www.gastmfg.com

ISO 9001 & 14001 CERTIFIED

®Registered Trademark/™Trademark of Gast Manufacturing Inc., Copyright ©2003 Gast Manufacturing Inc. All Rights Reserved.

PART NO. 70 - 3000 G442PL (REV-J)

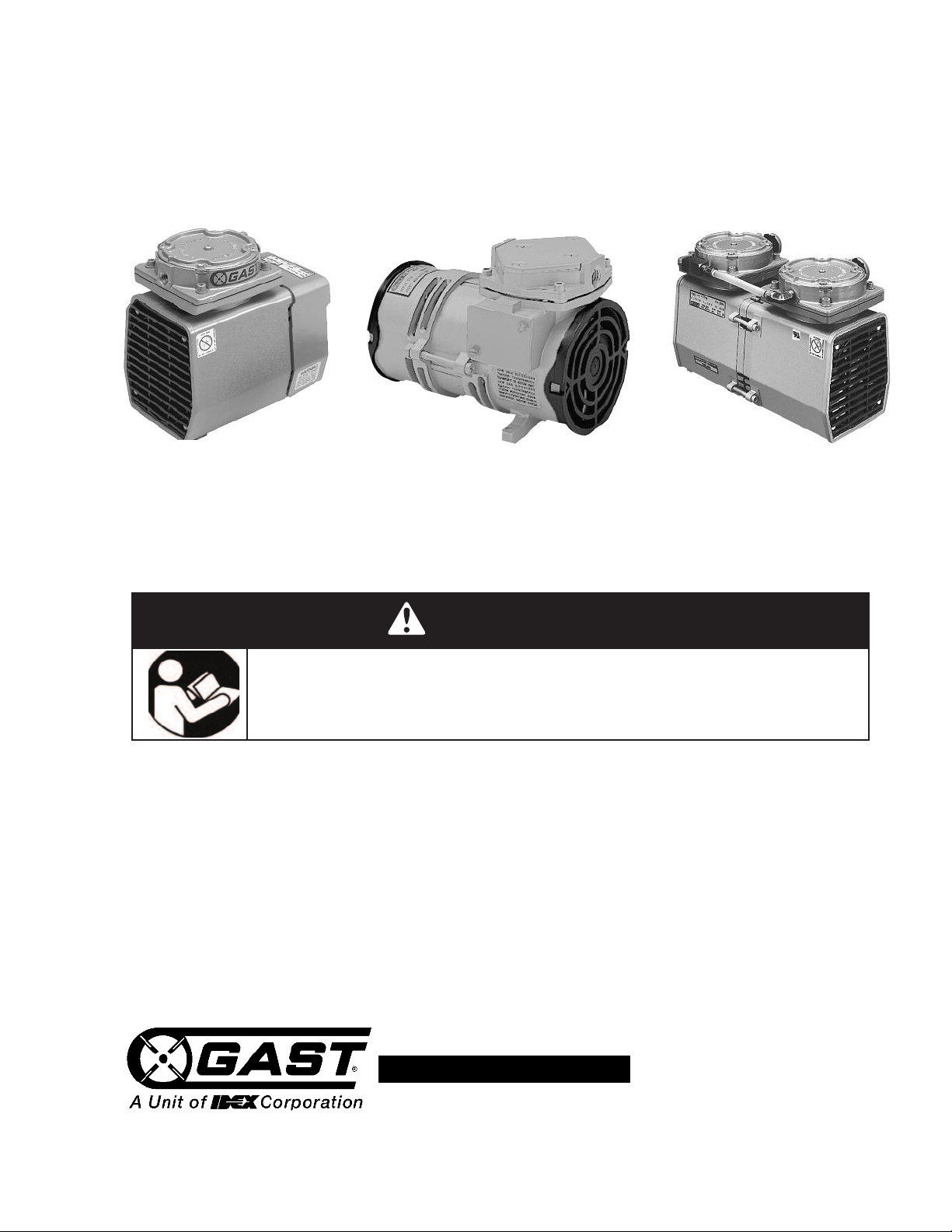

OIL-LESS DIAPHRAGM

VACUUM PUMPS & COMPRESSORS

OPERATION & MAINTENANCE MANUAL

Model DOA Shown

Thank you for purchasing this Gast product. It is manufactured to the highest standards

using quality materials. Please follow all recommended maintenance, operational

and safety instructions and you will receive years of trouble free service.

PLEASE READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND USING

THIS PRODUCT. SAVE THIS MANUAL FOR FUTURE REFERENCE AND

Product Use Criteria:

• Pump only clean, dry air.

• Operate at 40ºF - 104ºF (4.4ºC - 40ºC).

• Protect unit from dirt & moisture.

• Do not pump flammable or explosive gases or

use in an atmosphere that contains such gases.

• Protect all surrounding items from exhaust air. This

exhaust air can become very hot.

• Corrosive gases and particulate material will

damage unit. Water vapor, oil-based contaminants

or other liquids must be filtered out.

• Consult your Gast Distributor/Representative

before using at high altitudes.

Model MOA Shown

KEEP IN THE VICINITY OF THE PRODUCT

Model DAA Shown

WARNING

Your safety and the safety of others

c

WARNING

is extremely important.

e have provided many important safety messages in

W

this manual and on your product. Always read and

obey all safety messages.

his is the safety alert symbol. This symbol

T

alerts you to hazards that can kill or hurt you and

others. The safety alert symbol and the words

“DANGER” and “WARNING” will precede all safety

essages. These words mean:

m

Plumbing

Remove plugs from the IN and OUT ports. Connect

ith pipe and fittings that are the same size or larger

w

than the productʼs threaded ports. Be sure to connect

the intake and exhaust plumbing to the correct inlet and

outlet ports.

Accessories

ilters and mufflers are supplied with some models.

F

These should be checked periodically and replaced

when necessary. Please consult your Gast

Distributor/Representative for additional filter

ecommendations.

r

DANGER

e killed or seriously injured if you donʼt follow

b

ou will

Y

instructions.

WARNING

You can

instructions.

All safety messages will identify the hazard, tell you

how to reduce the chance of injury, and tell you what

can happen if the safety instructions are not followed.

INSTALLATION

be killed or seriously injured if you donʼt follow

WARNING

Electrical Shock Hazard

Disconnect electrical power at the circuit breaker

or fuse box before installing this product.

Install this product where it will not come into

contact with water or other liquids.

Install this product where it will be weather

protected.

Electrically ground this product.

Failure to follow these instructions can result in

death, fire or electrical shock.

Correct installation is your responsibility. Make sure you

have the proper installation conditions and that

installation clearances do not block air flow.

Blocking air flow over the product in any way can cause

the product to overheat.

Mounting

This product can be installed in any orientation.

Mounting the product to a stable, rigid operating surface

and using shock mounts will reduce noise and vibration.

Install relief valves and gauges at inlet or outlet, or both,

to monitor performance. Check valves may be required

to prevent back streaming through the pump.

Motor Control

It is your responsibility to contact a qualified

electrician and assure that the electrical installation is

adequate and in conformance with all national and local

codes and ordinances. The metal capacitor shell must

be grounded.

Determine the correct overload setting required to

protect the motor (see motor starter manufacturerʼs

recommendations). Select fuses, motor protective

switches or thermal protective switches to provide

protection. Fuses act as short circuit protection for the

motor, not as protection against overload. Incoming line

fuses must be able to withstand the motorʼs starting

current. Motor starters with thermal magnetic overload

or circuit breakers protect motor from overload or

reduced voltage conditions.

The wiring diagram supplied with the product provides

required electrical information. Check that power

source is correct to properly operate the dual-voltage

motors.

OPERATION

Injury Hazard

Install proper safety guards as needed.

Product surfaces become very hot during operation,

allow product surfaces to cool before handling.

Air stream from product may contain solid or liquid

material that can result in eye or skin damage,

wear proper eye protection.

Failure to follow these instructions can result in

burns, eye injury or other serious injury.

It is your responsibility to operate this product at

recommended pressures or vacuum duties and room

ambient temperatures.

Start Up

If motor fails to start or slows down significantly under

load, shut off and disconnect from power supply. Check

that the voltage is correct for motor and that motor is

turning in the proper direction.

2

MAINTENANCE

c

WARNING

c

WARNING

WARNING

Electrical Shock Hazard

Disconnect electrical power supply cord before

performing maintenance on this product.

If product is hard wired into system, disconnect

electrical power at the circuit breaker or fuse box

before performing maintenance on this product.

Failure to follow these instructions can result in

death, fire or electrical shock.

Injury Hazard

Product surfaces become very hot during operation,

allow product surfaces to cool before handling.

Air stream from product may contain solid or liquid

material that can result in eye or skin damage,

wear proper eye protection.

Clean this product in a well ventilated area.

Failure to follow these instructions can result in

burns, eye injury or other serious injury.

SHUTDOWN PROCEDURES

It is your responsibility to follow proper shutdown

procedures to prevent product damage.

NEVER ADD OIL TO THIS OIL-LESS PUMP.

roper shutdown procedures must be followed to

P

prevent pump damage. Failure to do so may result in

premature pump failure. Gast Manufacturing Oil-Less

Diaphragm Vacuum Pumps and Compressors are

onstructed of ferrous metals or aluminum which are

c

subject to rust and corrosion when pumping

condensable vapors such as water. Follow the steps

below to assure correct storage and shutdown between

perating periods.

o

1. Disconnect plumbing.

2. Operate product for at least 5 minutes without

plumbing.

3. Run at maximum vacuum for 10 to 15 minutes.

4. Repeat step 2.

5. Disconnect power supply.

6. Plug open ports to prevent dirt or other

contaminants from entering product.

SERVICE KIT IN STALLAT ION

It is your responsibility to:

• Regularly inspect and make necessary repairs to

product in order to maintain proper operation.

• Make sure that pressure and vacuum is released

from product before starting maintenance.

Check intake and exhaust filters after first 500 hours of

operation. Clean filters and determine how frequently

filters should be checked during future operation. This

one procedure will help to assure the productʼs

performance and service life.

Solvent Cleaning

Use only Gast recommended Solvent or other

non-petroleum based solvent. Do Not use kerosene or

ANY other combustible solvent to clean product.

1. Remove the four (MOA) or five (DOA) screws in the

top of the product. Remove the top plate.

2. Remove filters and clean with Gast recommended

solvent or other non-petroleum based solvent.

Use compressed air to dry filters and make

sure that all moisture is removed. Reinstall filters.

3. Clean the gasket with water and dry thoroughly.

Reinstall gasket.

4. Reinstall top plate and screws.

Check that all external accessories such as relief valves

and gauges are attached to cover and are not damaged

before re-operating product.

Electrical Shock Hazard

Disconnect electrical power supply cord before

installing service kit.

If product is hard wired into system, disconnect

electrical power at the circuit breaker or fuse box

before installing service kit.

Disconnect air supply and vent all air lines to

release pressure or vacuum.

Failure to follow these instructions can result in

death, fire or electrical shock.

Gast will NOT guarantee field-rebuilt product

performance. For performance guarantee, the product

must be returned to a Gast Authorized Service Facility.

Service Kit contents vary. Most contain gaskets and

filter parts.

1. Disconnect electrical power to pump.

2. Disconnect air supply and vent all air lines to

release pressure or vacuum.

3. Remove the socket cap screws from the head of the

pump. Remove the head of the pump.

3

Loading...

Loading...