Page 1

Data Sheet

July 14, 2010

Features

Applications

Options

Description

75Vdc Input Voltage Maximum; 7A Output Current Maximum

FLT007A0Z/FLT007A0-SRZ Input Fi lter Modules

Distributed power architectures

Intermediat e bus voltage applications

Telecommunications equipment

Wireless Base stations

Enterprise Networks

Industrial equipment

Surface Mount Interconnect (-SR)

Compliant to RoHS EU Directive 2002/95/EC (Z

versions)

Compatible in a Pb-free or SnPb reflow environment

(Z versions)

Surface Mount and Through hole vers ions

Common-mode and Differential-mod e filtering

Small size and low profile

25.4 mm x 25.4 mm x 12.2 mm

(1 x 1 x 0.48 in)

Same footprint as FLTR75V5 module

Cost efficient open frame design

Wide operating temperature range (-40°C to +85°C)

Meets the voltage isolation requirements for

ETSI 300-132-2 and complies with and is licensed

for Basic Insulation rating per E N 60950-1

UL* 60950-1 Recognized, CSA

03 Certified, and VDE

Licensed

CE mark meets 73/23/EEC and 93/68/EEC

directives

ISO** 9001 and ISO 14001 certified manufacturing

facilities

§

‡

0805:2001-12 (EN60950-1)

†

C22.2 No. 60950-1-

The FLT007A0Z,FLT007A0-SRZ filter module is designed to oper ate over an input voltage range up to 75Vdc at

output currents up to 7A in an ambient temperatur e of -40ºC to 85ºC. The filter module is optimi zed for use with

dc/dc converter modules, to s ignificantly reduce th e conducted d ifferential and common-mode noise returned to the

power source. This filter module enables designers to meet the requirements of EMI standards CISPR 22

(EN55022) and FCC Class B by insertion in-line bet ween the power sour ce and the dc/d c converter modul e. These

modules are designed and manufactured t o be either surface mounted (-SR version) or through hole mounte d on

PCBs.

* UL is a registered trademark of Underwriters Laboratories, Inc.

†

CSA is a registered trademark of Canadian Standards Association.

‡

VDE is a trademark of Verband Deutscher Elektrotechniker e.V.

** ISO is a registered trademark of the International Organization of Standards

Document No:DS05-028 ver 1.26

PDF name: FLT007A0Z.pdf

Page 2

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Absolute Maximum Ratings

Stresses in excess of the absolute ma ximum ratings can cause permanent damage to the device. These are

absolute stress ratings only, functional operation of the device is not implied at these or any other conditions in

excess of those given in the operations s ections of the data sheet. Exposure t o absolute maximum ratings for

extended periods can adversely affec t the device reliability.

Parameter Device Symbol Min Max Unit

Input Voltage

Continuous All V

Operating Ambient Temperature All T

(see Thermal Considerations section)

Storage Temperature All T

I/O to Ground Isolation (100% Factory Tested) All

IN

A

stg

−

0 100 Vdc

-40 85 °C

-55 125 °C

−

1500 Vdc

Electrical Specifications

Unless otherwise indicated, specifications apply over all operat ing input voltage, resistive load, and temperature

conditions.

Parameter Device Symbol Min Typ Max Unit

Operating Input Voltage All VIN 0 24/48 75 Vdc

Maximum Input-to-Output Current

(VIN= 0 to V

Resistance per leg All R

) All I

iN,max

max

7 Adc

25

mΩ

CAUTION: This power module is not internally fused. An input line fuse must always be used.

This power module can be used in a wid e variety of applications, ranging from simple standalone operation to an

integrated part of sophisticate d power architecture. To preserve maximum flexibility, internal fusing is not included,

however, to achieve maximum safety and system protection, always use an input line fuse. The safety agencies

require a fast-acting fuse with a maximum rating of 10 A (see Safety Considerations section). Based on the

information provided in this dat a s heet on inrush energy and maximum dc input current, the same type of fuse with a

lower rating can be used. Refer to the fuse manufacturer’s data sheet for further information.

LINEAGE POWER 2

Page 3

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

dB

dB

dB

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Insertion Loss Tables

Parameter Device Symbol Min Typ Max Unit

Common-mode Insertion Loss

50Ω circuit, 500kHz

50Ω circuit, 1MHz

50Ω circuit, 10MHz

Differential-mode Insertion Loss

50Ω circuit, 500kHz

50Ω circuit, 1MHz

50Ω circuit, 10MHz

All

All

All

All

All

All

44 50 dB

54 60

44 50

44 50

60 66

40 46

General Specifications

Parameter Min Typ Max Unit

Calculated MTBF (VIN= V

Telecordia SR 332 Issue 1: Method 1, case 3

Weight

IN, nom

, IO= 0.8I

, TA=40°C)

O, max

22,576,100 Hours

7.8 (0.275)

g (oz.)

dB

dB

LINEAGE POWER 3

Page 4

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

-80

-70

-60

-50

-40

-30

-20

-10

0

0.01 0.1 1 10 100

15Name = 4488 15Name = 4488

INPUT OUTPUT

GROUND

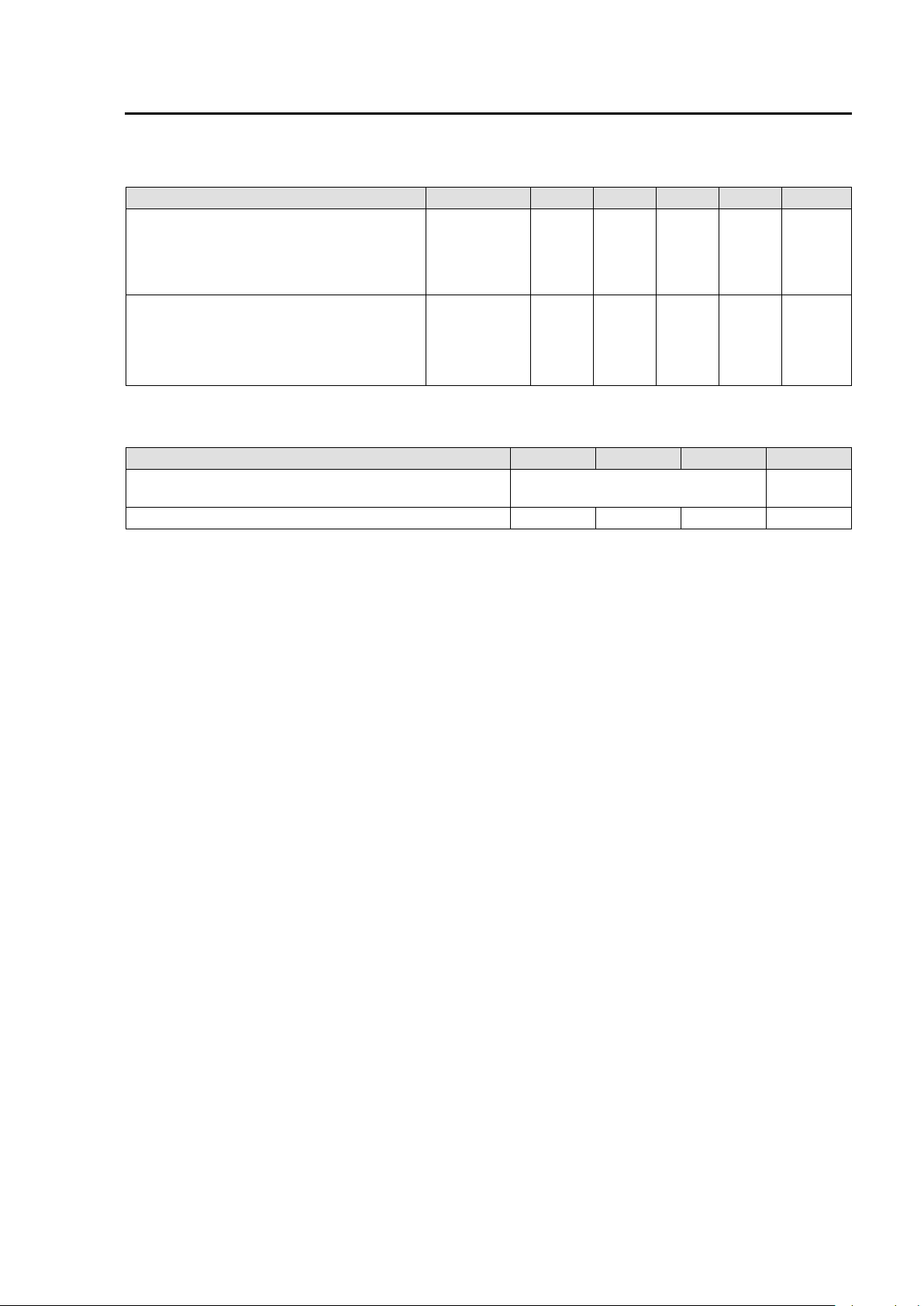

Figure 1. Typical Common-Mode Insertion Loss in a

Figure 4. Internal Schematic

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

0.01 0.1 1 10 100

FREQUENCY (MHz)

4

5

6

7

8

20 30 40 50 60 70 80 90

NC

0.5m/s ( 100LFM)

1m/s (200LFM)

2m/s (400LFM)

AMBIENT TEMPERATURE, TA OC

Figure 3. Derating Output Current versus Local

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Characteristic Curves

The following figures provide typical characteristics for the FLT007A0Z/FLT007A0-SRZ Module.

INSERTION LOSS (dB)

FREQUENCY (MHz)

50Ω circuit.

INSERTION LOSS (dB)

Figure 2. Typical Differential-Mode Insertion Loss in a

50Ω circuit.

OUTPUT CURRENT, Io (A)

Ambient Temperature and Airflow.

LINEAGE POWER 4

Page 5

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

DC/DC

CONVERTER

MODULE

VI(-)

VI(+)

VO(-)

VO(+)

C1

C2

C3

CHASSI S GR OU N D

FI LTER

MODULE

VI(+)

VI(-)

Figure 5. Schematic diagram showing

modules.

C2

Load

FLT007A0

MODULE

DC/DC

CONVERTER

VO+ PLANE

V

O

−

PLANE

C3

C1

VI+

VO+

VO−

VI−

VIN−

VO−

VIN+

GND

VIN+

VIN−

CHASSIS

GROUND

Input

VO+

Figure 6. Diagram showing recommended

open-frame DC/DC converter modules.

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Application Guidelines

Conducted noise on the input po wer lines can occur

as either differential-mode or common-m ode noise

currents. Differential-mode nois e is measured

between the two input lines, and is found mostly at

the low frequency end of the spectrum. This noise

shows up as noise at the fundamental switching

frequency and its harmonics. Common-mode noise is

measured between the input lines and ground and is

mostly broadband noise above 10 MHz. The highfrequency nature of common-mode noi s e i s mostly

due to the high-speed switching transitions of power

train components. Either or both types of noise may

be covered in a specification, as well as a

combination of the two.

Differential-mode noise is best at tenuated using a

filter composed of line-to-line capacit or s (X caps) and

series inductance, provided by either a discrete

inductor or the leakage inductance of a c ommonmode choke. In addition to the differ ential filtering

provided by the filter module, it is recommended that

an electrolytic capacitor be located at the converter

side of the filter to provide additi onal attenuation of

low-frequency differential noise and t o provide a low

source impedance for the converter, preventing input

filter oscillations and load transient induced input

voltage dips.

Open-frame DC/DC converter modules and the older

metal-cased DC/DC converter modules require

slightly different filtering arra ngements. The

FLT007A0Z series of modules are optimi zed for the

newer open-frame series of modules, but can also be

used with older metal-case modules. The main

differences in filtering recommendations between the

two types of modules are in common-mode filtering,

as explained below.

Filtering Open-Frame DC/DC

Converter Modules

For filtering open-frame DC/DC converter modules,

the recommended circuit is sho wn in Fig. 5. In

addition to the input electrolytic filter capacitor C1

(recommended value is a minimum of 100uF and

approximately 1uF/W at power levels above 100W),

common-mode filtering capacitors C2 and C3 should

be connected between the input and out puts as

shown. Suitable values for common-mode capacitors

C2 and C3 are in the range between 1000pF to 0.1µF

are usually indicated in the DC/DC converter data

sheet. These capacitors need to be r ated for the

isolation voltage desired

sides of the DC/DC converter module. The

recommended power layout of the modul es showing

where the two common-mode c apac i tors are to be

placed is shown in Fig. 6.

between the input and output

recommended connection of the FLT007A0Z

filter module with open-frame DC/DC converter

layout of the FLT007A0Z filter module with

Filtering Metal-Case DC/DC Converter

Modules

For metal-case DC/DC converter modules with a case

pin, a different filtering arrang em ent and layout is

recommended. Figure 7 shows the schem atic

diagram of the recommended circuit. The main

difference with open-frame module is the use of an

isolated shield plane located underneath the module

which is connected through capac i tors C2 through C5

to the input and output connections of the module.

The shield plane along with the case of t he module

serves as a Faraday shield helping reduce EMI. The

corresponding layout for metal-case modules is

shown in Fig. 8.

LINEAGE POWER 5

Page 6

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

CHASSI S GR OU N D

VI(+)

VI(-)

VO(+)

VO(-)

CASE

DC/DC

CONVERTER

MODULE

C1

FI LTER

MODULE

VI(+)

VI(-)

C3

C2

C4

C5

SHIELD PLANE

modules.

C2

Load

FLT007A0

MODULE

DC/DC

CONVERTER

C3

C1

VI+

VO+

V

O

−

VI−

CASE

C5

C4

SHIELD

PLANE

VIN+

VO+

VIN−

VO−

VIN+

VIN−

CHASSIS

GROUND

Input

GND

Figure 8. Diagram showing recommended

metal-case DC/DC converter modules.

0

10

20

30

40

50

60

70

80

Level [ dBµV]

150k 300k 500k 1M 2M 3M4M5M7M10M 30M

Frequenc y [ Hz]

Figure 9. Experimental results showing

module with a QBE025A0B1 DC/DC converter.

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Figure 7. . Schematic diagram showing

recommended connection of the FLT007A0Z

filter module with metal-cased DC/DC converter

conducted EMI measured using a FLT007A0Z

layout of the FLT007A0Z filter module with

Example Data Showing Results using

the FLT007A0Z Modules

Figure 9 shows example results obtained using a

QBE025A0B1 DC/DC converter module with the

FLT007A0Z filter module. The QBE025A0B1 module

is operated at an input voltage of 43.2V and output

loading corresponding to an input current of 6.2A, a

level close to the 7A capability of the F LT007A0Z filter

module. A 10nF ceramic capacitor was connected

between Vin(-) and Vo(-) and a 4700pF ceramic

capacitor between Vin(+) and Vo(+). The results show

that the filter module is capable of m eeting EN55022

Class B limits with sufficient margin.

LINEAGE POWER 6

Page 7

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

Air

flow

x

Power Module

Wind Tunnel

PWBs

12.7_

(0.50)

76.2_

(3.0)

Probe Location

for measuring

airflow and

ambient

temperature

25.4_

(1.0)

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Thermal Considerations

Power modules operate in a variety of thermal

environments; however, suffici ent cooling should

always be provided to help ensure reliable operation.

Considerations include ambie nt temperature, airflow,

module power dissipation, and t he need for increased

reliability. A reduction in the operating temperature of

the module will result in an increase in reliability. The

thermal data presented here is based on physical

measurements taken in a wind tunnel. The test setup is shown in Fig. 10. Note that the airflow is parallel

to the long axis of the module as shown in Fig. 10.

Figure 11. T

location.

Temperature measurement

ref

Figure 10. Thermal Test Set-up.

The thermal reference point, T

specifications is shown in Figure 11. For reliable

operation this temperature shoul d not exceed 125oC.

The output power of the module should not exceed

the rated output current of the module.

Please refer to the Application Note “Thermal

Characterization Process For Open-Frame BoardMounted Power Modules” for a detailed discussion of

thermal aspects including maximum device

temperatures.

LINEAGE POWER 7

used in the

ref

Page 8

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

Figure 12. Pick and Place Location.

Pick and

Location

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Post solder Cleaning and Drying

Considerations

Post solder cleaning is usually t he final circuit-board

assembly process prior to elect r i c al board testing. The

result of inadequate cleaning and drying can affect

both the reliability of a power modu le and the

testability of the finished circu i t-board assembly. For

guidance on appropriate soldering, cleaning and

drying procedures, refer to Lineag e Power Board

Mounted Power Modules: Soldering and Cleaning

Application Note.

Through-Hole Lead-Free Soldering Information

The RoHS-compliant through-hole products use the

SAC (Sn/Ag/Cu) Pb-free solder and RoHS-compliant

components. They are designed to be processed

through single or dual wave soldering machines. The

pins have an RoHS-compliant fini s h that is compatible

with both Pb and Pb-free wave soldering processes.

A maximum preheat rate of 3°C/s is suggested. The

wave preheat process should be such that the

temperature of the power module board is kept below

210°C. For Pb solder, the recommended pot

temperature is 260°C, while the Pb-free s older pot is

270°C max. Not all RoHS-compliant through-hole

products can be processed with paste-through-hole

Pb or Pb-free reflow process. If additional information

is needed, please consult with your Lin ea ge Power

representative for more details .

Surface Mount Information

Pick and Place

The FLT007A0-SRZ SMT modules use an open

frame construction and are design ed for a fully

automated assembly process. T he modules are fitted

with a label designed to provide a large surface area

for pick and place operations. The label meets all the

requirements for surface mount processing, as well as

safety standards, and is able to wit hs tand reflow

temperatures of up to 300

product information such as product code, serial

number and location of manufactur e.

Nozzle Recommendations

The module weight has been kept to a minimum by

using open frame construction. Even so, these

modules have a relatively large m ass when compared

to conventional SMT components. Variables such as

nozzle size, tip style, vacuum pressure and pick &

placement speed should be considered to optimize

this process. The minimum recommended nozzle

diameter for reliable operation is 5mm. The maximum

o

C. The label also carries

nozzle outer diameter, which will safely fit within the

allowable component spacing, is 8 mm max.

Place

Tin Lead Soldering

The FLT007A0-SRZ power modules are lead free

modules and can be soldered either in a lead-free

solder process or in a conventional Tin/Lead (Sn/Pb)

process. It is recommended that the customer review

data sheets in order to customize the s older reflow

profile for each application board ass embly. The

following instructions must be obs erved when

soldering these units. Failure to obs erve these

instructions may result in the failure of or cause

damage to the modules, and can adver sel y aff ect

long-term reliability.

In a conventional Tin/Lead (Sn/Pb) solder process

peak reflow temperatures are limited to less than

o

235

C. Typically, the eutectic solder m el ts at 183oC,

wets the land, and subsequently wicks the device

connection. Sufficient time must be allowed to fuse

the plating on the connection to ensur e a r el iable

solder joint. There are several types of SMT reflow

technologies currently used in t he industry. These

surface mount power modules can be rel i ably

soldered using natural forced convection, IR (radiant

infrared), or a combination of convect ion/IR. For

reliable soldering the solder ref l ow profile should be

established by accurately meas uring the modules CP

connector temperatures.

LINEAGE POWER 8

Page 9

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

Per J-STD-020 Rev. C

0

50

100

150

200

250

300

Reflow Time (Seconds)

Reflow Temp (°C)

Heating Zone

1°C/Second

Peak Temp 260°C

* Min. Time Above 235°C

15 Seconds

*Time Above 217°C

60 Seconds

Cooling

Zone

75Vdc Input Voltage Maximum, 7A Output Current Maximum

REFLOW TEMP (°C)

REFLOW TIME (S)

Figure 13. Reflow Profile for Tin/Lead (Sn/Pb)

process.

MAX TEMP SOLDER (°C)

Figure 14. Time Limit Curve Above 205oC Reflow

for Tin Lead (Sn/Pb) process.

Lead Free Soldering

The FLT007A0-SRZ SMT modules are lead-free (Pbfree) and RoHS compliant and are both forward and

backward compatible in a Pb-free and a SnPb

soldering process. Failure to observe the instructions

below may result in the failure of or c ause damage to

the modules and can adversely affect long-term

reliability.

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. C

(Moisture/Reflow Sensitivity Classification for

Nonhermetic Solid State Surface Mount Devices) for

both Pb-free solder profiles and MSL classification

procedures. This standard provides a r ecommended

forced-air-convection reflow prof i le based on the

volume and thickness of the packag e (table 4-2). The

suggested Pb-free solder paste is Sn/Ag/Cu (SAC).

The recommended linear reflow prof i le using

Sn/Ag/Cu solder is shown in Figure. 15.

MSL Rating

The FLT007A0-SRZ SMT modules have a MSL r ating

of 1.

Storage and Handling

The recommended storage environment and handling

procedures for moisture-sensit ive surface mount

packages is detailed in J-STD-033 Rev. A (Handling,

Packing, Shipping and Use of Moist ure/Reflow

Sensitive Surface Mount Devices). Moisture barrier

bags (MBB) with desiccant are required for MSL

ratings of 2 or greater. These sealed packages

should not be broken until time of use. Once the

original package is broken, the floor l ife of the product

at conditions of <= 30°C and 60% relative humidity

varies according to the MSL rating (see J-STD-033A).

The shelf life for dry packed SMT packages will be a

minimum of 12 months from the bag seal date, when

stored at the following conditio ns: < 40° C, < 90%

relative humidity.

Figure 15. Recommended linear reflow profile

using Sn/Ag/Cu solder.

LINEAGE POWER 9

Page 10

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

FLT007A0Z (Through Hole Version)

FLT007A0-SRZ (SMT Version)

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Mechanical Outline

Dimensions are in millimeters and [inches].

Tolerances: x.x mm ± 0.5 mm [x.xx in. ± 0.02 in.] (Unless otherwise indicated)

x.xx mm ± 0.25 mm [x.xxx in ± 0.010 in.]

Bottom View

Side View

Bottom View

Side View

* - May be either + or – polarity, but must be same for pin 1 and 4.

** - Pin 2 and 5 shall be polarity that is opposite from pins 1 and 4.

LINEAGE POWER 10

Page 11

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

FLT007A0Z (Through Hole Version)

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Recommended Pad Layout

Dimensions are in millimeters and [inches].

Tolerances: x.x mm ± 0.5 mm [x.xx in. ± 0.02 in.] (Unless otherwise indicated)

x.xx mm ± 0.25 mm [x.xxx in ± 0.010 in.]

FLT007A0-SRZ (SMT Version)

* - May be either + or – polarity, but must be same for pin 1 and 4.

** - Pin 2 and 5 shall be polarity that is opposite from pins 1 and 4.

LINEAGE POWER 11

Page 12

Data Sheet

July 14, 2010

FLT007A0Z/FLT007A0-SRZ Input Filter Modules

World Wide Headquarters

Lineage Power Corporation

601 Shiloh Road, Plano, TX 75074, USA

+1-800-526-7819

(Outside U.S.A.: +1-972-244-9428)

www.lineagepower.com

e-mail: techsupport1@lineagepower.com

Asia-Pacific Headquarters

Tel: +65 6593 7211

Europe, Middle-East and Africa Headquarters

Tel: +49 89 878067-280

India Headquarters

Tel: +91 80 28411633

Lineage Power reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or

application. No rights under any patent accompany the sale of any such product(s) or information.

Lineage Power DC-DC products are protected under various patents. Information on these patents is available at www.lineagepower.com/patents.

© 2009 Lineage Power Corporation, (Plano, Texas) All International Rights Reserved.

75Vdc Input Voltage Maximum, 7A Output Current Maximum

Ordering Information

Please contact your Lineage Po wer Sales Representative for pricing, availability and optional features.

Table 1. Device Codes

Device Code

FLT007A0Z 0 – 75Vdc 7A TH CC109108692

FLT007A0-SRZ 0 – 75Vdc 7A SMT CC109108701

Input

Voltage Range

-Z refers to RoHS-compliant codes

Output

Current

Connector

Type

Comcodes

Document No:DS05-028 ver 1.26

PDF name: FLT007A0Z.pdf

Loading...

Loading...