Page 1

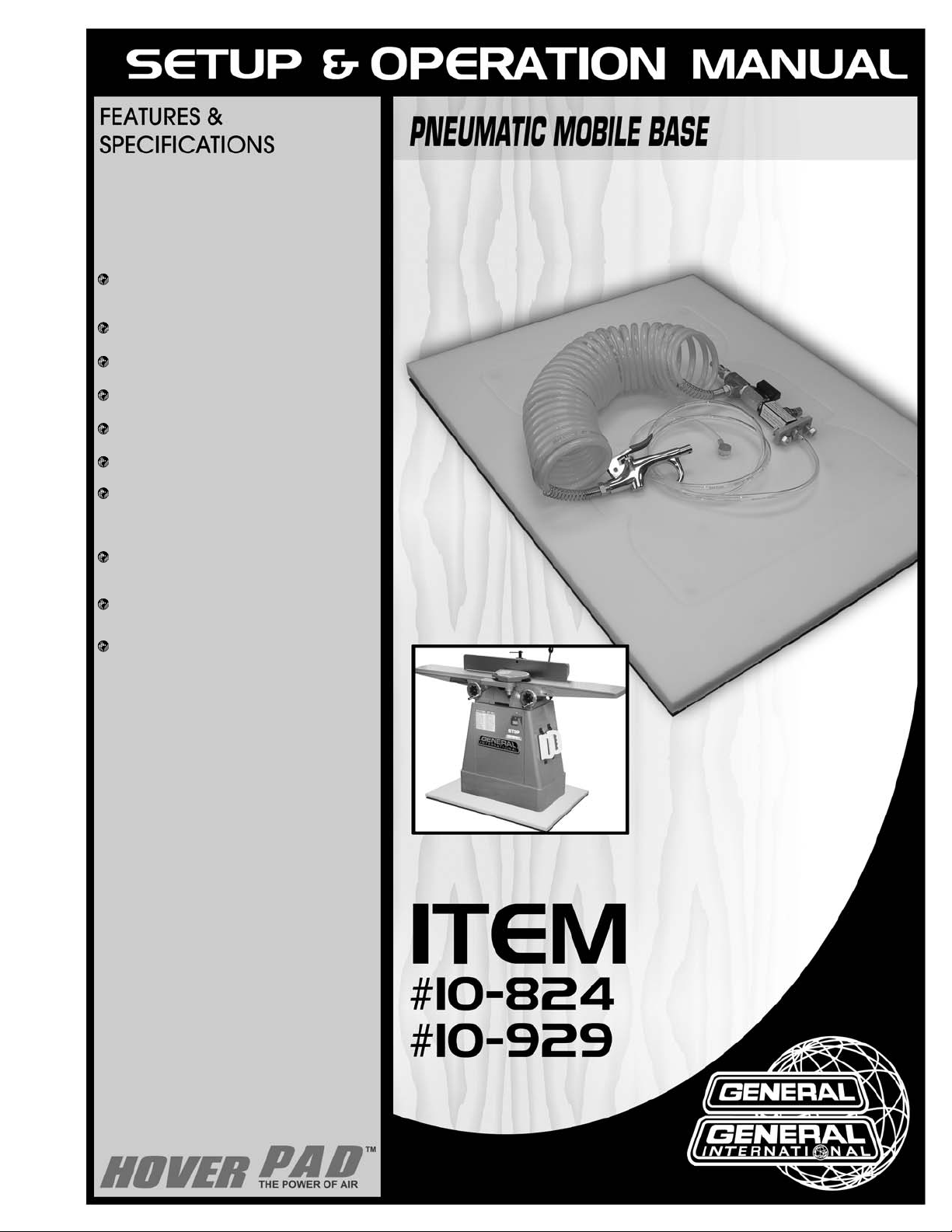

HOVERPAD PNEUMATIC MOBILE BASE ONLY JOINTER SOLD SEPARATELY

Available in 2 sizes:

18" X 24"

(457 x 610 mm) Model #10-824

29" X 29" (737 x 737 mm) Model #10-929

Customizable - May be cut to fit almost

any size exactly.

Effortless motion - Heavy objects move

freely on a cushion of air.

Zero rollback - Stays exactly where

parked.

Safe - Greater footprint and stability than

wheels – No tipping.

Requirements - Standard compressed air

and a smooth floor.

To prevent rocking when parked, the

Hoverpad is itself pliant and also has four

pliant rubber feet which compress and prevent rocking for the vast majority of cases.

The flow control allows adjustable lift from

1/8” to 1/2” (3 to 12 mm). The load is movable

as soon as it lifts.

Model #10-929 will lift up to 1200 LBS (544 kg),

Model #10-824, up to 600 LBS (272 kg).

The Hoverpad will fly over smooth, hard,

airtight surfaces. Flatness doesn’t matter,

but smoothness is critical. Test by applying a suction cup (supplied) to the floor –

if it sticks even slightly, it will work.

THE HOVERPAD™ PNEUMATIC MOBILE BASE IS A

GENERAL-PURPOSE FLAT BASE (LESS THAN ONE

INCH THICK) ONTO WHICH ANY LOAD CAN BE

PLACED AND EASILY MOVED.

REVISION 2 - APRIL 01/07

© COPYRIGHT GENERAL INTERNATIONAL 04/2007

Page 2

THANK YOU

for choosing this Hoverpad Pneumatic Mobile Base model 10-824

or 10-929 by General

® International. This Hoverpad has been carefully tested and inspected

before shipment and if properly used and maintained, will provide you with years of reliable

service. To ensure optimum performance and trouble-free operation, and to get the most from

your investment, please take the time to read this manual before assembling, installing and

operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this pneumatic mobile base as well as the set-up, maintenance and identification of its parts

and components. This manual is not intended as a substitute for formal woodworking instruction, nor to offer the user instruction in the craft of woodworking. If you are not sure about the

safety of performing a certain operation or procedure, do not proceed until you can confirm,

from knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

All component parts of this General® International product are carefully tested and inspected during all stages of

production, and each component is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of

90 days

from date of purchase, any genuine part or parts which, upon examination, prove to be defective in workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

GENERAL ® INTERNATIONAL WARRANTY

Disclaimer:

The information and specifications in this manual pertain to

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements, General

International reserves the right to make changes to components, parts

or features of this unit as deemed necessary, without prior notice and

without obligation to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure that the specifications and information in this manual corresponds with that of the unit

with which it was supplied. However, special orders and “after factory”

modifications may render some or all information in this manual inapplicable to your unit. Further, as several generations of this model of pneumatic mobile base and several versions of this manual may be in circulation, if you own an earlier or later version of this unit, this manual may

not depict your unit exactly. If you have any doubts or questions contact

your retailer or our support line with the model number of your unit for

clarification.

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

Page 3

Rules for Shop Safety

To help ensure safe operation, please take a moment to learn the machines’ applications and limitations, as well

as potential hazards. General® International disclaims any real or implied warranty and holds itself harmless for

any injury that may result from improper use of its equipment.

1. Do not operate machinery when tired, distracted, or

under the effects of drugs, alcohol or any medication

that impairs reflexes or alertness.

2. The working area should be well lit, clean and free of

debris.

3. Keep children and visitors at a safe distance when

the machine is in operation; do not permit them to

operate the machine.

4. Childproof and tamper proof your shop and all machinery with locks, master electrical switches and

switch keys, to prevent unauthorized or unsupervised

use.

5. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate saw dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector and wear

eye, ear and respiratory protection devices.

7. Do not wear loose clothing, gloves, bracelets,

necklaces and ornaments while the machine is in

operation.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the table surface before commencing operation.

9. Keep hands well away from blades and all moving

parts. Use a push stick to feed stock, and use a brush,

not hands, to clear away chips and sawdust.

10. Use recommended-speed blades, cutting tools and

accessories for the workpiece material.

11. Be sure the blade or cutting tool has gained full operating speed before beginning to cut.

12. Always use a clean, properly sharpened blade. Dirty

or dull blades are unsafe and can lead to accidents.

13. Do not push or force stock into the blade or cutting

tool. The machine will perform better and more safely

when working at the rate for which it was designed.

14. Use suitable support when cutting stock that does not

have a flat surface. Always hold stock firmly against

the fence when ripping, or against the miter gauge

when cross-cutting.

15. To minimize risk of injury in the event of work piece

kickback, never stand directly in-line with the blade or

in the potential kickback path of the work piece.

16. Avoid working from awkward or off balance positions.

Do not overreach during cutting operation; keep both

feet on floor. Never lean over or reach over the blade

and never pull the work piece over the blade from

behind. Use outfeed support or have an assistant help

when ripping long material.

17. Keep guards in place and in working order. If a guard

must be removed for maintenance or cleaning, be

sure it is properly reattached before using the tool

again.

18. Never leave the machine running with the power “ON”

when not in operation.

19. If using a power feeder, stop the feeder before

stopping the machine.

20. Use of parts and accessories NOT recommended by

General® International may result in equipment malfunction or risk of injury.

21. Never stand on machinery. Serious injury could result

if the tool is tipped over or if blade or cutting tool is

unintentionally contacted.

22. Always disconnect the tool from the power source

before servicing, changing accessories, performing

any maintenance, cleaning, adjustments, or if the

machine will be left unattended.

23. Make sure that switch is in the “OFF” position before

plugging in the power cord.

24. Make sure tool is properly grounded. If tool is equipped

with a 3-prong plug it should be used with a three-pole

receptacle. Never remove the third prong.

Page 4

1.

120 P.S.I. MAX. - ALW

AYS USE SUPPLIED AIR

FLOW CONTR

OL VALVE

Do not exceed 120 P.S.I. of air pressure to the

Hoverpad and never supply unrestricted air directly to your Hoverpad. Do not inflate so that the rubber bearings extend more than 1/2” (12 mm)

beyond the bottom surface of the pad – bearings

will be permanently damaged and warranty will

be void.

2. ABSOLUTELY NO PASSENGERS

This Hoverpad pneumatic mobile base is intended

for use to move machinery and other heavy

objects. It is not designed for people, pets or for any

other purpose. Any attempt to sit, kneel, stand, ride

or “surf” on a Hoverpad, or on a machine or load

installed on a Hoverpad, should be forbidden at all

times because it is dangerous, and can lead to

serious injury.

3. DEFLATE HOVERPAD BEFORE TURNING ON OR

OPERATING MACHINERY

Never turn on or operate any machine installed on

a Hoverpad until the Hoverpad has been deflated

and the air flow valve has been completely shut off.

Make sure the load is securely parked and sitting

stationary and stable on the floor. Failure to ensure

that your machine is completely immobile may

cause serious injury if the machine begins to move

across the floor when in use or as the workpiece is

fed into the blade(s) or cutting tool.

4. SELECT APPROPRIATE LOCATION AND SURFACE

FOR USE

Do not operate on slopes. Use only on hard, solid,

smooth, sturdy and stable surfaces, that are free of

debris or clutter and have minimal cracks, expansion joints or other imperfections that can dissipate

air flow. Tape floor cracks and expansion joints and

cross at an angle.

5.

LOOK BEFORE YOU MOVE THE MACHINE

Ensure that there is a clear path free of any debris,

clutter or obstructions, from your starting point to

the spot where you are re-locating the machine

before moving it. Avoid setting the machine down

on its power cord or air hose.

6. DO NOT FORCE OR OVEREXERT

The Hoverpad pneumatic mobile base is designed

to float and move smoothly (almost frictionless) up

to its rated weight capacity and requires only

steady firm and even pressure to re-locate the

machine or load. If you find that excessive force is

needed: STOP and check for obstructions, over

pressurization or improper installation such as

unevenly distributed load that may cause the

Hoverpad to skid or hop along the floor. Clear dust

or debris from around or beneath the pad, and

reposition the load (if needed) before proceeding.

7. FOLLOW ALL SAFETY RULES AND WARNINGS

SUPPLIED WITH YOUR COMPRESSOR

Improper handling of compressed air or incorrect

use of an air compressor can create hazardous

situations and lead to serious personal injury. Be

sure to read, understand and follow all instructions,

safety guidelines and warnings supplied with the

compressor you will use with this pneumatic mobile

base.

Additional Safety Instructions

Specific to this Mobile Base

BECAUSE EACH SHOP SITUATION IS UNIQUE, NO LIST OF SAFETY GUIDELINES CAN EVER BE COMPLETE.

THE MOST IMPORTANT SAFETY FEATURE IN ANY SHOP IS THE KNOWLEDGE AND GOOD JUDGEMENT OF THE USER.

USE COMMON SENSE AND ALWAYS KEEP SAFETY CONSIDERATIONS, AS THEY APPLY TO YOUR INDIVIDUAL SHOP

SITUATION FIRST AND FOREMOST IN MIND. IF YOU HAVE ANY DOUBTS ABOUT THE SAFETY OF AN OPERATION

YOU ARE ABOUT TO PERFORM: STOP! DO NOT PERFORM THE OPERATION UNTIL YOU HAVE VALIDATED FROM QUALIFIED

INDIVIDUALS IF THE OPERATION IS SAFE TO PERFORM AND WHAT IS THE SAFEST METHOD TO PERFORM IT.

4

Page 5

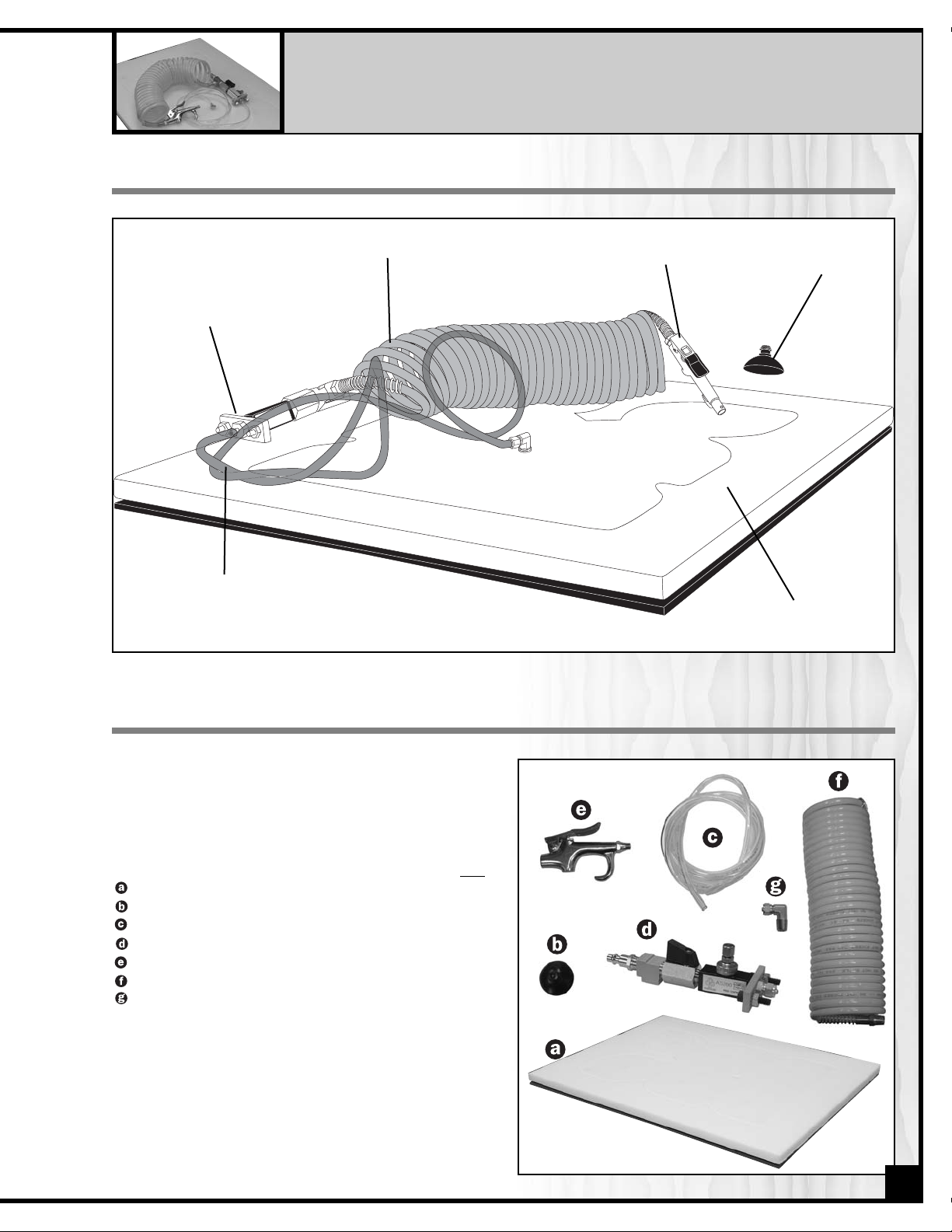

PNEUMATIC MOBILE BASE

10-824 or 10-929

IDENTIFICATION OF PARTS & COMPONENTS

Hoverpad

Suction Cup

Coiled Air Hose

5’ Air Hose

Blow Gun

Air Flow

Controller Assembly

Remove all parts and components from the box and

check for missing or damaged items as per the list of

contents below.

Note: please report any damaged or missing items to

your General International distributor immediately.

Qty

HOVERPAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SUCTION CUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5’ AIR HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

AIR FLOW CONTROLLER ASSEMBLY . . . . . . . . . . . . . .1

BLOW GUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

COILED HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

“L” FITTING WITH NUT . . . . . . . . . . . . . . . . . . . . . . . . . .1

UNPACKING & CHECKING CONTENTS

5

Page 6

BASIC FUNCTIONS OF THIS HOVERPAD PNEUMATIC MOBILE BASE

This Hoverpad pneumatic mobile base is a general purpose flat

base, less than 1”(25 mm) thick, onto which machinery or other

heavy objects can be placed and easily moved.

Standard compressed air and a smooth hard floor are needed

to operate this Hoverpad. The amount of air volume and pressure required will vary depending on the weight of the load and

the smoothness of the floor, but most loads under 600 LBS (272 kg)

can be floated using a small “pancake” style compressor

putting out 90-120 P.S.I. at between 3-8 CFM.

The Hoverpad cannot be

operated on carpeting, tile

flooring with grout lines, rough or

uneven surfaces or any soft or

unsmooth surface that would

absorb or dissipate the air pressure under the pad.

Compatible surfaces include:

smooth-finished concrete, smoothtextured vinyl, and epoxy painted

concrete floors.

To improve performance, gaps,

cracks or expansion joints can be

filled or taped over and rough surfaces such as broom-finished or

sand textured concrete may be

overlaid or covered with smooth

sheets of metal, plastic or

self-stick vinyl tile.

TEST YOUR FLOOR BEFORE PROCEEDING

Use the supplied suction cup to test the compatibility of your floor

before proceeding with installation.

Sweep or vacuum away any dust, dirt or debris on a small section of flooring in the intended usage area and press the cup

down on the floor until it flattens out.

Note: The cup does not need to be moistened.

If the cup adheres even slightly proceed to the set-up and installation steps described in the following

pages.

If the cup does not stick, the Hoverpad will not work with your flooring surface. Pack up the pad and all

its components in the original packaging for return to your place of purchase for a refund.

6

Page 7

7

ADDITIONAL REQUIREMENTS FOR SET UP

• An extra person for help with lifting • Adjustable wrench

• Phillips head screwdriver • Drill & drill bits

• Tape measure • Pencil

ASSEMBLY AND INSTALLATION INSTRUCTIONS

1. The control fittings are assembled at the factory as

shown.

2. Connect one end of the coiled air hose to the

threaded opening in the bottom of the “t-fitting”

and connect the blowgun to the other end of the

coiled air hose.

NOTE

If you plan to cut your Hoverpad to

size: A bandsaw, reciprocating saw or

other cutting tool will also be needed.

Note: The top of the pad (white side) has a thin protective layer. Peel off this protective layer before continuing.

AIRFLOW DIRECTION

Air inlet

T-Fitting

Ball valve

Adapter

Flow controller

Mounting bracket

with screws & nuts

Air outlet with nut

Air Flo

w Control Assembly Components

Unscrew the nut from the “L” fitting’s hose barb.

Slide the nut onto the 5’ air hose making sure the

threads of the nut are facing outward.

Insert the hose barb of the “L” fitting into the air hose.

Make sure the hose fully covers the hose barb of

the “L” fitting.

Slide the nut from step onto the threads on the

fitting and tighten.

Screw the hose barb “L” fitting into the threaded

hole in the top (white side) of the Hoverpad.

3. The 5’ air hose is connected to both the “L” fitting and the air outlet fitting in the same manner following the steps

listed below.

Use the same connection method to install the opposite end of the 5’ air hose onto the air outlet fitting on the flow

control assembly.

Page 8

4. Close the flow control valve by turning the knurled

knob clockwise.

5. With the help of an assistant, a hoist, or a fork-lift

place your machine or other load roughly

centered on the Hoverpad taking care to avoid

crushing the airhose or hitting the “L” fitting in the

center of the pad.

Note: Follow the manufacturer’s recommendations for

handling or lifting the machine.

6. Run the hose and control assembly up through any

practical or available opening in the base of your

machine.

Note: In some cases, if the base of your machine is

closed and there are no accessible openings in the

cabinet it may be necessary to drill a small hole in the

cabinet in order to pass the hose up through the

machine.

7. Temporarily connect to your compressed air

supply.

Note: Do not surpass 120 P.S.I. of air pressure from your

compressor.

8. Turn the lever to open the ball valve and then

adjust the flow control valve (step 4 above) to take

the minimum required airflow to lift the load.

9. Examine how the load floats and check for level –

an even relatively equal distance from the floor at

all four corners is ideal. If the load floats smoothly

and stays relatively level, skip ahead to the section

entitled “Final Installation”. If the load seems off

balance or does not float smoothly, follow the suggestions listed below in “Leveling the Load and Fine

Tuning” before proceeding to “Final Installation”.

8

OPEN

CLOSE

Page 9

LEVELING

For off balance or off center loads such as the example

shown where the motor

(the heaviest part of the machine) is

installed at one end, the load will not float level with the

floor if the machine is centered on the Hoverpad – this is

normal.

Close the ball valve to shut off the air flow and wait for the

load to settle on the floor. Reposition the load on the

Hoverpad as needed until it floats relatively level with the

floor.

Note: For badly off balance loads, it may be necessary to

apply additional weight or downward pressure to the high

side – minimize airflow and keep the load moving to avoid

hopping.

LEVELING THE LOAD AND FINE TUNING

FINE TUNING

Machines with fully enclosed bases that sit flush to the

floor on all four sides will provide best results with minimal

or no fine tuning required.

Excellent results can also be achieved with open,,or

partially open,,based machines by understanding the

basic principals of weight distribution and following the

suggestions below.

Machines or loads that have a full closed base that

sits flush to the floor distribute their weight best, around the

entire perimeter of the base and the weight is dispersed

evenly across the entire surface of the pad, .

For machines with open or partially open bases, the

weight distribution is limited to the points of contact with

the Hoverpad. Depending on the size and weight of the

load, concentrating the weight on only a few points

rather than evenly distributing it, may cause the Hoverpad

to flex inward at the center (concave) when floating, .

This will affect the performance of the Hoverpad and

cause the corners of the pad to drag or the load to skip

or hop when moved. To remedy this, the weight of the

load needs to be more evenly dispersed.

For open based machines or loads, simply place the

machine on a supplementary platform by cutting a 3/4”

plywood plank (or other flat rigid material) to the size of

the outside dimensions of the contact points (feet) of the

base. Make sure to drill a big enough hole in the center

of the supplementary platform to accommodate the air

hose fitting in the top of the Hoverpad, .

If possible, to avoid the machine shifting off of the supplementary platform, attach the feet of the machine to the

platform with mounting blocks, bolts or screws, .

Note: Make sure fasteners or hardware that are used do not

come into contact with or pierce through the top surface of

the Hoverpad within its penetration border (see illustration

on next page). If needed, countersink holes in the platform

from below to allow your supplementary platform to rest flush

against the Hoverpad.

9

Page 10

For partially open based machines or loads, cut hardwood wedge blocks to size and fit them between the

openings in the base and the Hoverpad as shown. Make

sure the fit is snug in order to more evenly distribute the

weight and to prevent the pad from flexing when floated.

With the load leveled, the weight evenly distributed and

the Hoverpad floating smoothly proceed to the next step

“Final Installation”.

Once the load has been leveled, the weight evenly distributed and the pad floats evenly and moves smoothly, the

final three installation steps involve cutting the Hoverpad to size (if desired), permanently securing the machine to

the Hoverpad (also if desired) and permanently installing the control assembly on the machine or load.

CUTTING OR RE-SIZING THE HOVERPAD

If you choose to, the Hoverpad can be cut or re-sized to

come close to, or match the footprint of your machine.

This can allow you to maximize floor space and limit gaps

between adjacent objects or walls.

Note: Mark the position and orientation of the load on the

Hoverpad before removing the load and cutting the pad.

Before trimming the Hoverpad, mark the outside perimeter of your cut and validate that the intended cut area is

outside the penetration border (see below defined by the

routed groove in the top and 1/4” (6.3 mm) outside the

edge of the rubber feet on the bottom) – Make no cuts or

penetrations of any kind inside of the border. Cutting or

piercing the pad in any way inside of the penetration

border will lead to unit failure and will void the warranty.

Using a bandsaw, reciprocating saw or other cutting tool

that is used to cut wood, trim the excess from the pad to

match the pad size

(outside of the limitations of the penetration

border) to the footprint of your machine.

If the footprint of your machine sits inside of the penetration border trim the pad only to the penetration border.

Do not move the machine to line up with an edge of the

border as this will shift the previously leveled weight.

SECURING

THE LOAD TO THE HOVERPAD

Bolts or screws (not supplied) may be installed into or

through the Hoverpad

(outside of the penetration border).

Cleats may also be used on either the inside or outside

corners

(as shown) of cabinet style bases to hold the

machine from sliding on the Hoverpad, .

FINAL INSTALLATION

PENETRATION BORDER

Do not cut inside the perimeter of

these dotted lines.

TOP VIEW

BOTTOM VIEW

10

Page 11

OPERATION

WARNING!

TO AVOID ACCIDENTS OR INJURIES: NO PASSENGERS ALLOWED! DO NOT ALLOW ANYONE, AT ANY

TIME FOR ANY REASON, TO RIDE ON THE HOVERPAD OR ON ANY LOAD OR MACHINE INSTALLED

ON A HOVERPAD.

When relocating a load installed on a Hoverpad, follow the basic instructions listed below.

1. Always turn off and unplug any machine installed

on a Hoverpad before moving or relocating it.

2. With the ball valve on the control assembly in the

“closed” position, connect the compressed air source

to the air inlet fitting – do not to exceed 120 P.S.I. of air

pressure from the compressor.

Note: Exceeding 120 P.S.I. will damage the Hoverpad.

3. If necessary, clear a path to the relocation point.

Remove any debris, tools, trash or other clutter on the

floor that may be in the way, and use the attached

blow gun to clear away sawdust or woodchips that

may obstruct, diffuse or impede airflow under the

pad .

4. Turn the ball valve to the “open” position and wait a

few seconds for the load to lift and level.

5. Move the machine or load to the desired location in

the shop. Depending on your type of flooring, when

moving a load, the Hoverpad will make a light hissing

or squeaking sound – this is normal.

6. Always maintain control over the load or machine you are moving by keeping your hands on the load at all

times . Never push on the load or machine and let it float away freely .

7. If the pad skips or hops along the floor when moving, adjust the flow control valve to take the least amount of

air pressure required to remedy the problem.

Helpful Hint: Start by turning down the air flow to remedy skipping or hopping. Assuming the load is leveled, evenly distributed on

the pad, and there are no obstructions or debris under the pad, a load that hops or skips when moving is usually an indication

that too much air (rather than too little) is being used to float the load.

8. Unlike mobile bases on fixed wheels, the Hoverpad allows for omni-directional movement. The load can be

moved or rotated as needed in any direction .

9. With the load or machine moved to the desired location, turn the ball valve to the “closed” position to shut

off the air flow and park the load.

Note: Avoid setting the machine down on its’ power cord or

air hose.

10. Make sure the load or machine is securely parked

and sitting stationary and stable on the floor and dis

connect from the compressed air source before plugging in or turning on the machine.

Squeeze down

Air

Dust

11

INSTALLING THE CONTROL ASSEMBLY

Install the controls in a convenient, accessible location on

the machine or load. The control mounting bracket hole

pattern, , shows the mounting hole size and placement

required to attach the mounting bracket (and the control

assembly) to your machine or load.

9/32” (7 mm)

1.5” (38 mm)

17/32” (13.4 mm)

Page 12

12

PARTS LIST

PNEUMATIC MOBILE BASE

PART N0. REF. NO. DESCRIPTION SPECIFICATION QTY

10824-03 19081004 FLAT WASHER WITH RUBBER 6

10824-04 50161035 METAL SCREW 3/16" X 1/2"L 6

10824-07 19081005 RUBBER FEET 4

10824-08 50161034 METAL SCREW 5/32" X 5/8" L 4

10824-09 51801001 AIR INLET P20 1/4" PT 1

10824-10 51804001 T-FITTING 1/4" PT 1

10824-11 51805001 BALL VALVE 1/4" PT 1

10824-12 51806001 FLOW CONTROLLER 02B 1/4" P-46445 1

10824-13 50152043 CAP SCREW 1/4"-18UNC X 7/8"L 2

10824-14 19081007 MOUNTING BRACKET 1

10824-15 50251001 NUT 1/4"-18UNC 2

10824-16 51802001 AIR OUTLET WITH NUT CIN1/4"PT 1

10824-17 51807001 AIR HOSE 6 X 5' 1

10824-18 51803001 “L” FITTING WITH NUT LIN1/4"PT90° X 6 MM 1

10824-20 19081008 SUCTION CUP RUBBER 1

10824-21 51807002 COILED HOSE 8 X 3M,1/4" PT 1

10824-22 51808001 BLOW GUN 1

10824-23 51802002 ADAPTER 1/4"PT 1

*

Hoverpad assembly not

available seperately

Page 13

13

NOTES

Page 14

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and part number. Also a brief description of each item and quantity

desired.

10-824 / 10-929

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

Tel.: (514) 326-1161

Fax : (514) 326-5565

Parts & Service

Fax : (514) 326-5555 Order Desk

orderdesk@general.ca

www.general.ca

Loading...

Loading...