Page 1

GE Energy

Industrial Solutions

EPM 1500

SINGLE POINT

Instruction Manual

Manual P/N: 1601-0155-A7

Manual Order Code: GEK-106554G

Copyright © 2010 GE Energy

GE Energy

Industrial Solutions

41 Woodford Avenue

SUBMETERING SYSTEM

Plainville, CT 06062

Internet: http://www.geindustrial.com

Page 2

These instructions do not purport to cover all details or variations in equipment nor provide

for every possible contingency to be met in connection with installation, operation, or

maintenance. Should further information be desired or should particular problems arise

which are not covered sufficiently for the purchaser’s purpose, the matter should be referred

to the General Electric Company.

To the extent required the products described herein meet applicable ANSI, IEEE, and NEMA

standards; but no such assurance is given with respect to local codes and ordinances

because they vary greatly.

© 2010 GE Energy. All rights reserved.

GE Energy EPM 1500 Sub-Meter instruction manual.

EPM 1500 Sub-Meter is a registered trademark of GE Energy Inc.

The contents of this manual are the property of GE Energy Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Energy. The content of this manual is for informational use only and is subject to

change without notice.

Part numbers contained in this manual are subject to change without notice, and should

therefore be verified by GE Energy before ordering.

Part number: 1601-0155-A7 (November 2007)

Page 3

TOC

Table of Contents

1: OVERVIEW GETTING STARTED ............................................................................................................1-1

ESCRIPTION ........................................................................................................................ 1-1

D

ONTACT INFORMATION ..................................................................................................... 1-1

C

APPLICATIONS ...................................................................................................................1-2

TAND-ALONE METER ........................................................................................................ 1-2

S

ETERING SYSTEM .............................................................................................................. 1-2

M

NTERIOR VIEW ....................................................................................................................1-3

I

AUTIONS AND WARNINGS ............................................................................................... 1-3

C

ROTECTIVE CONDUCTOR TERMINAL ............................................................................... 1-4

P

REVENTIVE MAINTENANCE ............................................................................................... 1-4

P

SPECIFICATIONS ................................................................................................................1-5

ECHNICAL SPECIFICATIONS .............................................................................................. 1-5

T

PPROVALS ........................................................................................................................... 1-5

A

ORDERING ..........................................................................................................................1-6

ATALOG NUMBERS ............................................................................................................ 1-6

C

ODIFICATIONS ................................................................................................................... 1-6

M

CCESSORIES ....................................................................................................................... 1-6

A

2: INSTALLATION GETTING READY ................................................................................................................2-1

ETERMINATION OF METERING SYSTEM REQUIREMENTS ..............................................2-1

D

VERVIEW OF METER WIRING .......................................................................................... 2-1

O

WIRING DIAGRAMS ..........................................................................................................2-2

VERVIEW ............................................................................................................................ 2-2

O

HASE, 4-WIRE WYE ..................................................................................................... 2-3

3-P

HASE, 3-WIRE CENTER-TAP-NEUTRAL 120/240 V .............................................. 2-4

1-P

HASE, 4-WIRE CENTER-TAP-NEUTRAL 120/240 V DELTA ................................. 2-5

3-P

HASE, 3-WIRE UNGROUNDED 480 V DELTA .......................................................... 2-6

3-P

HASE, 3-WIRE CORNER-GROUNDED 480 V DELTA .............................................. 2-7

3-P

IRING FOR 1600 A AND 3200 A MODELS ................................................................ 2-8

W

INSTALLATION OF METER AND CURRENT TRANSFORMERS ..................................2-9

ROCEDURE .......................................................................................................................... 2-9

P

NTERNAL SHORTING TERMINAL ........................................................................................ 2-11

I

INSTALLING THE PULSE INPUTS ....................................................................................2-12

ULSE INPUT OPTION .........................................................................................................2-12

P

INSTALLING THE GE TRANSPONDER ...........................................................................2-13

ROCEDURE .......................................................................................................................... 2-13

P

3: USING THE METER MENU NAVIGATION ..........................................................................................................3-1

SER INTERFACE ..................................................................................................................3-1

U

CT MULTIPLIER TABLE ......................................................................................................3-4

ULTIPLIERS .................................................................................................................. 3-4

CT M

VERIFYING METER FUNCTIONALITY .............................................................................3-5

VERVIEW ............................................................................................................................ 3-5

O

ERIFYING VOLTAGE ........................................................................................................... 3-5

V

ERIFYING KWH READING ................................................................................................. 3-5

V

ERIFYING CURRENT AND ENERGY ................................................................................... 3-6

V

RESETTING THE DEMAND VALUES ...............................................................................3-7

ROCEDURE .......................................................................................................................... 3-7

P

EPM 1500 SUB-METER – INSTRUCTION MANUAL TOC–1

Page 4

TOC

4: COMMUNICATIONS MODBUS COMMUNICATIONS ........................................................................................4-1

RS485 W

RS232 W

ODBUS COMMANDS ......................................................................................................... 4-2

M

IXED MODBUS VALUES ..................................................................................................... 4-2

F

ODBUS DATA REGISTER (R4 TYPE) GROUPS ................................................................ 4-2

M

NSTANTANEOUS DATA ITEMS ............................................................................................4-3

I

32-

IRING FOR MODBUS ......................................................................................... 4-1

IRING FOR MODBUS ......................................................................................... 4-2

BIT LONG AND FLOAT DATA FORMATS ..................................................................... 4-3

MODBUS ACTIVATION .....................................................................................................4-4

VERVIEW ............................................................................................................................ 4-4

O

ONFIGURING A NEW HYPERTERMINAL SESSION .......................................................... 4-4

C

ONFIRMING CONNECTION TO THE EPM 1500 ............................................................ 4-5

C

OGGING INTO THE METER ................................................................................................ 4-5

L

CTIVATING MODBUS COMMUNICATIONS ....................................................................... 4-6

A

HANGING MODBUS SETTINGS ......................................................................................... 4-7

C

OGGING OUT ...................................................................................................................... 4-7

L

ISABLING MODBUS COMMUNICATIONS ......................................................................... 4-7

D

MODBUS MEMORY MAP ..................................................................................................4-8

EMORY MAP ......................................................................................................................4-8

M

5: MISCELLANEOUS REVISION HISTORY ...........................................................................................................5-1

ELEASE DATES ...................................................................................................................5-1

R

HANGES TO THE MANUAL ................................................................................................ 5-1

C

WARRANTY .........................................................................................................................5-4

GE ENERGY

WARRANTY ..................................................................................................... 5-4

INDEX

TOC–2 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 5

GE Energy

Industrial Solutions

1.1 Getting Started

EPM 1500 Single Point

Submetering System

Chapter 1: Overview

Overview

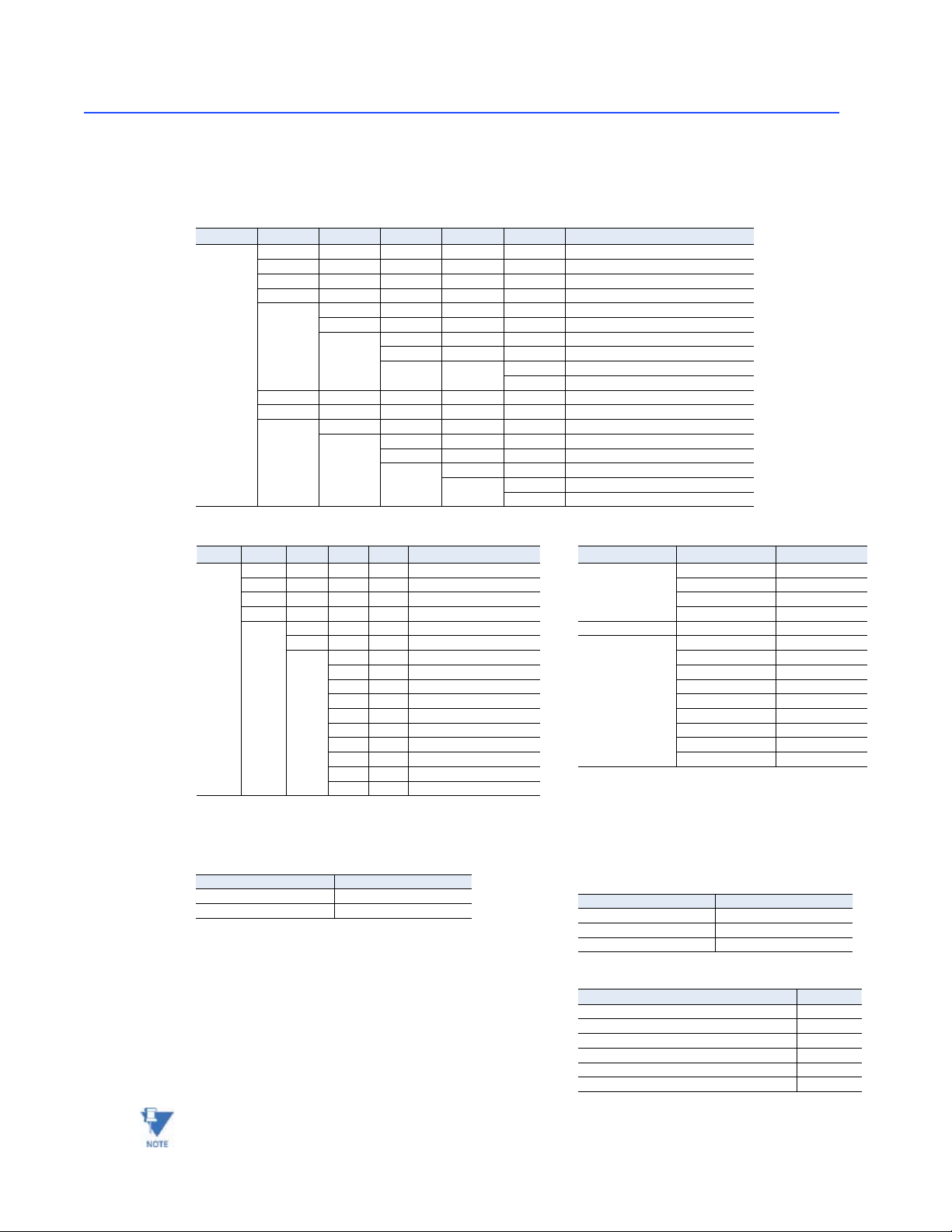

1.1.1 Description

Thank you for purchasing the GE Energy EPM 1500 sub-meter to monitor energy for your

residential, commercial, or industrial applications. At GE Energy, we pride ourselves by

providing our customers with best-in-class products, which have been carefully selected

by GE to best serve your solution needs.

The EPM 1500 is sold in KWh or Demand meter versions and is available for 120/208V and

277/480V applications. An integrated liquid crystal display (LCD) is standard on all versions,

providing local access to real-time and historical data. The meter provides two standard

communication modes: power line communications (PLC), which utilizes existing AC power

lines as the communication medium, eliminating dedicated wiring, and Modbus (RS232,

RS485, modem).

The EPM 1500 is packaged with either solid or split core CTs in various amperages to suit

both new construction and retrofit applications.

Note

1.1.2 Contact Information

The EPM 1500 is primarily used for commercial and industrial applications and is available

in voltages ranging from 120 to 600 V in both wye and delta forms. The following

installation instructions are applicable to the EPM 1500 meter only.

For assistance and contact information in connection with meter internal program setup

and configuration please contact GE Energy.

EPM 1500 SUB-METER – INSTRUCTION MANUAL 1–1

Page 6

1.2 Applications

1.2.1 Stand-Alone Meter

1.2.2 Metering System

CHAPTER 1: OVERVIEW

The GE Energy EPM 1500 can be installed as a stand-alone device that is locally accessed

via the LCD or remotely accessed via modem. A modem can be installed in each meter

allowing the meter(s) to be read remotely.

The GE Energy EPM 1500 family of meters are ideally designed to comprise a metering

system within a residential/commercial building or industrial site. This metering system

can measure electrical usage for each tenant, cost center, or common area space and

communicate this information over the building's power wires or dedicated

communication wiring (RS485). A metering system is comprised two or more EPM 1500

meters and a communication transponder (see figure below). The transponder collects all

of the metering data via the AC power lines and communicates data to an optional

transponder.

709704A1.CDR

FIGURE 1–1: Overview of Transponder Functionality

1–2 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 7

CHAPTER 1: OVERVIEW

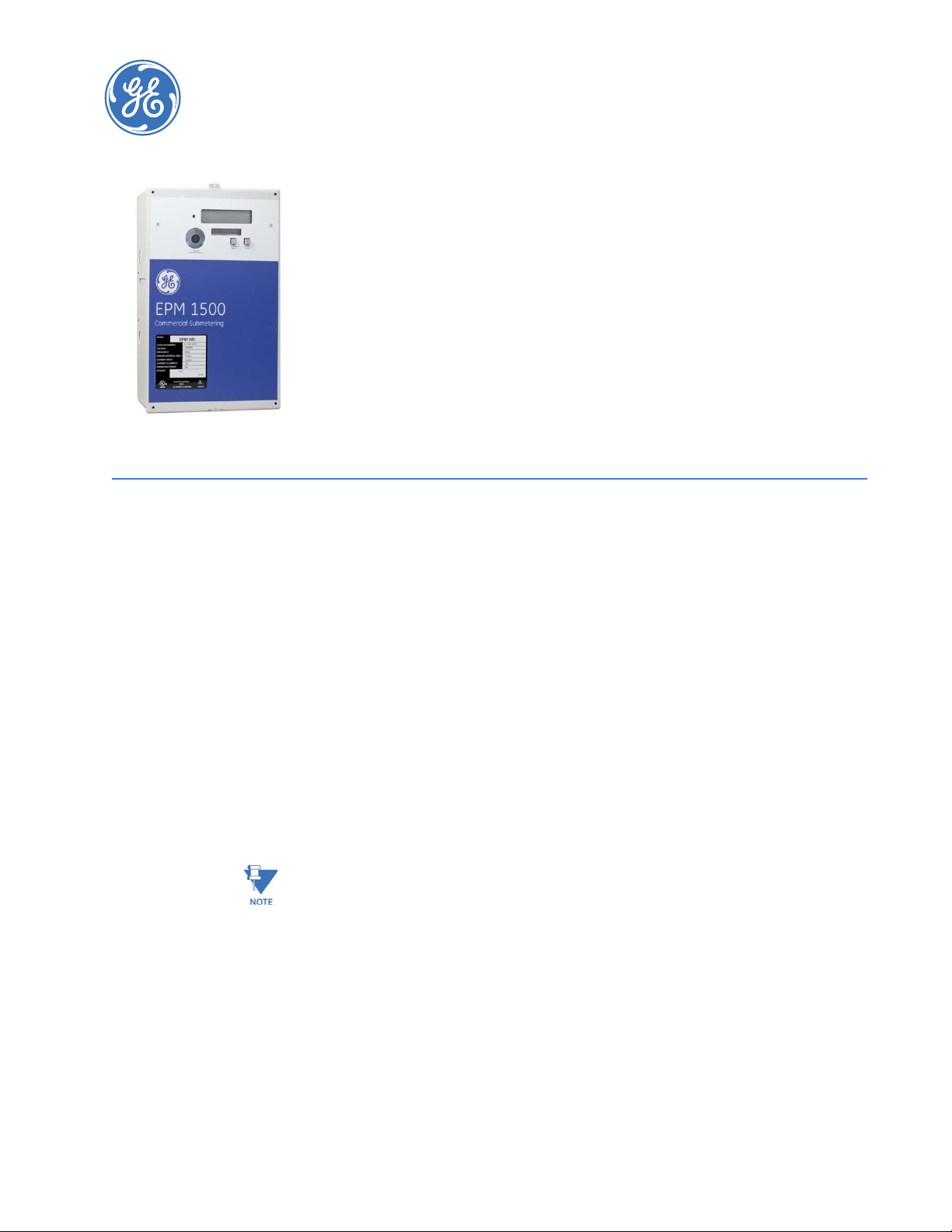

1.2.3 Interior View

The interior of the EPM 1500 is shown below.

709703A1.CDR

FIGURE 1–2: Interior View of the EPM 1500

Note

Where the and symbols are seen on the EPM 1500 meter, the manual must be

consulted to determine the nature of any potential hazard and/or actions to be taken.

1.2.4 Cautions and Warnings

• Do not install if the device is damaged. Inspect the housing for obvious defects such

as cracks in the housing.

• If the device is installed or used in a manner not specified by accompanying

documents, the protection of the device may be impaired.

• If the device functions abnormally, proceed with caution. The protection of the device

may be impaired.

• Do not install the meter around combustible gas or gas vapor.

• Do not install the meter in an electrical service with current or voltage outside of the

specified limit of the device.

• Do not operate the meter with the cover removed.

• To avoid electric shock, disconnect mains before replacing fuses!

• See instructions for connection diagram.

• Risk of electric shock. Beware of working around this meter when the voltage is live.

• For continued protection against fire, replace only with fuses of specified voltage and

current rating.

EPM 1500 SUB-METER – INSTRUCTION MANUAL 1–3

Page 8

1.2.5 Protective Conductor Terminal

Securely fasten one end of the earthing wire so that the screw cuts the paint on the back

box. Securely fasten other end of the wire to a true earth ground connection. When

earthing to the electrical conduit, use continuous pipes, bending when necessary instead

of using couplers.

1.2.6 Preventive Maintenance

There are no necessary preventative maintenance or inspection.

A Toshiba CR2032 coin battery is used in each device and is intended to be good for

decades before replacement. Return to manufacturer for replacement.

CHAPTER 1: OVERVIEW

1–4 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 9

1.3 Specifications

1.3.1 Technical Specifications

CHAPTER 1: OVERVIEW

OPERATING SPECIFICATIONS

Voltage:...............................................................120, 240, 277, 347, 480, 600 V (90% to 110%)

Frequency:.........................................................60 Hz

Power:..................................................................2 W for 120V; 5 W for 220 to 600 V

ENVIRONMENT

Usage:..................................................................For indoor use only

Temperature:....................................................–20°C to +60°C

Humidity:............................................................0 to 95% R.H. (non-condensing)

Pollution Degree: ............................................1

Maximum altitude:.........................................2000 m

CONTROL POWER

Input: ....................................................................120 V phase A to neutral

277 V phase A to neutral

480 V phase to phase

(internally powered through metered voltage; no external

source is required)

Frequency:.........................................................50 to 60 Hz

Operating power: ...........................................2 watts for 120 V

5 watts for 277 V and 480 V

Fuses:...................................................................1 - Buss fuse 250 V / 500 V 0.25 A / 0.125 A slow-acting

3 - Buss fuse 250 V /600 V 4.0 A fast-acting

TYPE TESTS

Transient/surge suppression: ..................ANSI C37.90.1-1989

Installation category: III. .............................This product falls under Installation Category III because

of its distribution level, fixed installation and has smaller

transient overvoltages than an Installation Category IV.

METERING

Metered Voltage: ............................................120, 220, 240, 277, 347, 380, 480, 600 V Delta or Wye, 50/

60 Hz

Current Input:...................................................0.1 A, 5.0 A

Secondary inputs: ..........................................50 to 4000 A primary available

Minimum current sensitivity:.....................0.06 A

INPUT AND OUTPUT CONNECTIONS

See installation diagram

INSULATION OF EXTERNAL CIRCUITS

See installation diagram

PHYSICAL

Dimensions:.......................................................13.5"H × 8.5"W × 4.5"D

1.3.2 Approvals

APPROVALS

UL and CUL: ......................................................recognized under E204142

ANSI: .....................................................................C12.1 and C12.16 accuracy

EPM 1500 SUB-METER – INSTRUCTION MANUAL 1-5

Page 10

1.4 Ordering

1.4.1 Catalog Numbers

The order codes for the EPM 1500 are indicated below.

EPM 1500 Without CTs

Family Voltage Version CTs Delta Options Description

PL1500 * * * * *

CHAPTER 1: OVERVIEW

120 120/208V 3 phase

277 277/480V 3 phase

347 347/600V 3 phase

K KWh version

D Demand version

L 0.1 amps CT secondary input

H 5 amps CT secondary input

P Pulse data module

MOD Modbus communications

480 480V Delta

600 600V Delta

D Demand version

L 0.1 amps CT secondary input

H 5 amps CT secondary input

DTA Delta 3P3W

P Pulse data module

MOD Modbus communications

EPM 1500 With CTs

Family Voltage Version CTs Option Description

PL1500 * * * *

120 120/208V 3 phase

277 277/480V 3 phase

347 347/600V 3 phase

1.4.2 Pulse Modules

The following modifications are available:

Description Cat. No.

KYZ Pulse output option PL1500 KYZ

Input module for 4 pulse inputs PL1500PULSIN10

K KWh version

D Demand version

SP050 Split core 50A CTs -set of 3

SP100 Split core 100A CTs - set of 3

SP200 Split core 200A CTs- set of 3

SP400 Split core 400A CTs - set of 3

SP800 Split core 800A CTs - set of 3

SP3200 Split core 3200A CTs - set of 3

SL050 Solid core 50A CTs - set of 3

SL100 Solid core 100A CTs - set of 3

SL200 Solid core 200A CTs - set of 3

SL400 Solid core 400A CTs - set of 3

CTs

Type Description Cat. No.

Solid Core - 0.1 A

Secondary

Solid Core - Canadian CT-2/5DARL (200A/5A) PLSUBCTSL201CDN

Split Core - 0.1 A

Secondary

1.4.3 Transponders

The following transponder options are available:

1. Order Back Box

Description Cat. No.

120V service back box TRANS BBA 120V

277V service back box TRANS BBA 277V

347V service back box TRANS BBA 347V

2. Order Transponder Model with options

Description Cat. No.

120/208V with modem TRANS120M

120/208V with RS485 and RS2332 connections TRANS120RS

277/480V with modem TRANS277M

277/480V with RS485 and RS232 connections TRANS277RS

347/600V with modem TRANS347M

347/600V with RS485 and RS 232 connections TRANS347RS

CT-50 (50/0.1A) PLSUBCTSL050

CT-1 (100/0.1A) PLSUBCTSL101

CT-2 (200/0.1A) PLSUBCTSL201

CT-4 (400/0.1A) PLSUBCTSL401

CTSP-50 (50/0.1A) PLSUBCTSP050

CTSP-1 (100/0.1A) PLSUBCTSP101

CTSP-2 (200/0.1A) PLSUBCTSP201

CTSP-4 (400/0.1A) PLSUBCTSP401

CTSP-8 (800/0.1A) PLSUBCTSP801

CTSP-12 (1200/0.1A) PLSUBCTSP1201

CTSP-20 (2000/0.1A) PLSUBCTSP2001

CTSP-30 (3000/0.1A) PLSUBCTSP3001

CTSP-40 (4000/0.1A) PLSUBCTSP4001

1–6

The transponder can handle up to 150 meter points (i.e. 150 EPM 1500 points).

EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 11

GE Energy

Industrial Solutions

2.1 Getting Ready

EPM 1500 Single Point

Submetering System

Chapter 2: Installation

Installation

2.1.1 Determination of Metering System Requirements

Determine if the application is for a metering system or for a stand-alone meter. If the

application is for a stand-alone meter, proceed directly to the next section. If the

application is for a metering system, then please read Installing the GE Transponder on

page 2–13.

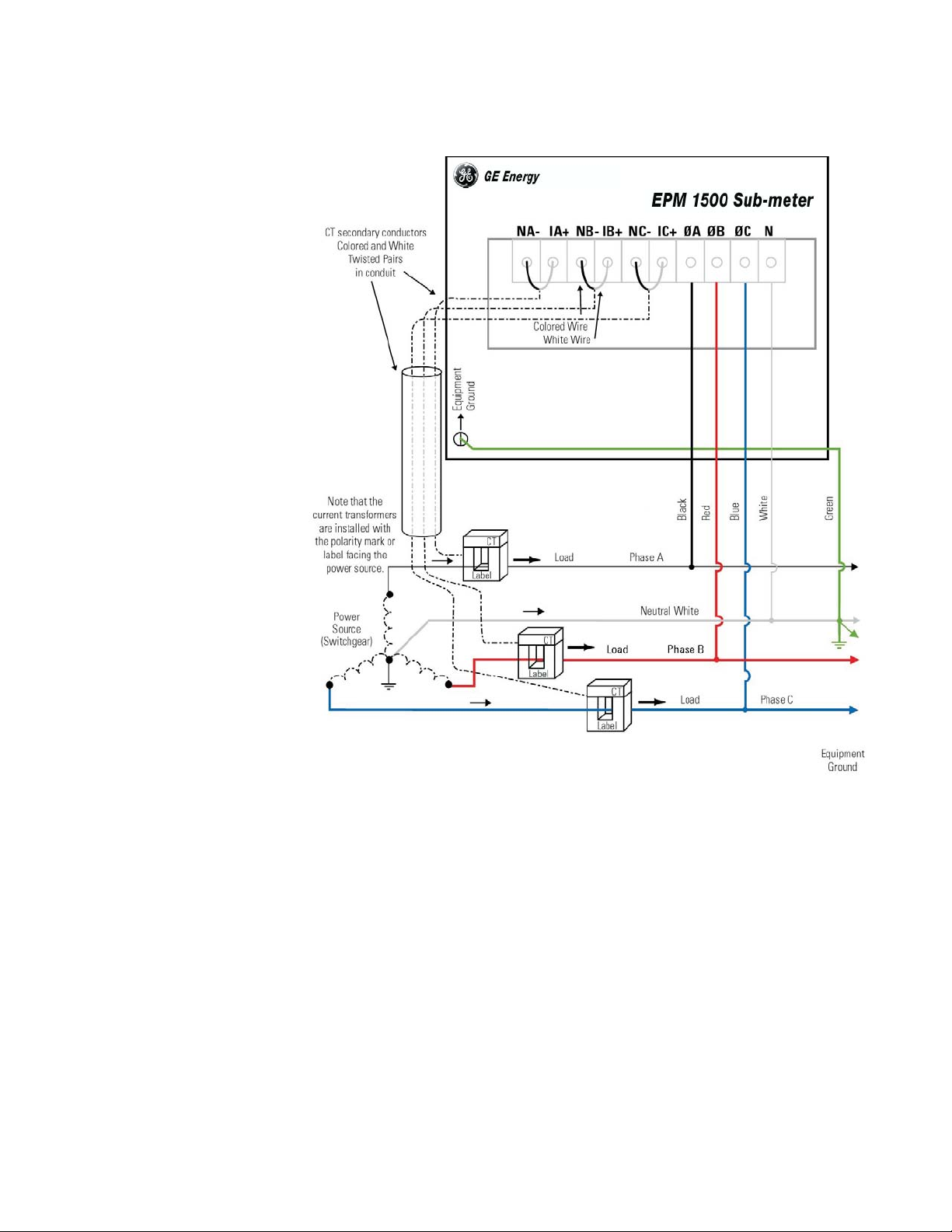

2.1.2 Overview of Meter Wiring

Although this document treats the installation and certification stages separately, this

does not imply that the recommended procedure is to install the entire system at once and

then proceed to certification.

The recommended procedure is to install and certify the system in stages. By doing this,

systematic error can be corrected before it propagates through the entire installation. To

follow the recommended procedure, divide the job up into manageable stages and install

and certify at each stage before proceeding to the installation of the next stage.

For the purposes of this discussion, the colors black, red and blue have been chosen to

distinguish among the three phases of a three-phase network. White is the designated

color of neutral and green is the color of earth ground. Please substitute the correct color

according to local electrical code. For a two-phase installation, ignore the third phase (the

blue phase in the following description).

Failure to follow the proper procedures and reference the correct wiring diagram can

result in damage to the equipment and/or physical harm.

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–1

Page 12

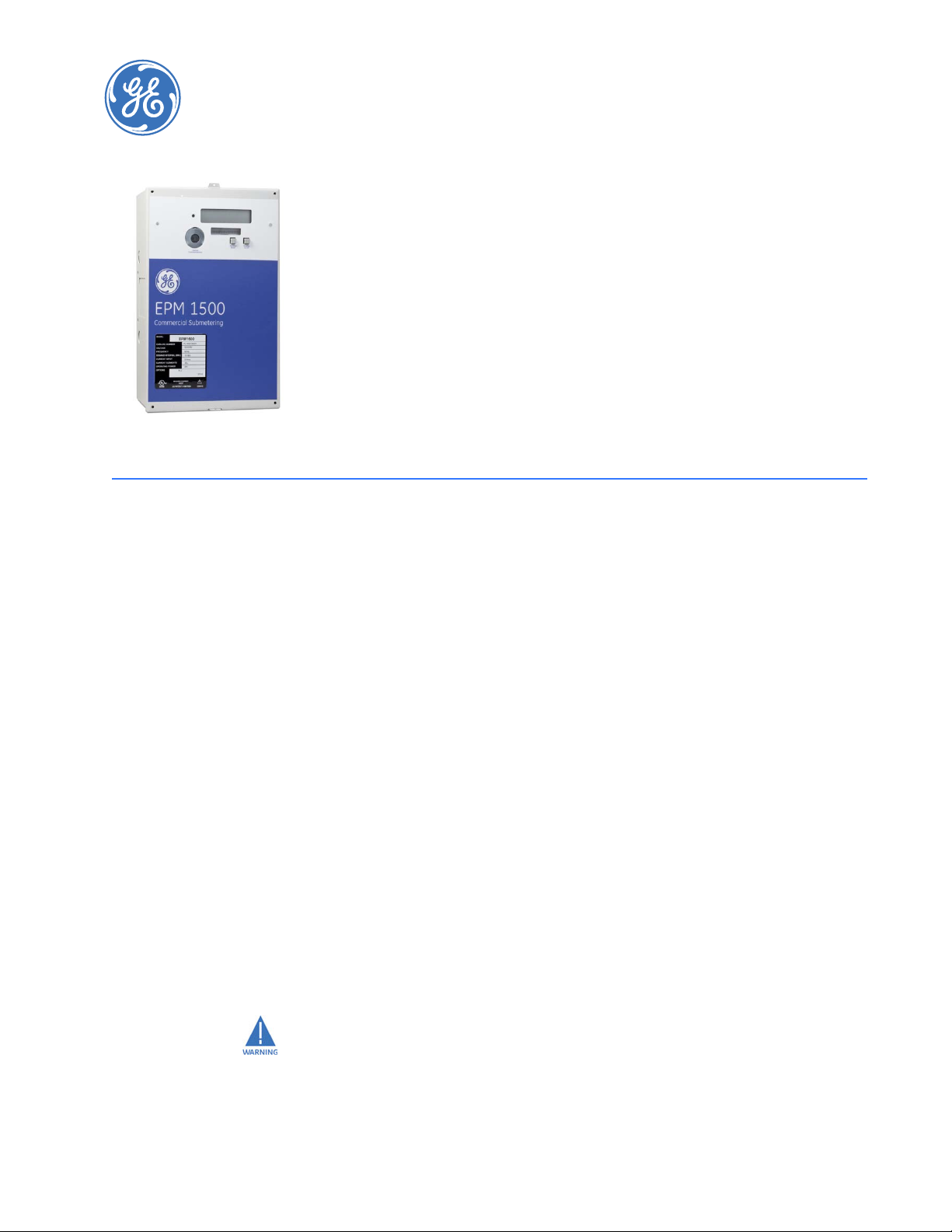

2.2 Wiring Diagrams

2.2.1 Overview

Review the following wiring diagrams and select the one that matches your installation

requirements and part number using the following table.

FIGURE 2–1: 3-Phase, 4-Wire Wye Wiring on page 2–3

CHAPTER 2: INSTALLATION

Table 2–1: Wiring Diagram / Model Reference

Figure Applicable Models

PL1500208S****K

PL1500208S****D

PL1500480S****K

PL1500480S****D

FIGURE 2–2: 1-Phase, 3-Wire Center-Tap-Neutral 120/240 V

Wiring on page 2–4

FIGURE 2–3: 3-Phase, 4-Wire Center-Tap-Neutral 120/240 V Delta

Wiring on page 2–5

FIGURE 2–4: 3-Phase, 3-Wire Ungrounded 480 V Delta Wiring on

page 2–6

FIGURE 2–5: 3-Phase, 3-Wire Corner-Grounded 480 V Delta Wiring

on page 2–7

FIGURE 2–6: CT Terminations for 1600 A and 3200 A Models on

page 2–8

PL1500208S****K

PL1500208S****D

PL1500208S****K

PL1500208S****D

PL1500480DELTA

PL1500480DELTA

PL1500***SP162*

PL1500***SP322*

2–2 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 13

CHAPTER 2: INSTALLATION

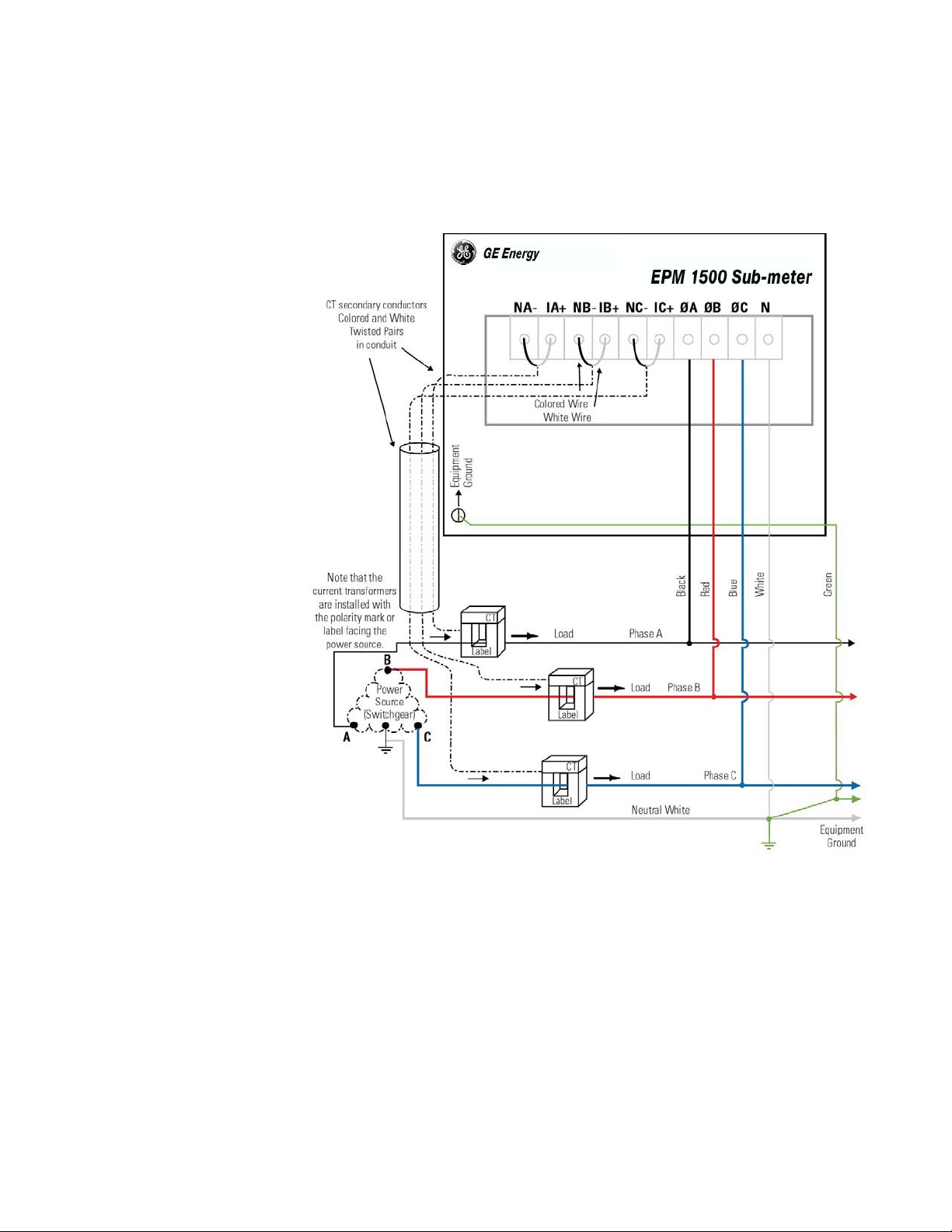

2.2.2 3-Phase, 4-Wire Wye

709709A2.CDR

FIGURE 2–1: 3-Phase, 4-Wire Wye Wiring

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–3

Page 14

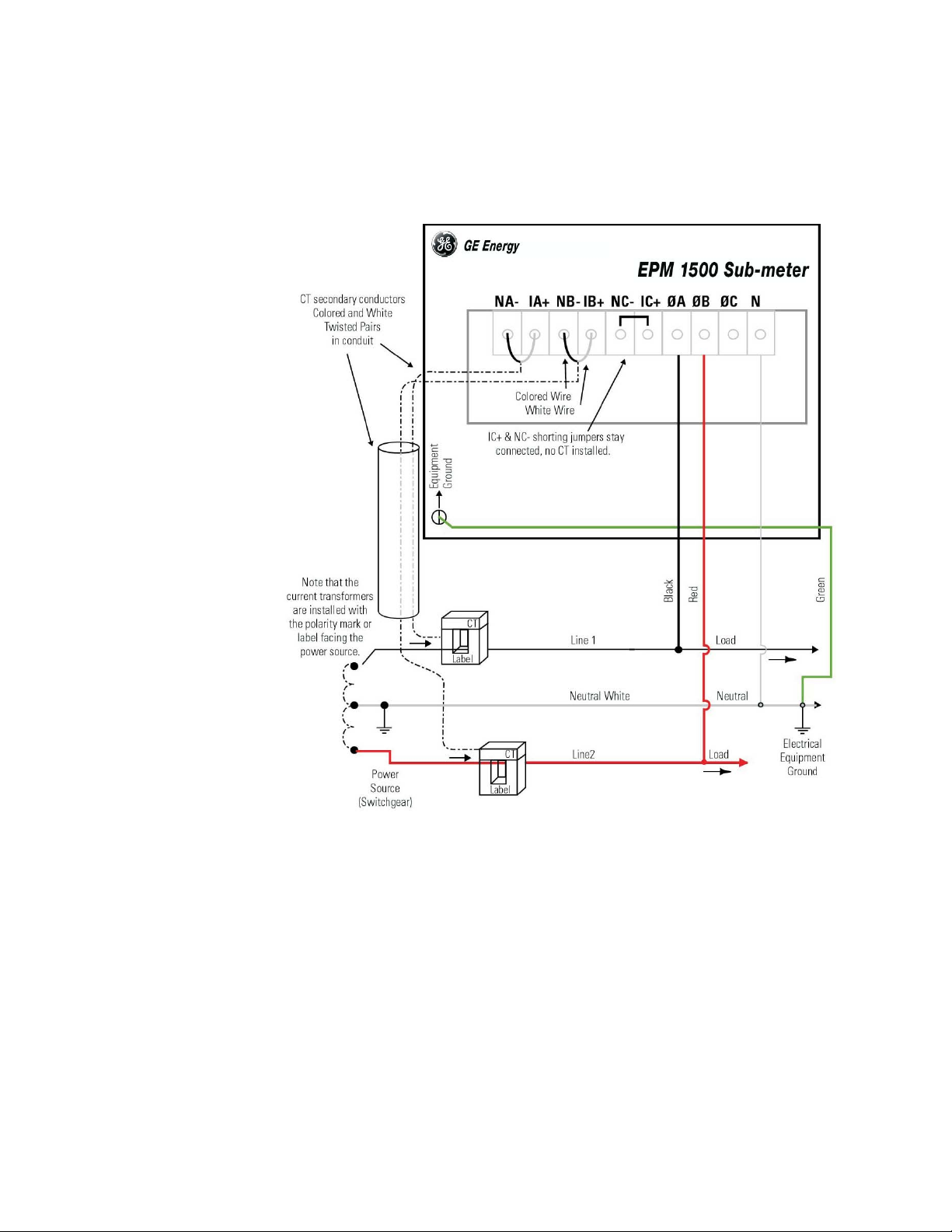

2.2.3 1-Phase, 3-Wire Center-Tap-Neutral 120/240 V

CHAPTER 2: INSTALLATION

709705A2.CDR

FIGURE 2–2: 1-Phase, 3-Wire Center-Tap-Neutral 120/240 V Wiring

2–4 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 15

CHAPTER 2: INSTALLATION

2.2.4 3-Phase, 4-Wire Center-Tap-Neutral 120/240 V Delta

709708A1.CDR

FIGURE 2–3: 3-Phase, 4-Wire Center-Tap-Neutral 120/240 V Delta Wiring

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–5

Page 16

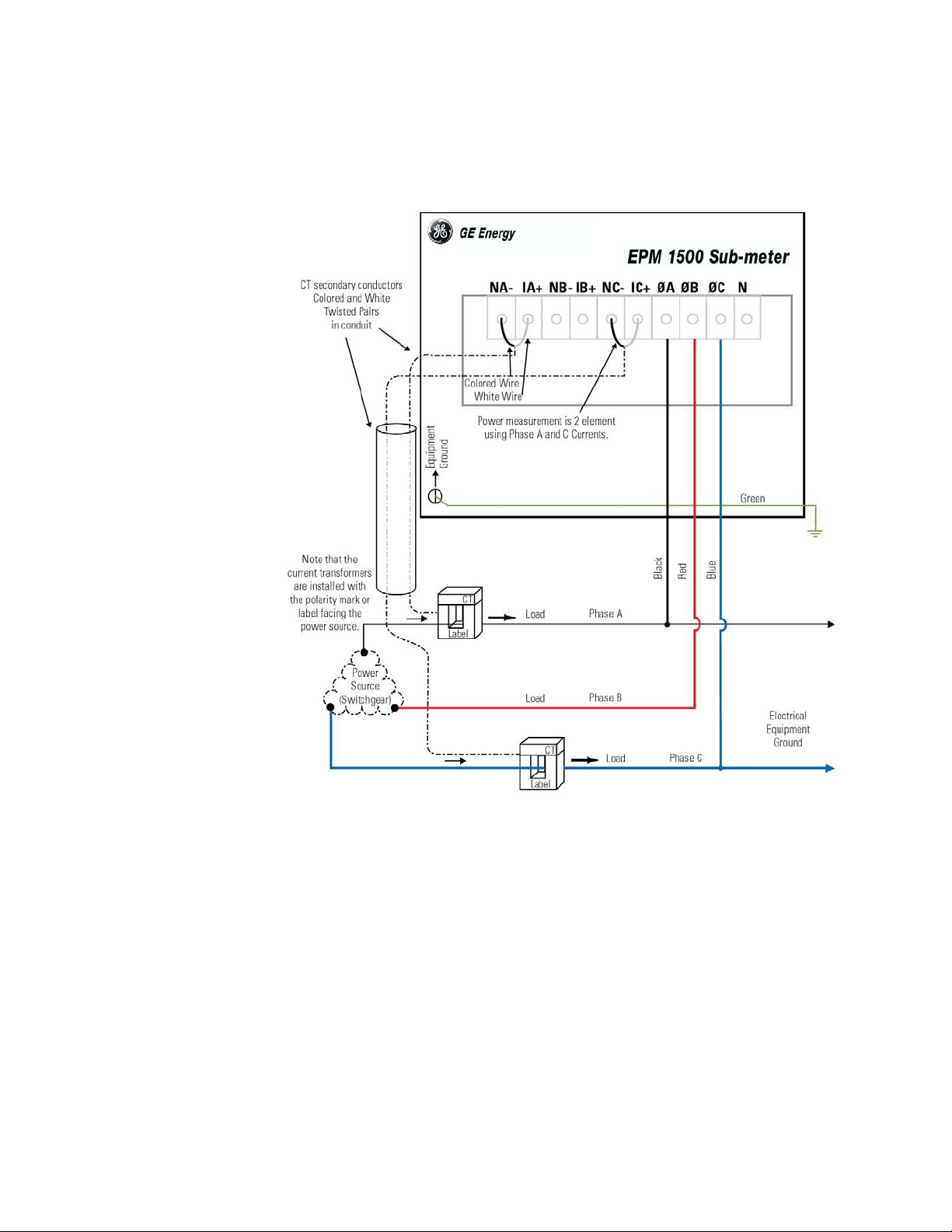

2.2.5 3-Phase, 3-Wire Ungrounded 480 V Delta

CHAPTER 2: INSTALLATION

709707A1.CDR

FIGURE 2–4: 3-Phase, 3-Wire Ungrounded 480 V Delta Wiring

2–6 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 17

CHAPTER 2: INSTALLATION

2.2.6 3-Phase, 3-Wire Corner-Grounded 480 V Delta

709706A1.CDR

FIGURE 2–5: 3-Phase, 3-Wire Corner-Grounded 480 V Delta Wiring

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–7

Page 18

2.2.7 Wiring for 1600 A and 3200 A Models

For the 1600 A and 3200 A models (order codes PL1500***SP162* and PL1500***SP322*),

the CT terminations are made on the HCA-2 module to allow the EPM 1500 to accept 5 A

secondary current inputs. CAREFULLY observe the following figure and terminate the CT

leads on the included HCA-2 module, NOT the fuse block.

CHAPTER 2: INSTALLATION

709717A1.CDR

FIGURE 2–6: CT Terminations for 1600 A and 3200 A Models

2–8 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 19

CHAPTER 2: INSTALLATION

2.3 Installation of Meter and Current Transformers

2.3.1 Procedure

Note

The use of the following procedure is mandatory. Certification requires a visual inspection

of the current transformers and the voltage taps on the incoming feeder phase wires.

Z Mount the back box to the wall, or in the wall for flush mount

installations.

Connect the breaker panel box to the back box of the meter with a

metal conduit through which the 3 or 4 feeder phase taps and the 6

CT wires will be run.

Make sure to use at least a ¾-inch ID conduit to allow for all 9 or 10

wires to pass easily.

Z Locate the incoming feeder phase (hot) wires at the top of the

breaker panel.

Tape the incoming feeder wires according to phase with black, red

and blue electrical tape for identification purposes.

Z Extend the CT wires with AWG #16 stranded with black, red and

blue jackets so as to be the correct length to pass through the

conduit and reach the fuse block in the meter back box.

Extend the white wire of each CT with a white wire, but place a

black, red or blue electrical tape on the end of the extended wire to

identify the correct neutral.

Refer to these CT white wires with tape as white/black, white/red

and white/blue respectively.

Z Remove the incoming feeder hot wires one at a time and place

each CT over the proper feeder wire.

Make sure that the colors of the CT leads correspond to the color of

the tape on the phase feeder.

Make certain that the white wire from the CT is closest to the line

side of the feed, away from the top of the breaker panel.

For split-core CTs, make sure that the X1 is toward the line side.

Run the CT secondary wires through conduit to the back box of the

meter.

Z Tap the three feeder wires with AWG #12 stranded wire with black,

red and blue jackets taking care to match the color of the

insulation of the #12 wires to correspond to the color of the tape on

the feeder wire.

Z If the service is 4-wire, tap the neutral connection with a #12 AWG

stranded wire with a white jacket.

Z Run the six (6) current transformer wires black, white/black, red,

white/red and blue, white/blue to IA+, NA–, IB+, NB–, IC+, NC–

respectively on the fuse block (see Internal Fuse Block on page 2–

11).

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–9

Page 20

CHAPTER 2: INSTALLATION

Z Take the black, red, blue and white (if available) #12 AWG feeder

phase tap wires and run them to ⇔A, ⇔B, ⇔C, and N (if available)

respectively (see Internal Fuse Block on page 2–11).

Z Plug the fuse block into the meter head and hang the meter head

on the back box.

Z Close up the breaker panel until the certification inspector arrives.

2–10 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 21

CHAPTER 2: INSTALLATION

2.3.2 Internal Shorting Terminal

709721A1.CDR

FIGURE 2–7: Internal Fuse Block

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–11

Page 22

2.4 Installing the Pulse Inputs

2.4.1 Pulse Input Option

The EPM 1500 with the Pulse Input option will provide a 5-wire harness from the back of

the meter head. The color coding on the harness is as follows and the M# and Q# refers to

meter registers that will appear if the meter has pulse inputs:

• COMMON (WHITE)

• M2 Q14 (GREEN)

• M2 Q13 (ORANGE)

• M1 Q14 (RED)

• M1 Q13 (BLACK)

CHAPTER 2: INSTALLATION

2–12 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 23

CHAPTER 2: INSTALLATION

2.5 Installing the GE Transponder

2.5.1 Procedure

If your application is for a metering system, use the following procedure to install the

transponder.

Z Plan for the transponders.

Z Determine the number of tenant spaces.

Z Determine the service size and type of meter for each metering

Z Determine the number of telephone lines required and ensure the

• Determine the number of services in order to determine the

number of transponders. Do not rely solely on the memory of the

local engineers or of the existing drawings. Drawings may not

have been properly updated to reflect as-built conditions and

memories are not always accurate. Use these as guidelines and

then perform a survey. Open electrical cabinets as necessary and

locate every master meter from the utility.

• Make careful note of the voltages of the various transponders.

• In residential applications, this number should be fixed. Often

apartments are laid out on a grid, such as by floor and by line. In

this case, the number of meters is simply the number of floors

times the number of lines. This information is needed before any

meters are installed or entered into the transponders.

• Determine which service feeds each metering point. This

information is vital to proper system operation. Without this

information, a laborious process of trial and error is necessary to

determine which transponder must be used for each meter. This

will increase the cost of certification and commissioning of the

system.

point.

• In residential applications, this is probably a constant amperage

across the entire job (either 50A or 100A with Series 10 meters).

lines are installed before the installation of any metering

equipment.

Z Determine the number of independent services.

• Typically there is one service per distribution transformer that

feeds the property, unless distribution transformers have parallel

secondaries, which is rare.

Locating the best location for each transponder.

This is the closest point to the first point at which the feeders for the service branch out

into sub-feeders. To find this point, follow the feeders from the secondary of the

distribution transformer (or the service entrance if the transformer is off the property) and

place the transponder at the last point before the feeder breaks into multiple feeders.

EPM 1500 SUB-METER – INSTRUCTION MANUAL 2–13

Page 24

CHAPTER 2: INSTALLATION

Z Determine which of the transponders should have a telephone

modem, and order a telephone line to terminate at that point.

Do not proceed with the installation until the telephone line is

installed.

Z After the telephone line is installed, install the transponder with

the modem next to the telephone line.

Install all three phases and the neutral to the transponder (see

Installation of Meter and Current Transformers on page 2–9 for

details).

Z If there is more than one transponder, install the other

transponders and the interconnecting RS485 line, if required, which

links all of the transponders

(Go directly to Installation of Meter and Current Transformers on

page 2–9 if there is only one transponder in the system or if each

transponder in the system has a modem and telephone line

connection).

• An RS485 line is a pair of wires, AWG #20 or larger in diameter,

which begins at one transponder where a terminator is placed.

• The RS485 line runs from transponder to transponder ending at

the final transponder, where another terminator is placed.

Note

It is critically important that there should never be three RS485 pairs entering or

leaving a transponder box.

• For the two transponders which have terminators, only one

RS485 pair leaves each box.

• For the other transponders, if there are more than two, exactly

two RS485 lines should leave the box: each line goes to another

transponder in the daisy-chain.

Only one modem should be installed in a data link system. If there

are two or more modems in a data link system, the transponders

will not communicate with each other.

• There may be no more than 32 transponders on a daisy-chain. If

there are more than 32, special care must be taken, which is

beyond the scope of these instructions.

Z If possible, run the RS485 lines in a conduit to protect them from

damage.

Note

It is critically important to observe the polarity of the wires. The RS485 data link uses a

black and yellow color code. Match black to black and yellow to yellow; otherwise the

data link will not work.

Z To test the data link, measure the DC voltage across the yellow to

black wire.

This should measure between 0.1 and 0.3 V. If it is negative or

outside of that range, re-check all of the transponder boxes

according to the above specifications.

2–14 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 25

GE Energy

Industrial Solutions

EPM 1500 Single Point

Chapter 3: Using the Meter

Using the Meter

3.1 Menu Navigation

Submetering System

3.1.1 User Interface

The following figure shows the EPM 1500 user interface located on the front panel of the

meter. It is easy to navigate the various sub-menus to read metering data, reset values and

view configuration data.

Press and hold the “Display Scroll” button. After two seconds, the LCD will display the

REVERSE message. Two seconds later, the LCD will display FORWARD. Two seconds later,

a different sub-menu register heading as shown on the following page (the top row) in will

be displayed in two-second intervals. Note that the EPM 1500 defaults to the kWh register.

709719A1.CDR

FIGURE 3–1: EPM 1500 User Interface

EPM 1500 SUB-METER – INSTRUCTION MANUAL 3–1

Page 26

CHAPTER 3: USING THE METER

Releasing the display scroll button at a given submenu heading will allow you to cycle

through the registers listed under the selected submenu heading. Pressing and releasing

the display button will advance to the next block of registers in the sub-menu.

To reverse scrolling direction at either the heading level or within a submenu, press and

hold the display scroll button. When

REVERSE is displayed after two seconds, release the

display scroll button. You can now go backwards through the menu selections by pressing

and releasing the display scroll button.

To go back to the forward scrolling option, follow the same procedure, except release the

display scroll button when

FORWARD is displayed.

3–2 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 27

CHAPTER 3: USING THE METER

709720A1.CDR

FIGURE 3–2: EPM 1500 Display Structure

EPM 1500 SUB-METER – INSTRUCTION MANUAL 3–3

Page 28

3.2 CT Multiplier Table

3.2.1 CT Multipliers

CHAPTER 3: USING THE METER

Note

The following table MUST BE used to verify the correct current readings, based on the

rating of the CT installed.

Table 3–1: CT Multiplier Table

CT Size Multiplier

50 A × 0.5

100 A × 1

200 A × 2

400 A × 4

800 A × 8

1600 A × 32

3200 A × 64

Note

The multiplier that corresponds with the CT rating MUST BE applied to the current reading

shown on the display of the EPM 1500 by multiplying that reading by the multiplier shown

above. The multiplier MUST also be applied in the same manner when calculating kW and

kWh. Failure to use the appropriate multiplier will result in an incorrect diagnosis of the

meter's functionality and incorrect revenue billing.

3–4 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 29

CHAPTER 3: USING THE METER

3.3 Verifying Meter Functionality

3.3.1 Overview

Once you have familiarized yourself with the EPM 1500 menu structure, it is critical to verify

that the meter and CTs are properly installed.

Note

To correctly diagnose the meter, there must be loads on all three phases of the meter.

3.3.2 Verifying Voltage

Z Press and hold the Display Scroll button until the following menu

heading is displayed:

Phase Diagnostic

Registers

Z Release the Display Scroll button. Scroll down by pressing and

releasing the Display Scroll Button until the following submenu is

displayed:

Volts 125.3 A

124.0 B 124.7 C

Z Verify that phases A, B and C are displaying voltages; i.e., for a

120 V AC, the reading should be 117 V +10%/–15%.

3.3.3 Verifying kWh Reading

Z Press and hold the Display Scroll button until the following menu

heading is displayed:

kWH Registers

Registers

Z Release the Display Scroll button. Scroll down by pressing and

releasing the Display Scroll button until the following sub-menu is

displayed:

AllHrs kWH

1.046

Z Verify that the kWh value increases as you view the LCD.

EPM 1500 SUB-METER – INSTRUCTION MANUAL 3–5

Page 30

3.3.4 Verifying Current and Energy

Z Press and hold the Display Scroll button until the following menu

Z Release the Display Scroll button. Scroll down by pressing and

The A(mperage) reading in the display above will always be a positive number, even if the

CT was incorrectly installed. Check the reading to see if it indicates the approximate

current you expected. Remember that this applies to Phase 1 only. If all the numbers on the

multiplier screen were 1.00 and the current transformers are 100:0.1, your multiplier is 1

and the readings are the actual values. If the CTs are 200:0.1, multiply the current reading

by 2.

The W(att) reading will also count forward as your view the LCD. A negative power reading

is indicative of an incorrectly installed CT, or one that is cross-phased with the wrong

voltage (phase) leg. The R(eactive) reading can be negative, depending on the nature of the

load. Negative values indicate a capacitive load while positive values indicate an inductive

load.

CHAPTER 3: USING THE METER

heading is displayed:

Phase Diagnostic

Registers

releasing the Display Scroll button until the following submenu is

displayed:

Phase 1 7.468 A

818.7 W 100.5 R

Z Scroll down by pressing and releasing the Display Scroll Button

until the following submenu is displayed:

Ph 1 935.4 VA

6.8° .875 PF

Under normal conditions the phase angle (x.x°) should be close to 0° and the power factor

should be a number close to 1 (one). Resistive loads will have a power factor close to 1,

while inductive loads will typically reflect a power factor between 0.80 to 0.95, or even

lower.

If the phase angle on the lower left is a number close to 180°, it indicates the CT was

installed backwards, or 180° out-of-phase. If the number is close to 120°, at least two CTs

have been cross-phased, and a similar number will appear in the phase angle data in

Phase 2.

Z To view screens for Phases 2 and 3, repeat the same steps as

above.

3–6 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 31

CHAPTER 3: USING THE METER

3.4 Resetting the Demand Values

3.4.1 Procedure

Use the following procedure to reset the Demand registers to zero:

Z Press and hold the Demand Reset button.

Z Keep the Demand Reset button depressed until the screen updates

• The LCD will initially display a

• The LCD will then display the

copyright message.

Dmdreset event screen:

Dmdreset 1

20:00 06/14/2003

and displays the current date and time. This signifies that the

demand has been reset.

EPM 1500 SUB-METER – INSTRUCTION MANUAL 3–7

Page 32

CHAPTER 3: USING THE METER

3–8 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 33

GE Energy

Industrial Solutions

EPM 1500 Single Point

Chapter 4: Communications

Communications

4.1 Modbus Communications

Submetering System

4.1.1 RS485 Wiring for Modbus

The wiring for Modbus communications for two-wire and four-wire RS485 is indicated

below.

For two-wire RS-485:

For four-wire RS-485:

Color Function DB-9 Pinout

Yellow RX (+) 2

Black TX (–) 8

Color Function DB-9 Pinout

Yellow (A) RX (+) 2

Black (B) RX (–) 3

Green (Y) TX (+) 7

Red (Z) TX (–) 8

709725A1.CDR

FIGURE 4–1: RS-485 Serial Connections

EPM 1500 SUB-METER– INSTRUCTION MANUAL 4–1

Page 34

CHAPTER 4: COMMUNICATIONS

Note

The EPM 1500 optical port is disabled for units with 2-wire RS485 connections.

4.1.2 RS232 Wiring for Modbus

The wiring for Modbus communications for RS232 is indicated below.

Color Function DB-9 Pinout

Black TX 2

Red RX 3

Green GND 5

4.1.3 Modbus Commands

The EPM 1500 is capable of acting as a remote slave unit to a Modbus master device via

modem, RS232, RS485, or PLC. Up to 32 EPM 1500 meters (or other RS485 devices) can be

daisy-chained together on a single LAN.

The EPM 1500 communicates at a default baud rate of 19200, with no parity and 1 stop bit.

The default Modbus address is 100. Changes to the default baud rate or address can be

accomplished through the configuration file upload.

The following Modbus commands are supported by the EPM 1500:

• 03: Read R4 type register(s)

• 06: Write single register; address “0” is used as the broadcast address

• 16: Write multiple registers; address “0” is used as the broadcast address

4.1.4 Fixed Modbus Values

The EPM 1500 provides fixed register values indicating the meter's serial number, the

meter's version number, and the Modbus addresses.

4.1.5 Modbus Data Register (R4 Type) Groups

The EPM 1500 has divided the supported register map (see following pages) into the

following register groups for various fixed and dynamic data values:

•Setup Information

•Interval

• Average Interval Data

• Instantaneous Data

• Three-Phase Data

•Real Time Data

• Meter Configuration Data

The EPM 1500 provides access to stored-interval data channels via Modbus command. The

data items as defined in the following register map are based on default data channels

that include the following 3-phase-totaled values (interval average) per meter:

4–2 EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 35

CHAPTER 4: COMMUNICATIONS

4.1.6 Instantaneous Data Items

• Real Power in kW

• Reactive Power in kvar

• Apparent Power in kVA

• Power Factor

Data is logged per the configurable time interval value. The default log interval is 15

minutes.

The Modbus master can request stored interval data by writing the interval date and time

to the appropriate registers and by setting the data status register to 1. Upon the data

ready flag (address 67) being written to 1, the interval data registers (addresses 100 to 107)

are simultaneously updated with the appropriate values for the requested interval. The

data ready flag returns a 0 for “data is ready”, or “2” for “invalid time interval requested.”

The EPM 1500 also provides registers that constantly hold the oldest stored-interval

(addresses 58 to 60) and most recent stored-int

to 63).

The EPM 1500 provides registers for per-phase instantaneous values (see below).

Instantaneous register values are updated once per second.

•Frequency

• Total Harmonic Distortion (% for volts)

• Voltage

• Current

• Real Power in kW

• Reactive Power in kvar

• Apparent Power in kVA

erval time

and date stamps (addresses 61

The EPM 1500 provides one-second updated inputs, including the following 3-phasetotaled values per 3-phase-meter:

• Energy: kWh and kvarh

• Power: kW, kvar, and kVA

• Power Factor

4.1.7 32-bit Long and Float Data Formats

The EPM 1500 supports standard format for 32-bit Long (signed or unsigned). The first of

the two 16-bit Modbus register set contains the HIGH order 16 bits of the 32-bit Long data.

The second of the two 16-bit Modbus register set contains the LOW order 16 bits of the 32bit Long data.

The EPM 1500 supports Intel 32 bit (IEEE) FLOAT format. That means, unlike the standard

Long format, the first of the two 16-bit Mo

of the 32-bit Float data. The second of the two 16-bit Modbus register set contains the

HIGH order 16 bits of the 32-bit Float data.

EPM 1500 SUB-METER– INSTRUCTION MANUAL 4–3

dbus register

set contains the LOW order 16 bits

Page 36

4.2 Modbus Activation

4.2.1 Overview

The EPM 1500 is shipped with Modbus not activated. To activate the Modbus protocol, it is

necessary to use the Hilgraeve HyperTerminal Private Edition software. This software is

available from the following website:

Once Modbus is activated, the meter will ignore the following ASCII commands unless the

login string is sent using the “Key Macros” function within HyperTerminal. Set up “Key

Macros” to send the login string (see Logging into the Meter on page 4–5) followed by

[ENTER].

CHAPTER 4: COMMUNICATIONS

http://www.hilgraeve.com/htpe

Note

The login string must be sent without breaking up packets.

A direct connection from a serial port to the EPM 1500 RS485 port (via RS232/485

converter) is highly recommended. GE's Ethernet Gateway will break up this login string

into packets and prevent login.

The EPM 1500 only allows login at 9600, 19200 or 38400 baud when NOT in Modbus mode.

This is displayed as HUNT in the meter display under Serial # Regi

ste

rs. Once in Modbus,

the EPM 1500 only responds at the programmed baud rate.

4.2.2 Configuring a New HyperTerminal Session

Use the following procedure to configure a new HyperTerminal session.

Z Enter the New Connection Name.

Z Select the COM port to connect to the meter.

Z Select the COM port properties.

The following window will appear – use the setting shown below.

Z Select the File > Properties > Settings > ASCII Setup menu item.

4–4 EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 37

CHAPTER 4: COMMUNICATIONS

4.2.3 Confirming Connection to the EPM 1500

Z Check the Echo typed characters locally option, as shown below.

Z To confirm a proper RS485 connection to the EPM 1500, enter the

following command:

attn -D (followed by the [ENTER] key)

If meter is properly connected, it will respond with a serial number and poll

address. Once in Modbus mode, this command will no longer work.

For example, entering the command

attn -D

followed by the [ENTER] key returns:

60005866 256

for a meter with serial number 60005866 and poll address 256.

4.2.4 Logging into the Meter

Use the following procedure to login to the EPM 1500.

Z Setup a ‘key macro’ in HyperTerminal by selecting the View > Key

Macros menu item.

Z Click New and select an appropriate macro key sequence (ALT-1 is

used the example below.

Z Enter the following command in the Action area:

attn -S[serialNumber] -5lEvElbAl<ENTER>

The password is -s5 followed by the LABLEVEL text spelled

backwards, with the vowels in upper case. This login string must

be followed by the ENTER command within the key macro.

Z For example, for a unit with serial number 60005866, enter the

following text:

EPM 1500 SUB-METER– INSTRUCTION MANUAL 4–5

Page 38

4.2.5 Activating Modbus Communications

Use the following procedure to activate Modbus communications.

Z Enter the following command to activate Modbus:

CHAPTER 4: COMMUNICATIONS

stty -M1 (followed by [ENTER] twice)

Z Select the baud rate by entering the following command.

The baud rate options for Modbus communication are 9600, 19200,

and 38400.

stty 19200 (followed by [ENTER] twice)

Z Save Modbus activation by entering:

stty -W1234

Z Display Modbus activation by entering:

stty

This command displays meter port setting, baud rate, etc. If Modbus is active, it returns

“Modbus”; if Modbus is not active, it returns “no Modbus”.

For example, consider the following set of commands sets the activates Modbus, sets the

baud rate to 19200, and saves the Modbus activation. The text returned by the meter is

also indicated.

CIP#stty

hunt 19200 baud 8 bits no parity no echo no modem no

modbus

CIP#stty -M1

CIP#stty 19200

CIP#stty -W1234

CIP#stty

hold 19200 baud 8 bits no parity no echo no modem modbus

4–6 EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 39

CHAPTER 4: COMMUNICATIONS

4.2.6 Changing Modbus Settings

4.2.7 Logging Out

Use the following procedure to change the Modbus address setting:

Z Enter the following command to set the Modbus address:

attn -p#

# is replaced by the actual address desired (for example, attn -p100).

where

Z Save the Modbus address as follows

attn -W1234

Z Enter the following command to display and verify the Modbus

address:

attn -d

This command displays the meter serial number and the poll/Modbus number.

Use one of the following commands to logout of the meter:

attn or exit

Note

Once Modbus is set, it is best to type [HALT] followed by [ENTER] or cycle power to the

meter. Otherwise, Modbus will become active one minute after logout.

To log into meter once Modbus is active, use hot keys to program the login sequence. The

login sequence must include either the serial number or the Modbus address.

Example hot key sequences are shown below:

attn -S60005866 -3Super3

attn 256 -3Super3

4.2.8 Disabling Modbus Communications

Use the following procedure to disable Modbus communications:

Z Turn off Modbus with the following command:

stty -M0

Z Save Modbus settings:

stty -W1234

EPM 1500 SUB-METER– INSTRUCTION MANUAL 4–7

Page 40

4.3 Modbus Memory Map

4.3.1 Memory Map

The Modbus memory map is shown below.

CHAPTER 4: COMMUNICATIONS

Table 4–1: Modbus Memory Map (Sheet 1 of 4)

Hex

Addr

0000

0002

0004

0006

0008 0008 Meter Modbus Address R --- 8-bit Modbus Address in LSB

0009 0009 Baud Rate R

000C 0012 Meter Status R --- Always 1 for Modbus.

000D 0013 Meter Ready R --- Always 1 for Modbus.

000E 0014 Number of Meters Configured R --- Always 1 for EPM 1500

000F 0015

0010 0016

0011 0017

0012 0018

Addr Description R/W Units Notes

Fixed Value Registers (Read Only)

+

0000 Meter Serial Number R 32-bit long integer

+

0002 Meter Serial Number Extension R

+

0004 Meter Version Number R 32-bit long integer

+

0006 Meter Version Number Extension R

Setup Information

Number of Real-Time Points

Configured

Number of Interval Points

Configured

Number of Max/Min Points

Configured

Maximum Number of Intervals

That Can Be Recorded

R

R Returns 0 if intervals are disabled

R Always returns 0

R

Returns same value as address 0000

32-bit long integer

Returns same value as address 0000

32-bit long integer

Dependent upon the number of

parameters optioned and the number of

meters returned in address 0015

0013 0019

0014 0020

Interval Setup

0031 0049 Store Interval Length R/W minutes

Read Clock

0032 0050 Internal Time - Hours/Minutes R/W

0033 0051 Internal Time - Seconds R/W seconds

0034 0052 Internal Date - Month/Day R/W month/day

0035 0053 Interval Date - Year R/W year

Number of slots configured for

Transponder

Current slot being read in

Transponder

R

R/W

hours/

minutes

Interval length in minut es must be evenly

divisible into 60 (1, 2, 3, 4, 5, 6, 10, 12, 15,

20, 30, 60)

16-bit, Hours: 0-23 (bitmask = FF00)

Minutes: 0-59 (bitmask = 00FF

4–8 EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 41

CHAPTER 4: COMMUNICATIONS

Table 4–1: Modbus Memory Map (Sheet 2 of 4)

Hex

Addr

0036 0054 Internal Time - Hours/Minutes R/W

0037 0055 Internal Time - Seconds R/W month/day

0038 0056 Internal Date - Month/Day R/W Year 16-bit Unsigned Integer

0039 0057 Interval Date - Year R/W 16-bit Unsigned Integer

003A 0058

003B 0059

003C 0060 Date/T ime of Oldest Interval - Year R/W Year 16-bit Unsigned Integer

Addr Description R/W Units Notes

Date/Time of Oldest Interval Hours/Minutes

Date/Time of Oldest Interval Month/Day

hours/

minutes

Hours/

R/W

Minutes

R/W Month/Day

16-bit, Hours: 0-23 (bitmask = FF00)

Minutes: 0-59 (bitmask = 00FF

16-bit, Hours: 0-23 (bitmask = FF00)

Minutes: 0-59 (bitmask = 00FF)

DDE Data is COM Compatible,

Date/Time Numeric

16-bit

Month: 1=Jan., 12=Dec. (bitmask = FF00)

Day: 1-31 (bitmask = 00FF)

DDE Data is COM Compatible,

Date/Time Numeric

003D 0061

003E 0062

003F 0063

0040 0064

0041 0065

0042 0066

0043 0067 Data Ready Flag R/W

3-Phase Totaled Values

0063 0099 Interval Data Qualifying Register R

0064 0100 3-Phase Totaled kW R kW Stored Interval 1

0066 0102 3-Phase Totaled kvar R kvar Stored Interval 2

Date/Time of Newest Interval Hours/Minutes

Date/Time of Newest Interval Month/Day

Date/Time of Newest Interval Year

Date/Time of Currently Selected

Interval - Hours/Minutes

Date/Time of Currently Selected

Interval - Month/Day

Date/Time of Currently Selected

Interval - Year

Hours/

R/W

Minutes

R/W Month/Day

R/W Year 16 Bit Unsigned Integer

Hours/

R/W

Minutes

R/W Month/Day

R/W Year 16 Bit Unsigned Integer

16-bit, Hours: 0-23 (bitmask = FF00)

Minutes: 0-59 (bitmask = 00FF)

16-bit

Month: 1=Jan., 12=Dec. (bitmask = FF00)

Day: 1-31 (bitmask = 00FF)

DDE Data is COM Compatible,

Date/Time Numeric

16-bit, Hours: 0-23 (bitmask = FF00)

Minutes: 0-59 (bitmask = 00FF

16-bit

Month: 1=Jan., 12=Dec. (bitmask = FF00)

Day: 1-31 (bitmask = 00FF)

DDE Data is COM Compatible,

Date/Time Numeric

16 Bits: Mask out/ignore Bit 15.

0=Data is ready for read

1=Populate registers with timestamp

data

2=Invalid Timestamp Requested

Stored Dynamic Data Ready for Read

16-bit Unsigned Integer, 8 = Invalid

Interval

0068 0104 3-Phase Totaled kVA R kVA Stored Interval 3

006A 0106 3-Phase Totaled Power Factor R % Stored Interval 4

Metered Values

0162 0354 Frequency (Phase A) R Hz Instantaneous Frequency

016A 0362 Voltage (A-N) R V Instantaneous Voltage

016C 0364 Voltage (B-N) R V Instantaneous Voltage

016E 0366 Voltage (C-N) R V Instantaneous Voltage

EPM 1500 SUB-METER– INSTRUCTION MANUAL 4–9

Page 42

CHAPTER 4: COMMUNICATIONS

Table 4–1: Modbus Memory Map (Sheet 3 of 4)

Hex

Addr

0170

0172* 0370 Amps (CT01) R A Instantaneous Current

0174* 0372 kW (CT01) R kW Instantaneous Power

0176* 0374 kvar (CT01) R kvar Instantaneous Reactive Power

0178* 0376 kVA (CT01) R kVA Instantaneous Apparent Power

017A* 0378 Voltage (CT02) R V Instantaneous Voltage

017C* 0380 Amps (CT02) R A Instantaneous Current

017E* 0382 kW (CT02) R kW Instantaneous Power

0180* 0384 kvar (CT02) R kvar Instantaneous Reactive Power

0182* 0386 kVA (CT02) R kVA Instantaneous Apparent Power

0184* 0388 Voltage (CT03) R V Instantaneous Voltage

0186* 0390 Amps (CT03) R A Instantaneous Current

0188* 0392 kW (CT03) R kW Instantaneous Power

018A* 0394 kvar (CT03) R kvar Instantaneous Reactive Power

018C* 0396 kVA (CT03) R kVA Instantaneous Apparent Power

Addr Description R/W Units Notes

*

0368 Voltage (CT01) R V Instantaneous Voltage

Three-Phase Metered Values

0288* 0648 3-Phase kWh R kWh Real Time Input 1

028A* 0650 3-Phase kvarh R kvarh Real Time Input 2

028C* 0652 3-Phase kW R kW Real Time Input 3

028E* 0654 3-Phase kvar R kvar Real Time Input 4

0290* 0656 3-Phase kVA R kVA Real Time Input 5

0292* 0658 3-Phase Power Factor R % Real Time Input 6

Total Harmonic Distortion (THD)

03E8* 1000 THD Phase A R % Total Harmonic Distortion

03EA* 1002 Phase Angle A R degrees Phase Angle

03EC* 1004 Phase-to-Phase Voltage A R V Instantaneous Voltage

03EE* 1006 THD Phase B R % Total Harmonic Distortion

03F0* 1008 Phase Angle B R degrees Phase Angle

03F2* 1010 Phase-to-Phase Voltage B R V Instantaneous Voltage

03F4* 1012 THD Phase C R % Total Harmonic Distortion

03F6* 1014 Phase Angle C R degrees Phase Angle

03F8* 1016 Phase-to-Phase Voltage C R V Instantaneous Voltage

Counters

07D0 2000 Number of phases offset

16-bit Unsigned Integer

1, 2, 3, or 24 phases available

4–10 EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 43

CHAPTER 4: COMMUNICATIONS

Table 4–1: Modbus Memory Map (Sheet 4 of 4)

Hex

Addr

07D1 2001 Demand Window Offset

07D2 2002 I Multiplier Type Offset

07D3 2003 Number of Pulse Counters Offset

07D4 2004 Overlap Offset

07D5 2005 Number TOU's Offset

07D6 2006 MDT_M_TABLE_REG_START 16-bit Unsigned Integer

07D7 2007 NUM_MDT_M_TABLE_COLUMNS 16-bit Unsigned Integer

07D8 2008 NUM_MDT_M_TABLE_REGS 16-bit Unsigned Integer

07D9 2009 MDT_M_TABLE_REG_END 16-bit Unsigned Integer

Addr Description R/W Units Notes

16-bit Unsigned Integer

5, 15, or 30 minutes available

16-bit Unsigned Integer

Internal calibration value

16-bit Unsigned Integer

Number of external pulse inputs installed

16-bit Unsigned Integer

Number of adjacent demand windows

that are averaged to determine peak

demand

16-bit Unsigned Integer

Number of different TOU periods defined

in the time-of-use table

* 32-bit floating point register.

+

32-bit long integer - Range: 00000000h to FFFFFFFFh

Note

1. 32-bit floating point numbers are as per the IEEE 754-1985 standard.

2. Registers 0X0063 to 0X025E are all read-only and cannot be modified. They break

down as follows:

• Registers 0X0064 to 0X0122 are not real-time, but are populated with

stored interval data based on user inputs to registers 0X0040 to 0X0043.

• Registers 0X0162 to 0X025E are all real-time data registers.

EPM 1500 SUB-METER– INSTRUCTION MANUAL 4–11

Page 44

CHAPTER 4: COMMUNICATIONS

4–12 EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 45

GE Energy

Industrial Solutions

EPM 1500 Single Point

Chapter 5: Miscellaneous

Miscellaneous

5.1 Revision History

Submetering System

5.1.1 Release Dates

MANUAL GE PART NO. EPM 1500

GEK-106554 1601-0155-A1 1.0x 21 May 2004

GEK-106554A 1601-0155-A2 1.0x 20 October 2004

GEK-106554B 1601-0155-A3 1.0x 1 December 2004

GEK-106554C 1601-0155-A4 1.0x 14 February 2005

GEK-106554D 1601-0155-A5 1.0x 08 April 2005

GEK-106554E 1601-0155-A6 1.0x 30 June 2006

GEK-106554F 1601-0155-A7 1.0x 15 November 2007

5.1.2 Changes to the Manual

Table 5–1: Release Dates

RELEASE DATE

REVISION

Table 5–2: Major Updates for 1601-0155-A7 (Sheet 1 of 2)

PAGE

(A6)

Title Title Update Manual part number to 1601-0155-A7

EPM 1500 SUB-METER – INSTRUCTION MANUAL 5–1

PAGE

(A7)

CHANGE DESCRIPTION

Page 46

CHAPTER 5: MISCELLANEOUS

Table 5–2: Major Updates for 1601-0155-A7 (Sheet 2 of 2)

PAGE

(A6)

PAGE

(A7)

CHANGE DESCRIPTION

3-5 3-6 Update Text change re on-screen copyright statement

4-7 4-8 Update Changes to Modbus Memory Map

Table 5–3: Major Updates for 1601-0155-A6

PAGE

(A5)

PAGE

(A6)

CHANGE DESCRIPTION

Title Title Update Manual part number to 1601-0155-A6

4-1 4-1 Update Updated RS485 WIRING FOR MODBUS section

4-2 4-2 Add Added RS232 WIRING FOR MODBUS section

Table 5–4: Major Updates for 1601-0155-A5

PAGE

(A4)

PAGE

(A5)

CHANGE DESCRIPTION

Title Title Update Manual part number to 1601-0155-A5

4-3 4-3 Update Updated MODBUS ACTIVATION section

Table 5–5: Major Updates for 1601-0155-A4

PAGE

(A3)

PAGE

(A4)

CHANGE DESCRIPTION

Title Title Update Manual part number to 1601-0155-A4

--- 4-1 Add Added RS485 WIRING FOR MODBUS section

Table 5–6: Major Updates for 1601-0155-A3

PAGE

(A2)

PAGE

(A3)

CHANGE DESCRIPTION

Title Title Update Manual part number to 1601-0155-A3

4-3 4-3 Update Updated MODBUS ACTIVATION section

5–2 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 47

CHAPTER 5: MISCELLANEOUS

Table 5–7: Major Updates for 1601-0155-A2

PAGE

(A1)

PAGE

(A2)

CHANGE DESCRIPTION

Title Title Update Manual part number to 1601-0155-A2

1-3 1-3 Update Updated OPERATING SPECIFICATIONS

--- 2-7 Add

2-8 2-8 Update

Added CT TERMINATIONS FOR 1600 A AND 3200 A

MODELS diagram

Updated INTERNAL SHORTING TERMINAL diagram

and renamed to INTERNAL FUSE BLOCK

--- 4-1 Add Added MODBUS COMMUNICATIONS chapter

EPM 1500 SUB-METER – INSTRUCTION MANUAL 5–3

Page 48

5.2 Warranty

5.2.1 GE Energy Warranty

CHAPTER 5: MISCELLANEOUS

General Electric Energy (GE Energy) warrants each device it manufactures to be free from

defects in material and workmanship under normal use and service for a period of 24

months from date of shipment from factory.

In the event of a failure covered by warranty, GE Energy will undertake to repair or replace

the device providing the warrantor determined that it is defective and it is returned with all

transportation charges prepaid to an authorized service centre or the factory. Repairs or

replacement under warranty will be made without charge.

Warranty shall not apply to any device which has been subject to misuse, negligence,

accident, incorrect installation or use not in accordance with instructions nor any unit that

has been altered outside a GE Energy authorized factory outlet.

GE Energy is not liable for special, indirect or consequential damages or for loss of profit or

for expenses sustained as a result of a device malfunction, incorrect application or

adjustment.

For complete text of Warranty (including limitations and disclaimers), refer to GE Energy

Standard Conditions of Sale.

5–4 EPM 1500 SUB-METER – INSTRUCTION MANUAL

Page 49

INDEX

Index

Index

A

APPLICATIONS ...............................................................................................1-2

B

C

CATALOG NUMBERS ......................................................................................1-6

CHANGES TO MANUAL ................................................................... 5-1, 5-2, 5-3

COMMUNICATIONS

activating Modbus communications ................................................................4-6

memory map .................................................................................................4-8

Modbus.........................................................................................................4-2

Modbus data groups ......................................................................................4-2

CT INSTALLATION ..........................................................................................2-9

CT MULTIPLIERS ............................................................................................3-4

CURRENT TRANSFORMER INSTALLATION .................................................... 2-9

CURRENT, VERIFYING ...................................................................................3-6

D

DEMAND, RESETTING ....................................................................................3-7

DESCRIPTION ................................................................................................1-1

DIMENSIONS ..................................................................................................1-5

DISPLAY STRUCTURE....................................................................................3-3

E

ENERGY, VERIFYING .....................................................................................3-6

ENVIRONMENTAL SPECIFICATIONS ..............................................................1-5

F

G

GETTING STARTED ........................................................................................1-1

H

I

INSTALLATION ....................................................................................... 2-1, 2-9

INSTALLATION CATEGORY ............................................................................1-5

INTERIOR VIEW..............................................................................................1-3

INTERNAL FUSE BLOCK............................................................................... 2-11

EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 50

J-L

M

MENU NAVIGATION ....................................................................................... 3-1

MENU STRUCTURE ....................................................................................... 3-3

METER INSTALLATION .................................................................................. 2-9

METERING SYSTEM REQUIREMENTS ........................................................... 2-1

MODBUS

activating ..................................................................................................... 4-6

commands.................................................................................................... 4-2

data register groups ..................................................................................... 4-2

memory map ................................................................................................ 4-8

wiring ........................................................................................................... 4-1

N

O

ORDER CODES .............................................................................................. 1-6

INDEX

P

POLLUTION DEGREE..................................................................................... 1-5

PREVENTIVE MAINTENANCE ........................................................................ 1-4

PROTECTIVE CONDUCTOR TERMINAL ......................................................... 1-4

PULSE INPUTS ............................................................................................ 2-12

Q

R

RS232 WIRING FOR MODBUS........................................................................ 4-2

RS485 WIRING FOR MODBUS........................................................................ 4-1

S

SCAN TRANSPONDER

functionality.................................................................................................. 1-2

installing .................................................................................................... 2-13

location ...................................................................................................... 2-13

SPECIFICATIONS........................................................................................... 1-5

T

TRANSIENT/SURGE SUPRESSION ................................................................ 1-5

U

USER INTERFACE ......................................................................................... 3-1

EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 51

INDEX

V

VERIFYING CURRENT ....................................................................................3-6

VERIFYING ENERGY ......................................................................................3-6

VERIFYING METER FUNCTIONALITY .............................................................3-5

VERIFYING VOLTAGE.....................................................................................3-5

VOLTAGE, VERIFYING....................................................................................3-5

W

WARNINGS .....................................................................................................1-3

WARRANTY ....................................................................................................5-4

WIRING

1-phase, 3-wire center-tap-neutral ................................................................. 2-4

3-phase, 3-wire corner-grounded delta...........................................................2-7

3-phase, 3-wire ungrounded delta ..................................................................2-6

3-phase, 4-wire center-tap-neutral delta.........................................................2-5

3-phase, 4-wire Wye .....................................................................................2-3

diagrams.......................................................................................................2-2

overview ....................................................................................................... 2-1

XYZ

EPM 1500 SUB-METER– INSTRUCTION MANUAL

Page 52

INDEX

EPM 1500 SUB-METER– INSTRUCTION MANUAL

Loading...

Loading...