Page 1

DEH-237 R01

g

GE Entellisys™ Low Voltage

Switchgear

Installation and Maintenance Instructions

Page 2

Page 3

WARNINGS

CAUTIONS

NOTES

DEH237

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury are present in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not taken.

Notes call attention to information that is especially significant to understanding and operating the

equipment.

This document is based on information available at the time of its publication. While efforts have

been made to ensure accuracy, the information contained herein does not cover all details or

variations in hardware and software, nor does it provide for every possible contingency in

connection with installation, operation, and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE Consumer & Industrial assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Consumer & Industrial makes no representation or warranty, expressed, implied, or statutory,

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warrantees of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Company:

EntelliGuard™, EntelliGuard Messenger™, Entellisys™

©Copyright 2005 GE Company

All Rights Reserved

Page 4

Entellisys Low Voltage Switchgear

Table of Contents

Chapter 1. Introduction

1-1 General Information........................... 1

1-2 Instruction Book Arrangement.......... 1

1-3 Related Publications........................... 2

Chapter 2. Receiving, Handling, and

Storage

2-1 Receiving............................................. 3

Equipment Packages..................... 3

Inspecting for Damage.................. 3

Filing a Claim................................ 3

2-2 Handling ............................................. 4

Lifting ............................................ 4

Rollers............................................ 5

Forklifts ......................................... 5

Jacks ................................................ 6

2-3 Storage ..................................................7

Switchgear....................................... 7

Circuit Breakers.............................. 7

Chapter 3. Description

3-1 General.................................................. 8

3-2 Summary Description...........................8

3-3 Compartment Area.............................10

3-4 EntelliGuard Messenger....................10

3-5 Breaker Compartment ....................... 11

3-6 Circuit Breakers ................................. 16

EGS/EGH/EGX-08 Circuit Breaker16

EGF-08 Fused Circuit Breaker ...... 16

EGS/EGH-16 Circuit Breaker ........16

EGF-16 Fused Circuit Breaker ...... 16

EGS/EGF-20 Circuit Breaker.........16

EG-32 Circuit Breaker....................17

EG-40 Circuit Breaker....................17

EG-50 Circuit Breaker....................17

3-7 Fuse Rollout Elements.......................17

EGF-32 Rollout Carriage................17

EGF-40 Rollout Carriage................17

EGF-50 Rollout Carriage................17

3-8 Compartments for Future Breakers.. 18

3-9 Auxiliary/Transition Sections............18

3-10 Bus Area.............................................. 19

Busing System....................................19

Insulated/Isolated Bus System..........20

3-11 Feeder Cable and Busway

Compartment......................................22

3-12 Ground Bus......................................... 23

Chapter 4. Equipment Installation

4-1 General................................................ 24

Site Location..................................24

Foundation Requirements............24

Foundation Preparation................24

4-2 Assembly and Installation of Switchgear

Equipment ............................................27

General Requirements....................27

Detailed Assembly and Installation

Instructions ..........................................27

Anchoring Switchgear Equipment.33

Busway Connections............................ 35

Control Wire Connections.................... 35

Power Cable Connections .................... 36

Breaker Hoist....................................... 37

Final Inspection ................................... 38

4-3 Installation of Wall-Mount HMI ........ 39

General Requirements......................... 39

Enclosure Installation ......................... 39

Device Wiring....................................... 39

Chapter 5. Installing and Removing

Circuit Breakers

5-1 General................................................. 41

Inspection and Preparation of

Circuit Breakers................................... 41

Circuit Breaker Installation................ 41

Rejection Feature................................. 41

5-2 Installing EG-08/16/20

Circuit Breakers................................... 42

Prior to Installation ............................. 42

Installation Procedures........................ 42

5-3 Installing EG-32/40/50

Circuit Breakers................................... 45

5-4 Removing the EGS-08/16/20

Circuit Breakers................................... 46

5-5 Removing the EGH-32, EGS-32/40/50

Circuit Breakers .................................. 46

5-6 Installing and Removing EGF-08/16

Fused Circuit Breakers ....................... 46

5-7 Installing Fuses in EGF-08/16 Circuit

Breakers .............................................. 47

5-8 Installing and Removing Fuse Rollout

Elements (FRE) 30 and 38-inch Wide

Compartments...................................... 49

Chapter 6. Testing and Inspection

6-1 General ............................................... 51

6-2 Key Interlocks..................................... 51

6-3 Breaker Operation Test ..................... 51

6-4 Entellisys System Test Kit ................ 51

6-5 Final Steps to Be Taken Before

Energizing Equipment....................... 52

i

Page 5

Entellisys Low Voltage Switchgear

Table of Contents

Chapter 7. Operating the Switchgear

7-1 Circuit Breaker Operation .................53

General.........................................53

Manually Operated Breakers .....53

Closing Manually Operated

EntelliGuard Circuit Breakers .53

Opening Manually Operated

EntelliGuard Circuit Breakers .53

Electrically Operated Breakers .. 53

Electrically Opening EntelliGuard

Breakers.......................................53

7-2 Circuit Breaker Drawout Operation..53

Breaker Positions........................53

Drawout Operation......................54

7-3 Front Doors......................................... 54

Operation.....................................54

Removal and Installation............54

Door Removal...........................54

Door Installation......................54

7-4 Entellisys Switchgear Accessories.....55

Future Circuit Breaker

Compartments............................. 55

Circuit Breaker Key Interlock ....55

General.....................................55

Key Interlock Operation Check55

Test and Disconnect Padlock

Device...........................................55

General.....................................55

Padlocking the EG-08/16/20

Breakers...................................56

Padlocking the EG-32/40/50

Breakers & EG-32/40/50 FRE.56

Padlocking the EG-08/16/20,

EG-32/40/50 & EG-32/40/50

FRE Compartments.................56

Installing and Removing

Current Transformers ............. 56

Removing Shutter Units .............57

Removing a EG-08/16/20

Shutter Unit.............................58

Removing a EG-32/40/50 or

Fuse Rollout Shutter Unit....... 58

Installing a Shutter Unit............59

Installing a EG-08/16/20

Shutter Unit.............................59

Installing a EG-32/40/50 Fuse

Rollout Shutter Unit................59

Chapter 8. Energizing the Switchgear

8-1 Before Energizing............................... 60

8-2 Energizing Procedures ....................... 60

Chapter 9. Maintaining the Switchgear

9-1 Maintenance Requirements............... 61

General ........................................ 61

9-2 Breaker and Instrument

Compartments.................................... 61

Breakers ...................................... 61

Test for Proper Operation ....... 61

Checks after Breaker is De-

energized.................................. 61

Lubrication............................... 62

Entellisys Instrumentation and

Instrument Transformers ....... 62

Breaker Compartment Interiors 62

9-3 Bus Area ............................................. 62

9-4 Cable and Busway Compartment...... 62

9-5 Overall Switchgear............................. 63

9-6 Paint Refinishing ............................... 63

9-7 Circuit Breaker Lifting Mechanism.. 63

Appendices

A. Torque Values..................................... 65

B. Circuit Breaker Rejection Features... 66

C. Circuit Breaker Ratings..................... 70

D. Circuit Breaker Accessory Devices.... 71

E. Circuit Breaker Weights.................... 73

F. Circuit Breaker Repetitive Duty

Data..................................................... 73

G. Fuses for EGF-08/16 and FRE

Elements............................................. 74

These instructions do not purport to cover all details or

variations in equipment or to provide for every possible

contingency to be met in connection with installation,

operation or maintenance. Should further information be

desired or should particular problems arise which are not

covered sufficiently for the Purchaser's purposes, the

matter should be referred to the General Electric

Company. These instructions are intended for use by

qualified personnel only.

ii

Page 6

Page 7

Entellisys Low Voltage Switchgear

Chapter 1. Introduction

1-1 General Information

This manual contains procedures for receiving, handling,

storage, equipment installation, operation, maintenance, and

service of Entellisys Low Voltage Switchgear.

NOTE: The personnel responsible for installing,

operating, and servicing this equipment should be

thoroughly familiar with the contents of this manual.

NOTE: La ou les personnes responsables de l’installation,

l’opération et du service d’entretien de cet équipement

devraient être pleinement familiers en ce qui concerne le

contenu de ce manuel.

Before any installation work is performed, thoroughly read

and understand the material in this instruction manual and

the drawings furnished with the equipment. The

documentation shipped with the equipment includes the

Summary, Front View, Elementary Diagram, Connection

Diagram and Instruction Book. This material is located in a

forward compartment tagged "INSTRUCTIONS IN THIS

COMPARTMENT." The documentation provides all of the

information necessary for installation of the switchgear.

When requesting information from the General Electric

Company, include the complete data appearing on the

equipment nameplate, requisition number, summary

number, and elementary diagram number. The nameplate is

located in the lower left, front corner of the lineup.

When requesting information concerning any specific item

furnished with the switchgear, refer to that item by

description, part number, its location within this manual,

and any applicable drawing number. Any material external

to the equipment, which may be required to meet local codes

(such as mats, screens, railings, etc.), is not furnished by the

General Electric Company.

If there are any questions or requirements not covered in this

manual or in the accompanying drawings, please contact the

local sales office of the General Electric Company.

1-2 Instruction Book Arrangement

Information and procedures in this instruction book are

divided into Chapters as follows:

• Chapter 1, Introduction, gives a brief account of the

equipment's function and provides for general

information, and applicable data for the equipment and

its components.

• Chapter 2, Receiving, Handling and Storage,

describes procedures required for receiving and handling

the equipment and how to prepare it for short- or longterm storage.

• Chapter 3, Description, describes the Entellisys Low

Voltage Switchgear and its various components.

Included are the section enclosure, breaker

compartment, circuit breakers, instrument panels and

instrument compartments, bus bar arrangement,

incoming cable and busway, ground and neutral bus, and

auxiliary section. This section also explains how the

electrical and mechanical components perform their

assigned functions.

• Chapter 4, Equipment Installation, provides the

information needed prior to installation, site location and

foundation requirements, and how to anchor the

equipment properly and safely. It also covers

installation of peripheral equipment and includes

information on electrical connections and mechanical

construction.

• Chapter 5, Installing and Removing Circuit

Breakers, gives a step-by-step procedure for lifting the

breaker from the floor, installing it on drawout rails, and

moving it into the connected position. A further

procedure is given to withdraw a breaker, remove it from

the drawout rails, and lower it to the floor. Also included

is a description of the rejection system provided to avoid

the inadvertent use of an incorrect breaker in a breaker

compartment.

• Chapter 6, Testing and Inspection, reviews items

that should be tested or inspected prior to energizing and

operating the switchgear.

• Chapter 7, Operating the Switchgear, covers how to

operate the breakers, and contains information

concerning draw-out provisions, doors, and various

accessories.

• Chapter 8, Energizing the Switchgear, outlines the

steps to be taken before and during the electrical

energization of the equipment.

• Chapter 9, Maintaining the Switchgear, provides

instructions for all preventive maintenance, servicing,

and lubrication information for the switchgear

equipment. Included is service and maintenance data for

the circuit breakers, instrument compartments,

instruments, bus bar joints, and cable and busway

connections. This section also includes paint refinishing

requirements.

• Appendices A through F, contain information

concerning screw and bolt torque values, circuit breaker

ratings, rejection features, accessory device ratings,

repetitive duty data, and fuse data.

1

Page 8

Entellisys Low Voltage Switchgear

Chapter 1. Introduction

1-3 Related Publications

Service and maintenance publications are supplied

separately for circuit breakers and Entellisys

instrumentation not described in this instruction book.

In addition to instruction books, the following drawings will

be supplied as required for each order of Entellisys

switchgear equipment:

1. General arrangement drawings, including front view

and floor plan.

2. Elementary and connection drawings (or wiring routing

tables) which identify test and connection points

including terminal blocks, device studs, switch contact

developments, and remote connections.

3. Summary of all the components furnished with the

switchgear, including the breakers, identified by catalog

number.

These are all documents necessary to install, operate, and

maintain the equipment. One complete set of drawings and

select instruction books are shipped with the equipment.

Fig. 1-1. General Electric Entellisys Low Voltage Switchgear

2

Page 9

Entellisys Low Voltage Switchgear

Chapter 2. Receiving, Handling, and Storage

2-1 Receiving

Equipment Packages

Every package leaving the factory is plainly marked with the

shop order number, requisition number, and customer's order

number. If the equipment has been split for shipment, the

section numbers of the equipment enclosed in each shipping

package are identified.

NOTE: To avoid the loss of any parts when unpacking,

the contents of each container should be carefully checked

against the packing list before discarding the packing

material.

NOTE: Le contenu de chaque conteneur devrait être

soigneusement vérifié avec la liste d’emballage avant de

décharger le matériel empaqueté, ceci dans le but d’éviter

la perte de pièces lors du déballage.

The contents of each shipping package are listed on the

Master Packing List. In addition, this list includes the

number of the shipping crate in which miscellaneous parts

needed to install and operate the equipment (such as

hardware, contact lubricant, touch-up paint, breaker closing

devices, etc.) are located. Normally, such devices are packed

in a cardboard carton and the carton secured in an empty

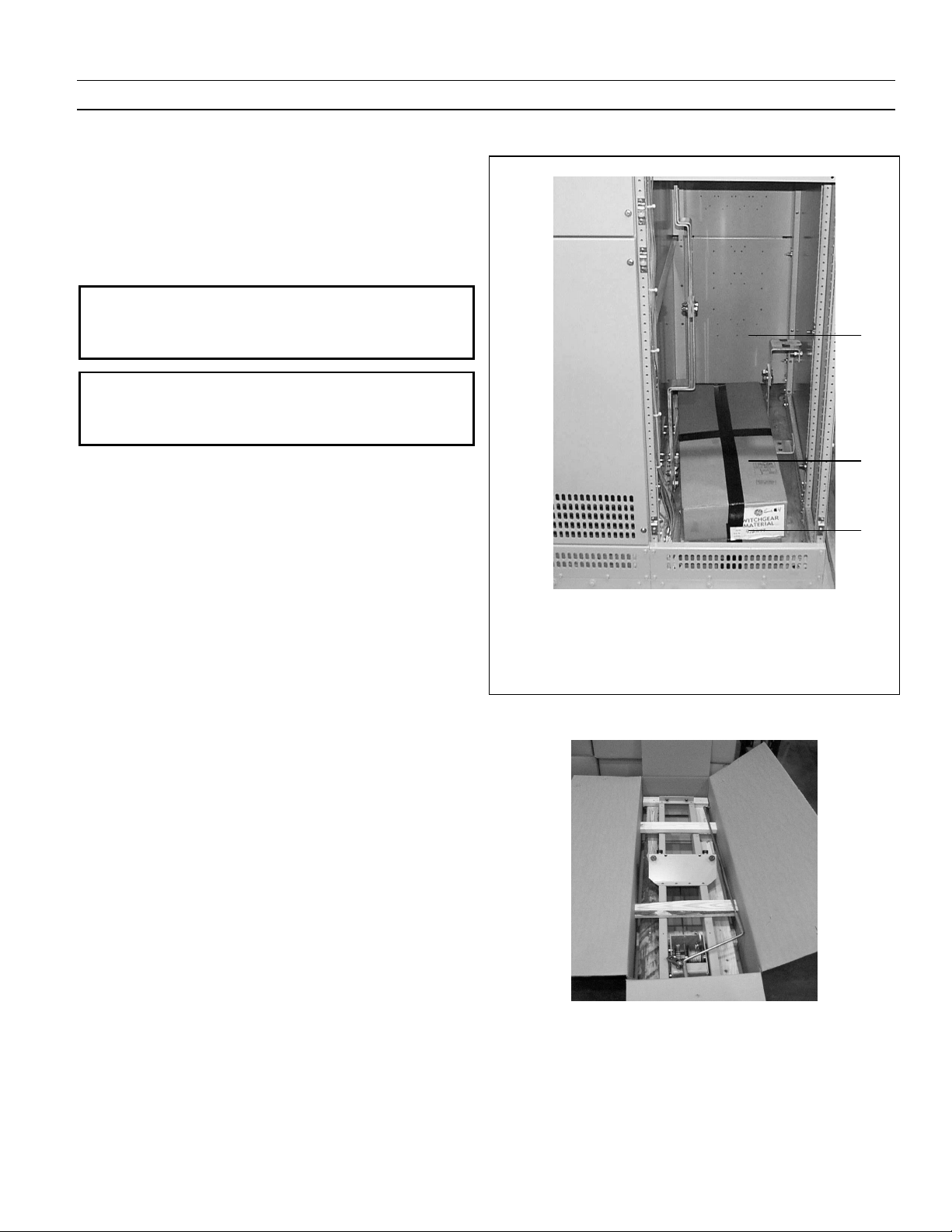

switchgear compartment. See Fig. 2-1. If such items are

packed in a switchgear section instead of a separate crate,

the list will indicate the appropriate section number in which

they are stored. Large items (such as hoist dollies and hoist

carriages used with indoor equipment) will always be shipped

in separate crates or cartons. See Fig. 2-2.

Inspecting for Damage

All equipment leaving the factory is carefully inspected and

packed by personnel experienced in the proper handling and

packing of electrical equipment. Upon receipt of any

equipment, immediately perform a visual inspection to

ascertain if any damage has been sustained in shipping or if

there are any loose parts.

Circuit breakers may be shipped separately in individual

containers with the breaker in the open position. Circuit

breakers should be unpacked and visually inspected for

damage or loose parts as soon as possible after they have

been received.

Be sure to inspect all devices mounted or packed inside

compartments of each section to see if any have been

dislodged or damaged.

Filing a Claim

If any damage is evident, or indication of rough handling is

visible, file a claim for damage at once with the

transportation company and notify the nearest General

Electric Company Sales Office immediately. Information on

damaged parts, part number, case number, requisition

number, etc., should accompany the claim.

1

2

3

1. Spare compartment

2. Carton containing loose material

3. Shipping label listing contents of carton

Fig. 2-1. Packaging of loose material for shipment

Fig. 2-2. Carton containing breaker lifting device

3

Page 10

Entellisys Low Voltage Switchgear

Chapter 2. Receiving, Handling, and Storage

2-2 Handling

NOTE: It is preferable to leave the shipping skids in

place under the switchgear until it reaches its final

location. The equipment should be installed in its final

location prior to installing the circuit breakers.

NOTE: Il est préférable de laisser l’emballage

d’expédition en place sous le dispositif de commutation

jusqu’à ce qu’il atteigne son emplacement final.

L’équipement devrait être installé à son emplacement

final avant que ne soient installés les disjoncteur.

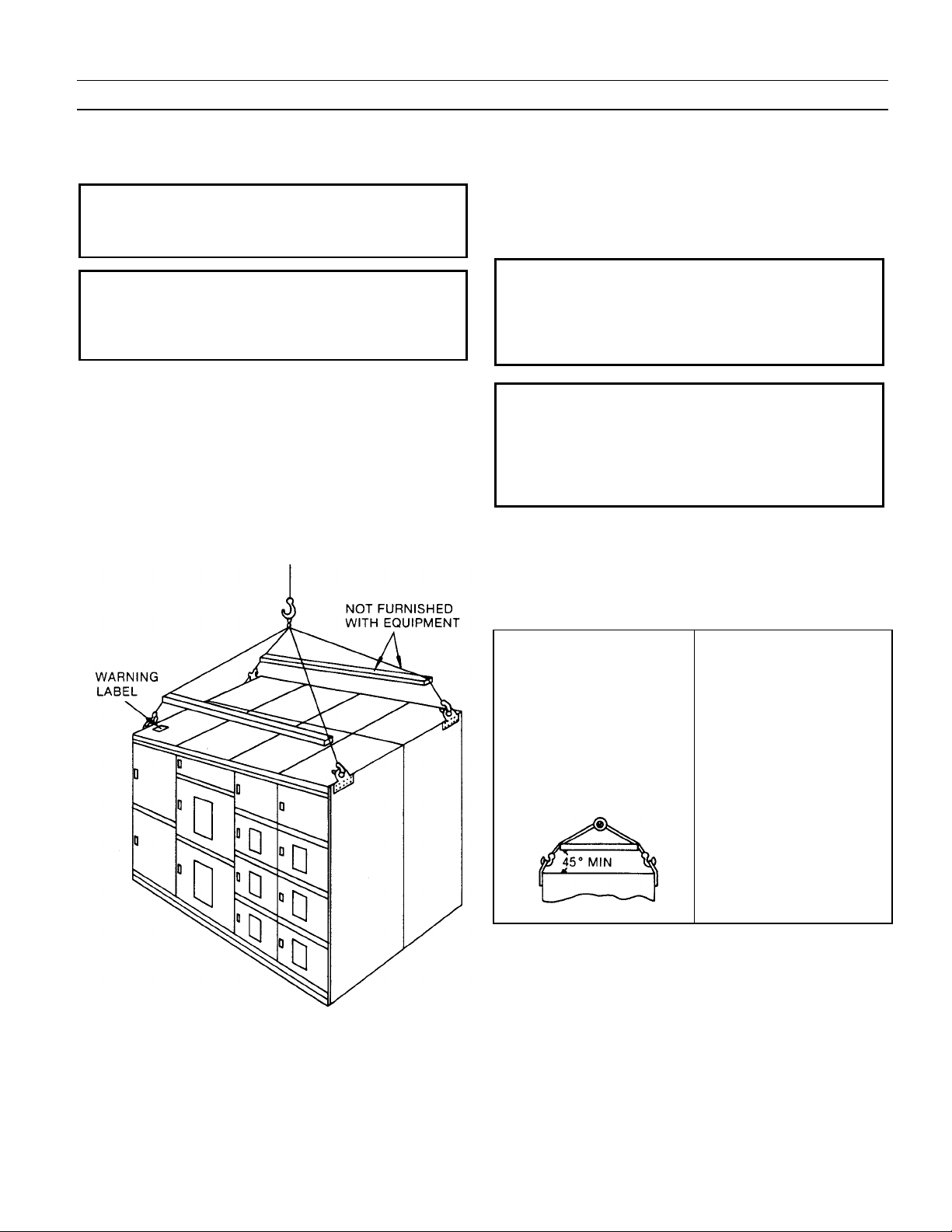

Lifting

The switchgear sections are best handled by lifting with a

crane as shown in Fig. 2-3. Removable lifting plates are

provided, as standard equipment, on the top of each

switchgear shipping section. To preserve the external

appearance of the equipment, it is suggested that the lifting

plates be left in place except where adjacent equipments

must be bolted together, i.e. shipping splits, etc.

Utilize four equal length cables and an overhead crane, each

with a minimum load rating of twice the weight of the

switchgear. Estimated weights for shipping splits appear on

the Front View drawings.

Example: Switchgear Section Weight = 5,000 pounds. The

crane and the four lift cables must have a minimum load

lifting capacity of 10,000 pounds.

NOTE: The angle between the cables and the top of the

equipment must be at least 45 degrees. If this is not

possible because of lack of headspace, spreader bars must

be used. Also, lift cables with greater load capability may

be necessary, depending upon the angle between the

cables and the crane hook.

NOTE: Il faut que l’angle entre les câbles et le haut de

l’équipement soit d’au moins 45 degrés. Si cela est

impossible à cause d’une insuffisance d’espace de

dégagement, il faut utiliser des barres d’extension. Il se

peut aussi que des câbles de levage ayant une capacité de

poids supérieure soient nécessaires dépendant de l’angle

entre les câbles et le crochet de la grue.

Connect a cable from the crane to the four lifting plates

located on the top-front and rear of the switchgear (Fig. 2-3).

WARNING ADVERTISSEMENT

WHEN LIFTING THIS

EQUIPMENT, USE LIFTING

HOLES PROVIDED. ANGLE

OF SLING MUST NOT BE

LESS THAN 45 DEGREES. IF

HEAD SPACE IS

INSUFFICIENT, USE A

SPREADER BAR.

Lorsque cet équipement

est levé, il faut utiliser les

trous de levage qui sont

fournis. Il ne fuat pas que

l’angle d’élinguje soit de

moins de 45 degrés.

Si l’espace de dégagement

est insuffisant utiliser une

barre d’écartement.

THIS LABEL IS LOCATED

ON EACH CORNER BY

THE LIFTING HOLE

Fig. 2-3. Recommended method of lifting Entellisys enclosure

4

Page 11

Entellisys Low Voltage Switchgear

Chapter 2. Receiving, Handling, and Storage

Take up the slack in the lifting device very carefully and

manually stabilize the switchgear to prevent it from rotating.

WARNING: Do not stand under switchgear while it is

being moved. Serious injury may occur if the cables or

lifting device fail.

AVERTISSEMENT: Ne vous tenez pas sous le dispositif

de commutation lorsqu’il est bougé. Des blessures graves

peuvent survenir si les câbles ou l’appareil de levage

tombent en panne.

CAUTION: Gently lower the switchgear section onto the

level site location. If the switchgear is roughly handled or

jarred, it is possible to damage or misalign internal

components.

ATTENTION: Abaisser doucement la section du

dispositif de commutation sur l’endroit d’installation

nivelé. Une détérioration ou un désenlignement des

composantes internes sont possibles si le dispositif de

commutation est manipulé grossièrement ou soumis à des

vibrations.

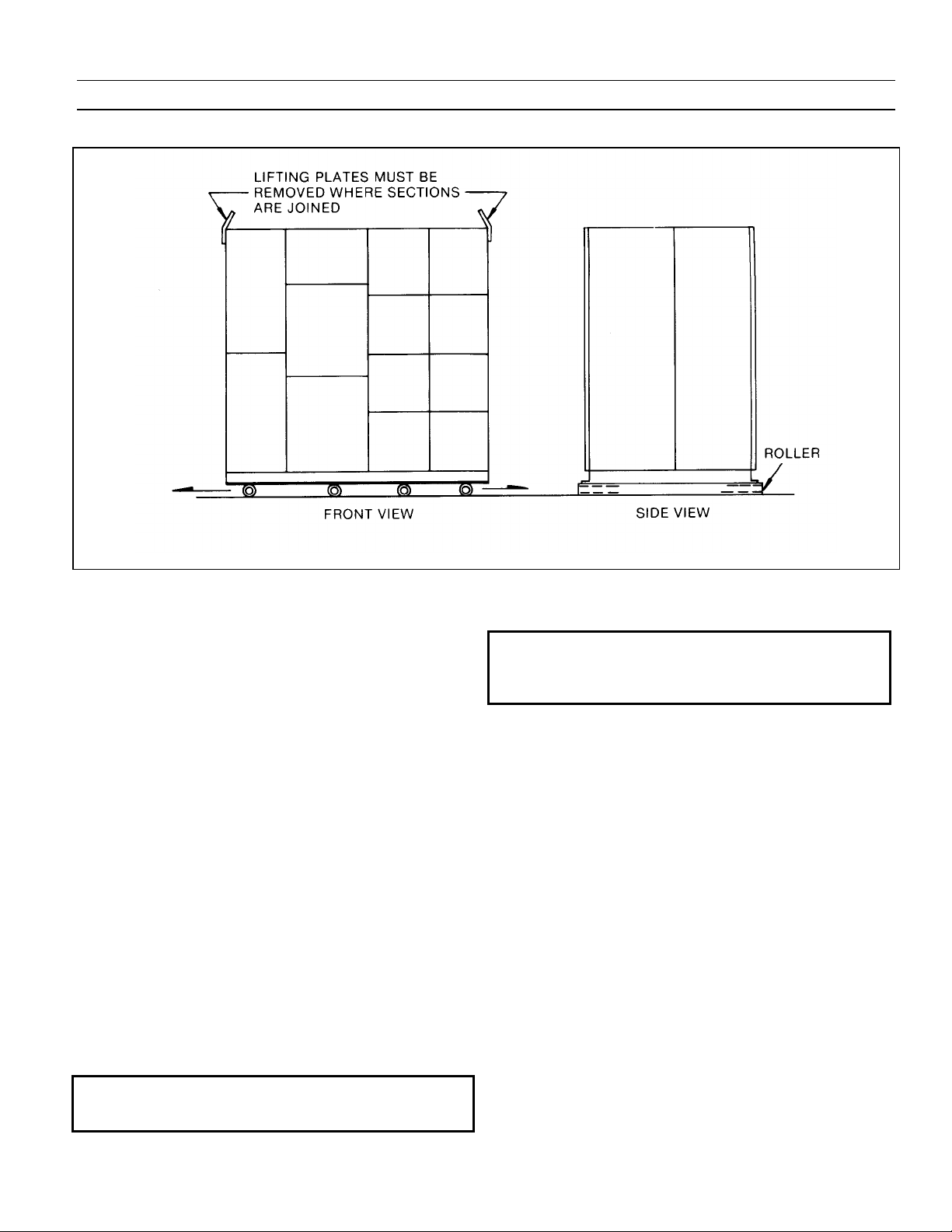

Rollers

If crane facilities are not available, the equipment may be

moved into position by means of construction rollers placed

under the shipping skids. The switchgear may be raised

enough for the placement of rollers by means of a forklift or

jack.

There should never be less than four rollers under the

equipment unless the line-up is less than five feet long. Use

one roller for each 18 inches of equipment length.

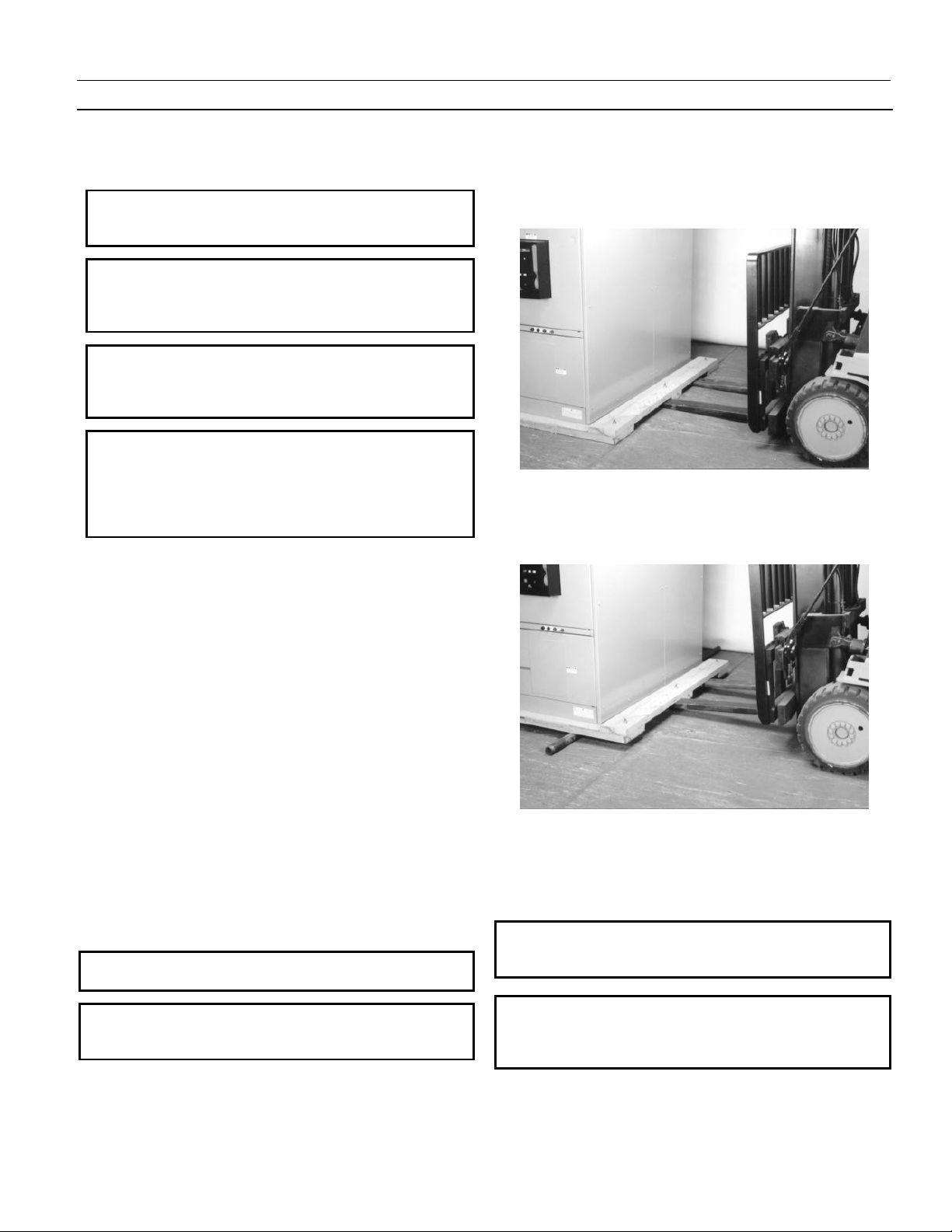

Forklifts

When using a forklift to raise the line-up to position rollers

underneath, proceed as follows:

1. Expand forklift tines to their maximum (widest)

extension.

2. Carefully insert tines of forklift below one side of the

switchgear line-up at the approximate center of the

panel as shown in Fig. 2-4.

NOTE: Do not attempt to lift or move the equipment with

a forklift positioned in the front or rear of the equipment.

NOTE: Ne pas essayer de lever ou bouger cette pièce

d’équipement à l’aide d’un chariot élévateur placé à l’avant

ou à l’amère de celle-ci.

3. Raise equipment and position one roller under the skids

close to the raised end of the line-up.

4. Carefully lower the gear until it rests on the roller as

shown in Fig. 2-5.

5. Repeat the lifting process at the other end and place the

appropriate number of rollers under the skids spacing

them evenly across the width of the line-up.

Fig. 2-4. Placing forklift tines under Entellisys

equipment shipping skid

Fig. 2-5. Placement of rollers under shipping skid

6. Carefully lower the gear until it rests on the rollers

(Fig. 2-6).

NOTE: If shipping skids are removed prior to final

placement of equipment, rollers may only be used to move

the equipment in a direction parallel to the front.

NOTE: Si l’emballage d’expédition a été enlevé avant que

l’équipement ne soit rendu à son emplacement final,

l’utilisation de rouleaux pour bouger l’équipement n’est

permise qu’en direction parallèle à l’avant.

5

Page 12

Entellisys Low Voltage Switchgear

Chapter 2. Receiving, Handling, and Storage

Fig. 2-6. Method of rolling equipment into place

7. While carefully pushing the switchgear to its final site

position, the rollers that are freed from the rear of the

switchgear are then repositioned at the forward end.

This procedure should be continued until the

switchgear is in its final location. See Fig. 2-6.

8. When the switchgear is in its final position, remove all

lag bolts holding the shipping skids to the switchgear

line-up.

9. Insert the tines of the forklift at one end of the line-up,

raise slightly, and remove the loose rollers.

10. Lower the end of the gear carefully to the floor.

11. Raise the other end of the line-up slightly and remove

the remaining roller at that end.

Jacks

Jacks may be used in place of forklifts to raise and lower

switchgear.

1. Place a jack under the front and rear corners of one end

of the line-up.

CAUTION: Do not place jacks in any other location other

than the front and rear corners of the switchgear. Doing so

may result in serious damage to the switchgear equipment.

ATTENTION: Il ne faut pas placer de vérins en aucun

endroit autre que les coins avants et arrières du dispositif

de commutation. L’équipement peut être sérieusement

endommagé si l’on ne respecte pas cette directive.

2. Raise the switchgear evenly and just enough to position

a roller beneath the equipment. Gently lower the

switchgear onto the roller. Repeat the procedure at the

opposite end of the switchgear, raising the gear far

enough to place the appropriate number of rollers under

the skids, spacing them evenly across the width of the

line-up. Gently lower the gear onto the rollers.

3. While carefully pushing the switchgear to its final site

position, the rollers that are freed from the rear of the

switchgear are then repositioned at the forward end.

This procedure should be continued until the switchgear

is in its final location.

4. When the switchgear is in its final position, remove all

lag bolts holding the shipping skids to the switchgear

line-up.

5. Place one jack at each corner, front and rear, of the

switchgear. Carefully raise the line-up evenly and

remove the rollers and the shipping skids. Evenly lower

the line-up to the floor and remove the jacks.

6

Page 13

Entellisys Low Voltage Switchgear

Chapter 2. Receiving, Handling, and Storage

2-3 Storage

Switchgear

If it is necessary to store the switchgear equipment for any

length of time, the following precautions should be taken to

prevent corrosion or deterioration.

1. Remove protective covering. Check thoroughly for

damage.

2. Store in a clean, dry, rodent-free location with moderate

temperature and provide protective coverings to prevent

dirt, water, or other foreign substances from entering

the switchgear.

CAUTION: Remove all cartons, containers and any other

miscellaneous packaging and packing material from inside

the switchgear sections before energizing any internal

heaters. To prevent fire, remove any plastic or polyethylene

shrouding from the switchgear sections before energizing

any internal heaters.

ATTENTION: Enlever tous les cartons, contenants et tout

autre objet varié servant à l’emballage et au matériel

d’emballage de l’intérieur des sections du dispositif de

commutation avant de procéder à la mise sous tension de

tout radiateur interne. Pour éviter un incendie, enlever tout

résidu de plastique ou de polyéthylène des sections du

dispositif de commutation avant de procéder à la mise sous

tension de tous les radiateurs internes.

3. If dampness or condensation may be encountered in the

storage location, heaters must be placed inside the

switchgear sections to prevent moisture damage.

Approximately 250 watts of heat in each section is

required. Incandescent lamps may be used for this

purpose. These lamps should be located in the bottom

breaker compartment of each section and supported so

the bulbs will not touch adjacent materials.

CAUTION: If the space heaters are to be temporarily

energized from an external source, it is important to

remove the fuses on the secondary side of the control

power transformer. This precaution is to prevent a feed

back of higher voltage to other portions of the equipment

through the CPT primary.

ATTENTION: Il est important de retirer les fusibles du

côté secondaire du contrôle du pouvoir du transformateur

si les espaces des radiateurs doivent être temporairement

mis sous tension par une source externe. Cette précaution

prévient une rétroaction d’un voltage supérieur à d’autres

portions de l’équipement par le contrôle de pouvoir du

transformateur primaire.

Circuit Breakers

If circuit breakers are not to be placed into service at once,

remove them from their shipping cartons and thoroughly

inspect them for damage. If the breakers are in satisfactory

condition, replace the breakers in their shipping cartons for

storage. Do not remove the circuit breaker shipping members

at this time.

Store the circuit breakers in a clean, dry location in an

upright position. They must be properly supported to

prevent bending of the studs or damage to any of the breaker

parts. Do not remove any protective grease until the circuit

breakers are ready to be installed. A plastic or canvas-type

cover should be provided to reduce the possibility of damage

to the breakers due to dust and water.

7

Page 14

Entellisys Low Voltage Switchgear

Chapter 3. Description

3-1 General

This section contains a description of the General Electric

Entellisys Low Voltage Switchgear. It also describes the

functions of the electrical and mechanical systems.

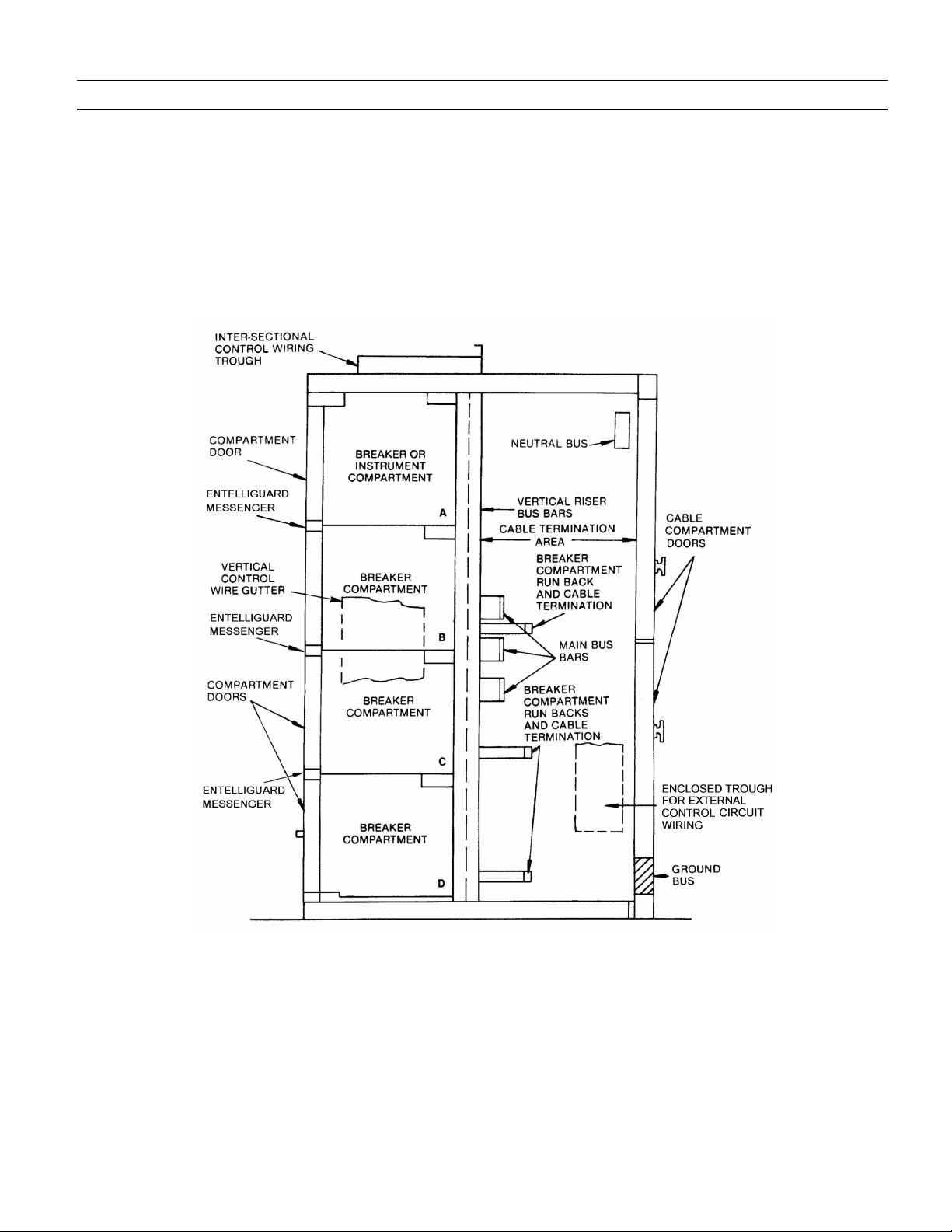

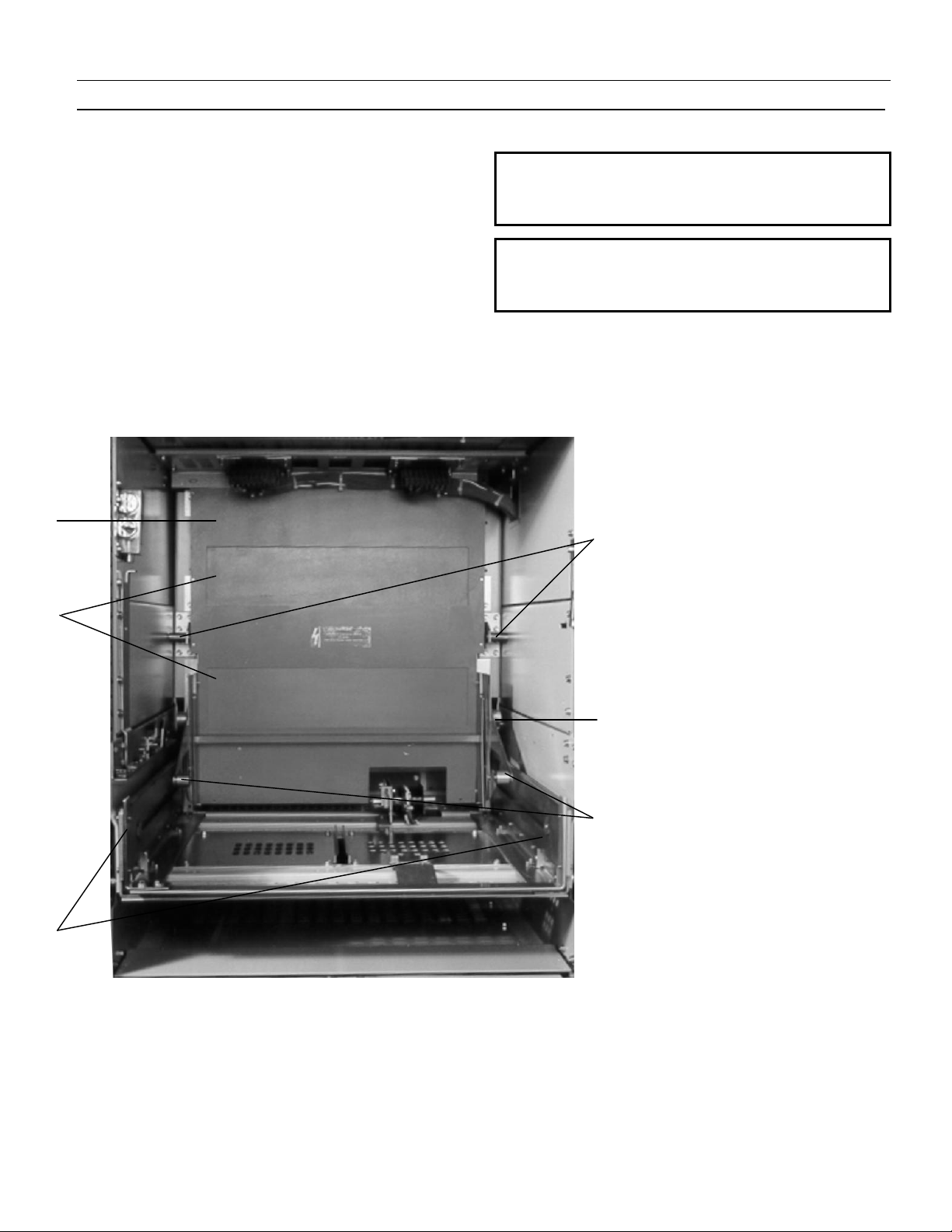

Fig. 3-1 is a side view of a typical section showing

compartmentalization.

3-2 Summary Description

General Electric Entellisys Low Voltage Switchgear is a

freestanding assembly of metal-enclosed sections containing

low-voltage power circuit breakers, bus bars, cable

termination provisions, and Entellisys instrumentation. It

may also be an integral part of a load center unit substation,

either single-ended or double-ended.

Fig. 3-1. Side-view of Entellisys Switchgear

8

Page 15

Entellisys Low Voltage Switchgear

Chapter 3. Description

All of the primary circuit switching and protective devices,

Entellisys instrumentation, control fuses, and instrument

transformers are mounted in the enclosure. The breaker

compartments include drawout rails, stationary breaker

contacts, interlocks, and EntelliGuard Messengers. The

breakers are provided with self-aligning primary and

secondary disconnect contacts and a breaker mechanism

locking unit. The individual sections, compartments, and

devices are described in the following paragraphs.

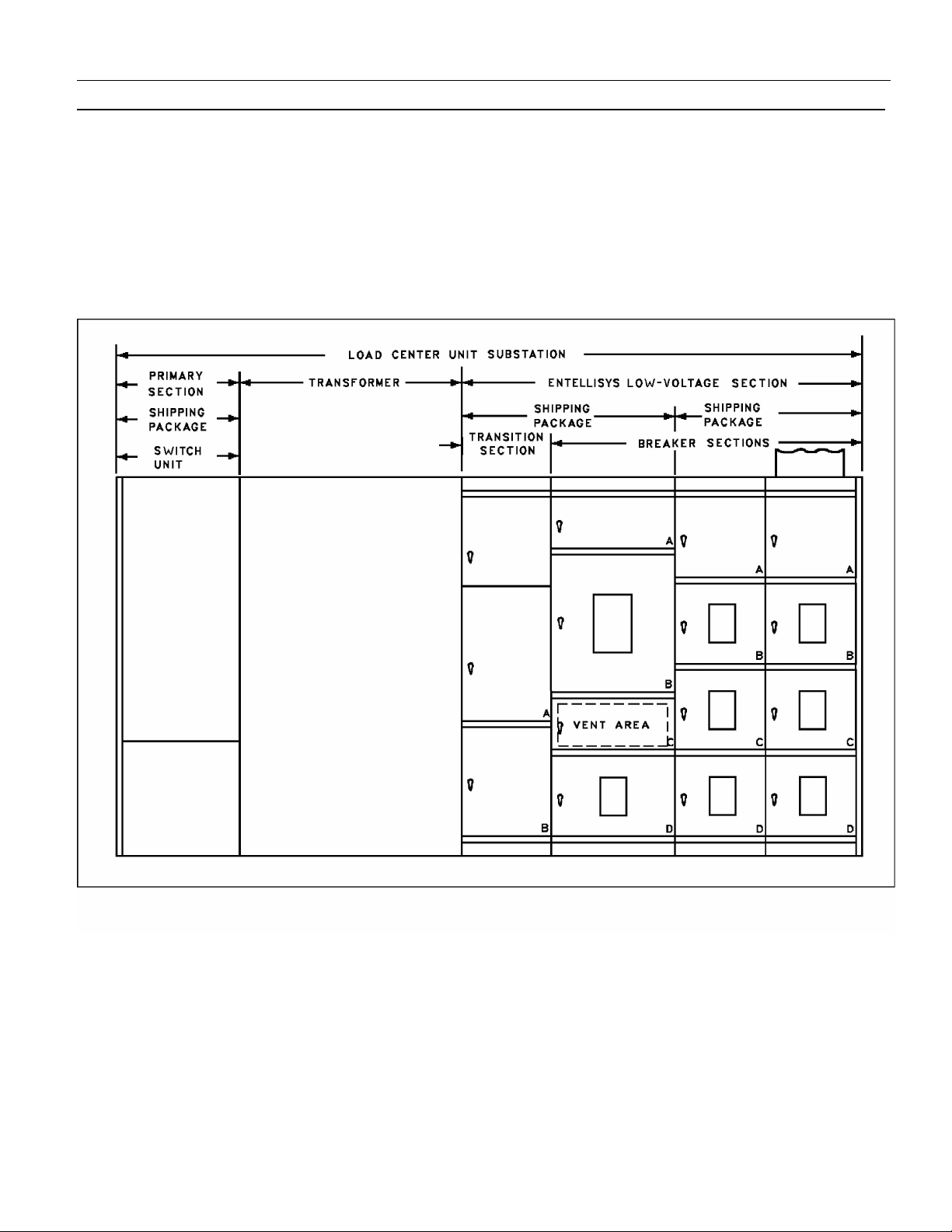

Fig. 3-2 is an outline of a typical single-ended load center

unit substation illustrating the nomenclature used for all

equipment.

Fig. 3-2. Outline of a typical Entellisys Load Center Unit Substation

9

Page 16

Entellisys Low Voltage Switchgear

Chapter 3. Description

3-3 Front Compartment Area

The front enclosure of each section is divided into individual

compartments. These compartments typically house

EntelliGuard low voltage power circuit breakers or Entellisys

instrumentation.

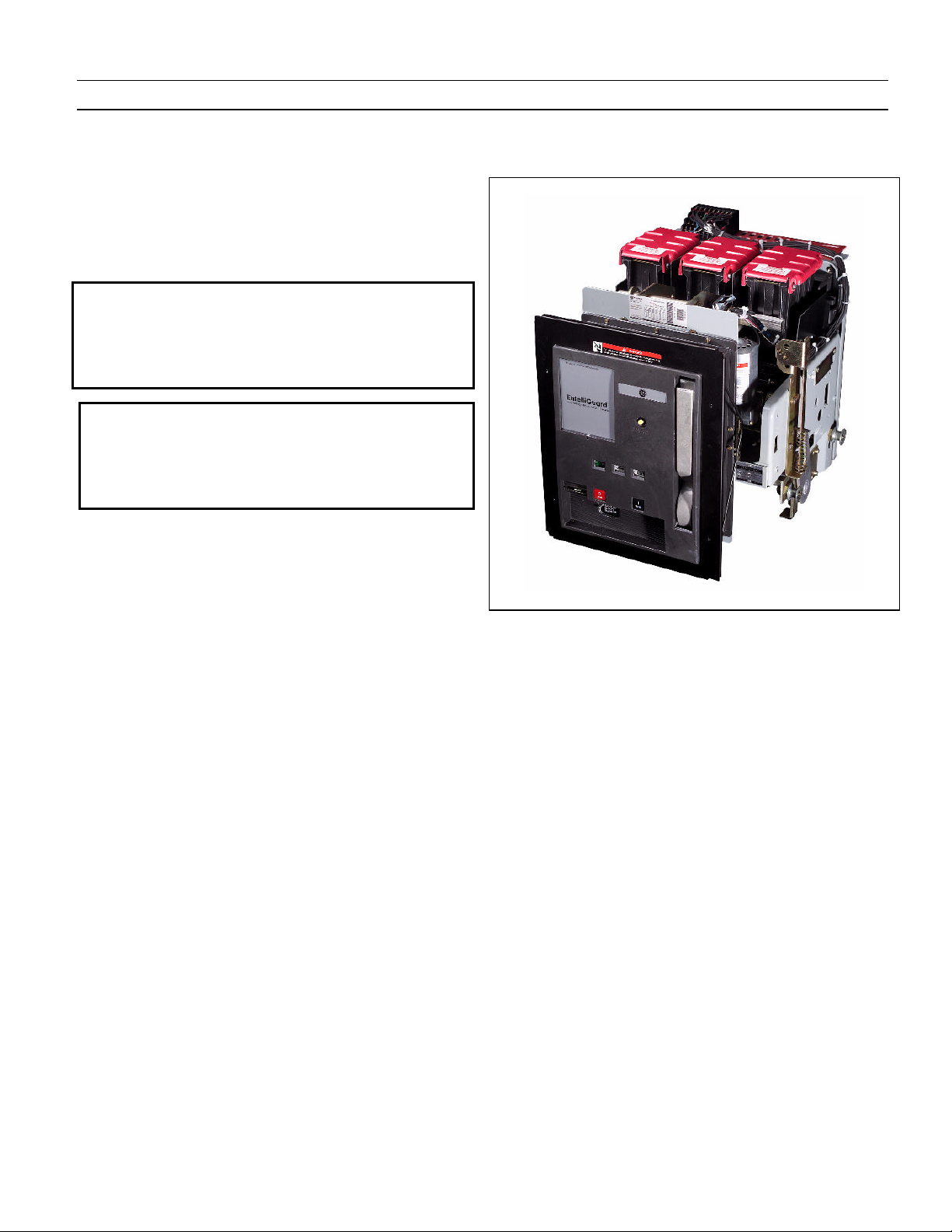

3-4 EntelliGuard Messenger

An EntelliGuard Messenger is mounted above each

EntelliGuard breaker. The Messenger provides an interface

between the breaker, the compartment, and the central

Entellisys system. See DEH-231 (Entellisys Low Voltage

Switchgear System User’s Manual) for further instructions.

Each Entellisys low voltage switchgear lineup contains

standard devices housed within the instrument

compartments. Two CPUs (Central Processing Units) provide

the processing capability to support all switchgear functions.

At least one HMI (Human-Machine Interface) provides user

access to the Entellisys system. Network switches provide

communication links between the CPU, the HMI, the

EntelliGuard Messengers, and the external world. A pair of

uninterruptible power supplies (UPSs) and control power

throwover relays supply highly reliable control power to these

system devices.

Fig. 3-3. EntelliGuard Messenger

10

Page 17

Entellisys Low Voltage Switchgear

Chapter 3. Description

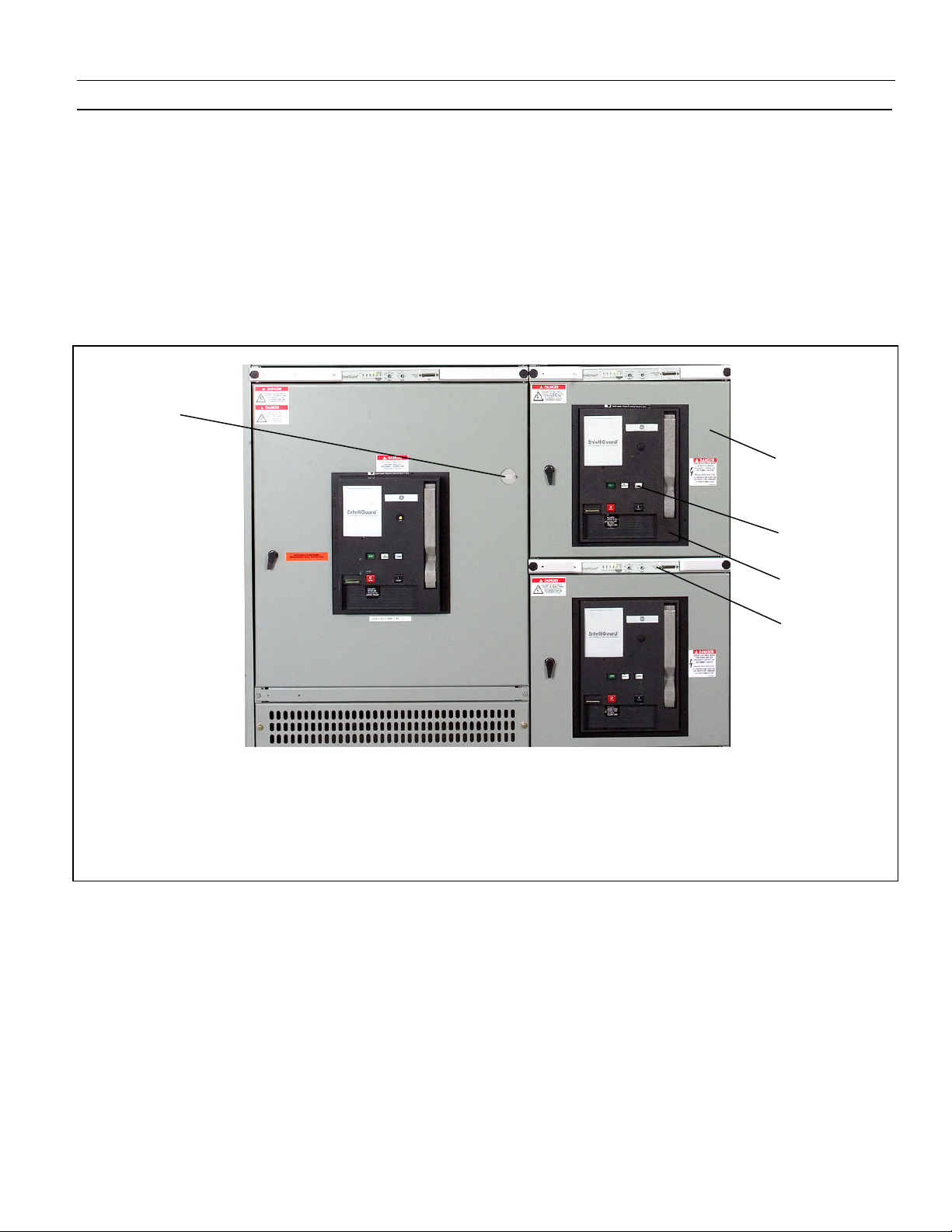

3-5 Breaker Compartment

Closed-door drawout circuit breaker compartments, Fig. 34, are standard construction with all Entellisys switchgear

equipment. The circuit breaker compartment doors

remain closed and latched while the breaker is racked out

from the connected position, through test, to the

disconnected position.

Breaker compartment doors do not have any ventilation

slots, thus protecting operators from hot ionized gases

2

that may be vented by the breaker during circuit

interruption.

Additionally, the breaker compartment, Fig. 3-5, is enclosed

by grounded steel barriers on the top, sides, bottom, and

front. In the back, a flame-retardant, track resistant, glassfilled polyester base minimizes the possibility of fault

communication between compartments or to the bus.

1

1. Compartment door

2. Access port to racking mechanism

3. Breaker position indicator

4. Circuit breaker escutcheon

5. EntelliGuard Messenger

Fig. 3-4. EntelliGuard circuit breaker compartments

3

4

5

11

Page 18

Entellisys Low Voltage Switchgear

Chapter 3. Description

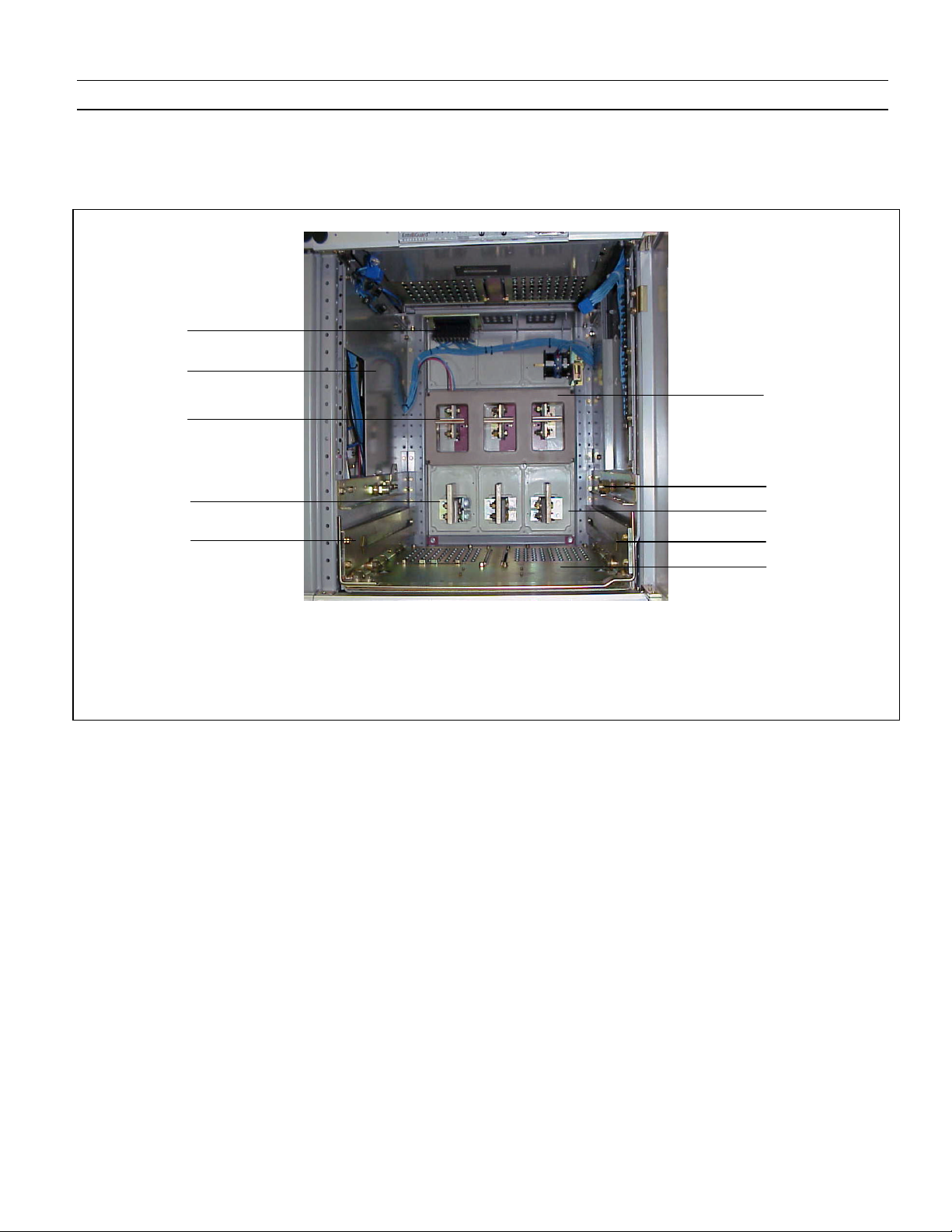

9

1

5

4

6

7 7

1. Side barrier 6. Primary disconnects -- load

2. Bottom barrier 7. Drawout rails

3. Rear base/barrier 8. Racking anchor pins

4. Primary disconnects – line 9. Secondary Disconnect

5. Current Transformers

Fig. 3-5 Circuit breaker compartment (22-inch)

8

3

2

12

Page 19

Entellisys Low Voltage Switchgear

Chapter 3. Description

Fuses for the charge, close, and trip circuits of electrically

operated breakers are mounted in the upper left corner of the

breaker compartment behind the door. Fuses for the set and

reset coils of the optional Network Interlock breaker

accessory are mounted in the upper right corner of the

compartment.

Primary disconnect shutters are available as options to

provide protection against contact with the energized

stationary primary disconnects when the breaker is removed

from its compartment. Shutters are supplied as standard

components in the source (main, generator) and tie breaker

compartments of multi-source lineups. The shutters are

constructed from glass-reinforced polyester insulating

material.

1

2

5

Fig. 3-6. Circuit breaker compartment (30-inch wide) with shutters

NOTE: If a fuse rollout (FRE) carriage is used with an

EGF-32/40/50 circuit breaker whose compartment is

equipped with shutters, the FRE compartment will also be

equipped with shutters.

NOTE: Si on utilise un chariot porte-fusibles à roulettes

avec un disjoncteur EGS-32/40/50 dont les compartiments

sont munis de volets, le compartiment du porte-fusible à

roulettes sera aussimuni de volets.

The combination of the stationary and movable portions of

the shutters prevent frontal access to the primary disconnect

line and load power stabs.

1. Stationary barrier

2. Shutters (retractable barrier)

3. Operating lever

4. Operating lever springs

6

5. Drawout rails

6. Racking anchor pins

4

3

13

Page 20

Entellisys Low Voltage Switchgear

Chapter 3. Description

The shutters are partially retracted when the breaker is in

the Disconnect Position. As the circuit breaker is racked from

the Disconnect Position to the Test Position, the rear of the

circuit breaker frame depresses the shutter operating lever

(3) to cause the shutters to fully retract. The operating lever

springs (4) cause the operating lever (3) to remain in contact

with the circuit breaker frame during operation. As the

breaker is racked from the Test Position to the Connected

Position, the shutters remain fully retracted.

Fig. 3-7 also shows the shutter assembly with the shutters

manually retracted to show the location of the primary

disconnect stabs (5) behind the shutter assembly.

1

2

Circuit breakers mounted in 22-inch wide compartments

(EG-08, EG-16, EG-20) are supported on drawout rails (7),

Fig. 3-5. Larger EG-32 and EG-40 circuit breakers and fuse

rollout carriages are installed in 30-inch wide compartments

and are supported on drawout rails (5), Fig. 3-6. The EG-50

circuit breaker is installed in a 38-inch wide compartment

and is supported on drawout rails (similar to Item 5, Fig. 3-

6).

5

4

1. Stationary barrier

2. Shutters (not visible in

retracted position)

3. Operating lever

4. Operating lever springs

5. Primary disconnect stabs

3

Fig. 3-7. Entellisys primary disconnect shutter assembly (30-inch wide compartment).

Shutters manually retracted

14

Page 21

Entellisys Low Voltage Switchgear

2 3

Chapter 3. Description

2

1

1

1. Racking arm

2. Drawout interlock

Fig. 3-8. EGX-08 circuit breaker

EntelliGuard breakers do not contain current transformers.

Instead, current transformers are mounted over the primary

disconnect stabs of all Entellisys breaker compartments.

Primary disconnects are equipped with short-circuit braces

when breakers are fused or when extra-deep breaker

compartments are used.

The breaker racking arm slots engage fixed racking anchor

pins (6), Fig. 3-6, mounted in the breaker compartment. As

the racking arms are rotated by operation of the breaker

racking crank, the breaker is pulled into the compartment,

and locked in its final connected position.

A breaker should always be OPEN when it is moved into or

out of the CONNECTED position. As a safeguard, the

drawout interlock (2), Fig. 3-8, will cause the breaker to open

before the primary disconnects lose contact if a closed

breaker is moved out of the CONNECTED position.

EntelliGuard circuit breakers having higher continuous or

interrupting current ratings may be substituted for those

having lesser ratings. The compartment, however, retains the

factory-configured ratings and protection settings.

Substitution of manual for electric or electric for manual

EntelliGuard breakers is not recommended.

1. Racking arm

2. Secondary disconnects

3. Racking screw

Fig. 3-9. EGS-40 circuit breaker

Each breaker compartment has four positions as described

below:

1. CONNECTED POSITION-The breaker is in operating

position, both primary and secondary contacts made,

and the door closed.

2. TEST POSITION-The secondary contacts are made, but

the primary contacts are not made. Any breaker test

that requires control power may be made in this

position.

3. DISCONNECTED POSITION-All primary power and

secondary control electrical circuits between the breaker

and the equipment are disconnected. The door may be

closed. The breaker may be stored in this position with

the door closed.

4. WITHDRAWN POSITION-The breaker is completely

out of its compartment ready for removal from the

equipment. The door must be open. The optional

primary disconnect shutters, positioned in front of the

primary stabs, would be closed with the breaker in the

WITHDRAWN position.

15

Page 22

Entellisys Low Voltage Switchgear

Chapter 3. Description

Movement of the breaker between the CONNECTED, TEST,

and DISCONNECTED positions is performed by the use of a

racking crank that engages the racking mechanism mounted

on the breaker. Movement to the WITHDRAWN position is

manually performed after opening the compartment door.

These positions are illustrated and described more fully in

Chapter 5 of this instruction book.

CAUTION: The door should not be opened when the circuit

breaker is closed and in the CONNECTED position.

Although the breaker compartment door may be opened in

any position, it is recommended that the door only be

opened when the breaker is in the DISCONNECTED or

WITHDRAWN position.

ATTENTION: Il ne faut pas que la porte soit ouverte

lorsque le disjoncteur est fermé et branché. Bien que la

porte du compartiment du disjoncteur puisse être ouverte

lorsque le disjoncteur est en n’importe quelle position, il

est préférable que la porte ne soit ouverte que lorsque le

disjoncteur est en position débranchée ou retirée.

3-6 Circuit Breakers

The General Electric EntelliGuard Low Voltage Power

Circuit Breaker includes spring-operated, stored energy, close

and trip mechanisms for either manual or electrical

operation.

Six General Electric EntelliGuard Circuit Breakers form

the complete family of breakers used in the Entellisys

switchgear. These circuit breakers range from 800 to 5000

ampere frame sizes and are built with the following ratings

and characteristics:

EGS/EGH/EGX-08 Circuit Breaker

• 800-ampere frame size

• Standard 30,000-ampere interrupting and short-time

capability (480 volts)

• Four-high stacking, 22-inch wide sections

• Increased IC and short-time rating 42,000 amperes

(EGH-08) or 65,000 amperes (EGX-08) at 480 volts

EGF-08 Fused Circuit Breaker

• 800-ampere frame size

• 300- through 1600-ampere integral fusing

• 200,000-ampere interrupting rating

• Four-high stacking, 22-inch wide sections

EGS/EGH-16 Circuit Breaker

• 1600-ampere frame size

• Standard 50,000-ampere interrupting and short-time

capability at 480 volts

• Four-high stacking, 22-inch wide sections

• Increased IC and short time rating 65,000-ampere at 480

volts (EGH-16)

Fig. 3-10. EGX-08 circuit breaker (electrically operated)

EGF-16 Fused Circuit Breaker

• 1600-ampere frame size

• 450- through 2500-ampere integral fusing

• 200,000-ampere interrupting rating

• Four-high stacking, 22-inch wide sections

EGS/EGF-20 Circuit Breaker

• 2000-ampere frame size

• Standard 65,000-ampere interrupting and short-time

capability at 480 volts

• 200,000-ampere interrupting rating

• Three-high stacking, 22-inch wide sections (See DET-

447)

16

Page 23

Entellisys Low Voltage Switchgear

Chapter 3. Description

EGS/EGH/EGX/EGF -32 Circuit Breaker

• 3200-ampere frame size

• Standard 65,000-ampere interrupting and short-time

capability at 480 volts

• 30-inch wide sections, Two-high stacking in 38-inch wide

sections

• Increased IC and short-time rating 85,000 amperes

(EGH-32) or 100,000 amperes (EGX-32) at 480 volts.

EGS/EGX/EGF -40 Circuit Breaker

• 4000-ampere frame size

• Standard 85,000-ampere interrupting and short-time

capability at 480 volts

• 30-inch wide sections, Two-high stacking in 38-inch wide

sections

• Increased IC and short-time rating 100,000 amperes

(EGX-40) at 480 volts.

EGF-32 Rollout Carriage

• 3200-ampere rating

• 200,000-ampere interrupting rating

• Accepts 2000- through 4000-ampere fusing

• Also used for EGF-20 breaker

EGF-40 Rollout Carriage

• 4000-ampere frame size

• 200,000-ampere interrupting rating

• Accepts 2000- through 5000-ampere fusing

EGF-50 Rollout Carriage

• 5000-ampere frame size

• 200,000-ampere interrupting rating

• Accepts 2000- through 5000-ampere fusing

Fig. 3-11. EGS-32 circuit breaker (electrically operated)

EGS/EGX/EGF -50 Circuit Breaker

• 5000-ampere frame size, fan cooled

• Standard 85,000-ampere interrupting and short-time

capability at 480 volts

• One-high stacking, 38-inch wide sections

• Increased IC and short-time rating 100,000 amperes

(EGX-50) at 480 volts.”

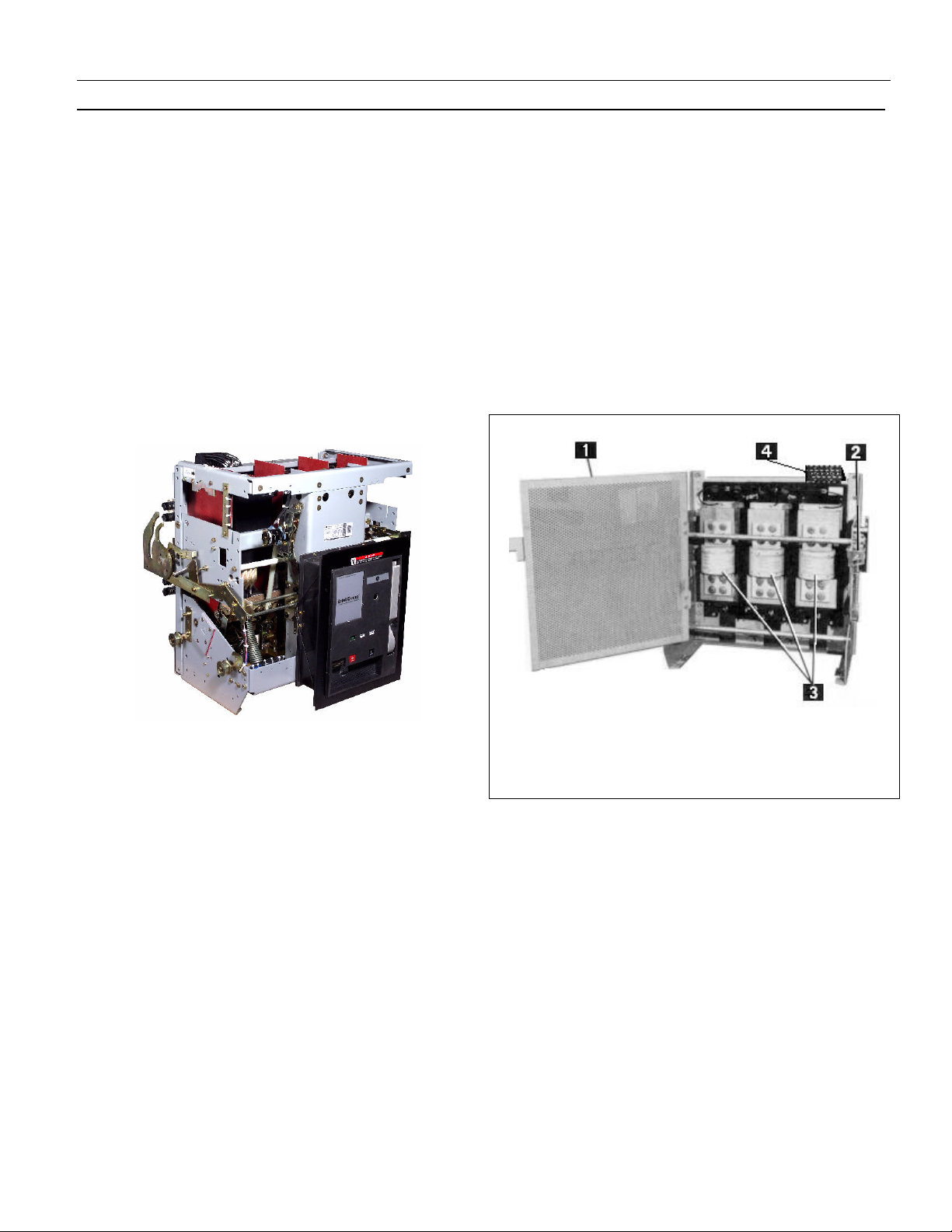

3-7 Fuse Rollout Elements

When the system available short-circuit current exceeds the

unfused breaker ratings, current-limiting fuses can be used

in series with EGF-20, EGF-32, EGF-40, and EGF-50

breakers to increase the short-circuit rating of the

combination to 200,000 amps. When used, such fuses are

housed in a separate drawout compartment located adjacent

to the breaker compartment; they are mounted on a drawout

carriage similar to a breaker frame and referred to as a fuse

rollout element (FRE).

1. Protective hinged screen

2. Racking mechanism

3. Fuses

4. Secondary disconnects

Fig. 3-12. Fuse roll-out carriage

17

Page 24

Entellisys Low Voltage Switchgear

2 1

Chapter 3. Description

3

1. Quarter-turn latch

2. Steel plate (future breaker cubicle)

Fig. 3-13. Future breaker compartment

3-8 Compartments for Future

Breakers

When specified, compartments may be supplied for future

addition of circuit breaker elements. These compartments

are fully equipped with drawout rails, primary

disconnects, and ancillary devices as required (i.e.

secondary disconnects, accessory devices, etc.) The

opening in the breaker compartment door (3), Fig. 3-13, is

closed with a bolted-on steel plate (2) to deter accidental

contact with energized electrical circuits. (I.e. primary

disconnect stabs).

3. Compartment door

3-9 Auxiliary/Transition Sections

Sections may be provided for any one or more of several

reasons including:

• Transition to a close-coupled transformer

• Incoming cable or busway when a main breaker

section is not provided

Auxiliary sections may be 22-inch, 30-inch, or 38-inch

wide as required to accommodate the space requirements.

The compartment doors on the front of the sections are

hinged and latched in the same manner as breaker

compartment doors.

Generally, transition sections will be 22-inches wide for

close-coupling to transformers.

Power company metering requirements generally require

either a 38-inch or 49-inch wide auxiliary section to

accommodate the current transformers, meters, test

switches, etc. as required by their individual practices,

tariff schedules, and/or regulatory commissions.

18

Page 25

Entellisys Low Voltage Switchgear

Chapter 3. Description

3-10 Bus Area

The bus area, Fig. 3-14, contains the main horizontal bus and

vertical riser bus bars (1) for the particular section. The

vertical bus bars are supported at the breaker run-ins (2)

that are bolted to the molded bases (3) that form the rear

wall of the breaker compartment. The horizontal bus bars

are supported by the power connectors (4), which are bolted

to the vertical bus bars. All bolted supports and connections

are accessible from the rear for maintenance. The bus area is

fully isolated from the breaker, instrument and auxiliary

compartments by the molded bases or glass polyester sheet.

Busing System

Bus bars are fully tin-plated copper with bolted joints. The

standard construction is open bus. A barrier system (Bus

compartmentalization) that isolates the main and vertical

bus bars from the cable area is available as an option. All

run-backs (load-side power conductors) from the breaker

compartment to the cable termination area are covered with

non-PVC insulated tubing.

The typical arrangement is shown in Fig. 3-15.

The standard bracing is 65,000 amperes, RMS symmetrical.

Bracing for 100,000, 150,000 and 200,000 amperes, RMS

symmetrical is available as an option.

In general, when the switchgear equipment has no more than

four sections or does not exceed 10 feet in length, it will be

shipped as one complete lineup. In such cases, the only field

assembly would be to a close-coupled transformer if, the

switchgear were part of a Load Center Unit Substation. If,

because of shipping and/or handling considerations, the

equipment cannot be handled in one piece, it can be split into

two or more shipping sections at the factory. The individual

shipping splits require both mechanical and electrical

connections between sections to be made in the field. At

these shipping splits, provisions are made for bolting all

buses and making the necessary electrical and mechanical

connections. These are described in Chapter 4 of this

publication.

On main and tie breakers, the bus area, Fig. 3-15, is divided

into an upper (1) and lower (2) section by a glass reinforced

polyester isolation barrier (3). For typical unit substation

main circuit breakers, the upper section contains the

incoming line bus (4). The lower section of the bus area

contains the load side main bus (5) (protected by the main

breaker) that feeds all sections of the switchgear equipment.

Similarly, barriers at tie breakers isolate the two main bus

sections from each other.

1 Vertical riser bus

2. Run-ins to breaker compartment

3. Molded base

4. Power Connector

5. Run-backs from breaker compartment

6. Short-circuit brace

Fig. 3-14. Bus construction

19

Page 26

Entellisys Low Voltage Switchgear

Chapter 3. Description

4

Insulated/Isolated Bus System

A bus insulation system, Fig. 3-16, that fully insulates each

phase of the horizontal main bus and isolates each phase of

the vertical bus, is optionally available for Entellisys

switchgear when specified. With the INSULATED/ISOLATED BUS system, there are no live connections

accessible in the rear of each section except the cable lugs.

1

1

5

1. Upper section vertical bus-incoming line

2. Lower section vertical bus-load side

3. Barrier between upper and lower vertical

bus sections

4. Incoming bus connections

5. Main horizontal bus connections

Fig. 3-15. Main breaker bus arrangement

2

3

1. Vertical riser bus covers

2. Run-backs to feeder cables

3. Horizontal main bus

4. Lower neutral bus with 4th wire

sensors

Fig. 3-16. Insulated/Isolated-Bus system

2

3

4

20

Page 27

Entellisys Low Voltage Switchgear

Chapter 3. Description

A vertical barrier (2), Fig. 3-17, between the transition

section (1) and the first breaker section is always

furnished.

The buswork in the device/auxiliary/transition sections is

not insulated at the termination points to the other

connected equipments such as transformers, busway, or

existing equipments.

the bus bars. (The top portion of the vertical bus is shown

with the cover removed.)

The phase isolation barriers and riser bus covers are

constructed from insulating material. Insulation of the

horizontal main bus bars (5) is achieved by an oven cured

coating of epoxy.

1. Transition compartment

2. Barrier

3. Main incoming bus

4. Neutral bus

5. Ground bus

Fig. 3-17. Transition section

Insulation and isolation of the vertical riser bus bars (2),

Fig. 3-18, is provided by installing phase isolation barriers

(3) between the bus bars and by mounting covers (4) over

1. Molded base

2. Vertical riser buses (cover removed to show bus

location)

3. Phase isolation barriers

4. Covers over riser bus

5. Insulated horizontal main buses

6. Covers for vertical/horizontal bus joints

7. Insulated run backs

Fig. 3-18. Bus insulation system

21

Page 28

Entellisys Low Voltage Switchgear

Chapter 3. Description

Fig. 3-19 illustrates the various components comprising the

insulation/isolation system for the horizontal main bus bars.

The horizontal bus bars (2) are insulated with an epoxy

coating applied by a fluidized bed process. The vertical/

horizontal bus bar joints are covered with collars (3) and caps

(4) held in place with nylon thumb screws (5). The collars

and caps are constructed from insulating material.

3-11 Feeder Cable and Busway

Compartment

The rear cable and terminal compartment, Fig. 3-20, provides

for cable installation and terminations. The cable bending

space meets the requirements of the 2005 National Electric

Code. Various arrangements of single or double cable

terminals are provided, depending upon the purchaser's

requirements.

1. Vertical bus barrier

2. Insulated bus bar (powder coated)

3. Joint collars

4. Joint caps

5. Nylon thumbscrews

Fig. 3-19. Horizontal bus insulation system

1. Support rack for customer's feeder cables

2. Cable lugs - mechanical type

3. Cable lugs - compression type

Fig. 3-20. Cable termination provisions

When specified, racks (1), Fig. 3-20, for the support of feeder

cables are located in the cable compartment. The actual

support of the cables is provided by lashing them to these

racks.

A neutral bus, insulated from ground, is provided in the bus

area on switchgear designed for four-wire systems. The

neutral bus is located near the top of the cable compartment.

It includes provisions for terminating the neutral conductor

of four-wire feeder cables and also direct mounting of the

neutral CT as required for those feeder system circuit

breakers having an integral ground fault trip function.

22

Page 29

Entellisys Low Voltage Switchgear

Chapter 3. Description

3-12 Ground Bus

All General Electric Entellisys switchgear sections are

grounded to the internal equipment ground bus (4), Fig. 3-21,

located at the bottom of the cable compartment.

1

2

1. Feeder runbacks

2. Vertical riser bus covers

3. Horizontal main bus

4. Ground bus

Fig. 3-21. Cable termination compartment

3

4

23

Page 30

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

4-1 General

This chapter contains complete instructions for installing

General Electric Entellisys Low-Voltage Switchgear.

CAUTION: Personnel installing this equipment must be

thoroughly familiar with this instruction manual and all

articles of the National Electrical Code applicable to the

installation of this switchgear. In addition, all drawings,

both mechanical installation and electrical, must be

understood and strictly followed to prevent damage to the

switchgear or equipment being protected by the

switchgear.

ATTENTION: La ou les personnes procédant à

l’installation de cet équipement doivent être tout à fait

familier avec ce livre d’instruction ainsi que tous les

articles du Code national d’électricité s’appliquant à

l’installation de ce dispositif de commutation. De plus, tous

les dessins se rapportant tant à l’installation mécanique

qu’électrique doivent être compris et suivis à la lettre afin

de prévenir des dommages au dispositif de commutation ou

à l’équipement protégé par celui-ci.

NOTE: Before installation work is started, it is important

to review all of the drawings provided, including the

General Electric equipment arrangement drawings, site

installation drawings, elementary and remote connection

drawings, mechanical connection drawings, and the

summary of equipment list.

NOTE: Il est important de reviser tous les dessins fournis,

incluant les dessins de disposition de l’équipement de

General Electric, les dessins d’installation du site, les

dessins de raccords élémentaires et à distance, les dessins

de raccords mécaniques et le sommaire de la liste

d’équipement avant que ne débutent les travaux

d’installation.

All expendable hardware for shipping purposes only, is

painted yellow or tagged with yellow adhesive and may be

discarded at completion of the installation phase.

Site Location

In general, the location of the switchgear equipment will

have been predetermined during the specification and/or

procurement of equipment phases. Indoor locations within

buildings impose certain requirements that must be met so

that the switchgear may operate efficiently with a minimum

of maintenance.

In locating the Entellisys Switchgear, adequate aisle space

must be provided at the front and rear of the equipment to

ensure proper ventilation of the equipment and to allow

service and maintenance of the equipment with the front and

rear doors open. The recommended aisle space is shown on

the floor plan supplied with the equipment drawings.

The switchgear equipment should be placed in an area where

clean, dry air is free to circulate around and above it. Since

air is taken into the equipment at the bottom of each section

and exhausted at the top, a location with good airflow must

be provided for efficient operation. A minimum of 30 inches

of clear space above the equipment is recommended.

Foundation Requirements

For optimum performance of your General Electric

switchgear equipment, the foundation requirements

expressed in this chapter should be strictly adhered to.

NOTE: The foundation for the outdoor switchgear must

provide proper drainage of ground and/or surface water

accumulations away from the equipment.

NOTE: La fondation du dispositif de commutation situé à

l’intérieur doit être en mesure de drainer correctement les

accumulations d’eau du sol et de surface loin de

l’équipement.

The foundation must be strong enough to prevent sagging

due to the weight of the switchgear structure and to

withstand the shock stress caused by the opening of the

breakers under fault conditions. The shock loading is

approximately 1-1/2 times the static load.

The foundation must be flat and level in all planes. Refer to

Fig. 4-1 for definition of flat and level.

Fig. 4-1. Definition of flat and level

Foundation Preparation

Refer to Fig. 4-2 along with the owner's foundation

construction drawings, and the General Electric supplemental installation drawings. Although the indoor

switchgear equipment can be mounted directly on a smooth,

level floor, it is recommended that recessed steel channels be

installed for supporting the equipment. Anchor bolts and

channels are to be provided by the purchaser.

24

Page 31

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

NOTE: When the equipment is installed on a surface

subject to impact (shock) loads due to operating

conditions or environmental seismic (earthquake)

conditions, the anchor bolts should be fabricated of

medium carbon steel (grade 5 load rating).

NOTE: Lorsque l’équipement est installé sur une surface

sujette à des charges d’impact (choc) causées par les

conditions d’opération ou des séismes environnementaux

(tremblements de terre), les boulons d’ancrage devraient

être fabriqués d’acier à moyenne teneur en carbone

(spécification de charge classe 5).

The floor channels under the front and rear switchgear

anchor points (see Fig. 4-2) should be embedded in a level

concrete slab with their top surfaces flush with the finished

floor. It is essential that these steel channels be level and

aligned with each other prior to final anchoring, to prevent

distortion of the switchgear structure, to assure proper

mechanical and electrical connections between shipping

splits, and to assure proper interfacing to other close-coupled

equipments.

Entellisys Switchgear and Load Center Substations are

frequently mounted on steel floors and/or structural steel in

industrial installations (such as a mezzanine) to minimize

usage of production floor space. Regardless of the type of

mounting surface, the requirements for a smooth level

surface remain.

Fig 4-2. Location of equipment anchor points

25

Page 32

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

If studs or anchor bolts are to be used, they should be

installed in the foundation as it is poured. It is important

that the studs or bolts are spaced to agree with

dimensions given on the General Electric job drawings.

The dimensions between anchor bolts for a particular

installation are dependent upon the configuration of

equipment ordered. The dimensions shown on Fig. 4-2

cover all of the standard enclosures available for

Entellisys Switchgear.

Fig. 4-3 illustrates the space available for conduit and/or

cable entrance through the bottom or top of each

equipment section. The space required for control wiring

entry to the optional wiring trough is also shown.

NOTE: BUS COMPARTMENT

BARRIER LOCATION - WHEN

THIS OPTION IS PROVIDED, IT

REDUCES AVAILABLE SPACE FOR

CABLES ABOVE BY (5) INCHES

Fig 4-3. Floor plan and cable entry space

Equipment

Depth “A”

60” non-fused or Below 19

67” with fused EGF-08/16 Above 24

67” non-fused or Below 26

74” with fused EGF-08/16 Above 31

74” non-fused or Below 33

81” with fused EGF-08/16 Above 38

Direction

of Leads

26

B

Page 33

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

4-2 Assembly and Installation of

Switchgear Equipment

General Requirements

Before assembling or installing the switchgear equipment, all

components should be available at the site location. This will

facilitate switchgear component identification as well as

installation. The foundation should be prepared in

accordance with the instructions in Sections 4-1 and 4-2, and

all embedded conduits installed and capped.

NOTE: If rollers are to be used for movement of the

equipment to its permanent installation, it is

recommended that the shipping skid not be removed until

the equipment is placed in position over the anchor bolts.

NOTE: Au cas où l’utilisation de rouleaux s’avérerait

nécessaire afin d’apporter l’équipement à son

emplacement permanent, nous recommandons que

l’emballage d’expédition ne soit pas enlevé tant que

l’équipement n’est pas positionné au dessus des boulons

d’ancrage.

If a transformer is not part of the installation, and/or the

equipment has been split for shipment, place the center

section on the foundation first. Assemble the remaining

sections outward from the center section, in each direction.

If the switchgear equipment is part of a Load Center Unit

Substation, the transformer section should be set on its pad

first in accordance with the instructions furnished with the

transformer. All remaining sections of the switchgear should

then be installed.

NOTE: Before assembling and installing the switchgear

equipment, the foundation must be absolutely level and

clear of debris to prevent damage and possible

misoperation of the switchgear equipment.

NOTE: Il faut avant de procéder à l’assemblage et à

l’installation s’assurer que la fondation soit absolument

au niveau et exempte de débris afin de prévenir des

dommages à l’équipement du dispositif de commutation.

Detailed Assembly and Installation

Instructions

The recommended procedure for installation of a switchgear

or Load Center Unit Substation is as follows:

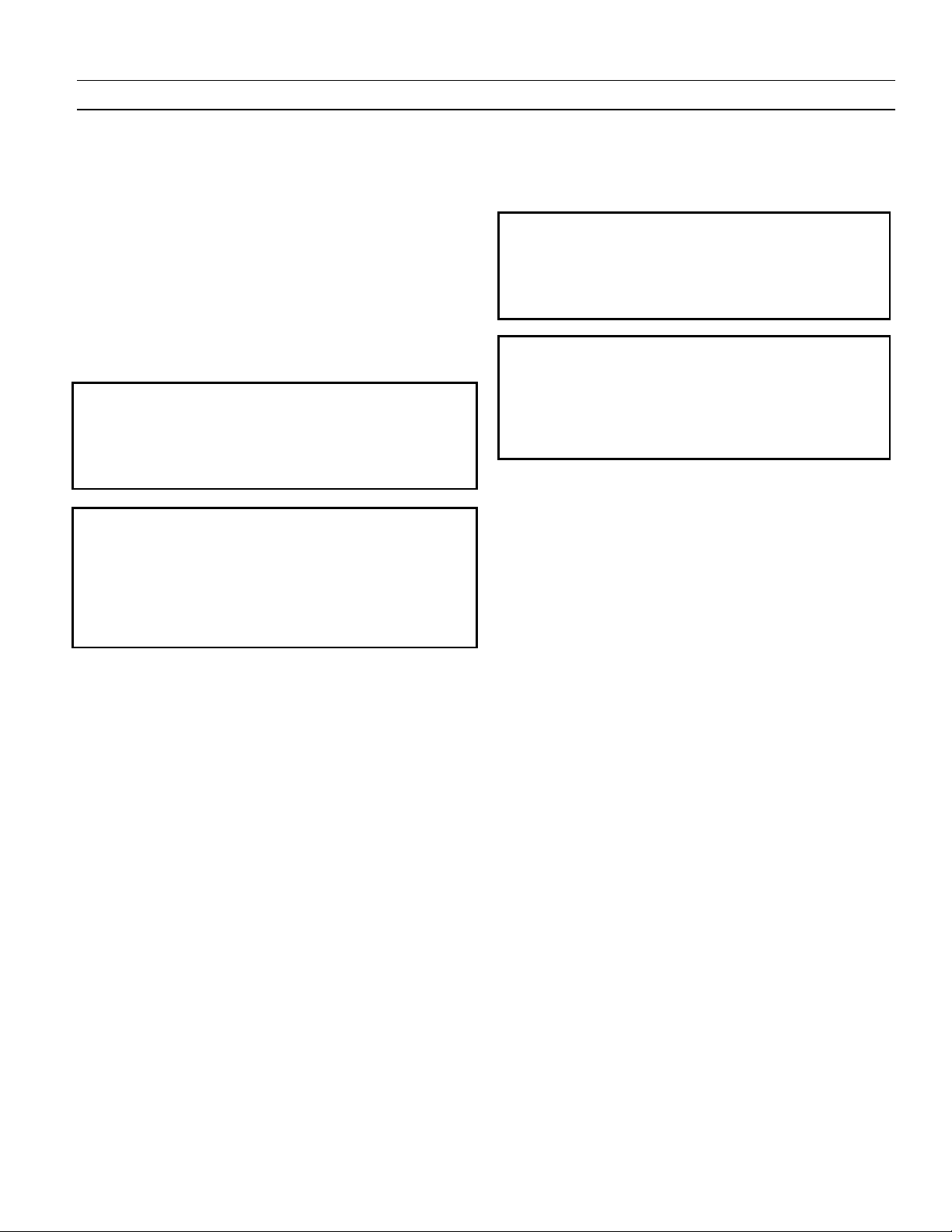

1. POSITION THE EQUIPMENT-Position the equipment

or sections of the complete equipment in their final

location.

Fig. 4-4. Lifting plate location

NOTE: If the equipment line-up was split into shipping

sections, the lifting plates on corners of adjacent sections

shown in Fig. 4-4 must be removed. Failure to remove

these plates will interfere with mating adjacent sections

and prevent installation of bus splice plates, structure tie

plates, etc.

NOTE: Si l’ensemble de l’équipement a été séparé en

sections pour l’expédition, il faut que les plaques de

soulèvement aux coins des sections adjacentes montrées à

la Fig. 4–4 soient enlevées. L’omission d’enlever ces

plaques viendra en interférence avec les sections barres

omnibus, de l’attache de la structure des plaques, etc.

Once the lifting plates have been removed, they may be

discarded.

NOTE: In the event the lifting plates must be

reassembled on the equipment for lifting purposes, they

must be moved to locations where unused screw holes are

avail-able, generally achieved by shifting the plate

horizontally on the mounting surface one bolt hole from its

previous location. When remounting the lifting plates,

torque the mounting bolts to 7-9 ft-lbs.

NOTE: Dans l’éventualité où les plaques de levage doivent

être réassemblées sur l’équipement à des fins de levage,

elles doivent être déménagées aux endroits où il y a des

trous de boulons inutilisés, on y arrive habituellement en

décalant la plaque horizontalement sur la surface de

montage d’un trou de boulon de son emplacement

précédent. Lors du remontage des plaques de levage,

serrer les boulons d’assemblage à un couple de 7–9 livrespied.

27

Page 34

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

Fig. 4-5. View showing method of attaching equipment to shipping

skids

NOTE: All mating sections of the equipment line-up

(including transformer, if applicable) must be securely

fastened together prior to tightening anchor bolts

fastening the equipment to the mounting surface.

NOTE: Toutes les sections se rapportant à la disposition

de l’équipement (incluant le transformateur si tel est le

cas) doivent être retenues ensembles solidement avant de

resserrer les boulons d’ancrage qui retiennent

l’équipement à la surface de montage.

2. REMOVE THE SHIPPING SKIDS-The equipment is

fastened to the shipping skids with 3/8-3 lag screws

through the equipment anchoring holes. See Fig. 4-5.

Equipment shipping sections up to 10 feet long will be

fastened to the skids with four lag screws, one in each

corner. Longer sections will have two additional lag screws

which are located near the middle of the equipment. The

shipping skid and lag screws are expendable material and

may be disposed of at the purchaser's discretion.

3. FASTEN SECTIONS TOGETHER-After placement of

the equipment and installing the anchor bolts loosely,

the various shipping sections must be rigidly fastened

together. Through-bolts fasten each section of the

switchgear equipment to the adjacent section. Fig. 4-6

shows the location of the through-bolts.

Fig. 4-6 Location of through-bolts

28

Page 35

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

Fig. 4-7 illustrates the installation of the through-bolts. The

through-bolts are in the front and rear compartments. The

nut and bolt assembly should be tightened with a torque of

25-30 ft-lbs.

survenir si l’on omet de mettre l’équipement à la terre

correctement.

Fig. 4-8 illustrates the general location of the buses that

must be spliced across the shipping splits.

Fig. 4-7. Through-bolt installation

All of the hardware required for assembling the equipment

across the shipping splits is furnished with the equipment. If

a transformer is included in the line-up of equipment, the

transformer flange should be aligned with the opening in the

side of the transition compartment and fastened together

using the 3/8-16 bolts, nuts and washers supplied with

switchgear. The fastener assembly should be tightened with

a torque of 25-30 ft-lbs.

4. COMPLETE THE ELECTRICAL

INTERCONNECTIONS - After completing the

mechanical connections between the several sections of

equipment, the electrical interconnections should be

completed. This includes the installation of splice

plates for the main bus bars, the neutral bus, and the

ground bus in addition to the Entellisys control and

communication circuitry.

WARNING: All switchgear equipment must be

adequately grounded for safety. Failure to ground

equipment properly may result in serious injury.

ADVERTISSEMENT: Tout l’équipement du dispositif de

commutation doit être mis à la terre adéquatement de

manière sécutaire. Des blessures sérieuses peuvent

Fig. 4-8. Typical location of buses at shipping split

29

Page 36

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

The ground bus is mounted directly on the rear upright

channels.

NOTE: It is particularly important that the ground bus be

connected first since it provides an integral ground for all

the equipment. It must also be connected to the station

ground prior to proceeding with the installation.

NOTE: Il est particulièrement important que la barre

omnibus de mise à la terre soit branchée en premier, étant

donné qu’elle fournit une mise à la terre intégrale à tout

l’équipement. Elle doit aussi être branchée à la mise à la

terre du poste avant de procéder à la installation.

A 4/0 AWG cable connector is located in the bottom of the

transition section (or in the incoming line compartment if a

transition section is not included) for terminating the

purchaser's cable connection to ground. The specific location

of the station ground connection is shown on the site floor

plan drawing and in the frontview drawings supplied with

the equipment. All grounding of the switchgear should be in

accordance with National Electrical Code.

If a GE transformer (rated above 750 kVA) is present in the

line-up, a ground bar located in the transition compartment,

Fig. 4-10, is provided for connection of the transformer

ground pad to the equipment ground termination point.

Fig. 4-9. Plan view of ground bus splice installation

Fig. 4-9 illustrates the installation of the ground bus splice

plate across a shipping split. In addition to the bolted

fastening of the splice plate to the two ends of the ground

bus, self-tapping 1/4-20 bolts pass through the splice plate

and ground bus stubs, and thread into the equipment frame.

These bolts should be fastened with a torque of 7-9 ft-lbs.

Fig. 4-10. Flange opening on a transition section to a GE transformer

(above 750 kVA)

As shipped, the ground bar is mounted so it does not protrude

beyond the outer surface of the equipment. When the

equipment is installed in its final location, the ground bar

must be reassembled using the outer bolt holes in the

horizontal ground bus spanning the width of the transition

compartment. In this mounting location, the offset portion of

the ground bar will permit connection to the transformer

ground pad with the 1/2-13 bolt assembly supplied with the

switchgear equipment. If an optional floor plate is supplied

for the transition compartment, it will be necessary to remove

the floor plate to permit relocation of the ground connection

bar.

30

Page 37

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

All bolted bus joints should be made using the proper torque

as shown in Table A-1 in Appendix A of this manual.

Transformers not manufactured by General Electric may

require special mounting and bus connection hardware.

The neutral bus may be insulated from the grounded frame of

the switchgear equipment; thus, it is mounted on insulators

throughout the equipment. Installation of the neutral bus

splice plate across a shipping split is similar to the ground

bar splice except that the splice plate is not bolted to the

equipment frame. Fig. 4-11 illustrates the installation of the

neutral splice plate.

Fig. 4-11. Plan view of neutral bus splice installation

The installation of the horizontal bus splice bars is with

bolted joints.

Figs. 4-12 and 4-13 illustrate the assembly of the main bus

splice plates on the bolted bus system. Copper bus systems

are normally supplied with flat washers and lock washers.

Fig. 4-12 shows the rear view of the main bus area with the

installed splice bus indicated with cross-hatching.

Fig. 4-13 shows that a spacer is used both between the

busbars when more than one bar is used per phase (normally

the 2500 ampere and larger main bus ratings) and over the

outer bars of a single or multiple bar joint.

After assembly of the splice plates and spacers, the 1/2-13

bolts should be tightened to a torque of 35-40 ft-lbs.

Fig. 4-12. Rear view of main bus at a shipping split

Fig. 4-13. Plan view of a two bar main bus connection

31

Page 38

Entellisys Low Voltage Switchgear

Chapter 4. Equipment Installation

After completing the installation of the main bus splice bars,

the joint covers may be mounted and secured by a 3/8-16

nylon bolt and polyester flat washer if the bus insulation

option has been supplied with the equipment.

5. CONNECT THE TRANSFORMER SECONDARY - The

connection of the transformer secondary to the incoming

bus bars in the transition is made using the flexible