Page 1

1

Envelope

Size

Catalog #

Envelope 1

G20HCHT

Envelope 2

G40MCHT

Envelope 3

G64LCHT

Envelope 3-

200kA

G64WCHT

EntelliGuard ® G Circuit Breaker

Accessories

Arc Chute Assembly

WARNING: Before installing any accessories, turn the

breaker OFF, disconnect it from all voltage sources,

and discharge the closing spings.

AVERTISSEMENT: Avant d’installer tout accessoire,

mettre le disjoncteur en position OFF, le déconnecter

de toute tension d’alimentation , et décharger les

resorts d’armement

DEH-41389 Installation Instructions

.

Arc Chute:

Arc chutes are supplied with the Entelliguard

breaker. In cases where it needs the field

replacement, they are supplied as spares.

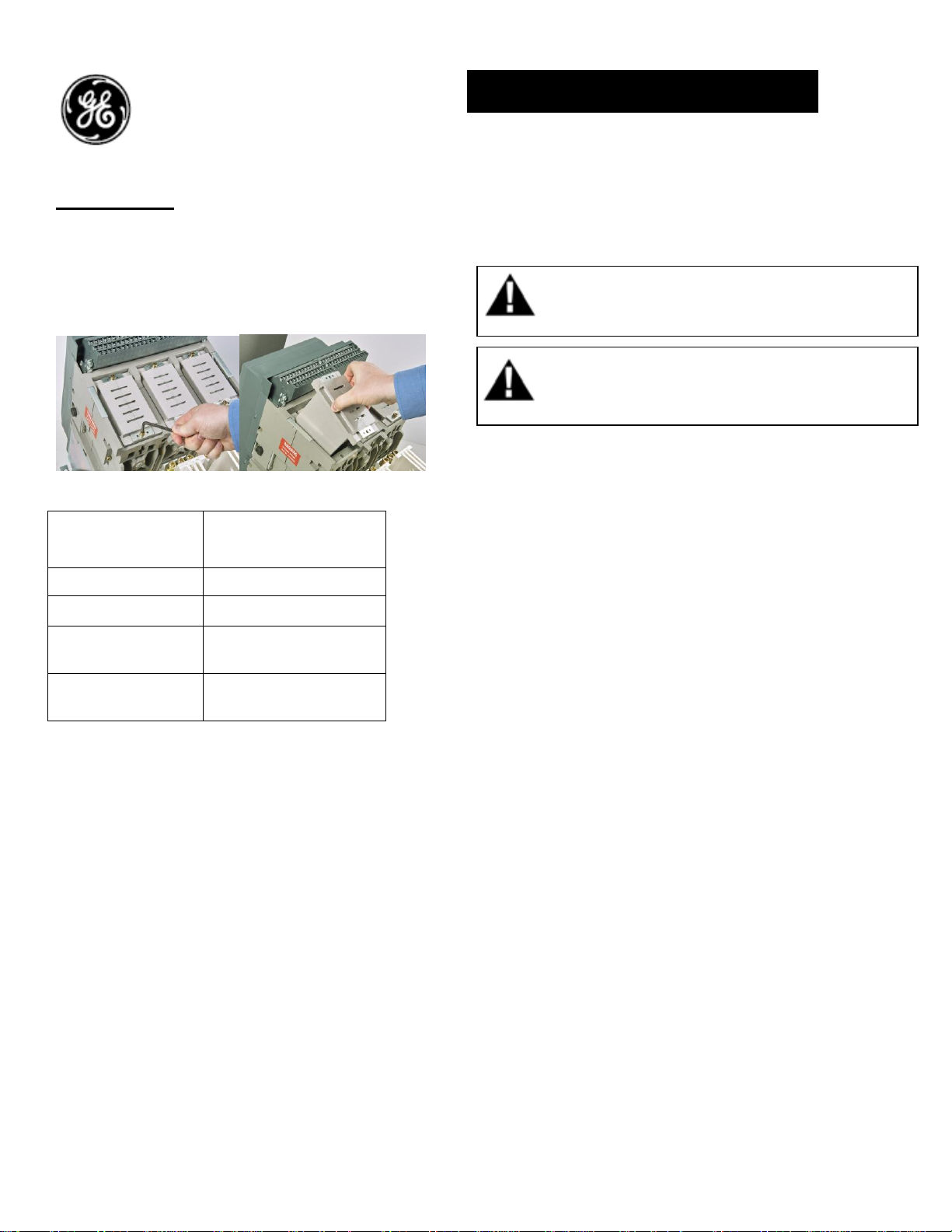

Figure A Figure B

Arc chamber assembly removal & inspection:

1 Turn the breaker off and discharge the

closing springs by depressing the OFF and

ON buttons in the sequence OFF-ON-OFF.

Verify that the breaker OFF-ON indicator

shows OFF on a green background and

that the charge indicator shows

DISCHARGE on a white background. If

installing in a draw-out type breaker

remove breaker from adaptor (cassette)

before continuing.

2 The breaker should be safely isolated and

fully removed from the cassette (for

drawout breaker)

3 Loosen the M6 mounting screws of arc

chamber to the housings as shown in fig

A

4 Gently lift the Arc chamber assembly as

shown in fig B.

5 Inspect the arc plates and sides of the

moldings for signs of wear or damage

and replace if necessary.

6 Install the arc chamber assembly by

tightening the mounting screws to torque

of 8-10 Nm (5.9 – 7.4 ft-lbs)

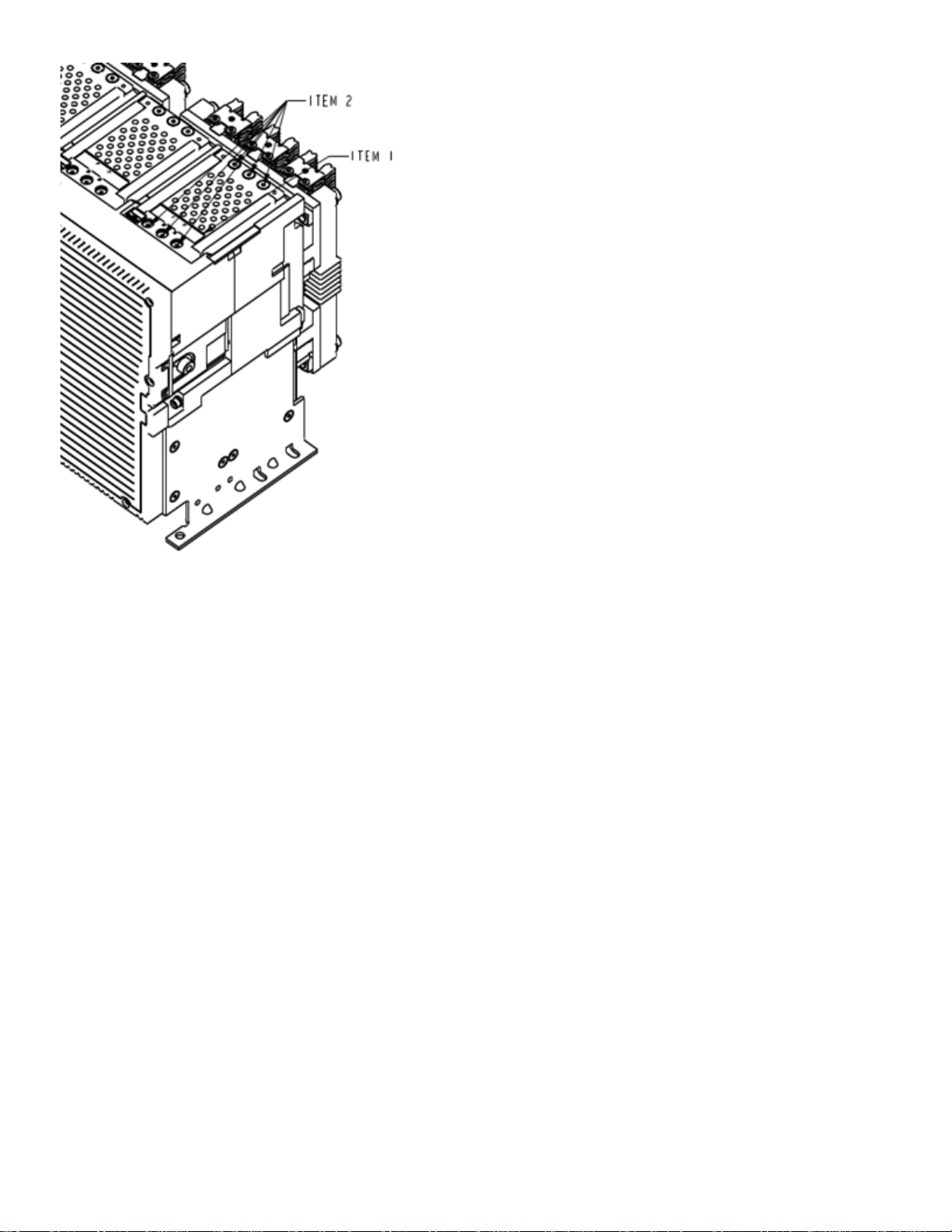

Arc chamber assembly removal & inspection for

Fr-3 200kA:

1 Follow Step 1 and 2

2 Slide out ITEM No 1 and loosen six numbers

of M6 mounting screws of arc chamber to

the housing as shown in figure C

3 Gently lift the Arc chamber assembly as

shown in fig B.

Page 2

2

4 Inspect the arc plates and sides of the

moldings for signs of wear or damage

and replace if necessary.

5 Install the arc chamber assembly by

tightening the mounting screws to

torque of 8-10 Nm (5.9 – 7.4 ft-lbs)

6 Slide in the slider back to original

position

Figure C

Page 3

3

These instructions do not purport to cover all details or variations in equipment nor, to provide contingency to be met in connection

with installation, operation, or maintenance. Should further information be desired, or should particular problems arise which are not

covered sufficiently for the purchaser’s purposes, the matter should be referred to GE.

GE

41 Woodford Ave, Plainville, CT 06062

www.geelectrical.com

© 2009 General Electric Company

Loading...

Loading...