive gases

Flow Measurement

Correlation Transit-Time

Meter Body Materials

Low temperature carbon steel, SA352 Gr. LCC

Stainless steel, SA351 Gr. CF8M

Duplex stainless steel, SA995 Gr. CD3MWCuN

Flange Ratings

ASME: 150 lb, 300 lb or 600 lb

DIN: PN10, PN16, PN25; PN40 or PN63

Meter Body Certifications

PED Cat III, Module B+C2

CRN (All Canadian Provinces)

NACE MR01-75/MR-01-03

Calibration

All meters are air calibrated and supplied with a

calibration certificate.

Measurement Parameters

Mass flow, standard and actual flow, totalized flow, and

flow velocity

Enclosure

NEMA Type 4X explosion-proof and weatherproof (IP66)

• Standard: Epoxy-coated aluminum

• Optional: Stainless steel

Electronics Mounting

Local or remote mounting

Hazardous Area Certification

US/CAN: Class 1, Div. 1 Group B,C,D

ATEX: II 2 G Ex d IIB+H2 T6 IP66

IECEx: Ex d IIB+H2 T6 Gb IP66

Other hazardous area certifications are available upon

request.

Input Power

• Standard: 85 to 240 VAC

• Optional: 12 to 28 VDC, ±5%

Cable Entries

3/4” NPT

M20 adapters

Keypad

Built-in infrared, six-button keypad for full functionality

operation

Power Consumption

20 W maximum

Process Temperature Range

–40 to 302°F (–40 to 150°C)

Note: -40 to 257°F (-40 to 125°C) range when used with

pressure and temperature sensor option.

Ambient Temperature Range

• -4 to 140°F (–20 to 60°C)

• -40 to 140°F (–40 to 60°C) available in remote

mount upon request

Storage Temperature

-40 to +185°F (-40 to +85°C)

Pressure Range

Up to maximum allowable flange operating pressure at

temperature per ASME B16.5 or EN1092-1

Inputs/Outputs

Standard:

• Two 4-20 mA isolated outputs: 600 Ω

maximum load

• Two 4-20 mA inputs: pressure and

temperature

Optional:

• Two pulse or frequency outputs: optically

isolated, 3 A maximum, 100 VDC maximum,

1 W maximum, from DC to 10 kHz maximum

• Two alarm relays: 120 VAC, 28 VDC

maximum, 5 A maximum, DC 30 W

maximum, AC 60 VA maximum

Digital Communication

• Standard: RS485

• Optional: HART

• Optional: Modbus

• Optional: Foundation Fieldbus

®

®

®

Display Languages

English

Display

Optional: 2 line x 16 character backlit LCD display,

configurable to display up to four measurement

parameters in sequence

Page 5

Weights and Dimensions

Example Dimensions - 3” [80 mm] Flowcell (see below)

Flange

Rating

ASME

150# RF

ASME

300# RF

ASME

600# RF

Refer to the table below for weights and dimensions for all line sizes.

A C D X Y Z CX CY CZ

12.7

[322]

12.7

[322]

12.7

[322]

19.0

[481]

19.0

[481]

19.0

[481]

7.5

[190]

8.3

[209]

8.3

[209]

20.0

[508]

20.0

[508]

20.0

[508]

22.7

[576]

23.1

[586]

23.1

[586]

9.8

[247]

9.8

[247]

9.8

[247]

Reference Drawings

Drawing Number Drawing Description

712-2158 General arrangement drawing, PanaFlow ZXG, Local Mount

712-2160 General arrangement drawing, PanaFlow ZXG, Remote Mount

44.0

[1117]

44.0

[1117]

44.0

[1117]

34.7

[881]

35.1

[890]

35.1

[890]

33.8

[857]

33.8

[857]

33.8

[857]

Approx.

Weight

66.7 kg

70.7 kg

72.9 kg

“C”

Allow 12.0 [305] minimum recommended

maintenance on either side

15.5 [394]

“CX”

“A”

“X”

Allow 12.0 [305] minimum

“Z”

recommended maintenance

on either side

“CZ”

8.3 [212]

6.2 [157]

Notes: A 3”-2 Path flowcell is shown

as an example. See the drawings listed

above for details on other sizes.

All dimensions are inches [mm]

Allow 12.0 [305] minimum

“Y”

“CY”

above recommended

maintenance clearance

Port Configuration

for 2” and 3” Diametric-Dual Plane

∅“D”

Page 6

PanaFlow Gas Meter System Part Number

AAAA - B - CC D EE F G H - I - J - K L M N O - P - QQ - R - Z

Model:

PF8M PANAFLOW GAS ULTRASONIC FLOW METER SYSTEM

B: PATH:

Z1G

SINGLE PATH METER BODY

Z2G

DUAL PATH METER BODY

C: METER BODY SIZE:

02

2 in. (50 mm) METER BODY

03

3 in. (80 mm) METER BODY

04

4 in. (100 mm) METER BODY

06

6 in. (150 mm) METER BODY

08

8 in. (200 mm) METER BODY

10

10 in. (250 mm) METER BODY

12

12 in. (300 mm) METER BODY

14

14 in. (350 mm) METER BODY

16

16 in. (400 mm) METER BODY

D: PROCESS FLANGE RATING:

1

ASME 150# RF (WN)

2

ASME 300# RF (WN)

3

ASME 600# RF (WN)

E

EN 1092-1/PN 10 (WN/Type 11)

F

EN 1092-1/PN 16 (WN/Type 11)

G

EN 1092-1/PN 25 (WN/Type 11)

H

EN 1092-1/PN 40 (WN/Type 11)

J

EN 1092-1/PN 63 (WN/Type 11)

E: METER BODY MATERIAL:

CC

LOW TEMPERATURE CARBON STEEL (SA-352 GR. LCC)

S6

316 STAINLESS STEEL (SA-351 GR. CF8M)

SD

DUPLEX STAINLESS STEEL (SA-995 GR. CD3MWCuN)

F: METER BODY SCHEDULE:

4

SCHEDULE STD

5

SCHEDULE 40

7

SCHEDULE XS

8

SCHEDULE 80

F

SCHEDULE 10S

G

SCHEDULE 40S

H

SCHEDULE 80S

G: PAINTING:

1 2NO PAINT (SS & DSS METER BODY ONLY)

STANDARD PAINTING

H: SYSTEM DESIGN:

1

ASME B31.3, PED & NACE MR0175/MR0103

2

ASME B31.3, CRN & NACE MR0175/MR0103

3

ASME B31.3 & NACE MR0175/MR0103

I: PRESSURE & TEMPERATURE SENSOR:

0 PT SENSOR NOT INCLUDED

J: ELECTRONICS MOUNTING:

L

LOCAL MOUNTED ELECTRONICS - PROCESS TEMP -40°C to 85°C

R25

REMOTE MOUNTED ELECTRONICS WITH 25 FT REMOTE CABLE - PROCESS TEMP >85°C

R50

REMOTE MOUNTED ELECTRONICS WITH 50 FT REMOTE CABLE - PROCESS TEMP >85°C

R100

REMOTE MOUNTED ELECTRONICS WITH 100 FT REMOTE CABLE - PROCESS TEMP >85°C

R150

REMOTE MOUNTED ELECTRONICS WITH 150 FT REMOTE CABLE - PROCESS TEMP >85°C

K: ELECTRONICS ENCLOSURE:

1 2TYPE 7/ TYPE 4X EXPLOSIONPROOF AND WEATHERPROOF (IP66) EPOXY COATED

ALUMINUM ENCLOSURE

TYPE 7/ TYPE 4X EXPLOSIONPROOF AND WEATHERPROOF (IP66) 316 SS ENCLOSURE

L: POWER SUPPLY:

1 285-240 VAC INPUT POWER

12-28 VDC INPUT POWER

M: DIGITAL COMMUNICATION:

2

MODBUS DIGITAL OUTPUT

3

HART

4

FOUNDATION FIELDBUS

N: ADDITIONAL I/O:

0

NO ADDITIONAL I/OS

F

2 FREQUENCY OUTPUTS

T

2 TOTALIZER OUTPUTS

A

2 STANDARD ALARMS

(continued on next page)

Page 7

PanaFlow Gas Meter System Part Number (cont.)

AAAA - B - CC - D - EE - F - G - H - I - J - K - L - M - N - O - P - QQ - R - Z

O: CABLE ENTRIES:

1 2STANDARD 3/4” NPT (FEMALE)

M20 (FEMALE)

P: CALIBRATION

1 Calibration (Fluid: Air)

Q: PREAMP:

00

NO PREAMP

02

2X GAIN PREAMP

10

10X GAIN PREAMP

20

20X GAIN PREAMP

40

40X GAIN PREAMP

R: HAZARDOUS AREA

CERTIFICATION:

1

2

3

US/CANADA CLASS 1, DIVISION

1, GROUP B,C,D T6 Ta = -40°C

to + 60°C TYPE4X/IP66

ATEX CERT. FOR Exd IIB T6 Gb

IP66 Ta = -40°C to +60°C

IECEx CERT. FOR Exd IIB T6 Gb

IP66 Ta = -40°C to +60°C

Z: SPECIALS:

0 SNONE

SPECIAL

PF8M - Z2G - 06 - 1 - CC - 4 - 1 - 3 - 0 - L - 1 - 1 - 3 - 0 - 1 - 1 - 20 - 1 - 0

(EXAMPLE PART NUMBER

STRING)

Page 8

Panametrics.com

Copyright 2019. Baker Hughes Company. This material contains one

or more registered trademark of Baker Hughes Company and its

subsidiaries in one or more countries. All third-party product and

company names are trademarks of their respective holders.

920-677A

Loading...

Loading...