Page 1

g

p

g

quip

p

y

GEH5673 Installation Instructions R03

Spectra Series™ Power Panelboards

Circuit Breakers and Modules

WARNING: Danger of electrical shock or injury.

OFF

Turn

switchboard before workin

ment or removing any component. Do

e

not remove circuit

other component until the power is turned

OFF.

ower ahead of the panelboard or

inside the

rotective devices or an

General

These instructions apply to the following catalog numbers:

• Circuit breaker modules AMC4GB and AMC6GB

• Circuit breaker frames SGDA, SGHA, SGLA and

SGPA

Installation

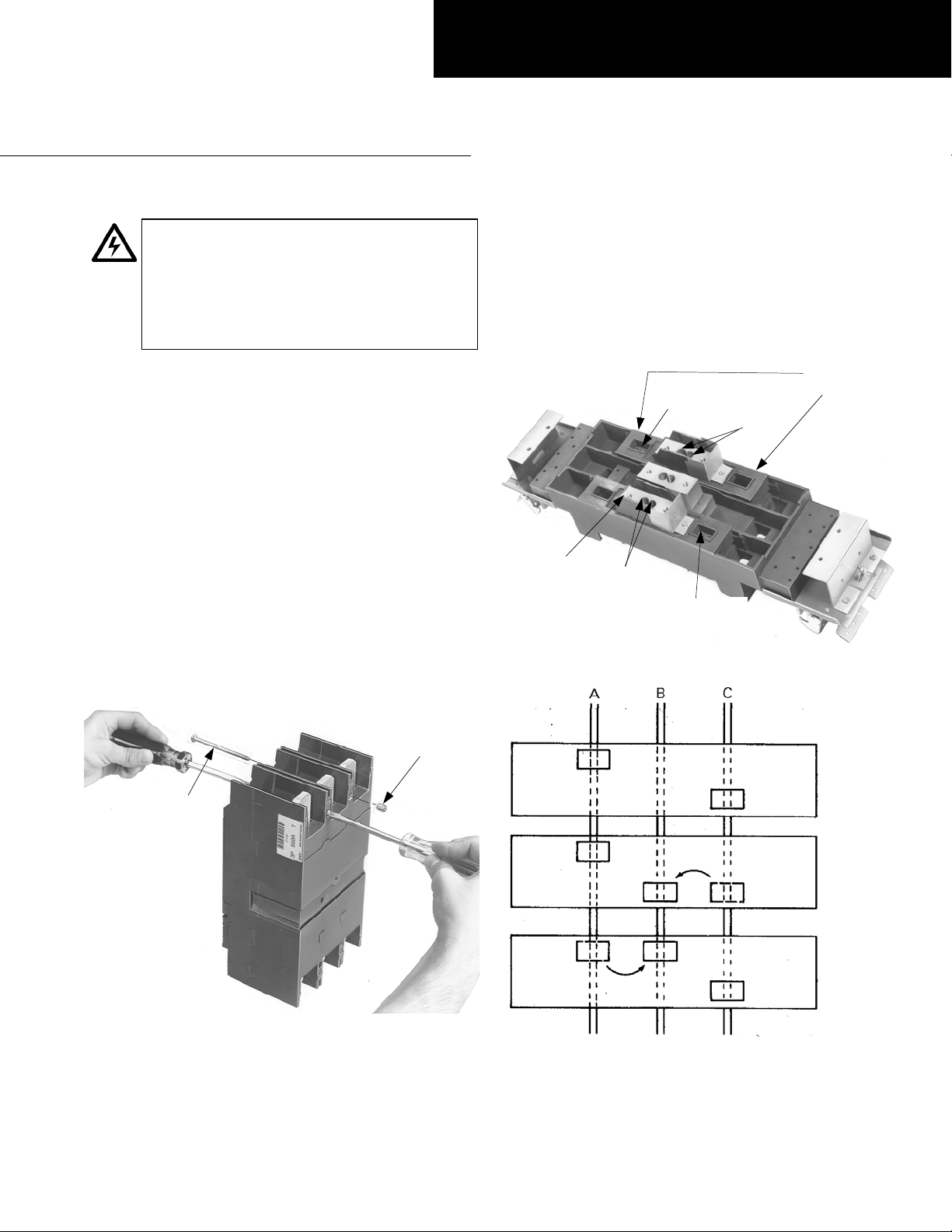

1. Prepare the circuit breaker(s). Before installing the

breakers, install line-end mounting screws into the ON

side of each breaker. Place the breaker vertically on a

flat surface with the ON side up and the OFF side

down, as shown in Figure 1. Install #10-32 pan-head

screws into the ON-side holes on the top of the

breaker. Install #10-32 inserts into the ON-side holes

on the bottom of the breaker. Using two screw drivers,

tighten both the insert and the screw to 20–25 in-lb.

2. Phase balancing for two-pole devices on three-phase

systems. Reposition the bus clip assembly from A or C

phase to B phase, as shown in Figures 2 and 3.

Remove the screws in the bus clip assembly and move

the bus clip to the B-phase position. Fasten the bus

clip assembly in the new location with the slotted hexhead SEMS screws provided and tighten to 27–32 inlb.

A & C

Screws & Bus

Clip Assembly

B Phase

SEMS

Screws

Screws & Bus

Clip Assembly

Figure 2. Repositioning the bus clip assembly.

SEMS

Screws

Phase

#10-32

Insert

#10-32

Screw

Figure 1. Installing line-end mounting screws in the breaker.

A & C Phase

As Received

A & B Phase

B & C Phase

Figure 3. Phase diagram showing locations of bus clips.

Page 2

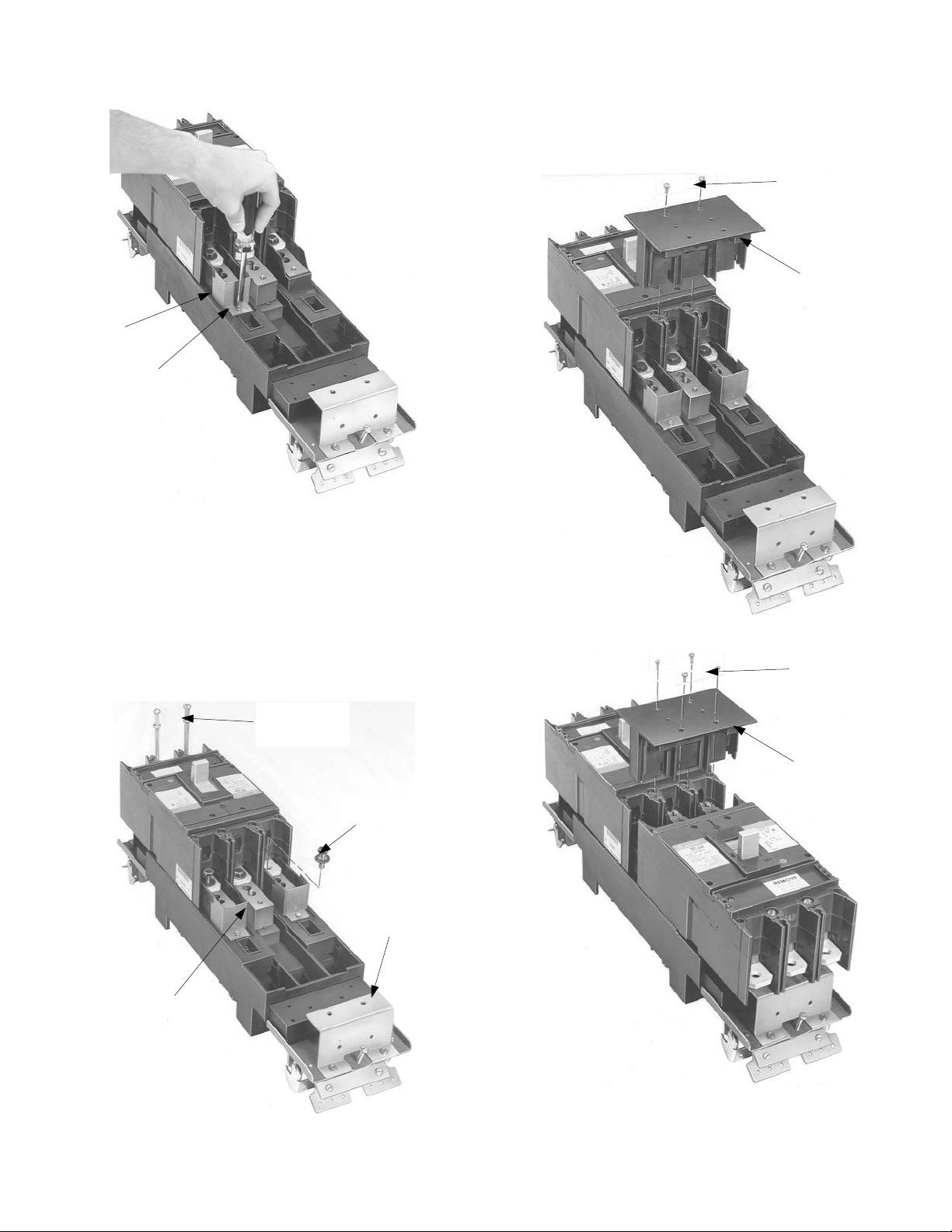

3. Prepare the breaker module (for two breakers only).

Before installing the breakers on the module, remove the

barriers and screws, as shown in Figure 4.

Barrier

Mounting

Screw

Figure 4. Preparing the breaker module for a two-breaker installation.

5. Install the center barrier. The center barrier must be

installed after the breaker has been secured to the

module. Slide the center barrier onto the breaker, as

shown in Figure 6 for a single breaker and in Figure 7 for

two breakers . Secure the center ba rrier with two threa dcutting screws into each breaker and tighten to 10 in-lb.

Figure 8 shows a complete two-breake r installation.

Thread-Cutting

Screws

Center

Barrier

4. Install the circuit breaker(s). Place the Belleville washers

and hex-head screws into the line straps of the circuit

breaker, as shown in Figure 5. Position the ON side of the

breaker on the module, as shown in F igure 5. Align the

hex-head scr ew s in th e stu d -p ost h ol es a nd tigh te n t o 90 –

110 in-lb. Fasten the OFF side of the breaker to the

mounting brackets with the round-head SEMS screws

and flat washers and tighten to 40–50 in-lb. Repeat the

procedure for a second breaker.

Round-Head

SEMS Screw &

Flat Washer

Hex-Head Screw &

Belleville Washer

Mounting

Bracket

Figure 6. Installing the center barrier with one breaker on the module.

Thread-Cutting

Screws

Center

Barrier

Stud Post

Figure 7. Installing the center barrier with two breakers on the module.

Figure 5. Installing the breaker on the module.

Page 3

Figure 8. Completed center barrier installation with two breakers.

6. Install the module. Fully retra ct the latches an d hook

one side of the breake r module to the inter ior rail, as

shown in Figure 9. Release the latch. P ivot the m odule

onto the bus bars and engage the second latch.

Release the la tch. Ti ghten t he latch s crews to 25 in-l b,

as shown in Figure 10.

Latch

Latch

Screw

Figure 10. Securing the module to the interior.

7. Wire the circuits. Refer to the label on the circuit

breaker for the proper tightening torque.

8. Filler plate kits. Install filler plate kit AFP4SGC on the

module.

Attention – Procedure for Aluminum

Terminations

1. Strip the insulation, being careful to not nick the wire.

2. Clean the wire strands with a wire brush.

3. Thoroughly coat the stripped conductor with a

suitable antioxidant compound, such as ALNOX or

PENETROX A13.

4. Insert the conductor and tighten the connector screw

to the indicated torque on the rating label.

Figure 9. Positioning the breaker module on the interior rail.

Latch

Screw

Page 4

g

These instructions do not cover all details or variations in e

quip

y

p

ma

be met in connection with installation, operation, or maintenance. Should further information be desired or should

articular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

ment nor do they provide for every possible contingency that

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH5673 R03 0701 © 2001 General Electric Company

Loading...

Loading...