Page 1

Data Sheet

October 2009

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Features

RoHS Compliant

Applications

n

Common-mode and differential-mode filtering of

power supply dc input and output lines

n

Distributed power architectures

n

Telecom

n

Datacom

n

Compatible with RoHS EU Directive 200295/EC

n

Compatible in Pb- free or SnPb reflow environment

n

Small size: 25.4 mm x 25.4 mm x 10.2 mm

(1.0 in. x 1.0 in. x 0.4 in.)

n

Optimized for use with high-frequency switching

dc-to-dc power modules

n

Printed-circuit board mountable

n

Operating case temperature range:

–40 °C to +100 °C

Options

n

Choice of pin lengths

Description

The FLTR75V05 Filter Module is designed to reduce the conducted common-mode and differential-mode noise

on input or output lines of high-frequency switching power supplies. The module has a maximum current rating

of 5 A. It provides high insertion loss throughout the frequency range regulated by the U.S. Federal Communications Commission (FCC) and the International Special Committee on Radio Interference (CISPR) for conducted emissions.

The module is 25.4 mm long, 25.4 mm wide, and 10.2 mm high (1.0 in. x 1.0 in. x 0.4 in.) and mounts on a PC

board in a natural convection or forced-air environment.

Page 2

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Data Sheet

October 2009

Introduction

High-density power modules are usually designed to operate at a high switching frequency to reduce the size of

the internal filter components. The small EMI filters internal to the modules are often inadequate to meet stringent

international EMI requirements. Many high-density electronic packaging techniques can increase the noise conducted onto the modules’ input and output lines. For example, the close proximity of switching components to the

input pins increases internal noise coupling; and planar transformers, designed to handle high-power levels in lowprofile packages, have high interwinding capacitance that can increase common-mode current levels. Also, metal

substrates used to facilitate heat transfer from the power train components to an external heat sink add to common-mode noise because of the large capacitance between switching components and the metal substrate.

Many international agencies specify conducted and radiated emissions limits for electronic products. Included

among these are CISPR, FCC, VCCI, and the new CE specifications. Most agency-conducted noise limits apply

only to noise currents induced onto the ac power lines in finished products. European Telecommunication Standard

Instructions (ETSI) are an exception, applying CE requirements to dc supplies with cables over three meters long.

Although not required to do so by agency standards, some system designers apply the conducted emissions

requirements to subassemblies within the product to reduce internal interference between subsystems and to

reduce the difficulty of meeting overall system requirements.

To meet these requirements, external filtering of the power module is often required. When used in conjunction with

the recommended external components and layout, the Lineage Power filter module will significantly reduce the

conducted differential and common-mode noise returned to the power source. CISPR and FCC class B requirements can be met by using the filter as described in the following sections.

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the operations sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Input Voltage:

Continuous

Transient (100 ms)

Voltage from GND to Either Input Lead — — 1500 Vdc

Operating Case Temperature T

Storage Temperature T

I

V

VI, trans

C –40 100 °C

stg –55 125 °C

—

—

75

100

Vdc

V

2 Lineage Power

Page 3

Data Sheet

October 2009

75 Vdc Input Maximum, 5 A Maximum

FLTR75V05 Filter Module

Electrical Specifications

Unless otherwise indicated, specifications apply over all operating input voltage and temperature conditions.

Parameter Symbol Min Typ Max Unit

Resistance per Leg R — — 20 mΩ

Maximum Average Current

(T

A = 60 °C, 2.03 m/s (400 lfm) air)

Maximum Average Current

A = 60 °C, natural convection)

(T

Common-mode Insertion Loss

(50 Ω circuit, 500 kHz)

Differential-mode Insertion Loss

(50 Ω circuit, 500 kHz)

I

max —— 5 A

I

max ——3.3A

——28—dB

——25—dB

Lineage Power 3

Page 4

FLTR75V05 Filter Module

6

75 Vdc Input Maximum, 5 A Maximum

Data Sheet

October 2009

Characteristics

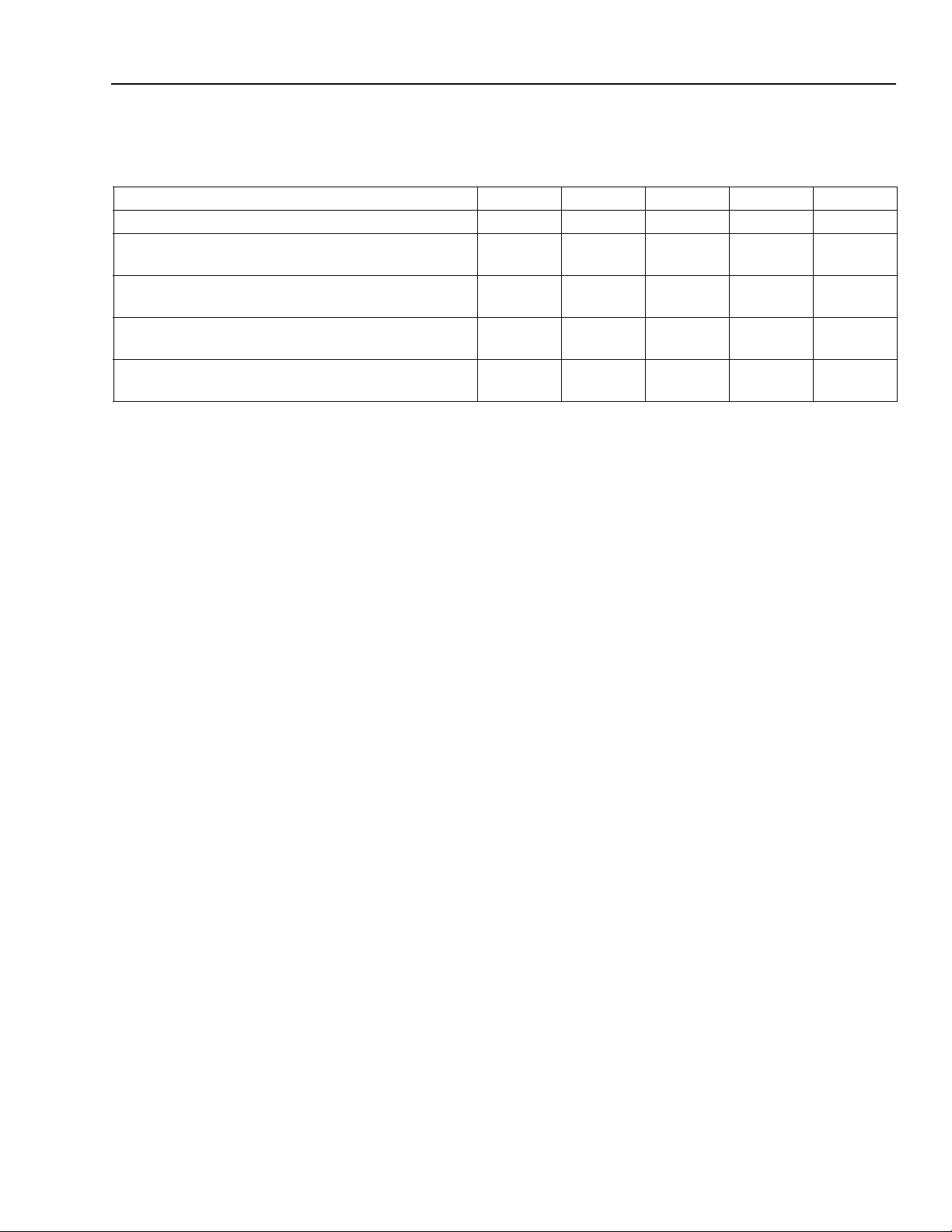

30

0 m/s (0 ft./min.)

20

10

RISE, ΔT (˚C)

TEMPERATURE

0

12345

Figure 1. Typical Case Temperature Rise vs.

0

-10

-20

-30

-40

-50

-60

COMMON MODE

-70

INSERTION LOSS (dB)

-80

10E+3 100E+3 1E+6 10E+6 100E+6

1.0 m/s (200 ft./min.)

2.0 m/s (400 ft./min.)

CURRENT (A)

Average Current (Case Temperature

Must Be Kept Below 100 °C)

FREQUENCY (Hz)

1-0352

20

10

0

-10

-20

-30

-40

-50

-60

DIFFERENTIAL MODE

INSERTION LOSS (dB)

-70

10E+3 100E+3 1E+6 10E+6 100E+

FREQUENCY (Hz)

1-0319

Figure 3. Typical Differential-Mode Insertion Loss

in a 50 Ω Circuit

Internal Schematics

IN

GND

OUT

8-1324 (F).b

1-0320

Figure 4. Internal Schematic

Figure 2. Typical Common-Mode Insertion Loss in

a 50 Ω Circuit

44 Lineage Power

Page 5

Data Sheet

October 2

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Application

Conducted noise on the input power lines can occur as

either differential-mode or common-mode noise currents. Differential-mode noise is measured between the

two input lines, and is found mostly at the lowfrequency end of the spectrum. This noise shows up as

noise at the fundamental switching frequency and its

harmonics. Common-mode noise is measured

between the input lines and ground and is mostly

broadband noise above 10 MHz. The high-frequency

nature of common-mode noise is mostly due to the

high-speed switching transitions of power train components. Either or both types of noise may be covered in

a specification, as well as a combination of the two. An

approved measurement technique is often described,

as well.

Differential-mode noise is best attenuated using a filter

composed of line-to-line capacitors (X caps) and series

inductance, provided by either a discrete inductor or

the leakage inductance of a common-mode choke. In

addition to the differential filtering provided by the filter

module, it is recommended that an electrolytic capacitor be located at the converter side of the filter to provide additional attenuation of low-frequency differential

noise and to provide a low source impedance for the

converter, preventing input filter oscillations and loadtransient induced input voltage dips.

Common-mode noise is best attenuated by capacitors

from power module input to power module output,

capacitors from each input line to a shield plane

(Y caps), and common-mode chokes. It is recommended that ceramic capacitors be added around each

power module from each input and output pin to a

shield plane under the module. The shield plane should

be connected to the CASE pin.

The GND pin of the filter module is attached to Y caps

within the module. This pin should be tied to a quiet

chassis ground point away from the power modules.

GND of the filter module should not be tied to the

CASE pin of the power module since this is a noisy

node and will inject noise into the filter, increasing the

input common-mode noise.

If no quiet grounding point is available, it is best to

leave the filter module GND pin unattached. Each

power system design will be different, and some experimentation may be necessary to arrive at the best configuration.

Figure 5 shows a typical schematic of a power module

with filter module and recommended external components. Figure 6 is a proposed layout. More than one

power module may be attached to a single filter module

as long as input current does not exceed 5 A. Figure 7

shows the recommended schematic for two power

modules attached to a single filter.

In applications where the addition of input to output

capacitors is undesirable, do not use C3 and C4 shown

in Figures 5 and 6, and do not use C3, C4, C8, and C9

shown in Figure 7.

In –48 V applications where the shield plane and the

power module case must be tied to a signal, remove

C1 in Figures 5 and 6, remove C1 and C6 in Figure 7,

and connect the shield plane and CASE pin to the V

plane.

In +48 V applications where the shield plane and the

power module case must be tied to a signal, remove

C2 in Figures 5 and 6, remove C2 and C7 in Figure 7,

and connect the shield plane and CASE pin to the V

plane.

I(+)

I(–)

Lineage Power 5

Page 6

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Application (continued)

Data Sheet

October 2009

SHIELD PLANE

C1

Vdc INPUT(–)

CHASSIS GROUND

Vdc INPUT(+)

Note: C1 through C4 can be 0.01 µF to 0.1 µF. Select the voltage rating to meet input-to-output isolation requirements. C5 should be the

recommended value indicated in the power module data sheet.

VI(–)

GND

VI(+)

MODULE

FILTER

V

V

O(–)

C5

O(+)

VI(–)

V

I(+)

C2

CASE

POWER MODULE

C3 C4

O(–)

V

V

O(+)

8-1325 (F).b

Figure 5. Recommended Schematic When Used as the Input Filter to a High-Frequency dc-to-dc Converter

C1

POWER

MODULE

C4

FILTER

MODULE

V

I(+)

Vdc INPUT(+)

Vdc INPUT(–)

CHASSIS

GROUND

Note: Vdc input(+) and Vdc input(–) planes should overlay each other, as should the VI(+) and VI(–) planes, as should the VO(+) and VO(–)

planes. Avoid routing signals or planes under the power module or the filter module. Ensure all connections are low impedance.

C5

I(–)

V

CASE

C2

SHIELD

PLANE

C3

V

O(+)

V

O(–)

1-0118

Figure 6. Recommended Layout When Used as the Input Filter to a High-Frequency dc-to-dc Converter

6 Lineage Power

Page 7

Data Sheet

October 2009

Application (continued)

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

SHIELD PLANE

C6

C1

VI2(–)

I2(+)

V

V

I1(–)

C7

CASE 2

POWER MODULE 2

SHIELD PLANE

C2

CASE 1

C8 C9

V

O2(–)

O2(+)

V

C3 C4

V

O1(–)

Vdc INPUT(–)

CHASSIS GROUND

Vdc INPUT(+)

Note: C1 through C4 and C6 through C9 can be 0.01 µF to 0.1 µF. Select the voltage rating to meet input-to-output isolation requirements.

C5 should be the recommended value indicated in the power module data sheet.

V

I(–)

GND

I(+)

V

MODULE

FILTER

V

O(–)

VO(+)

C5

VI1(+)

POWER MODULE 1

V

O1(+)

8-1362 (F).a

Figure 7. Recommended Schematic of Filter Module with Two Power Modules

Lineage Power 7

Page 8

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Data Sheet

October 2009

Application (continued)

Figures 9, 10 & 11 show some experimental results for

various Lineage Power modules obtained by using the filter module, together with the recommended external

components shown in Figures 5 and 6. Measured

noise is highly dependent on layout, grounding, cable

orientation, and load characteristics and will, vary from

application to application.

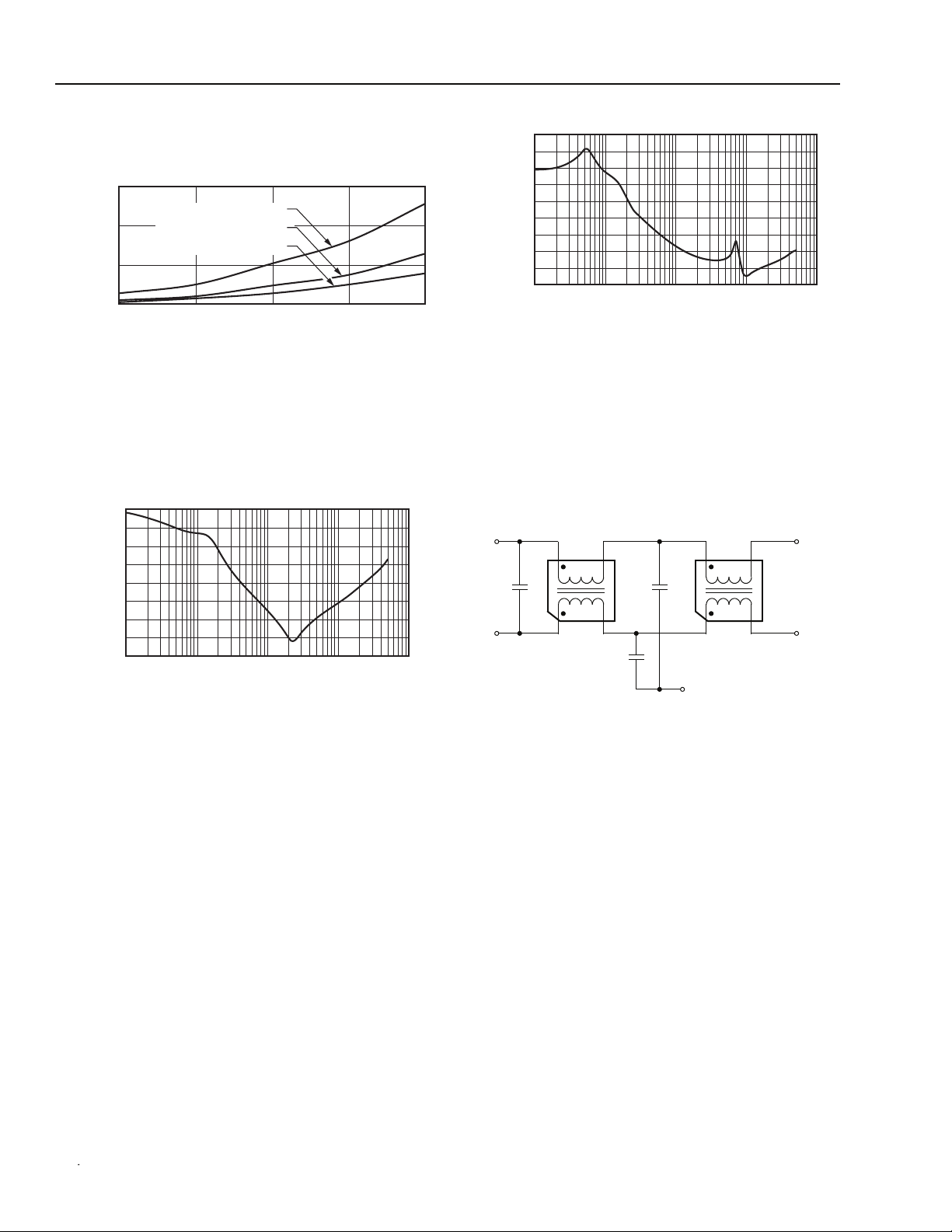

Thermal Considerations

The case temperature must be kept below 100 °C. The

case temperature (T

tion indicated in Figure 8. Therefore, for a particular

current and ambient temperature, the airflow at the filter must be adequate.

Example:

Given: I

Therefore ΔT

O, max = 4 A; TA, max = 95 °C

, max allowable = 5 °C

Determine airflow required (Figure 1): v = 2.0 m/s

(400lfm)

VI(-)

GND

I(+)

V

Note: Top view, pin locations are for reference only. Measurements

are shown in millimeters and (inches).

Figure 8. Case Temperature Measurement

Location

C) should be measured at the posi-

V

O(-)

O(+)

V

6.1

(0.24)

MEASURE CASE

TEMPERATURE HERE

12.7

(0.5)

1-0146

Other Considerations

It is essential for good EMI performance that the input

lines not be contaminated with noise after passing

through the filter. Filtered input traces should therefore

be kept away from noise sources such as power modules and switching logic lines. If input voltage sense

traces must be routed past the power modules from the

quiet side of the filter module, they should be filtered at

the point where they leave the quiet input lines. Input

traces should be kept as far away from output power

traces as possible.

The fundamental switching frequency noise spike can

be somewhat reduced by adding a high-frequency

capacitor of a few microfarads across the input lines of

the filter module.

Adding additional components to the input filter to

improve performance usually has very limited payback,

and may actually increase the noise conducted onto

the input lines. Adding Y caps to the input side of the filter module couples any noise in the ground plane

directly into the input lines, usually degrading performance. Adding additional X and Y caps to the power

module side of the filter module produces lowimpedance loops for high-frequency currents to flow,

possibly degrading performance.

Adding additional common-mode or differential-mode

filtering to the power module output leads decreases

the power module output noise, and also frequently

reduces the input noise by decreasing the noise coupled from output leads to input leads. Common-mode

output filtering is particularly important if the load is tied

to chassis ground. If common-mode filtering is added

to the power module output, ensure that remote-sense

leads sense the output voltage before the commonmode filter. Do not use remote-sense on the load side

of an output common-mode filter.

If input noise performance is unsatisfactory after applying the filter module as described previously, the best

remedy is to modify the layout and grounding scheme.

It is often useful to make a model of the power card,

using copper tape and a vector card, to experiment

with various layout and grounding approaches prior to

committing to a printed-wiring board.

88 Lineage Power

Page 9

Data Sheet

October 2009

Other Considerations (continued)

80

70

60

50

40

30

20

LEVEL (dBµV)

10

0

0.15 0.50 1 2 3 4 5 7 10 30

FREQUENCY (MHz)

Figure 9. HW050FG Conducted Noise with Filter

Compared to Class B Limits

80

70

60

50

40

30

20

LEVEL (dBµV)

10

0

0.15 0.50 1 2 3 4 5 7 10 30

FREQUENCY (MHz)

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

1-0321

1-0322

Figure 10.JAW075A1 Conducted Noise with Filter

Compared to Class B Limits

90

80

70

60

50

40

30

20

LEVEL (dBµV)

10

0

0.15 0.50 1 2 3 4 5 7 10 30

FREQUENCY (MHz)

1-0323

Figure 11.QHW100F1 Conducted Noise with Filter

Compared to Class B Limits

Lineage Power 9

Page 10

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

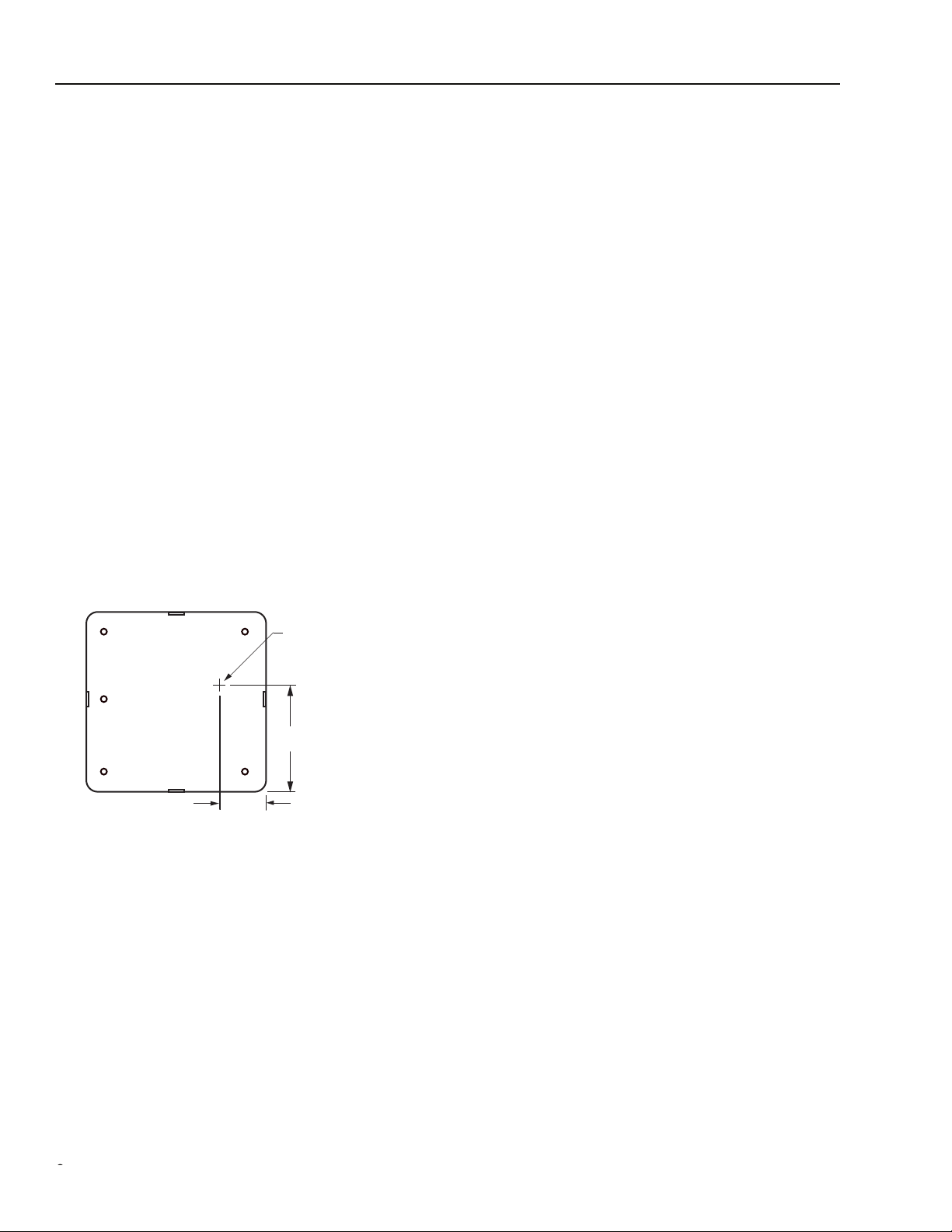

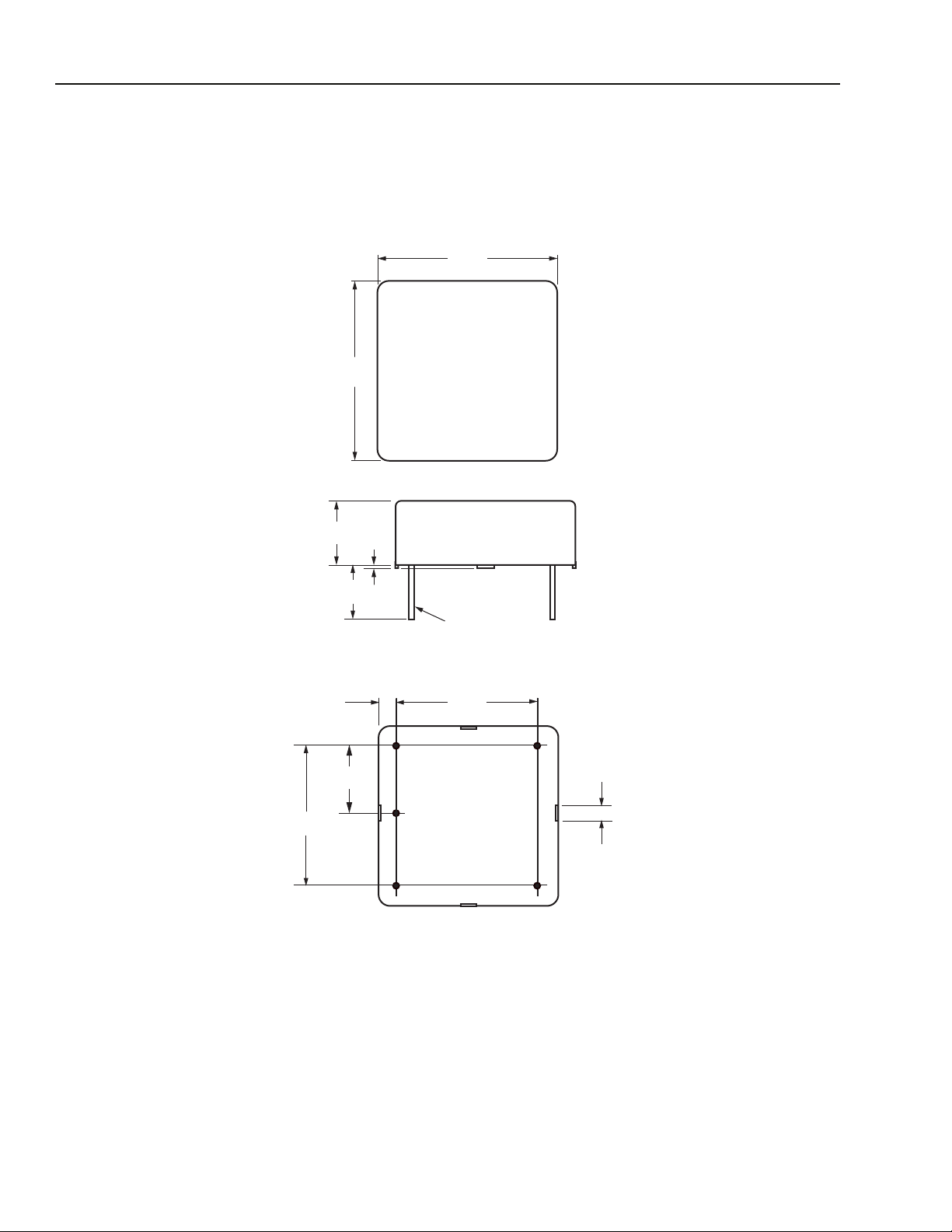

Outline Diagram

Dimensions are in millimeters and (inches).

Tolerances: x.xx ± 0.50 mm (0.02 in.), x.xxx ± 0.250 mm (0.010 in.).

Top View

25.40

(1.000)

25.40

(1.000)

Side View

Data Sheet

October 2009

Bottom View

(0.385)

2.8

(0.11)

19.81

(0.780)

9.78

0.38

(0.015)

8.3 (min)

(0.325 min)

9.91

(0.390)

1.02 (0.040) DIA

SOLDER-PLATED

BRASS, 5 PLACES

19.81

(0.780)

VI(+)

GND

I(-)

V

V

O(+)

V

O(-)

2.03 (0.08

STANDOFFS,

4 PLACES

1-0119

10 Lineage Power

Page 11

Data Sheet

October 2009

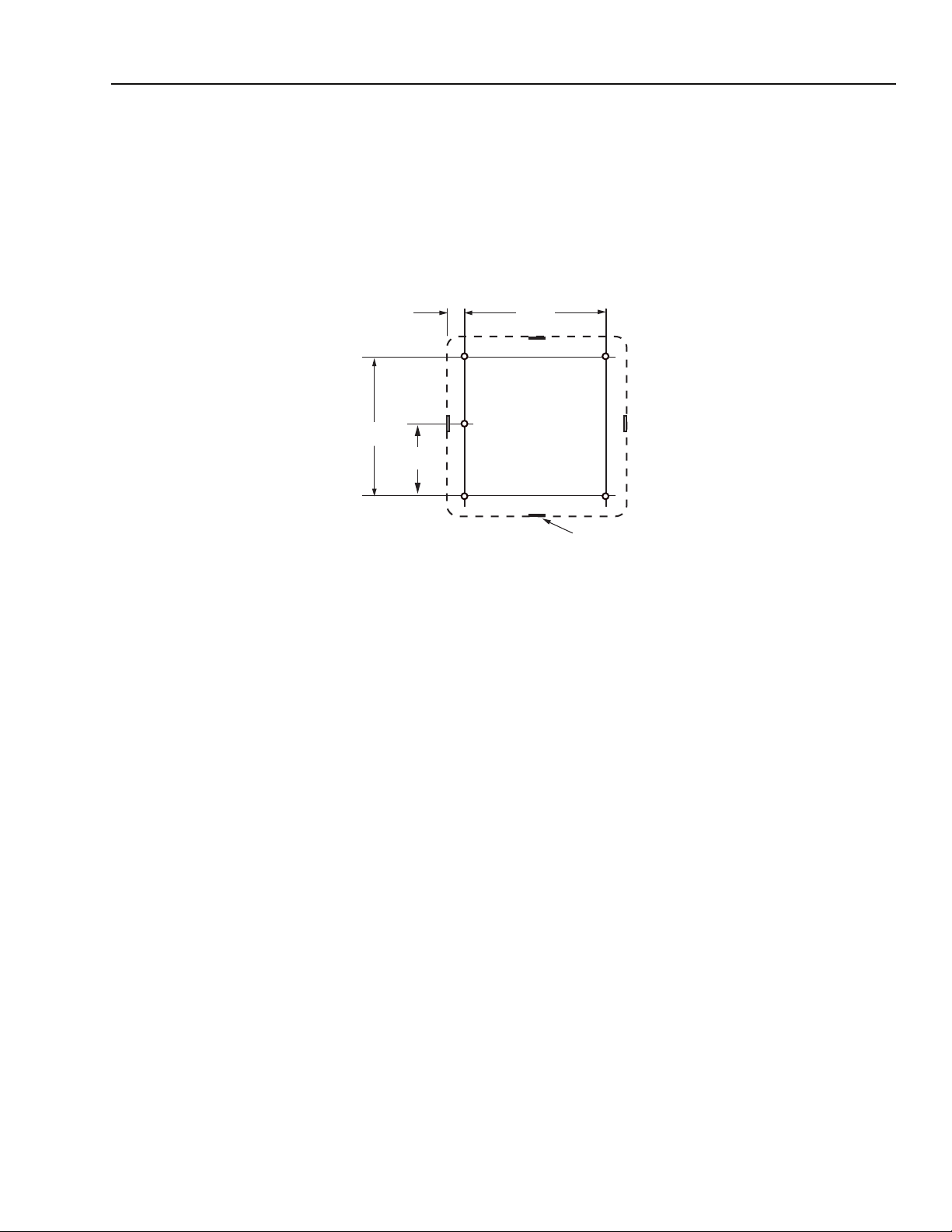

Recommended Hole Pattern

Component-side footprint.

Dimensions are in millimeters and (inches).

Tolerances: x.xx ± 0.50 mm (0.02 in.), x.xxx ± 0.250 mm (0.010 in.).

Note: Do not route copper paths beneath power module standoffs.

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

2.8

(0.11)

19.81

(0.780)

9.91

(0.390)

VI(-)

GND

I(+)

V

19.81

(0.780)

V

O(-)

O(+)

V

STANDOFFS,

4 PLACES

1-0119

Lineage Power 11

Page 12

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Post Solder Cleaning and Drying Consideratrions

Post solder cleaning is usually the final circuit-board

assembly process prior to electrical board testing.The

result of inadequate cleaning and drying can affect

both the reliability of a power module and the testability

of the finished circuit-board assembly.For guidance on

appropriate soldering,cleaning and drying procedures,refer to

Modules:Soldering and Cleaning Application Note.

Lineage Power Board Mounted Power

Through-Hole Lead Free Soldering Information

The RoHS-compliant through-Hole products use the

SAC(Sn/Ag/Cu) Pb-free solder and RoHS- compliant

components.They are designed to be processed

through single or dual wave soldering machines.The

pins have an RoHS-compliant finish that is compatible

with both Pb and Pb-free wave soldering processes.A

Maximum preheat rate 3

preheat process should be such that the temperature

of the power module board is kept below 210

solder,the recommended pot temperature is

0

C,while the Pb-free solder pot is 2700C max.Not

260

all RoHS-compliant through-hole products can be processed with paste-through-hole Pb or Pb-free reflow

process.If additional information is needed,please consult with your Lineage Power representative for more details.

0

C/s is suggested.The wave

0

C.For Pb

Data Sheet

October 2009

12 Lineage Power

Page 13

FLTR75V05 Filter Module

75 Vdc Input Maximum, 5 A Maximum

Data Sheet

October 2009

Ordering Information

Please contact your Lineage Power Account Manager or Field Application Engineer for pricing and availability.

Table 1. Device Codes

Device Code Comcode

FLTR75V05 108900739

FLTR75V05Z CC109102654

FLTR75V058Z CC109310818

FLTR75V605Z CC109101433

FLTR75V055Z CC109128237

Optional features may be ordered using the suffixes shown in the Table below.

Option Codes

Option Device Code Suffix

ort pins: 2.79 mm (+0.38 mm/ –0.25 mm)

Sh

(0.110 in. (+0.015 in./ –0.010 in.))

Sh

ort pins: 3.68 mm (+0.38 mm/ –0.25 mm)

(0.145 in. (+0.015 in./ –0.010 in.))

Short pins: 4.57 mm (+0.38 mm/ –0.25 mm)

(0.180 in. (+0.015 in./ –0.010 in.))

Compliant

RoHS

8

6

5

Z

Asia-P acific Head qu arters

Tel: +65 6 41 6 42 83

Eu ro pe, M id dle-East an d Afr ic a He adquar ters

World W i de Headq u arter s

Lineag e Power Corpor ation

Shiloh Roa d, Pla no , TX 75 074, U SA

601

Tyco Electronics Power Systems, Inc.

+1-800-526-781 9

Skyline Drive, Mesquite, TX 75149, USA

3000

(Outs id e U .S.A .: +1- 972-244 -942 8)

-800-526-7819 FAX: +1-888-315-5182

+1

www.l ine agep owe r .co m

utside U.S.A.: +1-972-284-2626, FAX: +1-972-284-2900)

(O

e-m ail: tec h support1 @ lineagep ower .co m

http://power.tycoelectronics.com

Lineage Power reserves the right to ma ke cha nges to the pro duct(s) or in forma tion co ntain ed herein witho ut notice. No liab ility is a ssume d as a res ult of the ir use or

Tyco Electronics Corporation reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application.

ap

plication. No ri ghts und er any pa tent a ccomp any the sale o f any s uch pr oduct(s) o r info rmation.

No rights under any patent accompany the sale of any such product(s) or information.

Lineage Power DC-DC Products are protected under various patents. Information on these patents is available at www.lineagepower.com/patents

© 2001 Tyco Electronics Corporation Power Systems, Inc., (Mesquite, Texas) All International Rights Reserved.

Printed in U.S.A.

© 2008 Line age Power Co rporation, (P la no , Texas) Al l Inte rnatio nal R ights Res erved.

October 2009

ADS01-0

52EPS (Replaces ADS01-051EPS)

Tel: +49 898 780 672 80

Ind ia Head qu arter s

Tel: +91 8 0 2841 1633

Loading...

Loading...