Page 1

DEH40920 Installation Instructions

g

Motor Operator, Type FCEMF3,

FCEMF6, FCEMFF, FCEMFG

Congratulations and thank you for choosing the

Record Plus™

breakers. The UL-listed type motor operator kit for

catalogs shown in Table 1 is suitable for use with

the FC100 circuit breaker series.

Record Plus™

a full line of integrated accessories. All units use

the latest in integrated modular circuit breaker

technology for flexibility in application and

maximizing the product’s utilization and

capabilities.

All

Record Plus™

Underwriters Laboratories to the UL489 standard

and the CSA Standard C22.2, No. 5. These circuit

breakers are certified to IEC60947-2.

family of current-limiting circuit

circuit breakers are designed with

circuit breakers are listed by

Record Plus

™

Molded Case Circuit Breaker

Accessories

These accessories are also for use with our MAGBREAK® instantaneous trip-only circuit breakers,

which meet the same standards and are ULrecognized components for use in motor

applications. They can also be used with our

molded case switches, which are listed per

Underwriters Laboratories to the UL489 standard.

Record Plus™

accessories are designed and manufactured to

exceed our global customers’ high standards for

reliability and quality.

WARNING

injury. Ensure that ALL electrical power

supplies are OFF before installing or removing

any devices. The breaker, trip unit, or

accessories MUST ONLY be installed and

serviced by QUALIFIED personnel. See NEMA

publication AB4.

AVERTISSEMENT: Danger contre les risques

d'électrocutions. S'assurer avant TOUTES

manipulations du disjoncteur que les

différentes sources d'alimentation sont en

position OFF. Les disjoncteurs, unités de

protection, ou accessories doivent être installés

par des personnes qualifiées et habilitées. Lira

NEMA publication AB4.

: DANGER of electrical shock or

circuit breakers and their

CAUTION:

use in equipment not specifically design to

accept it. Contact the equipment manufacturer

for possible equipment modifications.

ATTENTION:

employe dans un equipement non

specialement adapte a cet effet. Contactez le

constructeur concernant les possibles

modifications a apporter a l'equipement.

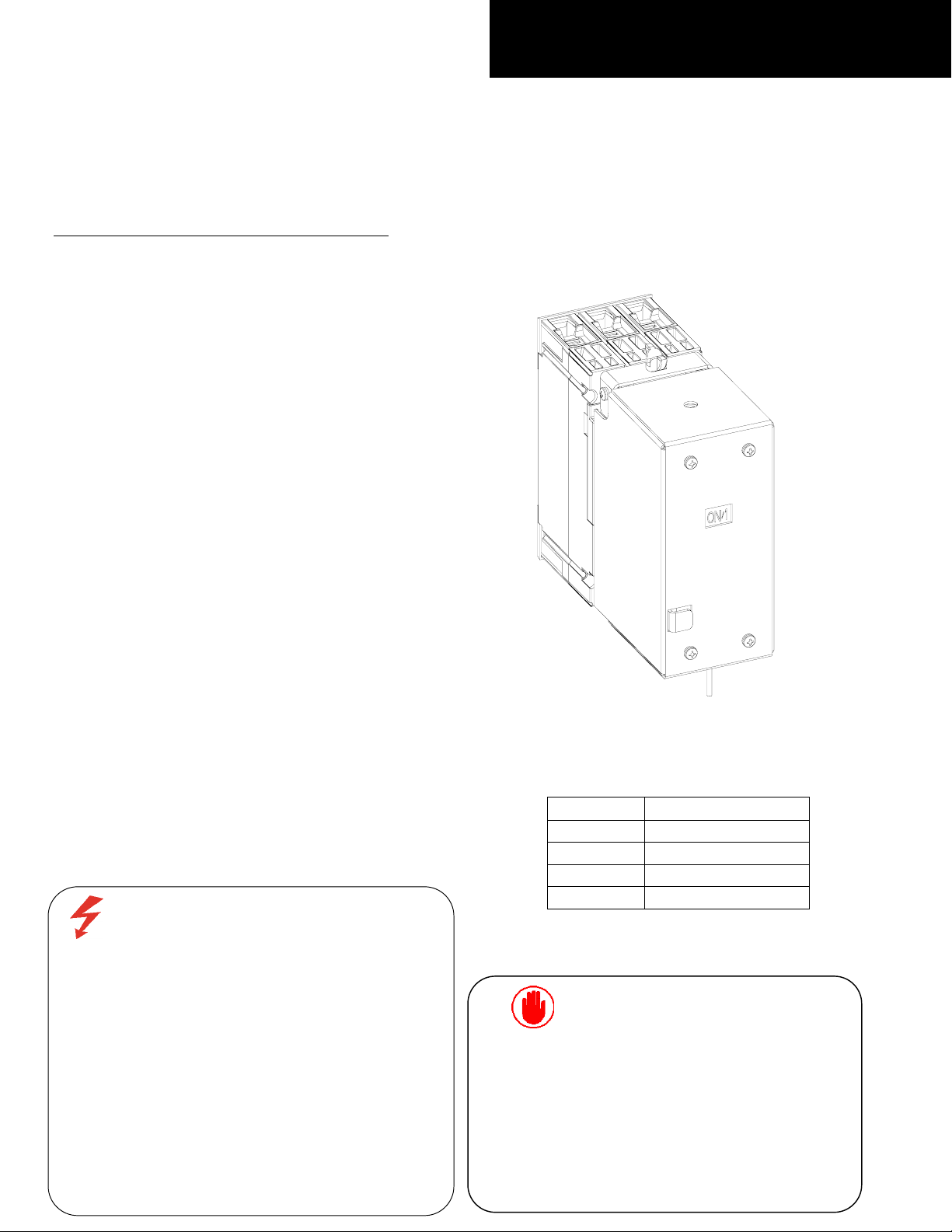

Figure 1. Motor operating Mechanism mounted on

5HFRUG3OXV FC100 circuit breaker.

Catalog Rating

FCEMF3 120V AC/ 125V DC

FCEMF6 240V AC/ 250V DC

FCEMFF 24V DC

FCEMFG 48V DC

Table 1. Catalog Details

This product is NOT suitable for

Cet appareil nedoit pas etre

Page 2

[9]

[4,5]

[8]

[7]

[1]

[2]

[3,5]

[1]

[2]

[3]

[6]

Product Description

These instructions describe the installation

procedures for the Motor Operator Mechanism

accessory on

Record Plus™

circuit breakers, as

illustrated in Figure 1.

The complete kits are available in the catalog

numbers mentioned in Table 1.

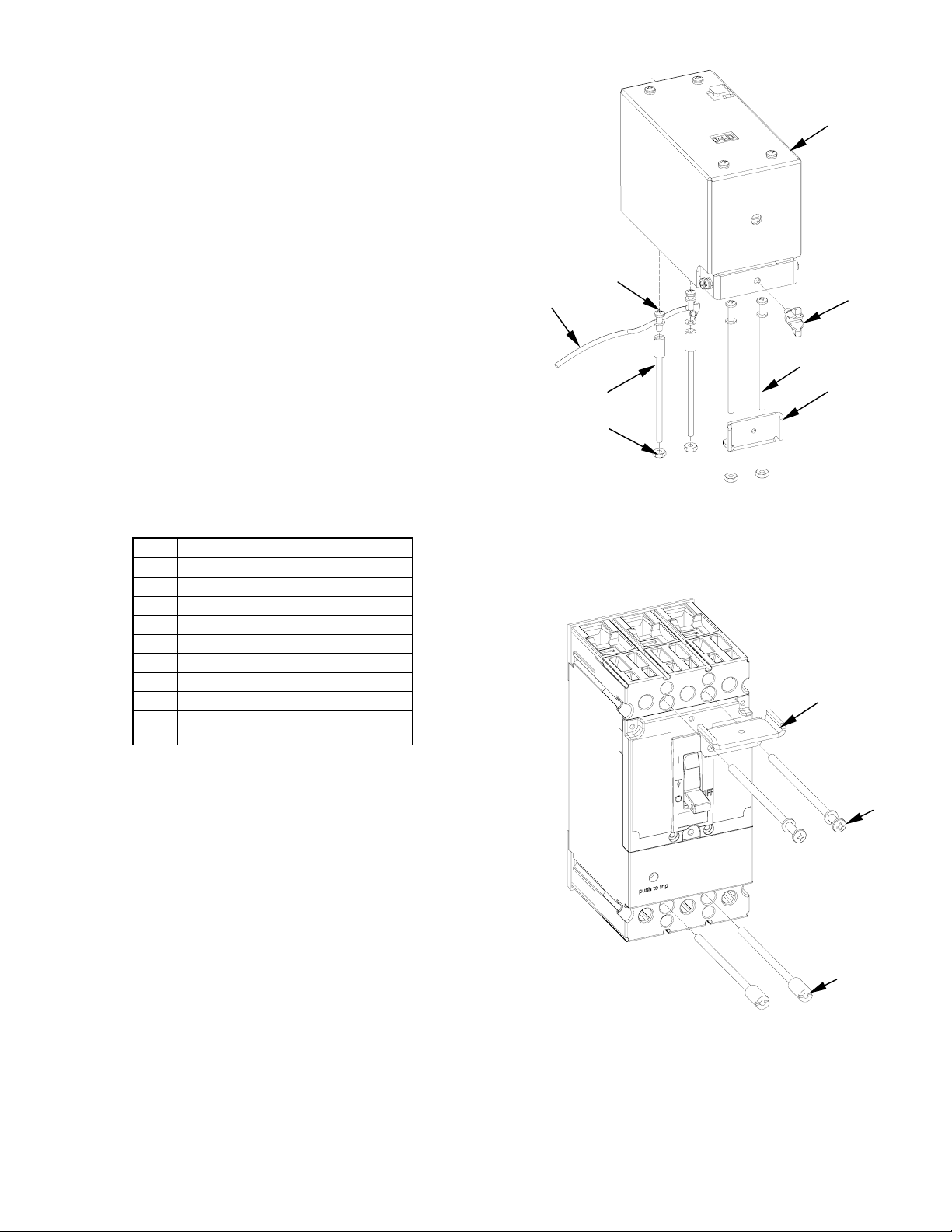

The kit is common to all the catalogs, providing

the necessary parts for mounting the motor

operator mechanism on the breaker as shown in

Figure 2.

Step 1 – Unpack and Inspect

Unpack the Motor operating mechanism kit and

inspect the parts for any shipping damage. Verify

that all parts are supplied, as listed in

parts are illustrated in Figure 2.

Note that the numbers in brackets in the following

figures and installation instructions refer to the

item numbers in Table 2.

Item Description Qty.

1 Top Bolting Plate 1

2 Mounting Screw 2

3 Screw, #8-32 x 3.50" 2

4 Screw, #8-32 x 0.375" 2

5 Lock Washer 4

6 Nut, Hex #8-32 4

7 Wing Screw #10-24 1

8 Grounding Wire 1

9 Motor Operator

Mechanism

Table 2. List of parts included in the Motor operator

Mechanism kit.

Table 2. The

1

Figure 2. Parts supplied in the Motor operator kits.

Step 2 – Install the Breaker and

Motor Operating Mechanism

1. Move the breaker handle to the OFF position.

2. Mount the breaker with mounting screws[2],

# 8-32

plate[1], as illustrated in Figure 3. Tighten the

screws to 16 - 20 in-lb.

of the circuit breaker according to installation

instructions DEH40463.

3. Position the Mounting bracket of motor

operator assembly on the breaker, as illustrated

in Figure 4. Insert two #8-32 x 0.375" screws

[4] through the mounting holes in the

mounting bracket and into the heads of the

breaker mounting screws [1], with the

grounding wire [8] attached to one of the

screws. Tighten the screws to 16 - 20 in-lb.

Secure the other end of the grounding wire to a

suitable ground location.

x 3.50" screws [3] and Top bolting

Complete the installation

Figure 3. Mounting the breaker.

Page 3

4. Align the Mounting brackets parallel to each

A

A

[4,5,8]

[7]

A

other as shown in Figure 5.

Align the breaker handle with the operator

5.

mechanism, by adjusting the mechanism

position with the screw as shown in Figure 4

Close the operator and fasten the wing

screw [7]

Step 3 – Operation

Description

A motor Operated mechanism is designed to

open, close, and reset a circuit breaker by remote

control.

In an operating installation, the customer must

supply normally open ON and OFF push –

buttons, external wiring, a control power source

and any control circuitry.

ACCESS TO SCREW, FOR

MECHANISM ADJUSTMENT

‘OFF’ SIDE

LIGN BREAKER

HANDLE TO THIS

REA

Electrical Operation

With the breaker and operating mechanism in

their OFF positions, press ON button to energize

the motor, closing the breaker. When the breaker

handle reaches the ON position, an internal limit

switch disconnects the control circuitry.

When the OFF button is pressed, the motor is

energized, opening the breaker. After the breaker

handle reaches the OFF position, a limit switch deenergizes the control circuit.

When the circuit breaker trips automatically, there

is no external trip indication, unless a separate bell

alarm accessory is provided to actuate a warning

device. It is necessary to press OFF to reset the

breaker.

Automatic Reset

For automatic reset, an auxiliary switch, available

as an accessory, returns the breaker to the

OFF/RESET position after it has tripped. The

switch is mounted inside the breaker and wired in

parallel with the OFF button. When the breaker

trips, the switch closes, moving the breaker handle

to OFF/RESET position. After the motor-operated

mechanism has reset the breaker, the limit switch

again opens the circuit. To use automatic reset,

the ON push – button must be SPDT type and

wired as in Figure 7. (The Auto/ Reset scheme

applies to AC devices only and is not applicable to

DC applications).

MOUNTING

BRACKET

Figure 4. Mounting of Motor Operating Mechanism on

Breaker

PARALLEL

LIGNMENT

Manual Operation

Unscrew the wing nut and lift the operator to

disengage the handle and operate the breaker

handle. To return to electrical operation, align

the breaker handle with the operator mechanism

and close the operator and fasten the wing screw.

Figure 6 is the outline view of completed

installations with dimensions.

Figure 5. Alignment of mounting brackets

Page 4

Electrical Data

Table 3 contains the electrical specifications for

the motor operated mechanism.

Catalog

No.

FCEMF3

FCEMF6

FCEMFF 24V AC 31.0 15.5

FCEMFG 48V DC 20.0 7.0

Volts

120V AC 10.5 5.0

125V DC 13.5 4.0

240V AC 6.5 3.0

250V DC 8.0 2.5

Control Timing (Sec)

In-Rush

Amps

Running

Amps

Table 3. Electrical Specifications

Closing

Opening

.15 .13

Recommended

UL Listed Fuse

1 Amp

Time Delay

2 Amp

Time Delay

Figure 6. Outline view of completed installations with dimensions.

Page 5

Figure 7. Wiring diagram for the FC100 Motor Operating Mechanism

Page 6

r

These instructions do not cover all details or variations in equipment nor do they provide for every possible

contingency that may be met in connection with installation, operation, or maintenance. Should furthe

information be desired or should particular problems arise that are not covered sufficiently for the purchaser’s

purposes, the matter should be referred to the GE Company. The circuit breaker is a sealed unit that contains no

user-serviceable parts. Tampering with the seal will void the warranty.

g

________________________________________________________

General Electric Company

41 Woodford Ave., Plainville, CT 06062

www.geindustrial.com

DEH40920 R01 0704 © 2003 General Electric Company

GE Consumer & Industrial

Loading...

Loading...