Page 1

Moisture Monitor

Series 35 IS

Page 2

June 2004

Process Control Instruments

Moisture Monitor Series 35 IS

User’s Manual 910-182B1

Page 3

March 2003

Warranty

Each instrument manufactured by GE Pana metrics is warranted to

be free f rom defe cts in ma teria l and workm anship . L iabil ity under

this warran ty is limited to restoring the instrument to normal

operation or replaci ng the instrum ent, at the sole discretion of GE

Panametrics. Fuses and batteries are specifically excluded from

any liability. This warranty is effective from the date of delivery

to the original purchaser. If GE Panametrics determines that the

equipment was defective, the warranty period is:

• one year from delivery for electronic or mechanical failures

• one year from delivery for sensor shelf life

If GE Panametrics determines that the equipment was damaged

by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines

specified by GE Panametrics, the repairs are not covered under

this warranty .

The warranties set f ort h he re in are exclusive and are in

lieu of all other warranties whether statutory, express

or implied (i ncl uding warranties or m erchantability and

fitness for a particular purpose, and warranties arising

from course of dealing or usage or trade).

iii

Page 4

March 2003

Return Policy

If a GE Panametrics instrument malfunc tions within the warrant y

period, the following procedure must be completed:

1. Notify GE Panametric s, giving f ull de tails of the probl em, and

provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for

factory service, GE Panametrics will issue a RETURN

AUTHORIZATION NUMBER (RAN), and shipping

instructions for the return of the instrument to a service center

will be provided.

2. If GE Panametrics instructs you to se nd your instrument to a

service center, it must be ship ped p repai d to the aut ho ri zed

repair station indic ated in the shipping instructi ons.

3. Upon receipt, GE Panametrics will evaluate the instrument to

determin e the caus e o f the ma lfu nc tion .

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and

returned.

• If GE Panametrics determine s that the damage is not covered

under the te rms of the warranty, or if the warranty has expired,

an estimate fo r the cos t of the repairs at standard rates w i ll be

provided. Upon receip t of the owner’ s a pproval to p roceed , the

instrument will be repair ed and returned.

iv

Page 5

Table of Contents

Chapter 1: Features & Capabilities

The Electronics Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Moisture Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

The Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

The User Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Chapter 2: Installing the Seri es 35 IS

Choosing a Measurement Site . . . . . . . . . . . . . . . . . . . . . .2-2

Moisture Probe Considerations. . . . . . . . . . . . . . . . . . . . . .2-3

Sampl e S y s te m G u id elines . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Mounting an External Sample System . . . . . . . . . . . . . . . .2-6

The Self-Contained Sample System. . . . . . . . . . . . . . . . . .2-7

Installing a Probe into a Sample System . . . . . . . . . . . . . .2-8

External Sample System . . . . . . . . . . . . . . . . . . . . . . .2-8

Self-Contained Sample System . . . . . . . . . . . . . . . . .2-10

Making External Probe Connections . . . . . . . . . . . . . . . .2-11

Using Modified or Non-GE Panametrics Cables. . . .2-14

Performing a Calibration Adjustment . . . . . . . . . . . .2-15

June 2004

v

Page 6

June 2004

Table of Contents (cont.)

Chapter 3: Operating the Series 35 IS

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Starting Up and Shutting Down the Sample Syste m . .3-3

Powering Up the Series 35 IS . . . . . . . . . . . . . . . . . . .3-4

Using the Keypad to Enter and Change Data. . . . . . . . . . .3-5

How to Use the Programming Keys. . . . . . . . . . . . . . .3-5

How to Enter and Exit the User Program. . . . . . . . . . .3-6

How to Move Through the User Program . . . . . . . . . .3-7

How to Enter Numeric Data. . . . . . . . . . . . . . . . . . . . .3-8

Ver ifying and Changing Factory Setup Data . . . . . . . . . . .3-9

Entering the Dew Point Range. . . . . . . . . . . . . . . . . .3-10

Entering Calibration Data . . . . . . . . . . . . . . . . . . . . .3-11

Enter i n g the Probe Serial Numb er . . . . . . . . . . . . . . . 3 - 1 2

Enter i n g Hi g h an d Lo w Referen ce V a l u es . . . . . . . . .3-13

Changing the Measurement Display. . . . . . . . . . . . . . . . .3-14

Enter i n g an O ffset Value for Dew/ Frost Poi n t . . . . . . . . .3 - 1 5

Enter i n g a Co n s ta n t Pressur e Value . . . . . . . . . . . . . . . . . 3 -1 6

Entering a PPMv Constant Multiplier . . . . . . . . . . . . . . .3-18

Enter i n g an In te r v al for Automa ti c C a li b ration . . . . . . . .3 - 1 9

Viewing the B at t er y Stat u s . . . . . . . . . . . . . . . . . . . . . . . .3-2 1

Enter i n g a Backligh t -O n Time In t e rv al . . . . . . . . . . . . . .3-22

Setting Up Computer-Enha nced Response. . . . . . . . . . . .3-23

Settin g U p Ra n g e E r ro r P ro cessing . . . . . . . . . . . . . . . . .3 - 2 5

Selecting AC Line Frequency (60/50 Hz) . . . . . . . . . . . .3-26

Adjusting the Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Setting the Clock Values. . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Settin g U p th e D a ta L og g e r . . . . . . . . . . . . . . . . . . . . . . .3-3 0

Setting the Data Logger Time Inter val. . . . . . . . . . . .3-31

Enter i n g the Parame ter(s) to Lo g . . . . . . . . . . . . . . . . 3 - 3 2

Viewi n g L o g Sta tu s , Su mmary an d D at a. . . . . . . . . .3-3 4

Using the Built-In RS232 Interf ace . . . . . . . . . . . . . .3-39

Dumping Logged Data Via the RS232 Interface. . . .3-41

vi

Page 7

Table of Contents (cont.)

Chapter 4: Troubleshooting and Maintenance

Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Screen Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Calibration Error Processing. . . . . . . . . . . . . . . . . . . . . . . .4-7

Recharging and Replacing the Battery . . . . . . . . . . . . . . . .4-8

Recharging the Battery. . . . . . . . . . . . . . . . . . . . . . . . .4-9

Repla c i n g the Battery. . . . . . . . . . . . . . . . . . . . . . . . . 4 -1 0

Replacing the User Program. . . . . . . . . . . . . . . . . . . . . . .4-13

Removing the Circuit Board . . . . . . . . . . . . . . . . . . .4-14

Replacing the EPROM. . . . . . . . . . . . . . . . . . . . . . . .4-17

Replacing the Circuit Board. . . . . . . . . . . . . . . . . . . .4-19

Replacing and Recalibrating the Moisture Probe. . . . . . .4-20

Chapter 5: Specifications

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

June 2004

vii

Page 8

June 2004

Table of Contents (cont.)

Appendix A: Application of the Hygrometer

Moisture Monitor Hints . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Contaminants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Non-Conductive Partic ulates . . . . . . . . . . . . . . . . . . . A-7

Conductive Particula tes . . . . . . . . . . . . . . . . . . . . . . . A-8

Corro si v e Particul a tes . . . . . . . . . . . . . . . . . . . . . . . . A - 8

Alumi n u m O x id e P r o be Maint en an c e . . . . . . . . . . . . . . . A-9

Corro si v e G a s es A nd L iqu i d s. . . . . . . . . . . . . . . . . . . . . A -11

Mater i al s of Co n s t r u ct io n . . . . . . . . . . . . . . . . . . . . . . . . A -1 2

Calculations and Useful Formulas in Gas Applications. A-13

Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Parts per Million by Volume . . . . . . . . . . . . . . . . . . A-14

Parts per Million by Weight. . . . . . . . . . . . . . . . . . . A-15

Relative Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Weight of Water per Unit Volume of Carrier Gas. . A-16

Weight of Water per Unit Weight of Carrier Gas . . A-16

Comp ari s o n of P P M V Calcula tio n s . . . . . . . . . . . . . A -2 6

Liquid Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . A-27

Moisture Content Measurement in Organic Liquids A-27

Empirical Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . A-34

Solids Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-40

Appendix B: Outline and Installation Drawings

Appendix C: Menu Map

Appendix D: Data Information Sheet

Series 35 IS Data Information Sheet . . . . . . . . . . . . . . . . D-2

Appendix E: Series 35 IS Hygrometer Spare Parts List

viii

Page 9

March 2003

Chapter 1

Features & Capabilities

The Series 35 IS , a microp ro ce s sor-bas ed , singl e- ch an nel

hygrometer , measures moistur e content in g ases. The S eries 35 IS

is suitable for use in a wide range of proc ess conditions requiring

real-time moistur e measurement. It measures dew/frost points

over a temperature range of –110 to +60°C (–166 to +140°F).

The followi ng topi cs are discussed in this chap t er:

• The Electro nic s Un it [pag e 1 -2]

• Moisture Probes [page 1-3]

• The Sample System [page 1-3]

• The User Program [page 1-4]

Features & Capabi li ties 1-1

Page 10

March 2003

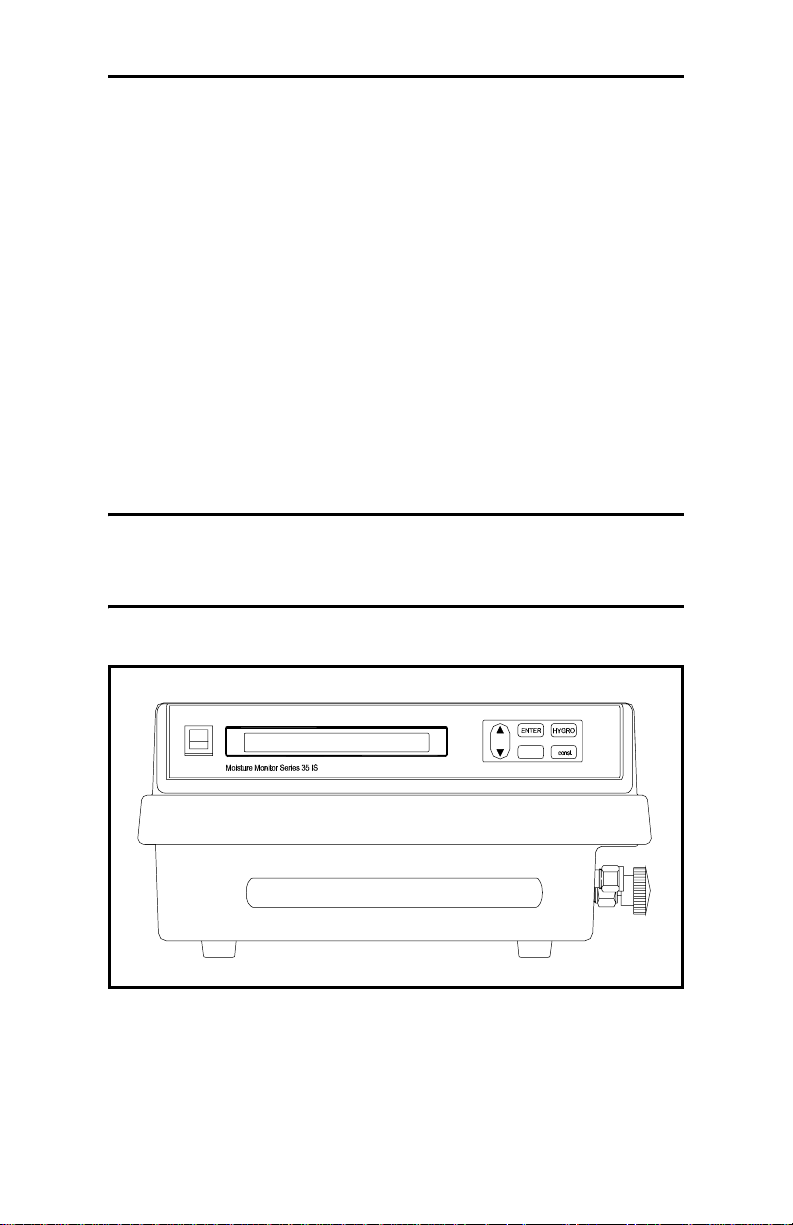

The Electr on ic s Un it

The Series 35 IS portable moisture monitor is available in two

configurations:

• with a self-contain ed sample syste m

• without a self-contained sample system.

Both Series 35 IS configurations display measurement data on a

one-line, 16-character alpha-numeric LCD display screen. All

probe informatio n is entered into the unit usi ng the programming

keys on the front panel keypad (see Figure 1-1 below). The

Series 35 IS operates on an interna l 6 VDC battery, and t he unit

can operate while being charged with a 12 VDC charger.

Caution!

Do not use AC power in hazardous areas. Charge

the battery only in a no n-hazardous area.

POWER

P

ESC

Figure 1-1: Series 35 IS Front Panel

1-2 Features & Capabi lities

Page 11

March 2003

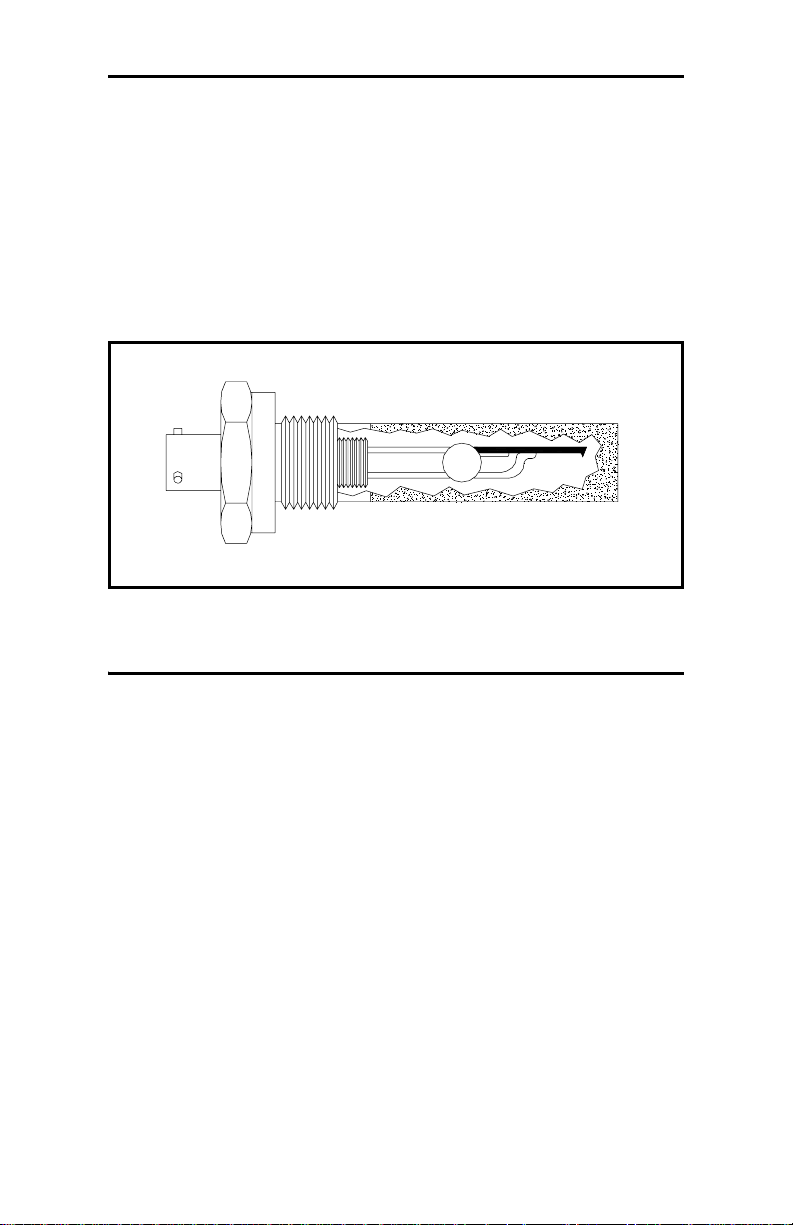

Moisture Probes

The moisture probe is the part of the system that comes in cont act

with the process, and is usually installed in a sample system. The

Series 35 IS uses any M Series probe to measure dew point

temperature in °C or °F. A sensor assembly is secured to the

probe mount and protected with a sinte red sta inless steel shield

(see Figure 1-2 below). Other types of shields are available.

Figure 1-2: The M Series Probe

The Sample System

The sample system conditions or controls a sample stream to the

specificati on s of the m eas urement probe. Typically, the sample

system is kept very simple, with as few component s as possible

located upstream of the measurement probe. The sample system

may include a filter to remove particulates from the sample

stream and/or a pressure regulator to reduce or control the

pressure of the sample stream. In gene ral, stainless steel is the

preferred material for all the sample system’s wetted parts.

If it was specified at the time of purchase, your Series 35 IS will

include a self-contained sa mple system.

Features & Capabi li ties 1-3

Page 12

March 2003

The User Pr o gram

The Series 35 IS contains a user program that en abl es you to

change moisture calibration data and selec t a number of userdefined program functions.

All functions and feature s of the Series 35 IS user program are

discussed in Chapter 3, Operating the Series 35 IS.

1-4 Features & Capabi lities

Page 13

March 2003

Chapter 2

Installing the Series 35 IS

This chapter d isc uss es ins tal l ing the Series 35 IS in all its

configurations. Use the following list of procedures to help you

install your unit.

Depending on the type of unit you have, refer to the appropriate

section(s) that fo llow to install your Series 35 IS correctly.

Installing your Seri es 35 IS consists of the following proc edures:

• Choosing a Measurement Site [page 2-2]

• Moisture Probe Considerations [page 2-3]

• Sample Sys tem G u ide lin es [p ag e 2 -5]

• Mounting an External Sample System [pag e 2-6]

• The Self-Contained Sample System [page 2-7]

• Installing a Probe into a Sample System [page 2-8]

• Making External Probe Connections [page 2-11]

Proceed to the appropriat e sec tion to install your Series 35 IS.

Installing the Series 35 IS 2-1

Page 14

March 2003

Choosing a Measurement Site

You should have disc ussed environmental factors with a GE

Panametrics applications engine er or field sales person before

you receive your Series 35 IS. The equipment should be sui ted to

both the application and the measurement site.

Read the following guide lines to verify th at you have se lected t he

best measurement site.

• Choose a measurement site for the probe and sa mple syste m as

close to the process line as possi ble. Avoid long lengths of

connecting tubing. If long distances are unavoidable, a fastsampling bypass loop is recommende d.

• Do not install any other components, such as filters, upstre am

of the probe or sample system unless instruc ted to do so by GE

Panametrics. Many common components, suc h as filters and

pressure reg ulators, are not suitable for sample systems. These

components contain wett ed parts that may absorb or release

materials (e.g. , moi sture) into the sample stream or allow

ambient contamination to e nter the sample stream. In general,

use stainless-s teel for all parts in contact with the sample.

• Observe all normal safety precautions. Use the probes within

their maximum pressure and tempera ture ratings.

• Do not expose the electronic s unit to high te mperatur es, strong

electrical transients, mechanical vibrations, corrosive

atmospheres, or any other conditions that could damage or

interfere with the Seri es 35 IS operation. See Chapter 5,

Specifications, for limits.

• If you are using an external sample system, you should

observe the proper cable restrictions for the probes. The M

Series probes require specially shielded cable. For units with

separate sample system s, you can locate the M Series probes

up to 100 meters (330 feet) from the Series 35 IS.

• Protect the probe cables from excessive strain (bending,

pulling, twisting, etc.). In addition, do not subject the cables to

temperatures above 65°C (149°F) or below –50° C (–58°F).

2-2 Installing the Seri es 35 IS

Page 15

March 2003

Moisture Probe Considerations

The M Series probes consist of an alu minum oxide se nsor l ocated

on a connector and covered by a protective stainless-steel shield.

The probe sensor material s and housing maximize durability an d

minimize water absorbing sur faces in the vicinity of the

aluminum oxide surface. A sintered sta inless-steel shield protects

the sensor from high flow rates and particulate matter (other

shields are available ) . Do not remov e the shield except upon

advice from GE Panametrics.

The sensor design permits the device to withstand normal shock

and vibration. Be sure t o avoid touching the active sensor surface

or allowing it to come into direct contac t with foreign objects.

Such contact may ad v ersel y aff ect pe rformance.

Observing these precau tions should ensure a long and useful

probe life. GE Panametrics recommends that you check probe

calibration routinely, at one-yea r int ervals, or as rec ommended by

the applications engineers for your particular application.

Because the probe measures water vapor pressure in its

immediate vicinit y, proximity to the system walls, materials of

construction, and other environmental factors can influence

readings. You can operate the sensor under vacuum or pressure

and under dynamic or static condi tions. Observe the following

environmental precautions.

1. Tempera ture Ran g e: the standard probe is operable from

–110°C to +70°C (–166°F to +158°F).

2. Moisture Condensation : be sure the temperature is at least

10°C higher than the dew/frost point temperature. If this

condition is not maintai ned, moisture condensation could

occur on the sensor or in the sample system and cause reading

errors. If reading errors occur, refer to “Aluminum Oxide

Probe Maintenance” in Appendix A.

Installing the Series 35 IS 2-3

Page 16

March 2003

Moisture Probe Considerations (cont.)

3. Static or Dynamic U se: the sensor perform s equally well in

still air or where con sid er ab le flow o ccurs . Its smal l size

makes it ideal for measuring moist ure conditions within

completely sealed cont ainers or dry boxes. It also performs

well under gas flow li near ve lociti es as hi gh as 10,0 00 cm/sec,

and liquid flow linear velocities to 10 cm/sec. Refer to Tables

A-2 and A-3 in Appendix A for maximum gas and liquid flow

rates.

4. Pressure: the moisture probe always sens es the exist ing water

vapor pressure regardless of the total ambient pres sure. The

moisture sensor measure s water vapor under vacuum or high

pressure conditions from as little as a few microns Hg to as

high as 5000 psi total pressure .

5. Long-Term Storage & Operational Stability: continuous

abrupt humidity changes do not affect the sensor, and

exposure to satura tion conditions does not damag e the sensor,

even when sto red.

6. Freedom from Interference: the pr esence of a wid e var iety

of gases or organic liquids does not affect the sensor. Also,

large concentrations of hydrocarbon gases, Freon®, carbon

dioxide, carbon monoxide, a nd hydrogen do not affect sensor

water vapor indications. The sensor functions pr operly in a

multitude of gaseous or non-c onductive liquid environments.

7. Corrosive Mat erials: avoid all materials that are corrosive or

otherwise damaging to alumin um or aluminum oxide. These

include strongly acidic or basic materials and primar y amines.

Freon is a registered tr ademark of E.I. du Pont de Nemours and Company.

2-4 Installing the Seri es 35 IS

Page 17

March 2003

Sample System Guidelines

A sample system, although not mandatory, is highly

recommended for moisture measur ement. The purpose of a

sample system is to condition or control a sample stream to

within the spe cifications of the probe. The application

requirements dete rmine the design of the sample system. GE

Panametrics applications engine ers can make recommendations

based on the following general guidelines:

• Typically, keep the sample sys tem simple. Include as few

components as possible and loca te all or most of the

components downstream of the measure ment probe. A simple

sample system consists of an explosion-proof housing with a

sample cell, a filter, and inlet and outlet needle va lves.

• Do not use any material for sample system components that

can affe ct measur ements. A sample sy stem may inc lu de a f ilter

to remove particulat es fro m the sample stream and/or a

pressure regulator to reduce or control the pressure of the

stream. However, most common filters and pressure re gulators

are not suitable for sample syste ms because their wetted parts

may absorb or release components (such as moisture) into the

sample stream. They may also allow ambient contamination to

enter the sample stream. In general, use stainless-steel for all

wetted parts.

Note: The actual sam ple system design depends on the

application requirements.

Installing the Series 35 IS 2-5

Page 18

March 2003

Mounting an External Sample System

Note: If you have a Series 35 IS with a self-containe d sample

system, disregard this section and p roceed to The SelfContained Sample System on page 2-7.

The sample sys tem is usually fastened t o a me tal pla te that ha s

four mounting holes. GE Panametrics can provide the sample

system in an enclosure, if reque sted. Sample system outline and

dimension drawings are included in your shipment, if you

ordered them.

Use the following steps to mount the external sample sys tem and

connect it to the process:

1. Fasten the sam ple sys tem p lat e or encl os u re to a soli d stab l e

surface with bolts and washers in each of its four corners.

2. Connect the process supply a nd return lines to the sample

system inlet and outlet using the required stainless-st eel

fittings and tubing.

Caution!

Do not start a flow through the system until the

probe h as been properl y ins tall ed.

Note: For common applications, GE Panametrics ca n pr ovide a

standar d sample system. If applicable, additional

instructions on how to start up and shut down the sample

system may be included.

2-6 Installing the Seri es 35 IS

Page 19

March 2003

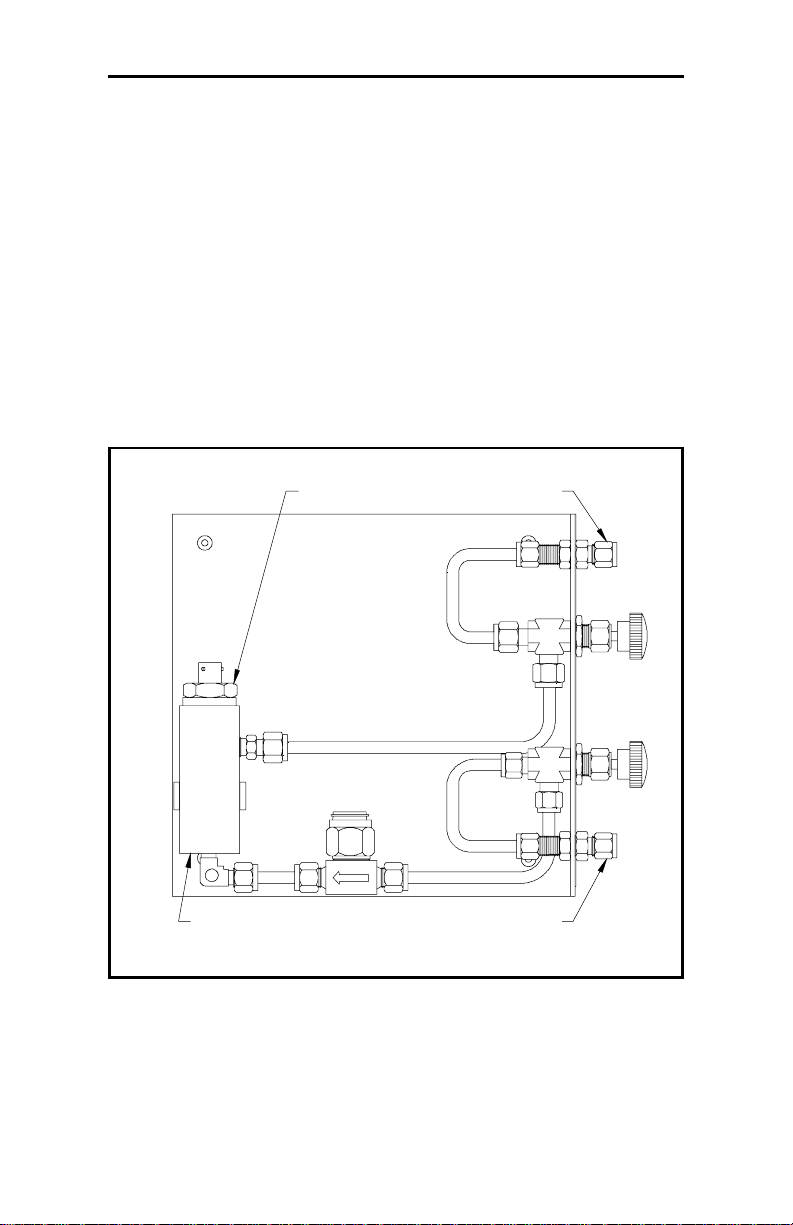

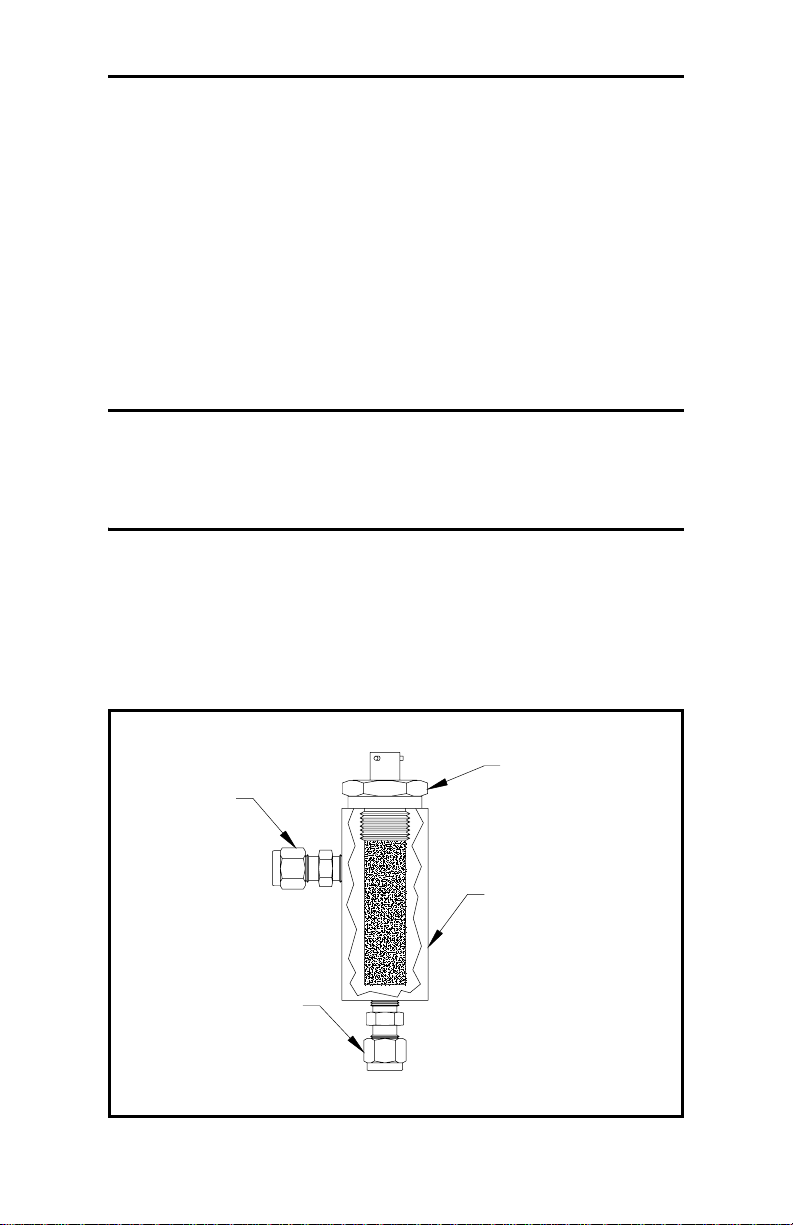

The Self-Contained Sample System

The Portable Series 35 IS can include a self-contained sample

system as shown in Appendix B. This sample system is

constructed with 1/4" Swagelok® inlet and outlet compression

fittings and 1/4" stainless-ste el tubing.

The sample system also includes inle t and outlet needle valves

and a 7-micron sintered stainless-steel filter with a replaceable

element. All wetted parts are Series 300 stainless steel, Viton®,

or Teflon®. The maximum allowable pressure for the sample

system is 4500 psig. See Figure 2-1 below.

Probe Outlet

Sample Cell

Inlet

Figure 2-1: Self-Contained Sample System with Probe

Swagelok is a registered trademark of Crawford Fitting Company.

Teflon is a registered trademark of E.I. du Pont de Nemours and Company , Inc.

Viton is a registered t rademark of DuPont Dow Elastomers, L.L.C.

Installing the Series 35 IS 2-7

Page 20

March 2003

Installing a Probe into a Sample System

The sample system design protect s the aluminum oxide moisture

probe from particulates and is recommended for process gases

such as dry instrument/pl ant air or other similar process gas.

Other sample handling equipment ( pr essure regulators, cooling

coils, additional filte rs, pressure gauges, rota- meters, etc.) may be

required for some applications. Contact GE Panametrics or see

Appendix A for general information about using GE

Panametrics’ Aluminum Oxide Moist ure Probe. Proceed to the

appropriate probe insta llation sect ion for your system.

Caution!

If you mount the probe directly into the process line,

cons ult GE Panametri c s f or proper installation

instruct ions and prec autions.

External Sample System

Use the following steps to inst all the probe into the external

sample cell. Refer to Figure 2-2 below.

Probe

Inlet

Sample Cell

Outlet

Figure 2-2: A Typical Probe Insta llation

2-8 Installing the Seri es 35 IS

Page 21

March 2003

External Sample Syst em (cont.)

1. Insert the probe int o the sample cell so that it is perpendic ular

to the sample inlet.

IMPORTAN T: For maximum protection of the aluminum oxide

sensor, always leave the shield in place.

2. Screw the probe into the receptacle fitting, making sure not to

cross the threads.

Note: M2 probes have 3/4- 16 straight threads with an o-ring

seal for installation either into the sample system or

dir ectly into the process line. Other mounts are available

for special applications.

3. Hand-tighten the probe in a clockwise direction , then tighten it

an additional 1/8 turn with a wrench .

Figure 2-2 on page 2-8 shows a typical probe install ation wi th the

probe mounted into a sample cell.

Installing the Series 35 IS 2-9

Page 22

March 2003

Self-Contained Sample System

Use the following steps to install the pro be into the sample cel l of

a self-contained sa mple syste m:

1. Loosen the two quarter -turn screws on the back of the

Series 35 IS cover.

2. Remove the cover b y gently lifting it off the unit from back to

front. Be careful not to pull on the cable s that connect to the

cover.

3. Insert the probe into the sample cell.

4. Screw the probe into the receptacle fitting, making sure not to

cross the threads.

Note: Insert the probe into the cylindrical shaped container

called the sample cell, which is included as part of your

sample system. M2 probes have 3/4-16 straight threads

and an o-ring seal for installa tion of the pro be into the

standar d sample cell (see Figure 2-1 on page 2-7).

5. Hand-tighten the probe in a clockwise direction , then tighten it

an additional 1/8 turn with a wrench .

6. Connect the blue probe cable to the probe by inserting the

bayonet-type connector onto the probe and twisting the shell

clockwise until it snaps into a locked position.

Note: The connector on the probe cable must be rotated until it

aligns with the pins in the probe connector, before the

cable may be properly inserted into the probe and

secured.

7. Close the Series 35 IS cover and tighten the two quarter-turn

screws on the back of the cover.

2-10 Installing the Series 35 IS

Page 23

March 2003

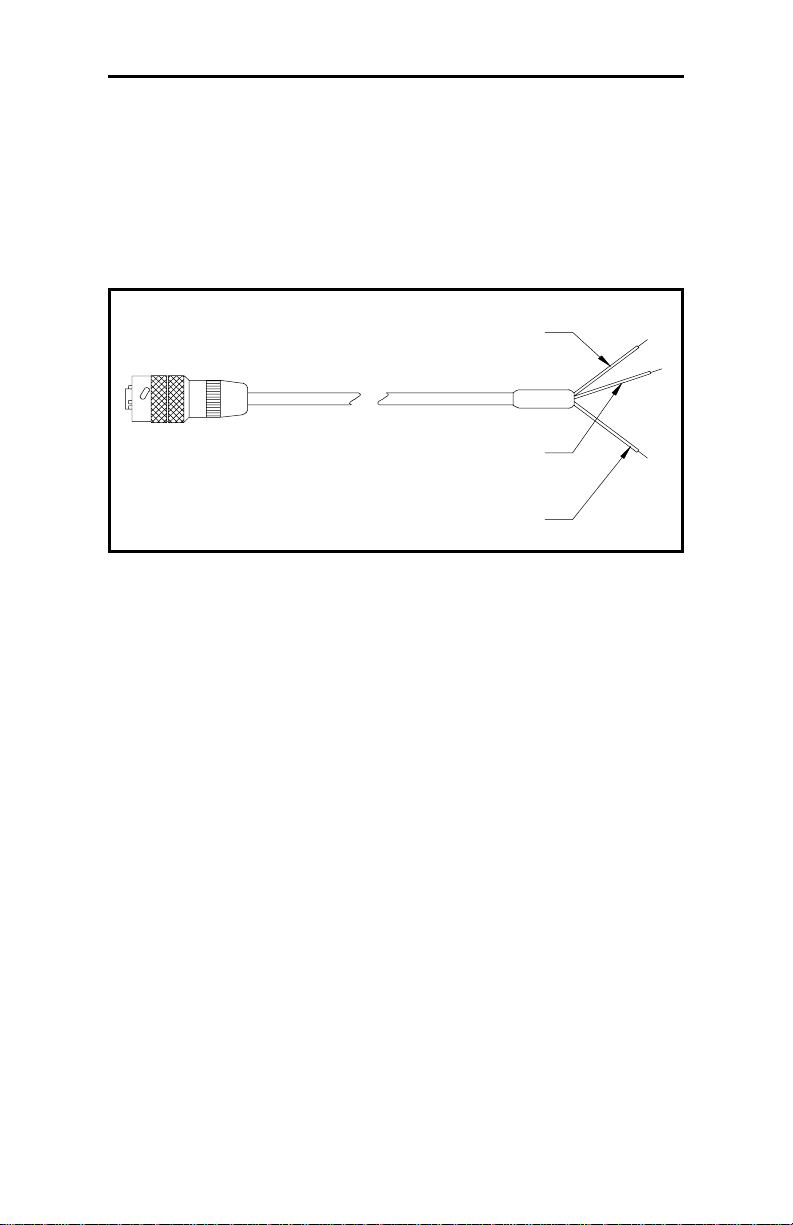

Making External Probe Connections

Probe connections may differ, depending on the type of sample

system you are using. Connect the moisture probe using a

continuous run of GE Panametrics two-wire shielded cable (see

Figure 2-3 below).

Red

Shield

Green

Figure 2-3: Two-Wire Shielded Cable

Protect all cables fr om excessive strain (bending, pulling, etc.).

Do not subject cables to temperat ures above +65°C (149°F) or

below –50°C (–58°F). You can order standard cable assemblies

(including connector s) from GE Panametrics in any length up to

100 meters (330 feet).

Use the following steps to make probe connections:

Note: Probe conn ections for an internal sampl e system have

been described in the previous section. The following

instructions are for an external sample system only.

1. Turn off the Series 35 IS.

2. Connect the cable to the probe by insert ing the bayonet-type

connector ont o the probe and twist ing the shell cloc kwise until

it snaps into a locked position.

Installing the Series 35 IS 2-11

Page 24

June 2004

Making External Probe Connections (cont.)

Note: The connector on the probe cable must be rotated until it

aligns with the pins in the probe connector, before the

cable may be properly inserted into the probe and

secured.

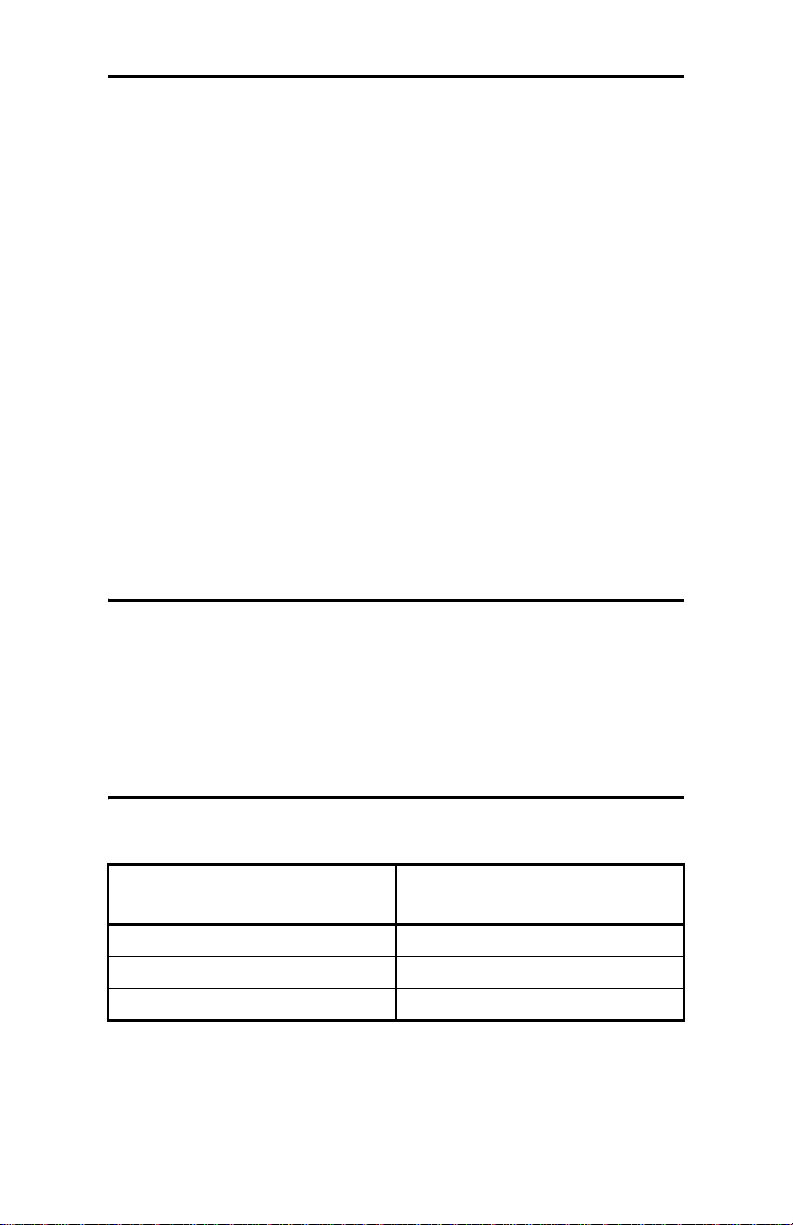

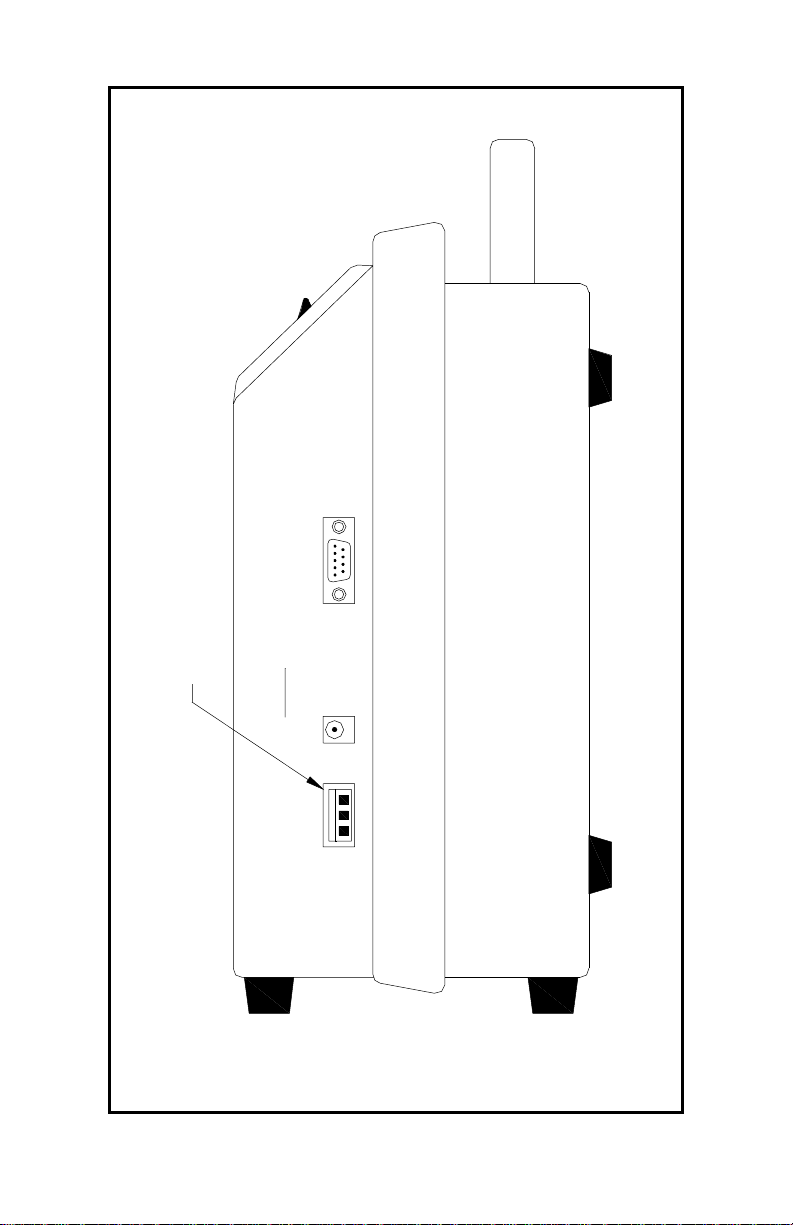

3. Connect the other end of the probe cable to the terminal block

on the Series 35 IS side panel (see Table 2-1 below and

Figure 2-4 on page 2-13).

IMPORTAN T: To maintain good contact at each terminal block

and to avoid damagi ng th e pins on the c onnec tor,

pull the connector strai ght off (not at an angle),

make cable connections while the connector is

away from the unit, and push the connector

straight on (not at an angle) when the wiring is

complete.

NOTICE FOR BASEEFA CERTIFICATION

The M Ser ies probe may not be c apable of

withstand ing the 500 V ins ulation test required

by clause 5.7 of EN50 020 when installed in the

proces s m edia. This must be taken into acco unt

in any ins tal lat ion in which it is u se d.

(See Cert. #Ex95C2002X in its entirety.)

Table 2-1: Probe Connections

To PROBE

Connect:

Red (H2) wire pin 1

Shield pin 2

Green (H1) wire pin 3

2-12 Installing the Series 35 IS

Terminal Block

Page 25

k

c

o

l

B

l

a

n

i

m

r

e

T

e

b

o

r

P

June 2004

R

2

S

3

E

2

A

G

S

E

R

R

R

A

A

H

S

C

U

E

O

S

D

U

R

T

A

O

Z

A

N

H

O

N

D

I

-

2

3

G

2

N

I

S

N

R

R

R

A

O

R

W

E

G

R

A

H

C

T

U

3

P

N

I

2

E

B

1

O

R

P

Figure 2-4: Probe Te rminal Block Location

Installing the Series 35 IS 2-13

Page 26

June 2004

Using Modified or Non-GE Panametrics Cables

In some installations, it may be desirable to use a pre-existing

moisture cable or to modify the standard GE Panametrics

moisture cable. If this a pproach is taken, it is essential that the

following precaution s be observed. Further more, after connectin g

the moisture probe, a calibration adjustm ent must be performed

to compensate for any electrical offset s introduced by the nonstandard cable .

Caution!

GE Pana m et ric s c annot guarantee operation

of the Ser ies 35 IS to the spe c ifi ed accuracy

unless a s tan dard GE Pana m et ric s

hygrome t er c able is used.

1. Use cable that matches the electrical characteristics of GE

Panametrics cable (contact the factory for specific information

on cable characteristics).

2. If possible, avoid all splices. Splices will

impair the

performance of the instrum ent. When possible, instead of

splicing, coil the excess cable.

3. If you must splice cables, be sure the splice introduces

minimum resistive leakage or capac itive coupling between

conductors.

4. Carry the shie ld through any splice. A common mistake is to

not connect the shields over the splice. If you are modifying a

GE Panametrics cable, the shield will not be accessible

without cutting ba ck the cable insulation. Also, do not

ground

the shield at both ends. The shi eld should be grounded only at

the hygrometer end, as described in Table 2-1 on page 2-12.

2-14 Installing the Series 35 IS

Page 27

June 2004

Performing a Calibration Adjustment

After completing the installation of a modified or non-standard

moisture cable , it is necessa ry to perfor m a calibr atio n adjust ment

on the Series 35 IS. This procedure will adjust the electronics to

compensate for any error or offset introduced by splices or long

cable lengths. It is also recommended that a calibration be

performed after the installation of a new GE Panametrics cabl e,

to ver i f y the acc u r a cy of the unit.

Use the following steps to perfor m a calibr ation adjustment:

1. Power up the Series 35 IS.

2. To check the new cable, se t up the screen to display “MH”.

See Chapter 3, Operating the Series 35 IS, for instructions on

how to navigate through the user progra m.

3. Note the high, low and zero reference values that are recorded

on the sticker located on the inside of the Series 35 IS chassis.

4. Disconnect the cable from the probe only (leave the cable

connected to the Series 35 IS), and verify that the displayed

MH value equals the zero refere nce value within ± 0.0003 MH.

If this reading is within spe cifications, no further testing is

necessary.

5. If the zero refere nce value r eading above wa s out of range , the

low referenc e value must be adjusted . For readi n gs mo re tha n

0.0003 below the previously recorded zero reference value,

add the difference to the low reference value. For readings

more than 0.0003 above the previously recorded zero

reference value, subtract the difference from the low reference

value. Record the fi nal cor rec te d low refere n ce val u e.

6. Reprogram the Series 35 Is with the new, corrected low

reference value. See Entering High and Low Reference V al ues

in Chapte r 3.

7. Make sure the ca ble is still disconnected from the probe but is

connected t o the Seri es 35 IS.

Installing the Series 35 IS 2-15

Page 28

June 2004

Performing a Calibration Adjustment (cont.)

8. Recheck the zero reference reading and verify that it is now

within ±0.0003 MH of the previously recorded value.

9. Fill out a new reference sticker with the final low reference

value and/or record the information on the Data Information

Sheet in Appendix D. Make sure the following information is

included:

• HIGH REF = Original Value

• LOW REF = New Corrected Value

• ZERO REF = Original Recorded Value

10.Re co nn ect the cabl e t o the prob e .

Note: If the cable is changed in any way, repeat the above

proce dure for maximum accuracy of the unit.

The Series 35 IS is now ready for operation. Proceed to

Chapter 3, Operating the Series 35 IS.

2-16 Installing the Series 35 IS

Page 29

March 2003

Chapter 3

Operat ing the Series 35 IS

Your factory-programmed Series 35 IS can begin taking

measurements as soon as you turn the power on. The user

program enables you to enter and change setup information.

Note: The Series 35 IS suspends taking measurements when you

enter the user pr ogram listed below. Refer to the menu

map in Appendix C to navigate the user program.

This section explains the following procedures:

• Getting Started [page 3-2]

• Using the Keypad to Enter and Change Data [page 3-5]

• Verifying and Changing Factory Setup Data [pa ge 3-9]

• Changing the Measurement Displ ay [page 3-14]

• Entering an O ffset Value for Dew/Frost Point [pag e 3-1 5 ]

• Entering a Constant Pressure Value [page 3-16]

• Entering a PPMv Constant Multiplier [page 3-18]

• Entering an Interval for Automatic Calibration [page 3-19]

• Viewing the Battery Status [page 3- 21]

• Entering a Bac klig h t-O n Time Interval [pag e 3 -22 ]

• Setting Up Computer-Enhanced Response [page 3-23]

• Setting Up Range Error Processing [page 3-25]

• Selecting AC Line Frequency (60/50 Hz) [page 3-26]

• Adjusting the Contrast [page 3-27]

• Setting the Clock Values [page 3-28]

• Setting Up the Data Logger [ page 3-30]

Operating the Series 35 IS 3-1

Page 30

March 2003

Getting Started

Your unit is completely set up at the factory. To begin taking

measurements, you only need to apply power to the unit and start

up the sample system. Complete the instructions in the fol lowing

sections to get your unit up and runnin g:

• Starting Up and Shutting Down the Sample System

• Powering up the Series 35 IS

3-2 Operat ing the Series 35 IS

Page 31

March 2003

St art ing U p and Shu tti ng D own th e Sam ple S yste m

If your Series 35 IS has a self-contained sample system, use this

section to properly start up the sample system before you begin

taking measurements, and to shut down the sample system when

you have finished taking measurements.

Note: If you are using an external sample system, refer to the

separate manual supplied with your order.

Starting Up the Sample System

In order to operate the self-contained sample system correctly,

first dete rmine if you need to make measurements a t atmospheric

pressure or a t process pressure. After determining the pressure,

use the appropriat e section that follows to start up and shut down

the sample system.

Note: The maximum allowable pressure for the self-contained

sample system for the Series 35 IS is 4500 psig.

At Atmospheric Pressure:

1. Begin with the Series 35 IS inlet and outle t valves in the

closed position, then open the outlet

2. Open the inlet

valve slightly to allow only a small amount of

valve completely.

flow from the process.

At Proce ss Pressure:

1. Begin with the Series 35 IS inlet and outle t valves in the

closed position, then slowly open the inlet

2. Open the outlet

valve slightl y to allow only a small amount of

valve fully.

flow.

Operating the Series 35 IS 3-3

Page 32

March 2003

Shutting Down the Sample System

At Atmospheric or Process Pressure:

1. Close the inle t valve completely.

2. Wait for the flow from the outlet valve to stop.

3. Close the outlet valve to keep the probe sensor from being

affected by ambient moisture.

Powering Up the Series 35 IS

T o turn on the Ser i e s 35 IS, press the POWER switch (located on

the left side of the front panel ) to the ON position. (If the battery

is depleted, see Ch ap ter 4, Troubleshooting, to recharge the

battery.)

The Series 35 IS displays “Load ing. . . .”, followed by a series of

additional screens. This indicates that the system is loading

calibration and refere nce data. After thi s da ta is l oaded, the Series

35 IS automatic ally calibrates (Autoc al) the moisture circuitry,

and then begins taking measurements.

3-4 Operat ing the Series 35 IS

Page 33

March 2003

Using the Keypad to Enter and Change Data

The Series 35 IS user program enables you to change factory setup data and user-def ined program functions .

Use the appropriate sections that follow to learn how to:

• Use the programming keys

• Enter and exit the user program

• Move through the user program

• Enter numeric data

How to Use the Programming Keys

The membrane keypad to the right of the display window on the

front panel of the Series 35 IS contai ns six (6) keys:

• ENTER - Use this key to: enter a menu option; switch from

viewing to editing data; move to the next digit position during

numeric entry; confirm an entry.

• ESC - Use this key to: cancel an entry; move back up one

level in the menu sequence.

• ∆ - This key scrolls upward through the menu options and

increases the value during numeric entry.

• ∇ - This key scrolls downward through the me nu options and

decreases the valu e dur ing num er ic entry.

• HYGRO - Press this key in measurement mode to display the

dew/frost point temperature in the selected units.

• P

pressure in the selected units.

Operating the Series 35 IS 3-5

- Press this key in measurement mode to display the

const

Page 34

March 2003

How to Enter and Exit the User Program

T o enter programming mode, perform the following sequenc e

within five (5) seconds, or the Series 35 IS will time out and

return to meas urement mode.

P: +0.00 Kcmg

ESC

While in measurement mo de,

press the

[ESC] key.

Within 5 seconds of the

appearance of th is display, press

the

[ENTER] key followed by

the

[ESC] key.

PROGRAM MENU

DP RANGE

This will display for 1 second.

You are now in the user progra m

menu.

From the main menu, use the arrow keys to scroll through the

options to your selecti on. Use the

selection or the

[ESC] key to cancel your selection.

T o exit the user program, press the

displays, the n press the

[ENTER] key to return to displaying

[ENTER] key to confirm your

[ESC] key until RUN ?

measurements.

DP RANGE

RUN?

Exiting......

P: +0.00 Kcmg

Press th e [ESC] key.

Press the [ENTER] key.

This will display for 1 second.

You have now returned to

measurement mode.

3-6 Operat ing the Series 35 IS

Page 35

March 2003

How to Move Through the U ser Program

Use the arrow keys to scroll through the f ollowing menu options.

Refer to the Menu Map (Figure C-1) in Appe ndix C as a guide,

while moving through the user progr am.

Note: While in the pr ogramming mode, the Series 35 IS

suspends taking measure ments.

• DP RANGE - Use to enter high and low dew points for the

calibration cur ve. This input determines the number of points

in the Moisture Probe Calibration Data entry, and shows the

maximum/minimum dew point values in degree s celsius (°C),

as shown on the Moisture Probe Calibration Data Sheet.

• MH CURVE - Use to enter a value for each point in the

calibration cur ve. This Moisture Probe Calibration Data Entry

accepts only MH values. The dew point automatically

increases at 10°C intervals.

• SERIAL # - Input the moisture probe seria l number.

• HYGRO REFERENCE - Use to enter high and low reference

values for moisture measurement.

• USER - Use to set up user-defined program functions, such as

offset value, constant pressure, PPMv multiplier, Autocal

interval, battery, backlight interval, computer enhanced

response (optional) , range error handling, selecting 60/50 Hz,

contrast, and clock.

• FACTORY SETUP - Used for GE Panamet ri cs fie ld serv i ce

and factory use only. A passcode is required to access this

function.

• LOGGER - This optional s ection lets you program the unit to

log data at pre-selected time intervals and access the logged

data for viewing or for sending to a dump terminal. It includes

log interval, log setup, log display, and log dum p settings.

Operating the Series 35 IS 3-7

Page 36

March 2003

How to Enter Numeric Data

To enter numbers one digit at a time, use the a rrow keys to scroll

to the desi red number, then press the

next digit position. Repeat this procedure until all numbers have

been entered.

Note: In the pr ogramming mode, pressing an arrow key lets you

enter the edit mo de. Pressing

mode without changing any data. In edit mode, check all

characters before pressing the

to the next digit position.

[ENTER] key to move to the

[ESC] termina tes the edit

[ENTER] key and moving

3-8 Operat ing the Series 35 IS

Page 37

March 2003

Verifying and Changing Factory Setup Data

Use this section to confir m, or make any necessary changes to,

the factory setup data. The setup data includes information

regarding the moisture probe as listed below:

• Dew point range

• Calibration data

• Probe serial number

• High and low reference values

Note: Remember to re cord all setup data in Appendix D, Data

Information Sheet, in the back of this manual.

The factory enters all the necessary data into your Series 35 IS.

Therefore, you should not need to re-e nter this data unless you

• Purchase a new probe

• Recalibrate an existing probe

• Have reason to believe the data is corrupted.

Use the appropriate sections that follow to verify and/or change

the setup data.

Operating the Series 35 IS 3-9

Page 38

March 2003

Entering the Dew Point Range

Use the DP RANGE to enter high and low dew point values. The

Series 35 IS uses this range to determi ne the number of points in

the calibration curv e.

Note: Enter the user program as described on page 3-6.

DP RANGE

Hi DP

Use the arrow keys to scroll to

DP RANGE and press the

[ENTER] key.

Scroll to th i s sc reen w ith the

arrow keys and press the

[ENTER] key.

Hi DP +20°C

Use the arrow keys to scroll to

the desired dew point value, then

press the

[ENTER] key.

Note: The high and low dew points are listed on the Moisture

Probe Cali bration Data Sheet located in the probe box.

The default values are: Low = -110°C, High = +20°C.

Hi DP

Low DP

Low DP -110° C

Press the down arrow key.

Press the [ENTER] key.

Use the arrow keys to scroll to

the desired value. Then, press

the

[ENTER] key.

Low DP

Press [ESC] to return to the main

menu, and proceed to the next

section.

IMPORTAN T: If you change the dew point settings, you must

change the calibration curve also.

3-10 Operating the Series 35 IS

Page 39

March 2003

Entering Calibration Data

After entering the high and low dew point val ues, use the MH

CURVE

accordance with the following procedure.

Note: Remember to re cord all set-up data in Appendix D, Data

Moisture probe calibr ation data is taken at fixed dew point val ues

in 10°C intervals. After the high and low dew point values have

been entered, the appropriate number of da ta points for the

moisture probe is automati cally determined. Starting with the

minimum dew point value, the MH values must be entered in

10°C increments until the maximum dew point is reached.

Note: Changing the dew point setting affe cts the MH curve.

option to enter calibration data for the moistur e probe in

Informati on Sheet, in the back of this manual.

MH CURVE

-1 10°C MH 0.1890

Use the arrow keys to scroll to

MH CURVE and press the

[ENTER] key.

Press the arrow keys to scroll

through the

[ENTER] then the a r row keys to

edit a value. (

mode and

MH values. Press

ED displays in edit

MH displays in view

mode.) Using the arrow keys

and the

[ENTER] key, edit the

value one digit at a time, and

then press

[ENTER].

Note: To abort the editing functio n at any time wi thout changing

the value, press th e

[ESC] key.

Repeat the above procedure for each point in the MH Curve.

Then, press

[ESC] until you return to main menu and proceed to

the next section.

Operating the Series 35 IS 3-11

Page 40

March 2003

Entering the Probe Serial Number

The probe serial number is liste d on the Calib ration Data Sheet

and is inscribed on the hex nut of the moisture probe.

Note: Remember to re cord all set up data in Appendix D, Data

Informati on Sheet, in the back of this manual.

USER

SERIAL #

xxxxxx S/N

123456 S/N

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

Use the arrow keys to scroll to

SERIAL # and press the

[ENTER] key.

The unit displays the current

serial number.

T o edit the serial number, press

an arrow key a nd a blinking

cursor appear s at the le ft-most

digit. Use the arrow keys to

scroll to the desired value and

press

[ENTER] to move the

cursor to the next digit. Repeat

until you have entered all six

serial number digits . Pre ss the

[ENTER] key to confirm the

change or the

[ESC] key to

cancel the change.

SERIAL #

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

3-12 Operating the Series 35 IS

[ESC] until

Page 41

March 2003

Entering High and Low Reference Values

The Series 35 IS requires high and low reference values for its

moisture measurement circuitry. These factory calibration values,

specific to each unit, are listed on a label inside the unit.

IMPORTAN T: Do not change the high and/or low reference

values unles s instr uct ed to do so by GE

Panametrics.

Note: Remember to re cord all setup data in Appendix D, Data

Informati on Sheet, in the back of this manual.

HYGRO REFERENCE

High REF

HX.XXXX

Use the arrow keys to scroll to

HYGRO REFERENCE and

press the

[ENTER] key.

Press either arrow key to scroll

to the

High REF option, then

press the

[ENTER] key.

Use the arrow a nd [ENTER] keys

to change the valu e one digit at a

time, then press

[ENTER].

Note: To abort the editing functio n at any time wi thout changing

the value, press th e

Low REF

LX.XXXX

[ESC] key.

Press either arrow key to scroll

to the

Low REF option, then

press the

[ENTER] key.

Use the arrow a nd [ENTER] keys

to change the valu e one digit at a

time, then press

[ENTER].

Operating the Series 35 IS 3-13

Page 42

March 2003

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

[ESC] until

Changing the Measurement Display

The front panel of the Series 35 IS contains two ke ys that let you

quickly change the L.C.D. display mode during operation of the

unit. These display keys are labeled

HYGRO and P

const

.

• HYGRO - Press this key to display and scroll through all the

available moistur e measurement units (DP/°C, DP/°F, PMv,

MH).

• P

- Press this key to display and scroll through all

const

available consta nt pressure units (PSG, Bar, KPAg, Kcmg).

After you select a specific display mode , that display remains on

the screen until you choose anot her display mode or until you

enter the programming mode. Upon exiting the programming

mode and returning to measurement mode, the screen

automatically retur ns to the previously selected dis play mode.

3-14 Operating the Series 35 IS

Page 43

March 2003

Entering an Offset Value for Dew/Frost Point

Use this option to a djust the displayed dew/frost point reading. A

positive number increa ses the reading and a negative number

decreases the readi ng. The offset value always displays in dew/

frost point degrees C.

Note: Enter the user program as described on page 3-6.

USER

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

OFFSET

Use the arrow keys to scroll to

OFFSET and press the [ENTER]

key.

OFFSET +5.0 °C

The current offset value is

displayed.

OFFSET +10.0 °C

Press either arrow key to delete

the current value and enter the

edit mode. Use the arrow an d

[ENTER] keys to change the

value one digit at a time, then

press the

[ENTER] key.

Note: To abort the editing functio n at any time wi thout changing

the value, press th e

[ESC] key.

OFFSET

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

Operating the Series 35 IS 3-15

[ESC] until

Page 44

March 2003

Entering a Constant Pressure Value

This option lets you enter a fixed val ue for the pressure of the

sample gas at the moisture probe location. The value is used to

calculate the moistur e conte nt in

Note: Enter the user program as described on page 3-6.

PPM

.

v

USER

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

key to view the options.

CONSTANT PRESSUR

KP PSIg

Use the arrow keys to scroll to

CONSTANT PRESSUR and

press the

[ENTER] key.

The current units choice is

displayed. Use th e arr ow keys to

scroll to the desired pres sure

units, then press the

key. See Table 3-1 below for the

available choices.

Table 3-1: Constant Pres su r e Units

Available Units Description of Units

KP psig pounds per square inch gauge

KP bar bars absolute

KP KPag kilopascals gauge

KP Kcmg kilograms per square centimeter gauge

USER

[ENTER]

[ENTER]

KP: +XXX.XX PSG

The current constant pressur e

value is displayed.

Note: To abort the editing functio n at any time wi thout changing

the value, press th e

3-16 Operating the Series 35 IS

[ESC] key.

Page 45

March 2003

Entering a Constant Pressure Value (cont.)

KP: +500.00 PSG

Press either arrow key to delete

the current value and enter edit

mode. Use the arrow and

[ENTER] keys to change the

value one digit at a time, then

press

[ENTER].

KP: +XXX.XX PSG

KP PSIg

The new constan t pressur e va lue

is displayed. Press

[ESC].

The current units choice is

displayed. Press

[ESC] to return

to the options menu.

CONSTANT PRESSUR

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

[ESC] until

Operating the Series 35 IS 3-17

Page 46

March 2003

Entering a PPMv Constant Multiplier

Use this option to apply a user- defined constant multiplier to the

the PPMv value.

Note: Enter the user program as described on page 3-6.

USER

PPMv MULTIPLIER

KPPMv 1.0000

KPPMv X.XXXX

PPMv MULTIPLIER

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

Use the arrow keys to scroll to

PPMv MULTIPLIER and press

the

[ENTER] key.

The current value is displa yed.

Press either arrow key to delete

the current value and enter the

edit mode.

Use the arrow a nd [ENTER] keys

to enter the new multiplier, one

digit at a time. Then , pres s

[ENTER] twice to return to the

options menu.

Press the [ESC] key to ret urn to

the main menu.

Note: PPMv constant multiplier values up to 999.9999 may be

enter ed, but the value should be set at 1.0000 unless

otherwise advised by GE Panametric s. Be sure to record

all enter ed data in Appendix D, Data Information Sheet, in

the back of this manual.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

3-18 Operating the Series 35 IS

[ESC] until

Page 47

March 2003

Entering an Interval fo r Au to matic Calibration

The Series 35 IS automatically calibrates itself (Autocal) at userprogrammable time inte rvals, in orde r to compensa te for a ny drift

in the electronics . An Autocal interval value between 0 and 1440

minutes (24 hours) m ay be enter ed. GE Panametr ics re commends

setting the Autocal int erval to eight hours (480 minutes). If the

Series 35 IS is exposed to extreme temperatures or weather

conditions, a shorter Autocal interval may be more appropriate.

Note: Enter the user program as described on page 3-6.

USER

AUTOCAL INT ERVAL

ACAL (Mins) 30

ACAL (Mins) XX

AUTOCAL INT ERVAL

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

Use the arrow keys to scroll to

AUTOCAL INTERVAL and pr ess

the

[ENTER] key.

The current Autocal interval

value is displayed.

Press either arrow key to delete

the current value and enter the

edit mode. Use the arrow an d

[ENTER] keys to change the

value one digit at a time, then

press

[ENTER] to return to the

options menu.

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

Operating the Series 35 IS 3-19

[ESC] until

Page 48

March 2003

Entering an Interval for Automatic Calibration

(cont.)

After you confirm the Autocal interval a nd return to the main

menu, the Series 35 IS immediately performs an Autocal. The

next time Autocal occurs depends on the length of the time

interval setti ng.

The Series 35 IS determines the times of subsequent Autocals by

establishing a fixed schedule, beginning at midnight, using the

specified inter val. For example, if you enter a 90-minute time

interval, Auto ca l occu r s 16 times p er day

(1 day = 1440 minutes ÷ 90 minutes = 16).

The following fixed schedul e applies:

1. 1:30 a.m. 9. 1:30 p.m.

2. 3:00 a.m. 10. 3:00 p.m.

3. 4:30 a.m. 11. 4:30 p.m.

4. 6:00 a.m. 12. 6:00 p.m.

5. 7:30 a.m. 13. 7:30 p.m.

6. 9:00 a.m. 14. 9:00 p.m.

7. 10:30 a.m. 15. 10:30 p.m.

8. 12:00 p.m.(noon) 16. 12:00 a.m.(midnight)

If you enter a time interval not evenly divisible into 1440

minutes, the Series 35 IS rounds up to the next acceptable

interval. For example, if you set the 90- minute Autoc al int erval a t

6:10 p.m., the next Autocal occurs at 7:30 p.m. (excluding the

Autocal performed when you exit the Autoc al menu).

3-20 Operating the Series 35 IS

Page 49

March 2003

Viewing the Battery Sta tus

Make sure that the batte ry cha rge r is disconne cted be fore v iewing

the battery status.

Note: Enter the user program as described on page 3-6.

USER

BATTERY

DISCONNECT A.C.

Press ENTER

BAT: +6.89 V

BA T: 100%

BATTERY

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

Use the arrow keys to scroll to

the

BATTERY option and press

the

[ENTER] key.

The display alternat es between

the two messages shown. Press

the

[ENTER] key when the AC

power has been disconnected.

The display alternat es between

the two messages shown. Press

the

[ESC] key to return to the

options menu.

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

Operating the Series 35 IS 3-21

[ESC] until

Page 50

March 2003

Entering a Backlight-On Time Interval

Your Series 35 IS is equipped with a backlight, which can be

programmed to turn off aut omatically after a pre-determined

time. Values between 0 and 1440 minutes (24 hours) may be

entered.

Note: Enter the user program as described on page 3-6.

USER

BACKLIGHT

BLITE (Mins) 30

BLITE (Mins) XX

BACKLIGHT

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

Use the arrow keys to scroll to

BACKLIGHT and press the

[ENTER] key.

The current backlight inte rval

value is displayed.

Press either arrow key to delete

the current value and enter the

edit mode. Use the arrow an d

[ENTER] keys to change the

value one digit at a time, then

press

[ENTER] to return to the

options menu.

Press the [ESC] key to ret urn to

the main menu.

Note: Constant use of the backlight shortens the battery life. All

units ar e shipped wit h a default bac klight-on ti me int erval

of 5 minutes.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

3-22 Operating the Series 35 IS

[ESC] until

Page 51

March 2003

Setting Up Computer-Enhanced Response

Note: This option may not be installed on your Seri es 35 IS.

Using a dynamic moisture calibr ation technique, ComputerEnhanced Response extrapolates the moisture level to the end

point, when making measurements in abrupt “dry down”

conditions. Response time depends on the relative change in dew

point. For example, the Series 35 IS can respond in three to f ive

minutes to reflect a change from ambient moisture to trace levels.

The accuracy of Computer -Enhanced Response equals ±2°C of

the sensor reading, assuming an equilibrium with the gas. To

ensure accuracy, your application should:

• Have a reasonably constant f low rate and final dew point.

• Maintain a minimum flow rate of one standard cubic foot per

hour (SCFH).

• Operate at atmo sp h eric p res su re (0 psi g )

• The actual moisture content mus t be above –85°C frost point

and must be stable.

You can enable or disable the Computer-Enhanc ed Response

feature. If the feature is not available, the display reads

Not Avail

Note: Enter the user program as described on page 3-6.

USER

ENHANCE RESPO NSE

Operating the Series 35 IS 3-23

. Otherwise, the Enhance Response display appears.

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

key to view the options.

Use the arrow keys to scroll to

the

ENHANCE RESPONSE

option and press the

key.

Option

USER

[ENTER]

[ENTER]

Page 52

March 2003

Setting Up Computer-Enhanced Response

(cont.)

ENHANCE OFF

Use the arrow keys to scroll to

one of the option screens shown

ENHANCE ON

ENHANCE RESPO NSE

and press the

[ENTER] key.

Press the [ESC] key to ret urn to

the main menu.

Note: An activated Computer Enhanced Resp onse displays a

reverse video “E” on the left side of the display. After

determining the final va lue, the reverse video “E”

changes to a regular “E”.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

[ESC] until

3-24 Operating the Series 35 IS

Page 53

March 2003

Setting Up Range Error Processing

Range errors occur when an input signal within the capacity of

the analyzer is outsi de the ra nge of t he probe cali br ation data . The

Series 35 IS displays Range Errors with a n

UNDER RANGE message. The error condition extends to all

OVER RANGE or

displayed measurements of that mode. For example, if dew point

displays

OVER RANGE.

OVER RANGE, then moisture in PPMv also displays

There are two available Range Error processing options:

• No Action - the range error is not displaye d.

• Display - the range error is displayed.

Note: Enter the user program as described on page 3-6.

USER

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

RANGE ERROR

R_ERR = Display

Use the arrow keys to scroll to

the

RANGE ERROR option and

press the

[ENTER] key.

Use the arrow keys to scroll to

one of the options shown and

R_ERR = No Action

RANGE ERROR

press the

[ENTER] key.

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

[ESC] until

Operating the Series 35 IS 3-25

Page 54

March 2003

Selecti ng AC Line Frequency (60/50 Hz)

Select this setting acc ording to the AC line frequency in the

country where the Series 35 IS is installed.

Note: Enter the user program as described on page 3-6.

USER

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

SELECT 60/50 HZ

60HZ

Use the arrow keys to scroll to

the

SELECT 60/50 HZ option

and press the

[ENTER] key.

Use the arrow keys to scroll to

one of the options shown and

50HZ

SELECT 60/50 HZ

press the

[ENTER] key.

Press the [ESC] key to ret urn to

the main menu.

Note: For refe rence, recor d all entered data in Appendix D,

Data Inform ati on Sh ee t , in the back of this manual.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

[ESC] until

3-26 Operating the Series 35 IS

Page 55

March 2003

Adjusting the Contrast

Use this option to adapt to the lighting conditions of the Series 35

IS installation.

Note: Enter the user program as described on page 3-6.

USER

CONTRAST

Adj. Contrast

CONTRAST

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

USER

[ENTER]

key to view the options.

Use the arrow keys to scroll to

the

CONTRAST option and

press the

[ENTER] key.

Press the up-arrow key to

increase contrast o r the downarrow key to decrease, contrast.

Hold the key down for large

changes or press repeatedly for

small changes. Press the

[ENTER] key to confirm the new

setting.

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

Operating the Series 35 IS 3-27

[ESC] until

Page 56

March 2003

Setting the Clock V alues

The Series 35 IS has no backup power source, and the time/date

must be reset wh enev er the ba tte ry has been tot all y dep let ed.

Note: Enter the user program as described on page 3-6.

USER

From the main menu, use the

arrow keys to scroll to the

prompt, then press the

key to view the options.

CLOCK

Read Time

hh:mm mm/dd/yy

Use the arrow keys to scroll to

the

CLOCK option and press the

[ENTER] key.

Use the arrow keys to scroll to

READ TIME then press the

[ENTER] key.

The current tim e an d date are

displayed for 2 seconds, before

the

CLOCK prompt returns.

T o edit the time, use the following steps:

CLOCK

Set Time

Press the [ENTER] key.

Use the arrow keys to scroll to

SET TI ME. Then, press the

[ENTER] key.

USER

[ENTER]

hh:mm

Use the arrow a nd [ENTER] keys

to scroll to the correct hour and

minutes values. Then, press the

[ENTER] key.

Set Time

3-28 Operating the Series 35 IS

Press [ESC] to return to the

CLOCK prompt.

Page 57

Setting the Clock Values (cont.)

T o edit the date, use the following steps:

March 2003

CLOCK

Set Date

MM/DD/YY

Press the [ENTER] key.

Use the arrow keys to scroll to

SET DATE. Then, press the

[ENTER] key.

Use the arrow a nd [ENTER] keys

to scroll to the correct month,

day and year values. Then, press

the

[ENTER] key.

Note: The Series 35 IS clock is year 2000 compliant.

Set Date

CLOCK

Press [ESC] to return to the

CLOCK prompt.

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press [ESC] until

the

RUN ? prompt appears and then press the [ENTER] key.

Operating the Series 35 IS 3-29

Page 58

March 2003

Setting Up the Data Logger

The Series 35 IS optional data logging feature enables you to

internally vie w and store measurement data. The main menu

displays the

your unit.

Data is logged at user-selected tim e intervals and stored in the

unit’s FRAM. Up to three diff erent parameters may be logged at

any one time.

Note: Because the Series 35 IS contains a fixed amount of

The Series 35 IS assigns a record and a header to all logged data.

The record consists of logged measurement value s. The header

includes the time the log star ted, the constant pressure value, the

log time intervals, and the selected measurement modes. By

assigning eac h log a hea der , th e Serie s 35 I S disti nguis hes one log

from another.

LOGGER prompt only if this option is available on

memory , the more parameters you select and the more

freque ntly you log data, the shorter the total available

logging time.

The Series 35 IS can store more than one log. Each time the log

setting is changed, the Series 35 IS queries if you want to

overwrite or append to the existing log(s). If overwrite mode is

chosen, the Series 35 IS writes over the logs c urrently stored in

memory. If append mode is chosen, the Series 35 IS adds new log

data to the end of the previously stored log data. In either case,

the Series 35 IS con tinues logging measurement data until it runs

out of memory.

Note: Before beginning setup of the data logger, check to make

sure that the clock is set to the correct time and date. See

“Setting the Clock Values” on page 3-28 for the

proce dure to follow .

3-30 Operating the Series 35 IS

Page 59

March 2003

Setting the Data Logger Time Interval

The Series 35 IS logs measurement data at a time interval that is

specified by the user.

Note: Enter the user program as described on page 3-6.

LOGGER

LOG INTERVAL

LINTV (Mins) 15

LINTV (Mins) XX

LINTV (Mins) 30

From the main menu, use the

arrow keys to scroll to the

LOGGER prompt, then press the

[ENTER] key.

Use the arrow keys to scroll to

the

LOG INTERVAL option and

press the

[ENTER] key.

The current log interval is

displayed. Press either arrow

key to delete the current value

and enter the edit mode.

Use the arrow a nd [ENTER] keys

to change the valu e one digit at a

time, then press

[ENTER] to

confirm the new value.

The new log interval is

displayed. Press

[ENTER] to

return to the options menu.

LOG INTERVAL

Press the [ESC] key to ret urn to

the main menu.

Note: Data logging is suspended when you enter the

progr amming mode. If you r emai n in the programming

mode longer than the log intervals, the System 35 IS

appends a new log when you exit in or der to track the log

time prope rly. Also, a new log is appended to the current

log on power up.

Operating the Series 35 IS 3-31

Page 60

March 2003

Enteri ng the Parameter(s) to Log

Use this option to enter the para meters to be logged. You may log

up to three differe nt parameters at the same time.

Note: Enter the user program as described on page 3-6.

LOGGER

From the main menu, use the

arrow keys to scroll to the

LOGGER prompt, then press the

[ENTER] key.

LOG SETUP

Use the arrow keys to scroll to

the

LOG SETUP option and

press the

[ENTER] key.

Note: Before beginning setup of the data logger, check to make

sure that the clock is set to the correct time and date. See

“Setting the Clock Values” on page 3-28 for the

proce dure to follow .

L/MODE# X

Select the desired parameter

number (1, 2, or 3) with the

arrow keys and then press the

[ENTER] key.

LM=HYG

Use the arrow keys to select the

desired mode (

BAT). Pr ess th e [ENTER] key.

HYG, NONE, or

LM=HYG DP/°C

Use the arrow keys to select the

desired units setti ng (

DP/°F, DP/°C, or DVM). Then,

press the

[ENTER] key.

MH, PMv,

Note: If the NONE or BAT mode is chosen, the units setting

scre en will not appear. Simply press

[ENTER] to return to

the parameter number screen.

3-32 Operating the Series 35 IS

Page 61

Enteri ng the Parameter(s) to Log (cont.)

March 2003

L/MODE# X

If desired, repeat the above

procedure to set up the other two

param e ters. When f ini s h e d ,

press the

[ESC] key.

Note: Because the Series 35 IS contains a fixed amount of

memory , the more parameters you select and the more

freque ntly you log data, the shorter the total available

logging time.

LOG SETUP

Press the [ESC] key to ret urn to

the main menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

[ESC] until

Operating the Series 35 IS 3-33

Page 62

March 2003

Viewing Log Status, Summary and Data

Use this option to view the log status, log summary and log data.

Be aware that the nature of the 16-character L.C.D. display will

limit the ability to view the log dat a.

Note: Enter the user program as described on page 3-6.

LOGGER

From the main menu, use the

arrow keys to scroll to the

LOGGER prompt, then press the

[ENTER] key.

LOG DISPLAY

Use the arrow keys to scroll to

the

LOG DISPLAY option and

press the

[ENTER] key.

Viewing Log Status

Note: The log status applies only to the current log.

VIEW LOG STATUS

Records: 109

Use the arrow keys to scroll to

VIEW LOG STATUS and press

the

[ENTER] key.

The number of data points

logged and the remaining

Rem: 10h 10m

logging time screens will be

displayed for about 2 seconds

each.

VIEW LOG STATUS

Press the [ESC] key to ret urn to

the options menu.

T o enter more setup data, proceed to the appropriate section of

this manual. To return to measurement mode, press

the

RUN ? prompt appears and then press the [ENTER] key.

3-34 Operating the Series 35 IS

[ESC] until

Page 63

Vie w ing the Log Summar y

Follow these instructions to view the log summary.

March 2003