Page 1

GDT™ 43

Installation Instructions

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

chartplotter or fishfinder product box for product warnings and

other important information.

You are responsible for the safe and prudent operation of your

vessel. Sonar is a tool that enhances your awareness of the

water beneath your boat. It does not relieve you of the

responsibility of observing the water around your boat as you

navigate.

CAUTION

Failure to install and maintain this equipment in accordance with

these instructions could result in damage or injury.

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

When drilling or cutting, always check what is on the opposite

side of the surface.

This equipment should be installed by a qualified marine

installer.

To obtain the best performance and to avoid damage to your

boat, you must install the Garmin® device according to these

instructions.

Read all installation instructions before proceeding with the

installation. If you experience difficulty during the installation,

contact Garmin Product Support.

Registering Your Device

Help us better support you by completing our online registration

today.

• Go to my.garmin.com/registration.

• Keep the original sales receipt, or a photocopy, in a safe

place.

Garmin Support Center

Go to support.garmin.com for help and information, such as

product manuals, frequently asked questions, videos, software

updates, and customer support.

Mounting Location Considerations

• On fin-keel vessels À, the transducer should be mounted

more than 25 cm (10 in) and less than 75 cm (30 in) in front

of the keel and less than 10 cm (4 in) to the side of the

centerline.

• On full-keel vessels Á, the transducer should be mounted at

a slight angle that aims at the bow, not parallel to the

centerline.

• On power boats and hulls with chines Â, the transducer

should not be mounted near the edge of sharp hull chines.

• On single-drive boats, the transducer must not be mounted in

the path of the propeller.

• On twin-drive boats, the transducer should be mounted

between the drives, if possible.

• The transducer should be mounted parallel to the bow-stern

axis of your vessel.

• The transducer should be mounted in a location that allows

accessibility to the transducer from the inside of the vessel.

• The transducer should not be mounted behind strakes, struts,

fittings, water intake or discharge ports, or anything that

creates air bubbles or causes the water to become turbulent.

• The transducer should not be mounted in a location where it

might be jarred when launching, hauling, or storing.

• The transducer can cause cavitation that can degrade the

performance of the boat and damage the propeller.

• The transducer must be in clean (non-turbulent) water for

optimal performance.

• If you have a question about the location of the thru-hull

transducer, contact your vessel builder or other owners of

similar vessels for advice.

Tools Needed

• Drill

• 43 mm (1 11/16 in.) hole saw

• 52 to 55 mm (2 1/16 to 2 3/16 in.) hole saw (cored-fiberglass

hull installations)

• Marine sealant

• Silicone grease

• Cable cutter

• Metal file (metal-hull installations)

• Fiberglass cloth and resin (option for sealing a coredfiberglass hull)

• 43 mm (1 11/16 in.) cylinder, wax, tape, and casting epoxy

(option for sealing a cored-fiberglass hull)

Installing the Thru-Hull Transducer

If you are installing the transducer in a cored-fiberglass hull, you

must first prepare the hull (Preparing a Cored-Fiberglass Hull,

page 2).

April 2017

190-02112-02_0C

Page 2

Use a 43 mm (1 11/

1

the mounting location.

Insert the thru-hull fitting in the hull.

2

Apply marine sealant to the outer flange of the thru-hull fitting

3

and tighten the nut by hand.

Slide both rubber O-rings onto the plug.

4

Apply silicone grease to the outside of the plug.

5

Using a slow, twisting motion, insert the plug into the thru-hull

6

fitting.

Verify that the plug is properly seated into the fitting.

7

Mount the fitting with the pin at a 90 degree angle to the

8

centerline of the boat.

After the marine sealant applied in step 3 has cured, remove

9

the nut and apply sealant on the fitting inside the hull.

Replace the nut and tighten it by hand.

10

After installation of the fitting, replace the plug with the actual

11

transducer.

NOTE: It is recommended that you keep the plug for use

while cleaning or servicing your transducer.

Install the wire locking device onto the transducer.

12

in.) hole saw to cut through the hull at

16

Preparing a Cored-Fiberglass Hull

NOTICE

If the core of a cored-fiberglass hull is not sealed properly, water

may seep into the core and severely damage the boat.

Fiberglass or casting epoxy (not included)

À

Cylinder spacer (not included)

Á

Inner fiberglass skin

Â

Core

Ã

Outer fiberglass skin

Ä

• If the pilot hole is not in the correct location, seal the hole

with epoxy and repeat step 1.

• If the pilot hole is in the correct location, use a 43 mm (1

11

/16 in.) hole saw to cut a hole from the outside of the

boat through the outer fiberglass skin only. Do not cut

completely through the hull.

On the inside of the boat, at the pilot hole location, use a hole

3

saw to cut a hole 9 to 12 mm (3/8 to 1/2 in.) larger than the

hole you cut in the outside of the boat in step 2.

Cut through the inner fiberglass skin and most of the core,

without cutting the outer skin.

NOTE: When cutting the inner fiberglass skin and core, be

careful to not cut the outer fiberglass skin, or you will not be

able to correctly seal the hull.

Remove the inner fiberglass skin and core you cut in step 3.

4

You should be able to see the inside of the outer fiberglass

skin.

Sand the inside of the hole and the areas immediately around

5

both the inside and outside fiberglass skin.

Clean the area using a mild detergent or weak solvent, such

6

as isopropyl alcohol, to remove any dust and dirt.

Sealing the Hull with Fiberglass

From inside the boat, coat a layer of fiberglass cloth with

1

fiberglass resin and place it inside the hole to seal the core.

Add layers of fiberglass cloth and resin until the hole is the

2

correct diameter of 43 mm (1 11/

After the fiberglass has hardened, sand and clean inside and

3

around the hole.

The cored-fiberglass hull is now prepared, and you can

complete the transducer installation.

Sealing the Core with Casting Epoxy

To properly seal the core with casting epoxy, you must create a

cylinder with a diameter of 43 mm (1 11/

as the epoxy sets.

Coat a 43 mm (1 11/

1

Insert the cylinder in the hole through the outer skin and tape

2

it in place on the outside of the boat.

Fill the space between the cylinder the core with casting

3

epoxy.

After the epoxy has hardened, remove the cylinder, and sand

4

and clean inside and around the hole.

The cored-fiberglass hull is now prepared, and you can

complete the transducer installation.

in.) cylinder with wax.

16

in.).

16

in.) to act as a spacer

16

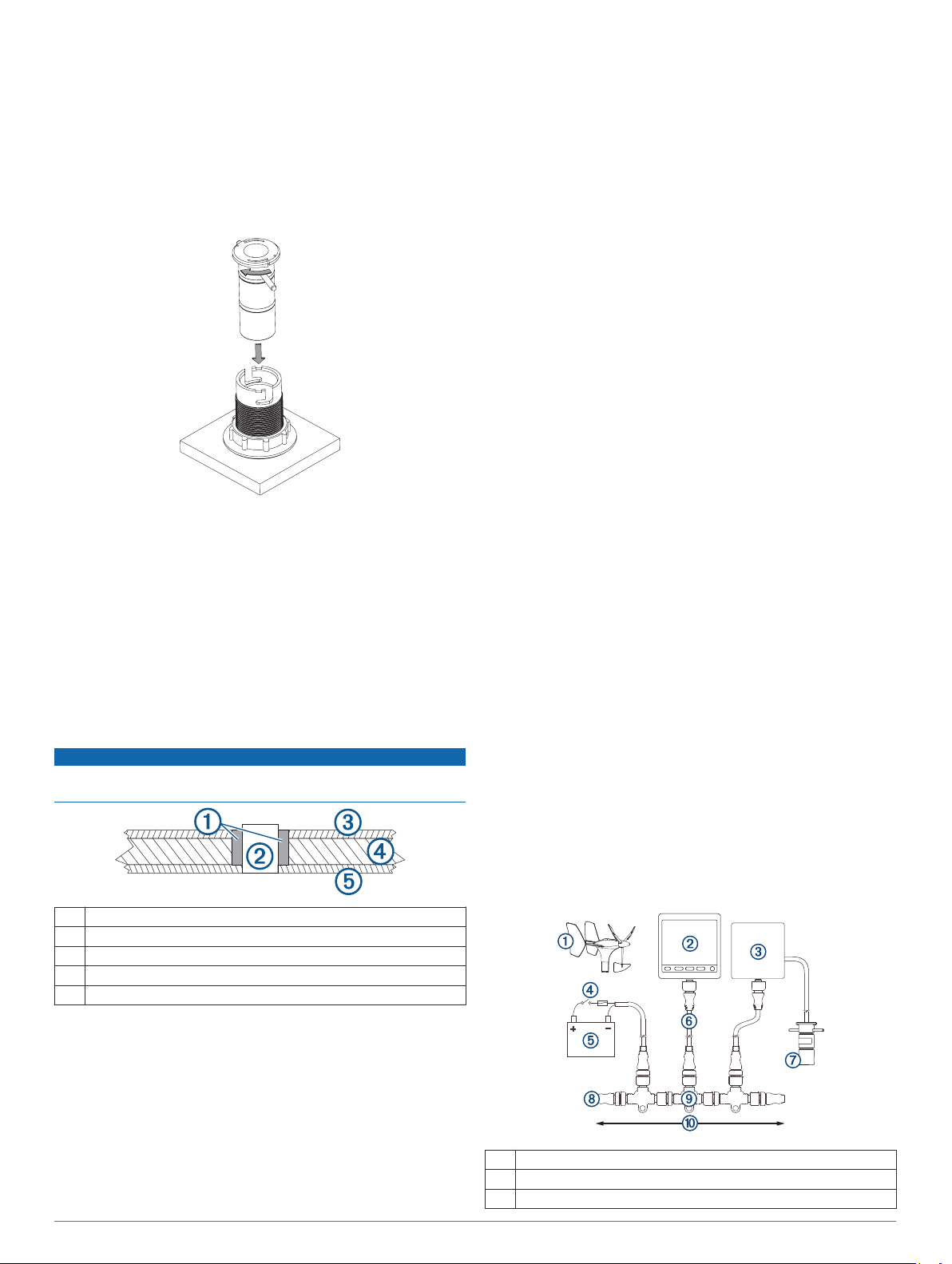

NMEA 2000® Connection

The GDT 43 transducer connects to the NMEA 2000 network

through the NMEA 2000 adapter.

Drill the hole through the hull.

1

Seal the core inside the hull using either fiberglass (Sealing

2

the Hull with Fiberglass, page 2) or casting epoxy (Sealing

the Core with Casting Epoxy, page 2).

Drilling a Hole in a Cored-Fiberglass Hull

From inside the boat, drill a 3 mm (1/8 in.) pilot hole

1

completely through the hull.

Examine the pilot hole on the outside of the boat, and select

2

an option:

2

gWind™ Wireless 2 transducer

À

GNX™ Wind instrument

Á

NMEA 2000 adapter

Â

Page 3

Ignition or in-line switch

Ã

12 Vdc power source

Ä

Drop cable

Å

GDT 43 transducer

Æ

NMEA 2000 terminator or backbone cable

Ç

NMEA 2000 T-connector

È

Existing NMEA 2000 network

É

NMEA 2000 Adapter Specifications

Dimensions (W x L x D) 101.4 x 116.3 x 76.2 mm (4 x 4 19/32 x 3 in.)

Weight Adapter: 120.9 g (4.26 oz.)

With bracket: 200.7 g (7.08 oz.)

Power input From 9 to 16 Vdc

Power consumption Max. 2.4 W

Temperature range From -15 to 70ºC (from 5 to 158°F)

Nexus® Wiring

When you connect the GDT 43 to a Nexus system, you must cut

the GDT 43 cable to the desired length and connect the wires to

the dedicated depth port on the Nexus device.

GDT 43 Nexus

Black Black

Red Blue

Screen Screen

White Do not use

Transducer Calibration

NOTE: If you are using a Nexus system or if the transducer data

does not appear, the transducer must be calibrated.

You can use the NexusRace™ software to calibrate the

transducer. To download the NexusRace software, go to

garmin.com/NexusRace.

Maintenance

Testing the Installation

NOTICE

You should check your boat for leaks before you leave it in the

water for an extended period of time.

The transducer must be in the water to work properly.

When your boat is in the water, check for leaks near the

1

transducer installation site.

If leaks are found, apply marine sealant around the

2

installation site, let the sealant cure, and repeat step 1.

Cleaning the Transducer

Aquatic fouling accumulates quickly and can reduce your

device's performance.

Remove the fouling with a soft cloth and mild detergent.

1

If the fouling is severe, use a scouring pad or putty knife to

2

remove growth.

Wipe the device dry.

3

NMEA 2000 PGN

Type PGN Description

Transmit and

receive

Transmit 126996 Product information

© 2017 Garmin Ltd. or its subsidiaries

Garmin®, the Garmin logo, and Nexus® are trademarks of Garmin Ltd. or its subsidiaries,

registered in the USA and other countries. GDT™, GST™, and NexusRace™ are

trademarks of Garmin Ltd. or its subsidiaries. These trademarks may not be used

without the express permission of Garmin.

NMEA 2000® and the NMEA 2000 logo are registered trademarks of the National Marine

Electronics Association.

005932 ISO acknowledgment

059904 ISO request

060928 ISO address claim

126208 NMEA®:Command, request, and

acknowledge group function

126464 Transmit and receive PGN list group function

128267 Water depth

130312 Temperature

Specifications

GDT 43 Specifications

Dimensions (W x L) 42 x 86 mm (1.65 x 3.38 in.)

Hull thickness Min. 6 mm (0.24 in.)

Max. 42 mm (1.65 in.)

Temperature range Operating: From -10 to 70ºC (from 14 to

158°F)

Storage: From -35 to 70ºC (from 31 to 158°F)

Transducer cable length 6 m (19.7 ft.)

Sonar frequency 200 kHz

Sonar depth* 275 m (900 ft.)

*Dependent upon the water conditions.

3

Page 4

Loading...

Loading...