Page 1

COLOR MONITOR

SERVICE MANUAL

CHASSIS NO. : CL-29

F ACT OR Y MODEL: LB782F

MODEL: FPD1700

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Page 2

CONTENTS

SPECIFICATIONS ................................................... 2

PRECAUTIONS ....................................................... 4

TIMING CHART ....................................................... 5

OPERATING INSTRUCTIONS ................................ 6

WIRING DIAGRAM ................................................. 7

DISASSEMBLY ....................................................... 8

BLOCK DIAGRAM AND DESCRIPTION ................ 9

SPECIFICATIONS

1. LCD CHARACTERISTICS

Type : TFT Color LCD Module

Size : 17 inch (43.2 cm diagonal)

Pixel Pitch : 0.264(H) x 0.264(V)

Elecctrical Interface : LVDS

Color Depth : 8-bits, 16,777,216 colors

Size (mm) : 383.5(H) x 306(V) x 20.0(D) Typ

Surface Treatment : Anti-Glare, Hard Coating (3H)

Operating Mode : Normally white

Backlight Unit : Four-CCFL (Cold Cathode

Fluorescent Lamp)

2. OPTICAL CHARACTERISTICS

≥

2-1. Viewing Angle by Contrast Ratio

Left : 70° Typ. , Right : 70° Typ.

Top : 45° Typ. , Bottom : 65° Typ.

10

ADJUSTMENT ...................................................... 12

TROUBLESHOOTING GUIDE .............................. 13

PRINTED CIRCUIT BOARD................................... 18

EXPLODED VIEW...................................................22

REPLACEMENT PARTS LIST ...............................24

PIN CONFIGURATION............................................29

SCHEMATIC DIAGRAM......................................... 31

4. POWER SUPPLY

4-1. Power

AC 100~240V, 50/60Hz , 1.0A

4-2. Power Consumption

MODE

POWER ON (NORMAL)

STAND-BY

SUSPEND

OFF

POWER OFF

5. ENVIRONMENT

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

VIDEO

POWER CONSUMPTION

ACTIVE

OFF

OFF

OFF

-

-

less than 45 W

less than 3 W

less than 3 W

less than 3 W

less than 3 W

LED COLOR

GREEN

AMBER

AMBER

AMBER

OFF

2

2-2. Luminance : 170 cd/m

(min) --- 9300K

200 (min.) 250 (typ.) --- 6500K

2-3. Contrast Ratio : 400 typ.

3. SIGNAL (Refer to the Timing Chart)

3-1. Sync Signal

• Type : Separate TTL (Positive/Negative)

Composite TTL (Positive/Negative)

SOG (Sync On Green)

Digital

3-2. Video Input Signal

1) Type : R, G, B Analog

2) Voltage Level : 0~0.714 V

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.714 Vp-p

3) Input Impedance : 75 Ω

3-3. Operating Frequency

Horizontal : 30 ~ 80 kHz

Vertical : 56 ~ 85 Hz

5-1. Operating Temperature: 10°C ~ 35°C (50°F ~ 95°F)

(Ambient)

5-2. Relative Humidity : 5% ~ 95%

(Non-condensing)

6. DIMENSIONS (with TILT/SWIVEL)

Width : 400 mm (15.74'')

Depth : 235 mm (9.25'')

Height : 427 mm (16.81'')

7. WEIGHT (with TILT/SWIVEL)

Net. Weight : 7.5 kg (16.54 lbs)

Gross Weight : 9.3 kg (20.51 lbs)

Page 3

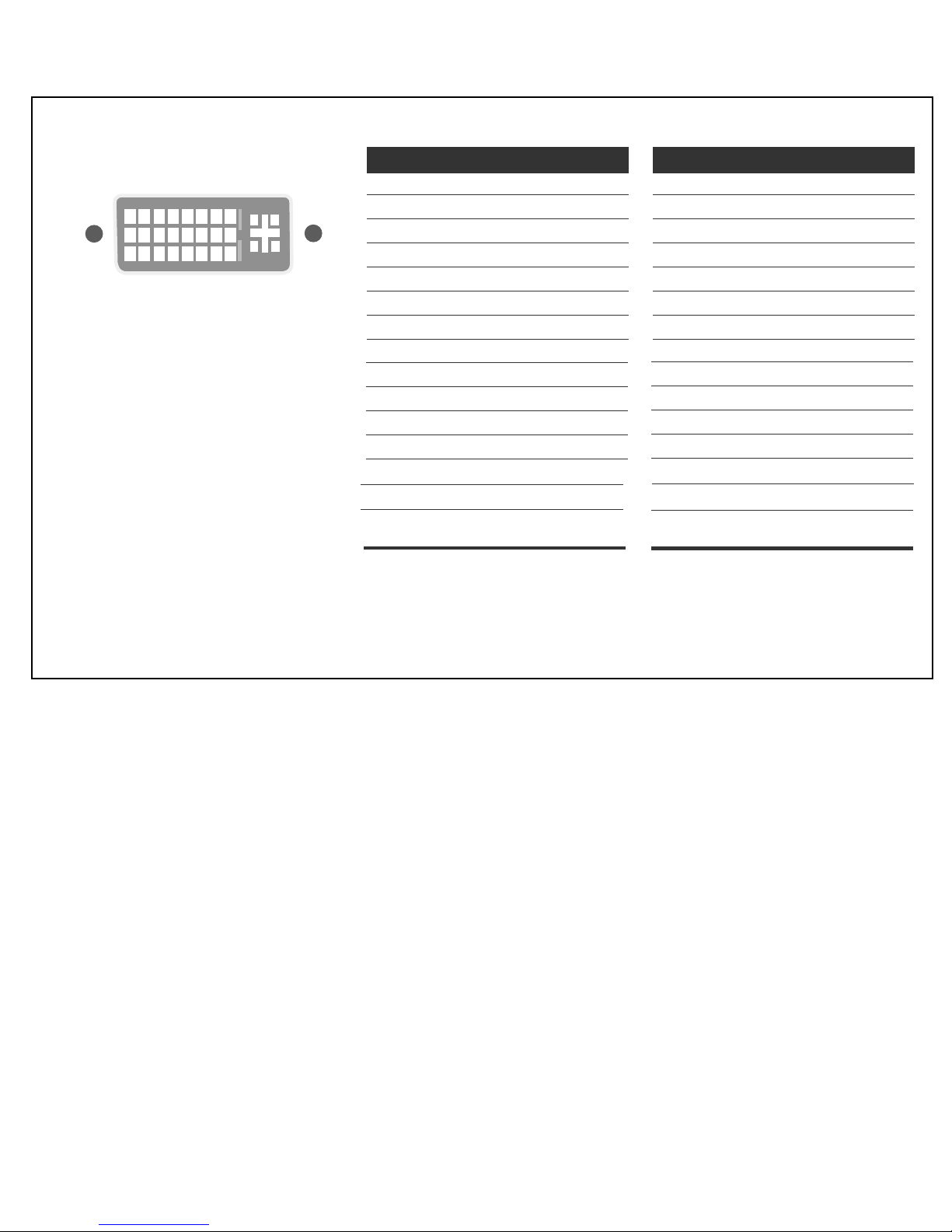

Signal Connector Pin Assignment

1

8

9

17

24

16

C1

C4

C3

C2

C5

• DVI-I Connector (Digital/Analog)

Pin Signal (DVI-I)

T. M. D. S. Data2-

1

T. M. D. S. Data2+

2

T. M. D. S. Data2/4 Shield

3

T. M. D. S. Data4-

4

T. M. D. S. Data4+

5

DDC Clock

6

DDC Data

7

Analog Vertical Sync.

8

T. M. D. S. Data1-

9

10

11

12

13

14

15

T. M. D. S. (Transition Minimized Differential Signaling)

T. M. D. S. Data1+

T. M. D. S. Data1/3 Shield

T. M. D. S. Data3T. M. D. S. Data3+

+5V Power

Ground

H. Sync. and V. Sync.)

(return for +5V,

Pin Signal (DVI-I)

16

17

18

19

20

21

22

23

24

C1

C2

C3

C4

C5

Hot Plug Detect

T. M. D. S. Data0T. M. D. S. Data0+

T. M. D. S. Data0/5 Shield

T. M. D. S. Data5T. M. D. S. Data5+

T. M. D. S. Clock Shield

T. M. D. S. Clock+

T. M. D. S. ClockAnalog Red

Analog Green

Analog Blue

Analog H. Sync.

Analog Ground

Page 4

PRECAUTION

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked on the schematic diagram and the

replacement parts list. It is essential that these critical

parts should be replaced with the manufacturer’s

specified parts to prevent electric shock, fire or other

hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the

original parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly

or electric shock as this will result in damage to the

screen.

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or

inverter circuit, must disconnect the AC adapter

because high voltage appears at inverter circuit about

650Vrms.

• Handle with care wires or connectors of the inverter

circuit. If the wires are pressed cause short and may

burn or take fire.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are

grounded through wrist band.

• Do not leave the module in high temperature and in

areas of high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

the module.

• If the surface of panel become dirty, please wipe it off

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

Page 5

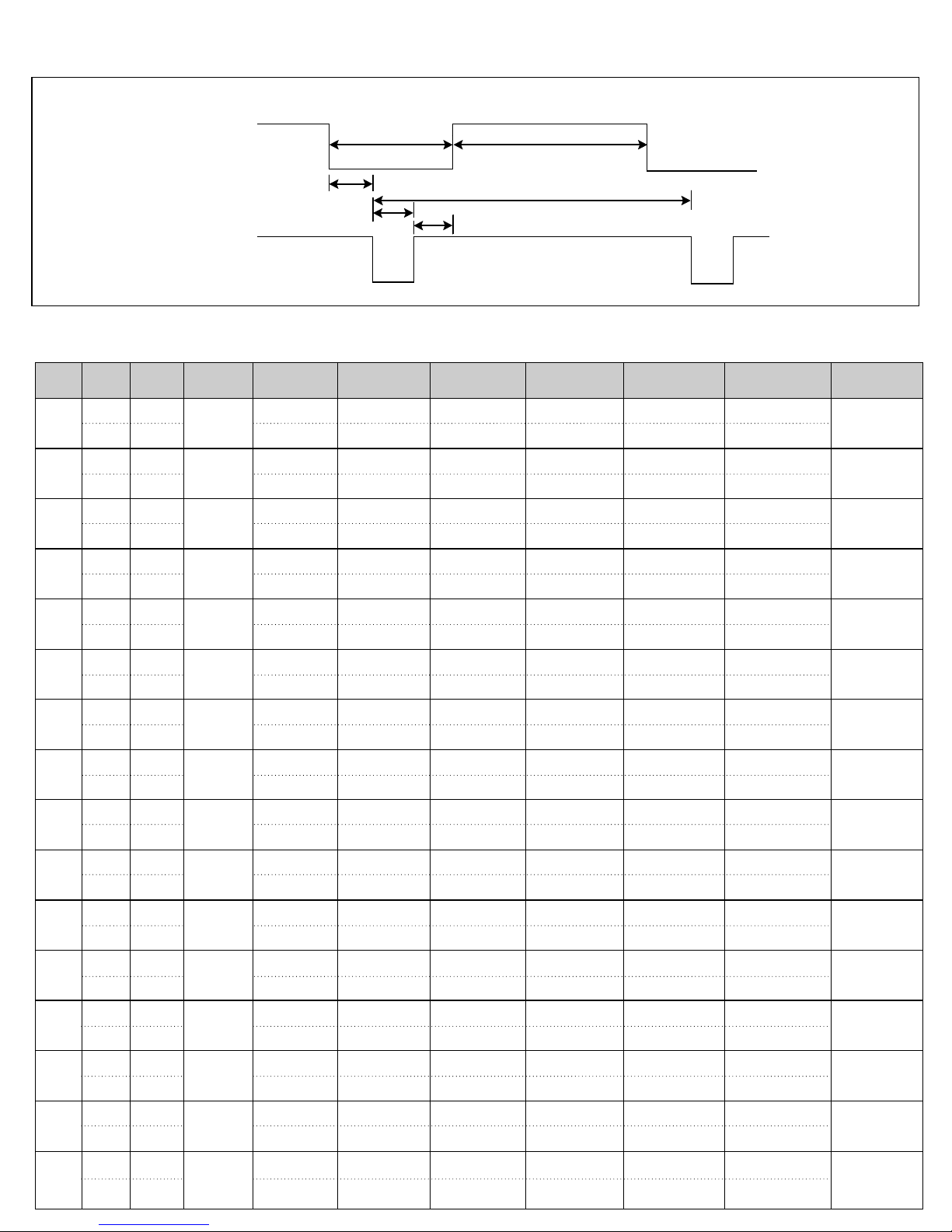

TIMING CHART

VIDEO

SYNC

B

D

C

F

E

A

<< Dot Clock (MHz), Horizontal Frequency (kHz), Vertical Frequency (Hz), Horizontal etc... (µs), Vertical etc... (ms) >>

Sync

Mode

10

11

12

13

14

15

16

H/V

Polarity

Sort

1

2

3

4

5

6

7

8

9

H + 31.469 800 640 16 96 48

V – 70.8 449 350 38 2 59

H – 31.468 900 720 18 108 54

V – 70.8 449 400 12 2 35

H – 37.5 840 640 16 64 120

V – 75 500 480 1 3 16

H – 43.269 832 640 56 56 80

V – 85.0 509 480 1 3 25

H – 31.469 800 640 16 96 48

V + 59.94 525 480 10 2 33

H + 37.879 1056 800 40 128 88

V + 60.317 628 600 1 4 23

H + 46.875 1056 800 16 80 160

V + 75.0 625 600 1 3 21

H + 53.674 1048 800 32 64 152

V + 85.061 631 600 1 3 27

H+/– 49.725 1152 832 32 64 224

V+/– 74.55 667 624 1 3 39

H – 48.363 1344 1024 24 136 160

V – 60.0 806 768 3 6 29

H – 60.123 1312 1024 16 96 176

V – 75.029 800 768 1 3 28

H + 68.677 1376 1024 48 96 208

V + 84.997 808 768 1 3 36

H+/– 68.681 1456 1152 32 128 144

V+/– 75.062 915 870 3 3 39

H+/– 61.805 1504 1125 18 134 200

V+/– 65.96 937 900 2 4 31

H + 63.981 1688 1280 48 112 248

V + 60.02 1066 1024 1 3 38

H + 79.976 1688 1280 16 144 248

V + 75.035 1066 1024 1 3 38

25.175

28.321

25.175

57.283

92.978

DOT

Clock

31.5

36.0

40.0

49.5

56.25

65.0

78.75

94.5

100.0

108.0

135.0

Frequency

Total Period

(E)

Video Active

Time (A)

Front Porch

(C)

Sync Duration

(D)

Back Porch

(F)

Resolution

640x350

70Hz

720x400

70Hz

640x480

75Hz

640x480

85Hz

640x480

60Hz

800x600

60Hz

800x600

75Hz

800x600

85Hz

832x624

75Hz

1024x768

60Hz

1024x768

75Hz

1024x768

85Hz

1152x870

75Hz

1152x900

65Hz

1280x1024

60Hz

1280x1024

75Hz

Page 6

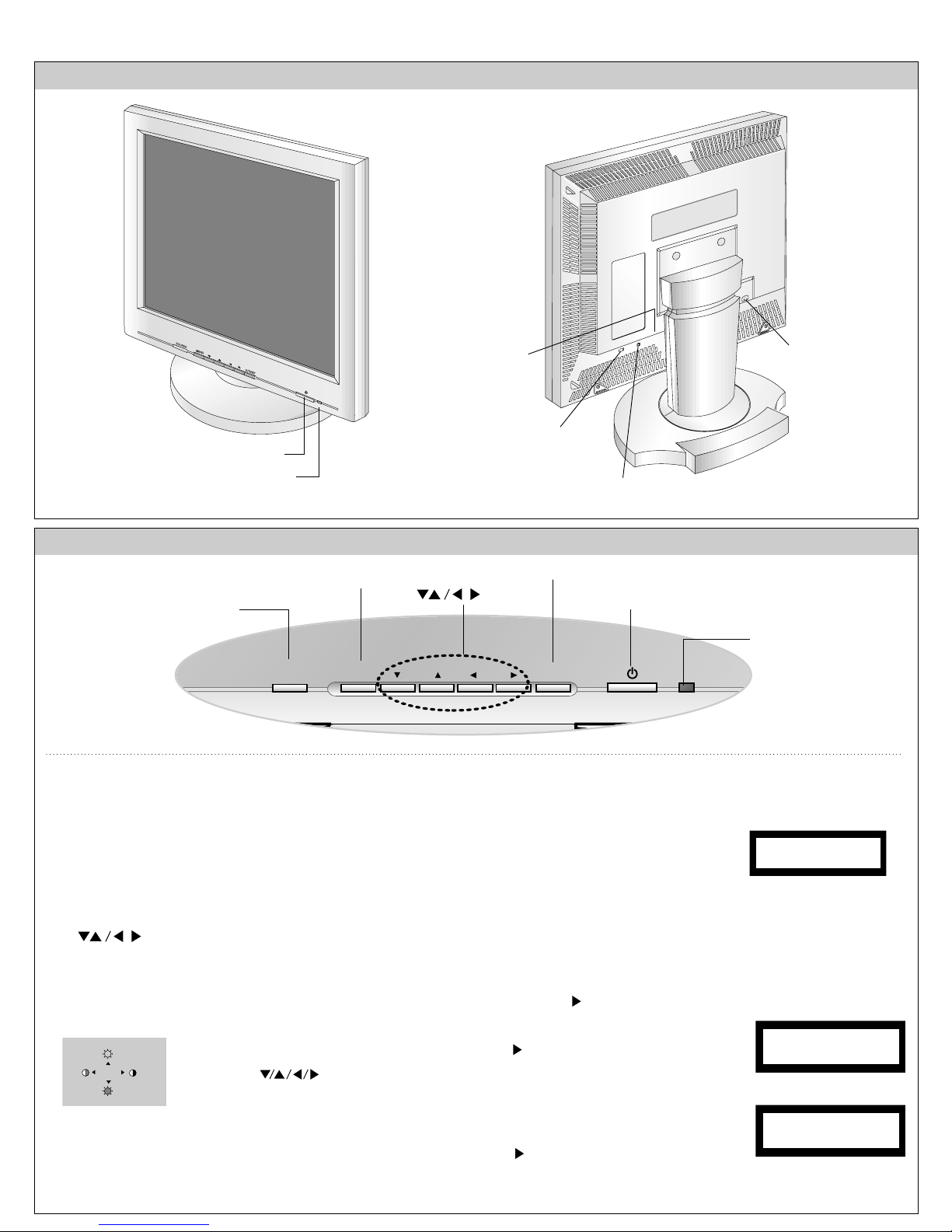

OPERATING INSTRUCTIONS

D

AUDIO

DC OUT

MENU

SOURCE AUTO/SET

100

100

PROCESSING

AUTO CONFIGURATION

CONTROLS LOCKED

CONTROLS UNLOCKED

FRONT VIEW REAR VIEW

Power ON/OFF Button

Power (DPMS) Indicator

Front Control Panel

MENU Button

SOURCE Button

1. SOURCE Button

• Use this button to make Dsub or DVI connector

active. This feature is used when two computers are

connected to the monitor. The default setting is Dsub.

2. MENU Button

Use this button to enter or exit the on screen display.

3.

Use these buttons to choose or adjust items in the on

screen display

Button

AUDIO DC OUT

AUTO/SET Button

Button

AUTO/SET Button

4.

Use this button to enter a selection in the on screen

display.

* AUTO adjustment function

TO the AUTO/SET button before

using OSD menu. This button is

for the automatic adjustment of the screen position, clock

and phase.

Note: Some signal from some graphics boards may not

function properly. If the results are unsatisfactory, adjust

your monitor’s Position, Clock and Phase manually.

Power Connector

DVI port

D-Sub Signal Port

Power Button

Power Indicator

<Shortcut Keys>

• Brightness and Contrast can be

adjusted directly without entering the

On Screen Display (OSD) system.

Touch the buttons to adjust

the settings and then the OSD button

to save all changes. The Brightness

and Contrast functions are also

available in the On Screen Display

(OSD) menu.

MENU, Button

5.

Press the hold the MENU button and

button for 3 seconds: the message

“CONTROLS LOCKED” appears.

You can unlock the OSD controls

at any time by pushing the MENU,

button for 3 seconds:

the message “CONTROLS UNLOCKED” will appear.

Page 7

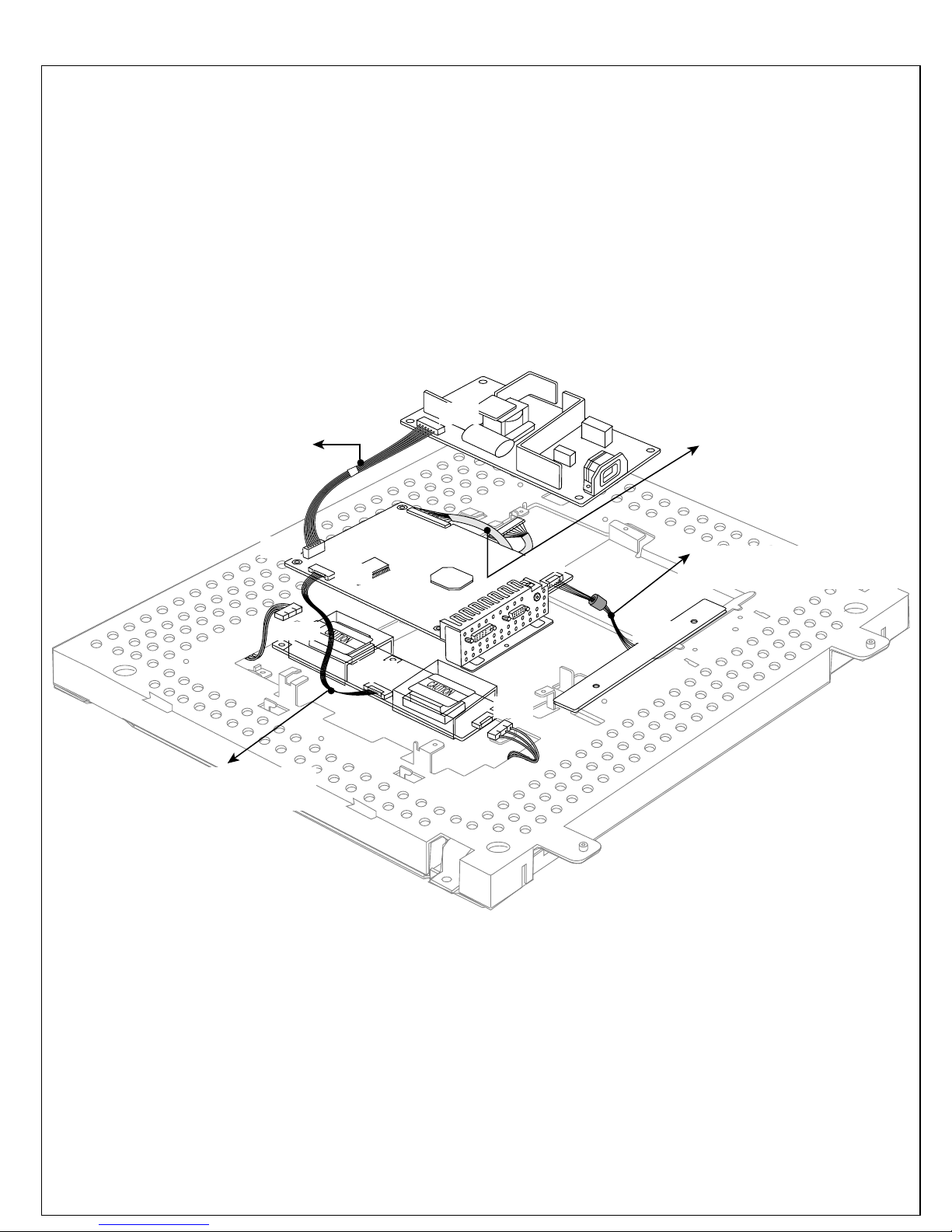

WIRING DIAGRAM

J801

P902

J710

J706

J702

CN1

CN2

J1

CN3

Connector Ass’y P/No.:

6631T1012Q

Connector Ass’y P/No.:

6631T25008R

Connector Ass’y P/No.:

6631T20015A

Connector Ass’y P/No.:

6631T20008P

Page 8

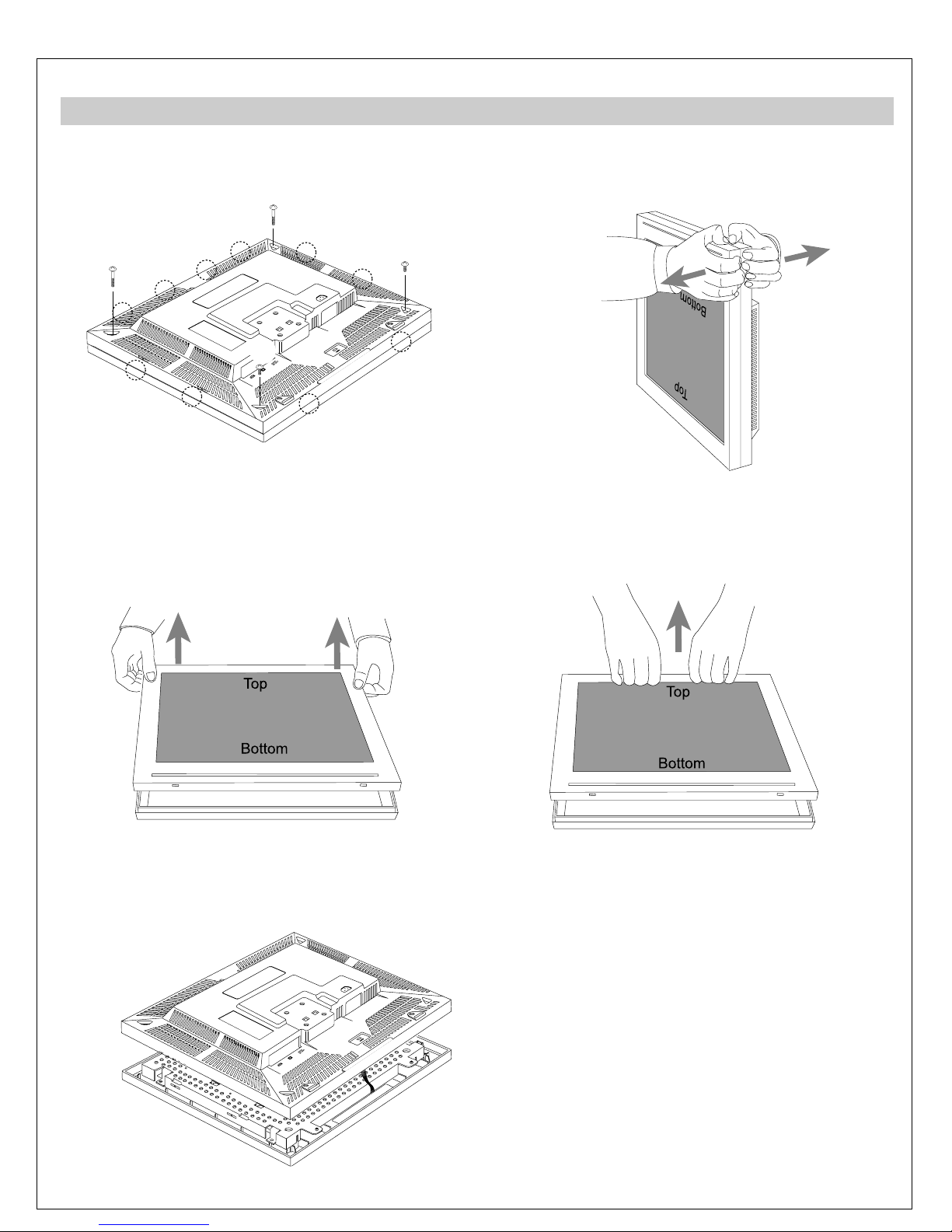

DISASSEMBLY

(a)

(a)

(a)

(a)

BACK COVER REMOVAL

※ Caution: When you open the Back cover, Be careful! Dont stress the Control Board Connector.

(b)

(b)

(b)

(b)

(b)

(b)

(b)

(b)

(b)

(b) Latch Point

1) Set the Monitor face downward.

2) Remove four screws (a).

(b)

3) Set the Monitor as picture.

4) Release the bottom & side latch.

5) Set the Monitor face upward.

6) Release the up side latch.

7) Release the center positon latch.

8) Set the Monitor face downward.

9) Remove the Back cover.

Page 9

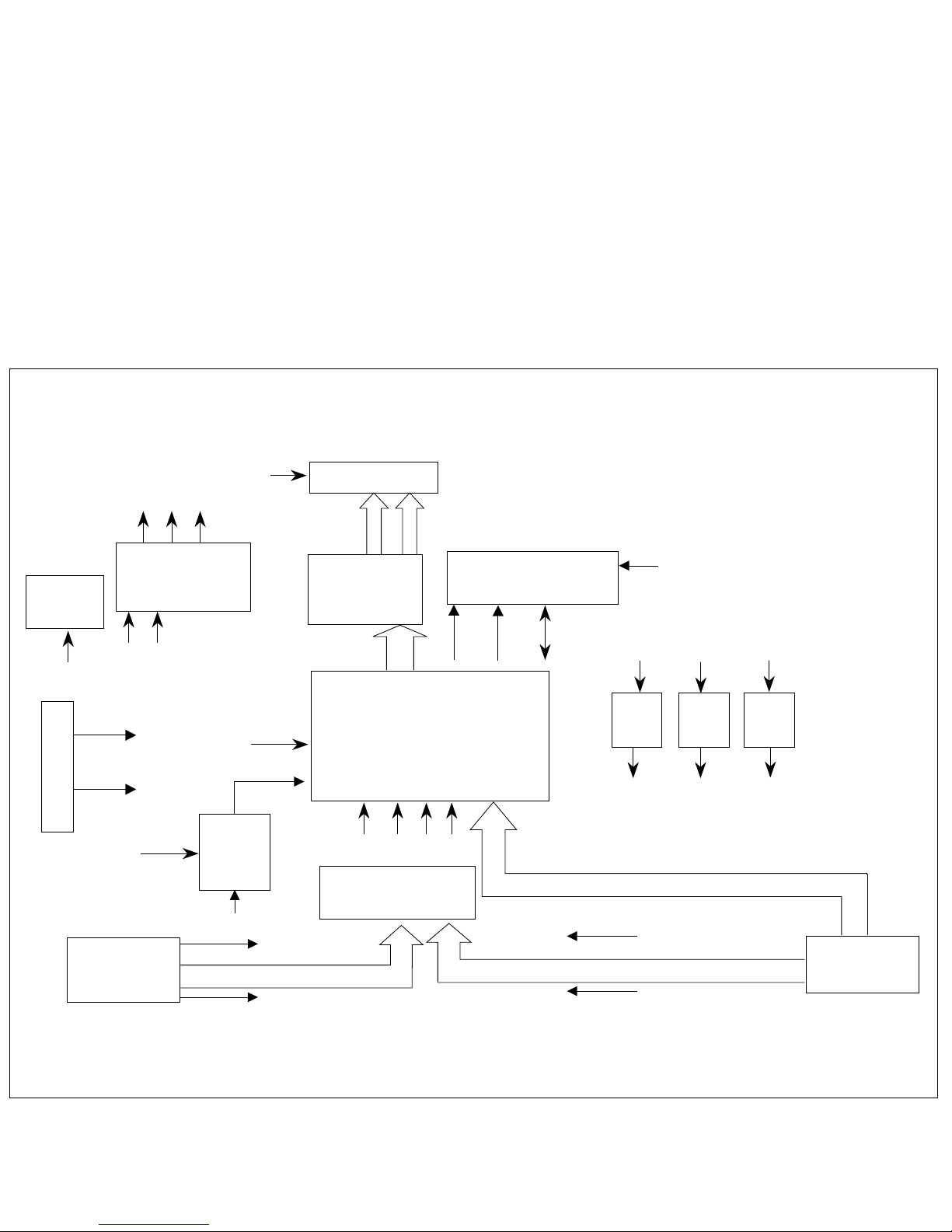

D-SUB

DVI-I

Gm5020

including

(ADC / TMDS Rx )

LVDS

(LVDS823)

Memory

(KM416S102BT)

H-Sync A

V-Sync A

Micom

68HC08-BD48

M-CLK

Out - CLK

DE ,H/V Sync out

R,G,B Even/Odd

LCD Module

R,G,B

differential

LVDS:Low Voltage Differential Signaling

Data 48Bit

Address

Inverte r CTL

Module CTL

R,G,B

Inverter

Digital Signal

3.3V

Reg.

DVDD 3. 3 V

AVD D 3. 3 V

12V

Powe r CTL

V-Sync

ADC CLK

5V

2.5V

Reg.

DVDD2.5V

AVDD2.5V

3.3V

Reg.

PVDD 3 .3 V

3.3 VM

5V 5V

DVI-Analog Signal

R,G,B

H-Sync B

V-Sync B

BA7657

(Video Switch)

R,G,B

5V

H/V-Sync

Hsync

Switch

(A or B)

H-Sync A

H-Sync

H-Sync B

3.3 VM

Power Board

12V

5V

MAIN BOARD

Page 10

DESCRIPTION OF BLOCK DIAGRAM (Main Board)

1. Input signal switching part.

There are two inputs which are analog and digital input.

They come from each 15 pin D-Sub and 29 pin DVI-I connector.

2. Video Controller Part.

This part amplifies the level of video signal for the digital conversion and converts from the analog video signal to

the digital video signal using a pixelclock.

The pixel clock for each mode is generated by the PLL.

The range of the pixel clock is from 25MHz to 135MHz.

This part consists of the Scaler and frame buffers which converts frame rate of input signal to 60Hz frame rate.

The Scaler gets the video signal converted analog to digital, interpolates input to1280 X 1024 resolution signal

and outputs 8-bit R, G, B signal to transmitter.

Especially pre-amp / ADC / Video controller are merged to one chip ‘Gm5020’ by Genesis.

Also FRC is separate.

3. Display Data Transmitter Part.

This part transmit digital signal from the Scaler to the receiver of module.

4. Power Part.

This part consists of the one 5V, two 3.3V and one 2.5 regulators to convert power which is provided 12V, 5V in

Power Board.

12V is provided for inverter, 5V is provided for Micom and LCD Panel.

Also, 5V is converted 3.3V and 2.5V by regulator. Converted power is provided for IC in the main board.

5. MICOM Part.

This part consists of EEPROM IC which stores control data, Reset IC and the Micom.

The Micom distinguishes polarity and frequency of the H/V sync which are supplied from signal cable.

The controlled data of each modes is stored in EEPROM.

6. Inverter

The inverter converts from DC12V to AC 700V and operate back-light lamp of module.

Page 11

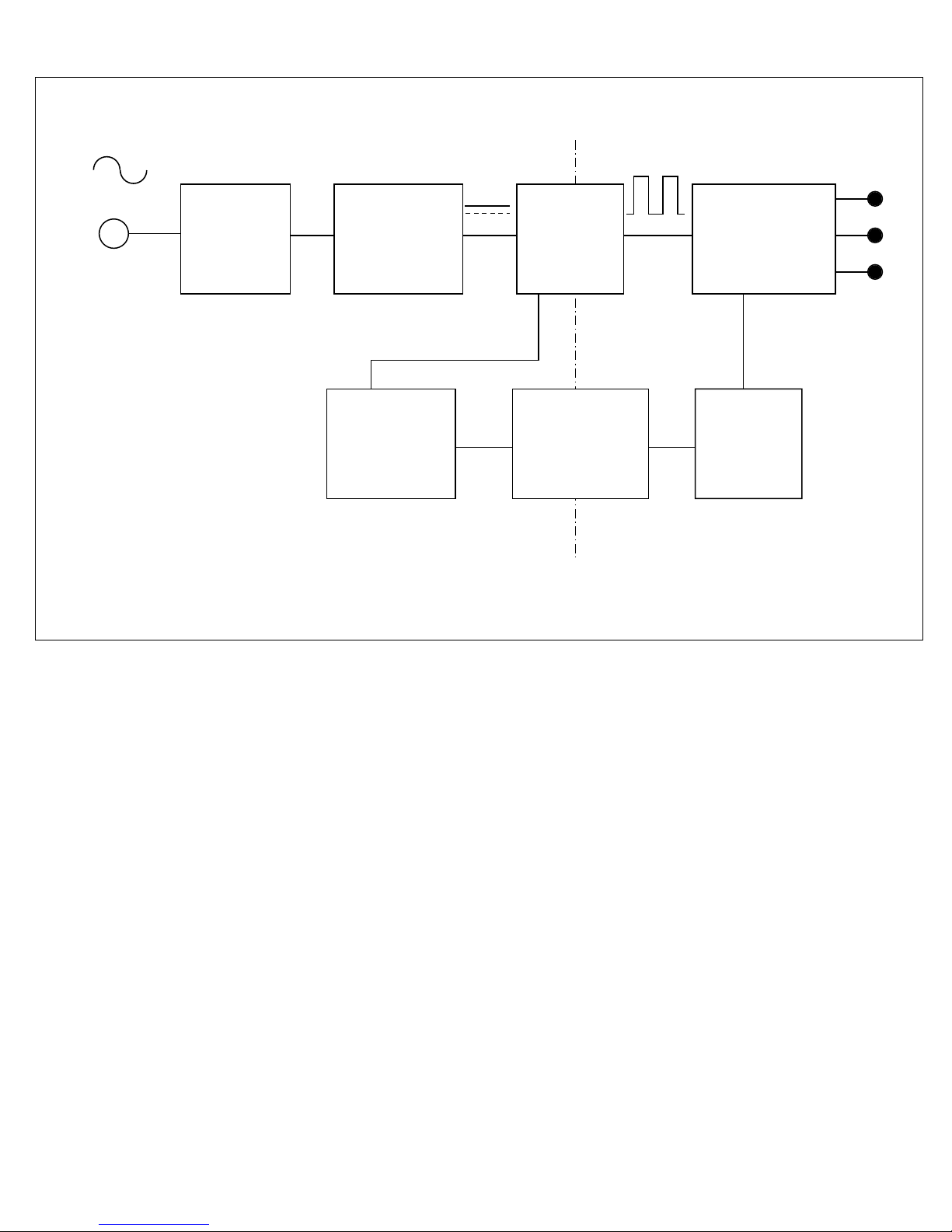

EMI

COMPONENTS

LINE

100 ~ 240V

INPUT RECTIFIE R

AND FILTER

ENERGY

TRANSFER

OUTPUT RECTIFI ER

AND FILTER

12V

5V

GND

SIGNAL

COLLECTION

PHOTO-COUPLER

ISOLATION

PWM CONTROL

CIRCUIT

HVDC

100KHz

PRIMARY

SECONDARY

50 ~ 60Hz

POWER BOADR

BLOCK DIAGRAM

DESCRIPTION OF BLOCK DIAGRAM

1. EMI components.

This part contains of EMI components to comply with global marketing EMI standards like FCC, VCCI CISPR,

the circuit included a line-filter, across line capacitor and of course the primary protection fuse.

2. Input rectifier and filter.

This part function is for transfer the input AC voltage to a DC voltage through a bridge rectifier and a bulk capacitor.

3. Energy Transfer.

This part function is transfer the primary energy to secondary through a power transformer.

4. Output rectifier and filter.

This part function is to make a pulse width modulation control and to provide the driver signal to power switch, to

adjust the duty cycle during different AC input and output loading condition to achive the dc output stablize, and also

the over power protection is also monitor by this part.

5. Photo-Coupler isolation.

This part function is to feed back the dc output changing status through a photo transistor to primary controller to

achive the stablized dc output voltage.

6. Signal collection.

This part function is to collect the any change from the dc output and feed back to the primary through photo

transistor

Page 12

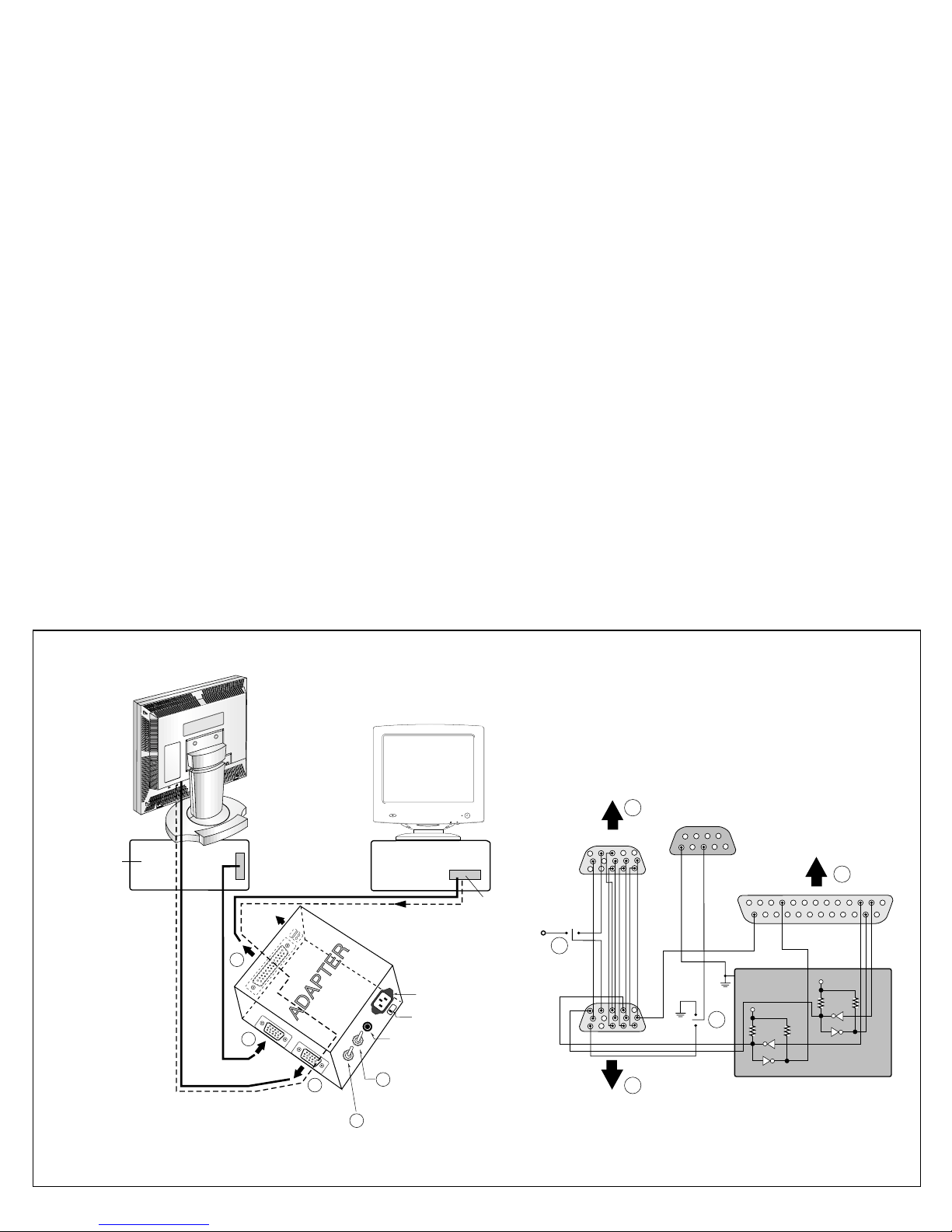

ADJUSTMENT

D

AUDIO

DC OUT

220

IBM

Compatible PC

Video Signal

Generator

PARALLEL PORT

Power inlet (required)

Power LED

ST Switch

Power Select Switch

(110V/220V)

Control Line

Not used

RS232C

PARALLEL

V-SYNC

POWER

ST

VGS

MONITOR

E

E

V-Sync On/Off Switch

(Switch must be ON.)

F

F

A

A

B

B

C

C

15

10

5

5

69

1

1

1

14

13

25

6

5V

5V

5V

4.7K

4.7K

4.7K

74LS06

74LS06

OFF ON

OFF

ON

11

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several minor adjustment may be required.

Adjustment should be following procedure and after

warming up for a minimum of 10 minutes.

• Alignment appliances and tools.

- IBM compatible PC

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- E(E)PROM with each mode data saved.

1. Adjustment Start

1) Display any pattern at any Mode.

2) Run alignment program for LB782F on the IBM

compatible PC.

3) Select EEPROM → ALL INIT command and Enter

4) This will make all data to default state.

5) Select COMMAND → PRESET START command

and Enter.

2. Adjustment for Factory Preset Mode

1) Select DIST. ADJ → FOS DEFAULT command

and Enter.

2) It will copy all factory default data to EEPROM

automatically.

3. Adjustment for White Balance

1) Display color 0,0 pattern at Mode 15.

2) Set External Bright to MAX position and Contrast to

MAX Position.

3) Select PRESET START → BIAS CAL command

and Enter.

4) No attempt to manually adjust, BIAS data is automatically adjusted and saved to the EEPROM.

5) Display color 15,0 pattern at Mode 15.

6) Select DRIVE CAL command and Enter.

7) 6500K and 9300K are automatically adjusted and

saved to the EEPROM.

8) Select PRESET EXIT command and Enter.

4. Adjustment for EDID

1) Use this procedure only when there is some

probelm on EDID data.

2) Connect the D-sub cable.

3) Select EEPROM → EDID Write command and

Enter.

4) Select DDC(A) Write command and Enter.

5) Connect the DVI-I cable.

6) Select DDC(D) Write command and Enter.

Figure 1. Cable Connection

Page 13

TROUBLESHOOTING GUIDE

NO POWER

(POWER INDICATOR OFF)

1. NO POWER

CHECK J801

INPUT VOLTAGE

(12V) ?

YES

CHECK J801

5VST VOLTAGE

(5V) ?

YES

CHECK

U501’s PIN 6.

IS THIS PIN

OSCILLATED?

NO

NO

NO

TROUBLE IN

BULT-IN POWER

TROUBLE IN

BULT-IN POWER

TROUBLE IN

U501 or X501

YES

TROUBLE

SOMEWHERE ELSE

Page 14

NO RASTER

2. NO RASTER

CHECK

J702 PIN 1, 2, 3

(12V) ?

YES

CHECK

J702 PIN 8 (5V) ?

YES

CHECK

X501

H. PULSE ?

YES

CHECK

U201(GM5020) ?

NO

NO

NO

NO

TROUBLE IN

BULT-IN POWER

or L703, L704

TROUBLE IN

INVON PATTERN

TROUBLE IN

X501

TROUBLE IN

U201

YES

CHECK

L201, L202, L203

PULSE?

YES

CHECK

U301, U302, U303

PIN 35

MEMORYCLK?

NO

NO

TROUBLE IN

U201

TROUBLE IN

U201

Page 15

YES

CHECK

L204

PULSE ?

YES

CHECK

U401 PIN 10

PULSE ?

YES

CHECK

U401 PIN 8

V.PULSE?

NO

NO

NO

TROUBLE IN

U201

CHECK DOT CLOCK

PATTERN

CHECK

DVS PATTERN

YES

CHECK

U401 PIN 7

V.PULSE?

YES

TROUBLE IN

LCD MODULE

NO

CHECK

DHS PATTERN

Page 16

NO DOT CLOCK

YES

3. NO CLOCK (CLOCK GENERATOR)

CHECK

X201 24MHz ?

YES

CHECK

L201

CLOCK ?

NO

NO

TROUBLE IN

X201

TROUBLE IN

U201

Page 17

TROUBLE IN DPM

4. TROUBLE IN DPM

CHECK

R233, R234?

YES

CHECK

U501 PIN 6

WAVEFORM

(24MHz) ?

YES

CHECK

U501 PIN 11

(0V) ?

NO

NO

NO

CHECK PC

PC IS NOT GOING

INTO DPM OFF MODE

TROUBLE IN

X501

TROUBLE IN

SIGNAL CABLE

YES

TROUBLE IN PC

Page 18

ZD721

U301

C301

U302

C302

U303

C318

Q703

R730

R740

R741

ZD722

J705

1

C526

30

1

J706

20

30

30

20

20

C533

Q704

U504

C729

R731

R744

U507

R742

R743

J710

50

4030

C408

L401

10

10

10

RA238

RA239

C547

60

U401

20

50

R236

RA225

1

50

50

1

1

RA237

RA240

RA242

RA241

R587

R588

R591

R585

R586

R572

R573

C546

J802

R570

R571

70

10

1

L403

CA201

RA226

RA227 RA228 RA229 RA230 RA231 RA232 RA233

RA234

RA235 RA236

Q501

R592

U508

D502

D501

C817

C409

80

C410

90100

C413

CA202

RA216 RA214

VWY

L206

C229

R218

D503

D504

C532

R574

R575

ZD711

ZD704

ZD703

U802

R810

L402

CA211 CA210 CA209 CA208

CA207

CA212CA203

RA220 RA218

N

P

R

T

U

M

L207

C230

R219

R593

R594

R597

X201

C115

R595

R596

C114

R705

R807

R809

R406

RA212

CA206

CA205 CA204

RA222RA224

C271

R235

L

KJH

G

F

C548

C117

C118

C116

R704

C850

C844

U821

RA208RA210 RA206 RA204 RA202

20

U201

1918171615141312111098765432

C270

EDC

B

A

1

C278

C279 R220

R221

C258

R223

R145

U509

C119

R703

C845

C834

R582

R545

C201

C202

C203

C206

C205

C204

C276

C280

R222

R224

C259

C260

C261

J704

L820

L810

C531

U503

C517

C516

R581

R542

R543

R544

R508

R510

MODEL:LB886F

DATE :2001.11.23

C822

P/N :6870T402A12

C828

L805

C825

C130

U109

L101

C128

C124

R225

U106

C109

C113

C111

R767

R766

C112

ZD705

C707

C840

R514

R515

C831

L804

R151

R153

R152

C125

C122

C108

R765

C110

C701

R517

R502

U502

U820

C160

C161

Q104

C727

R726

R129

R122

R149

R148

D738

D739

ZD702

D716

L821

L811

R702

C706

R701

R520

C502R501

X501

U803

C870

C871

C841

R822

U107

U110

C106

Q102

C107

R727R131

R130

Q103

D734 D736

ZD701

C728

D735

D737

J801

J702

R745

R746

C522

C501

C503

C872

U804

C843

R821

R824

U105

U108

R133

R132

D733

C521

U501

C873

C842 D732

J708

Page 19

C740

C710

L703

L704

R534

R535

R539

R825

C835

C836

C818

L822

C412

L823

C860

C819

C820

C411

R752

C861

R540

R136

C406

C404

C403

C520

R538

R536

30

C519

C505

R537

R564

C504

R513

R505

C508

C514

R512

R511

20

40

R519

R522

R541

R523

C511

R529

1

C530

C510

R518

R516

10

C506

R580

R528

C513

R531

R527

R526

R525

C507

R524

C515

C257

C236

C232

C405

C407

R404

R405

R403

C401

R402

R401

C314

C402

C308

C221

C235

C234

R202

C228

C269

R240

D702D703

C240

C227

C225

C231

R201

C239

C224

C222 C223

C226

C265

C264

C217

C218

R233

C216

C219

R234

C214

C215

C210

D704

C262

C212

C208

C213

C211

L205

C209

C263

C207

R232

R237

R238

R208

R209

R211

R212

C317

R213

C315

C310C316

C313

R214

C309

C311

R215

C312

R204

C305

C306

R216

C304

C303

R207

C307

R203

R210

R205

R206

C731

C730

C738

R732

R828

R830

C121

R134

R754

R820

R829

R819

R811

R812

U701

R818

R817

R813

R816

R814

R827

U702

R719

R815

R831

R718

R826

C123

C833

R761R768

D713

C832

R146

R154

D714

R155

C824

C830

C826

C131

C827

R135

C823

C120

C829

D715

R138

R147

R137

R769

R140

R139

R141

R760

C274

C238

R142

C272

R150

L204

R239

L203

C237

C275

C233

C273

D701

L201

L202

C220

D712

R753

R713

R716

R751

R750

C741

R729

R728C742

D730

D731

R715

R714

C715

R712

C714

R711

Page 20

3. POWER BOARD (Component Side)

4. POWER BOARD (Solder Side)

Page 21

5. CONTROL BOARD (Component Side)

6. CONTROL BOARD (Solder Side)

Page 22

1

2

17

18

15

16

5

6

13

3

9

14

4

12

10

19

8

7

11

20

Page 23

EXPLODED VIEW PARTS LIST

SAFETY MarkNote:

Ref. No.

1

2

3

4

5

6

7

8

9

10

11

12

Part No.

3091TKL031D

6304FHD002A

3809TKL021B

3043TKK037M

4951TKS082A

6633TZA011A

4814TKK200A

3313TL7001B

6631T11012Q

6871TST276A

6871TPT220A

4814TKK187A

Description

CABINET ASSEMBLY, LB782F G/WAY 3090TKL031 -17" LCD

LCD(LIQUID CRYSTAL DISPLAY) HT17E11-200 HYUNDAI 17.0 INCH SXGA(1280 X 1024)

BACK COVER ASSEMBLY, LB782F 3808TKL026A

TILT SWIVEL ASSEMBLY LB782F . NO USB

METAL ASSEMBLY, FRAME HYDIS LB782F

INVERTER ASSEMBLY, LG-PHILIPS NMC1804,4-LAMP AU MODULE LB782

SHIELD INVERTER LB782F

MAIN TOTAL ASSEMBLY LB782F AXAGE G/WAY CL-29

CONNECTOR ASSEMBLY, 30P H-H 150MM UL20276 PANEL LINK LB782F

PWB(PCB) ASSEMBLY,SUB, LB782F CONTROL TOTAL BRAND

PWB(PCB) ASSEMBLY,POWER, LB782F POWER TOTAL BRAND NO SWITCH

SHIELD REAR LB886F

13

14

15

16

17

18

19

20

4950TKS189A

3550TKK053A

3550TKK050A

3550TKK051J

3550TKK052K

6866TDV004C

6850TD9001A

6634TFZ004A

METAL REAR LB782F

COVER LB880B HINGE BRAND 18.1" LCD

COVER LB880B STAND FRONT BRAND 18,1" LCD

COVER LB782F STAND REAR

COVER LB782F STAND TOP -GATEWAY

CABLE,DVI, UL20276 DT 2000MM GRAY(85964) LB885C DM

CABLE,D-SUB, UL 2990-9C(7.5) DT 1870MM GRAY(85964) BRAND DM

ADAPTER,SIGNAL, DVI-I(MAIL)-VGA(FMAIL) UNIXTAR 19P 15P LB885C

Page 24

- 24 -

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C106 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C107 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C108 DCH7476C621 47UF 6.3V M 3528 TP(-)

C109 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C110 DCH7476C621 47UF 6.3V M 3528 TP(-)

C111 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C112 DCH7476C621 47UF 6.3V M 3528 TP(-)

C113 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C114 DCH7476C621 47UF 6.3V M 3528 TP(-)

C115 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C116 DCH7476C621 47UF 6.3V M 3528 TP(-)

C117 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C118 DCH7476C621 47UF 6.3V M 3528 TP(-)

C119 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C120 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C122 0CH8106F611 10UF 16V M 85STD(CYL) R/TP

C123 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C124 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C125 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C128 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C130 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C131 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C160 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C161 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C201 0CH3103K516 10000PF 50V K B 2012 R/TP

C202 0CH3103K516 10000PF 50V K B 2012 R/TP

C203 0CH3103K516 10000PF 50V K B 2012 R/TP

C204 0CH3103K516 10000PF 50V K B 2012 R/TP

C205 0CH3103K516 10000PF 50V K B 2012 R/TP

C206 0CH3103K516 10000PF 50V K B 2012 R/TP

C207 0CH3103K516 10000PF 50V K B 2012 R/TP

C208 0CH3103K516 10000PF 50V K B 2012 R/TP

C209 0CH3103K516 10000PF 50V K B 2012 R/TP

C210 0CH3103K516 10000PF 50V K B 2012 R/TP

C211 0CH3103K516 10000PF 50V K B 2012 R/TP

C212 0CH3103K516 10000PF 50V K B 2012 R/TP

C213 0CH3103K516 10000PF 50V K B 2012 R/TP

C214 0CH3103K516 10000PF 50V K B 2012 R/TP

C215 0CH3103K516 10000PF 50V K B 2012 R/TP

C216 0CH3103K516 10000PF 50V K B 2012 R/TP

C217 0CH3103K516 10000PF 50V K B 2012 R/TP

C218 0CH3104K566 0.1UF 50V K X 2012 R/TP

C219 0CH3103K516 10000PF 50V K B 2012 R/TP

C220 0CH6330K416 33PF 50V J NP0 2012 R/TP

C221 0CH6330K416 33PF 50V J NP0 2012 R/TP

C222 0CH3103K516 10000PF 50V K B 2012 R/TP

C223 0CH3103K516 10000PF 50V K B 2012 R/TP

C224 0CH3103K516 10000PF 50V K B 2012 R/TP

C225 0CH3103K516 10000PF 50V K B 2012 R/TP

C226 0CH3103K516 10000PF 50V K B 2012 R/TP

C227 0CH3104K566 0.1UF 50V K X 2012 R/TP

C228 0CH3103K516 10000PF 50V K B 2012 R/TP

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C229 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C230 0CH6150K416 15PF 50V J NP0 2012 R/TP

C231 0CH6680K416 68PF 50V J NP0 2012 R/TP

C232 0CH6680K416 68PF 50V J NP0 2012 R/TP

C233 0CH3103K516 10000PF 50V K B 2012 R/TP

C234 0CH3103K516 10000PF 50V K B 2012 R/TP

C235 0CH6680K416 68PF 50V J NP0 2012 R/TP

C236 0CH6680K416 68PF 50V J NP0 2012 R/TP

C237 0CH3104K566 0.1UF 50V K X 2012 R/TP

C258 0CH6150K416 15PF 50V J NP0 2012 R/TP

C259 0CH3682K516 6800PF 50V K B(Y5P) 2012 R/TP

C260 0CH3682K516 6800PF 50V K B(Y5P) 2012 R/TP

C261 0CH3682K516 6800PF 50V K B(Y5P) 2012 R/TP

C262 0CH6330K416 33PF 50V J NP0 2012 R/TP

C264 0CH6221K416 220PF 50V J NP0 2012 R/TP

C265 0CH6470K416 47PF 50V J NP0 2012 R/TP

C269 0CH3103K516 10000PF 50V K B 2012 R/TP

C270 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C271 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C272 0CH3104K566 0.1UF 50V K X 2012 R/TP

C273 0CH3103K516 10000PF 50V K B 2012 R/TP

C274 0CH3103K516 10000PF 50V K B 2012 R/TP

C275 0CH3104K566 0.1UF 50V K X 2012 R/TP

C276 0CH3103K516 10000PF 50V K B 2012 R/TP

C278 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C279 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C280 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C301 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C302 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C303 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C304 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C305 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C306 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C307 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C308 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C309 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C310 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C311 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C312 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C313 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C314 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C315 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C316 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C317 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C318 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C401 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C402 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C403 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C404 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C405 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C406 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C407 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C408 0CH8226F691 22UF 16V M 105STD (CYL) R/TP

C409 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

REPLACEMENT PARTS LIST

CAUTION: BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

* NOTE : S SAFETY Mark

AL ALTERNATIVE PARTS

MAIN BOARD

CAPACITORS

Page 25

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C410 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C411 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C412 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C413 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C501 0CC180CK41A 18PF 1608 50V 5% R/TP NP0

C502 0CC180CK41A 18PF 1608 50V 5% R/TP NP0

C503 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C504 0CC470CK41A 47PF 1608 50V 5% R/TP NP0

C505 0CC470CK41A 47PF 1608 50V 5% R/TP NP0

C506 0CC470CK41A 47PF 1608 50V 5% R/TP NP0

C507 0CC470CK41A 47PF 1608 50V 5% R/TP NP0

C508 0CK222CK51A 2200PF 1608 50V 10% R/TP B(Y5P

C510 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C511 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C513 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C514 0CC470CK41A 47PF 1608 50V 5% R/TP NP0

C515 0CC470CK41A 47PF 1608 50V 5% R/TP NP0

C516 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C517 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C519 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C520 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C521 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C522 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C526 0CH8106J691 10UF 35V M 105STD (CYL) R/TP

C531 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C532 0CH8106J691 10UF 35V M 105STD (CYL) R/TP

C533 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C548 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C701 0CE477EH618 470UF KMG 25V M FL TP 5

C706 0CC221CK41A 220PF 1608 50V 5% R/TP NP0

C707 0CH8106J691 10UF 35V M 105STD (CYL) R/TP

C710 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C714 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C715 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C727 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C728 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C729 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C730 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C731 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C738 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C740 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C817 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C818 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C819 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C820 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C822 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C823 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C824 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C825 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C826 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C827 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C828 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C829 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C830 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C831 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C832 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C833 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C834 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C835 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C836 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C840 0CE477EH618 470UF KMG 25V M FL TP 5

C841 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C842 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y5P

C843 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C844 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD) SM

C845 0CE477EH618 470UF KMG 25V M FL TP 5

C850 0CE477EH618 470UF KMG 25V M FL TP 5

C860 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C861 0CK105CD56A 1UF 1608 10V 10% R/TP X7R

C870 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C871 0CH6101K416 100PF 50V J NP0 2012 R/TP

C872 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C873 0CH6101K416 100PF 50V J NP0 2012 R/TP

D501 0DS301109AA MMBD301LT1 TP MOTOROLA SOT23 3

D502 0DS301109AA MMBD301LT1 TP MOTOROLA SOT23 3

D503 0DS301109AA MMBD301LT1 TP MOTOROLA SOT23 3

D504 0DS301109AA MMBD301LT1 TP MOTOROLA SOT23 3

D701 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D702 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D703 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D704 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D712 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D713 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D714 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D715 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D716 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D730 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D731 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D732 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D733 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D734 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D735 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D736 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D737 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D738 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

D739 0DS226009AA KDS226 TP KEC SOT-23 80V 300M

ZD701 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD702 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD703 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD704 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD705 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD711 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD721 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

ZD722 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

U105 0IMO741420B MC74HCT14ADR2 14P,SOIC TP LEVE

U106 0IRH765700B BA7657F 24P,SOP TP INPUT SIG.

U107 0ITI748600N SN74F86DR 14SOIC TP 2-INPUT EX

U108 0IPH740800H 74F08D 14P,SOIC TP QUAD 2-INPU

U109 0TFFC80009A FAIRCHILD FDC6326L R/TP SOT-6

U110 0ISS780500H KA78M05-R 3P,D-PAK TP 5V 0.5A

U201 0IPRPGN001A GM5020 GENESIS 292P,PBGA TRAY

U301 0IEB121616A M12L16161A-7T 50P TSOP ST 16M(

U302 0IEB121616A M12L16161A-7T 50P TSOP ST 16M(

U303 0IEB121616A M12L16161A-7T 50P TSOP ST 16M(

U401 0ILNRTH001A THC63LVD823 THINE MICROSYSTEMS

U501 0IZZTSZ164A LB782F 42PIN DIP BK MICOM

U502 0IKE704200J KIA7042AF SOT-89 TP 4.2V VOLTA

U503 0ICS240813B CAT24WC08J-TE13 8P,SOIC R/TP 8

U504 0ISS524202A S524C20D21-SCT0 8SOP-225 R/TP

- 25 -

DIODEs

ICs

Page 26

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

U509 0ISS524202A S524C20D21-SCT0 8SOP-225 R/TP

U701 0DZ560009DA UDZ S 5.6B TP ROHM-K SOD323 20

U802 0TFFC80009A FAIRCHILD FDC6326L R/TP SOT-6

U803 0IPMGFA003B RC1117S-2.5 FAIRCHILD SOT-223

U804 0TFFC80009A FAIRCHILD FDC6326L R/TP SOT-6

U820 0IRH033200A BA033FP-E2 MOLD-3 TP REGULATOR

U821 0IRH033200A BA033FP-E2 MOLD-3 TP REGULATOR

L101 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L201 0RH0562D622 56 1/10W 5 D.R/TP

L202 6210TCE001P HB-1S2012-121JT CERATECH 2012M

L203 6210TCE001P HB-1S2012-121JT CERATECH 2012M

L204 6210TCE001P HB-1S2012-121JT CERATECH 2012M

L205 6210TCE001R HB-1S2012-400JT CERATECH 2012M

L206 6210TCE001P HB-1S2012-121JT CERATECH 2012M

L207 6210TCE001P HB-1S2012-121JT CERATECH 2012M

L401 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L402 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L403 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L703 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L704 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L804 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L805 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L810 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L811 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L820 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L821 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

L822 6210TCE001P HB-1S2012-121JT CERATECH 2012M

L823 6210TCE001G HH-1M3216-501 CERATEC 3216MM R

Q102 0TR390409AE FAIRCHILD KST3904(LGEMTF) TP S

Q103 0TR390409AE FAIRCHILD KST3904(LGEMTF) TP S

Q104 0TR162309CA KSC1623 TP SAMSUNG SOT23 NPN

Q703 0TR162309CA KSC1623 TP SAMSUNG SOT23 NPN

Q704 0TR162309CA KSC1623 TP SAMSUNG SOT23 NPN

R122 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R129 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R130 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R131 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R132 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R133 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R134 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R135 0RJ4703D677 470K OHM 1/10 W 5% 1608 R/TP

R139 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R140 0RJ1003D677 100K OHM 1/10 W 5% 1608 R/TP

R141 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R142 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R145 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R146 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R147 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R149 0RJ2000D677 200 OHM 1/10 W 5% 1608 R/TP

R150 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R151 0RJ1500D677 150 OHM 1/10 W 5% 1608 R/TP

R153 0RJ2202D677 22K OHM 1/10 W 5% 1608 R/TP

R154 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R155 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R201 0RH2001D622 2.0K 1/10W 5 D.R/TP

R202 0RH2001D622 2.0K 1/10W 5 D.R/TP

R203 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R204 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R205 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R206 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R207 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R208 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R209 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R210 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R211 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R212 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R213 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R214 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R215 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R216 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R218 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R219 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R220 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R221 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R222 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R223 0RJ1500D677 150 OHM 1/10 W 5% 1608 R/TP

R224 0RJ1500D677 150 OHM 1/10 W 5% 1608 R/TP

R225 0RJ1500D677 150 OHM 1/10 W 5% 1608 R/TP

R233 0RH0222D622 22 1/10W 5 D.R/TP

R234 0RH0222D622 22 1/10W 5 D.R/TP

R235 0RJ2201D677 2200 OHM 1/10 W 5% 1608 R/TP

R236 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R237 0RH0000D622 0 1/10W P-TYPE TAPPING

R238 0RH0000D622 0 1/10W P-TYPE TAPPING

R239 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R240 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R401 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R402 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R404 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R405 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R406 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R501 0RJ1004D677 1000000 OHM 1/10 W 5% 1608 R/T

R502 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R505 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R508 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R511 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R512 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R513 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R514 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R515 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R516 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R517 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R518 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R519 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R522 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R523 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R524 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R525 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R526 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R527 0RJ1003D677 100K OHM 1/10 W 5% 1608 R/TP

R528 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R529 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R531 0RJ3302D677 33K OHM 1/10 W 5% 1608 R/TP

R534 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R535 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

- 26 -

RESISTORs

TRANSISTOR

COILs & COREs

Page 27

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R536 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R537 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R538 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R539 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R540 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R541 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R542 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R543 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R544 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R545 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R564 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R580 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R581 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R582 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R585 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R586 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R587 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R588 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R591 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R592 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R593 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R594 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R595 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R596 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R597 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R701 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R703 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R704 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R705 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R711 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R712 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R713 0RJ0472D677 47 OHM 1/10 W 5% 1608 R/TP

R714 0RJ1801D677 1.8K OHM 1/10 W 5% 1608 R/TP

R715 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R716 0RJ0472D677 47 OHM 1/10 W 5% 1608 R/TP

R718 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R719 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R726 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R727 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R729 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R730 0RJ2700D677 270 OHM 1/10 W 5% 1608 R/TP

R731 0RJ2700D677 270 OHM 1/10 W 5% 1608 R/TP

R740 0RH0000D622 0 1/10W P-TYPE TAPPING

R741 0RH0000D622 0 1/10W P-TYPE TAPPING

R742 0RH0000D622 0 1/10W P-TYPE TAPPING

R743 0RH0000D622 0 1/10W P-TYPE TAPPING

R744 0RH0000D622 0 1/10W P-TYPE TAPPING

R745 0RH0000D622 0 1/10W P-TYPE TAPPING

R746 0RH0000D622 0 1/10W P-TYPE TAPPING

R752 0RJ1003D677 100K OHM 1/10 W 5% 1608 R/TP

R753 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R760 0RJ0472D677 47 OHM 1/10 W 5% 1608 R/TP

R761 0RJ0472D677 47 OHM 1/10 W 5% 1608 R/TP

R765 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R766 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R767 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R768 0RJ1801D677 1.8K OHM 1/10 W 5% 1608 R/TP

R769 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R809 0RJ2202D677 22K OHM 1/10 W 5% 1608 R/TP

R810 0RH5600D622 560 1/10W 5 D.R/TP

R811 0RH0332D622 33 1/10W 5 D.R/TP

R812 0RH0332D622 33 1/10W 5 D.R/TP

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R813 0RH0332D622 33 1/10W 5 D.R/TP

R814 0RH0332D622 33 1/10W 5 D.R/TP

R815 0RH0332D622 33 1/10W 5 D.R/TP

R816 0RH0332D622 33 1/10W 5 D.R/TP

R817 0RH0332D622 33 1/10W 5 D.R/TP

R818 0RH0332D622 33 1/10W 5 D.R/TP

R819 0RH0332D622 33 1/10W 5 D.R/TP

R820 0RH0332D622 33 1/10W 5 D.R/TP

R821 0RJ2202D677 22K OHM 1/10 W 5% 1608 R/TP

R822 0RH5600D622 560 1/10W 5 D.R/TP

R824 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R825 0RH0000D622 0 1/10W P-TYPE TAPPING

R826 0RH0332D622 33 1/10W 5 D.R/TP

R827 0RH0332D622 33 1/10W 5 D.R/TP

R828 0RH0332D622 33 1/10W 5 D.R/TP

R829 0RH0332D622 33 1/10W 5 D.R/TP

R830 0RH0332D622 33 1/10W 5 D.R/TP

RA202 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA204 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA206 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA208 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA210 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA212 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA214 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA216 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA218 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA220 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA222 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA224 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA225 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA226 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA227 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA228 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA229 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA230 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA231 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA232 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA233 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA234 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA235 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA236 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA237 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA238 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA239 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA240 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA241 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

RA242 0RHZTCZ001A 100 OHM 1/16 W 5% 3215 R/TP CH

X201 6202TST001E SX-1 SUNNY CHIP 24MHZ 30PPM 20

X501 6202TST001E SX-1 SUNNY CHIP 24MHZ 30PPM 20

BD901 0DD360000DA D3SBA60 BK SHINDENGEN 600V 2

C901 0CBZTBU002B BULK PCX2 335 474K

C902 0CKZTBU003C SC E 472M 14.0BW7 250V BK7.5 S

C903 0CKZTBU003C SC E 472M 14.0BW7 250V BK7.5 S

C904 0CBZTBU002C BULK PCX2 335 104M

C905 0CZZTAB002C KMF 18*40 SYE / SWE 400V 120UF

C906 0CK10302945 0.01UF 2KV Z F TR

- 27 -

OTHERs

POWER BOARD

Page 28

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C907 0CE476EK638 47UF KMG 50V M FM5 TP 5

C908 0CQ2721N419 2700PF 100V J PE NI TP

C909 0CK1020K515 1000PF 50V K B TR

C911 0CE228EF630 2200UF KMG 16V M FM5 BULK

C913 0CE108BF630 1000UF KME 16V M FM5 BULK

C914 0CE228ED630 2200UF KMG,RD 10V 20% BULK FM5

C915 0CE228ED630 2200UF KMG,RD 10V 20% BULK FM5

C916 181-288L MKT 100V 823JTR PHS26823

C918 0CE228ED630 2200UF KMG,RD 10V 20% BULK FM5

C919 0CKZTBU003C SC E 472M 14.0BW7 250V BK7.5 S

C921 0CE228EF630 2200UF KMG 16V M FM5 BULK

C922 0CKZTTA002E EKR3A102K09FK5 SAMWHA 1KV 1000

C923 0CKZTTA002E EKR3A102K09FK5 SAMWHA 1KV 1000

C924 0CE336BH638 33UF KME 25V M FM5 TP5

D901 0DD400709CB UF4007 TP G.I DO204AL 1000V 1

D902 0DR400409AB UF4004 TP G.I DO204AL 400V 1A

D903 0DRIR00011B 16CTQ100 I.R ST TO220 100V 16A

D906 0DRIR00021A 30CTQ060 I.R ST TO220 60V 30A

D907 0DS113309AA 1SS133 TP ROHM KOREA DO34 90V

F901 131-040C 3150MA 250V 5.2X20 CY/GL UL /

FH1 430-858C AFC-520 BAE EUN TA

FH2 430-858C AFC-520 BAE EUN TA

IC901 0IPMGIH001A ICE2AS01 INFINEON 8P,DIP ST OF

IC904 0IKE431000B KIA431 (TP)

IC905 0ISS780500F KA7805

L901 150-A85F LX31 GET BAR CHOKE,3.3UH,LB886

L902 150-A85F LX31 GET BAR CHOKE,3.3UH,LB886

LF901 6200TZZ001A - GO BK L/FILTER,9MH,LB886F

LF902 6200TZZ001A - GO BK L/FILTER,9MH,LB886F

P901 6620TKB002A BAE EUN AC UNIVERSAL 3PIN BLAC

P902 6602T25008G SMW250-08 YEONHO 2.5MM LOCK S/

PC1 0ILI817000E LTV-817M B 4P BK PHOTO COUPLER

Q902 0TFFN10003A INFINEON SPA07N60C2 ST TO220 6

R901 0RD6803A609 680K OHM 1/2 W (7.0) 5% TA52

R902 0RD3902A609 39K OHM 1/2 W (7.0) 5% TA52

R903 0RD3902A609 39K OHM 1/2 W (7.0) 5% TA52

R906A 0RX5102J609 51KOHM 1 W 5% TA52

R906B 0RX5102J609 51KOHM 1 W 5% TA52

R907 0RD0102Q609 10 1/4W(3 5% TA52

R908 0RD0222Q609 22 1/4W(3 5% TA52

R909 0RD1001Q609 1K 1/4W(3 5% TA52

R910 0RD0431A609 4.3 OHM 1/2 W (7.0) 5% TA52

R911 0RD1004A609 1.0M OHM 1/2 W (7.0) 5% TA52

R912 0RD1004A609 1.0M OHM 1/2 W (7.0) 5% TA52

R913 0RN1102F409 11K 1/6W 1% TA52

R914 0RD1002Q609 10K 1/4W(3 5% TA52

R917 0RD1201Q609 1.20K 1/4W(3 5% TA52

R918 0RD1000Q609 100 1/4W(3 5% TA52

R920 0RN4702F409 47K 1/6W 1% TA52

R921 0RN2701F409 2.70K 1/6W 1% TA52

R923 0RB0330K607 0.33 OHM 2 W 5% TA62

R924 0RD0752Q609 75 1/4W(3 5% TA52

R925 0RD1002Q609 10K 1/4W(3 5% TA52

R926 0RN0820H609 0.82 1/2W 5 TA52

R927 0RD0102A609 10 OHM 1/2 W (7.0) 5% TA52

R928 0RD0202Q609 20 1/4W(3 5% TA52

T901 6170TMZ125A EER3016 340UH V-10PIN LB886F S

TH901 6322TA080AA TP8D13 DAEWOO +/- 15% 110/220

ZD901 0DZ470009BC GDZ4.7B TP GRANDE DO34 0.5W 4.

DATE: 2002. 2. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R1 0RD4701Q609 4.70K 1/4W(3 5% TA52

R2 0RD4701Q609 4.70K 1/4W(3 5% TA52

R3 0RD8200Q609 820 1/4W(3 5% TA52

R4 0RD8200Q609 820 1/4W(3 5% TA52

R5 0RD1501Q609 1.50K 1/4W(3 5% TA52

R6 0RD1501Q609 1.50K 1/4W(3 5% TA52

R7 0RD2201Q609 2.20K 1/4W(3 5% TA52

R8 0RD2201Q609 2.20K 1/4W(3 5% TA52

SW1 140-058E SKHV10910B LGEC NON 12V 20A HO

SW2 140-058E SKHV10910B LGEC NON 12V 20A HO

SW3 140-058E SKHV10910B LGEC NON 12V 20A HO

SW4 140-058E SKHV10910B LGEC NON 12V 20A HO

SW5 140-058E SKHV10910B LGEC NON 12V 20A HO

SW6 140-058E SKHV10910B LGEC NON 12V 20A HO

SW7 140-058E SKHV10910B LGEC NON 12V 20A HO

SW8 140-058E SKHV10910B LGEC NON 12V 20A HO

ZD1 0DZ560009CE MTZJ5.6B TP ROHM-K DO34 500MW

ZD2 0DZ560009CE MTZJ5.6B TP ROHM-K DO34 500MW

- 28 -

CONTROL BOARD

Page 29

- 29 -

BA7657 Multimedia ICs

1

24

BLOCK DIAGRAM

PIN CONFIGURATION

Red 1 input

HD Sync Signal detector

Green 1 input

Ground

Blue 1 input

Ground

Red 2 input

Ground

Green 2 input

1

2

3

4

5

DET.

6

7

Syncsepa

8

9

Logic

HD 1 input

24

HD 2 input

23

HD output

22

21

Red output

Vcc

20

Green output

19

Composite video input

18

(Sync on Green)

Composite sync output

17

CTL (H:IN, L:IN2)

16

Ground

Blue 2 input

VD 1 input

10

11

12

15

14

13

Blue output

VD output

VD 2 input

Page 30

- 30 -

BA033 Low Saturation Voltage type 3-terminal Regulator

OUT

Reference Voltage

Vcc

1

2

3

GND

BLOCK DIAGRAM

1. Vcc

2. GND

3. OUTPUT

1

3

2

KA7812 ( KA7808 , KA7805) Positive Voltage Regulator 5V (8V, 12V)

1: Input

2: GND

3: Output

1

2

3

BLOCK DIAGRAM

PARTSTYPE

PARTSTYPE

KA78M05R

1. INPUT

2. GND

3. OUTPUT

1

3

2

KSC1623

1. BASE

2. EMITTER

3. COLLECTOR

2

3

1

Regulator

Transistor

1

3

2

1: REFERENCE

2: ANODE

3: CATHODE

KIA431

(Programmable

Shunt Regulator)

KIA7042

E

B

C

Page 31

1. GM5020

Page 32

- 32 -

Page 33

- 33 -

Page 34

- 34 -

Page 35

- 35 -

Page 36

- 36 -

Page 37

- 37 -

Page 38

- 38 -

Page 39

- 39 -

Loading...

Loading...