Page 1

GE

Entellisys™ Low Voltage Switchgear

Integrator’s Guide

Page 2

DEH-232

Warnings, Cautions, and Notes as used in this publication

Warnings

WARNING! Warning notices are used in this publication to emphasize that hazardous voltages,

currents, or other conditions that could cause personal injury exist in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Cautions

CAUTION: Caution notices are used for situations in which equipment might be damaged if care is

not taken.

Notes

NOTE: Notes call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts have been

made to ensure accuracy, the information contained herein does not cover all details or variations in

hardware and software, nor does it provide for every possible contingency in connection with

installation, operation, and maintenance. Features may be described in here that are not present in all

hardware and software systems. GE Consumer & Industrial assumes no obligation of notice to holders

of this document with respect to changes subsequently made.

GE Consumer & Industrial makes no representation or warranty, expressed, implied, or statutory, with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warrantees of merchantability or fitness for purpose shall apply.

Entellisys™, EntelliGuard™, and FlexLogic™ are trademarks of the General Electric Company.

Modbus RTU is a registered trademark of AEG Schneider Automation.

©Copyright 2005 General Electric

All Rights Reserved

Page 3

How to contact us

Please have your Entellisys System Summary # and Sub # ready when calling. This information can be

found on the Entellisys HMI on the System Health screen by clicking the Job Info button.

Post Sales Service

GE Switchgear

510 Agency Road

West Burlington, IA 52655

Phone (toll free): 1-888-437-3765

Additional information:

www.entellisys.com/support

Page 4

Page 5

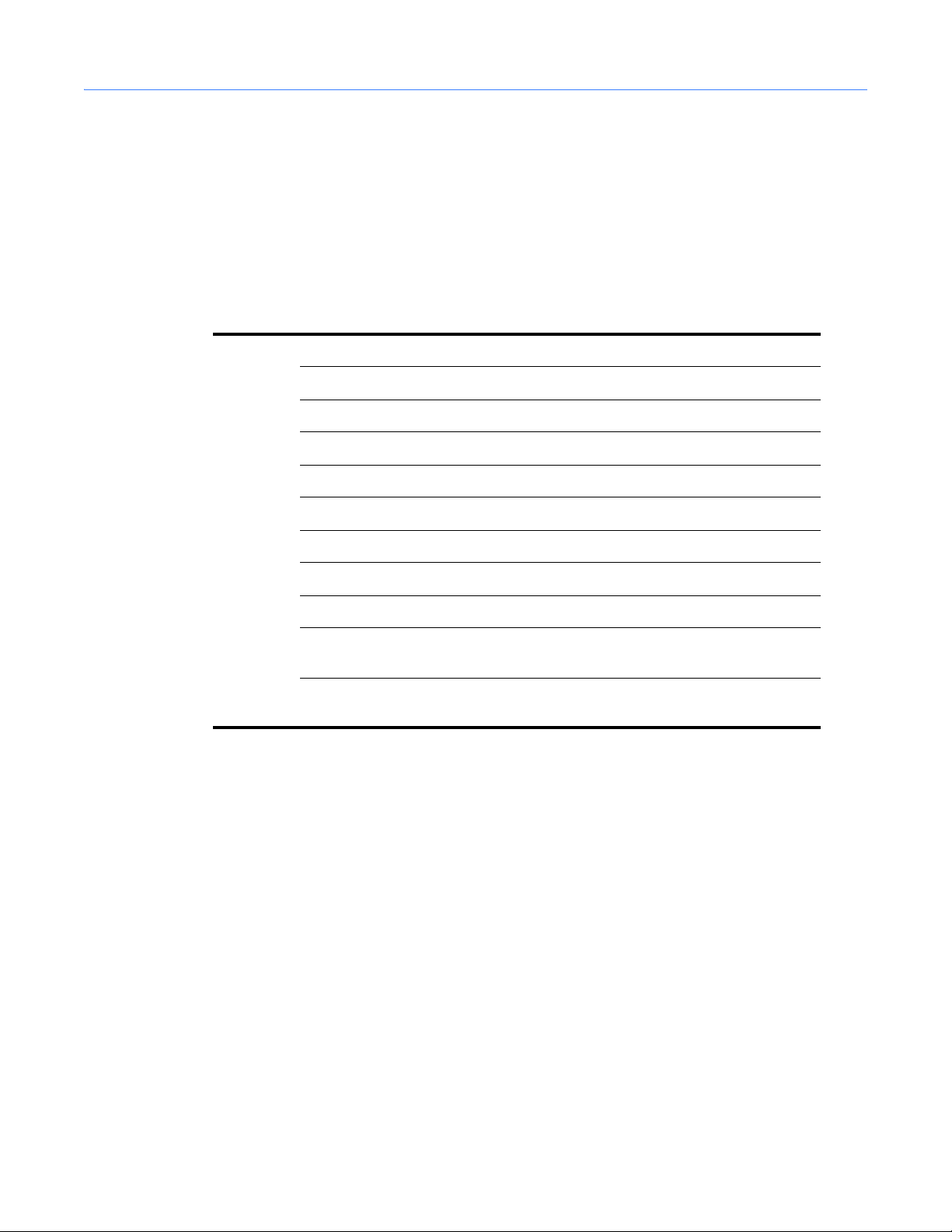

Contents

1 Integrator’s Guide

1.1 Modbus® protocol implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.2 Physical layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.3 Data link layer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.4 CRC-16 Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.5 Supported function codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.5.1 Function Code 03H/04H – Read Actual Values or Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.5.2 Function Code 05H – Execute Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.5.3 Function Code 06H – Store Single Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1.5.4 Function Code 10H – Store Multiple Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.1.5.5 Exception responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1.6 File transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.6.1 Obtaining CPU files using Modbus protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.6.2 Modbus password operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 Interfacing to the Alarm Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents 5

Page 6

6 Contents

Page 7

1 Integrator’s Guide

1.1 Modbus® protocol implementation

1.1.1 Introduction

The CPU supports a number of communications protocols to allow connection to the HMI

computer, as well as other equipment which includes personal computers, RTUs, SCADA

masters, and programmable logic controllers. The Modicon Modbus

basic protocol supported. Modbus is available via ethernet as specified by the Modbus/TCP

specification. Note that:

• The CPU always acts as a slave device, meaning that it never initiates communications; it

only listens and responds to requests issued by a master computer.

• For Modbus, a subset of the Remote Terminal Unit (RTU) protocol format is supported that

allows extensive monitoring, programming, and control functions using read and write

register commands.

• The CPU will support a maximum of 8 concurrent Modbus sessions. Four sessions are

reserved for use by HMI computers. A remote device that attempts to connect when all

sessions are in use will receive a response message indicating the number of maximum

connections has been exceeded. If a remote device does not make a request within

30 seconds, the session will be timed out and made available to the next device that

establishes a session.

®

RTU protocol is the most

1.1.2 Physical layer

The Modbus RTU protocol is hardware-independent so that the physical layer can be any of a

variety of standard hardware configurations. The CPU includes a faceplate (front panel)

100BaseT Ethernet port. Data flow is auto-configuring full or half-duplex. Each data byte is

transmitted in an asynchronous format consisting of 1 start bit, 8 data bits, 1 stop bit, and

possibly 1 parity bit. This produces a 10 or 11 bit data frame. The master device in any system

must know the address of the slave device with which it is to communicate. In the case of

ModbusTCP communications, the CPU will not act on a request from a master if the address in

the request does not match the CPU’s slave address. A single setting selects the slave address

used for ModbusTCP. The default slave address for a CPU is 1.

Modbus® protocol implementation 7

Page 8

1.1.3 Data link layer

Communications takes place in packets, which are groups of asynchronously framed byte data.

The master transmits a packet to the slave and the slave responds with a packet. The end of a

packet is marked by ‘dead-time’ on the communications line. The following describes general

format for both transmit and receive packets. For exact details on packet formatting, see the

subsequent sections describing each function code.

MODBUS PACKET FORMAT

DESCRIPTION SIZE

SLAVE ADDRESS 1 byte

FUNCTION CODE 1 byte

DATA N b ytes

CRC 2 bytes

DEAD TIME 3.5 bytes transmission time

SLAVE ADDRESS

This is the address of the slave device that is intended to receive the packet sent by the master

and perform the desired action. Only the addressed slave will respond to a packet that starts

with its address. Note that since Modbus/TCP also relies on a correct IP address to receive the

packet, and each CPU responds as a single device, it is generally not necessary to change the

Modbus address of the device.

FUNCTION CODE

This is one of the supported function codes of the unit which tells the slave what action to

perform. See Supported function codes on page 10

for complete details. An exception response

from the slave is indicated by setting the high order bit of the function code in the response

packet. See Exception responses on page 15

for further details.

DATA

This will be a variable number of bytes depending on the function code. This may include actual

values, settings, or addresses sent by the master to the slave or by the slave to the master.

CRC

This is a two byte error checking code. The RTU version of Modbus includes a 16-bit cyclic

redundancy check (CRC-16) with every packet which is an industry standard method used for

error detection. If a Modbus slave device receives a packet in which an error is indicated by the

CRC, the slave device will not act upon or respond to the packet thus preventing any erroneous

operations. See CRC-16 Algorithm on page 9

for a description of how to calculate the CRC.

Integrator’s Guide8

Page 9

1.1.4 CRC-16 Algorithm

The CRC-16 algorithm essentially treats the entire data stream (data bits only; start, stop and

parity ignored) as one continuous binary number. This number is first shifted left 16 bits and

then divided by a characteristic polynomial (11000000000000101B). The 16-bit remainder of

the division is appended to the end of the packet, most significant byte first. The resulting

packet including CRC, when divided by the same polynomial at the receiver, will give a zero

remainder if no transmission errors have occurred. This algorithm requires the characteristic

polynomial to be reverse bit ordered. The most significant bit of the characteristic polynomial is

dropped, since it does not affect the value of the remainder.

CRC-16 ALGORITHM

SYMBOLS --> data transfer

A 16-bit working register

Alow low order byte of A

Ahigh high order byte of A

CRC 16-bit CRC-16 result

i,j loop counters

(+) logical EXCLUSIVE-OR operator

N total number of data bytes

Di i-th data byte (i = 0 to N-1)

G 16-bit characteristic polynomial = 1010000000000001 (binary) with

MSbit dropped and bit order reversed

shr (x) right shift operator (th LSbit of x is shifted into a carry flag, a ‘0’ is

shifted into the MSbit of x, all other bits are shifted right one location)

ALGORITHM:

1. FFFF (hex) --> A

2. 0 --> i

3. 0 --> j

4. Di (+) Alow --> Alow

5. j + 1 --> j

6. shr (A)

7. Is there a carry? No: go to 8 Yes: G (+) A --> A and continue.

8. Is j = 8? No: go to 5 Yes: continue

9. i + 1 --> i

10. Is i = N? No: go to 3 Yes: continue

11. A --> CRC

Modbus® protocol implementation 9

Page 10

1.1.5 Supported function codes

Modbus officially defines function codes from 1 to 127 though only a small subset is generally

needed. The CPU supports some of these functions, as summarized in the following table.

Subsequent sections describe each function code in detail.

1.1.5.1 Function Code 03H/04H – Read Actual Values or Settings

This function code allows the master to read one or more consecutive data registers (actual

values or settings) from a relay. Data registers are always 16 bit (two byte) values transmitted

with high order byte first. The maximum number of registers that can be read in a single packet

is 125. See the MODBUS MEMORY MAP table on page 17 for exact details on the data registers.

Since some PLC implementations of Modbus only support one of function codes 03h and 04h,

the CPU interpretation allows either function code to be used for reading one or more

consecutive data registers. The data starting address will determine the type of data being read.

Function codes 03h and 04h are therefore identical. The following table shows the format of the

master and slave packets. The example shows a master device requesting 3 register values

starting at address 4050h from slave device 11h (17 decimal); the slave device responds with the

values 40, 300, and 0 from registers 4050h, 4051h, and 4052h, respectively.

FUNCTION CODE MODBUS DEFINITION CPU DEFINITION

HEX DEC

03 3 Read Holding Registers Read Actual Values or Settings

04 4 Read Holding Registers Read Actual Values or Settings

05 5 Force Single Coil Execute Operation

06 6 Preset Single Register Store Single Setting

10 16 Preset Multiple Registers Store Multiple Settings

Master and Slave Device Packet Transmission Example

MASTER TRANSMISSION

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 04

DATA STARTING ADDR - hi 40

DATA STARTING ADDR - lo 50

NUMBER OF REGISTERS - hi 00

NUMBER OF REGISTERS - lo 03

CRC - lo A7 DATA #2 - lo A7

CRC - hi 4A DATA #3 - hi 4A

Integrator’s Guide10

Page 11

SLAVE RESPONSE

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 04

BYTE COUNT 06

DATA #1 - h i 00

DATA #1 - lo 28

DATA #2 - h i 01

DATA #2 - lo 2C

DATA #3 - h i 00

DATA #3 - lo 00

CRC - lo 0D

CRC - hi 60

1.1.5.2 Function Code 05H – Execute Operation

This function code allows the master to perform various operations in the CPU.

The following table shows the format of the master and slave packets. The example shows a

master device requesting the slave device 11H (17 dec) to perform a reset. The hi and lo CODE

VALUE bytes always have the values ‘FF’ and ‘00’ respectively and are a remnant of the original

Modbus definition of this function code.

Master and Slave Device Packet Transmission Example

MASTER TRANSMISSION

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 05

OPERATION CODE - hi 00

OPERATION CODE - lo 01

CODE VALUE - hi FF

CODE VALUE - lo 00

CRC - lo DF

CRC - hi 6A

Modbus® protocol implementation 11

Page 12

SLAVE RESPONSE

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 05

OPERATION CODE - hi 00

OPERATION CODE - lo 01

CODE VALUE - hi FF

CODE VALUE - lo 00

CRC - lo DF

CRC - hi 6A

Integrator’s Guide12

Page 13

1.1.5.3 Function Code 06H – Store Single Setting

This function code allows the master to modify the contents of a single setting register in a CPU.

Setting registers are always 16-bit (two byte) values transmitted high-order byte first . The

following table shows the format of the master and slave packets. The example shows a master

device storing the value 200 at memory map address 4051h to slave device 11h (17 dec).

Master and Slave Device Packet Transmission Example

MASTER TRANSMISSION

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 06

DATA STARTING ADDR - hi 40

DATA STARTING ADDR - lo 51

DATA - hi 00

DATA - lo C8

CRC - lo CE

CRC - hi DD

SLAVE RESPONSE

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 06

DATA STARTING ADDR - hi 40

DATA STARTING ADDR - lo 51

DATA - hi 00

DATA - lo C8

CRC - lo CE

CRC - hi DD

Modbus® protocol implementation 13

Page 14

1.1.5.4 Function Code 10H – Store Multiple Settings

This function code allows the master to modify the contents of a one or more consecutive

setting registers in a CPU. Setting registers are 16-bit (two byte) values transmitted high-order

byte first. The maximum number of setting registers that can be stored in a single packet is 60.

The following table shows the format of the master and slave packets. The example shows a

master device storing the value 200 at memory map address 4051h, and the value 1 at memory

map address 4052h to slave device 11h (17 dec).

Master and Slave Device Packet Transmission Example

MASTER TRANSMISSION

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 10

DATA STARTING ADDR-hi 40

DATA STARTING ADDR-lo 51

NUMBER OF SETTINGS-hi 00

NUMBER OF SETTINGS-lo 02

BYTE COUNT 04

DATA #1 - h i 00

DATA #1 - lo C8

DATA #2 - h i 00

DATA #2 - lo 01

CRC – lo 12

CRC – hi 62

Integrator’s Guide14

Page 15

SLAVE RESPONSE

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 10

DATA STARTING ADDR - hi 40

DATA STARTING ADDR - lo 51

NUMBER OF SETTINGS - hi 00

NUMBER OF SETTINGS - lo 02

CRC - lo 07

CRC - hi 64

1.1.5.5 Exception responses

Programming or operation errors usually happen because of illegal data in a packet . These

errors result in an exception response from the slave. The slave detecting one of these errors

sends a response packet to the master with the high order bit of the function code set to 1. The

following table shows the format of the master and slave packets. The example shows a master

device sending the unsupported function code 39h to slave device 11.

Master and Slave Device Packet Transmission Example

MASTER TRANSMISSION

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE 39

CRC - low order byte CD

CRC - high order byte F2

SLAVE RESPONSE

PACKET FORMAT EXAMPLE (HEX)

SLAVE ADDRESS 11

FUNCTION CODE B9

ERROR CODE 01

CRC - low order byte 93

CRC - high order byte 95

Modbus® protocol implementation 15

Page 16

1.1.6 File transfers

1.1.6.1 Obtaining CPU files using Modbus protocol

The CPU has a generic file transfer facility, meaning that you use the same method to obtain all

of the different types of files from the unit. The Modbus registers that implement file transfer are

found in the “Modbus File Transfer (Read/Write)” and “Modbus File Transfer (Read Only)”

modules, starting at address 030Eh in the Modbus Memory Map. To read a file from the CPU, use

the following steps:

1. Write the filename to the “Name of file to read” register using a write multiple registers

command. If the name is shorter than 80 characters, you may write only enough registers

to include all the text of the filename. Filenames are not case sensitive.

2. Repeatedly read all the registers in “Modbus File Transfer (Read Only)” using a read multiple

registers command. It is not necessary to read the entire data block, since the CPU will

remember which was the last register read. The “position” register is initially zero and

thereafter indicates how many bytes (2 times the number of registers) you have read so far.

The “size of...” register indicates the number of bytes of data remaining to read, to a

maximum of 244.

3. Keep reading until the “size of...” register is smaller than the number of bytes you are

transferring. This condition indicates end of file. Discard any bytes you have read beyond

the indicated block size.

4. If you need to re-try a block, read only the “size of...” and “block of data”, without reading the

position. The file pointer is only incremented when you read the position register, so the

same data block will be returned as was read in the previous operation. On the next read,

check to see if the position is where you expect it to be, and discard the previous block if it is

not (this condition would indicate that the CPU did not process your original read request).

The CPU retains connection-specific file transfer information, so files may be read

simultaneously on multiple Modbus connections.

a. Obtaining files from the CPU using other protocols

All the files available via Modbus may also be retrieved using the standard file transfer

mechanisms in other protocols (for example, TFTP).

b. Reading event recorder files

To read the entire event recorder contents in ASCII format (the only available format), use

the following filename:

•EVT.TXT

c. Reading fault report files

The file name for fault report data is faultReport#####.txt . The ##### refers to the

fault report record number. This number is identical to the event record number

associated with the fault report. A request for a non-existent fault report file will yield file

with no data below the header.

d. Reading waveform capture files

Waveform records comply with COMTRADE 1999 format (IEEE Std C37.111-1999). The file

names as required by the standard for waveform capture data are wfc#####.dat and

wfc#####.cfg. The ##### refers to the waveform record number. Note that this number

is not the same as the event number cited in the case of the fault report above. If an

event has a waveform capture associated with it, the waveform number will be shown in

the WF Number field as indicated in the header of the event log.

Integrator’s Guide16

Page 17

1.1.6.2 Modbus password operation

The COMMAND password is set up at memory location 0458h. Storing a value of “0” removes

COMMAND password protection. When reading the password setting, the encrypted value (zero

if no password is set) is returned. COMMAND security is required to change the COMMAND

password.

Similarly, the SETTING password is set up at memory location 045Ah. To gain COMMAND level

security access, the COMMAND password must be entered at memory location 045Ch. To gain

SETTING level security access, the SETTING password must be entered at memory location

045Eh. The entered SETTING password must match the current SETTING password setting, or

must be zero, to change settings or download firmware.

COMMAND and SETTING passwords each have a 30-minute timer. Each timer starts when you

enter the particular password, and is restarted whenever you “use” it. For example, writing a

setting restarts the SETTING password timer and writing a command register or forcing a coil

restarts the COMMAND password timer. The value read at memory location 0460h can be used

to confirm whether a COMMAND password is enabled or disabled (0 for Disabled). The value

read at memory location 0461h can be used to confirm whether a SETTING password is

enabled or disabled.

COMMAND or SETTING password security access is restricted to the particular port or particular

TCP/IP connection on which the entry was made. Passwords must be entered when accessing

the relay through other ports or connections, and the passwords must be reentered after

disconnecting and reconnecting on TCP/IP.

Modbus® protocol implementation 17

Page 18

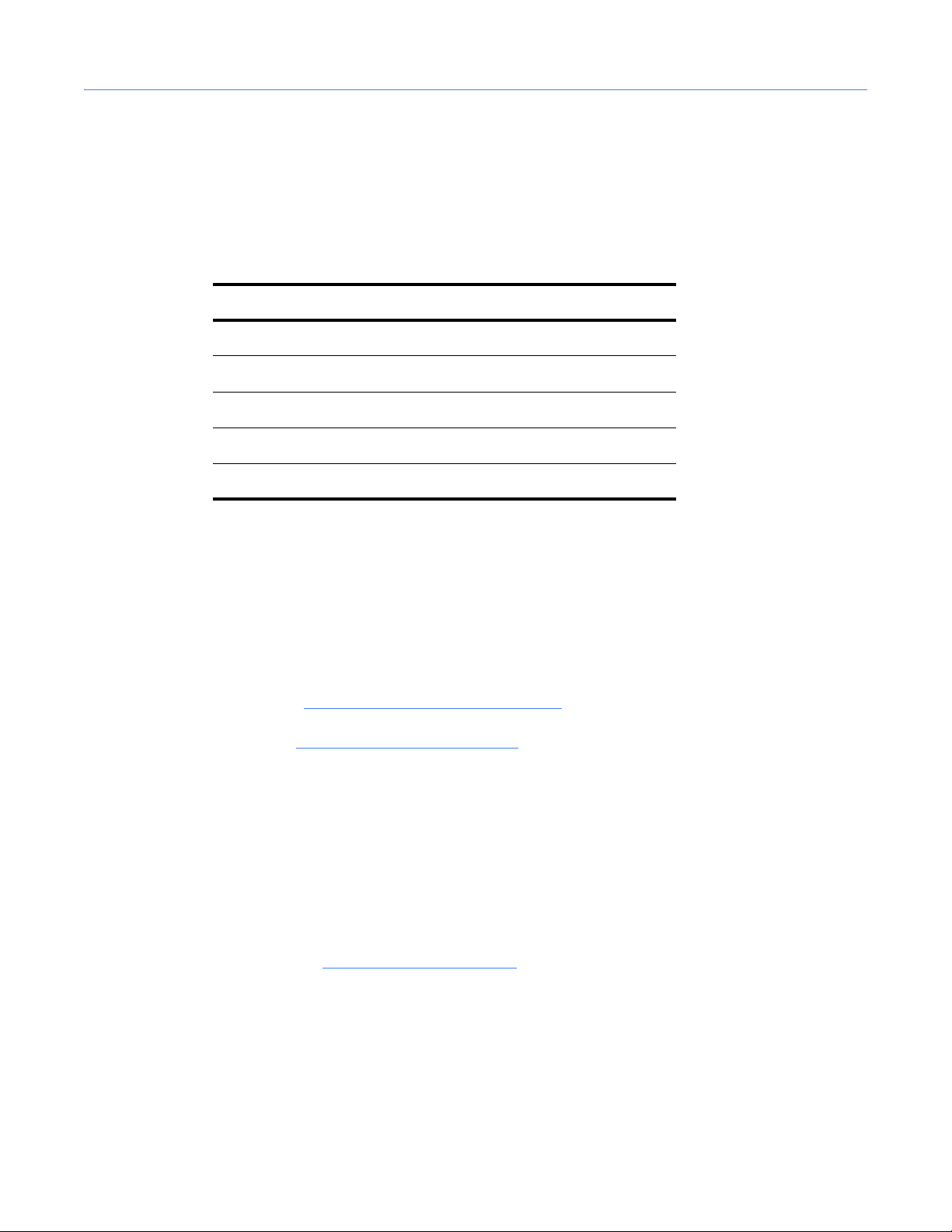

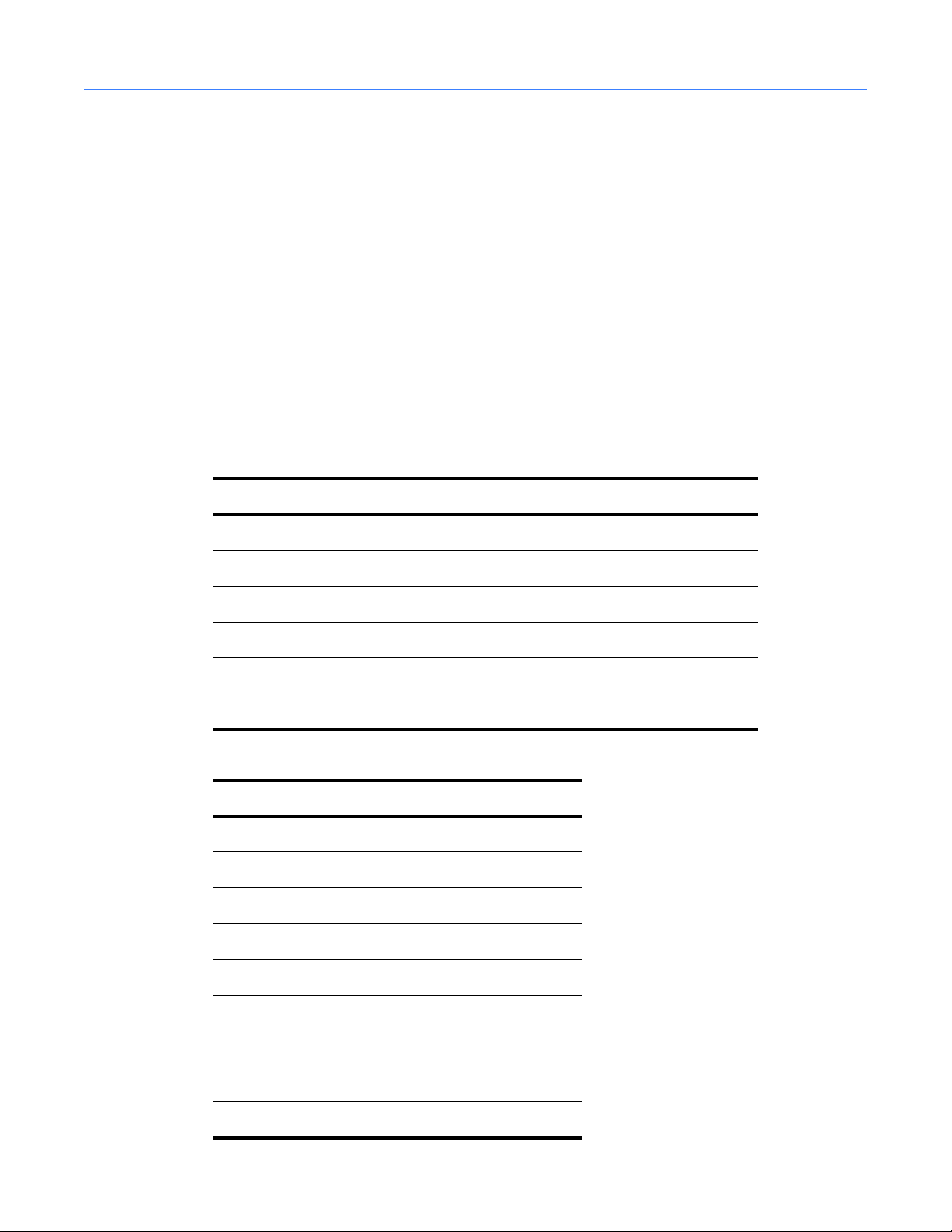

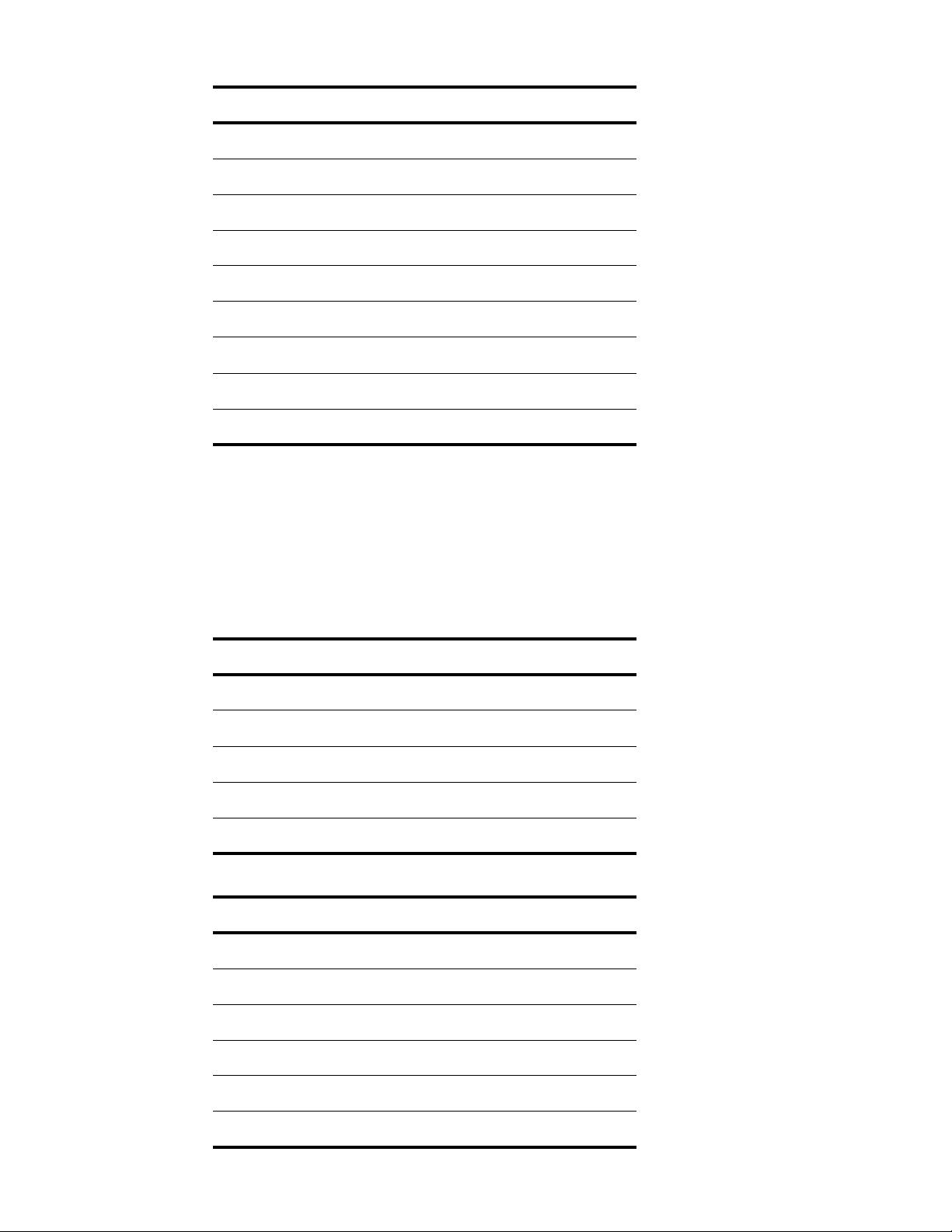

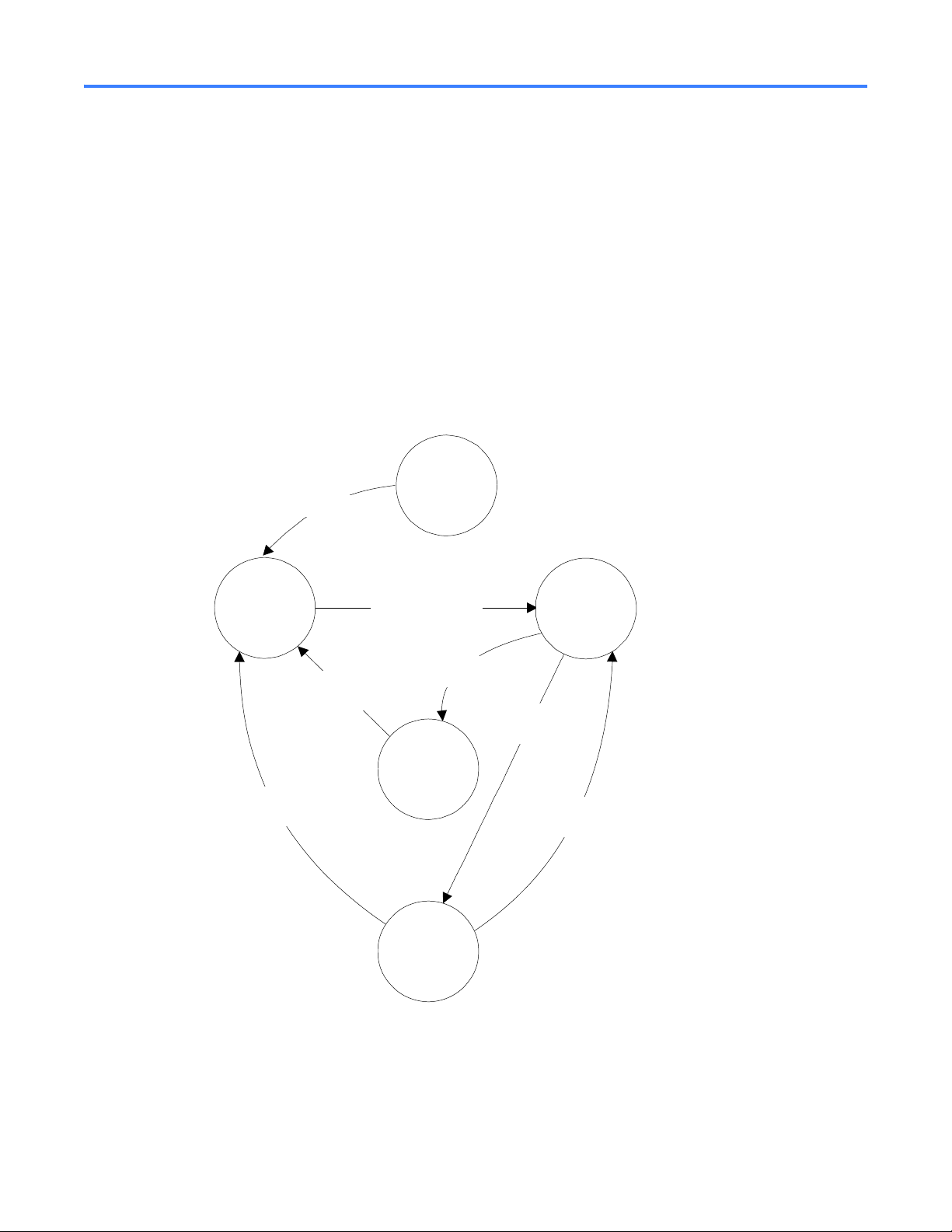

1.2 Interfacing to the Alarm Handler

The set of registers beginning at 0648h provides the means to interface to each CPU’s Alarm

Handler functionality. Each pair of 32-bit values represent the current state (read only) and the

acknowledge setting (read/write) for each alarm type. Each value represents the states for all of

the circuit breakers in the system as denoted in Format Code F722, one bit for each. A 1 in the

bit field position for a given circuit breaker in the state register indicates that the alarm

condition is currently active, while a 0 indicates the condition is not currently active.

When a condition passes from inactive to active, the corresponding ACK bit in the next register

will be set to 1. At this point an external program may acknowledge the alarm by writing a 0 to

that bit location. It is important for the external program to first read the ACK register and mask

the new value such that the states represented by the other bits remain intact. The following

state table describes how the HMI interfaces with the CPU to update its indicators.

Figure 1-1 Alarm state transition diagram

Start

System Initialization

ACK: 0

Status: 0

HMI Color:

Green

HMI

ACK

Alarm Condition

Condition

Goes Normal

Occurs

HMI

ACK

ACK: 0

Status: 1

HMI Color:

Solid

Red

ACK: 1

Status: 0

HMI Color:

Yellow

ACK: 1

Status: 1

HMI Color:

Blinking

Red

Condition

Goes Normal

Condition

Recurs

Alarm State Transition Diagram

Integrator’s Guide18

Page 19

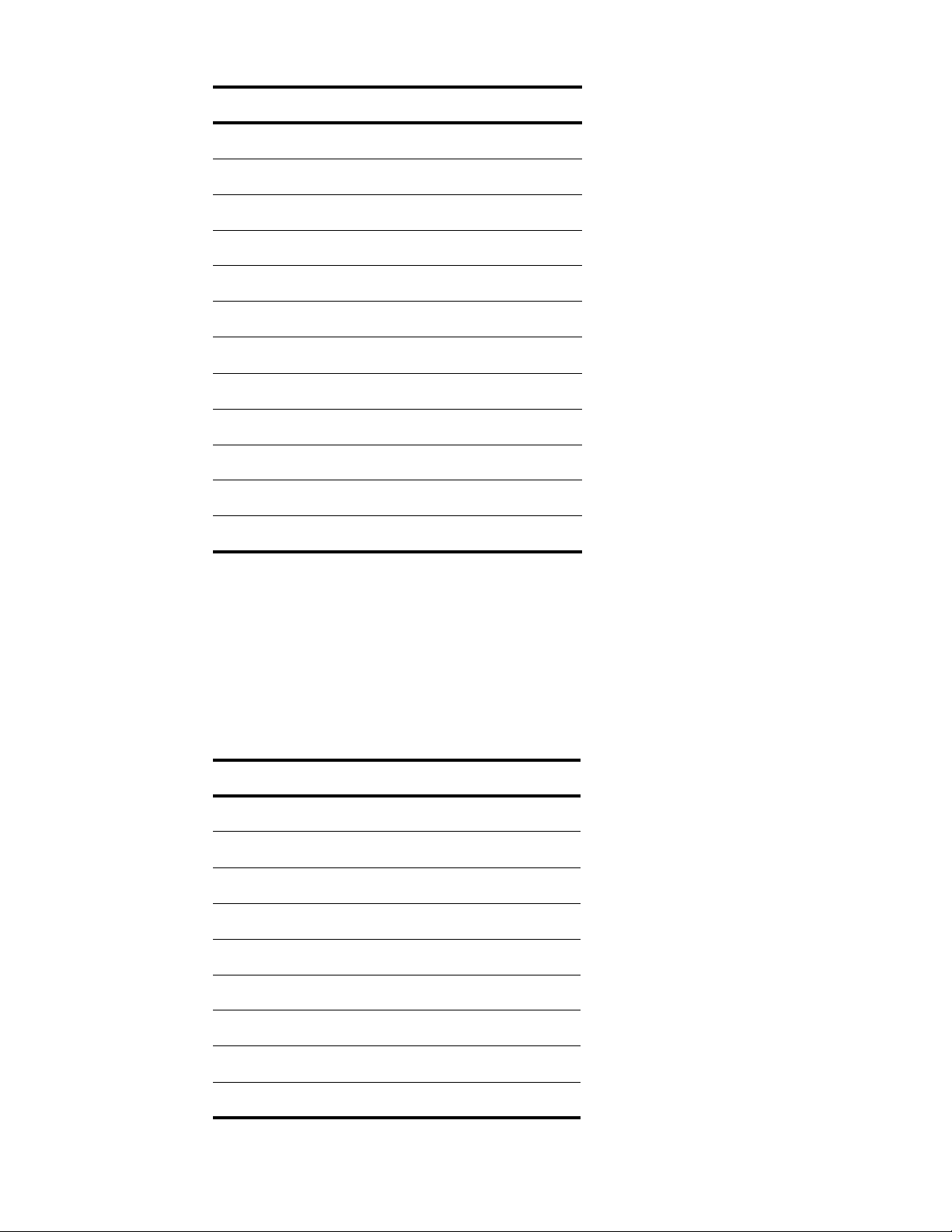

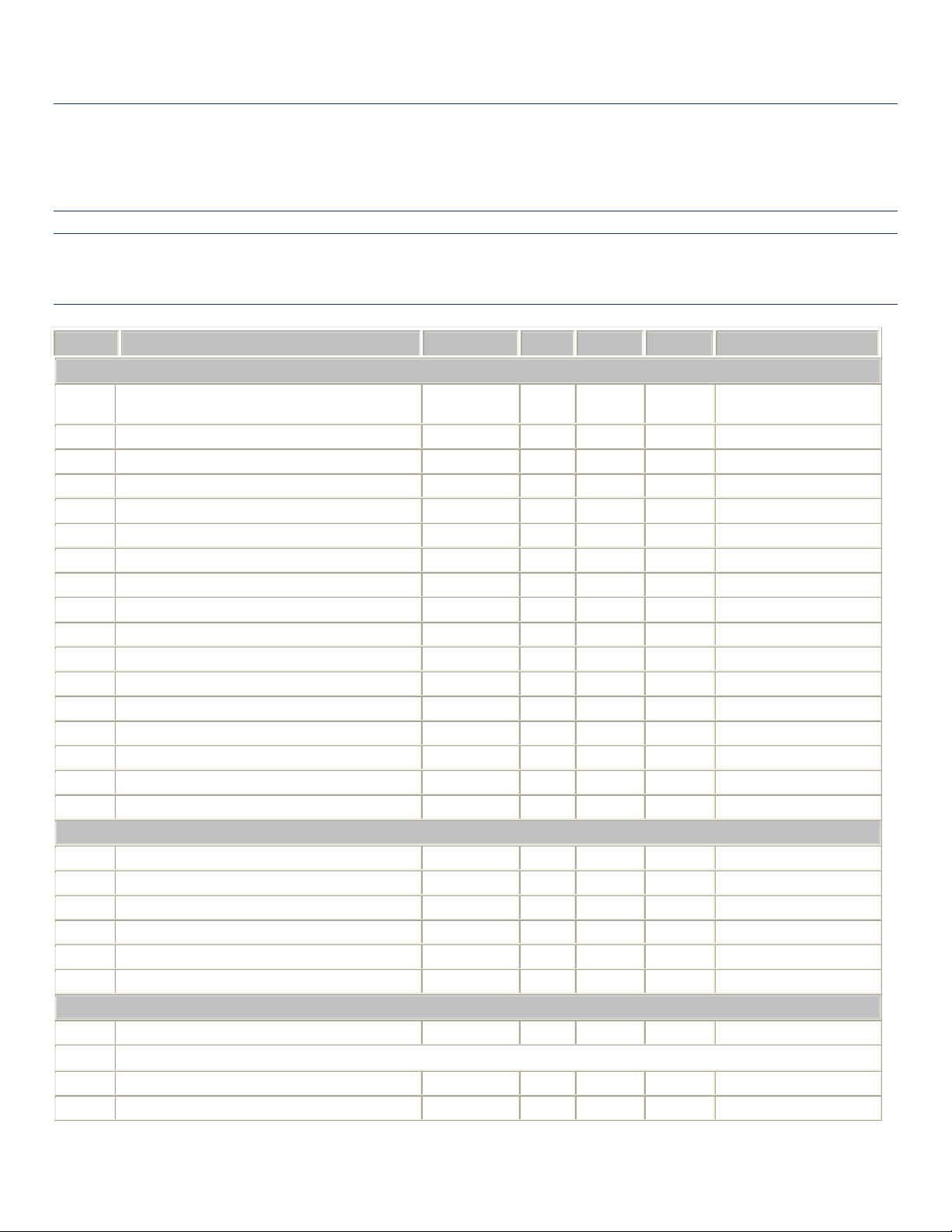

Modbus Memory Map

NOTE: A multiplier factor may be necessary in cases where an integer value is returned but the Range and/or Step imply a

greater precision. In these cases, it is necessary to divide the returned value by 10 for a step of "0.1" or "0.5"; by 100 for a step of

".01"; and so on. Similarly, it is necessary to multiply by these factors prior to writing a settings value. This note does not apply

to any step value greater than 1 (a step of "10" does not require a multiplier, for example). This note also does not apply to

values returned in floating point format. See the format codes at the end of the map for more information.

NOTE: Discrete I/O output state registers (Contact Output x State – register range from x9180 to x91FF and Contact Output

States – register range from xB256 to 0xB25D) contain correct information only when FlexLogic Active register (x0034) contains

value 1 (yes).

Addr Register Name Range Units Step Format Factory Default

Product Information (Read Only)

0000 Product Type

0001 Serial Number

0009 External Ethernet MAC Address

000C Reserved (3 items)

000F CPU Hardware Version

0010 CPU Firmware Version

0011 CPU Firmware Boot Code Version

0012 Build Date

0026 Synchronizer Board Status

0027 Synchronizer Board Frequency Setting

0028 Last Energy Clear Date

002A Last CPU Commissioned Date

002C Expected Node Protocol Version

002D Summary Number

0033 Line Up

0034 FlexLogic Active

0035 Reserved (203 items)

0 to 2

---

---

--0 to 655.35

0 to 655.35

0 to 655.35

---

0 to 1

50 to 60

0 to 4294967295

0 to 4294967295

0 to 655.35

---

0 to 99

0 to 1

---

--- 1 F716

--- --- F203 "0"

--- --- F072 0

--- --- F001 0

--- 0.01 F001 100

--- 0.01 F001 100

--- 0.01 F001 100

--- --- F200 "0"

--- 1 F102 0 (Disabled)

Hz 10 F001 60

--- 1 F050 0

--- 1 F050 0

--- 0.01 F001 0

--- --- F205 "0"

--- 1 F001 1

--- 1 F126 0 (No)

--- --- F001 0

0 (Low Voltage

Switchgear)

Installation (Read/Write Setting)

0100 CPU ID

0101 CPU Commissioned

0102 CPU Name

0116 System Frequency

0117 Phase Rotation

0118 Reserved (232 items)

Clock (Read/Write Command)

0200 RTC Set Time

Clock (Read Only)

0202 Date Time Changed

0204 Reserved (8 items)

0 to 1

0 to 1

---

50 to 60

0 to 1

---

0 to 4294967295

0 to 4294967295

---

--- 1 F717 0 (CPU A)

--- 1 F102 0 (Disabled)

--- --- F200 "UNNAMED"

Hz 10 F001 60

--- 1 F106 0 (ABC)

--- --- F001 0

--- 1 F050 0

--- 1 F050 0

--- --- F001 0

19

Page 20

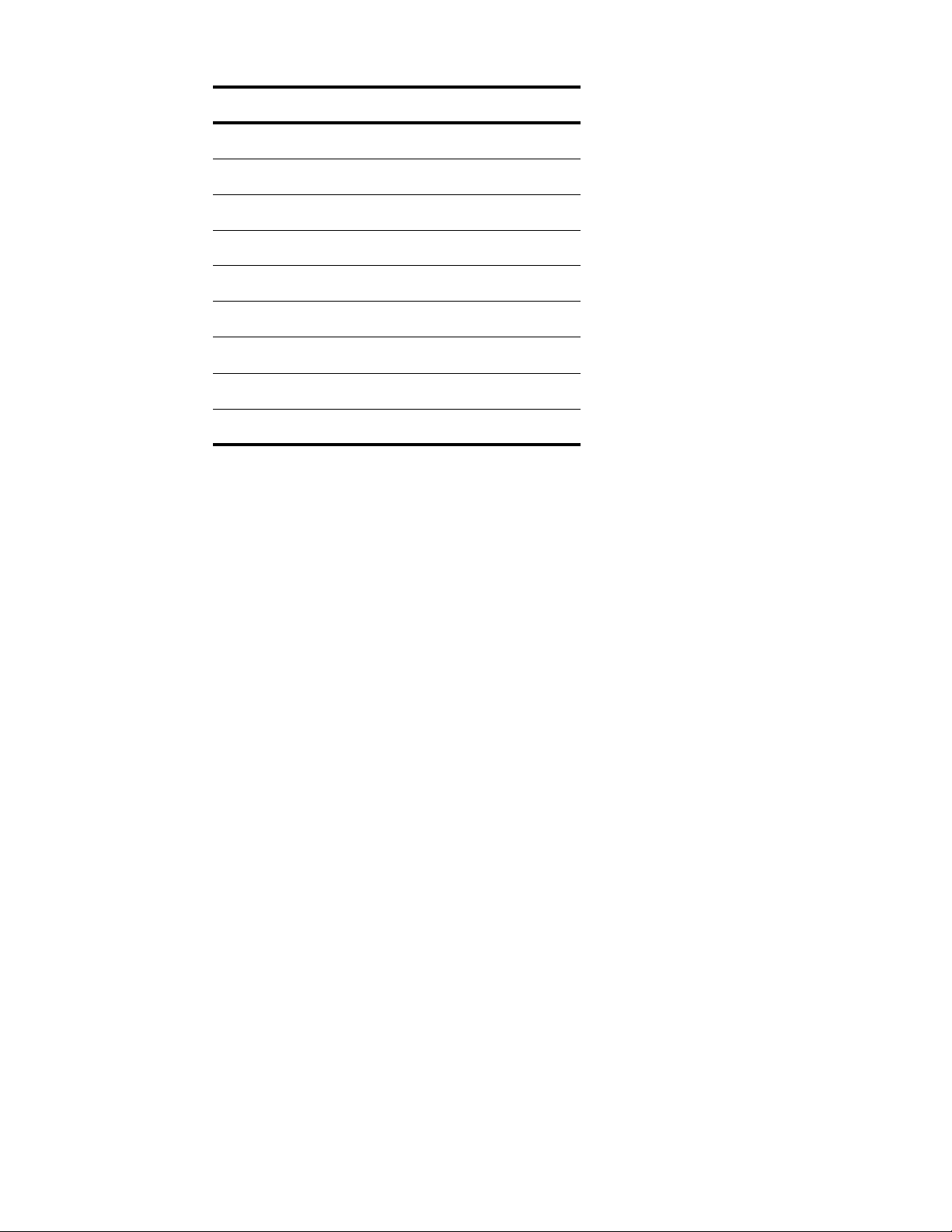

Communications (Read/Write Setting)

0210 External Ethernet IP Address

0212 External Ethernet IP Subnet Mask

0214 External Ethernet Gateway IP Address

0216 Reserved (205 items)

0 to 4294967295

0 to 4294963200

0 to 4294967295

Event Recorder (Read Only)

0308 Events Since Last Clear

030A Number of Available Events

030C Event Recorder Last Cleared Date

0 to 4294967295

0 to 4294967295

0 to 4294967295

Modbus File Transfer (Read/Write)

030E Name of file to read

Modbus File Transfer (Read Only)

0336 Character position of current block within file

0338 Size of currently-available data block

0339 Block of data from requested file (122 items)

0 to 4294967295

Modbus File Transfer Area 2 (Read/Write)

03B3 Name of file to read

Modbus File Transfer Area 2 (Read Only)

03DB Character position of current block within file

03DD Size of currently-available data block

03DE Block of data from requested file (122 items)

0 to 4294967295

1 to 254

---

0 to 65535

0 to 65535

---

0 to 65535

0 to 65535

--- 1 F003 3232235876

--- 1 F003 4294967040

--- 1 F003 0

--- 1 F001 1

--- 1 F003 0

--- 1 F003 0

--- 1 F050 0

--- --- F204 (none)

--- 1 F003 0

--- 1 F001 0

--- 1 F001 0

--- --- F204 (none)

--- 1 F003 0

--- 1 F001 0

--- 1 F001 0

Passwords (Read/Write)

045C Command Password Entry

045E Setting Password Entry

0 to 4294967295

0 to 4294967295

--- 1 F003 0

--- 1 F003 0

Passwords (Read Only)

0460 Command Password Status

0461 Setting Password Status

0 to 1

0 to 1

--- 1 F102 0 (Disabled)

--- 1 F102 0 (Disabled)

Zone Manager (Read Only)

04E4 Current Topology State

0 to 255

--- 1 F001 0

Zone Manager (Read/Write Setting)

04E5 Maintenance Mode Setting

0 to 1

--- 1 F102 0 (Disabled)

Zone Manager (Read Only)

04E6 Current Zone1 Topology

04E7 Current Zone2 Topology

04E8 Current Zone3 Topology

04E9 Current Zone4 Topology

04EA Zone Manager Reserved (22 items)

0 to 255

0 to 255

0 to 255

0 to 255

0 to 65535

--- 1 F001 1

--- 1 F001 1

--- 1 F001 1

--- 1 F001 1

--- 1 F001 1

Event Recorder Commands (Read/Write Command)

0500 Event Recorder Clear Command

0 to 1

--- 1 F126 0 (No)

Energy Commands (Read/Write Command)

0501 Energy Clear Command

Demand (Read/Write Setting)

0504 Demand Subinterval Length

0505 Demand Subintervals Per Interval

20

0 to 1

1 to 60

1 to 15

--- 1 F126 0 (No)

--- 1 F001 1

--- 1 F001 1

Page 21

Demand (Read/Write Command)

0506 Demand Reset All Command

0 to 1

--- 1 F126 0 (No)

Demand (Read Only)

0507 Number Of Demand Resets All

0509 Last Demand Reset All DateTime

0 to 4294963200

0 to 4294967295

--- 1 F003 0

--- 1 F050 0

Demand (Read/Write Command)

050B Demand Log Clear All Command

0 to 1

--- 1 F126 0 (No)

Demand (Read Only)

050C Demand Log Last Cleared All Date

050E Demand Reserved (10 items)

0 to 4294967295

0 to 65535

--- 1 F050 0

--- 1 F001 0

Waveform Capture (Read Only)

0518 Number WF Records Available

0 to 65535

--- 1 F001 0

Waveform Capture (Read/Write Command)

0519 Waveform Clear Command

0 to 1

--- 1 F126 0 (No)

Waveform Capture (Read Only)

051A Waveform Last Clear Date

0 to 4294967295

--- 1 F050 0

Waveform Capture (Read/Write Command)

051C Waveform Trigger Command

0 to 1

--- 1 F126 0 (No)

Waveform Capture (Read/Write Setting)

051D Waveform Trigger Mode

051E Waveform Trigger Position

Waveform Capture (Read Only)

051F Waveforms Since Last Clear

0523 Reserved (8 items)

0 to 4294967295

Preventive Maintenance (Read/Write Setting)

052B Load Life Rating 800A

052C Load Life Rating 1600A

052D Load Life Rating 2000A

052E Load Life Rating 3200A

052F Load Life Rating 4000A

0530 Load Life Rating 5000A

0531 Mechanical_Life_Rating_800A

0532 Mechanical_Life_Rating_1600A

0533 Mechanical_Life_Rating_2000A

0534 Mechanical_Life_Rating_3200A

0535 Mechanical_Life_Rating_4000A

0536 Mechanical_Life_Rating_5000A

0537 Load Life Max Current 800A

0538 Load Life Max Current 1600A

0539 Load Life Max Current 2000A

053A Load Life Max Current 3200A

053B Load Life Max Current 4000A

053C Load Life Max Current 5000A

0 to 1

0 to 119

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

1 to 50

1 to 50

1 to 50

1 to 50

1 to 50

1 to 50

--- 1 F118 0 (Automatic Overwrite)

Half

Cycles

F001 60

1

--- 1 F003 0

--- 1 F001 0

--- 1 F001 2800

--- 1 F001 1200

--- 1 F001 1000

--- 1 F001 600

--- 1 F001 500

--- 1 F001 400

--- 1 F001 12500

--- 1 F001 4000

--- 1 F001 4000

--- 1 F001 1500

--- 1 F001 1500

--- 1 F001 1500

--- 1 F001 15

--- 1 F001 15

--- 1 F001 15

--- 1 F001 13

--- 1 F001 9

--- 1 F001 7

21

Page 22

Hardware Information (Read Only)

053D Flash Lifetime

Source Vectors (Read/Write Setting)

0600 Expected Nodes x State

0602 Source Node Identifier LED x State

0604 Node Setting Changed x State

Source Vectors (Read Only)

0630 Nodes Communicating x State

0632 Nodes Commissioned x State

0634 Duplicate Nodes x State

0636 Node Internal Diagnostics x State

0638 Node System Diagnostics x State

063A Node Hardware Diagnostics x State

063C Node Reflected CPU Diagnostics x State

063E Breaker Contact Position x State

0640 Breaker Primary Connection x State

0642 Breaker Lockout x State

0644 Summations Suspended x State

0646 Breaker Tripped x State

0648 Undervoltage Trip Alarm State

1 to 10

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

--- 1 F001 1

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

Source Vectors (All Ack Vectors are Read/Write Setting; All State Vectors are Read Only)

064A Undervoltage Trip Alarm Ack

064C Undervoltage Alarm State

064E Undervoltage Alarm Ack

0650 Overvoltage Trip Alarm State

0652 Overvoltage Trip Alarm Ack

0654 Overvoltage Alarm State

0656 Overvoltage Alarm Ack

0658 Phase Loss Trip Alarm State

065A Phase Loss Trip Alarm Ack

065C Phase Loss Alarm State

065E Phase Loss Alarm Ack

0660 Reverse Power Trip Alarm State

0662 Reverse Power Trip Alarm Ack

0664 Reverse Power Alarm State

0666 Reverse Power Alarm Ack

0668 High Current Alarm State

066A High Current Alarm Ack

066C Underfrequency Trip Alarm State

066E Underfrequency Trip Alarm Ack

0670 Underfrequency Alarm State

0672 Underfrequency Alarm Ack

0674 Overfrequency Trip Alarm State

0676 Overfrequency Trip Alarm Ack

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

22

Page 23

0678 Overfrequency Alarm State

067A Overfrequency Alarm Ack

067C High Resistance Ground Fault Alarm State

067E High Resistance Ground Fault Alarm Ack

0680 Breaker Open Failed Alarm State

0682 Breaker Open Failed Alarm Ack

0684 Long Time Overcurrent Trip Alarm State

0686 Long Time Overcurrent Trip Alarm Ack

0688 Short Time Overcurrent Trip Alarm State

068A Short Time Overcurrent Trip Alarm Ack

068C Ground Fault Trip Alarm State

068E Ground Fault Trip Alarm Ack

0690 Ground Fault Alarm State

0692 Ground Fault Alarm Ack

0694 Analog IOC Trip Alarm State

0696 Analog IOC Trip Alarm Ack

0698 IOC Trip Alarm State

069A IOC Trip Alarm Ack

069C Node Control Power Lost State

069E Node Control Power Lost Ack

06A0 Node Communication Lost State

06A2 Node Communication Lost Ack

06A4 Breaker Load Life 50 State

06A6 Breaker Load Life 50 Ack

06A8 Breaker Load Life 75 State

06AA Breaker Load Life 75 Ack

06AC Breaker Load Life 90 State

06AE Breaker Load Life 90 Ack

06B0 Breaker Accum Service Alarm State

06B2 Breaker Accum Service Alarm Ack

06B4 Breaker Mechanical Life 12 5 State

06B6 Breaker Mechanical Life 12 5 Ack

06B8 Breaker Mechanical Life 25 State

06BA Breaker Mechanical Life 25 Ack

06BC Breaker Mechanical Life 37 5 State

06BE Breaker Mechanical Life 37 5 Ack

06C0 Breaker Mechanical Life 50 State

06C2 Breaker Mechanical Life 50 Ack

06C4 Breaker Mechanical Life 62 5 State

06C6 Breaker Mechanical Life 62 5 Ack

06C8 Breaker Mechanical Life 75 State

06CA Breaker Mechanical Life 75 Ack

06CC Breaker Mechanical Life 87 5 State

06CE Breaker Mechanical Life 87 5 Ack

06D0 Breaker Mechanical Life 100 State

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

23

Page 24

06D2 Breaker Mechanical Life 100 Ack

06D4 Bus Differential Trip Alarm State

06D6 Bus Differential Trip Alarm Ack

06D8 Bus Differential Alarm State

06DA Bus Differential Alarm Ack

06DC Multi Source Ground Fault Trip Alarm State

06DE Multi Source Ground Fault Trip Alarm Ack

06E0 Multi Source Ground Fault Alarm State

06E2 Multi Source Ground Fault Alarm Ack

06E4 Hardware Synch Card Lost State

06E6 Hardware Synch Card Lost Ack

06E8 Reserved

06EA Compartment ID Button Missing Alarm State

06EC Reserved

06EE Compartment ID Button Missing Alarm Ack

06F0 Control Alarm State

06F2 Control Alarm Ack

06F4 Redundant CPU Node Comm Loss State

06F6 Redundant CPU Node Comm Loss Ack

06F8 Redundant CPU Hardware Synch Loss State

06FA Redundant CPU Hardware Synch Loss Ack

06FC Discrete IO Misconfigured State

06FE Discrete IO Misconfigured Ack

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

0 to 4294967295

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

--- 1 F722 0

Voltage (Read Only) (30 modules)

1000 Phase AG Voltage RMS

1002 Phase BG Voltage RMS

1004 Phase CG Voltage RMS

1006 Phase AB or AC Voltage RMS

1008 Phase BC or BA Voltage RMS

100A Phase CA or CB Voltage RMS

100C Reserved (50 items)

103E

107C

10BA

10F8

1136

1174

11B2

11F0

122E

126C

12AA

12E8

1326

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

0 to 999999.999

0 to 999999.999

0 to 999999.999

0 to 999999.999

0 to 999999.999

0 to 999999.999

---

V 0.001 F060 0

V 0.001 F060 0

V 0.001 F060 0

V 0.001 F060 0

V 0.001 F060 0

V 0.001 F060 0

--- --- F001 0

24

Page 25

1364

13A2

13E0

141E

145C

149A

14D8

1516

1554

1592

15D0

160E

164C

168A

16C8

1706

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Current (Read Only) (30 modules)

1800 Phase A Current RMS

1802 Phase B Current RMS

1804 Phase C Current RMS

1806 Neutral Current RMS

1808 Ground Current RMS

180A Reserved (28 items)

1826

184C

1872

1898

18BE

18E4

190A

1930

1956

197C

19A2

19C8

19EE

1A14

1A3A

1A60

1A86

1AAC

1AD2

1AF8

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

0 to 999999.999

0 to 999999.999

0 to 999999.999

0 to 999999.999

0 to 999999.999

---

A 0.001 F060 0

A 0.001 F060 0

A 0.001 F060 0

A 0.001 F060 0

A 0.001 F060 0

--- --- F001 0

25

Page 26

1B1E

1B44

1B6A

1B90

1BB6

1BDC

1C02

1C28

1C4E

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Power (Read Only) (30 modules)

1D00 Three Phase Real Power

1D02 Phase A Real Power

1D04 Phase B Real Power

1D06 Phase C Real Power

1D08 Three Phase Reactive Power

1D0A Phase A Reactive Power

1D0C Phase B Reactive Power

1D0E Phase C Reactive Power

1D10 Three Phase Apparent Power

1D12 Phase A Apparent Power

1D14 Phase B Apparent Power

1D16 Phase C Apparent Power

1D18 Three Phase Power Factor

1D19 Phase A Power Factor

1D1A Phase B Power Factor

1D1B Phase C Power Factor

1D1C Reserved (4 items)

1D20

1D40

1D60

1D80

1DA0

1DC0

1DE0

1E00

1E20

1E40

1E60

1E80

1EA0

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-0.999 to 1

-0.999 to 1

-0.999 to 1

-0.999 to 1

---

W 0.001 F060 0

W 0.001 F060 0

W 0.001 F060 0

W 0.001 F060 0

var 0.001 F060 0

var 0.001 F060 0

var 0.001 F060 0

var 0.001 F060 0

VA 0.001 F060 0

VA 0.001 F060 0

VA 0.001 F060 0

VA 0.001 F060 0

--- 0.001 F013 0

--- 0.001 F013 0

--- 0.001 F013 0

--- 0.001 F013 0

--- --- F001 0

26

Page 27

1EC0

1EE0

1F00

1F20

1F40

1F60

1F80

1FA0

1FC0

1FE0

2000

2020

2040

2060

2080

20A0

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Energy (Read Only Non-Volatile) (30 modules)

2100 Positive Watthour

2102 Phase A Positive Watthour

2104 Phase B Positive Watthour

2106 Phase C Positive Watthour

2108 Negative Watthour

210A Phase A Negative Watthour

210C Phase B Negative Watthour

210E Phase C Negative Watthour

2110 Positive Varhour

2112 Phase A Positive Varhour

2114 Phase B Positive Varhour

2116 Phase C Positive Varhour

2118 Negative Varhour

211A Phase A Negative Varhour

211C Phase B Negative Varhour

211E Phase C Negative Varhour

2120 Vahour

2122 Phase A Vahour

2124 Phase B Vahour

2126 Phase C Vahour

2128 Reserved (8 items)

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

0 to

100000 00000 00

---

Wh 0.001 F060 0

Wh 0.001 F060 0

Wh 0.001 F060 0

Wh 0.001 F060 0

Wh 0.001 F060 0

Wh 0.001 F060 0

Wh 0.001 F060 0

Wh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

varh 0.001 F060 0

vah 0.001 F060 0

vah 0.001 F060 0

vah 0.001 F060 0

vah 0.001 F060 0

--- --- F001 0

27

Page 28

2130

2160

2190

21C0

21F0

2220

2250

2280

22B0

22E0

2310

2340

2370

23A0

23D0

2400

2430

2460

2490

24C0

24F0

2520

2550

2580

25B0

25E0

2610

2640

2670

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Source Harmonic Analysis (Read Only) (30 modules)

26A0 SRC x Phase A Voltage THD

26A1 SRC x Phase B Voltage THD

26A2 SRC x Phase C Voltage THD

26A3 SRC x Phase A Current THD

26A4 SRC x Phase B Current THD

26A5 SRC x Phase C Current THD

26A6 SRC x Phase N Current THD

26A7 SRC x Phase A K Factor

26A8 SRC x Phase B K Factor

26A9 SRC x Phase C K Factor

26AA SRC x Phase N K Factor

26AB SRC x Harmonic Analysis Reserved (5 items) --- --- --- F001 0

26B0

...Repeated for module number 2

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

0 to 6553.5

0 to 6553.5

0 to 6553.5

0 to 6553.5

--- 0.001 F001 0

--- 0.001 F001 0

--- 0.001 F001 0

--- 0.001 F001 0

--- 0.001 F001 0

--- 0.001 F001 0

--- 0.001 F001 0

--- 0.1 F001 10

--- 0.1 F001 10

--- 0.1 F001 10

--- 0.1 F001 10

28

Page 29

26C0

26D0

26E0

26F0

2700

2710

2720

2730

2740

2750

2760

2770

2780

2790

27A0

27B0

27C0

27D0

27E0

27F0

2800

2810

2820

2830

2840

2850

2860

2870

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Source Demand Peaks (Read Only Non-Volatile) (30 modules)

2880 SRC x Maximum kW

2882 SRC x Maximum kW DateTime

2884 SRC x Maximum kvar

2886 SRC x Maximum kvar DateTime

2888 SRC x Maximum kVA

288A SRC x Maximum kVA DateTime

288C SRC x Source Demand Reserved (5 items) --- --- --- F001 0

2891

28A2

28B3

28C4

28D5

28E6

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

-1000000000000

to 100000 00000 00

0 to 4294967295

-1000000000000

to 100000 00000 00

0 to 4294967295

-1000000000000

to 100000 00000 00

0 to 4294967295

W 0.001 F060 0

--- 1 F050 0

var 0.001 F060 0

--- 1 F050 0

VA 0.001 F060 0

--- 1 F050 0

29

Page 30

28F7

2908

2919

292A

293B

294C

295D

296E

297F

2990

29A1

29B2

29C3

29D4

29E5

29F6

2A07

2A18

2A29

2A3A

2A4B

2A5C

2A6D

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Power Peaks (Read Only Non-Volatile) (30 modules)

2A80 SRC x Three Phase Power Factor Min

2A81 SRC x Three Phase Power Factor Min Date

2A83 SRC x Phase A Power Factor Min

2A84 SRC x Phase A Power Factor Min Date

2A86 SRC x Phase B Power Factor Min

2A87 SRC x Phase B Power Factor Min Date

2A89 SRC x Phase C Power Factor Min

2A8A SRC x Phase C Power Factor Min Date

2A8C SRC x Three Phase Power Factor Max

2A8D SRC x Three Phase Power Factor Max Date

2A8F SRC x Phase A Power Factor Max

2A90 SRC x Phase A Power Factor Max Date

2A92 SRC x Phase B Power Factor Max

2A93 SRC x Phase B Power Factor Max Date

2A95 SRC x Phase C Power Factor Max

2A96 SRC x Phase C Power Factor Max Date

2A98 SRC x Last Clear Energy Date

2A9A SRC x Last Commissioned Date

2A9C SRC x Power Peak Reserved (50 items)

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

-0.999 to 1

0 to 4294967295

0 to 4294967295

0 to 4294967295

---

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 0.001 F013 0

--- 1 F050 0

--- 1 F050 0

--- 1 F050 0

--- --- F001 0

30

Page 31

2ACE

2B1C

2B6A

2BB8

2C06

2C54

2CA2

2CF0

2D3E

2D8C

2DDA

2E28

2E76

2EC4

2F12

2F60

2FAE

2FFC

304A

3098

30E6

3134

3182

31D0

321E

326C

32BA

3308

3356

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Source Demand (Read Only) (30 modules)

35AC SRC x Previous Internal kW

35AE SRC x Previous Interval kvar

35B0 SRC x Previous Interval kVA

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

-1000000000000

to 100000 00000 00

W 0.001 F060 0

var 0.001 F060 0

VA 0.001 F060 0

Source Demand (Read Only Non-Volatile) (30 modules)

35B2 SRC x Last Reset DateTime

35B4 SRC x Number Of Demand Resets

0 to 4294967295

0 to 4294967295

--- 1 F050 0

--- 1 F003 0

Source Demand (Read/Write Command) (30 modules)

35B6 SRC x Demand Reset

35B7 SRC x Demand Log Clear Command

0 to 1

0 to 1

--- 1 F126 0 (No)

--- 1 F126 0 (No)

Source Demand (Read Only Non-Volatile) (30 modules)

35B8 SRC x Demand Log Last Cleared Date

0 to 4294967295

--- 1 F050 0

31

Page 32

Source Demand (Read Only) (30 modules)

35BA SRC x Demand Log Records Since Last Clear

35BC SRC x Demand Log Interval Records Available

35BE SRCx Source Demand Reserved (10 items)

35C8

35E4

3600

361C

3638

3654

3670

368C

36A8

36C4

36E0

36FC

3718

3734

3750

376C

3788

37A4

37C0

37DC

37F8

3814

3830

384C

3868

3884

38A0

38BC

38D8

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

0 to 4294967295

0 to 4294967295

0 to 4294967295

--- 1 F003 0

--- 1 F003 0

--- 1 F001 0

Source Status (Read Only) (30 modules)

5000 SRC x Node ID

5001 Reserved (3 items)

5004 SRC x Frame Rating

5005 SRC x CT Rating

5006 SRC x Breaker Type

5007 SRC x NodeProt Protection Config

5008 SRC x Node Firmware Version

5009 SRC x Hardware Version

500A SRC x Message Protocol Version

0 to 29

--0 to 65535

0 to 65535

0 to 1

0 to 65535

0 to 655.35

0 to 255

0 to 655.35

--- 1 F001 0

--- --- F001 0

--- 1 F001 0

--- 1 F001 0

--- 1 F715 0 (UL)

--- 1 F705 0

--- 0.01 F001 0

--- 1 F001 0

--- 0.01 F001 0

32

Page 33

500B SRC x Product Type

500C SRC x NodeProt Rating Switch

500D SRC x NodeProt LT Setting

500E SRC x NodeProt IOC Threshold Setting

500F SRC x NodeProt Ground Fault Setting

5010 SRC x NodeProt Short Time Setting

5011 SRC x Node Internal Diagnostics

5012 SRC x Node System Diagnostics 1

5013 SRC x Node System Diagnostics 2

5014 SRC x Node Hardware Diagnostics

5015 SRC x Node Physical Status

5016 SRC x Node Logic and Trip Status

5017 SRC x Node Last Trip Sequence Number

5019 SRC x Reflected CPU Diagnostics

501A SRC x Reflected CPU 0 Command

501B SRC x Reflected CPU 1 Command

501C SRC x Fan Status

501D SRC x CT Rating Node Report

501E SRC x Node Serial Number

5024 SRC x Node Status Reserved (43 items)

504F

509E

50ED

513C

518B

51DA

5229

5278

52C7

5316

5365

53B4

5403

5452

54A1

54F0

553F

558E

55DD

562C

567B

56CA

5719

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

0 to 2

0 to 65535

0 to 655.35

0 to 655.35

0 to 1

0 to 1

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 4294967295

0 to 65535

0 to 65535

0 to 65535

0 to 1

0 to 65535

---

0 to 1

--- 1 F716

0 (Low Voltage

Switchgear)

--- 1 F001 0

--- 0.01 F001 0

--- 0.01 F001 0

--- 1 F102 0 (Disabled)

--- 1 F102 0 (Disabled)

--- 1 F701 0

--- 1 F702 0

--- 1 F703 0

--- 1 F704 0

--- 1 F708 0

--- 1 F709 0

--- 1 F003 0

--- 1 F706 0

--- 1 F707 0

--- 1 F707 0

--- 1 F108 0 (Off)

--- 1 F001 0

--- --- F205 (none)

--- 1 F001 0

33

Page 34

5768

57B7

5806

5855

58A4

58F3

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Source Settings (Read/Write Setting) (30 modules)

5C8A SRC x Node Commissioned

0 to 1

Source Settings (Read Only) (30 modules)

5C8B SRC x PT Source Node Identifier

0 to 29

Source Settings (Read/Write Setting) (30 modules)

5C8C SRC x Breaker Connection

5C8D SRC x IOC Enabled

5C8E SRC x IOC Pickup Setting Multiplier

5C8F SRC x Ground Fault Protection Switch

5C90 SRC x Short Time Protection Switch

5C91 SRC x Short Time Pickup Setting

5C92 SRC x Short Time I2T Curve

5C93 SRC x Short Time Delay Band Setting

5C94 SRC x Long Time Delay Band Setting

5C95 SRC x Ground Fault Protection Alarm Select

5C96 SRC x Ground Fault Protection I2T Curve

5C97 SRC x Ground Fault Protection Pickup Setting

5C98

SRC x Ground Fault Protection Delay Band

Setting

5C99 SRC x PT Rating

5C9A SRC x UV Trip Enable

5C9B SRC x UV Trip Curve Type

5C9C SRC x UV Trip Pickup Setting

5C9D SRC x UV Trip Time Delay

5C9E SRC x UV Trip Phase Requirement

5C9F SRC x UV Block Voltage Enable

5CA0 SRC x UV Trip Block Volt Setting

5CA1 SRC x UV Trip Open or Trip Setting

5CA2 SRC x UV Alarm Enable

5CA3 SRC x UV Alarm Curve Type

5CA4 SRC x UV Alarm Pickup Setting

5CA5 SRC x UV Alarm Time Delay

5CA6 SRC x UV Alarm Phase Requirement

5CA7 SRC x UV Alarm Block Volt Enable

5CA8 SRC x UV Alarm Block Volt Setting

5CA9 Reserved1 (5 items)

5CAE SRC x OV Trip Enable

5CAF SRC x OV Trip Pickup Setting

0 to 1

0 to 1

1.5 to 15

0 to 1

0 to 1

1.5 to 9

0 to 1

0 to 6

0 to 3

0 to 1

0 to 1

0.2 to 0.6

0 to 6

0 to 6

0 to 1

0 to 1

50 to 95

0.5 to 600

1 to 3

0 to 1

5 to 75

0 to 1

0 to 1

0 to 1

50 to 95

0.5 to 600

1 to 3

0 to 1

5 to 75

0 to 65535

0 to 1

105 to 125

--- 1 F102 0 (Disabled)

--- 1 F001 0

--- 1 F712 0 (Forward)

--- 1 F718 1 (Enabled)

--- 0.5 F001 60

--- 1 F102 0 (Disabled)

--- 1 F102 1 (Enabled)

--- 0.5 F001 50

--- 1 F102 0 (Disabled)

--- 1 F713 2 (BAND 3)

--- 1 F711 1 (BAND 2)

--- 1 F714 0 (Trip)

--- 1 F102 1 (Enabled)

--- 0.01 F001 24

--- 1 F713 2 (BAND 3)

--- 1 F719 0 (None)

--- 1 F102 0 (Disabled)

--- 1 F726 1 (Constant time curve)

--- 1 F001 50

--- 0.5 F001 300

--- 1 F001 1

--- 1 F102 0 (Disabled)

--- 1 F001 5

--- 1 F727

1 (Trip and activate

lockout)

--- 1 F102 0 (Disabled)

--- 1 F726 1 (Constant time curve)

--- 1 F001 50

--- 0.5 F001 150

--- 1 F001 1

--- 1 F102 0 (Disabled)

--- 1 F001 5

--- 1 F001 0

--- 1 F102 0 (Disabled)

--- 1 F001 120

34

Page 35

5CB0 SRC x OV Trip Time Delay

5CB1 SRC x OV Trip Phase Requirement

5CB2 SRC x OV Trip Open or Trip Setting

5CB3 SRC x OV Alarm Enable

5CB4 SRC x OV Alarm Pickup Threshold

5CB5 SRC x OV Alarm Time Delay

5CB6 SRC x OV Alarm Phase Requirement

5CB9 Reserved2 (7 items)

5CBE SRC x PL Trip Enable

5CBF SRC x PL Trip Pickup Setting

5CC0 SRC x PL Trip Time Delay

5CC1 SRC x PL Trip Block Volt Enable

5CC2 SRC x PL Open or Trip Setting

5CC3 SRC x PL Alarm Enable

5CC4 SRC x PL Alarm Pickup Setting

5CC5 SRC x PL Alarm Time Delay

5CC6 SRC x PL Alarm Block Volt Enable

0.5 to 600

1 to 3

0 to 1

0 to 1

105 to 125

0.5 to 600

1 to 3

0 to 65535

0 to 1

8 to 50

0.5 to 600

0 to 1

0 to 1

0 to 1

8 to 50

0.5 to 600

0 to 1

--- 0.5 F001 300

--- 1 F001 1

--- 1 F727

1 (Trip and activate

lockout)

--- 1 F102 0 (Disabled)

--- 1 F001 120

--- 0.5 F001 150

--- 1 F001 1

--- 1 F001 0

--- 1 F102 0 (Disabled)

--- 1 F001 8

--- 0.5 F001 300

--- 1 F102 0 (Disabled)

--- 1 F727

1 (Trip and activate

lockout)

--- 1 F102 0 (Disabled)

--- 1 F001 8

--- 0.5 F001 150

--- 1 F102 0 (Disabled)

Source Settings (Read Only) (30 modules)

5CC7 SRC x PL Trip Voltage Setting

5CC8 SRC x PL Alarm Blocking Voltage Setting

5 to 5

5 to 5

Source Settings (Read/Write Setting) (30 modules)

5CC9 Reserved3 (3 items)

5CCC SRC x Rev Power Trip Enable

5CCD SRC x Rev Power Trip Pickup Setting

5CCE SRC x Rev Power Trip Time Delay

5CCF SRC x Rev Power Alarm Enable

5CD0 SRC x Rev Power Alarm Pickup Setting

5CD1 SRC x Rev Power Alarm Time Delay

5CD2 SRC x Rev Power Trip or Open

5CD3 Reserved4 (4 items)

5CD7 SRC x High Curr Alarm Enable

5CD8 SRC x High Curr Alarm Pickup Setting

5CD9 SRC x High Curr Alarm Time Delay

5CDA Reserved5 (5 items)

5CDF SRC x Total Breaker Operations

5CE0 SRC x Total Breaker No Load Operations

5CE1 SRC x Total Breaker Load Operations

5CE2 SRC x Total Breaker Fault Operations

5CE3 SRC x Breaker Percent Load Life

0 to 65535

0 to 1

10 to 990

0.5 to 600

0 to 1

10 to 990

0.5 to 600

0 to 1

0 to 65535

0 to 1

50 to 200

1 to 15

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 65535

0 to 655.35

--- 1 F001 5

--- 1 F001 5

--- 1 F001 0

--- 1 F102 0 (Disabled)

--- 10 F001 990

--- 0.5 F001 300

--- 1 F102 0 (Disabled)

--- 10 F001 990

--- 0.5 F001 150

--- 1 F727

1 (Trip and activate

lockout)

--- 1 F001 0

--- 1 F102 0 (Disabled)

--- 5 F001 200

--- 1 F001 15

--- 1 F001 0

--- 1 F001 0

--- 1 F001 0

--- 1 F001 0

--- 1 F001 0

--- 0.01 F001 0

Source Settings (Read Only) (30 modules)

5CE4 SRC x Percent Mechanical Life

0 to 655.35

Source Settings (Read/Write Setting) (30 modules)

5CE5 SRC x Time Date Last Breaker Operation

0 to 4294967295

--- 0.01 F001 0

--- 1 F050 0

35

Page 36

5CE7 SRC x Time Date Initial Energization

0 to 4294967295

Source Settings (Read Only) (30 modules)

5CE9 SRC_X_Breaker_Service_Hours

0 to 4294967295

Source Settings (Read/Write Setting) (30 modules)

5CEB Reserved6 (5 items)

5CF0 SRC x UF Trip Enable

5CF1 SRC x UF Trip Pickup Setting

5CF2 SRC x UF Trip Time Delay

5CF3 SRC x UF Trip Blocking Voltage Enable

5CF4 SRC x UF Trip or Open setting

5CF5 SRC x UF Alarm Enable

5CF6 SRC x UF Alarm Pickup Setting

5CF7 SRC x UF Alarm Time Delay

5CF8 SRC x UF Alarm Blocking Voltage Enable

5CF9 SRC x OF Trip Enable

5CFA SRC x OF Trip Pickup Setting

5CFB SRC x OF Trip Time Delay

5CFC SRC x OF Trip Blocking Voltage Enable

5CFD SRC x OF Trip or Open setting

5CFE SRC x OF Alarm Enable

5CFF SRC x OF Alarm Pickup Setting

5D00 SRC x OF Alarm Time Delay

5D01 SRC x OF Alarm Blocking Voltage Enable

5D02 SRC x HRGF Enable

5D03 SRC x HRGF Pickup

5D04 SRC x HRGF Delay

5D05 SRC x HRGF Ground Resistance

5D06 SRC x HRGF CT Rating

5D07 SRC x Settings Reserved (41 items)

5D30

5DD6

5E7C

5F22

5FC8

606E

6114

61BA

6260

6306

63AC

6452

64F8

659E

...Repeated for module number 2

...Repeated for module number 3

...Repeated for module number 4

...Repeated for module number 5

...Repeated for module number 6

...Repeated for module number 7

...Repeated for module number 8

...Repeated for module number 9

...Repeated for module number 10

...Repeated for module number 11

...Repeated for module number 12

...Repeated for module number 13

...Repeated for module number 14

...Repeated for module number 15

0 to 65535

0 to 1

45 to 60

0.1 to 600

0 to 1

0 to 1

0 to 1

45 to 60

0.1 to 600

0 to 1

0 to 1

50 to 70

0.1 to 600

0 to 1

0 to 1

0 to 1

50 to 70

0.1 to 600

0 to 1

0 to 1

2 to 10

0.5 to 5

5 to 500

10 to 10

0 to 65535

--- 1 F050 0

--- 1 F003 0

--- 1 F001 0

--- 1 F102 0 (Disabled)

--- 0.1 F001 450

--- 0.1 F001 300

--- 1 F102 0 (Disabled)

--- 1 F727

1 (Trip and activate

lockout)

--- 1 F102 0 (Disabled)

--- 0.1 F001 450

--- 0.1 F001 150

--- 1 F102 0 (Disabled)

--- 1 F102 0 (Disabled)

--- 0.1 F001 500

--- 0.1 F001 300

--- 1 F102 0 (Disabled)

--- 1 F727

1 (Trip and activate

lockout)

--- 1 F102 0 (Disabled)

--- 0.1 F001 500

--- 0.1 F001 150

--- 1 F102 0 (Disabled)

--- 1 F102 0 (Disabled)

--- 0.1 F001 20

--- 0.1 F001 5

--- 1 F001 5

--- 1 F001 10

--- 1 F001 0

36

Page 37

6644

66EA

6790

6836

68DC

6982

6A28

6ACE

6B74

6C1A

6CC0

6D66

6E0C

6EB2

6F58

...Repeated for module number 16

...Repeated for module number 17

...Repeated for module number 18

...Repeated for module number 19

...Repeated for module number 20

...Repeated for module number 21

...Repeated for module number 22

...Repeated for module number 23

...Repeated for module number 24

...Repeated for module number 25

...Repeated for module number 26

...Repeated for module number 27

...Repeated for module number 28

...Repeated for module number 29

...Repeated for module number 30

Source Commands (Read/Write Command) (30 modules)

7000 SRC x Open Breaker

7001 SRC x Close Breaker

7002 SRC x Trip Breaker

7003 SRC x Clear Energy

7004 Reserved --- --- --- F001 0

7005 SRC x Remote Lockout Enable

7006 SRC x Remote Lockout Reset

7007 SRC x ATO Mode Enabled

7008 SRC x Command Reserved (42 items)

7032

7064