Page 1

DEH41181

Rev01

g

SMR2 Modbus User Manual

Page 2

Page 3

SMR2 Modbus User Manual

Table of Contents

Introduction .......................................................................................................................2

RTU Transmission Mode .......................................................................................................................... 2

Message frame............................................................................................................................................ 2

RTU Mode Message Frames ...................................................................................................................... 2

Message Format.......................................................................................................................................... 2

Electrical Interface .............................................................................................................2

Communication Environment...........................................................................................3

Register Map .....................................................................................................................2

Fixed Value Registers ................................................................................................................................. 2

Dynamic Value Registers............................................................................................................................ 7

Interpretation of SOS values...................................................................................................................... 9

Setpoint Registers....................................................................................................................................... 9

Event Registers......................................................................................................................................... 13

Interpretation of Event Codes.................................................................................................................. 15

Bit position in Bit map............................................................................................................................. 16

i

Page 4

SMR2 Modbus User Manual

Introduction

The SMR2 trip unit has an optional communications

module that facilitates monitoring of the trip unit via a

master Modbus device. Monitoring features include

breaker settings and the breaker status.

Communication with the SMR2 trip unit requires a

FAMECM module powered externally that provides

isolation and protection.

The Modbus communication protocol is a single

master multi-slave protocol that is hardware

independent and it interfaces with a 2-wire RS485

interface. A single master device initiates and controls

all communication with the other slave devices on the

network. A computer with a serial port and an external

RS-232/RS-485 converter can be used as the mastermonitoring device. The SMR II trip unit is always the

slave and cannot initiate communication. The

maximum number of devices on a Modbus network is

32, i.e. only 31 slave devices can be connected to a

master.

MODBUS devices usually include a Register Map.

MODBUS functions operate on Register map registers

to monitor, configure, and control module I/O. You

should refer to the Register map for your device to gain

a better understanding of its operation.

The transmission mode defines the bit contents of the

message bytes transmitted along the network, and how

the message information is to be packed into the

message stream and decoded.

Standard MODBUS networks employ one of two types

of transmission modes:

i) ASCII Mode ii) RTU Mode

The mode of transmission is usually selected along

with other serial port communication parameters

(baud rate, parity, etc.) as part of the device

configuration.

RTU Transmission Mode

In RTU (Remote Terminal Unit) Mode, each 8-bit

message byte contains two 4-bit Hexadecimal

characters, and the message is transmitted in a

continuous stream. The greater effective character

density increases throughput over ASCII mode at the

same baud rate.

Message frame

A message frame is used to mark the beginning and

ending point of a message allowing the receiving device

to determine which device is being addressed and to

know when the message is completed. It also allows

partial messages to be detected and errors flagged as a

result.

A MODBUS message is placed in a message frame by

the transmitting device. Each word of this message

(including the frame) is also placed in a data frame

that appends a start bit, stop bit, and parity bit.

In ASCII mode, the word size is 7 bits, while in RTU

mode; the word size is 8 bits. Thus, every 8 bits of an

RTU message is effectively 11 bits when accounting for

the start, stop, and parity bits of the data frame.

RTU Mode Message Frames

RTU mode messages start with a silent interval of at

least 3.5 character times. Implemented as a multiple of

character times at the baud rate being used on the

network. The first field transmitted is the device

address. The allowable characters transmitted for all

fields are hexadecimal values 0-9, A-F. A networked

device continuously monitors the network, including

the silent intervals, and when the first field is received

(the address) after a silent interval of at least 3.5

character times, the device decodes it to determine if it

is the addressed device. Following the last character

transmitted, a similar silent interval of 3.5 character

times marks the end of the message and a new message

can begin after this interval.

The entire message must be transmitted as a

continuous stream. If a silent interval of more than 1.5

character times occurs before completion of the frame

(not a continuous stream), the receiving device flushes

the incomplete message and assumes the next byte will

be the address field of a new message.

In similar fashion, if a new message begins earlier than

3.5 character times following a

previous message, the receiving device assumes it is a

continuation of the previous message. This will

generate an error, as the value in the final CRC field

will not be valid for the combined messages.

Message Format

The Modbus RTU Protocol is strictly based upon a

transaction scheme where a master device generates a

query and a slave device replies with a response. Each

query and response message transaction consists of the

following four parts

2

Page 5

SMR2 Modbus User Manual

MODBUS ADDRESSES

The master device addresses a specific slave device by

placing the 8-bit slave address in the address field of the

message (RTU Mode). The address field of the

message frame contains two characters (in ASCII

mode), or 8 binary bits (in RTU Mode). Valid

addresses are from 1-247.

When the slave responds, it places its own address in

this field of its response to let the master know which

slave is responding.

MODBUS FUNCTIONS

The function code field of the message frame will

contain two characters (in ASCII mode), or 8 binary

bits (in RTU Mode) that tell the slave what kind of

action to take. Valid function codes are from 1-255, but

not all codes will apply to a module and some codes are

reserved for future use.

MODBUS DATA FIELD

The data field provides the slave with any additional

information required by the slave to complete the

action specified by the function code. The data is

formed from a multiple of character bytes (a pair of

ASCII characters in ASCII Mode), or a multiple of two

hex digits in RTU mode, in range 00H-FFH. The data

field typically includes register addresses; count values,

and written data. If no error occurs, the data field of a

response from a slave will return the requested data. If

an error occurs, the data field returns an exception

code that the master's application software can use to

determine the next action to take.

The resulting value is compared to the error check

field.

Transmission errors occur when the calculated

checksum is not equal to the Checksum stored in the

incoming packet. The receiving device ignores a bad

packet.

Electrical Interface

The electrical interface is 2-wire RS485 where data flow

is bi-directional and half duplex. RS-485 lines from the

master device should be connected to a FAMECM

module, which is powered externally using a 19-29 VDC

power supply. Refer Figure 1 and 2.

The following wire types are recommended for network

wiring: Belden 3074F – Data Tray 600 V industrial

twinax 18 AWG (7X26); or Belden 9841 – 300 V

communication cable 24 AWG (7X32); or Alpha 6412 –

300 V Communication cable 24 AWG (7x32). Shielded

wire should always be used to minimize noise. Polarity

is important in RS485 communications and each '+'

terminal of every device must be connected together for

the system to communicate.

CRC Error Checking

RTU Mode message frames include an error checking

method that is based on a Cyclical Redundancy Check

(CRC). The error-checking field of a message frame

contains a 16-bit value (two 8-bit bytes) that contains

the result of a Cyclical Redundancy Check (CRC)

calculation performed on the message contents.

The checksum field lets the receiving device determine

if a packet is corrupted with transmission errors. In

Modbus RTU mode, a 16-bit Cyclic Redundancy Check

(CRC-16) is used. The sending device calculates a 16bit value, based on every byte in the packet, using the

CRC-16 algorithm. The calculated value is inserted in

the error check field.

The receiving device performs the calculation, without

the error check field; on the entire packet it receives.

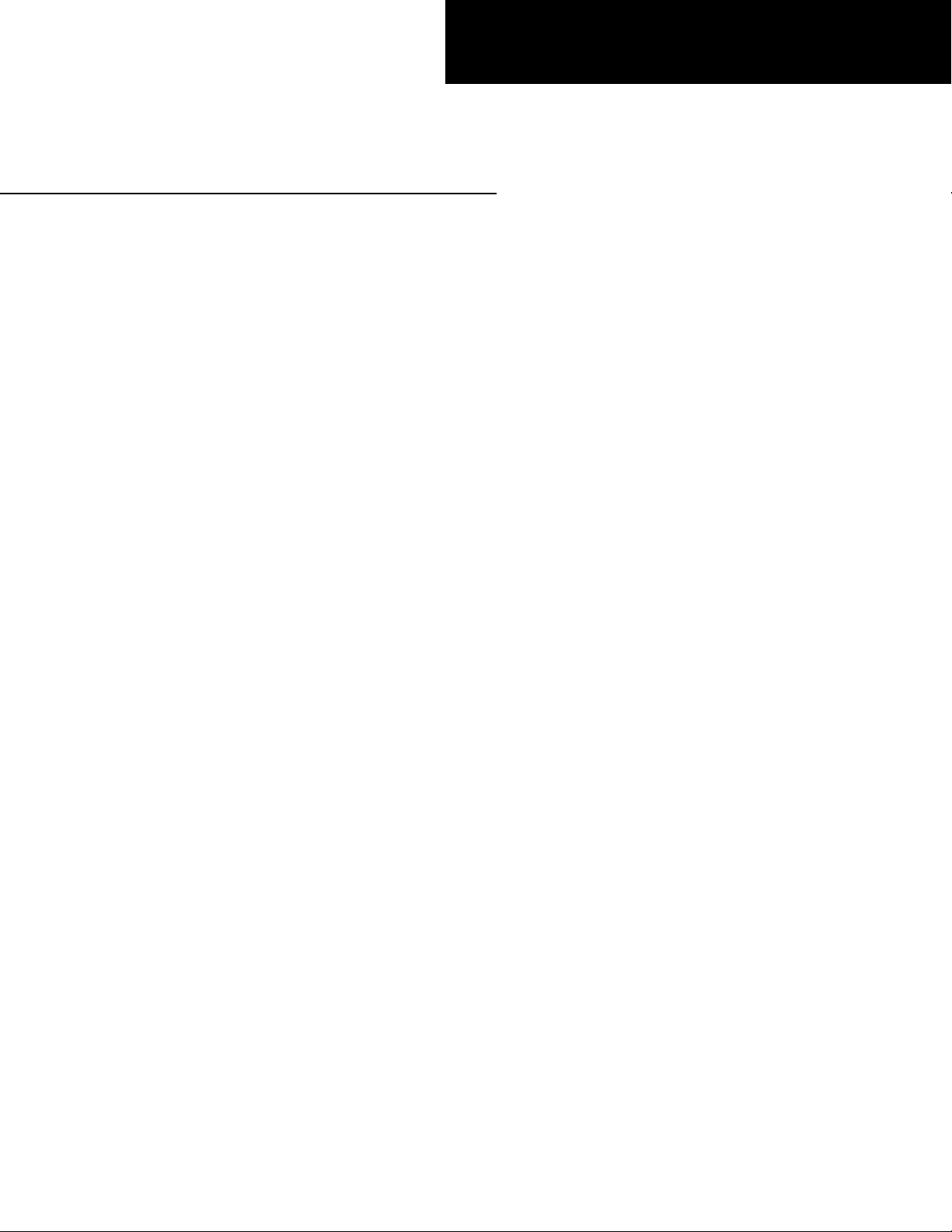

Figure1. Connection between ETU and FAMECM

module

2

Page 6

SMR2 Modbus User Manual

The communication happens at 19200bps with a

Modbus address of 100

Figure2. Connection between Breaker and FAMECM

module

Communication Environment

• The trip unit is always the slave and cannot

initiate communication

• All the registers are read-only

• Hardware layer

RS485: Data moves serially on a 2-wire differential line

(used for TX as well as Rx i.e.; half- duplex)

N-8-1, no parity, 1 start bit, 8 data bits & 1 stop bit (10

bits per character)

• Communication Protocol

RTU Modbus Master-Slave protocol Commandresponse (half-duplex) Min delay between messages is

3.5 char time Max delay within message is 1.5 char

time.

Slave Response time: minimum 3.5 char;

maximum 50mS + 1mS per register

Register order: MSB first, then LSB

• In the presence of a communication

module on Trip unit

A pair of rotary switch decides the Modbus address (0

to 255)

A pair of slide switch decides the baud rate (2400, 4800,

9600 or 19200bps). These switches are available on the

backside of the module

• In the absence of a communication

module on Trip unit

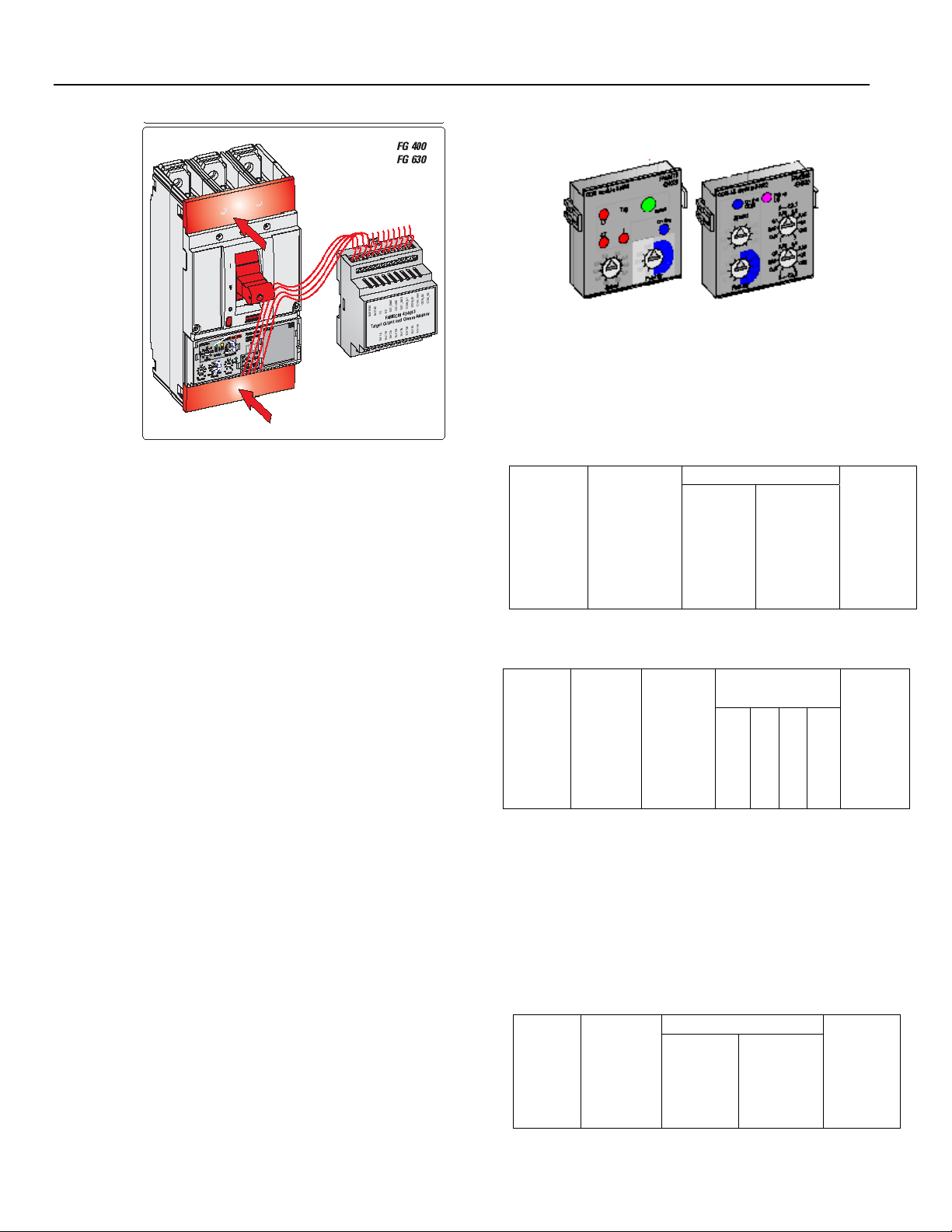

Figure3. Communication modules used with trip unit

Modbus Message Frames

Master’s Query

Data

Start

Data

Byte1

(n bytes)

(n bytes)

No. of

Registers

(2 bytes)

(n bytes)

Byte2

No. of

Registers

(2

bytes)

..

CRC

(2 bytes)

(2bytes)

Byte n

CRC

bytes)

CRC

(2

Slave

Address

(1 byte)

Function

Code

(1 byte)

Address

(2 bytes)

Slave’s Response

Slave

Address

(1byte)

Functio

n Code

(1 byte)

Number

of Bytes

(1 byte)

Examples :

Read Holding Registers (Function Code 03)

Use this command to read setpoint or fixed value

registers. It specifies the starting register and the

number of registers to be read. Read the registers 30103012 from device 100:

Slave

Addres

s

(1

byte)

Function

Code

(1 byte)

Data

Start

Address

(2

bytes)

3

Page 7

SMR2 Modbus User Manual

A

A

64h

Response: (register contents: 3010 = 022Bh, 3010 = 0000h,

3012 = 0066h)

Slave

Addres

s

(1byte)

64h

Read Input Registers (Function Code 04)

Use this command to read dynamic value or event

registers. Read the registers 1058 – 1060 from device

100:

Query:

Slave

Address

(1 byte)

64h

Response: (register content: 1058 = FFFFh, 1059 = A01Ah,

1060 11B1h)

Slave

Addres

s

(1

byte)

64h

Force Single Coil (Function Code 05)

Use this command to perform remote control. This

command sets a single coil to enter ON or OFF.

Force coil 4 of device 100 ON (FF00h force on, 0000h

force off)

Query:

Slave

Address

(1 byte)

Functio

n Code

(1 byte)

03h

Function

Code

(1 byte)

Function

Code

(1 byte)

04h

Function

Code

(1 byte)

03h

04h

0Bh

C2h

Numbe

r of

Bytes

(1byte)

06h

02h 2Bh 00h

Data

Start

Address

(2 bytes)

04h 22h 00h 03h

Number

of Bytes

(1 byte)

06h

FFh FFh A0h

Data

Coil

Address

(2 bytes)

00h

03h

Data

(n bytes)

Byte1

Byte2

00h 00h 66h

(n bytes)

No. Of

Registers

(2 bytes)

Data

(n bytes)

Byte2

-------

Byte1

1Ah 11h B1h

(n bytes)

Data

(2

bytes)

CRCl

CRCh

CRC

-------

(2

bytes

Byte n

)

CRCl

CRC

h

CRC

(2 bytes)

CRCl

CRCh

CRC

(2

bytes)

Byte n

CRCl

CRCh

CRC

(2 bytes)

64h

05h

00h 04h FFh 00h

CRCl

CRCh

Response: (echo query message)

Data

Coil

(n bytes)

Data

(2

bytes)

CRC

CRCl

(2 bytes)

CRCh

Slave

Address

(1 byte)

64h

Function

Code

(1 byte)

05h

Address

(2 bytes)

00h 04h FFh 00h

Preset Single Register (Function Code 06)

Use this command to write to a register. This presets a

value into a single holding register.

Preset register 0002 to 00 03 hex in slave device 17.

Query:

Data

Slave

Address

(1 byte)

11h

Function

Code

(1 byte)

06h

Register

(2 bytes)

00h 02h 00h 03h

(n bytes)

ddress

No. of

Registers

(2 bytes)

CRC

(2 bytes)

CRCl

CRCh

Response (echo query message)

Data

Slave

Address

(1 byte)

Function

Code

(1 byte)

Register

(2 bytes)

(n bytes)

ddress

No. of

Registers

(2

(2 bytes)

CRC

bytes)

11h

06h

00h 02h 00h 03h

CRCl

CRCh

Retransmit Last Message (Function Code 56)

Query:

Slave Address

(1 byte)

64h

Function Code

(1 byte)

38h

CRCl CRCh

CRC

(2 bytes)

Response

Slave Function

Data

(n bytes)

CRC

4

Page 8

Addres

s

(1

byte)

64h

Code

(1 byte)

38h

Previous transmitted

data

xxh xxh xxh xxh xxh

xxh xxh xxh xxh

(2 bytes)

CRCl

CRCh

Exception Response

If the slave receives a message without a

communications error, but is unable to process it, the

slave will return an exception response to inform the

master of the error. The high order bit will be set in

the function code and returned with the characterizing

exception response code:

01h - Invalid Function Code

The Function Code is not recognized or defined by the

SMR2.

02h - Invalid register

The Register address is not recognized or defined by

the SMR2

05h – Acknowledge

The SMR2 has accepted the request and is processing

it, but a long duration of time will be required to do so.

This response is returned to prevent a timeout error

from occurring in the master.

06h - Slave busy

Function

Code

Command Purpose Register Group

SMR2 Modbus User Manual

The SMR2 is busy processing a long duration

command. The master should retransmit the message

latter when the slave is free.

84h - Partial register access error

Command reads or writes to a register that represents

only part of the SMR2 register address. The multiple

register addresses must be read or written together.

Example: Long Time SOS consumes 2 register

addresses, thus both must be read together.

85h - Write protect violation

Command writes to a valid Register, which is defined as

Read Only.

88h - Invalid coil

The Coil address is not recognized or defined by the

SMR2.

Function Codes

The Modbus functions listed in below are supported:

03 Read Holding Registers Reading the setpoint

registers

04 Read Input Registers Reading actual value

registers

05 Force Single Coil Setting the signal coil or

executing single

command

06 Preset Single Register Write Data into single

Register

16

10 hex

56 Retransmit last message Retransmit last message N/A

Preset Multiple Registers Write Data into multiple

Registers

5

Setpoint registers, Fixed value registers

Actual value registers and event registers

Command coils

Setpoint registers, Fixed value registers

Setpoint registers, Fixed value registers

Page 9

SMR2 Modbus User Manual

Register Map

While modbus communication with Target

Communication Accessory module, all the registers are

read only registers. None of them can be written. But

while Modbus communication with Test Kit, most of

the Fixed value & Setpoint registers can be read as well

as written.

Fixed value registers start at 0000 and are read by

Function Code 03.

Actual value registers start at 1000 and are read by

Function Code 04.

Register

address

0000 Product Id 0-65535

0001 ETU Serial Number

0002 ETU Serial Number

0003 ETU Date Code

0004 ETU Date Code low 0-9999

0005

0006

Contents Range Type R/W Format

0-65535

high

0-65535

low

0-9999

high

Frame Size 1 to 3

Amp Rating 1 to 13 Normal

Event registers start at 2000 and are read by Function

Code 04.

Setpoint registers start at 3000 and are read by Function

Code 03.

Writing to the Coil registers, implement supervisory

control through remote commands

All registers composed of 16 bit integers, values less

than 256 stored in lower byte

Fixed Value Registers

Fixed value registers address starts at 0000, read by

Function Code 03. Written with Function code 06/16

(decimal)

The data stored in these registers are the data stored

during trip unit optioning.

Normal

mode –RO

Test mode

--- RW

Normal

mode -- RO

Test mode --

- RW

Normal

mode --- RO

Test mode

--- RW

Normal

mode --- RO

Test mode

--- RW

Normal

mode --- RO

Test mode

--- RW

Normal

mode --- RO

Test mode

--- RW

mode--- RO

Unsigned Int

Unsigned Int

Unsigned Int

Unsigned Int

Unsigned Int

Unsigned Int

1 G400

2 G630

3 K

Unsigned Int

1 7/7

2 25/25

3 60/63

4 125/125

2

Page 10

0007

0008

0009

0010

Information Memory

Option Byte 1

Software revision

number

Product revision

number

Max Number of

events stored

Bitmappe

d 0 to

FFFFh

0000 to

9999

0000 to

9999

Always 8 RO Unsigned Int

Dynamic Value Registers

Actual value registers start at 1000, read by Function

Code 04.All the dynamic value registers are 32-bit in

length. Hence, query of any variable results in two

Modbus register reads, each of 16-bit length. Even

numbered register holds upper-16 bits; Odd numbered

register holds lower –16 bits

SMR2 Modbus User Manual

Test mode

-- RW

Normal

mode--- RO

___________

Test mode

--- RW

RO 4 digit BCD

Normal

mode --- RO

Test mode

--- RW

Example: To find out Phase-A SOS, A Modbus query to

read 1002 and 1003 registers need to be sent to SMR2

by the master.

There are 32 bits in this data. The upper-16 bits would

appear in register 1002 and lower-16 bits in register

1003 as a part of the response.

5 150/160

6 250/250

7 400/400

8 600/630

9 800/800

10 1200/1250

11 1600/1600

12 350

13 500

b0 Instantaneous

0 enabled

1 disabled

b1 Short Time

0 enabled

1 disabled

b2 Long Time

0 enabled

1 disabled

b3 Watchdog

0 enabled

1 disabled

b4 Zone Select Interlock

0 enabled

1 disabled

b5 50-60/400 Hz

Operation

0 50/60 Hz

1 400 Hz

b6 Thermal Watchdog

0 disabled

1-99 enabled

b7 Unused

4 digit BCD

7

Page 11

SMR2 Modbus User Manual

LT Accumulators (A, B, C & N) give normalized values

and are typically max 1.25. Hence, they are multiplied

Reg. Contents Range Type

1000-01 Number of pending

0 - 4294967295 RO Unsigned Int

event

1002-03 SOS Current Phase A 0 - 4294967295 RO Unsigned Int

1004-05 SOS Current Phase B 0 - 4294967295 RO Unsigned Int

1006-07 SOS Current Phase C 0 - 4294967295 RO Unsigned Int

1008-09 SOS Current Phase N 0 - 4294967295 RO

1010-11 LT Accumulator A*1040 - 4294967295 RO Unsigned Int

1012-13 LT Accumulator B*1040 - 4294967295 RO Unsigned Int

1014-15 LT Accumulator C*1040 - 4294967295 RO Unsigned Int

1016-17 LT Accumulator N*1040 - 4294967295 RO Unsigned Int

1018-19 ST Accumulator 0 - 4294967295 RO Unsigned Int

1020-21

GF Accumulator

0 - 4294967295 RO Unsigned Int

1022-23 PL Accumulator 0 - 4294967295 RO Unsigned Int

1024-25 Breaker Status

Note:

If system is in pickup

corresponding bit is set to

1.

Battery status 1 indicates

healthy battery.

ZSI active is set 1 when

ZSI is ACTIVE.

When breaker is open

AUXS1bit is set to 1.

Bitmapped 0 to

FFFFh

1026-27 Push-Button Status 0 - 1 RO Unsigned Int

1028-29 Measured ETU

0 - 100 RO Unsigned Int

Temperature

1030-31 ETU Trip Count 0-655350 RO Unsigned int

1032-33 LT Trip Count 0-65535 RO Unsigned int

1034-35 ST Trip Count 0-65535 RO Unsigned int

1036-37 Instantaneous Trip

0-65535 RO Unsigned int

Count

1038-39 GF Trip Count 0-65535 RO Unsigned int

1040-41 PL Trip Count 0-65535 RO Unsigned int

1042-43 Software Fault Trip

0-65535 RO Unsigned int

Count

1044-45 Remote Trip Count 0-65535 RO Unsigned int

1046-47 RP Missing Trip Count 0-65535 RO Unsigned int

1048-49 Flash Erased Count 0-65535 RO Unsigned int

1050-51 No module Trip Count 0-65535 RO Unsigned int

1052-53 Over temperature Trip

0-65535 RO Unsigned int

Count

with 10,000 and sent out on Modbus for reading

purposes.

Format

R/W

Unsigned Int

RO B0: Unused

B1: ST Pickup

B2: GF Pickup

B3: PL Pickup

B4 (unused)

B5: LT 105 Pickup (PU >= 105)

B6: LT 95 Pickup (95 <= PU < 105)

B7: LT 75 Pickup (75 <= PU < 95)

B8: LT 60 Pickup (60 <= PU < 75)

B9: LM 1

B10: LM 2

B11: ZSI active

B12: Battery Status

B13: AUXS1

B14, B15 Unused

1 = Push button is pressed

0 = Push Button is released

8

Page 12

SMR2 Modbus User Manual

Interpretation of SOS values

The Sum Of Squares values (SOS) of a phase is a

measure of the RMS value of current flowing through

that Phase.SMR2 calculates this values in every half

cycle and use this value as a measure of current to

perform the protection algorithm. The no. of current

samples used for SOS calculation depends on the

frequency.

When a current equal to sensor rating (I

) value is

CT

For 500A, 50Hz input current SOS value will be

equal to 1297350.

Example: SOS to current conversion

flowing through the breaker, a SOS value of 830304 will

be displayed if supply frequency is 50 Hz. For 60 Hz,

This value will be 691920.

ICT _SOS_Value for 50 Hz =

ICT _SOS_Value for 60 Hz =

830304

691920

Using this value we can calculate SOS value for any

current or current for any given SOS value.

For given current , SOS value can be calculated

using the following equation:

SOS value

= (input current/sensor rating)

2

x

ICT _SOS_Value

For given SOS value ,Current amplitude can be

calculated using the following equation:

Input current

= (SOS Value /

ICT _SOS_Value

0.5

)

x Sensor Rating

Example: Current to SOS conversion

sensor rating = 400A

Input current=500A

Frequency =50Hz

select

ICT _SOS_Value

based on frequency

If SOS Value= 7472736 for 50 Hz , then

corresponding current is 1200A

Note:

UL/IEC bit (Bit 0) in Control Byte (Modbus Address

3012) is monitored and ETUs operating frequency is

determined based on this bit.

Setpoint Registers

Setpoint registers start at 3000, read by Function Code 03

Reg. Contents Range Type R/W Format

3000 Hour 0 - 23

3001 Minute 0 - 59

Normal

mode - RO

Test mode

RW

Normal

mode - RO

Test mode

RW

SOS value = (input current/sensor

2

x

rating)

ICT _SOS_Value

= (500/400)2 x 830304

= 1297350

Sensor rating = 400A

SOS Value= 7472736

Frequency =50Hz

Select

ICT _SOS_Value based on frequency

Input current = (SOS Value /

_SOS_Value

0.5

)

= (7472736/830304)

= 1200 A

UL/IEC bit (Bit

0) in Control

byte

0 - UL 60 Hz

1 - IEC 50 Hz

Unsigned int

(Unused)

Unsigned int

(Unused)

x Sensor Rating

Line

Frequency

ICT

0.5

x 400

9

Page 13

SMR2 Modbus User Manual

3002 Seconds 0 - 59

3003 Long Time Pickup 0-15 Normal

3004 Long Time delay 0-6 Normal

3005

3006 Short Time delay 0-9 Normal

3007 Ground Fault pickup 0-8 (in GF

Short time pickup 0-9 Normal

module

0-9 (in GFA

module)

Normal

mode - RO

Test mode

RW

Mode--RO

_________

Test Mode

RW

Mode--RO

_________

Test Mode

RW

Mode--RO

---------------------Test Mode

RW

Mode--RO

_________

Test Mode

RW

Normal

Mode--RO

_________

Test Mode

RW

Unsigned int

(Unused)

Unsigned int

0 0.625

1 0.65

2 0.675

3 0.7

4 0.725

5 0.75

6 0.775

7 0.8

8 0.825

9 0.85

10 0.875

11 0.9

12 0.925

13 0.95

14 0.975

15 1.0

Unsigned int

0 Line 1.25

1. Line 2.5

2. Line 5

3. Line 10

4. Motor 20

5. Motor 30

6.

Unsigned int

Value second I2T

0 40ms No

1 120ms No

2 210ms No

3 310ms No

4 420ms No

5 420ms Yes

6 310ms Yes

7 210ms Yes

8 120ms Yes

9 40ms Yes

Unsigned int

0 0.2X

1 0.3X

2 0.4X

3 0.5X

4 0.6X

5 0.7X

6 0.8X

7 0.9X

8 1.0X

10

Page 14

3008 Ground Fault delay 0-9 Normal

Mode

RO

_________

Test Mode

RW

3009 Inst. Pickup 0-9 Normal

Mode--RO

_________

Test Mode

RW

3010 Module Address 0 - 240

3011 Last Trip Data Bitmap

0 - 255

3012 Control Byte Bitmap

0-255

3013 Protection Multiplier 64-100 Normal

3014 Neutral Protection 0-100 Normal

3015 Temperature Limit 0-100 degree C Normal

3016 Product Reject Code Key 0 - 65535 RO

3017 Rating Plug Serial Number

high

3018 Rating Plug Serial Number

low

0-9999 RO

0-9999 Normal

Normal

Mode - RO

Test mode

RW

Normal

Mode--RO

_________

Test Mode

RW

Normal

Mode--RO

_________

Test Mode

RW

Mode --RO

_________

Test Mode

RW

Mode

RO

_________

Test Mode

RW

Mode

RO

_________

Test Mode

RW

mode - RO

SMR2 Modbus User Manual

9 GFA Reset (In GFA module

only)

Value second I2T

0 40ms No

1 120ms No

2 210ms No

3 310ms No

4 420ms No

5 420ms Yes

6 310ms Yes

7 210ms Yes

8 120ms Yes

9 40ms Yes

Unsigned int

Refer to the table

64% 100%

0%, 50%, 100%

11

Page 15

SMR2 Modbus User Manual

Test mode

RW

3019 Rating Plug Date Code

high

3020 Rating Plug Date Code low 0-9999

3021 Rating Plug LT Settings 0 - 255

3022 Number of Data bits 0-1

3023 Number of Stop bits 0-1

3024 Parity 0-2

3025 Baud Rate 0- 3

3026 Modbus Address 1-247 Normal

3027 LM1 Pickup 0-9

3028 LM2 Pickup 0-9

0-9999

Normal

mode – RO

Test mode

RW

Normal

mode - RO

Test mode

RW

Normal

mode - RO

Test mode

RW

Normal

mode RO

Test mode

RW

Normal

mode – RO

Test mode

RW

Normal

mode - RO

Test mode

RW

Normal

mode - RO

Test mode

RW

mode - RO

Normal mode

- RO

Normal mode

- RO

0 7-bits

1 8-bits

0 1-stop bit

1 2-stop bits

0 No parity

1 Even Parity

2 Odd Parity

0 2400

1 4800

2 9600

3 19200

ETU is known by this slave

address in the communication

network and communicates over

this address.

0 0.55

1 0.6

2 0.65

3 0.7

4 0.75

5 0.8

6 0.85

7 0.9

8 0.95

9 1.0

0 0.55

1. 0.6

2. 0.65

3. 0.7

4. 0.75

5. 0.8

6. 0.85

7. 0.9

8. 0.95

9. 1.0

12

Page 16

3029 Flag Cleared Byte 00 &

0xFF

3030 Test Kit Modbus Address 0 - 255 Normal

3031 Test Kit Baud Rate 0 - 3 Normal

3032 Ammeter Display Current 0 - 9999 Test mode

3033 Ammeter Display Current

Pushbutton

0 - 9999

Event Registers

The trip unit stores up to eight events, with each event

utilizing 8 registers to describe the details of the event.

Last eight events are stored in chronological order, with

EVENT 1 being the oldest event and EVENT n being

Normal

mode - RO

mode - RO

mode – RO

RW

Normal

mode - RO

Test mode

RW

Normal

mode - RO

the newest. An event is automatically cleared once read

by the host.

SMR2 Modbus User Manual

00 Cleared (trip history can

not be shown on Flag

Module LEDs)

0xFFFF

Not Cleared (trip history can

be shown on Flag Module

LEDs)

This is to test COMM

switches.

This returns the cumulative

Modbus address set through

two COMM switches.

00 – 2400

01 – 4800

02 – 9600

03 – 19200

This is to test DIP switches.

This holds the value which is

displayed on LCD display

Value greater than 9999 will

be displayed as “----“

Alternate value, which can be

written while testing

Ammeter module. As long as

Select_Phase is pushed, this

value gets displayed.

Value greater than 9999 will

be displayed as “----“

13

Page 17

SMR2 Modbus User Manual

If another event occurs before the master reads all the

existing events, the oldest event is lost, new event data

will be placed in the EVENT 8 register, and the older

event register contents are shifted. The total number of

events since the last reset will be kept counted at

register location 1000-1001. Events are read using

Function Code 04.

Reg Contents Units/

2000 Event Code – Event 1 0-256 RO Unsigned int

2001 Hour 0 RO Unsigned int

2002 Minute 0 RO Unsigned int

2003 Second 0 RO Unsigned int

2004 Milliseconds 0 RO Unsigned int

2005 Event specific data 1 0 - 65535 RO Unsigned int

2006 Event specific data 2 0 - 65535 RO Unsigned int

2007 Event specific data 3 0 - 65535 RO Unsigned int

2008 Event code – Event 2 0-256 RO Unsigned int

2009 Hour 0 RO Unsigned int

2010 Minute 0 RO Unsigned int

2011 Second 0 RO Unsigned int

2012 Milliseconds 0 RO Unsigned int

2013 Event specific data 1 0 - 65535 RO Unsigned int

2014 Event specific data 2 0 - 65535 RO Unsigned int

2015 Event specific data 3 0 - 65535 RO Unsigned int

… … … … …

2056 Event code – Event 8 0-256 RO Unsigned int

2057 Hour 0 RO Unsigned int

2058 Minute 0 RO Unsigned int

2059 Second 0 RO Unsigned int

2060 Milliseconds 0 RO Unsigned int

2061 Event specific data 1 0 - 65535 RO Unsigned int

2062 Event specific data 2 0 - 65535 RO Unsigned int

2063 Event specific data 3 0 - 65535 RO Unsigned int

Range

Type

R/W

Format

14

Page 18

SMR2 Modbus User Manual

Interpretation of Event Codes

The following table describes the meaning of each

event code

Event

Code

(Hex

)

1

2 Short Time O/C trip Fault SOS

3 Instantaneous O/C

4 Ground Fault Trip Fault SOS

5 Phase Loss Trip Phase Loss

6 Remote Trip Bitmap 16-bit

7

8

9

A

B

C

D

E Low Trip Voltage

F Software Fault

10 RAM Failure Bitmap 16-bit

11 ROM Failure Bitmap 16-bit

12

13 Rating Plug Missing Bitmap 16-bit

14 Short Time Switch

15

16 Instant Switch change Bitmap 16-bit

17 Module Switch/Type

18 Short Time Delay

19

1A Module Missing Trip

Meaning Register 1 Register 2 Register 3

Long Time Overcurrent Trip

Trip

Over-Temp Trip

Aux Switch Opened

Warning

Change

Long Time Switch

Change

Change

Switch Change

Long Time Delay

Switch Change

Fault SOS

Current

Current

Instantaneous

Fault Current

Current

Accumulator

Temperature

Bitmap 16-bit

Bitmap 16-bit

Bitmap 16-bit

Bitmap 16-bit

Bitmap 16-bit

Bitmap 16-bit

Bitmap 16-bit

Fault SOS Current

Fault SOS Current

Instantaneous Fault

Current

Fault SOS Current

Phase Loss

Accumulator

15

Page 19

SMR2 Modbus User Manual

Bit position in Bit map

Bit Position in Bitmap Meaning Event code (Hex)

0

1 0 Aux Switch Open

2 0 No Low Trip Voltage Warning

3 0 No RAM Failure

4 0 No ROM Failure

5 0 No Rating Plug Missing

6 0 No Short Time Switch Change

7 0 No Long Time Switch Change

8 0 No Instant Switch change

9 0 No Module Switch/Type Change

10 0 No Short Time Delay Switch Change

11 0 No Long Time Delay Switch Change

12 0 No Missing Module

0 No Remote Trip

1 Remote Trip

1 Aux Switch Closed

1 Low Trip Voltage Warning

1 RAM Failure

1 ROM Failure

1 Rating Plug Missing

1 Short Time Switch Change

1 Long Time Switch Change

1 Instant Switch change

1 Module Switch/Type Change

1 Short Time Delay Switch Change

1 Long Time Delay Switch Change

1 Missing Module

6

C

0E

10

11

13

14

15

16

17

18

19

12

16

Page 20

Page 21

SMR2 Modbus User Manual

g

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH41181 Rev01 © 2006 General Electric Company

GE Consumer & Industrial

17

Loading...

Loading...