Page 1

GE Industrial

Solutions

EntelliPro ES Motor Controller

Installation and Instruction Manual

EntelliPro ES Revision: 3.0

Manual Part Number: GEH-6000

Copyright©

2011 GE Industrial Solutions

Page 2

This page was intentionally left blank

Page 3

GE Industrial Solutions

Table of Contents

Chapter 1: Introduction

1.1 Overview ..................................................................................................................................... .............................................................. .. 1.1

1.1.1 Warnings, cautions, notes, and references............................................................................................................... 1.2

1.1.2 Definitions.................................................................................................................................................................. .............. 1.3

1.1.3 Description of the EntelliPro ES Motor Control Module ........................................................................................ 1.4

1.1.4 EntelliPro ES order code ................................................................................................................................................... .. 1.6

1.1.5 EntelliPro ES Current Transformer Definition ............................................................................................................ 1.8

1.2 Specifications ................................................................................................................................................. ........................................... 1.9

1.2.1 Protection Specifications ........................................................................................................................................... ........ 1.9

1.2.2 Metering and monitoring specifications ..................................................................................................................... 1.10

1.2.3 Input specification ................................................................................................................................................................ 1.10

1.2.4 Output specifications .......................................................................................................................................................... 1.12

1.2.5 Power supply specifications ............................................................................................................................................. 1.13

1.2.6 Communication specifications........................................................................................................................................ 1.13

1.2.7 Testing and certification .................................................................................................................................................... 1.14

1.2.8 Approvals .................................................................................................................................................................................. 1.15

1.2.9 Physical specifications ........................................................................................................................................................ 1.15

1.2.10 Environmental specifications........................................................................................................................................... 1.14

1.3 EntelliPro CP3/CP5 HMI ......................................................................................................................................................................... 1.16

1.4 WinESG Configuration Tool ................................................................................................................................................................. 1.17

Chapter 2: Installation / Configuration

2.1 Installation and initial operating ................................................................................................................................. ...................... 2.1

2.1.1 Mechanical installation................................................................................................................................... .................... 2.2

2.1.1.1 Dimensions................................................................................................................... ...................................... 2.2

2.1.1.2 Product

identification ......................................................................................................................................

2.1.1.2.1 Label Definition......................................................................................................... ................. 2.3

2.1.1.3 Mounting ................................................................................................................................ ............................. 2.4

2.1.1.4 EntelliPro ES Connector terminal

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

identification ...................................................................................

2.3

2.5

Page 4

TABLE O F CO NTENTS

2.1.2 Electrical installation............................................................................................................................... ................................. 2.6

2.1.2.1 Power supply connection ................................................................................................................................ 2.6

2.1.2.2 Communication connection ........................................................................................................................... 2.7

2.1.2.3 Thermistor connection ..................................................................................................... ................................. 2.7

2.1.2.4 Phase Current Connection .............................................................................................................................. 2.8

2.1.2.5 Input/output connection ............................................................................................................. ..................... 2.8

2.1.2.6 4-20mA output connection............................................................................................................................ 2.9

2.1.2.7 Dielectric strength testing ............................................................................................................................... 2.9

2.2 Motor Control Configuration ................................................................................................................................................................... 2.10

2.2.1 Motor Control Detailed Configuration.............................................................................................................................. 2.10

2.2.1.1 Local and remote sources listing.................................................................................................................. 2.11

2.2.1.1 Input configuration ………………………................................................................................................................. 2.11

2.2.1.3 Motor Control via Modbus configuration................................................................................................... 2.11

2.2.1.4 Motor Control via WinESG .............................................................................................................................. 2.13

2.2.1.5 Motor Control via Profibus Class 1.............................................................................................................. 2.13

2.2.1.6 ATEX Configuration ............................................................................................................................................2.13

2.2.2 Motor Control Pre-Programmed Configuration ......................................... .................................................................. 2.13

Control Variant 1 Configuration.......................................................................................................................................... 2.14

Control Variant 2 Configuration.......................................................................................................................................... 2.15

Control Variant 3 Configuration.......................................................................................................................................... 2.16

Control Variant 4 Configuration.......................................................................................................................................... 2.17

Control Variant 5 Configuration.......................................................................................................................................... 2.18

Control Variant 6 Configuration.......................................................................................................................................... 2.19

2.3 Motor Starter Configuration.................................................................................................................................................................... 2.20

2.3.1 Motor Starter Type - Full-voltage non-reversing starter ......................................................................................... 2.21

2.3.2 Motor Starter Type - Full-voltage reversing starter ................................................................................................... 2.26

2.3.3 Motor Starter Type - Star-delta open transition starter.......................................................................................... 2.31

2.3.4 Motor Starter Type - Star-delta reverse open transition starter .......................................................................... 2.36

2.3.5 Motor Starter Type – Soft starter

2.3.6 Motor Starter Type - Reverse Soft starter

type

............................................................................................................................. 2.40

type

.................................................... ........................................................ 2.45

2.3.7 Breaker Control .......................................................................................................................................................................... 2.51

2.3.9 Motor Starter Type – Pole changer starter

2.3.8 Motor Starter Type - Dahlander starter

2.3.10 Solenoid valve

2.3.11 Actuator

type....................................................................................................................................................................

type

.............................................................................................................................................................................. 2.72

type

.................................................... ............................................................ 2.56

type

.................................................. ........................................................ 2.61

2.66

Page 5

TAB L E OF CO N T E NTS

Chapter 3: Motor Protection

3.1 Thermal Ov

3.1.1 Unbalance and phase-loss biasing............................................................................................. ..................................... 3.2

3.1.2 Hot/cold biasing ........................................................................................................................................................ ............... 3.2

3.1.3 Overload curve ........................................................................................................................................................ .................. 3.3

3.1.4 Cooling rate ............................................................................................................................................ .................................... 3.6

3.1.5 Overload protection n-times reset .................................................................................................................................. 3.15

3.1.6 Overload protection programmable settings............................................................................................................. 3.17

3.2 Phase loss and current unbalance .................................................................................................................................................... 3.19

3.3 Ground fault ................................................................................................................................................................................................. 3.20

3.4 Overcurrent and stalled rotor protection ........................................................................................................................................ 3.21

3.5 Undercurrent protection......................................................................................................................................................................... 3.23

3.6 Thermistor (TMA)......................................................................................................................................................................................... 3.25

Chapter 4: Communication

4.1 Modbus RTU .................................................................................................................................................... .............................................. 4.1

4.1.1 Modbus address setting ................................................................................................................................ ........................ 4.1

4.1.2 Modbus baud rate and port configuration ........................................................ ................................................ ........... 4.3

4.1.3 Modbus function

4.1.4 Modbus topology.................................................................................................................................. .................................... 4.5

4.1.5 RS-485 connections ............................................................................................................................................... ................. 4.6

4.1.6 RS-485 termination

4.1.7 Grounding shielding

4.1.8 Implementation basics .......................................................................................................................................... ................ 4.7

4.1.9 Modbus RTU message format ................................................................................................... ......................................... 4.7

4.1.10 EntelliPro ES Function

4.1.11 Error Responses ....................................................................................................................................................................... 4.16

4.1.12 Modbus Register Map............................................................................................................................................................ 4.17

erload

...................................................... ........................................................................ ......................................................... 3.1

codes

...................................................... ........................................................................ ........................... 4.4

considerations ...................................................................................................................................

considerations

Code

..................................................................................................................................... ............ 4.8

.................................................... .................................................................... ........ 4.6

4.6

4.1.10.1 Function code 03H............................................................................................................................... .............. 4.8

4.1.10.2 Function Code 04H ........................................................................................................ .................................... 4.9

4.1.10.3 Function Code 05H ........................................................................................................ .................................... 4.10

4.1.10.4 Function Code 06H ........................................................................................................................................... 4.13

4.1.10.5 Function Code 10H ........................................................................................................................................... 4.14

4.1.10.6 Function Code 14H ........................................................................................................................................... 4.15

4.1.10.7 Function Code 15H ........................................................................................................................................... 4.15

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 6

TABLE O F CO NTENTS

4.2 Profibu s ....................................................................................................................................................................................................... 4.33

4.2.1 Definitions................................................................................................................................................................................ 4.33

4.2.2 Profibus System concept .................................................................................................................................................. 4.34

4.2.3 Profibus Interface................................................................................................................................................................. 4.35

4.2.4 Profibus termination............................................................................................................................................................ 4.36

4.2.5 Profibus DP-parameterization ........................................................................................................................................ 4.36

4.2.6 Communication set up and station

4.2.7 Profibus DP Cyclic Data ..................................................................................................................................................... 4.37

4.2.8 Profibus DP Cyclic Data .................................................................................................................................................... 4.48

4.2.9 Diagnostic Data .................................................................................................................................................................... 4.48

4.2.10 Profibus Protocol communication set-up.................................................................................................................. 4.50

4.2.7.1 EntelliPro ES Cyclic Read Telegram Definitions .................................................................................. 4.38

4.2.7.3 EntelliPro ES Cyclic Write Telegram Definitions.................................................................................. 4.46

addr

esses ............................................ ........................................................... 4.36

Chapter 5: WinESG

4.2.11 Profibus-DP Class1 Parameterizing ..............................................................................................................................4.53

5.1 File menu ...................................................................................................................................... .................................................................. 5.4

5.1.1 Win ESG Configuration ........................................................................................................................................................ .. 5.5

5.1.2 Slave Device Configuration ................................................................................................. ................................................ 5.6

5.2 Options Menu ................................................................................................................................................. .............................................. 5.7

5.2.1 Alarm protocol panel.............................................................................................................................................................. 5.7

5.2.2 Access protection panel……. ................................................................................................................................................ 5.8

5.2.3 Alarm panel………………………. .................................................................................................................................................... 5.9

5.2.4 Time synchronization panel................................................................................................................................................ 5.9

5.2.5 Read all Parameters…………… ................................................................................................................................................ 5.9

5.2.3 Send all Parameters ……………………….................................................................................................................................... 5.9

5.3 Windows menu .............................................................................................................................................................. ............................. 5.10

5.3.1 Control Panel ............................................................................................................................... .............................................. 5.10

5.3.2 Parameterization........................................................................................................................................ ............................. 5.12

5.3.2.1 Info panel .................................................................................................................................................... ......... 5.12

5.3.2.2 Device Setting panel ........................................................................................................................................ 5.14

5.3.2.3 Alarms panel ..................................................................................................................................................... 5.18

5.3.2.4 Function panel .................................................................................................................................................... 5.19

.

5.3.2.5 Timer panel .......................................................................................................................................................... 5.20

5.3.2.6 Counter panel ................................................................................................................................................... 5.21

5.3.2.7 Control panel ...................................................................................................................................................... 5.21

5.3.2.8 Typical settings panel ...................................................................................................................................... 5.23

5.3.2.9 I/O’s panel ............................................................................................................................................................ 5.25

5.3.2.10 Cyclic panel .......................................................................................................................................................... 5.26

Page 7

TAB L E OF CO N T E NTS

5.3.2.11 Modbus setting panel ..................................................................................................................................... 5.26

5.3.2.12 Char (Characteristic) panel ........................................................................................................................... 5.27

5.3.2.13 Diagnostic panel ................................................................................................................................................ 5.27

5.3.2.14 Measure panel .................................................................................................................................................... 5.27

5.3.2.15 Alarm panel.......................................................................................................................................................... 5.28

5.3.3 Debug panel ............................................................................................................................................................................. 5.28

5.4 Tools menu ................................................................................................................................................................ ................................... 5.37

5.4.1 Event protocol

5.4.2 Analog data panel..................................................................................................................................... .............................. 5.38

......

.....

..................

.................

...............................

.................................... ..........................

................

5.4.3 Flexible logic download................................................................................................................ ......................................... 5.39

Chapter 6: EntelliPro CP3 and CP5

6.1 EntelliPro CP3 main panel............................................................................................................................................................................. 6.1

6.2 EntelliPro CP3 application setting.............................................................................................................................................................. 6.6

6.3 EntelliPro CP3 screen saver display......................................................................................................................................................... 6.8

............... 5.37

6.4 EntelliPro CP3 application tree structure

6.5 EntelliPro CP5 main panel

...............................................................................................................................................

............................................................................................................................................... 6.9

......................

6.6 EntelliPro CP5 application setting......................................................................................................................................................... 6.13

6.7 EntelliPro CP5

6.8 EntelliPro CP5 device screen

6.

9 EntelliPro CP5 control screen

device addresses......................................................................................................................................................

....................................................................................................................................................

............... 6.15

..................................................................................................................................................................

6.10 EntelliPro CP5 screen saver display..................................................................................................................................................... 6.17

EntelliPro CP5 installation........................................................................................................................................................................ 6.18

6.11

6.12 EntelliPro CP5 application tree structure.......................................................................................................................................... 6.19

Chapter 7: Revision / Service / Sales

Revision........................................................................................................................................ ................................................................................ ... 7.1

Service for Low voltage equipment ………………………… .................................................................................... ................................................. 7.2

Sales ................................................... .............................................................. ............................... ................................................................................. 7.5

.... 6.11

...... 6.14

6.16

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 8

This page was intentionally left blank

Page 9

CHAPTER 1: INTR ODUCTION

GE Industrial

Solutions

EPOS Motor Management System

Chapter 1: Introduction

This chapter provides an overview of the EPOS Motor Control System. Additional details are provided in subsequent

chapters.

1.1 Overview

The EPOS Electronics Protection and Object Control System is a motor protection system designed specifically

for low-voltage motor applications. It is comprised of the following modules:

EntelliPro ES: a modular control unit that represents the lowest level in the control

The EntelliPro ES can be programmed as an EntelliPro ES retrofit, where the Profibus telegrams match the ESS

DP device. Alternatively, the EntelliPro ES can be programmed as a non-retrofit unit, where additional Profibus

telegrams are made available.

The EntelliPro ES provides the following key features:

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL 1.1

hierarchy of the EPOS system.

EntelliPro CT: a current transformer that is used in conjunction with EntelliPro

ES in a branch-drawout system.

WinESG: a Profibus base programmable software used to configure EntelliPro ES Alarm

handling, read and write parameters.

Optional EntelliPro CP3 or EntelliPro CP5: Modbus-based HMI (human-machine interface). One

HMI is provided as part of the MCC package and is programmed to display metering and other

parameters. Refer to chapter 6 for additional information.

Flexible protection, control, and communication options to suit any low-voltage motor

application.

Small footprint designed specifically for IEC and NEMA MCC applications.

Modular

DIN rail mounting.

Dual, simultaneous communication protocols (Modbus and Profibus) allow simple integration into

monitoring and control systems.

Multiple inputs and outputs.

Eleven pre-programmed motor starter types.

Programmable custom motor starter logic for complex systems.

design reduces the number of spare components for maintenance and testing.

Page 10

CHAPTER 1: INTR ODUCTION

1.1.1 Warnings, cautions, notes, and references

WAR NI NG notices are used in this publication to emphasize that hazardous voltages, currents, or other conditions

that could cause personal injury exist in this equipment or may be associated with its use. Warning notices are also

used for situations in which inattention or lack of equipment knowledge could cause either personal injury or damage

to equipment.

CAUTION notices are used for situations in which equipment might be damaged if care is not taken.

NOTES call attention to information that is especially significant to understanding and operating the equipment . This

document is based on information available at the time of its publication. While efforts have been made to ensure

accuracy, the information contained herein does not cover all details or variations in hardware and software, nor

does it provide for every possible

may be described herein that are not present in all hardware and software systems. GE Industrial Solutions assumes

no obligation of notice to holders of this document with respect to changes

ATEX sign is used to indicate mandatory settings and items for use of EntelliPro to protect motors in in potential

explosive environment.

contingency

in connection with installation, operation, and maintenance. Features

subsequently

made.

GE Industrial Solutions makes no representation or warranty, expressed, implied, or statutory, with respect to, and

assumes no

herein. No warrantees of merchantability or fitness for purpose shall apply.

responsibility

for the accuracy, completeness, sufficiency, or usefulness of the information contained

References

For details of the Modbus RTU protocol, refer to PI-MBUS-300 Rev. J from Modicon/AEG Schneider Automation. For

details of RS-485 communications, refer to the EIA-485 standard.

Modbus RTU® is a registered trademark of AEG Schneider Automation. Modbus® is a registered trademark of

Modicon Inc.

For additional information on the EntelliPro CP3 and CP5 HMI, please refer to the Beijer Electronics H-T40 and H-T70

installation and operation manuals.

For details on Profibus standards, refer to IEC 61158.

1.2 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 11

CHAPTER 1: INTR ODUCTION

1.1.2 Definitions

A, Amps amperes

ATEX EU directives describing what equipment is allowed in an explosive atmosphere environment.

AUX auxiliary

bps bits per second

CP EntelliPro CP3 or CP5

CT current transformer

COM, Comms communications

Ctrl control

DP decentralized peripheral

FLA full load amps

FV full voltage

EPOS electronic protection and object control system

EU European Union

FC Modbus function code

GF ground fault

GND ground

Hz Hertz

GSD device description data

HMI Human Machine Interface

lb pound

Ict primary current in EntelliPro CT

Ir

I/O input and outputs

normal motor operating current

Kohms (ku) kilo-ohms

LED light emitting diode

MAX maximum

MCC motor control center

MIN minimum

mSec (ms) milliseconds

NVM nonvolatile memory

Ops operations

PL phase loss

PLC programmable logical controller

PTC positive temperature coefficient

RTU remote terminal unit

SEC, s seconds

SEV 32, SEN GE Neumuenster switchboard systems

SOS sum of squares

spst single pole-single throw

TCP transmission control protocol

%UB percent unbalance

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 1.3

Page 12

OS

CHAPTER 1: INTR ODUCTION

1.1.3 Description of the EntelliPro ES Motor Control Module

The EntelliPro ES is used in conjunction with CTs in branch-drawout systems. This system consists of LEDs, fuses,

contactors, and additional components required for the control and switching of the branch. The EntelliPro ES

includes the following input/output capabilities:

The following additional functions are available:

Seven to sixteen inputs, depending on the catalog type

Three to eight outputs, depending on the catalog type

erload

Ov

protection

Thermistor protection

EntelliPro ES alarm modules configurable for fault (trip) or warning (alarm)

4–20 mA output sensing

Eleven predefined starter types

Six predefined controls

Start inhibits

Restart timer

Number of starts

Number of contactor closures (each relay has its own counter)

Operating hours

Non-operating hours

Counters for overload, ground fault , and thermistor faults

Time stamp event

Time stamp analog value

The thermal model uses motor protection curves according to IEC 60947 (IEC Class 5 to 40) and incorporates hot/cold

biasing, unbalance biasing, and exponential cooling.

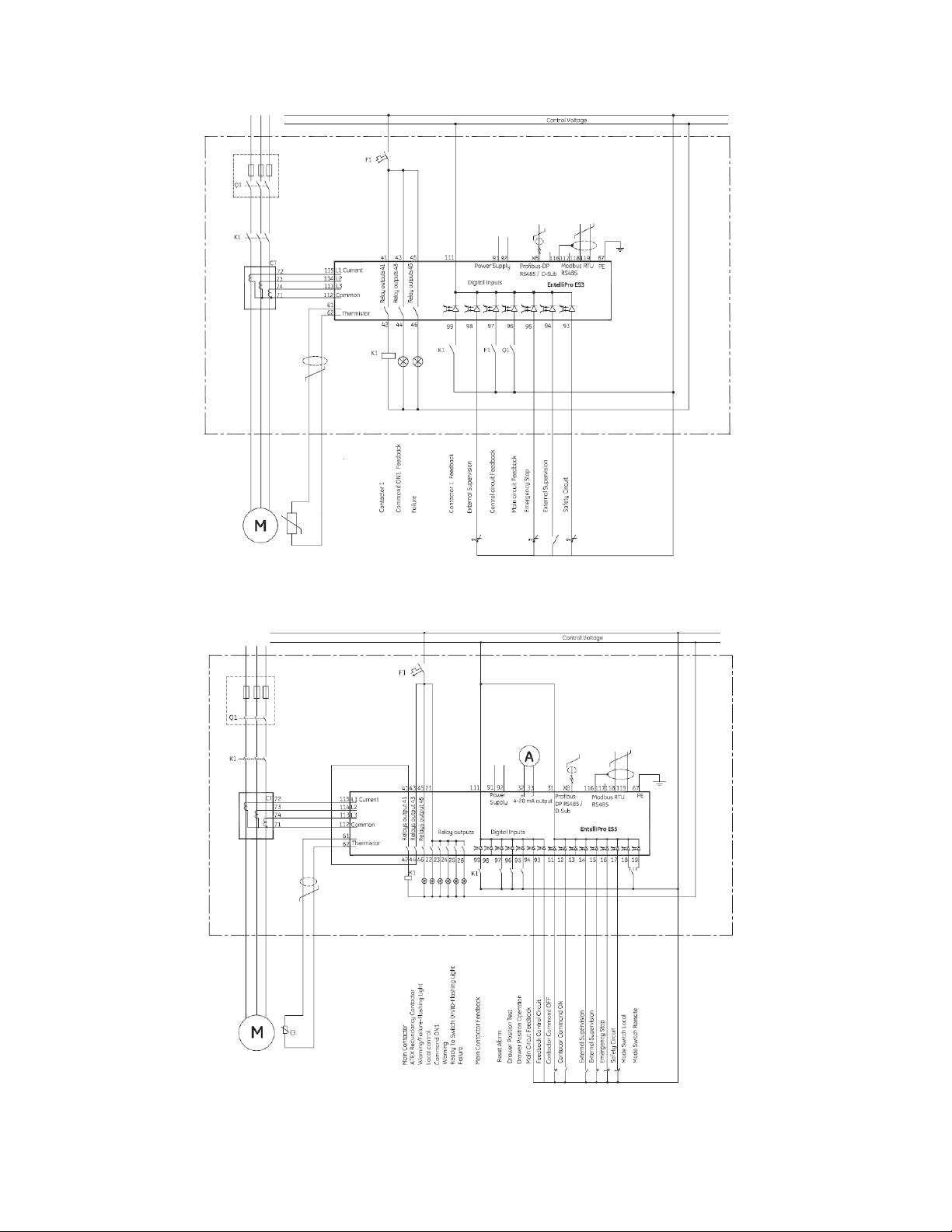

Figure 1-1 shows an example of a single-line system for EntelliPro ES3 and ES5.

1.4 EP

MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 13

CHAPTER 1: INTR ODUCTION

EntelliproES3DOLstandardconfiguration

EntelliPro ES5 DOL standard configuration

Figure 1-1: Single-line diagram

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 1.5

Page 14

CHAPTER 1: INTR ODUCTION

1.1.4 EntelliPro ES order code

Five unique catalog numbers are offered:

EntelliPro ES3 DP 2 0

EntelliPro ES3 DP 3 0

EntelliPro ES5 DP 2 2

EntelliPro ES5 DP 2 3

EntelliPro ES5 DP 3 3

The EntelliPro ES catalog configuration definition is shown below:

EntelliPro ES3 – basic functionally

EntelliPro ES5 – advanced

2 = Additional 9x external inputs rated

24Vdc

8

3 = Additional 9x external inputs rated

110

8

DP = Profibus DP / Modbus

2 = Power supply and 7x Digital Inputs rated

24Vdc.

3 = Power supply and 7x Digital Inputs rated

110/240Vac

0 = No external inputs available.

3

ouput

available.

available.

outputs

available.

- 240

Vac

outputs

available.

available

EntelliPro ES3 DP 2

f

unctionally

RTU

2

1.6 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 15

CHAPTER 1: INTR ODUCTION

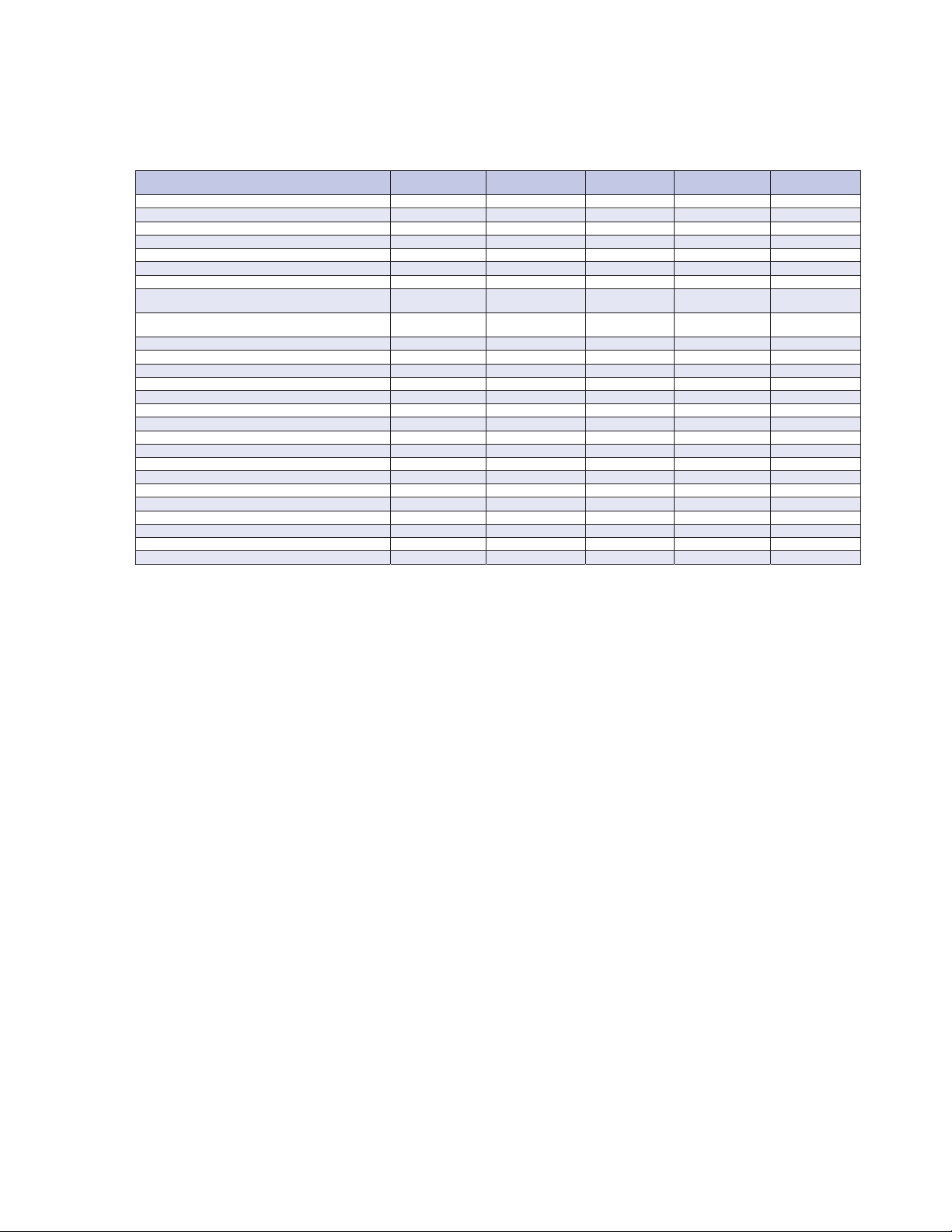

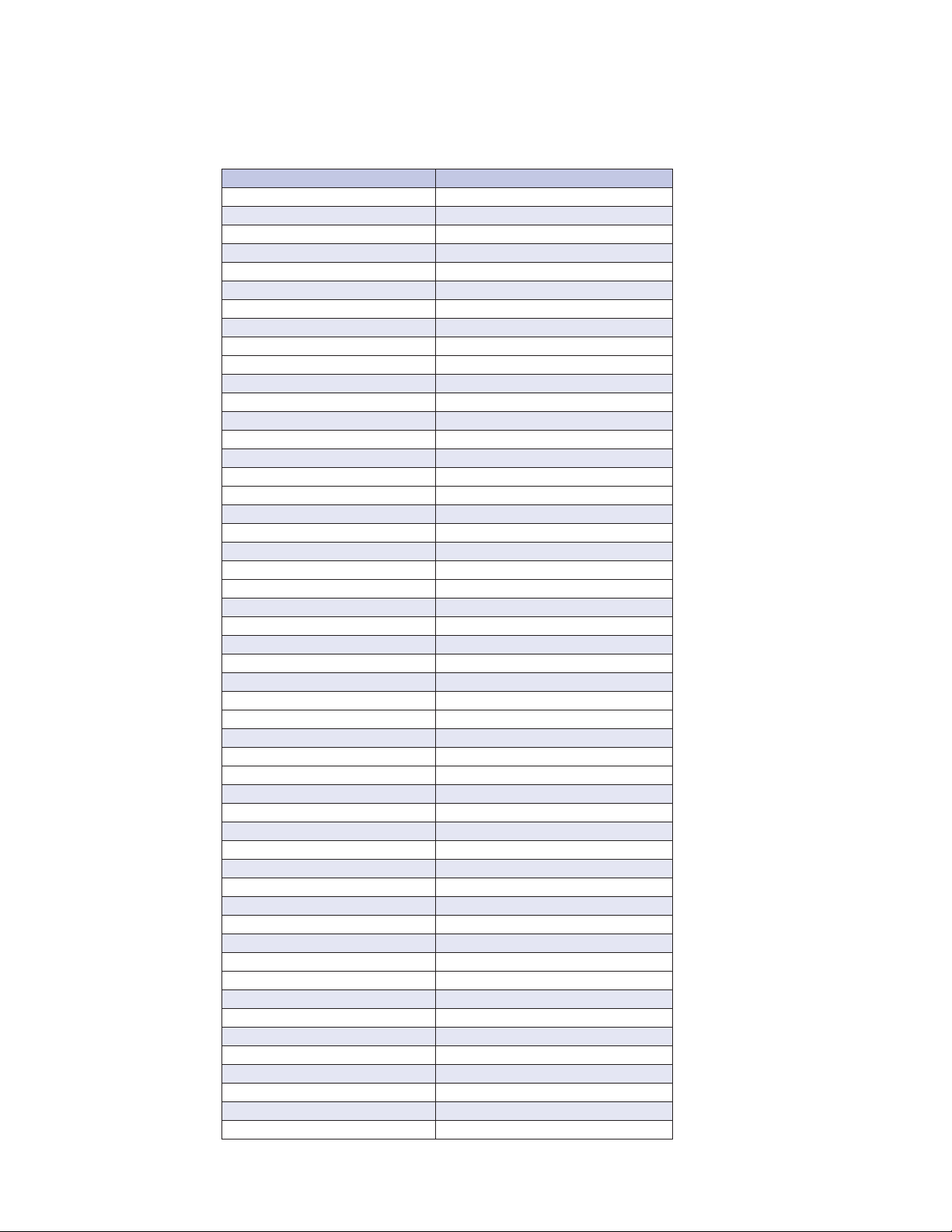

Table 1-1 shows features and protections available for the five catalogs.

Features / Protections

24Vdc

Supply

110/240Vac

24Vdc (7) Digital Input X X

24Vdc (16) Digital Input X

110/240Vac (7) Digital Input X

110/240Vac (9) Digital Input X

110/240Vac (16) Digital Input X

5A 240Vac/2.5A 24Vdc

Output Contact

2A 240Vac/2A 24Vdc

Output Contact

LT (Thermal Overload) X X X X X

Ground Fault X X X X X

Phase Loss X X X X X

Current Unbalance X X X X X

Thermistor function X X X X X

Stalled Rotor X X X X X

Under Current X X X X X

4-20mA Output X X X

Metering X X X X X

Unit

Communication LED X X X X X

Time stamped event logging X X X X X

Time stamped analog value logging X X X X X

11 Pre Programmed Motor Starter Logic X X X X X

Programmable thresholds X X X X X

Operating hours/Swit ch Counter register X X X X X

Communication (Modbus and Profibus) X X X X X

input X X X

Supply

input X X

(qty.

3)

(qty.

5)

Healthy

Indication LED X X X X X

Table 1-1: List of features and protections

EntelliPro

ES3 DP 2 0

X X X X X

EntelliPro

ES3 DP 3 0

EntelliPro

ES5 DP 2 2

X X X

EntelliPro

ES5 DP 2 3

EntelliPro

ES5 DP 3 3

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

1.7

Page 16

CHAPTER 1: INTR ODUCTION

1.1.5 EntelliPro ES Current Transformer Definition

There are three items that must be considered when configuring the motor load level of the EntelliPro ES. The items to

consider are the transformer type, the number of primary windings, and the EntelliPro ES full load current setting (FLA).

Four unique current transformer catalog numbers are offered:

EntelliPro CT 8

EntelliPro CT 32

EntelliPro CT 64

EntelliPro CT 630

The CT catalog configuration definition is shown below:

Current Transformer Designator

Nominal CT Currente

(refer to section 1.2.3 for

current ranges and

Use of the appropriate transformer will allow the FLA setting to be configured in the range of CT/6 to CT. For example , if the

EntelliPro CT 64 transformer is chosen, the FLA setting can be configured from 64/6=10.7 amps to 64 amps in 0.1 amp

increments.

There may be cases where the available transformer types have inappropriate ranges for the application. For example,

when trying to protect the motor load level at 77 amps, the EntelliPro CT 64 is too small. Considering the EntelliPro CT 630

would result in the lowest FLA setting of 630/6=105 amps, which is too large for this application.

This case would require using multiple turns on the CT primary (see figure 1-2 and equation below). The solution to the

77 amp example is to use an EntelliPro CT 630 with two primary turns. The nominal CT current = 630 / 2 = 315 amps. This

would set the FLA range from 52.5 amps (315/6) to 315 amps. So, 77 amps could be selected.

Use of the minimum number of primary turns is recommended.

In addition, these CTs can be used as interposing CTs to increase the primary current.

accuracy).

EntelliPro

CT

8

Nominal CT Current

# of loops

as 2A CT

Nominal Current (CT with loops)

Example using EntelliPro CT 8

Calculating # of primary loops required

# of primary loops = 8/2 = 4 Turns

=

Figure 1-2: Primary feeding loops

1.8 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 17

CHAPTER 1: INTR ODUCTION

1.2 Specifications

NOTE: Specifications are subject to change without notice.

1.2.1 Protection Specifications

Overload Fault (Thermal Model)

IEC Class curves ....................................................................5, 10, 15, 20, 25, 30, 35, 40 (IEC 60947)

Thermal overload pickup ..................................................1.20

Motor full-load current (FLA) ............................................1/6 Ict to Ict in steps of 0.1

Curve biasing

Phase loss: ....................................................................1.83 x Ir

Phase unbalance: .......................................................1.43 x Ir

Timing accuracy....................................................................±10% up to 8 x FLA and ±20% from 8 to 10 x FLA

Elements ................................................. ..................................fault (trip) and warning (alarm) - warning not valid for ATEX

Phase Loss

Range ........................................................................................fixed at 60% (any phase <40% of max phase)

Accuracy...................................................................................±5%

Time delay................................................................................0–15 seconds in steps of 1s (0 = disable)

Timing accuracy.................................................................... ±20%

Elements ................................................................................... fault (trip) and warning (alarm) - warning not valid for ATEX

Current Unbalance

Range.........................................................................................fixed at 30% (any phase <70% of max phase)

Accuracy...................................................................................±5%

Time delay................................................................................0–15 seconds in steps of 1s (0 = disable)

Timing accuracy....................................................................±20%

Elements ................................................. ..................................fault (trip) and warning (alarm)

immediately

Fix to 500ms when ATEX is selected

when ATEX is selected

Ground Fault

Pickup level..............................................................................20–100% of FLA in steps of 10%

Trip time delay band ...........................................................0.1–1.0s in steps of 0.1s (other values will generate an error)

Timing accuracy....................................................................±20%

Elements ................................................. ..................................fault (trip) and warning (alarm)

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 1.9

Page 18

CHAPTER 1: INTR ODUCTION

Thermistor

types:

Sensor

..........................................................................PTC (RHOT = 3.6 kΩ, RRESET = 1.5 kΩ)

Time delay................................................................................500ms

Elements ................................................. ..................................fault (trip) and warning (alarm) - warning not valid for ATEX

Connection ..............................................................................1, 3 or 6 thermistors in series

S

tandard

Max cable length to detect short ..................................AWG 14 = 266m AWG 16 = 160m AWG 20 = 70m

........................................................ .........................IEC 34-11-12

1.2.2 Metering and monitoring specifications

Event Recorder

Capacity....................................................................................250 events

Data storage...........................................................................non-volatile memory

Phase Metering

Accuracy...................................................................................±5% with external CT

Elements ...................................................................................single phase, average

1.2.3 Input specification

Digital Inputs

Fixed pickup ............................................................................16.8Vdc (24Vdc version)

77Vac (110/240Vac version)

Fixed drop-off .........................................................................10Vdc (24Vdc version)

30Vac (110/240Vac version)

UTION: The usage of voltage between the drop-off and pickup range is not recommended.

CA

Recognition time ...................................................................40 msec

Current draw at rated voltage ........................................5ma on 24Vdc (24Vdc version)

7ma on 240Vac (120/240Vac version)

Type

............................................................................................opto-isolated inputs

Maximum input voltage.....................................................28.8Vdc (24Vdc version)

275Vac (120/240Vac version)

1.10 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 19

Phase Current Inputs

Range...............................................................................................8A CT: 1.34–8.0A (10 x CT)

32A CT: 5.30–32A (10 x CT)

64A CT: 10.6–64A (10 x CT)

630A CT: 105–630A (10 x CT)

CHAPTER 1: INTR ODUCTION

Frequency

Accuracy...................................................................................with external CT: ±5% / direct: ±2%

.................................................................................47.5 to 63.0 Hz

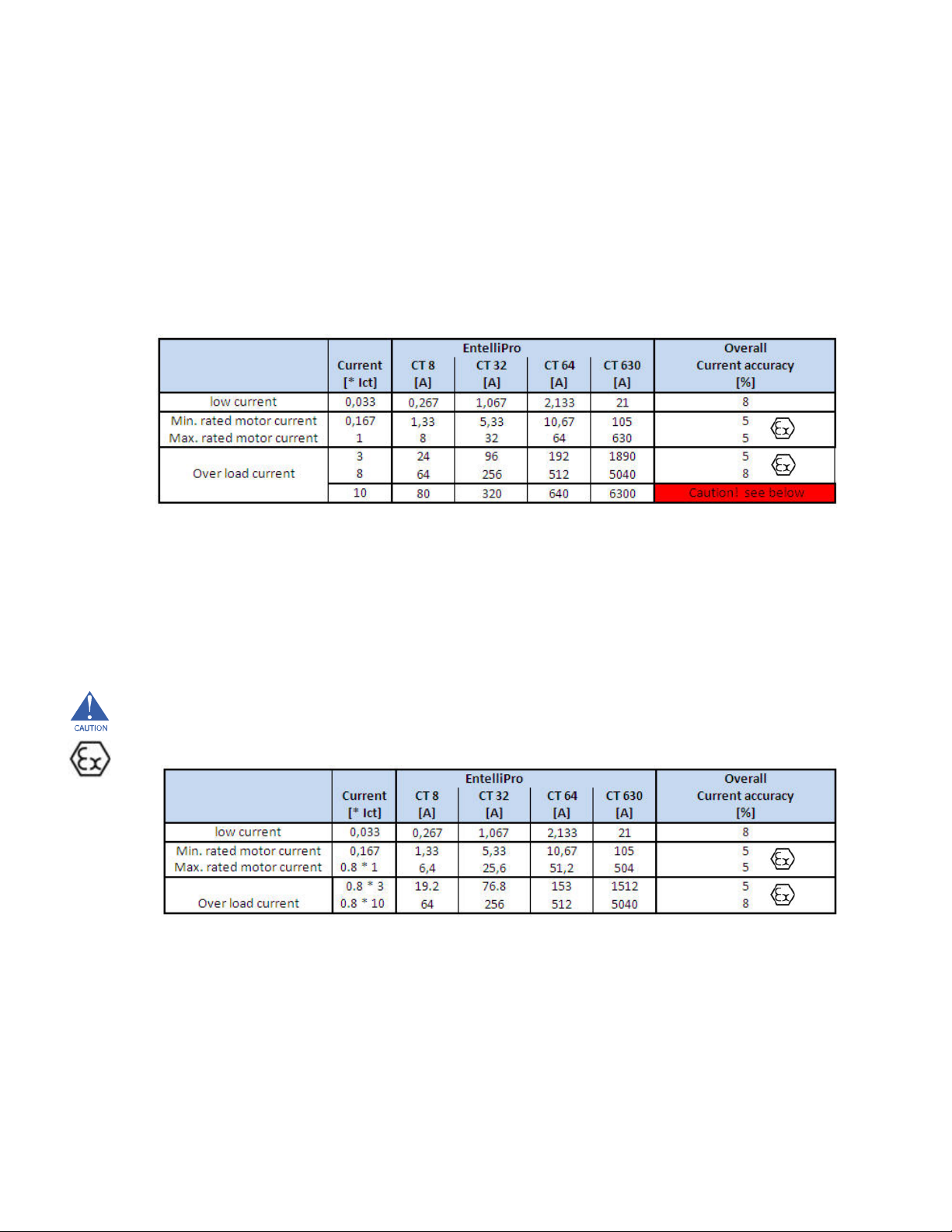

Table 1-2: EntelliPro ES CT types primary current ranges and accuracy

Table below shows the nominal motor current range that the EntelliPro CTs can be used.

The range can be enlarged by feeding multiple primary loops. refer to section 1.1.5.

CAUTION: The overcurrent range above 8*Ict cannot be used to protect motors in explosive areas, due to decrease

accuracy. If motor protection up to 10 *Ict is desired , the nominal current must be derated per the table below.

Example

Motor rated current X is 32 A and motor inrush current is 7X, that is 224 A. EntelliPro CT 32 can be used in ATEX area.

Motor rated current X is 25 A and motor inrush current is 9X, that is 225 A. EntelliPro CT 32 can be used in ATEX area.

Motor rated current X is 32 A and motor inrush current is 9X, that is 288 A. EntelliPro CT 32 must not be used in ATEX area.

Use EntelliPro CT 64 in ATEX area.

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 1.11

Page 20

CHAPTER 1: INTR ODUCTION

1.2.4 Output specifications

4 - 20 mA Output

Accuracy...................................................................................±1% from displayed RMS

Motor Contact Relays

Configuration..........................................................................electromechanical SPST

Contact material ...................................................................silver alloy

Operate time...........................................................................10ms

Minimum contact

load

.......................................................10mA at 5Vdc

Continuous current ..............................................................5A at 240Vac / 30Vdc

Resistive load capacity

Maximum switched power ...............................................150W or 1250VA

Maximum switched current .............................................5A

Maximum switched voltage.............................................150Vdc or 250Vac

Life expectancy

Mechanical ............................................ ..................................20 million operations

Electrical ..................................................................................100,000 operations at 5A, 30Vdc or 250Vac

Application category (for AC-15 and DC-13) ............5A/240VA – AC-15

2.5A / 24Vdc – DC-13

According to IEC-60947-5-1 Normal and Abnormal Conditions

A7DQS or gl 10Amps fuses required

Signal Relays

Configuration..........................................................................electromechanical SPST

Contact material ...................................................................silver alloy

Operate time...........................................................................10ms

Minimum contact

load

.......................................................10mA at 5Vdc

Continuous current ..............................................................3A at240Vac

Resistive load capacity

Maximum switched current .............................................3A

Maximum switched voltage.............................................150Vdc or 250Vac

Life expectancy

Mechanical ............................................ ..................................20 million operations

Electrical ..................................................................................100,000 operations at 5A, 30Vdc or 250Vac

1.12 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 21

CHAPTER 1: INTR ODUCTION

1.2.5 Power supply specifications

This section lists the specifications for the power supply. The power consumptions of the EntelliPro

modules are listed in Table 1-3.

Nominal.....................................................................................24Vdc (24Vdc version)/140mA (max)

110/240Vac (120/240Vac version)/60mA (max)

Range.........................................................................................19–28.8Vdc (24Vdc version)

77–264Vac (110/240Vac version)

Ride-through...........................................................................30ms

1.2.6 Communication specifications

Profibus

Port..............................................................................................opto-isolated

Modes ........................................................................................DP V1 slave, up to 12Mbps

Connector ................................................................................9-pin D connector

S

tandard

...................................................................................IEC 61158

Installation .................................................. .............................PI installation guidelines

Modbus RTU over RS485

Port...............................................................................................opto-isolated

Baud rates ...............................................................................up to 19.2kbps (Modbus

Protocol .....................................................................................half-duplex

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

1.13

Page 22

Pper

CHAPTER 1: INTR ODUCTION

1.2.7 Testing and certification

Test Reference Standard Test Level

Dielectric voltage

withstands

..........................................1.5kV

Impulse voltage

withstand

..............................................EN60255-5

Electrostatic discharge.......................................................EN61000-4-2/IEC60255-22-2 Level 4

RF

immunity

Fast transient

Surge

Conducted RF

............................................................................EN61000-4-3/IEC60255-22-3 Level 3

immunity

disturbance

................. ..................................................EN61000-4-5/IEC60255-22-5 Level 3

immunity

...............................................EN61000-4-4/IEC60255-22-4 Class A

....................................................EN61000-4-6/IEC60255-22-6 Level 3

Radiated and conducted emissions.............................CISPR11 /CISPR22/ IEC60255-25 Class A

Sinusoidal vibration ...........................................................IEC60255-21-1 Class 1

Voltage dip and interruption ..........................................IEC61000-4-11 0, 40, 70% dips, 250/300 cycle interrupts

Harmonics ..............................................................................IEC61000-4-13

Voltage ripple ........................................................................IEC61000-4-17 15% ripple

Environmental (cold)................................................. .........IEC60068-2-1 -25° C, 96 hrs

Environmental (dry heat) .................................................IEC60068- 2-2 70° C, 96 hrs

Relative humidity

cyclic

...................................................IEC60068- 2-30 6-day variant 2

Short-circuit current*.........................................................IEC60947-5-1

Pollution degree...................................................................I

Rated impulse withstand voltage ............................4kV

Overvoltage category II according to IEC 60947-1 7.2.3.1 item 2) b)

(when EntelliPro ES is directly connected to the main voltage)

Overvoltage category III according to IEC 60947-1 7.2.3.1 item 2) b)

(when EntelliPro ES is not directly connected to the main voltage)

ATEX certificatio

SIL1

Profibus certification

*CAUTION: A maximum A7DQS or gl 10A fuse is required on motor relays.

1.14 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 23

CHAPTER 1: INTR ODUCTION

1.2.8 Approvals

Applicable Council Directive According to Low-Voltage Directive EN60255-5, EN61010-1

CE compliance: EMC Directive EN50263 / EN61000-6-2/ EN61000-6-4

ISO: Manufactured under a registered quality program – ISO9001

ROSH compliance:

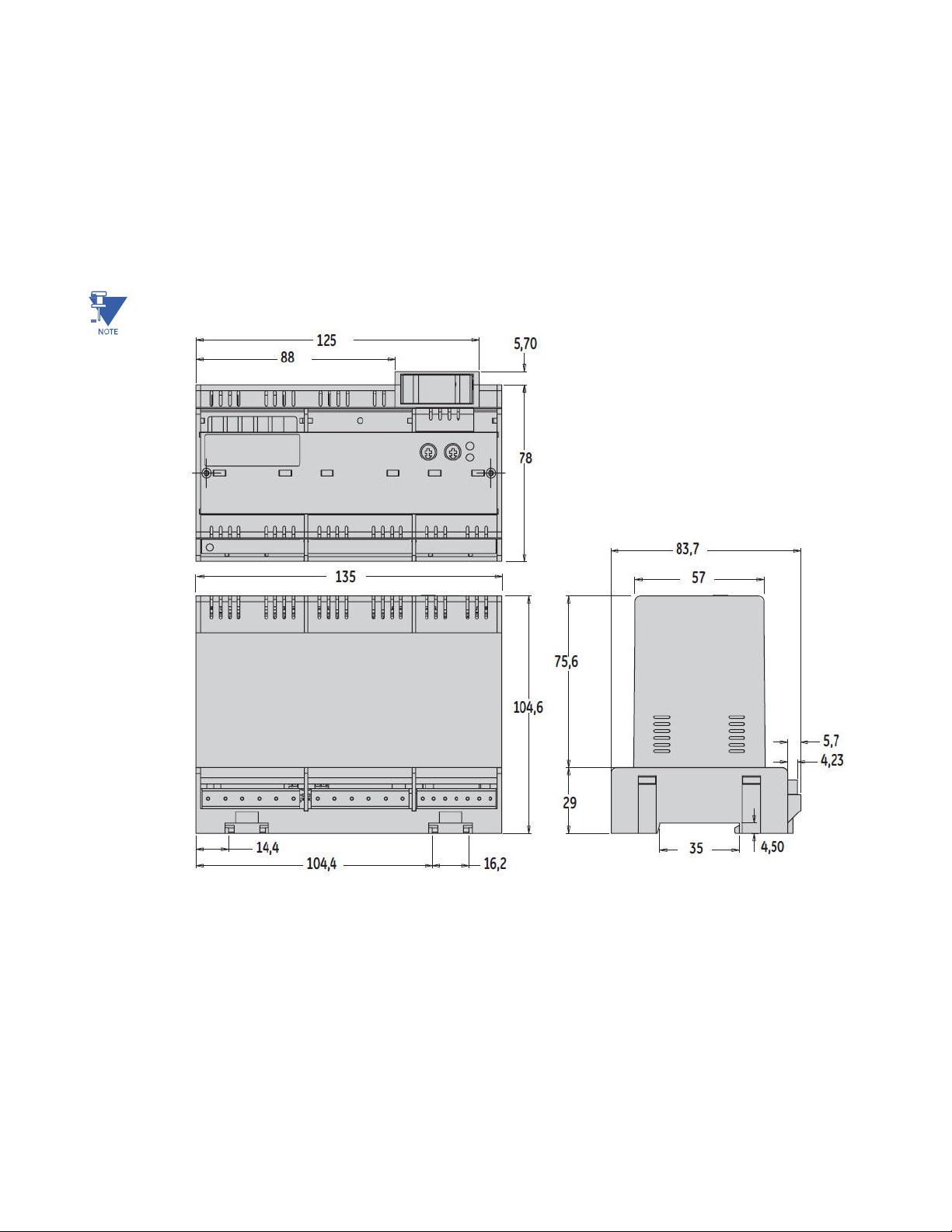

1.2.9 Physical specifications

The size and weight of the EntelliPro ES module is as follows:

Size ..............................................................................................135mm (W) x 82.5mm (H) x104.5mm (D)

Weight ………………………………….................................................0.45kg

1.2.10 Environmental specifications

Ambient temperatures .......................................................storage/shipping: –40° to 90° C

Humidity

...................................................................................operating up to 95% (non-condensing) at 55° C (per IEC60068

operating: –20° to 60° C

2- 30 Variant 2, 6

days)

operating up to 95% (non-condensing) at 55° C (per IEC60068-

2- 30 Variant 2, 6 days)

Altitude

......................................................................................2000m (max)

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

1.15

Page 24

CHAPTER 1: INTR ODUCTION

1.3 EntelliPro CP3/CP5 HMI

The EntelliPro CP3 and CP5 HMI, shown in Figure 1-3, is a microprocessor-based device that connects to an

standard

Modbus RTU on RS-485 wiring.

The HMI is factory programmed to communicate with the EntelliPro ES devices in a MCC environment in order to

provide a convenient station for viewing metering, status and setting information and controlling contactors

operations.

EntelliPro CP5 HMI can be connected to multiple EntelliPro ES devices in the MCC network, while the EntelliPro CP3

HMI is mainly connected to a single EntelliPro ES device.

For additional information on the HMI refer to www.beijerelectronics.com.

industry-

Figure 1-3: HMI front screen

1.16 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 25

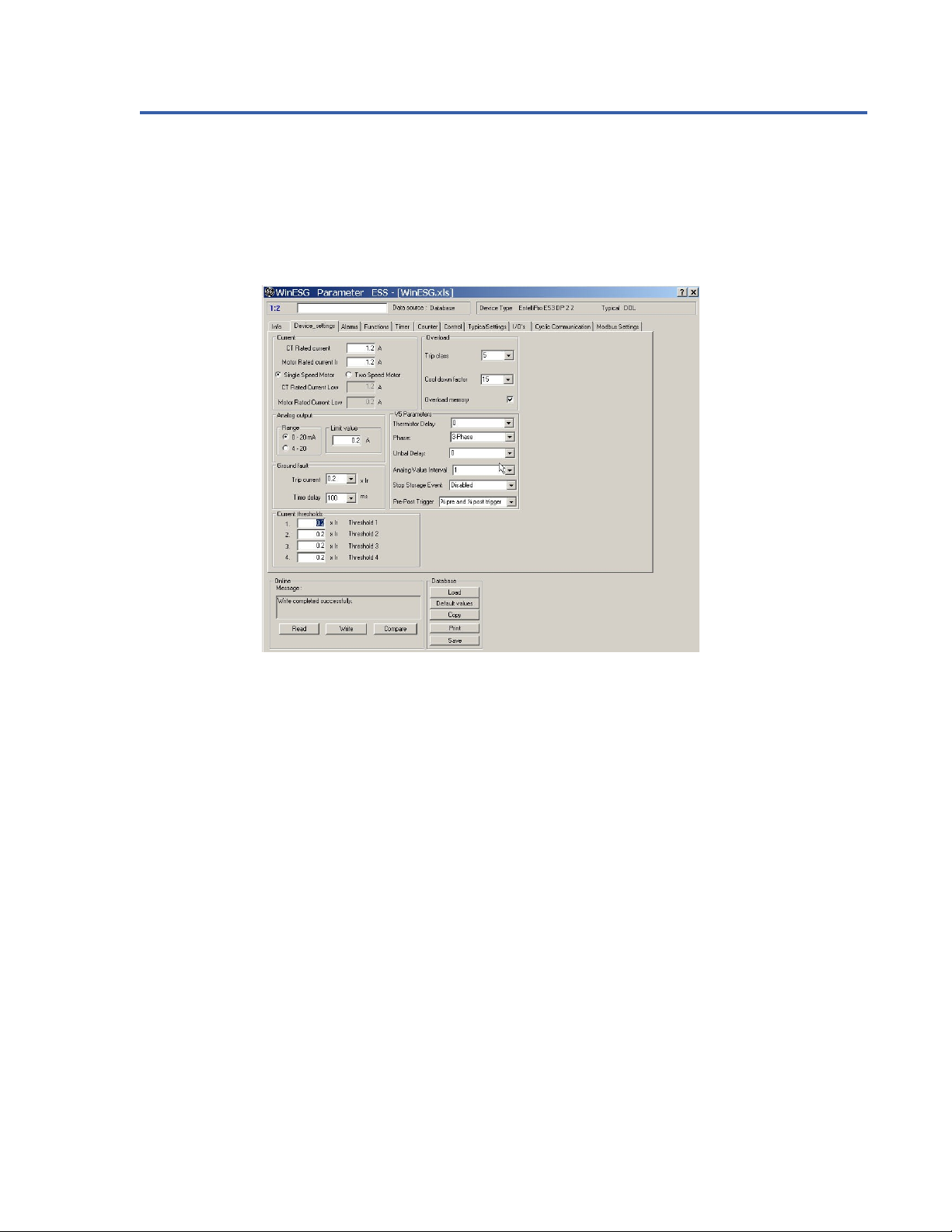

1.4 WinESG Configuration Tool

WinESG is a Profibus-based HMI used with the EPOS System to configure the EntelliPro ES. It provides the capability

for a full parameterization and configuration of the EntelliPro ES devices. In addition it supports metering, event log,

analog data retrieval, and downloading of custom logic application. Refer to Chapter 5 for detailed operation of the

WinESG.

Figure 1-4 shows the parameterization panel view of the WinESG Set-up software.

CHAPTER 1: INTR ODUCTION

Figure 1-4: WinESG Panel

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 1.17

Page 26

CHAPTER 2: INSTALL ATION/CONFIGURATION

GE Industrial Solutions

EPOS Motor Management System

Chapter 2: Installation / Configuration

2.1 Installation and initial operating

The EntelliPro ES is an intelligent motor control relay that is mainly installed in low voltage systems for industrial usage.

To ensure safe operation, several measures must be taken.

CAUTION: Only use genuine draw out units produced by the factory. Observe proper cable laying in the cable terminal

compartment and outside the switch cabinet.

CAUTION: Only qualified personnel are allowed to install, commission, maintain or modify this device in accordance

with relevant requirements.

The following tables show the recommended cable type and spacing.

Cable type Category

power cable (400VAC....) A

control cable B

function cable (TMA, ...) C

bus cable D

Table 2-1: Recommended EntelliPro ES Cable listing

Table 2-2: Recommended cable spacing

NOTES:

Do not use multi-stranded cable with combinations from categories A to D.

The PE-connection of the EntelliPro ES must be connected.

The maximum length of the connection cable to the current transformer is 20 cm.

Before initial commissioning of the installation the communication bus wiring and the signal quality must be

tested with a Profibus/Modbus test and diagnostic device.

All wires connected to the EntelliPro ES- modules must be checked prior to operation.

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 2.1

Page 27

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.1.1 Mechanical installation

This section describes the mechanical installation of the EPOS system, including dimensions for mounting and

information on module withdrawal and insertion.

2.1.1.1 Dimensions

The EntelliPro ES is packaged in a modular arrangement . Figure 2-1 shows the dimensions of the EntelliPro ES.

NOTE: All dimensions are in mm.

Figure 2-1: EntelliPro ES Dimension

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

2.2

Page 28

OS

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.1.1.2 Product identification

The product identification label is located on top of the EntelliPro ES module. This label indicates the product catalog

number (EntelliPro ES5 2 2), reference number, terminal numbers, relay rating, power supply rating, and agency

certification among other parameters. The fiigure below shows an example of the label.

Figure 2-2: EntelliPro ES label example

2.1.1.2.1 Label Definition

The following description is applicable to the label in figure 2-2.

EntelliPro ES5 DP 2 2 defines the catalog number of the device.

Ref-No. is a GE defined number for the unit .

Relays 41, 43, and 45 are motor relays rated AC-15 5A/240Vac and DC-13

2.5A/24Vdc Supply Voltage A1+ A2-: 24V DC, indicates that the power supply for this

unit is 24Vdc. Terminal definitions:

N Modbus – connection

P Mobdbus + connection

Gd Modbus common connection

Sh Shield connection

L1 Phase L1 connection

L2 Phase L2 connection

L3 Phase L3 connection

Phases L1/L2/L3 common connection

0V(111) Digital inputs (93…99) common

0V(31) External Digital inputs (11…19) common

DSub RS485 Profibus indicates the Profibus DP connection

EP

2.3

MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

Page 29

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.1.1.3 Mounting

CAUTION: To avoid the potential for personal injury from fire hazards, ensure the unit is mounted in a safe

location and/or within an appropriate enclosure. Unit must be un-powered and all connectors removed

during installation.

The EntelliPro ES can be DIN mounted using DIN rail to the equipment . The DIN rail mounting, removal, wire

connection and connector insertion and removal are illustrated in Figure 2-3.

Steps for installation and removal:

A. Secure DIN Rail (see Item A) to the panel with an appropriate fastener.

B. To insert the unit , snap the EntelliPro ES to the Din rail while releasing the pressure on the unit

mounting tabs (see Item B). To remove lift the unit out while holding the tabs up with a

screwdriver or another appropriate tool.

C. To insert the connector simply push the connecter toward the EntelliPro terminal (see Item

C). Ensure you have the appropriate connector. To remove, separate the connector from the

housing using the tip of a small screwdriver (see Item C) or other appropriate tool.

D. Insert each wire into the connector (see Item D) and tighten the connection using the torque

shown in the figure. Lightly pull on the wire to check the connection.

E. Use a small screwdriver or other appropriate tool to adjust the Modbus and Profibus

communication address switch (see Item E).

1 x

2,5mm²

AWG...

Address

A

D

9

C

119-111 99-91

EntelliProES

11-19 21-26 31-39 41-46 51-57 61-67

4 4

2 6 2

0 0

D

10

E

72-71

6

COM

8

RUN

50022

EN

12

Address

G = default

C

B

B

Figure 2-3: EntelliPro ES DIN rail mounting and removal

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

2.4

Page 30

OS

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.1.1.4 EntelliPro ES Connector terminal identification

The EntelliPro ES connectors pinout and description are shown in Table 2-3

Connector Number Description

11 Digital Input ( 24Vdc + or 110/230vac)

12 Digital Input ( 24Vdc + or 110/230vac)

13 Digital Input ( 24Vdc + or 110/230vac)

14 Digital Input ( 24Vdc + or 110/230vac)

15 Digital Input ( 24Vdc + or 110/230vac)

16 Digital Input ( 24Vdc + or 110/230vac)

17 Digital Input ( 24Vdc + or 110/230vac)

18 Digital Input ( 24Vdc + or 110/230vac)

19 Digital Input ( 24Vdc + or 110/230vac)

Table 2-3: Connector number and description

21 Common for

22 Signal

23 Signal

24 Signal

25 Signal

26 Signal

31 Digital Inputs Common for Inputs 11 to 19

32 4– 20 mA Output (+)

33 4-20 mA Output ( -)

41 Digital Motor

42 Digital Motor

43 Digital Motor

44 Digital Motor

45 Digital Motor

46 Digital Motor

61 PTC Temperature Sensor

62 PTC Temperature Sensor

67 Ground (PE)

91

92

93 Digital Input (24Vdc+ or 110/230Vac)

94 Digital Input (24Vdc + or 110/230vac)

95 Digital Input (24Vdc + or 110/230vac)

96 Digital Input (24Vdc + or 110/230vac)

97 Digital Input (24Vdc + or 110/230vac)

98 Digital Input (24Vdc + or 110/230vac)

99 Digital Input (24Vdc + or 110/230vac)

111 Digital Inputs Common for Inputs 93 to 99

112 CT output , Common

113 CT output , Phase L3

114 CT output , Phase L2

115 CT output , Phase L1

116 Shield

117 Communication Common

118 Modbus D-Positive

119 Modbus D-Negative

Supply

Supply

Relay

Outpus 22 to 26

Relay 22

Output

Relay 23

Output

Relay 24

Output

Relay 25

Output

Relay 26

Output

Relay

Output 41

Relay

Output 41 RTN

Relay

Output 43

Relay

Output 43 RTN

Relay

Output 45

Relay

Output 45 RTN

Voltage (24Vdc - or 110/230Vac)

Voltage (24Vdc + or 110/230Vac)

EP

2.5

MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

Page 31

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.1.2 Electrical installation

This section describes the electrical installation of the EntelliPro ES motor relay.

CAUTION: EntelliPro ES is not to be used in any way other than described in this manual.

2.1.2.1 Power supply connection

EntelliPro ES3 DP 2 0 and EntelliPro ES5 DP 2 2 are 24Vdc supply input versions, while EntelliPro ES3 DP 3 0,

EntelliPro ES5 DP 3 2, and EntelliPro ES5 DP 3 3 are 110 to 240Vac versions.

The operation range for the 24Vdc units is 19Vdc to 29Vdc. The operation range for the 110 to 240Vac units is

77Vac to 266Vac.

CAUTION: Check the voltage rating of the unit before applying control power. Control power outside of the operating

range of the power supply will damage the EntelliPro ES.

Figure 2-4 shows the EntelliPro wiring connections. Refer to Item A for power supply connections.

Figure2‐4:EntelliProESwiringconnections

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

2.6

Page 32

CHAPTER 2: INSTALL ATION/CONFIGURATION

phase current input connections.

2.1.2.2 Communication connection

Two two-wire RS485 ports (Modbus RTU and Profibus) are available. Up to 32 EntelliPro ES relays can be daisy- chained

together on a communication channel without exceeding the driver capability. Commercially available repeaters can

be used to add more than 32 relays. A suitable cable should have the characteristic impedance of

120 ohms (for example, Belden #9841) and total wire length should not exceed 1200 meters (4000 ft .). Commercially

available repeaters will allow for transmission distances greater than 1200 meters.

Voltage differences between remote ends of the communication link are not uncommon.

For this reason, surge protection devices are internally installed across all RS485 terminals. Internally, an isolated

power supply with an optocoupled data interface is used to prevent noise coupling.

CAUTION: To ensure that all devices in a daisy-chain are at the same potential, it is imperative that the common

terminals of each RS485 port are tied together and grounded only once at the master or at the EntelliPro ES. Failure to

do so may result in intermittent or failed communications.

Refer to Figure 2-4, Item B for Modbus communication connections. Profibus connections are made on

disconnect

. F or

information on Profibus cable types and lengths, refer to the installation guide for Profibus wiring on the PI

Center home page http://www.Profibus.com/nc/downloads.

2.1.2.3 Thermistor connection

A positive temperature coefficient (PTC) thermistor can be directly connected to the EntelliPro ES TMA terminals. Refer

to Figure 2-4, Item C, for thermistor connection. Connection must be in accordance to IEC 34-11-2.

2.1.2.4 Phase Current Connection

The EntelliPro ES has three channels for phase current inputs. The phase CTs should be chosen so the FLA is not less

than 1/6 of the rated phase CT primary. Ideally, the phase CT primary should be chosen such that the FLA

is 100% of the phase CT primary or slightly less, never more. This will ensure maximum accuracy for the current

measurements. The maximum phase CT primary current is 6400A, with additional interposing CT.

CAUTION: Polarity of the phase CTs is critical for the ground fault calculation. Refer to Figure 2-4, Item D for typical

2.1.2.5 Input/output connection

EntelliPro ES has 16 inputs, 3 form A motor output relays and 5 form A signal output relays.

NOTE: The number of Inputs and outputs depends on the catalog number.

Inputs can be mapped to any of the input functions, such as contactor 1 On command, contactor 2 On command,

contactor feedback, etc. Inputs can also be configured as active high or low signals. In an input is configured as active

low, the input will be active if the voltage is below the fixed drop-off threshold. If an input is configured as active high,

the input will be active if the voltage is above the fixed pick-up threshold. Refer to section 1.2.3 for input electrical

specification. The complete list of input mapping is shown in Table 2-4.

Refer to Figure 2-4, Items E (outputs) and F (inputs), for typical output and input connections.

EP OS MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL 2.7

Page 33

CHAPTER 2: INSTALL ATION/CONFIGURATION

Digital Input Mapping

Active High Signal Active Low Signal

ON1 Command ON1 Command

ON2 Command ON2 Command

OFF Command OFF Command

Main Contactor 1 Feedback

MCCB ON Feedback

Main Contactor 2 Feedback

MCCB OFF Feedback

Start Contactor Feedback Signal

Breaker Charged Status Signal

Bypass

Feedback

Limit Switch 2 Limit Switch 2

Limit Switch Close Limit Switch Close

Feedback 4 Feedback 4

Delta Contactor Feedback Signal

Soft Starter Up to Speed feedback

Torque Swit ch1

Torque Ope n Torque Ope n

Breaker tripped2 Breaker Tripped2

External Fault Signal 1 (External Supervision) External Fault Signal 1 (External Supervision)

External Supervision Feedback External Super vision Feedback

Breaker

ready

for Switch On Breaker

Torque Clo se Torque Cl ose

Torque Swit ch 2 Torque Switch 2

Drawer Test Position Signal Drawer Test Position Signal

Drawer Operation Position Signal Drawer Operation Position Signal

Remote Input Signal Remote Input Signal

Local Input Signal Local Input Signal

Reset Alarms Input Signal Reset Alarms Input Signal

Main Circuit Feedback Main Circuit Feedback

Control Circuit Feedback Control Circuit Feedback

Emergency

Stop Signal

Safety Circuitry

Limit Switch 1 Limit Switch 1

Limit Switch Open Limit Switch Open

Soft Starter External Fault Soft Starter External Fault

Breaker Tripped 1 Breaker Tripped 1

External Fault Signal 2 (External Supervision) External Fault Signal 2 (External Supervision)

Signal

Main Contactor 1 Feedback

MCCB ON Feedback

Main Contactor 2 Feedback

MCCB OFF Feedback

Start Contactor Feedback Signal

Breaker Charged Status Signal

Bypass

Feedback

Delta Contactor Feedback Signal

Soft Starter Up to Speed feedback

Torque Swit ch1

Ready

for Switch On

Emergency

Stop Signal

Safety Circuitry

Signal

Table 2-4: Input mapping

EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

2.8

Page 34

OS

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.1.2.6 4-20mA output connection

Refer to Figure 2-4, Item G, for typical 4-20mA connections.

2.1.2.7 Dielectric strength testing

It may be required to test a complete motor starter for dielectric strength (“flash” or “HIPOT”) with the EntelliPro ES

Installed. The EntelliPro ES is rated for 1.5 kV AC for 1 second isolation between relay contacts, EntelliPro ES

CT inputs and the PE terminal (66). Some precautions are required to prevent damage to the EntelliPro ES during

these tests.

To avoid damage to filter capacitors and transient suppressors by continuous high voltage, disconnect the PE

terminal during testing of power supply inputs. The CT inputs, inputs, and output relays do not require any special

precautions. Low voltage inputs (less than 30 volts), and RS485 communication ports are not to be tested for

dielectric strength under any circumstance.

EP

2.9

MOTOR MANAGEMENT SY STEM – INSTRUCTION MANUAL

Page 35

Profibus Class 1 master module.

CHAPTER 2: INSTALL ATION/CONFIGURATION

2.2 Motor Control Configuration

This section is split into two parts; one for an expert integrator requiring a full knowledge of all

parameters and configuration and the other requiring minimal knowledge to configure the EntelliPro ES.

For the expert user, refer to section 2.2.1. For non-expert user, refer to sections 2.2.2.

2.2.1 Motor Control Detailed Configuration

The EntelliPro ES can control the motor (start, stop, reset …) by four means: Profibus class 1, which can be

PLC or other automation systems, Modbus RTU master, which can be the EntelliPro CP or other Modbus

RTU base system, Hardwire and WinESG.

The first step in the configuration is to assign the four sources (Profibus class1, CP/Modbus RTU, Hardwire,

WinESG) as locals or remote. This is done in WinESG parameterization/control panel shown in the illustration

below or Modbus function code 6 register 115. If a source is not assigned as remote, it automatically becomes

a local source if enabled by checking the box to the right of the source. Only one remote source can be

selected.

NOTE: If Profibus Class 1 is enabled, the remote source selection can only be set to Class 1.

In addition EntelliPro ES provides a “local-remote-off” switch which selects if locals or remote sources control

the motor ON/OFF operation.

NOTE: Only one source can control the switch.

The following sources can be configured as the controller of the “local-remote-off ” switch configuration:

Profibus Class 1

CP / Modbus RTU The “local-remote-off” switch can only be configured

The “local-remote-off ” switch can only be configured over

over Entellipro CP / Modbus RTU module or other

Modbus masters modules.

Hardwire The “local-remote-off” switch can only be configured with

hardwired input. Switch must be connected to the input

and the input mapped accordingly.

2.10 EP OS MOTOR MANAGEMENT SYSTEM – INSTRUCTION MANUAL

Page 36

CHAPTER 2: INSTALL ATION/CONFIGURATION

Fixed Local Control commands (start, stop, reset etc) can only be issued

by local sources. See section 2.2.1.1 for the local source

listing.

NOTE: If the hardwire connection is set to 1-bit (level)

then locals CP / Modbus RTU and WinESG are disabled. If

hardwire connection is set to 2-bit (edge) input

configuration, the locals CP

/ Modbus RTU and WinESG controls are enabled. See

section 2.2.1.2 for detail of 1-bit and 2-bit configurations.

Fixed Remote Control commands (start, stop, reset etc) can only be issued

by the remote source. See section 2.2.1.1 for the

remote source listing.

The control of the “local-remote-off” switch can be set in WinESG parameterization/control panel or by configuring

Modbus RTU register 115. The switch control in WinESG is shown below:

2.2.1.1 Local and Remote Sources Listing

Local sources are defined as hardwire, CP / Modbus RTU or other Modbus RTU modules, and WinESG.

Remote control sources are defined as hardwire, Modbus RTU or other Modbus RTU modules, and Profibus Class 1,

which can be PLC or other Profibus based automation system.

2.2.1.2 Input Configuration

Input can be configured as 1-bit or 2-bit . If set to 1-bit then a single input is used to control the contactor closing

and opening. If set to 2-bit, one input will be mapped to close the contactor and a different input use to open the

contactor.

The same is applicable to Profibus communication. If set to 1-bit , a single ON1 (or ON2) bit is use to turn the

contactor on and off. If using 2-bit, ON1 (or ON2) bit is used to turn on the contactor and OFF bit is use to open the

contactor.

2.2.1.3 Motor Control via Modbus Configuration

Table 2-5 shows the Modbus register mapping of remote source and switch control selections. By setting register 115