Page 1

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

RoHS Compliant

Applications

Distributed Power Architectures

Wireless Networks

Access and Optical Network Equipment

Enterprise Networks including Power over Ethernet

(PoE)

Options

Negative Remote On/Off logic

Over current/Over temperature/Over voltage

protections (Auto-restart)

Features

Compliant to RoHS II EU “Directive 2011/65/EU”

Compliant to REACH Directive (EC) No 1907/2006

Compatible in a Pb-free or SnPb reflow environment

High efficiency – 95% at 12V full load

Industry standard, DOSA compliant, Eighth brick footprint

57.9mm x 22.9mm x 8.95mm

(2.28in x 0.90in x 0.352in)

Wide Input voltage range: 36-60 Vdc

Tightly regulated output

Constant switching frequency

Positive Remote On/Off logic

Input under/over voltage protection

Output overcurrent/voltage protection

Over-temperature protection

Remote sense

No minimum load required

No reverse current during output shutdown

Output Voltage adjust: 80% to 110% of V

Operating temperature range (-40°C to 85°C)

UL* 60950-1Recognized, CSA

and VDE

‡

0805:2001-12 (EN60950-1) Licensed

CE mark meets 73/23/EEC and 96/68/EEC directives

Meets the voltage and current requirements for ETSI 300-132-

2 and complies with and licensed for Basic insulation rating

per EN60950-1

2250 Vdc Isolation tested in compliance with IEEE 802.3

standards

**

ISO

9001 and ISO 14001 certified manufacturing facilities

o,nom

†

C22.2 No. 60950-1-03 Certified,

§

¤

PoE

* UL is a registered trademark of Underwriters Laboratories, Inc.

†

CSA is a registered trademark of Canadian Standards Association.

‡

VDE is a trademark of Verband Deutscher Elektrotechniker e.V.

§

This product is intended for integration into end-user equipment . All of the required procedures of end-use equipment should be followed.

¤ IEEE and 802 are registered trademarks of the Institute of Electrical and Electronics Engineers, Incorporated.

** ISO is a registered trademark of th e International Organization of Standards

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 1

Page 2

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

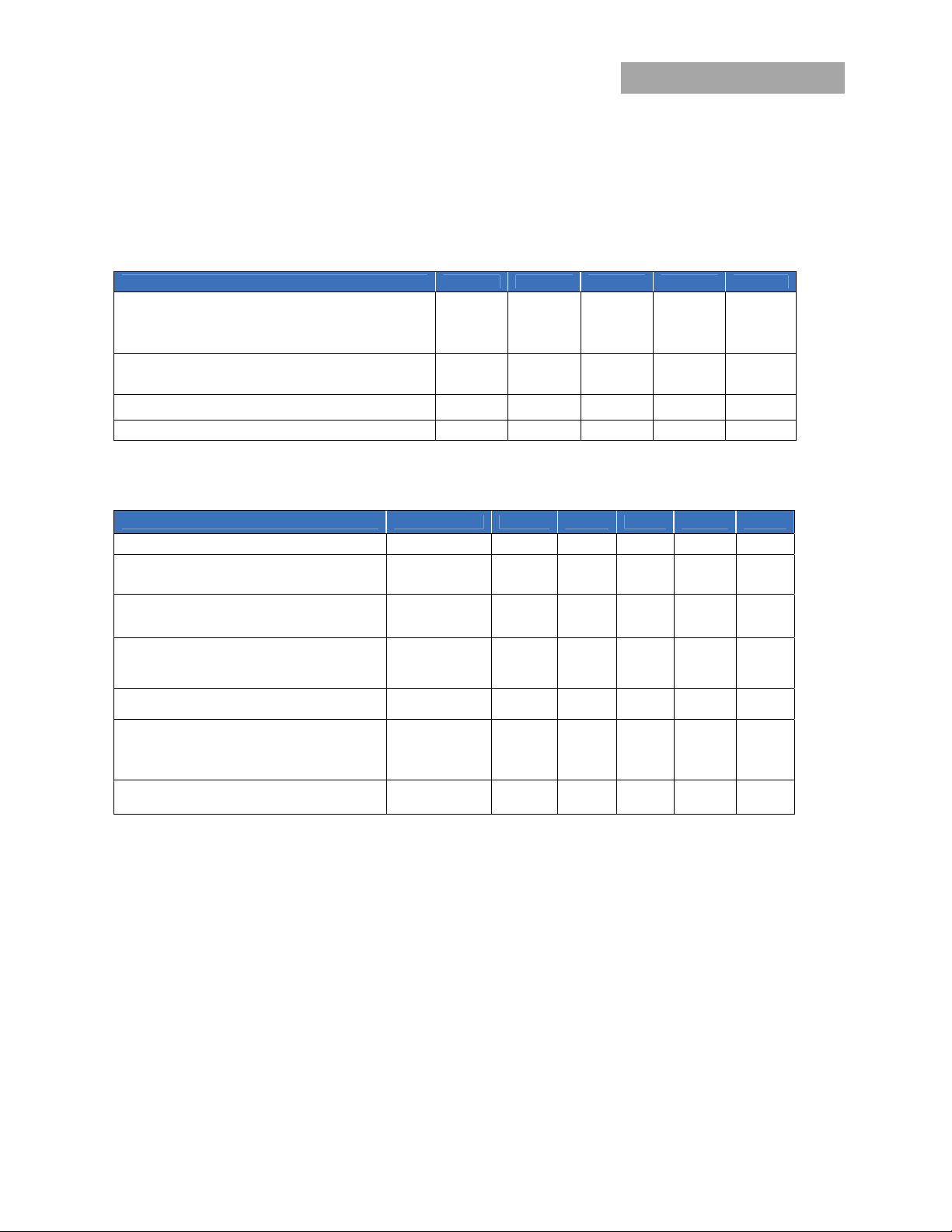

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings

only, functional operation of the device is not implied at these or any other conditions in excess of those given in the operations

sections of the data sheet. Exposure to absolute maximum ratings for extended periods can adversely affect the device reliability.

Parameter Device Symbol Min Max Unit

Input Voltage

Continuous All V

Transient (≤10 ms) All V

Operating Ambient Temperature All T

(see Thermal Considerations section)

Storage Temperature All T

I/O Isolation voltage (100% factory Hi-Pot tested) All

IN

IN,trans

A

stg

Electrical Specifications

Unless otherwise indicated, specifications apply over all operating input voltage, resistive load, and temperature conditions.

Parameter Device Symbol Min Typ Max Unit

Operating Input Voltage All VIN 36 48 60 Vdc

Maximum Input Current

(VIN= V

Input No Load Current

(VIN = V

Input Stand-by Current

(VIN = V

to V

IN, min

IN, nom

IN, nom

, IO=I

IN, max

, IO = 0, module enabled)

, module disabled)

O, max

)

All I

All I

All I

IN,max

IN,No load

IN,stand-by

-0.3 60 Vdc

-0.3 75 Vdc

-40 85 °C

-55 125 °C

2250 Vdc

4.0 4.4 Adc

75 mA

20 mA

Inrush Transient All I2t 0.5 A2s

Input Reflected Ripple Current, peak-to-peak

(5Hz to 20MHz, 1μH source impedance; V

IO= I

; See Test configuration section)

Omax

max,

Input Ripple Rejection (120Hz) All 50 dB

IN, min

to V

IN,

All 20 mA

p-p

CAUTION: This power module is not internally fused. An input line fuse must always be used.

This power module can be used in a wide variety of applications, ranging from simple standalone operation to an integrated part

of sophisticated power architectures. To preserve maximum flexibility, internal fusing is not included, however, to achieve

maximum safety and system protection, always use an input line fuse. The safety agencies require a time-delay fuse with a

maximum rating of 8 A (see Safety Considerations section). Based on the information provided in this data sheet on inrush energy

and maximum dc input current, the same type of fuse with a lower rating can be used. Refer to the fuse manufacturer’s data sheet

for further information.

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 2

Page 3

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

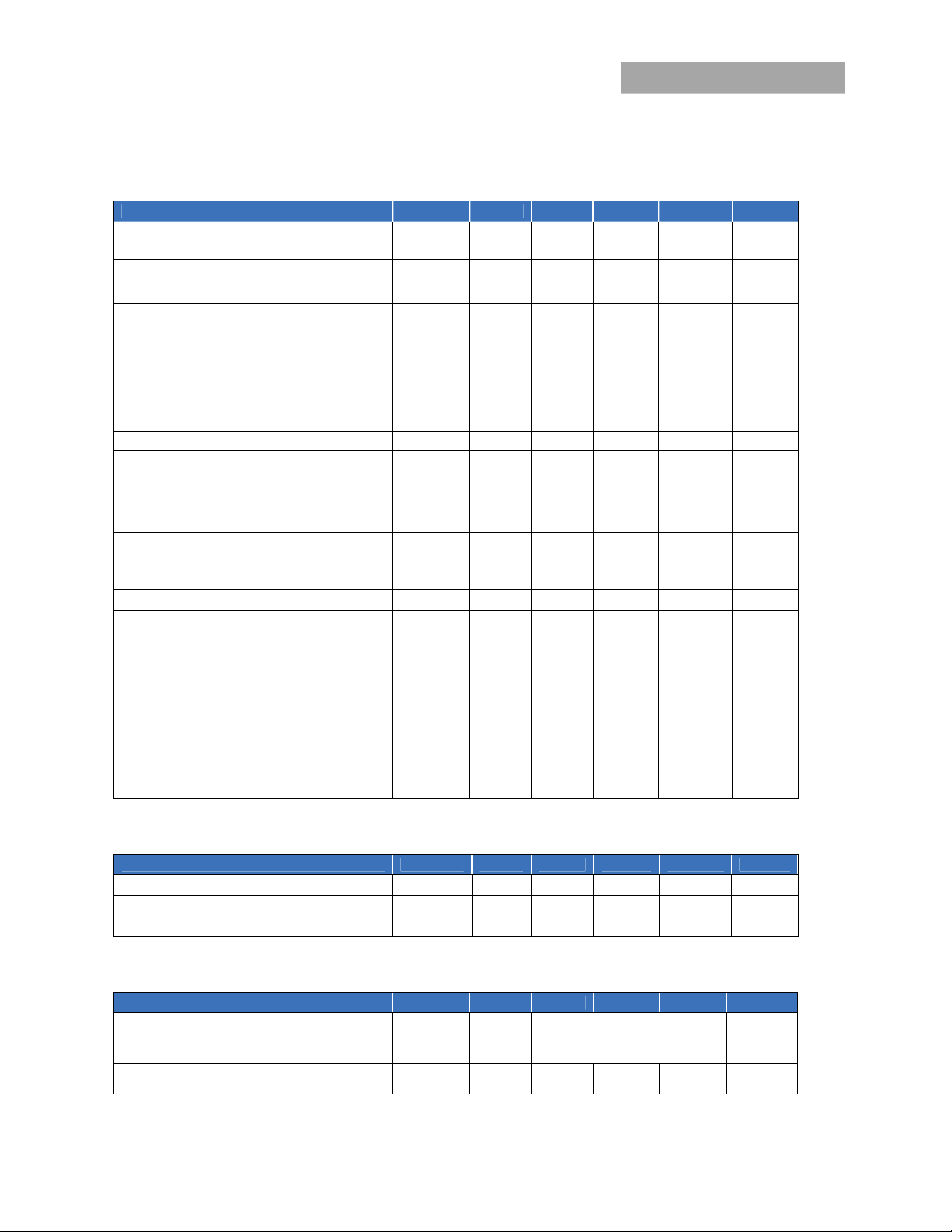

Electrical Specifications (continued)

Parameter Device Symbol Min Typ Max Unit

Nominal Output Voltage Set-point

VIN=V

IN, min

, IO=I

O, max

, TA=25°C)

All V

O, set

Output Voltage

(Over all operating input voltage, resistive load, and

All V

O

temperature conditions until end of life)

Output Regulation

Line (VIN=V

Load (IO=I

Temperature (T

IN, min

O, min

to V

to I

ref=TA, min

) All

O, max

IN, max

)

to T

) All

A, max

All

Output Ripple and Noise on nominal output

(VIN=V

IN, nom

,IO= I

O, max

, TA=T

A, min

to T

)

A, max

RMS (5Hz to 20MHz bandwidth) All

Peak-to-Peak (5Hz to 20MHz bandwidth) All

External Capacitance All C

Output Current All I

Output Current Limit Inception (Hiccup Mode ) All

(VO= 90% of V

Output Short-Circuit Current

(VO≤250mV) ( Hiccup Mode )

)

O, set

All I

I

O, lim

O, s/c

O

o

Efficiency All η 95 %

VIN= V

IO=I

Switching Frequency (Input ripple is ½ fsw) All f

, TA=25°C

IN, nom

= V

O, max , VO

O,set

sw

Dynamic Load Response

(dIo/dt=0.1A/s; VIN = V

IN, nom

; TA=25°C)

Load Change from Io= 50% to 75% or 25% to 50%

of Io,max;

Peak Deviation All V

Settling Time (Vo<10% peak deviation)

(dIo/dt=1A/s; VIN = V

IN, nom

; TA=25°C)

Load Change from Io= 50% to 75% or 25% to 50%

of Io,max;

Peak Deviation All V

Settling Time (Vo<10% peak deviation)

pk

All t

s

pk

All t

s

11.76 12.0 12.24 V

-3.0

100

0

+3.0 % V

0.2 % V

0.2 % V

1.0 % V

30 mV

100 mV

2,000 μF

11 Adc

105 115 130

3 5 A

% I

dc

O, set

O, set

O, set

O, set

rms

pk-pk

rms

o

330 kHz

3

200

% V

s

O, set

5

200

% V

s

O, set

Isolation Specifications

Parameter Device Symbol Min Typ Max Unit

Isolation Capacitance All C

Isolation Resistance All R

I/O Isolation Voltage (100% factory Hi-pot tested) All All

iso

iso

10

1000

2250 Vdc

pF

MΩ

General Specifications

Parameter Device Symbol Min Typ Max Unit

Calculated Reliability based upon Telcordia SR-332

Issue 2: Method

I Case 3 (I

=80%I

O

O, max

, TA=40°C,

airflow = 200 lfm, 90% confidence)

Weight (Open Frame) All

All FIT 315.1 10

All MTBF 3,173,243 Hours

19

(0.67)

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 3

9

/Hours

g

(oz.)

Page 4

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Feature Specifications

Unless otherwise indicated, specifications apply over all operating input voltage, resistive load, and temperature conditions. See

Feature Descriptions for additional information.

Parameter Device Symbol Min Typ Max Unit

Remote On/Off Signal Interface

(VIN=V

Signal referenced to V

Negative Logic: device code suffix “1”

Logic Low = module On, Logic High = module Off

Positive Logic: No device code suffix required

Logic Low = module Off, Logic High = module On

Turn-On Delay1 and Rise Times

(IO=I

Case 1: On/Off input is set to Logic Low (Module

ON) and then input power is applied (T

instant at which V

Case 2: Input power is applied for at least 1 second

and then the On/Off input is set from OFF to ON (T

instant V

Output voltage Rise time (time for Vo to rise from 10%

of V

Output voltage overshoot – Startup

IO= I

Remote Sense Range All V

(Max voltage drop is 0.5V)

Output Voltage Adjustment Range

Output Overvoltage Protection

Input Undervoltage Lockout All V

Input Overvoltage Lockout All V

Notes:

1. The module has an adaptable extended Turn-On Delay interval, T

rapid cycling of Vin from normal levels to less than the Input Undervoltage Lockout (which causes module shutdown), and then back to normal; or 2) toggling the

on/off signal from on to off and back to on without removing the input voltage. The normal Turn-On Delay interval, T

input voltage removed from the module for the preceding 1 second.

2. Maximum trim up possible only for Vin>40V.

to V

IN, min

Logic Low - Remote On/Off Current All I

Logic Low - On/Off Voltage All V

Logic High Voltage – (Typ = Open Collector) All V

Logic High maximum allowable leakage current All I

O, max , VIN=VIN, nom, TA

on/off

to 90% of V

o,set

; VIN=V

O, max

Turn-on Threshold

Turn-off Threshold

Hysterisis 1.5 2.0

Turn-off Threshold

Turn-on Threshold

Hysterisis 1 2

; open collector or equivalent,

IN, max

terminal)

IN-

on/off

on/off

on/off

on/off

-0.7

2.0 5.0 Vdc

1.0 mA

1.0 Vdc

10 μA

= 25 oC)

= V

until VO = 10% of V

IN

IN, min

toggles until VO = 10% of V

)

o, set

to V

IN, min

, TA = 25 oC

IN, max

2

delay

O, set

from

).

O,set

)

delay

All T

from

All T

All T

All

All 80 110 % V

All V

, of 4 seconds. The extended T

delay

— 25 30 msec

delay

— 12 20 msec

delay

rise

SENSE

O, limit

UVLO

OVLO

— 10 15 msec

— 3 % V

10 % V

13.8

16.5 Vdc

30 34.5 36 Vdc

30 32.5

60 62

64 66 V

will occur when the module restarts following either: 1) the

delay

, will occur whenever a module restarts with

delay

O, set

O, set

O, set

Vdc

Vdc

dc

Vdc

Vdc

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 4

Page 5

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Characteristic Curves

The following figures provide typical characteristics for the EVK011A0B (12V, 11A) at 25oC. The figures are identical for either

positive or negative remote On/Off logic.

(V) (200mV/div)

O

EFFICIENCY, (%)

OUTPUT CURRENT, IO (A) TIME, t (200µs/div)

Io(A) (5A/div) V

OUTPUT CURRENT OUTPUT VOLTAGE

Figure 1. Converter Efficiency versus Output Current. Figure 4. Transient Response to 1.0A/µS Dynamic Load

= V

IN

IN,NOM

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (2s/div)

Figure 2. Typical output ripple and noise (V

o,max).

I

(V) (200mV/div)

O

IN = VIN,NOM, Io

Change from 50% to 75% to 50% of full load (V

=100µF.

C

O

(V) (2V/div)

O

(V) (5V/div) V

On/Off

V

OUTPUT VOLTAGE On/Off VOLTAGE

TIME, t (10ms/div)

Figure 5. Typical Start-up Using Remote On/Off, negative

=

logic version shown (VIN = VIN,NOM, Io = Io,max).

(V) (20V/div)

IN

),

(V) (5V/div) V

O

Io(A) (5A/div) V

OUTPUT CURRENT OUTPUT VOLTAGE

Figure 3. Transient Response to 0.1A/µS Dynamic Load

Change from 50% to 75% to 50% of full load (V

=100µF.

C

O

TIME, t (200µs/div) TIME, t (10ms/div)

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 6. Typical Start-up Using Input Voltage (V

IN

= V

IN,NOM

),

o = Io,max).

I

IN = VIN,NOM,

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 5

Page 6

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Test Configurations

Vout+

Vout-

33-100μF

V

CURRENT P ROBE

RESISTIVE

LOA D

R

contact Rdistribution

O

R

contact Rdistribution

x 100 %

Vin+

Vin-

R

TO OSCILL OSCOPE

L

TEST

12μH

CS 220μF

BAT TERY

NOTE: M easure input r eflected r ipple c urrent with a s imulat ed

E.S .R.<0 .1

@ 20° C 100kHz

source inductance (L

possi ble batt ery impedance . Meas ure curre nt as show n

above.

) of 12μH. Capacitor CS offs ets

TEST

Figure 7. Input Reflected Ripple Current Test Setup.

COPPER STR IP

V O (+)

SCOP E

V O ( – )

NOTE: A ll volt age mea surements to be tak en at the module

termin als, as shown ab ove. If sock ets are used th en

Kelvi n conn ections are required at th e module te rminals

to av oid me asureme nt errors due to s ocket conta ct

resistance.

10uF

1uF

GROUND PLANE

Figure 8. Output Ripple and Noise Test Setup.

R

R

contact

distribution

R

R

contact

distribution

NOTE: All voltage measurements to be taken at t he module

terminals, as shown above. If sockets are used then

Kelvin connections are required at the module terminals

to avoid measurement errors due to socket contact

resistance.

Vin+

V

IN

Vin-

Figure 9. Output Voltage and Efficiency Test Setup.

V

. I

O

Efficiency

=

VIN. I

O

IN

LOAD

Design Considerations

Input Filtering

The power module should be connected to a low

ac-impedance source. Highly inductive source

impedance can affect the stability of the power module.

For the test configuration in Figure 7 a 33-100μF

electrolytic capacitor (ESR<0.1 at 100kHz), mounted

close to the power module helps ensure the stability of

the unit. Consult the factory for further application

guidelines.

Safety Considerations

For safety-agency approval of the system in which the

power module is used, the power module must be

installed in compliance with the spacing and separation

requirements of the end-use safety agency standard,

i.e., UL 60950-1-3, CSA C22.2 No. 60950-00, and VDE

0805:2001-12 (IEC60950-1).

If the input source is non-SELV (ELV or a hazardous

voltage greater than 60 Vdc and less than or equal to

75Vdc), for the module’s output to be considered as

meeting the requirements for safety extra-low voltage

(SELV), all of the following must be true:

The input source is to be provided with reinforced

insulation from any other hazardous voltages,

including the ac mains.

One V

pin and one V

IN

both the input and output pins are to be kept

floating.

The input pins of the module are not operator

accessible.

Another SELV reliability test is conducted on the

whole system (combination of supply source and

subject module), as required by the safety

agencies, to verify that under a single fault,

hazardous voltages do not appear at the module’s

output.

Note: Do not ground either of the input pins of the

module without grounding one of the output

pins. This may allow a non-SELV voltage to

appear between the output pins and ground.

The power module has extra-low voltage (ELV) outputs

when all inputs are ELV.

All flammable materials used in the manufacturing of

these modules are rated 94V-0, or tested to the

UL60950 A.2 for reduced thickness.

For input voltages exceeding –60 Vdc but less than or

equal to –75 Vdc, these converters have been evaluated

to the applicable requirements of BASIC INSULATION

between secondary DC MAINS DISTRIBUTION input

(classified as TNV-2 in Europe) and unearthed SELV

outputs.

The input to these units is to be provided with a

maximum 8 A time-delay fuse in the ungrounded lead.

pin are to be grounded, or

OUT

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 6

Page 7

GE

E

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Feature Description

V

I(+)

I(-)

V

SENSE(+)

SENSE(–)

VO(+)

O(–)

V

IO

CONTACT AND

DISTRIBUTION LOSS

Remote On/Off

Two remote on/off options are available. Positive logic turns the

module on during a logic high voltage on the ON/OFF pin, and

off during a logic low. Negative logic remote On/Off, device code

suffix “1”, turns the module off during a logic high and on during

a logic low.

SUPPLY

I

I

CONTACT

RESISTANCE

Figure 11. Circuit Configuration for remote sense .

LOAD

I

on/off

V

Vin+

ON/OFF

on/off

Vin-

Vout+

TRIM

Vout-

Figure 10. Remote On/Off Implementation.

To turn the power module on and off, the user must supply a

switch (open collector or equivalent) to control the voltage

) between the ON/OFF terminal and the VIN(-) terminal (see

(V

on/off

Figure 10). Logic low is 0V ≤ V

≤ 1.0V. The maximum I

on/off

on/off

during a logic low is 1mA, the switch should be maintain a logic

low level whilst sinking this current.

During a logic high, the typical maximum V

generated by the

on/off

module is 5V, and the maximum allowable leakage current at

= 5V is 1μA.

V

on/off

If not using the remote on/off feature:

For positive logic, leave the ON/OFF pin open.

For negative logic, short the ON/OFF pin to V

(-).

IN

Remote Sense

Remote sense minimizes the effects of distribution losses by

regulating the voltage at the remote-sense connections (See

Figure 11). The voltage between the remote-sense pins and the

output terminals must not exceed the output voltage sense

range given in the Feature Specifications table:

(+) – VO(–)] – [SENSE(+) – SENSE(–)] 0.5 V

[V

O

Although the output voltage can be increased by both the

remote sense and by the trim, the maximum increase for the

output voltage is not the sum of both. The maximum increase is

the larger of either the remote sense or the trim. The amount of

power delivered by the module is defined as the voltage at the

output terminals multiplied by the output current. When using

remote sense and trim, the output voltage of the module can be

increased, which at the same output current would increase the

power output of the module. Care should be taken to ensure

that the maximum output power of the module remains at or

below the maximum rated power (Maximum rated power =

Vo,set x Io,max).

Input Undervoltage Lockout

At input voltages below the input undervoltage lockout

limit, the module operation is disabled. The module will

only begin to operate once the input voltage is raised

above the undervoltage lockout turn-on threshold,

.

V

UV/ON

Once operating, the module will continue to operate

until the input voltage is taken below the undervoltage

turn-off threshold, V

UV/OFF

.

Overtemperature Protection

To provide protection under certain fault conditions, the

unit is equipped with a thermal shutdown circuit. The

unit will shutdown, if the thermal reference point (Figure

13), exceeds T

= 133 OC or T

ref1

= 140OC (typical), but

ref2

the thermal shutdown is not intended as a guarantee

that the unit will survive temperatures beyond its rating.

The module will automatically restart upon cool-down

to a safe temperature.

Output Overvoltage Protection

The output over voltage protection scheme of the

modules has an independent over voltage loop to

prevent single point of failure. This protection feature

latches in the event of over voltage across the output.

Cycling the on/off pin or input voltage resets the

latching protection feature. If the auto-restart option (4)

is ordered, the module will automatically restart upon

an internally programmed time elapsing.

Overcurrent Protection

To provide protection in a fault (output overload)

condition, the unit is equipped with internal

current-limiting circuitry and can endure current

limiting continuously. At the point of current-limit

inception, the unit enters hiccup mode. If the unit is

not configured with auto–restart, then it will latch off

following the over current condition. The module can be

restarted by cycling the dc input power for at least one

second or by toggling the remote on/off signal for at

least one second. If the unit is configured with the autorestart option (4), it will remain in the hiccup mode as

long as the overcurrent condition exists; it operates

normally, once the output current is brought back into

its specified range. The average output current during

hiccup is 10% I

O, max

.

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 7

Page 8

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Feature Descriptions (continued)

Output Voltage Programming

Trimming allows the output voltage set point to be increased or

decreased, this is accomplished by connecting an external

resistor between the TRIM pin and either the V

pin.

VIN(+)

ON/OFF

VIN(-)

VO(+)

VOTRIM

VO(-)

Figure 12. Circuit Configuration to Trim Output Voltage.

Connecting an external resistor (R

trim-down

and the Vo(-) (or Sense(-)) pin decreases the output voltage set

point. To maintain set point accuracy, the trim resistor tolerance

should be ±1.0%.

The following equation determines the required external resistor

value to obtain a percentage output voltage change of ∆%

511

kRdowntrim

%

Where

,

V

VV

desiredseto

100%

,

seto

For example, to trim-down the output voltage of the module by

8% to 11.04V, Rtrim-down is calculated as follows:

8%

511

kRdowntrim

8

R

downtrim

Connecting an external resistor (R

and the V

(+) (or Sense (+)) pin increases the output voltage set

O

point. The following equations determine the required external

resistor value to obtain a percentage output voltage change of

∆%:

22.10

trim-up

(+) pin or the VO(-)

O

R

trim-up

LOAD

R

trim-down

) between the TRIM pin

22.10

655.53

) between the TRIM pin

The voltage between the Vo(+) and Vo(–) terminals must

not exceed the minimum output overvoltage protection

value shown in the Feature Specifications table. This

limit includes any increase in voltage due to remotesense compensation and output voltage set-point

adjustment trim.

Although the output voltage can be increased by both

the remote sense and by the trim, the maximum

increase for the output voltage is not the sum of both.

The maximum increase is the larger of either the remote

sense or the trim. The amount of power delivered by the

module is defined as the voltage at the output terminals

multiplied by the output current. When using remote

sense and trim, the output voltage of the module can be

increased, which at the same output current would

increase the power output of the module. Care should

be taken to ensure that the maximum output power of

the module remains at or below the maximum rated

power (Maximum rated power = V

O,set

x I

O,max

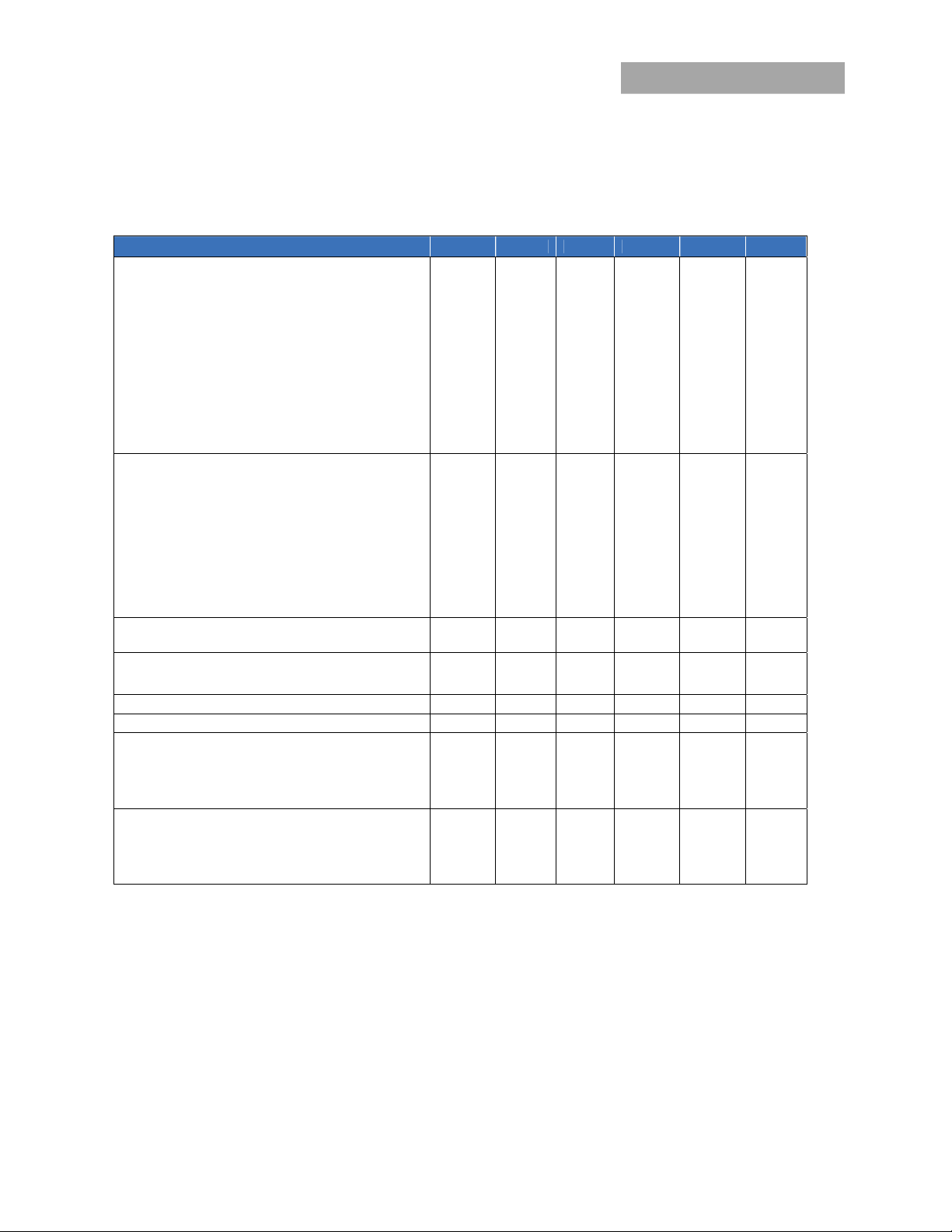

Thermal Considerations

The power modules operate in a variety of thermal

environments; however, sufficient cooling should be

provided to help ensure reliable operation.

Considerations include ambient temperature, airflow,

module power dissipation, and the need for increased

reliability. A reduction in the operating temperature of

the module will result in an increase in reliability. The

thermal data presented here is based on physical

measurements taken in a wind tunnel, using automated

thermo-couple instrumentation to monitor key

component temperatures: FETs, diodes, control ICs,

magnetic cores, ceramic capacitors, opto-isolators, and

module pwb conductors, while controlling the ambient

airflow rate and temperature. For a given airflow and

ambient temperature, the module output power is

increased, until one (or more) of the components

reaches its maximum derated operating temperature,

as defined in IPC-9592. This procedure is then repeated

for a different airflow or ambient temperature until a

family of module output derating curves is obtained.

).

%)100(11.5

511

%225.1

,

setodesired

100%

%

k

22.10

Where

V

R

uptrim

seto

,

VV

V

,

seto

For example, to trim-up the output voltage of the module by 5%

to 12.6V, R

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 8

is calculated is as follows:

trim-up

kRuptrim

kRuptrim

5%

511

)5100(0.1211.5

5225.1

5

8.938

22.10

Page 9

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Thermal Considerations (continued)

Heat-dissipating components are mounted on the top side

The thermal reference points, T

specifications for open frame modules is shown in Figure 13.

For reliable operation T

should not exceed 123oC .

Figure 13. T

Frame Module.

Temperature Measurement Location for open

ref

ref1

and T

ref1

should not exceed 128oC, and T

Heat Transfer via Convection

Increased airflow over the module enhances the heat

transfer via convection. Derating curves showing the

maximum output current that can be delivered by the open

frame module versus local ambient temperature (T

convection and up to 1.5m/s (300 ft./min) forced airflow are

shown in Figure 14.

used in the

ref2

ref2

A) for natural

Pb and Pb-free wave soldering processes. A maximum

preheat rate of 3

process should be such that the temperature of the

power module board is kept below 210

the recommended pot temperature is 260

Pb-free solder pot is 270

compliant through-hole products can be processed with

paste-through-hole Pb or Pb-free reflow process. If

additional information is needed, please consult with

your GE representative for more details.

C/s is suggested. The wave preheat

C. For Pb solder,

C max. Not all RoHS-

Post Solder Cleaning and Drying Considerations

Post solder cleaning is usually the final circuit-board

assembly process prior to electrical board testing. The

result of inadequate cleaning and drying can affect both

the reliability of a power module and the testability of

the finished circuit-board assembly. For guidance on

appropriate soldering, cleaning and drying procedures,

refer to GE Board Mounted Power Modules: Soldering

and Cleaning Application Note (AN04-001).

C, while the

(A)

O

OUTPUT CURRENT, I

Figure 14. Output Current Derating for the Open Frame

Module; Airflow in the Transverse Direction from Vout(+) to

Vout(-); Vin =48V.

Please refer to the Application Note “Thermal Characterization

Process For Open-Frame Board-Mounted Power Modules” for a

detailed discussion of thermal aspects including maximum

device temperatures.

AMBIENT TEMEPERATURE, TA (oC)

Through-Hole Soldering Information

The RoHS-compliant (Z codes) through-hole products use the

SAC (Sn/Ag/Cu) Pb-free solder and RoHS-compliant components.

The RoHS-compliant with lead solder exemption (non-Z codes)

through-hole products use Sn/Pb solder and RoHS-compliant

components. Both non-Z and Z codes are designed to be

processed through single or dual wave soldering machines. The

pins have an RoHS-compliant finish that is compatible with both

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 9

Page 10

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

EMC Considerations

The circuit and plots in Figure 15 shows a suggested configuration to meet the conducted emission limits of EN55022 Class B.

Figure 15. EMC Considerations

For further information on designing for EMC compliance, please refer to the FLT007A0 data sheet (DS05-028).

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 10

Page 11

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

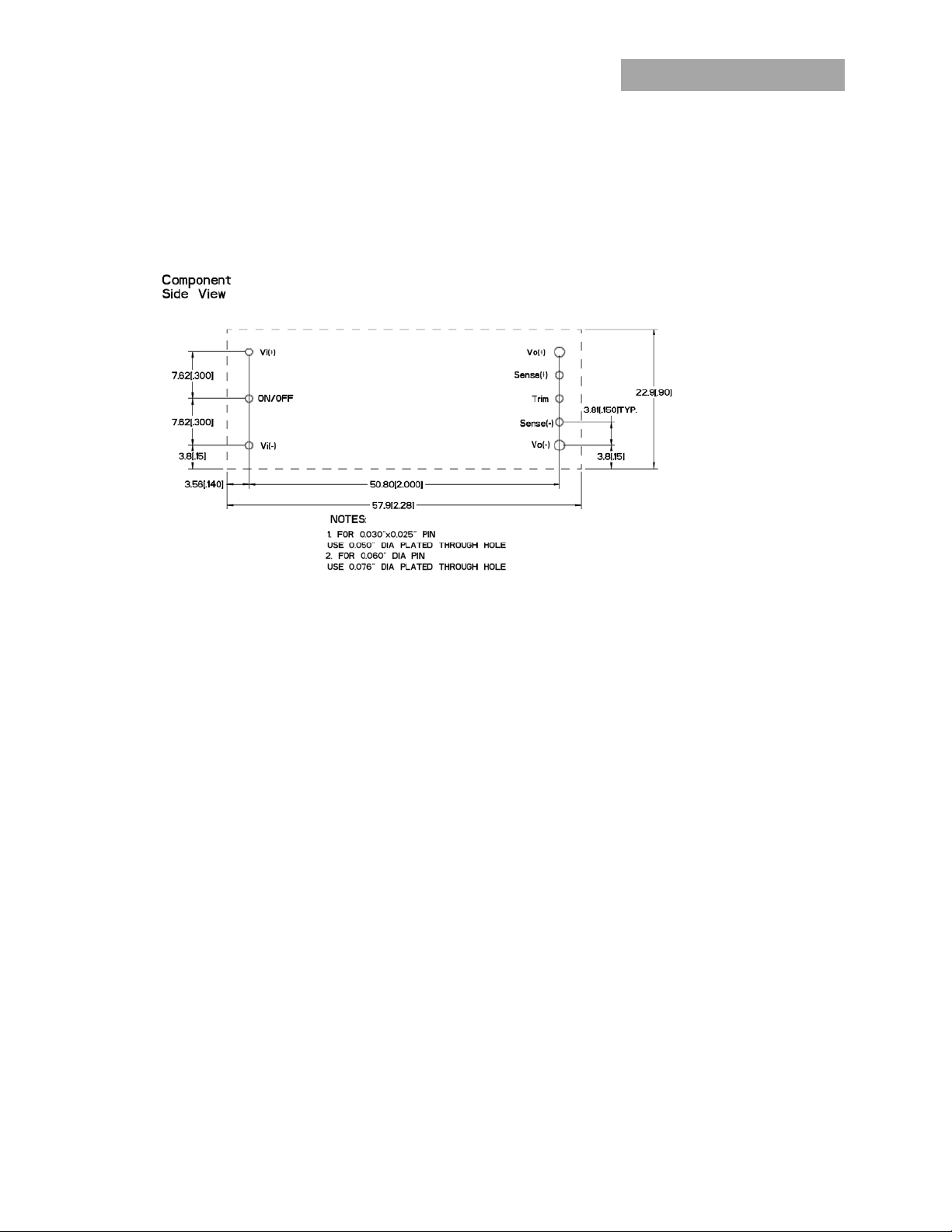

Mechanical Outline for Through-Hole Module

Dimensions are in millimeters and [inches].

Tolerances: x.x mm

x.xx mm

Top

#

View

0.5 mm [x.xx in. 0.02 in.] (Unless otherwise indicated)

0.25 mm [x.xxx in 0.010 in.]

#Top side label includes GE name, product designation and date code.

Side

View

Bottom

View

* For optional pin lengths, see Table 2 Device Options and Coding Scheme

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 11

Page 12

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

Recommended Pad Layout

Dimensions are in millimeters and [inches].

Tolerances: x.x mm

x.xx mm

0.5 mm [x.xx in. 0.02 in.] (Unless otherwise indicated)

0.25 mm [x.xxx in 0.010 in.]

TH Recommended Pad Layout (Component Side View)

May 15, 2013 ©2012 General Electric Company. All rights reserved. Page 12

Page 13

GE

Data Sheet

EVK011A0B Series (Eighth-Brick) DC-DC Converter Power Modules

36–60Vdc Input; 12.0Vdc Output; 11A Output Current

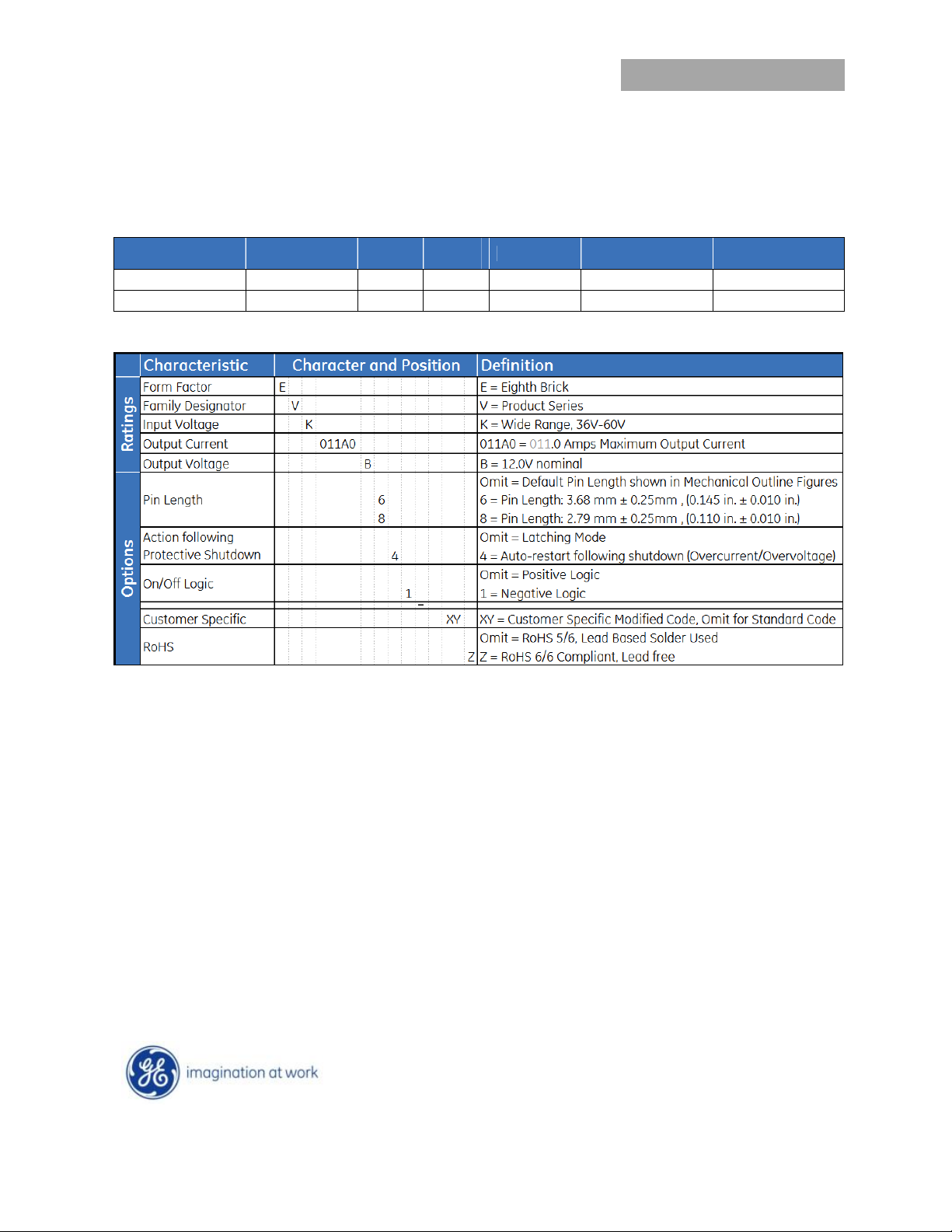

Ordering Information

Please contact your GE Sales Representative for pricing, availability and optional features.

Table 1. Device Codes

Product Codes Input Voltage

EVK011A0B41Z 48V (36-60Vdc) 12V 11A Negative Through hole 150027164

EVK011A0B641Z 48V (36-60Vdc) 12V 11A Negative Through hole 150030268

Table 2. Device Options and Coding Scheme

Output

Voltage

Output

Current

On/Off Logic

Connector

Type

Comcodes

Contact Us

For more information, call us at

USA/Canada:

+1 888 546 3243, or +1 972 244 9288

Asia-Pacific:

+86.021.54279977*808

Europe, Middle-East and Africa:

+49.89.878067-280

India:

May 15, 2013 ©2012 General Electric Company. All rights reserved. Version 1.1

+91.80.28411633

www.ge.com/powerelectronics

Loading...

Loading...