Page 1

Installation Guide 475A667AAP008 Rev 004

Fan Assisted Cooling (FAC) Dry-Type Transformers

Three Phase, 150-1000 kVA

Instructions for the Safe Handling, Installation, Operation and Maintenance.

Table of Contents Page Table of Contents (Cont.) Page

6.2

1.

General Information………………………...

2.

Temperature Class………………………….

3.

Handling……………………………………...

4.

Receiving…………………………………….

5.

Installation……………………………………

5.1

Preparation…………………………...

5.2

Mounting and Placement…………...

5.3

Ventilation…………………………….

5.4

Audible Sound Sources……………..

6. Connections………………………………….

6.1 Cable Conduit Entrance / Lugs…….

1

2

2

2

2

2

3

3

3

3

4

4

Grounding…………………………….

6.3

Lighting Tap Applications……..…….

6.4

Fans, Alarm and Shunt……………...

7.

Before Energizing…………………………...

8.

Operation…………………………………….

8.1

Loading……………………………….

8.2

Over-excitation……………………….

9.

Troubleshooting……………………………..

10.

Maintenance…………………………………

11.

Storage……………………………………….

12.

Renewal Parts……………………………….

13.

Typical Enclosure Information……………..

5

5

5

5

5

5

6

6

7

7

7

8

Page 2

1.

+ Hot Spot

General Information

Fan assisted cooling (FAC) dry type transformers have a ventilated, encased construction suitable for indoor service only unless

converted for protective outdoor service. All models are designed for floor or platform mounting. The core and coil structure is

mounted directly to the enclosure allowing all-around and floor access for cabling. Rubber isolation pads are included as a kit and

can be mounted at the base to minimize transmission of vibration. An optional bottom panel has to be in place for wall-mounted

transformers; however, the bottom panel installation is optional for transformers mounted on flat non-combustible surfaces.

Rain-shield conversion kits are available to convert standard indoor NEMA Type 2 enclosures to NEMA Type 3R enclosures

suitable for protected outdoor installation. The transformer nameplate specifies the proper kit to match the indoor enclosure and

transformer. The enclosure has vent guards that deter rodents, birds or debris from entering.

Each transformer is assembled and given complete electrical tests at the factory, after which it is inspected and packed for shipment.

2. Temperature Class

Industry standard UL 1561 classifies insulation systems in accordance with the following rating system:

Ambient + Winding Rise

40C 55C 10C 105C

40C 80C 30C 150C

40C 115C 30C 185C

40C 150C 30C 220C

Transformers for applications requiring lower temperature rise, generally 115C and 80C, are readily available.

Transformers operating at full load will have a maximum 50C/122F temperature rise on the surface areas of the enclosure. With a

40C ambient, the measured enclosure surface temperature could be as high as 90C/194F.

= Temp Class

All FAC dry-type transformers meet applicable IEEE, ANSI,

NEMA and UL standards.

These transformers are designed using a 220C insulation

system with a standard 150C temperature rise.

3. Handling

Provisions for lifting are provided. Because transformers are surprisingly heavy, check the weight shown on the nameplate or the

shipping label to assure adequate capacity of lifting equipment. For safety, spreaders should be used with lifting equipment.

CAUTION

THE ENCLOSURE IS AN INTEGRAL PART OF THE STRUCTURE SUPPORTING THE TRANSFORMER. NEVER LIFT

THE UNIT WITHOUT THE ENCLOSURE IN PLACE (OTHER THAN THE COVER WHICH HAS TO BE REMOVED TO

ACCESS LIFTING HOLES ON TOP CORE CLAMPS). ALWAYS MOVE TRANSFORMER IN AN UPRIGHT POSITION.

To move unit with a pallet jack or fork truck, remove the four bolts on front and rear lifting grills, reattach the lifting grill in the

raised position (using bottom holes in the grill) and lift on both grills (exercise caution to prevent damage to fan cables). When

transporting is complete, return lifting grills to the lowered position. Refer to enclosure assembly picture on last page.

4. Receiving

Upon receipt of shipment, examine the package for damage that may have been sustained in transit. If the unit must be opened

outdoors, take proper precautions to prevent the entrance of moisture. While unpacking, examine the product for broken, bent,

loose parts or other damage. If damage from shipment is evident, file a damage claim with the transportation company and notify

the nearest sales office.

5. Installation

Dry-type transformers should be located in an area where the transformer can be inspected at any time. It is a requirement of NEC

that sufficient access and working space be provided and maintained about all electrical equipment to permit maintenance.

Maintenance on FAC units can be done from the front, so working space clearance need only be provided to the front.

TO AVOID ELECTRICAL SHOCK DO NOT REMOVE COVERS WHILE TRANSFORMER IS ENERGIZED.

TRANSFORMERS OPERATE AT HAZARDOUS VOLTAGES THAT COULD CAUSE SEVERE INJURY OR DEATH!

2

WARNING

Page 3

CAUTION

ONLY EXPERIENCED AND QUALIFIED PERSONNEL SHOULD PERFORM INSTALLATION AND MAINTENANCE. NO

ATTEMPT SHOULD EVER BE MADE TO CHANGE THE TAPS OR MAKE CABLE CONNECTIONS WHILE THE

TRANSFORMER IS ENERGIZED.

TRANSFORMERS SHOULD BE INSTALLED IN SECURE, CONTROLLED ACCESS AREAS, NEVER IN AREAS SUBJECT

TO DELIBERATE, UNAUTHORIZED ACTS BY MEMBERS OF THE UNSUPERVISED PUBLIC. IF INSTALLED IN SUCH

AREAS, TAMPER RESISTANT ENCLOSURE SCREWS SHOULD BE USED.

5.1 Preparation

Remove any accumulation of dirt or dust by vacuuming, brushing or blowing dry air on the unit. If moisture is evident by the

appearance of rust or mildew or moisture is visible on the insulation surfaces or on the fans, the unit should be dried out by placing

it in an oven or by blowing heated air over it. In either case the temperature should not exceed 110C/230F. Insulation resistance

tests of the type used on liquid filled transformers are of little value on dry-type transformers. The nature of insulation used in dry

type transformers is such that megger readings are not reliable and may be misleading. Refer to ANSI/NEMA C57.12.91 paragraph

10.9 for additional information.

5.2 Mounting and Placement

The only foundation necessary is a non-combustible flat surface strong enough to support the weight of the unit. Note that

permanent and effective grounding of the metal case in accordance with NEC is recommended as a safety precaution.

Free circulation of ambient air is essential for the proper operation of all FAC dry-type transformers. The sides of the transformer

with ventilation openings require a minimum distance of six inches to adjacent noncombustible structures or equipment to ensure

proper circulation of air. Refer to enclosure assembly picture on last page.

CAUTION

TRANSFORMERS SHOULD BE INSTALLED AT LEAST TWELVE INCHES FROM COMBUSTIBLE MATERIALS,

INCLUDING MOUNTING SURFACE UNLESS SEPARATED BY FIRE RESISTANT HEAT INSULATING BARRIERS.

SPECIFIC REQUIREMENTS ARE DESCRIBED IN NEC, SECTION 450-21. CHECK LOCAL CODES.

5.3 Ventilation

FAC dry-type transformers are cooled both by free circulation of surrounding air and by forced circulation of air. They depend on

air to enter at the bottom, flow upward over the core and coil surfaces and exit through the openings near the top. These

transformers will carry full-rated loads continuously when the surrounding air does not exceed 30C/86F average, 40C/104F

maximum and adjacent structures permit free movement of cooling air.

The room in which dry-type transformers are located should be sized to permit locating transformers with sufficient spacing

between units and sufficient clearances to walls and other obstructions to permit the free circulation of air around each unit and to

minimize noise amplification. Sufficient space should also be maintained to permit routine inspection and maintenance.

Adequate ventilation is essential for the proper cooling of transformers. Clean dry air is desirable. Filtered air at or above

atmospheric pressure may reduce maintenance if dust or other contaminants present a problem. When transformers are located in

rooms or other restricted spaces, sufficient ventilation should be provided to hold the air temperature within established limits

(30C/86F average over 24 hours with a 40C/104F maximum) when measured near the transformer inlets.

5.4 Audible Sound Sources

The audible sound produced by FAC transformers is partially due to the energizing of the core by the alternating voltage applied to

the windings and also by the fans forcing air through the coils. The noise generated by the core creates vibrations whose

fundamental frequency is twice the frequency of the applied voltage. The audible sound will be present even under no load

conditions. The vibrations producing audible sound can occur in the core, coil, mounting, housing, and in the conduit. The

transmission of sound from the transformer can be by various media such as air, metal, concrete, wood or any combination.

Amplification of audible sound can occur in a given area due to the presence of reflecting surfaces.

3

Page 4

CONTROL OF AUDIBLE SOUND TRANSMISSION: Acoustical-absorbing material should be mounted on reflecting surfaces

to reduce sound reflection and possible amplification. Transformers should be mounted on a firm support having as great a mass as

possible. Vibration pads or properly designed isolation mounts under the transformer will reduce transmittal of sound. The

neoprene rubber isolation pads provided with the unit should be installed between the transformer and its mounting surface. This

will reduce case vibration and compensate for slight unevenness of the mount. Care must be taken to ensure proper and tight

installation of conduit. Flexible conduit is recommended. FAC units are provided with a noise insulation material inside the

enclosure to maintain continuous operation under limits set by NEMA.

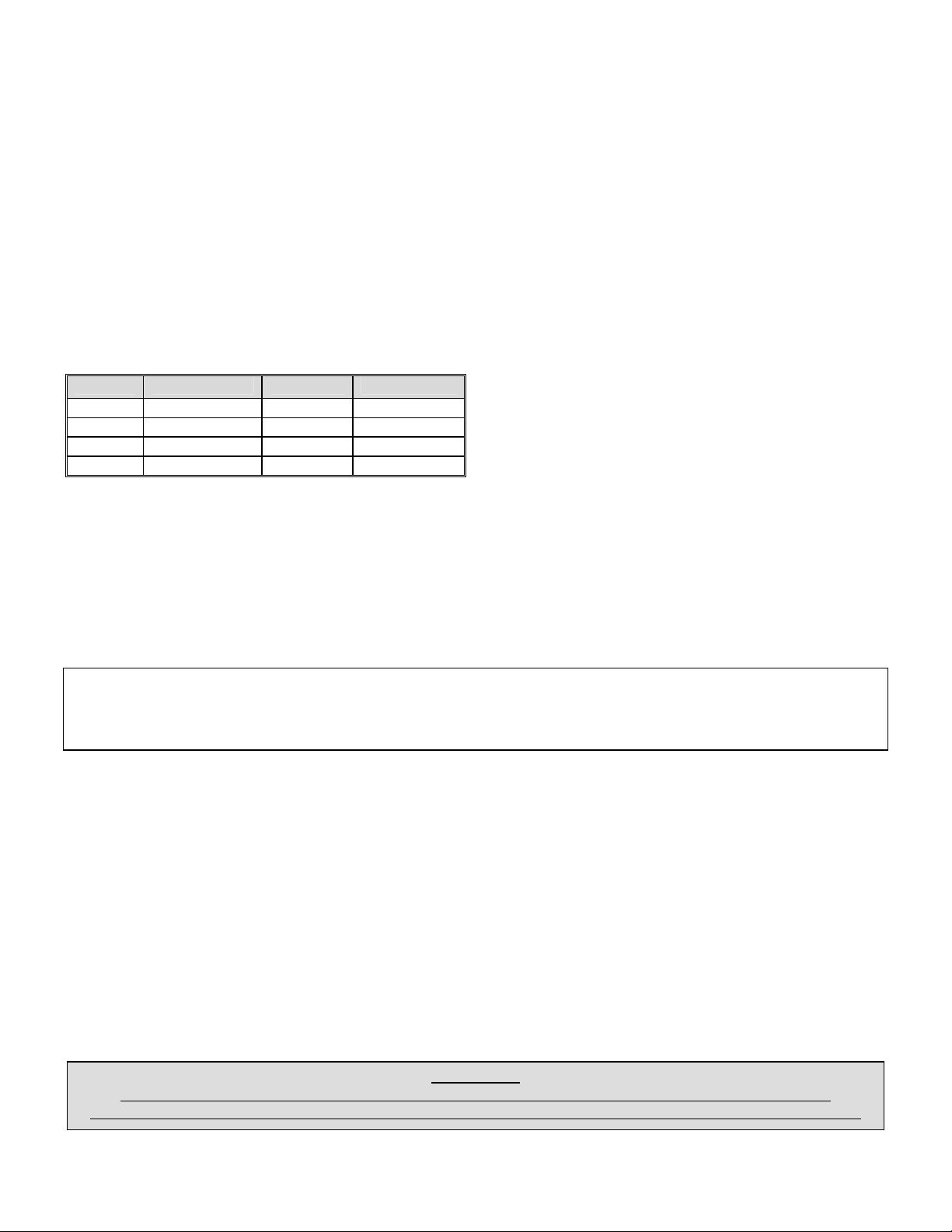

KVA

(150C RISE)

51-150 50

151-300 55

301-500 60

501-700 62

701-1000 64

All with FAC 67

Some circumstances that can cause high field readings are:

• Higher than rated voltage being applied to transformer windings (measured with a true RMS meter).

• Isolation pads were not installed.

• Transformer enclosure panels not properly tightened.

• Improper installation of conduit.

• Improper location of transformer. Mount the transformer as far away as possible from corners, walls or ceilings. Installing

transformers near hard surfaces such as concrete walls will amplify the sound requiring the use of sound absorbing materials.

AVERAGE SOUND

LEVEL IN DECIBELS

ANSI-C89.2

Dry type transformers are designed and manufactured to comply with

NEMA and ANSI standards. The decibel values referenced here

represent average values obtained in a sound laboratory per industry

standard test procedures. Decibel values obtained in field-testing are

unreliable and can be as much as 10 to 15 dB higher than actual test

lab values due to a variety of circumstances beyond the control of the

transformer manufacturer. In most cases transformers returned for

noise actually meet the ANSI standard when re-tested in a laboratory.

CAUTION

CARE SHOULD BE USED IN SELECTING SITES FOR TRANSFORMER INSTALLATION. SPECIFIC ATTENTION

SHOULD BE GIVEN TO OFFICE, CLASSROOM, MEDICAL AND HOSPITAL FACILITIES. WHEN TRANSFORMERS

ARE LOCATED IN ELECTRICAL CLOSETS ADJACENT TO HALLWAYS, SOUND CAN BE GREATLY AMPLIFIED.

TRANSFORMERS SPECIFICALLY DESIGNED FOR LOW NOISE ARE AVAILABLE, CONTACT YOUR DISTRIBUTOR.

6.0 Connections

6.1 Cable Conduit Entrance / Lugs

All cable connections to the transformer should be brought into the enclosure as low as possible to allow for the required cable

bending radius. When making cable connections ensure ventilation areas and fans remain unobstructed. When changing taps,

always use two wrenches for tightening or loosening bolted connections to prevent distortion or damage. Note: terminals must be

cleaned if it is necessary to change taps. Gently scrape the insulation/coating from the new connection and apply an electrical

joint compound.

All FAC units are designed for easy accommodation of cables and cable connectors. A three-phase

disconnect is included on the primary side and connections should be made to the lugs on the bottom

side of the disconnect. Bus bars are provided for secondary connections. Lug connectors can be

purchased commercially. The assembly of connectors to the line terminals is important. Follow

established installation procedures recommended by the connector manufacturer. Do not install washers

between the lug and the terminal since this would cause heating and arcing, resulting in failure of the

connector. Refer to the NEC and cable connection guide on front cover of transformer for sizing.

Follow torque recommendations of the connector manufacturer or use the adjacent guide.

WARNING

DO NOT REMOVE ENCLOSURE PARTS OR CHANGE CONNECTIONS WHILE THE UNIT IS ENERGIZED.

Bolt

Size

1/4” 60

5/16” 120

3/8” 220

1/2” 460

Torque

(In Lbs.)

4

Page 5

NOTE

AFTER INSTALLATION OF CONNECTORS AND CABLING, A MINIMUM OF 1” CLEARENCE MUST BE MAINTAINED

FROM ENERGIZED PARTS TO ALL CASE PARTS.

CAUTION

CARE MUST BE TAKEN TO PLACE ALL LEADS FROM A 3-PHASE LOAD THROUGH ONE KNOCKOUT AND THOSE

FROM THE SUPPLY/SOURCE THROUGH ONE KNOCKOUT SO THAT NO PART OF THE CASE IS BETWEEN SUCH

LEADS. IF MULTIPLE KNOCKOUT HOLES ARE REQUIRED, EACH KNOCKOUT HOLE MUST CONTAIN THE SAME

NUMBER OF CABELS ROUTED TO EACH PHASE OF THE TRANSFORMER. FAILURE TO DO SO CAN CAUSE

EXCESSIVE HEATING OF THE TRANSFORMER ENCLOSURE. TO PREVENT ENCLOSURE DAMAGE, PROVIDE

PROPER SUPPORT OF TRANSFORMER ENCLOSURE PANELS WHEN PULLING CABLES THROUGH PANEL.

6.2 Grounding

Consideration must be given to equipment grounding. Grounding methods and practices are well established and are beyond the

scope of this installation guide. The grounding conductor for a transformer should have a current carrying capacity in accordance

with the NEC. Refer to enclosure assembly picture on last page.

6.3 Lighting Tap Applications

Some transformers with a 240-volt delta connected secondary have a 120-volt single-phase lighting tap. The maximum single-phase

120-volt load should not exceed 5% of the three-phase kVA rating. The load should also be balanced at 2.5% maximum between

terminals X1 to X4 and 2.5% between terminals X3 to X4. Please note that fans obtain power from the secondary of the

transformer. On delta-wye transformers the fans will be connected to X0, X1, X2 and X3 while on delta-delta transformers they will

be connected to X4, X1 and X2 where X4 designates the lighting tap.

6.4 Fans, Alarm and Shunt

FAC units contain safety features to prevent overheating. An

audible alarm will sound when temperatures are over design

limits. If temperatures reach a critical point, a three-phase

disconnect (included on the primary side) will be activated

and all power will be shut off. For remote monitoring, the

following contacts on the terminal block will have 120 volts

(reference to Contact 1 on Terminal Block) when active and

0 volts when not active.

The fans, alarm and shunt that activates the three phase disconnect on FAC units are pre-wired in the factory and obtain power from

the secondary of the transformer.

Terminal on Block Significance if terminal has 120 volts.

Contact “6” Fans on phase 1 are running.

Contact “7” Fans on phase 2 are running.

Contact “8” Fans on phase 3 are running.

Contact “9” Alarm has been activated.

Contact “10”

(pulse only)

Three-phase disconnect has been

activated (power turned off).

7.0 Before Energizing

Visually inspect all parts of transformer for proper operation. Fans must not be obstructed, lever on three-phase disconnect must be

in raised position and noise insulation material must be adjacent to enclosure panels. Complete all connections to main harness if

remote monitoring is desired.

8.0 Operation

To maintain safe operating conditions do not remove panels of the enclosure while the transformer is energized.

CAUTION

NEVER ATTEMPT TO CHANGE TAPS OR CONNECTIONS UNLESS THE TRANSFORMER IS DE-ENERGIZED AND

ALL WINDINGS GROUNDED.

NOTE

TRANSFORMERS RUN HOT: AT FULL LOAD, TRANSFORMERS COULD HAVE A MAXIMUM 50C/122F

TEMPERATURE RISE ON THE SURFACE AREAS OF THE ENCLOSURE. WITH A 40C AMBIENT, THE MEASURED

TEMPERATURE COULD BE AS HIGH AS 90C/194F.

5

Page 6

8.1 Loading

In general, dry type transformers are designed to operate continuously at their nameplate kVA rating. ANSI C57.96 provides

guidance for loading under unusual conditions including: 1. Ambient temperatures higher or lower than the basis for rating; 2. Short

term loading in excess of nameplate kVA with normal life expectancy and; 3. Loading that results in reduced life expectancy.

If the transformer is experiencing increased temperatures, the following load characteristics should be considered immediately:

• Rigorous, frequent or multiple motor starting or impact loads for which a specific transformer for that application is required.

• Over excitation of unit due to excessive supply line voltage.

• Ambient temperatures above standard 40C maximum (30C average over 24 hours).

• Harmonic distortions of the supply line voltage or currents.

• Loads that are non-linear with harmonic distortion.

8.2 Over-excitation

Operation at voltages in excess of rating may cause core saturation, excessive core losses, overheating, abnormally high noise levels

and potential damage to fans. Special care should be taken where higher than rated primary voltage is anticipated. Most dry type

transformers incorporate primary taps to be able to match the supply voltage and are designed to reach rated temperature rise above

ambient air temperature when operated continuously at rated voltage, frequency and load.

WARNING

SERIOUS OVERHEATING RESULTING IN FIRE DAMAGE MAY RESULT IF THE UNIT IS OPERATED FOR

SUSTAINED PERIODS ABOVE RATED VOLTAGE OR CURRENT AND/OR AT OTHER THAN RATED FREQUENCY.

9.0 Troubleshooting

Problem: Circuit breaker (not three-phase disconnect included with unit) trips on start up

Possible causes:

Circuit breaker incorrectly sized for kVA rating of transformer.

Circuit breaker instantaneous trip (if applicable) set too low.

Supply voltage too high, over voltage being applied to transformer.

Supply voltage cables incorrectly connected to transformer secondary.

Transformer being reverse fed.

Primary ground cable connected to transformer secondary neutral bus.

Problem: Wrong secondary voltage or secondary voltage drifts

Possible causes:

Improper grounding.

Incorrect installation, review nameplate connection diagram.

Primary tap jumpers incorrectly installed.

Measurements must be taken with a true RMS meter.

Problem: Transformer noisy

Possible causes:

Transformer not installed per the recommended installation procedures outlined in this publication (paragraph 5.4).

Supply voltage to transformer higher than voltage rating of transformer.

Transformer overloaded.

Transformer enclosure panel screws not securely tightened.

Rubber isolation pads not installed.

Sound reverberating from reflecting surfaces.

Alarm is on (see below).

Problem: Transformer runs hot

Possible causes:

Overvoltage being applied to transformer.

Transformer being loaded at greater than nameplate kVA rating.

Higher than recommended (30C average / 40C maximum) ambient air.

Transformer enclosure ventilation openings obstructed or high content of dust and/or lint in transformer air ducts.

Clearance to walls (6.0”) not maintained.

Load contains large amount of harmonics.

Fans are obstructed, have been disconnected or are not working properly.

Problem: Alarm turns on

Possible causes:

Transformer is running over temperature limits (see above).

6

Page 7

Problem: Three-phase disconnect is being activated and power turned off

Possible causes:

Transformer is running over temperature limits (see above).

NOTE

TRANSFORMERS RUN HOT! UNITS LOCATED IN 40C AMBIENT, CAN HAVE ENCLOSURE TEMPERATURES CLOSE

TO 90C/194F WHEN FULLY LOADED.

10. Maintenance

Under normal environments and operating conditions, dry type transformers are virtually maintenance free. However, they do

require occasional internal cleaning, care and inspection. Fans may fail after life expectancy is reached, so they need to be inspected

regularly depending on load cycles. The frequency of inspection will depend on atmospheric and/or environmental conditions at a

given transformer installation or location.

CAUTION

ANY INTERNAL INSPECTION, ADJUSTMENT, CLEANING OR MAINTENANCE MUST BE DONE WITH THE

TRANSFORMER DE-ENERGIZED AND THE WINDINGS GROUNDED.

A continuously energized transformer needs periodic cleaning and maintenance only to remove accumulations of dust or dirt from

cooling ducts and other surfaces. Large accumulations may reduce cooling efficiency and lead to overheating. Cleaning is

recommended at least once a year in relatively clean installations and at more frequent intervals in more heavily contaminated

atmospheres.

Transformers that are de-energized for long periods of time generally require more frequent maintenance and cleaning to ensure

removal of contamination. Accumulation of dirt on insulating surfaces becomes a hazard when a considerable amount of moisture

is absorbed. Vacuuming is the recommended method for cleaning. Special attention should be given to cooling ducts within the

windings. Low-pressure dry air can be used if care is taken to avoid driving the contamination into the insulation.

Moisture is detrimental to most insulation systems. It is advisable to dry out any transformer that has been exposed for long periods

of time to high humidity. Whenever moisture is visible on insulation surfaces, the unit must be dried before being energized. If

moisture is evident, the unit should be dried out by placing it in an oven or by blowing heated air over it. The temperature of the

heated air should not exceed 110C/230F. Transformers may be subjected to flooding, direct rain or similar applications of water.

In such cases, normal drying techniques may not be adequate and the factory should be consulted. Additionally, if heavy moisture

and or direct contact with water has been allowed, the fans may no longer be functional.

Maintenance would include dust removal and/or drying, tap changing if applicable, tightening of bolted connections, inspection for

fan obstruction and general servicing and inspection of auxiliary devices. Additional information related to the installation and

maintenance of transformers can be found in ANSI publication C57.94, “Guide for Installation and Maintenance of Dry Type

Transformers”.

11. Storage

Condensation and moisture absorption must be prevented during storage. FAC units should be stored in a warm dry location having

a uniform temperature to prevent condensation. Openings should be covered to keep out dust. If outdoor storage cannot be

avoided, the transformer must be protected to prevent the entrance of water, moisture, dust, birds and other foreign material. If unit

is stored for extended periods of time, fans must be inspected to ensure they are functional.

12. Renewal Parts

The core-coil assembly precludes replacement parts. In most cases, field repairs are not recommended, are not economical and can

be dangerous. Renewal parts are available for all enclosure parts surrounding the core and coil assembly. Fan assemblies and

disconnects can also be replaced. Please contact the factory for replacement kits as well as for ordering a bottom panel for wall

mounting.

NOTE

These instructions do not purport to cover all details or variations in equipment or to provide for every possible contingency to be

met in connection with installation, operation or maintenance. Should further information be desired or should particular problems

arise which are not covered sufficiently for the purchasers purpose, the matter should be referred to the manufacturer.

7

Page 8

13. Typical Enclosure Information

HANDLING – Units are designed to be lifted and handled by a fork truck.

SHIPPING – Units are shipped with skids. Skids are to be removed at installation.

INSTALLATION – Enclosures are NEMA 2 rated and are intended for indoor use. By adding optional weather shields, the unit can

be rated NEMA 3R for outdoor use. The unit is shipped without a bottom plate. An optional bottom plate is available and must be

used if the unit is wall mounted.

Remove any packing materials and shipping hardware at installation and prior to energizing the unit.

8

Loading...

Loading...