Page 1

Sound hood for quiet operation.

Wet/dry operation.

Sealed, water resistant switch cover.

2 Stage air filtration.

Powerful 2 speed motor. (MODEL 10-300)

2 High efficiency motors. (MODEL 10-315)

Rated for heavy duty maintenance &

janitorial use.

Accessory tray included.

CAPACITY

10 GALLON

- #10-300

15 GALLON

- #10-315

V

OLTAGE

110 V

AIR MO

VEMENT

92 CFM

- #10-300

93 CFM & 122.4 CFM

- #10-315

SUCTION (WATER LIFT)

72” (MAX.)

- #10-300

73” (MAX.)

- #10-315

HOSE LENGTH

6’ (2 m)

SOUND RA

TING

75 TO 80 dB

- #10-300

75 TO 80 dB (2 MOTORS: 95 TO 100 dB)

- #10-315

MOTOR

1 1⁄2 HP (HI: 10 A / LOW: 7 A)

- #10-300

1 1⁄2 HP (1 MOTOR: 10 A / 2 MOTORS: 19 A)

- #10-315

WEIGHT

39.6 LBS (18 kg)

- #10-300

56 LBS (25.5 kg)

- #10-315

REVISION 3 - MAY 08/07

© COPYRIGHT GENERAL INTERNATIONAL 05/2007

Page 2

THANK YOU

for choosing this General International model 10-300 or model

10-315 Wet/Dry Vacuum cleaner. This vacuum cleaner has been carefully tested and inspected

before shipment and if properly used and maintained, will provide you with years of

reliable service. To ensure optimum performance and trouble-free operation, and to get the

most from your investment, please take the time to read this manual before assembling,

installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this vacuum cleaner as well as the set-up, maintenance and identification of its parts and

components. This manual is not intended as a substitute for formal woodworking instruction,

nor to offer the user instruction in the craft of woodworking. If you are not sure about the

safety of performing a certain operation or procedure, do not proceed until you can confirm,

from knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

All component parts of General® International machinery are carefully tested and inspected during all stages of

production, and each machine is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of 24

months from date of purchase, any genuine part or parts which, upon examination,prove to be defective in workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

GENERAL® INTERNATIONAL WARRANTY

Disclaimer:

The information and specifications in this manual pertain to

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements, General

International reserves the right to make changes to components, parts

or features of this unit as deemed necessary, without prior notice and

without obligation to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure that the specifications and information in this manual corresponds with that of the unit

with which it was supplied. However, special orders and “after factory”

modifications may render some or all information in this manual

inapplicable to your machine. Further, as several generations of this

model of vaccum cleaner and several versions of this manual may be

in circulation, if you own an earlier or later version of this unit, this

manual may not depict your machine exactly. If you have any doubts

or questions contact your retailer or our support line with the model and

serial number of your unit for clarification.

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555

www.general.ca

Page 3

Rules for Safe Operation

1. Learn the machine’s specific applications and limitations (what it can

and cannot do), as well as the specific potential hazards that are particular to this machine. Carefully

follow all operation instructions and

safety rules.

2. Do not operate the unit unless the

hose is installed on the dust outlet.

3. Keep the work area clean and well

lit.

4. Do not wear loose tilting clothing or

jewelry. Wear face, eye, ear, respiratory and body protection suitable to

the application or operation being

performed.

5. Do not vacuum near flammable or

combustible liquids, gases or vapors.

Avoid materials such as: gasoline or

other fuels, ligter fluid, cleaning fluid,

natural gas, hydrogen, or explosive

dust, magnesium dust, grain dust

or gun powder.

6. Never leave the power on or the machine running while it is unattended.

7. Do not handle the power cord or the

electrical plug with wet hands.

8. Do not vacuum anything that is burning or smoking such as cigarettes,

matches or hot ashes.

9. To avoid health hazards from vapors or

dusts, do not vacuum toxic materials.

10. The unit is equipped with a three prong

electric plug and should be plugged

into a three pole receptacle. Never remove the third prong.

11. Always disconnect the unit from the

power supply before servicing, emptying or when changing tools or filters.

12. Make sure that the switch is in the “OFF”

position before plugging in the power

cord.

13. Do not use this wet/dry vacuum for

purposes other than its intended use. If

used for other purposes, General International disclaims itself of any and

all warranty, real or implied, and holds

itself harmless for any injury which

may result from such use.

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and

holds itself harmless for any injury that may result from improper use of its equipment.

Page 4

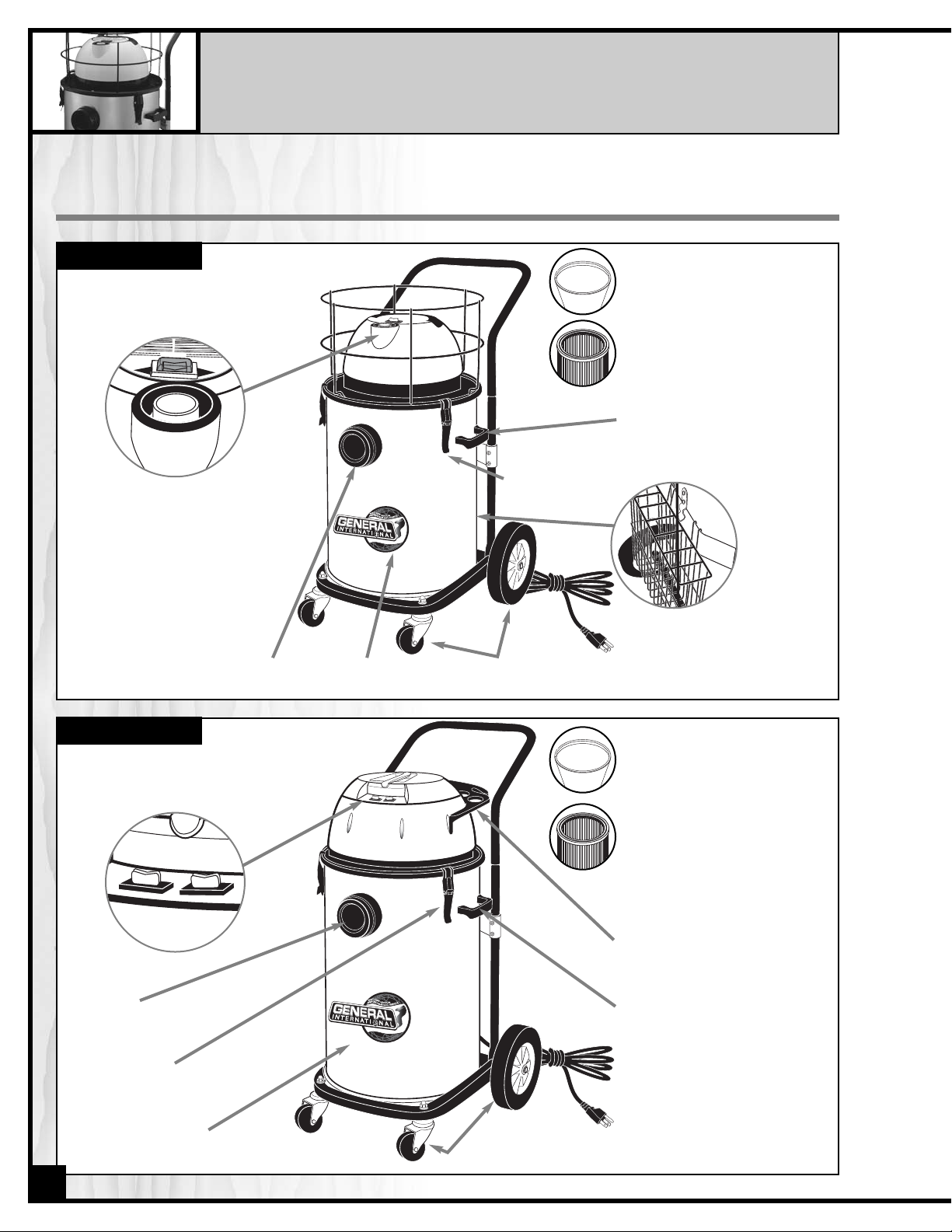

WET / DRY VACUUM CLEANER

10-300 / 10-315

IDENTIFICATION OF PARTS & COMPONENTS

POWER CORD/PLUG

110 Volt A.C. To prevent damage

to the power cord, to not unplug

by pulling on the power cord always handle by the plug.

FRONT CASTERS

& REAR FIXED WHEELS

10 GAL. TANK

MODEL 10-300

POWER SWITCH

Sealed, water resistant three position

switch: Low – Off – High.

FILTER BAG

Designed to keep dust in the

canister and away from the

motor.

POWER CORD/PLUG

110 Volt A.C. To prevent damage

to the power cord, to not unplug

by pulling on the power cord always handle by the plug.

FRONT CASTERS

& REAR FIXED WHEELS

LIFTING HANDLES

On each side of the tank.

15 GAL. TANK

HOSE INLET

MODEL 10-315

POWER SWITCH

Sealed, water resistant switch: On /Off.

FILTER BAG

Designed to keep dust in the

canister and away from the

motor.

PLEATED INNER FILTER CARTRIDGE

Should be removed for wet vacuuming. Provides secondary dust

filtration up to 3 microns.

4

ACCESSORY STORAGE RACK

AIRFLOW INDICATOR

When the unit is turned on the

airflow indicator will pop up

indicating that air is flowing

through unrestricted and the

unit is functioning properly. If

the airflow indicator does not

pop up, there may be an

obstruction or the tank may be

full: in this case, stop the unit

and check or empty the unit

as necessary.

HOSE INLET

ACCESSORY

STORAGE

RACK

LIFTING HANDLES

On each side of the tank.

PLEATED INNER FILTER CARTRIDGE

Should be removed for wet vacuuming. Provides secondary dust

filtration up to 3 microns.

LID CLAMPS

Secure the lid to

the tank creating

an airtight seal.

LID CLAMPS

Secure the lid to

the tank creating

an airtight seal.

Page 5

ELECTRICAL REQUIREMENTS

Plug the vacuum into a proper receptacle.Your power tools should be

connected to a dedicated electrical circuit of not less than #14 wire and

should be protected with a 15 amp time lag fuse.

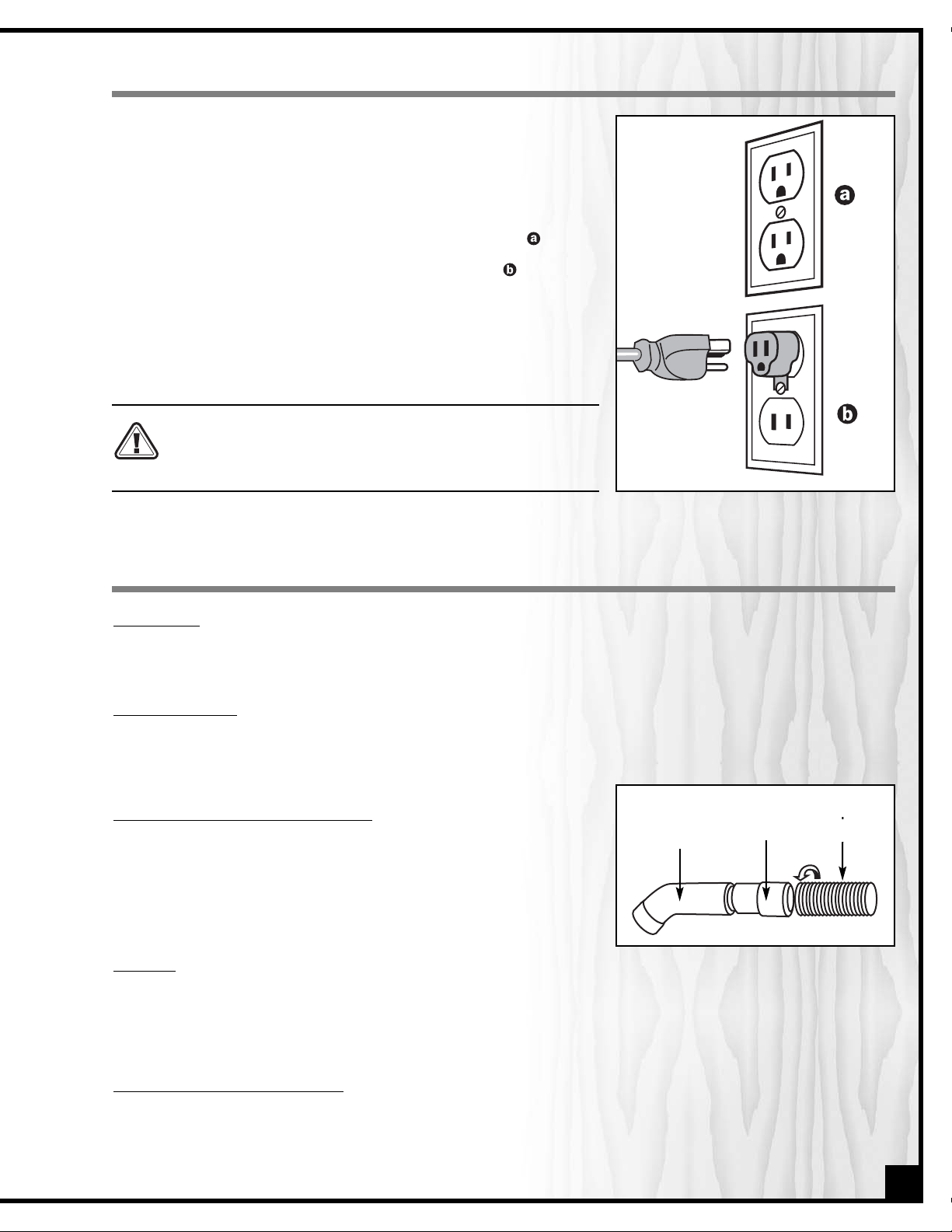

Grounding:

This tool must be grounded to protect the operator from

electrical shock. The supplied motor recommended for your vacuum is

wired for 110 Volt, single phase, and has a 3-conductor cord and 3prong grounded plug to fit a grounded-type receptacle, . Do not

remove the 3rd prong (grounding pin) from the plug to make it fit into

an old 2-hole wall socket. If an adapter plug is used, , it must be

attached to the metal screw of the receptacle.

Note: Use of an adaptor plug is illegal in some areas. Check your local

codes.

BEFORE CONNECTING THE MOTOR TO THE POWER LINE, MAKE SURE

THAT THE SWITCH IS IN THE OFF POSITION AND THAT THE ELECTRICAL

CURRENT IS OF THE SAME TYPE AS THAT STAMPED ON THE MOTOR

NAME PLATE. ALL ELECTRICAL CONNECTIONS SHOULD HAVE PROPER

CONTACT. RUNNING ON LOW VOLTAGE WILL DAMAGE THE MOTOR.

OPERATION INSTRUCTIONS

FLEXIBLE HOSE

Be sure that the hose is firmly connected to the inlet nozzle.When properly connected it can only be unclipped from

the air inlet by depressing the button on the hose end while pulling on the hose.

FILTER INSTALLATION

Install the bag filter on the rim of the tank. Proper installation of the bag filter creates a seal that will ensure maximum performance and prolong the life of the unit by protecting the motor against dust infiltration. The bag filter

should be used at all times, for both wet or dry vacuuming.

EXTENSION WAND AND NOZZLE CONNECTION

The 2 piece extension wand twist-fits into the female end of the curved

end pipe installed at one end of the flexible hose. The nozzles are

designed to twist fit into the female end of the extension wand. To

disassemble, pull while twisting to separate the components. To avoid

damaging the hose, pull on the hose fittings and not directly on the

hose.

FLOAT CUP

To prevent overfilling the tank with water which could damage the motor and/or cause electrical shock to the user,

the vacuum is equipped with a float cup. When the tank fills to its limit with water the sound of the motor will change

as the float cup rises and seals off the motor to prevent the rising water from entering. At this point the unit will not

vacuum up any more water or debris and the tank must be emptied before work can continue.

REMOVING AND RE-INSTALLING THE LID

• To remove the lid, release the three lid clasps and lift the lid from the canister.

• To re-attach the lid, fit the lid securely to the canister and using the three clasps, clip the lid in place.

Note: For maximum performance a proper seal is required between the lid and the canister.

5

CURVE PIPE

HOSE

HOSE END

Page 6

FILTRATION SYSTEM

This wet dry vacuum is designed with 2 stage air filtration comprised of a filter bag and a pleated inner filter

cartridge. To ensure maximum performance and to protect the motor against dust infiltration make sure that the filtration is properly installed and used at all times.

1. When vacuuming dry trash or dust, both the filter bag and the pleated inner filter cartridge should be installed.

2. When vacuuming wet trash or liquids, remove the pleated inner filter cartridge as only the filter bag is needed.

TURN OFF THE UNIT AND UNPLUG THE POWER CORD BEFORE REMOVING OR INSTALLING THE FILTERS.

WARNINGS FOR OPERATING

1. Do not use to vacuum up gasoline, or other flammable liquids or vapors. Also avoid using

for nails, blades, screws or other sharp objects that could damage the hose or perforate

the filter bag.

2. The airflow indicator will pop up when air is flowing unrestricted and the unit is functioning properly. If the air flow indicator does not pop up, there may be an obstruction or

the tank may be full: in this case, stop the unit and check or empty the unit as necessary.

(Model 10-300 only)

3. To avoid the build up a strong smells inside the tank, clean and empty the unit after each

use or before storing for prolonged periods.

4. Do not use the unit near sources of heat such as ovens, radiators or space heaters. Exposure

to heat may cause the tank to buckle, bulge or lose its shape preventing a good seal

between the tank and lid which will diminish performance and suction efficiency.

5. To avoid the build-up of static electricity in the extension wand, do not suck up too much

fine dust at one time.

6. To prevent damage to the motor, before operating, make sure that the filter bag is in place,

properly fitted and is not perforated. Periodically inspect the filter bag for holes or perforations. The filter bag should be replaced immediately if damaged or perforated.

ITEM #10-323

PROFESSIONAL

WET NOZZLE

Used for water removal.

ITEM #10300-35B

WET NOZZLE

Used for water removal.

ITEM #10-314

12” BRUSH NOZZLE

Used on floors or carpets.

ITEM #10-310

CREVICE

NOZZLE

Used in corners or

tight spaces.

ITEM #10300-11B

ROUND BRUSH

NOZZLE

Used on fabric or any

irregular surface.

ITEM #10-306

FLEXIBLE

6’ HOSE

ITEM #10-309

2 PIECE

EXTENSION WAND

ITEM #10-332

PLEATED FILTER

CARTRIDGE

ITEM #10-334

CLOTH FILTER BAG

REFERENCE GUIDE FOR REPLACEMENT & OPTIONAL ACCESSORIES

OPTIONAL

18’ FLEXIBLE HOSE

ITEM #10-318

6

Page 7

MAINTENANCE

1. Keep all parts and accessories such as the hose, power cord and filters in good condition

2. Clean the filter bag by hand, never by washing machine.

3. For smooth rolling, apply a small amount of lubricant to the castors.

4. Wipe the unit clean using a sponge, cloth or paper towel with warm water and mild detergent.

PROBLEMS

MOTOR STOPS OR

DOES NOT RUN

AIRFLOW INDICATOR

DOES NOT POP UP

(MODEL 10-300 ONLY)

CHECK THE FOLLOWING

1. Power cord properly plugged in?

2. Switch in the “off” position?

3. Overheating? If thermal protector shuts down the

unit, let the unit cool down or about 10 minutes

before restarting.

1. Hose and fittings connected tightly? Reconnect

hose and fittings.

2. Hose or fittings clogged? Dust tank full? Unblock

hose or fittings or empty tank.

3. Filter bag clogged with dust? Wash or replace

filter bag.

TROUBLESHOOTING

7

Page 8

8

MODEL 10-300

Page 9

9

PARTS LIST

10-300

PART N0.

10300-01

10300-02

10300-03

10300-04

10300-05

10300-06

10300-07

10300-08

10300-09

10300-10

10300-15

10300-16

10300-17

10300-18

10300-19

10300-20

10300-21

10300-22

10300-23

10300-23-1

10300-24

10300-25

10300-26

10300-27

10300-28

10300-29

10300-30

10300-31

10300-32

10300-33

10300-34

10300-35

10300-36

10300-37

10300-38

10300-39

10300-40

10300-41

10300-42

10300-43

10300-44

10300-45

10300-46

DESCRIPTION

LID HANDLE

WATER PROOF GASKET

WATER PROOF COVER

SWITCH

TOP HOOD

AIRFLOW INDICATOR

MUFFLER

MOTOR COVER GASKET

MOTOR COVER

AIRFLOW INDICATOR WASHER

SCREW

POWER CORD CLAMP

STRAIN RELIEF

POWER CORD

MOTOR MOUNT

MUFFLER

ROLL CAGE

MUFFLER

TWO STAGE MOTOR

MOTOR BRUSH

(NOT SHOWN)

FOAM GASKET

MOTOR BASE WASHER

FLAT SUPPORT

SCREW

FLOAT WASHER

FLOAT

FLOAT CAGE

SCREW

CANISTER FILTER (

ITEM

10-332)

CLOTH FILTER CAGE

CLOTH FILTER BAG (

ITEM

10-334)

WASHER

CAP NUT

SCREW

LID CLAMPS

SCREW

WASHER

CLAMP HOOK

SCREW

AIR DEFLECTOR

LIFTING HANDLE

HOSE INLET

10GL TANK

REF. N0.

V02001-00

E31011-01

E31010

E31004

V02011-01

V02123

V02090

V02134-00

V02148-2

V02110-00

S14015

V02107

V02108

E23063

V02034-00

V02090

V03059

V02091

M21117-2

M02017-1

V02111-00

V02113

V02047-00

S14051

V02012A

V02149

V02150

S14038

V03063

V03060

V03910

W10050

N11050

T54012

V03909

T95010

W10050

V03107

S54012

V02103

V02006-00

V02100-00

V03064

QTY

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

3

1

1

1

8

8

4

3

8

2

1

7

1

2

1

1

SPECIFICATION

4x12

PA

PVC

14 AWG X 3C X 10 M

ABS

110 V/1000/700 W

EVA FOAM

EVA FOAM

ABS

4 X 5

EVA FOAM

PP

PP

4 X 38

M5

4 X 12

SPCC

M5 X 10

SPCC

4 X 12

ABS

PP

ABS

SUS 304

Page 10

MODEL 10-315

10

Page 11

11

PARTS LIST

10-315

PART N0. REF. NO. DESCRIPTION SPECIFICATION QTY

10315-01 V03001-03 LID HANDLE PA 1

10315-02 V03002-01 LID ABS 1

10315-03 V03003 MUFFLER EVA FOAM 2

10315-04 V03004 LID GASKET PVC 2

10315-05 S14065 SCREW 4x65 8

10315-06 E23064 POWER CORD 12AWGX3CX7.5M 1

10315-07 T54012 SCREW 4x12 4

10315-08 V02108 STRAIN RELIEF PVC 1

10315-09 R01907-03 ACCESSORY RACK PA 1

10315-10 ACCESSORY RACK MOUNT PA 2

10315-14 E30002 SWITCH 2

10315-15 V03005-01A MIDDLE HOOD ABS 1

10315-16 FUSE CASE NUT 2

10315-17 S14065 SCREW 5x40 2

10315-18 S54020 SCREW 4x20 2

10315-19 WIRE AWG 16 2

10315-20 V03007 MUFFLER EVA FOAM 8

10315-21 V02134A MOTOR COVER GASKET EVA FOAM 2

10315-22 V02148 MOTOR COVER PA 2

10315-23 S54012 SCREW 4x12 2

10315-24 S55040 SCREW 4x16 2

10315-25 V02107 CORD CLAMP PA 1

10315-26 S53015 SCREW 3x15 2

10315-27 E11004 WIRE AWG 16 2

10315-28 E60019 WIRE CONNECTOR PA 1

10315-29 V03018-03 MOTOR MOUNT ABS 1

10315-30 V03009 GASKET EVA FOAM 2

10315-31 V03012 MUFFLER FOAM 2

10315-32 V02117 MOTOR BASE WASHER EVA FOAM 2

10315-33 M21210 TWO STAGE MOTOR 1000 W 2

10315-34 V03113 MOTOR BASE SBR 2

10315-35 V03020-03 PROTECTION PA 2

10315-36 V03019 MUFFLER FOAM 2

10315-37 V03013-03 FLAT SUPPORT PP 1

10315-38 VGH06 AIR CONCENTRATOR PP 1

10315-39 S54012 SCREW 4x16 3

10315-40 V02112-2 FLOAT WASHER EVA FOAM 1

10315-41 V03057 FLOAT PP 1

10315-42 V02150 FLOAT CAGE

(#10300-30)

PP 1

10315-43 S54015 SCREW 4x16 3

10315-44 V03063 CANISTER FILTER

(ITEM 10-332)

190x180 1

10315-45 V03060 CLOTH FILTER CAGE

(#10300-33)

1

10315-46 V03910 CLOTH FILTER BAG

(ITEM 10-334)

1

10315-47 W15013 WASHER 8

10315-48 N11050 CAP NUT

(#10300-36)

M5 3

10315-49 T96015 SCREW 4x12 4

10315-50 V03909 LID CLAMP ASS’Y

(#10300-38)

SPCC 3

10315-51 T95010 SCREW

(#10300-39)

M5x10 6

10315-52 T15012-1 WASHER 2

10315-53 V03107 CLAMP HOOK

(#10300-41)

SPCC 1

10315-54 T54015 SCREW 4x12 3

10315-55 V02103 AIR DEFLECTOR

(#10300-43)

ABS 1

10315-56 V03021 TANK HANDLE PP SPCE-1060 USE 2

10315-57 V02100-00 AIR INLET NOZZLE

(#10300-45)

ABS 1

10315-58 V03065 15GL TANK SUS304 SPCE-1060 USE 1

Page 12

12

PARTS LIST

STAND

PART N0.

10300-01A

10300-02A

10300-04A

10300-05A

10300-06A

10300-07A

10300-11A

10300-12A

10300-13A

10300-14A

10300-15A

10300-16A

10300-17A

10300-18A

10300-19A*

10315-19A*

10300-20A

10300-21A*

10300-22A

10300-23A

10300-24A

DESCRIPTION

CART HANDLE

HANDLE CONNECTOR

FIXTURE

CAP NUT

WASHER

SCREW

SHAFT BUSHING

WASHER

FIXED WHEEL

AXLE

WASHER

E-RING

CAP NUT

LOCK WASHER

BASE

(FOR 10-300)

BASE

(FOR 10-315)

CASTER

ACCESSORY STORAGE RACK

(ITEM 10-305)

LOCK WASHER

WASHER

LOCK WASHER

REFE. NO.

V03110

V03104

V03106

N11050

W15010

T15030

V03111

W10001

V03109

V03105

W10001

F10090

N21001

W10011

V03101

V03102

V03108

W20011

W10011

W20011

QTY

1

2

1

4

8

4

2

2

2

1

2

2

2

2

1

1

2

1

2

2

2

SPECIFICATION

M5

M5 X 30

S 45 C

1/2"

8"

S 45 C

1/2"

E9

3/8"UNC

3/8"

2 1/2"

(FOR 10-300 ONLY)

1/8”

1

2

5

6

4

7

20

19

17

22

18

23

24

11

12

13

14

15

16

21

*

*

STAND FOR #10-300 & 10-315

A

Page 13

13

ACCESSORIES FOR #10-300 & 10-315

B

Page 14

14

PARTS LIST

ACCESSORIES

PART N0.

10300-01B

10300-02B

10300-03B

10300-04B

10300-05B

10300-06B

10300-07B

10300-08B

10300-09B

10300-10B

10300-11B

10300-12B

10300-13B

10300-14B

10300-15B

10300-16B

10300-17B

10300-18B

10300-19B

10300-20B

10300-21B

10300-22B

10300-23B

10300-24B

10300-25B

10300-26B

10300-27B

10300-28B

10300-29B

10300-30B

10300-31B

10300-32B

10300-33B

10300-34B

10300-35B

10300-36B

10300-37B

10300-38B

10300-39B

10300-40B

DESCRIPTION

SCREW

BUTTON FIXTURE

BUTTON

BUTTON SPRING

FLEXIBLE HOSE HEAD

FLEXIBLE HOSE

(ITEM 10-306)

FLEXIBLE HOSE END

CURVED PIPE

EXTENSION WAND

(ITEM 10-309)

CREVICE NOZZLE

(ITEM 10-310)

ROUND BRUSH NOZZLE

ROUND BRUSH BASE

ROUND BRUSH RING

12” BRUSH NOZZLE

(ITEM 10-314)

ELBOW

ELBOW RING

NOZZLE

NOZZLE ROLLER SET

(INCLUDE#19/20/21)

ROLLER TIRE

NOZZLE ROLLER

ROLLER AXLE

BRUSH SET

PROFESSIONAL WET NOZZLE

(ITEM 10-323)

ELBOW

ELBOW RING

WET NOZZLE

RUBBER SCRAPER BASE

RUBBER SCRAPER

NOZZLE ROLLER SET

(INCLUDE#30/31/32)

ROLLER TIRE

NOZZLE ROLLER

ROLLER AXLE

SCRAPER HOLDER

SCREW

WET NOZZLE

ELBOW

NOZZLE

SCREW

FIXTURE

RUBBER SCRAPER

REFERENCE NO.

S24006

R02004-00

R02003-00

X00017

R02002-00

R02011-00

R02007-00

R02008-00

A-3-38

VCA-5

A-4-38

R02031-00

R02032-00

A-1-38

R02021-00

R03014-00

R02022-00

R01906

R02030

R02029

U44025

R02023

A-7-38

R02021-00

R03014-00

R02026

R02035

A-6-38

R03006

R02030

R02029

U44025

R02028

S54012

VCB-6-32

VCA-1-2-2

VCB-6-1

S13008

VCB-6-4

VCB-6-5

QTY

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

2

2

2

2

1

1

1

1

2

2

2

2

2

2

2

2

1

1

1

2

1

1

SPEC.

4 x 6

ABS

ABS

SWPA

ABS

38 x 2000

ABS

ABS

ABS

PP

ABS

PP &PA

ABS

ABS

PP

PVC

ABS

S 45 C

ABS & PA

ABS

ABS

PA

PVC

NBR

PVC

ABS

S 45 C

SPCC

4 X 12

ABS

ABS

3 X 8

ABS

PVC

*ALL ACCESSORIES ARE INTERCHANGEABLE FOR 10300 & 10-315

Page 15

15

NOTES

Page 16

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and part number. Also a brief description of each item and quantity

desired.

10-300 / 10-315

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

Tel.: (514) 326-1161

Fax : (514) 326-5555

Order desk

Fax : (514) 326-5565 Parts and service

orderdesk@general.ca

www.general.ca

Loading...

Loading...