Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

Thank you for purchasing a Futaba digital proportional radio control set.

Please read this manual carefully before using your set.

AM

FEATURES OF FP-4NBL

The FP-4NBL is a 4 channel AM proportional radio control

set

with

an

ergonomic

pursuit of easier operation, newly designed sticks for smooth

and positive operation, servo reversing switch for each channel, and other innovations based on the opinions and needs of

many RC modelers.

Please read this manual before using your new set.

case

created

as a result of the exhaustive

TRANSMITTER FP-T4NBL______________

• Servo reversing switch for each channel. Servos are reversed

by using this switch.

• Newly designed sticks operate smoothly and positively.

Spring tension mechanism allows adjustment of the operating feel of the stick lever.

• Nonslip adjustable lever head allows adjustment of the stick

length as desired.

• Functional case, created as a result of the exhaustive pursuit

of easier operation, has evolved a thick case which fits into

the palm of the hand.

• Easy to read transmitter battery voltage/output level meter.

• Neck strap bracket provided as standard. Operation is easier

if the transmitter is hung from your neck by using the neck

strap.

• Nicad operation as standard.

RECEIVER FP-R114H

• High performance AM 4 channel receiver in which miniature

size and light weight have been achieved by using the PC

board space to the maximum.

• Narrow band ceramic filter improves rejection of adjacent

channel interference.

RECEIVER WITH LINEAR CONTROLLER MCR-4A

• FET amplifier with miniature lightweight AM 4-channel receiver and motor controller in one pack.

• Since the drive motor power supply (7.2 V NiCd battery

pack, etc.) can also be used to power the receiver and servos,

troublesome wiring is unnecessary and the model can be

made lighter.

• Built-in high performance low voltage "autocut" circuit pre-

vents loss of control due to power supply voltage drop

during flight.

• Since the motor speed can be controlled steplessly from

maximum alow to high, acrobatics equal to those of engine

aircraft can be reproduced even with a motor aircraft.

FEATURES OF MCR-4A RECEIVER

• Narrow band design using a narrow band ceramic filter.

FEATURES OF MCR-4A AMP

• Built-in heat protector prevents overheating of the amplifier

by a continuous overcurrent.

• Motor idle or maximum slow can be arbitrarily set at the

transmitter throttle stick maximum slow position by built-in

idle point trimmer.

SERVO FP-S148 RUGGED, LOW-PROFILE SERVO

• Vibration and shock resistance have been improved further

by using a direct wiring system which directly connects the

servo amp, motor and potentiometer.

•

The height of the

high speed, and smooth movement equal to that of the coreless servo have been realized by using a new small, highperformance motor. (Output torque 3kg.cm, operating

speed 0.22 sec/60°).

servo

has

been

reduced and

high

torque,

SERVO FP-S133 HIGH-QUALITY MICROSERVO_

• Futaba hybrid custom 1C provides high starting output

torque, narrow dead-band, and excellent trackability.

• Thick film gold plated connector pins insure positive contact

connector shape increase reliability against shock and vibration. The connector housing has a reverse insertion prevention mechanism.

• Adjustable (splined) horn permits arbitrary setting of the

neutral position.

• Despite being a microservo, operating speed is a fast 0.21

sec/ 60° and output torque is a high 2.2 kg/cm.

SET CONTENTS AND RATINGS

(Specifications are subject to change without prior notice.)

FP-4NBL

Transmitter

Receiver

Servo

Charger

Nicad Battery

Switch

Accessories

For engine

powered plane

FP-R114H x 1

FP-S148 x 3

NR-4QBx1 | NR-4Kx1

SSW-J x 1

Servo tray ——

Extension cord. Neck strap. Frequency flag,

Spare horn. Screws

For glider

FP-T4NBL x 1

FBC-8B(4) x 1

For electric

powered plane

MCR-4A x 1

FP-S133x2

—

Page 2

TRANSMITTER FP-T4NBL

Operating system : 2 stick, all channels

servo reverse

Transmitting frequency : 72 MHz bands

Modulation system : AM

(amplitude modulation)

Power requirement : 9.6V 500 mAH Nicad

Battery

Current drain : 150mA

RECEIVER

Receiving frequency : 72 MHz bands

Crystal replacement system: Frequency can be

Intermediate frequency 455 kHz

Power requirement 4.8 V Nicd Battery

Current drain 18 mA (at 4.8 V)

Dimensions 1.3x1.87x0.78 in

Weight 0.9 5 oz (27.5 g)

Receiving range 500m on the ground

RECEIVER WITH LINEAR CONTROLLER MCR-4A

Dimensions

Weight

RECEIVER

Receiving frequency

Intermediate frequency

Current drain

Receiving range

AMP

Operating system

Voltage

Continuous maximum current

Momentary maximum current

Resistance loss

1.24x2.92x0.63 in (31.6x74.2x16.1mm)

(excluding protrusion at top)

1.5 oz (44.0 g) (excluding switches and

connectors)

72 MHz bands

455

kHz

26mA

500m on the ground 1000m in the air

with the FP-T4NBL

(under best conditions)

: idle to maximum speed, no brake, idle

point trimmer

:

6.0

to

8.4

:

100

:

450

: 0.01 ohm

V

A

A

FP-R114H___________

changed within the

same frequency band

by changing the precision crystal.

(shared with servo)

(33x47.4x19.8mm)

1000m in the air

with the FP-T4NBL

(under best conditions)

SERVO FP S133

Control system

Operating angle

Power supply

Power consumption

Output torque

Operating speed

Dimensions

Weight

SERVO FP-S148

Control system

Operating angle

Power requirement

Current drain

Output torque

Operating speed

Dimensions

Weight

+ pulse width control 1520 us neutral

One side 40° or greater (including trim)

trim)

4.8V

or

6.0V

oz

(shared

(19g)

6.0V, 8mA (at idle)

30.6 oz/in (2.2 kg.cm)

0.21 sec/60°

1.10 x 051 x 1.14 in (28 x 13x29 mm)

0.67

+putse width control

1520 us neutral

One side 45° or more

4.8V-6V

6.0V, 12mA (at idle)

42 oz-in (3kg.cm)

0.22 sec/60°

1.59x0.77x1.4 in

(40.4x19.8x36mm)

1.5oz

with

receiver)

(44.4

g)

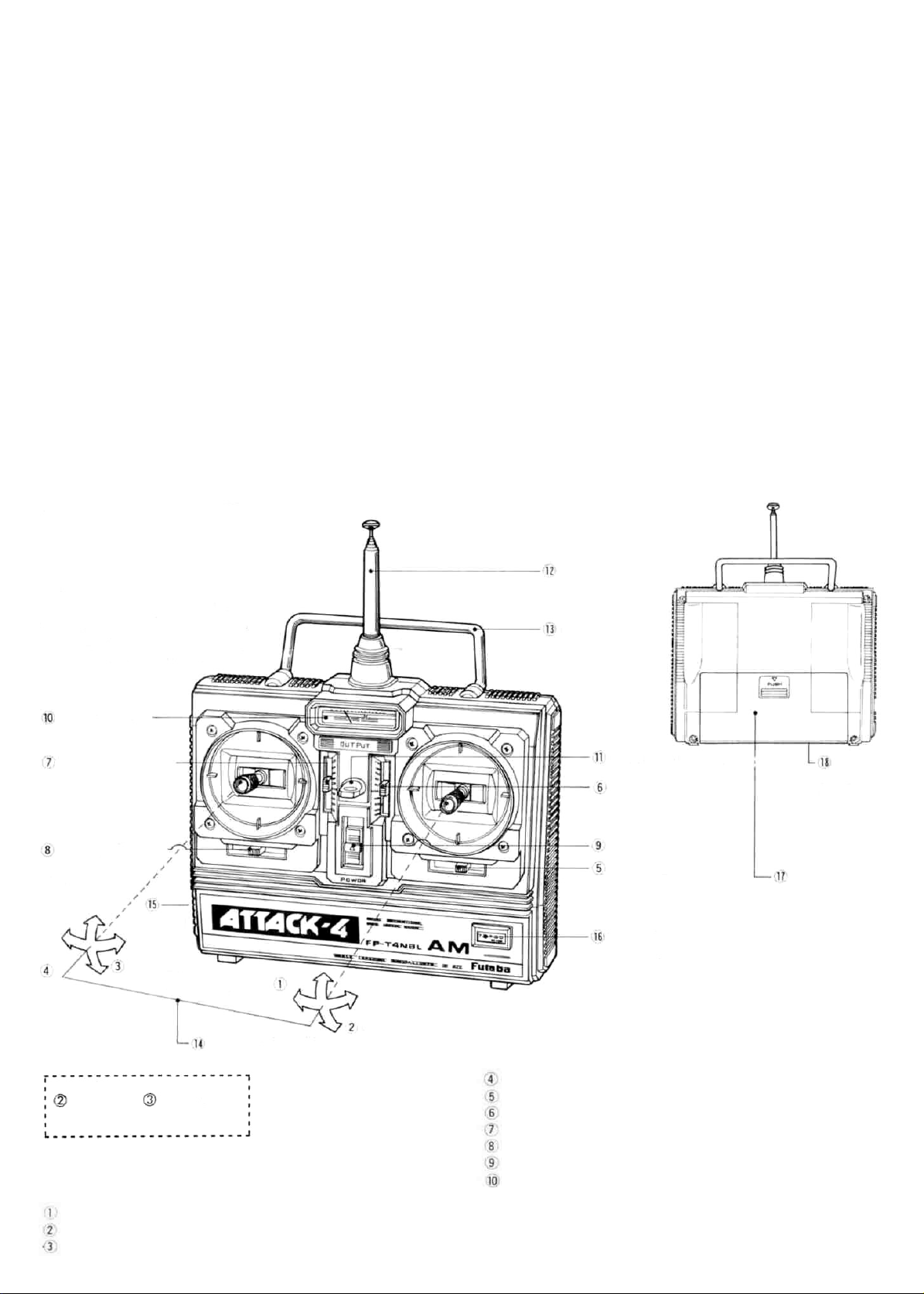

TRANSMITTER FP-T4NBL

CONTROLS

Fig. 1 and Fig. 2 show the name

of each part of the transmitter.

Memorize the position and oper-

ation of each switch and control.

Level meter

Throttle

Rudder trim lever

Rudder

MODE I

are opposite those shown in the

fiqure in Mode-l.

In the following descriptions, all the servo reversing switches

are assumed to be in the normal position. When they are in the

reverse position, operation is the opposite of that described.

trim

Elevator and

lever

Charging

jack

Throttle

MODE II

Aileron

Elevator

Nonslip adjustable

lever head

Engine throttle

Antenna

Handle

Neck strap bracket

Elevator trim lever

Power switch

Aileron trim lever

Transmitter

crystal

Fig.1

Rudder Rudder operation

Aileron trim lever Aileron trimmer

Elevator trim lever Elevator trimmer

Throttle trim lever Throttle trimmer

Rudder trim lever Rudder trimmer

Power switch ON in the up position

Level meter

Fig.

2

Servo

reversing

switches

Battery cover

Aileron Aileron operation

Elevator Elevator operation

Throttle Throttle operation

• This meter indicates the transmitter battery voltage.

• When the antenna is extended fully and the power switch is

set to ON, the pointer should deflect to the silver zone.

Page 3

Neck strap bracket

Bracket for neck strap. (Neck strap is sold separately.)

Antenna

Strong

telescoping

antenna. Extend

it

to

its

full

length

when using the transmitter.

Handle

Use this bar to carry the transmitter.

Nonslip adjustable lever head

The length of the lever head can be adjusted to suit the

operator.

Adjust to the length of your hand.

18 Servo reversing switches

Using the servo reversing switches

• The left side of each switch is the normal position.

• The servo reversing switches reverse the direction of operation of the servos.

Fig.

5

Lever head

Unlock lever heads

in the arrow direction, and adjust the head to

the most comfortable length, then lock it by

turning it in the direction opposite the arrows. Fig. 3

and

Lever head

, by turning them

Charging jack

Use this jack for charging.

Transmitter crystal

Battery cover

Charging of transmitter and receiver Nicad batteries

Recharge the receiver and transmitter Nicad batteries as

shown in Fig. 4.

AC-plug.

Charger PBC-8B

LED

Charging plug

for transmitter.

Transmitter

Nicad battery

NT-8JY

Tx

Rx

Rudder servo

reversing switch

Throttle servo

reversing switch

Elevator servo

reversing switch

Aileron servo

reversing switch

After linkage is complete, inspect the servos. If the direction of

operation of the stick lever and the direction of operation of a

servo are opposite, switch the appropriate servo reversing switch.

NORM-> Normal

REV-> Reverse

Fig.

The tension of the stick lever spring can be adjusted.

When these screws are

removed, the back cover

can be removed.

•The tension of the

spring can be adjusted by removing

the transmitter back

cover and turning

the screw for each

stick. Set the springs

for the best stick feel.

6

Fig.

4

Battery cover

NR-4QB

• Connect the charging plug of the dual charger to the transmitter charging jack. Connect the Rx-connector of the dual

charger to the receiver Nicad battery plug, and AC-plug the

dual charger to AC-outtet socket as shown in the figure.

• The receiver battery can be used about 10 times at 10 minutes per flight between rechargings.

• Charge the batteries for about 15 hours. When the set is not

in use for some time, repeat discharge and charge two to

three times before use. (If the batteries are not used for a

long time, their capacity will go down).

• The dual charger transmitter and receiver Nicad batteries

independently or simultaneously.

Notes

1) First connect the charger to the transmitter charge jack.

The LED on the charger will glow RED.

2) Next connect to the receiver switch harness charge cord.

The LED will change to GREENISH-RED (ORANGE).

3) In the case where only one battery pack is connected, the

LED color will be:

TXonly: GREEN

RXonly: RED

Aileron

Elevator

Nicad Battery

Connector

Caution

Do not pull the Nicad battery

connector when the back cover

is removed. The power switch

may be damaged if the battery

connector is strongly pulled.

Rudder

Use a small Phillips

screwdriver

Page 4

RECEIVER FP-R114H, SERVO FP-S1480R FP-S133(IN CASE OF ENGINE POWERED PLANE OR GLIDER)

Receiver, servos, switches, and

battery holder connections

In case of glider

In case of engine

powered plane

Pay careful attention to the polarity

of the connector.

SSW-J

Power switch

Antenna wire

Charging plug

The parts enclosed by the

dotted lines must

be purchased

separately.

Extension

cord

Three servos are

supplied as standard. (In case of

glider, two servos

are supplied as

standard.)

Aileron

servo

Elevator

servo

Throttle

servo

Rudder

servo

Fig.

7

RECEIVER WITH LINEAR CONTROLLER MCR-4A, SERVO FP-S133(IN CASE OF ELECTRIC POWERED PLANE)

MCR-4A, servo, and battery connection

Idle point trimmer

Antenna wire

Receiver crystal

Extension cord

• The MCR-4A can control 280 class to 540 class motors.

•6V (5 batteries), 7.2 V (6 batteries), or 8.4 V (7 batteries) NiCd

battery pack can be used with the MCR-4A. (When using a 540

class, etc. motor, purchase an NiCd battery pack connector off the

market. Be sure that the (+) and (—) polarities are correct. If the

(+) and (—) connections are reversed, the MCR-4A may be damaged beyond repair.)

Power switch

Motor terminal

The parts inside the dotted

lines are not included.

Always use a noise killer

capacitor on the electric motor.

Drive motor

Start switch

Rudder servo (CH4)

Elevator servo (CH2)

Aileron servo (CH1)

NiCd

battery pack

Fig.

8

The

idle

point

trimmer

• Set the transmitter throttle

servo reversing switch to the

normal position.

• Set the transmit throttle

stick to the slowest position

(stick all the way back ),

turn on the MCR-4A power

switch, press the start switch,

and set the idle point trimmer to the point at which

the motor idles.

• If the start switch is not

pressed, the drive motor will

not

run.

• Turn the idle point trimmer slowly and without too much

force.

sets

the

drive

motor

idling

point.

• If the drive motor rotates in the reverse direction, change

the connection of the lead wire from the MCR-4A at the

motor terminals.

• Before pressing the MCR-4A start switch, check that the

transmitter throttle stick is in the slowest position. Starting

the drive motor suddenly is dangerous. This also applies

when the idle point trimmer is changed. Be very careful.

• If an overcurrent flows continuously in the motor for some

reason, the heat protector will operate and stop the motor.

When the temperature drops after a short time, the motor

can be controlled once more.

Correct the cause of the continuous overcurrent before using

the

set.

• The heat protector does not protect the set against momen-

tary overcurrent caused by shorting of the drive motor lead

wires, etc.

• If the drive motor is stopped by the "autocut" function dur-

ing flight, land the aircraft immediately and safely.

Page 5

PRECAUTIONS

• Connect the receiver (or MCR-4A), servos, switches, and

battery firmly as shown in Fig. 7 (Fig. 8). Then extend the

transmitter and receiver antennas fully.

• Set the transmitter power switch to ON. Then set the receiver (or MCR-4A) power switch to ON. The servos stop near

the neutral position. Operate the transmitter sticks and

check that each servo follows the movement of the stick.

• Connect the pushrod to each servo horn, then check if the

direction of travel of each servo matches the direction of

operation of its transmitter stick. To reverse the direction of

servo travel, switch the servo reversing switch.

• Operate each servo over its full travel, and check if the push-

rod binds or is too loose. Applying unreasonable force to the

servo horn will adversely affect the servo and quickly drain

the battery. Always make the travel of each control mecha-

nism somewhat larger than the full travel (including trim) of

the servo horn. Adjust the servo horns so that they move

smoothly even when the trim lever and stick are operated

simultaneously in the same direction.

• Be alert for noise.

This set is noise-resistant, but is not completely immune to

noise. We recommend the use of noiseless parts and noise

killer capacitor.

• When installing the switch harness, cut a rectangular hole

somewhat larger than the full stroke of the switch and install

the switch so that it moves smoothly from ON to OFF. This

also applies to the switch mount when the switch is installed inside the fuselage and is turned on and off from the outside

with a piece of wire, etc. Install

not be exposed to engine oil, dust, etc.

• Even though the receiver antenna is long, do not cut or

bundle it.

• Install the servos securely. Tighten the mounting screws until the rubber grommet is crushed slightly. If the screws are

too tight, the cushioning effect will be adversely affected.

the

switch where

it

will

• Spare servo horns are supplied. Use them as needed.

• Wrap the receiver in sponge rubber. Waterproof and dustproof the receiver by placing it in a plastic bag and wrapping

a rubber band around the open end of the bag. Do the same

with the receiver/servo battery.

• Use the rubber bands wrapped around the receiver to hold

the servo and switch leads.

• After mounting is complete, recheck each part, then check

the range by making the transmitter antenna as short as

possible, extending the receiver antenna fully, and operating

the set from a distance of 20m to 30m. The movement of

each servo should follow the movement of each stick of the

transmitter.

• The motor controller connects to channel 3 in the MCR-4A.

•

Motor

aircraft vibrate

less

than engine aircraft, but the

receiver and servo should be vibration proofed.

•If the NiCd battery pack is connected in reverse,

the MCR-4A may be damaged beyond repair. Be

sure that the (+) and (—) connections are correct.

Black lead wire 0

Red lead wire +

Fig.

11

• After mounting and checking are complete, take your model

to the shop where you purchased the set, or to an experienced radio control modeler, and ask them to teach you how to

handle your radio control set in the proper manner and to

inspect your set-up carefully.

•

To

enjoy radio

control

models

fully,

be

sure

to

observe

all

safety standards.

USING THE ANTENNA FREQUENCY FLAG

SERVO MOUNTING

Fig.

10

This horn permits shifting of the

servo neutral position at the servo

horn. Setting and shifting the neutral position.

a) Angle divisions

Fig.

13

1) The splined horn has 25 segments. The amount of change per

segment is; 360-25=14.4°.

2) The minimum adjustable angle

is determined by the number of

arms or number of the holes. For

four arms, the minimum adjustable angle is:

b) Effect

Fig. 14

To shift the holes center line to

the right (clockwise) relative to

baseline A, shift arm 2 to the position of arm 1 and set it to the

position closest to baseline A.

[Example] For a four arm horn,

the angular shift per segment is

14.4". The shift to the right is 90°

-(14.4 x 6) = 3.6°.

To shift by the same angle in the

opposite direction, use the opposite arm number.

Attach the frequency flag to

the flag holder as shown in the

figure.

Fig.

15

For a six arm horn, turn the arm

counterclockwise and set arm 2

to the position of arm 1. The adjustable angle is 60° - (14.4 x 4)

=2.4°.

The flag can be attached to.

and removed from, the

antenna with one touch.

Arm 3 shift 4.8° to the right, arm

6 shifts 2.4° to the left, and arm 4

shifts 7.2° to the right and left.

Fig.

Fig.

12

16

Page 6

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

Upper case

1

2

Middle

Motor

3

4

Motor pinion

5

1st gear

2nd gear

6

7

3rd gear

4th gear

8

Final gear

9

Output shaft

Intermediate shaft

VR joint

VR drive plate

Potentiometer

Splined horn F

Horn mounting screw

Bottom case

Case mounting screw

Printed wiring board

Grommet

3PC cord 170

Name plate

case

Part name

Part No.

S05850

S05860

S91241

S02781

S02782

S02783

S02784

S02785

S02786

S05880

S04285

S05872

S05626

i39600

S01241

J55171

S05870

S40070

AS

1259

S90045

AT2213

S60122

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

Upper case

Middle case

2

Bottom case

3

4

Metal bearing Metal bearing

5

6

Potentiometer

7

Potentiometer drive plate

Motor

8

Motor pinion

9

Screw

1 st gear

2nd gear

3rd gear

Final gear

Intermediate shaft

2nd shaft

Servo horn D

Binding head tapping screw 2.6x8

Printed wiring board

3PB-WRB300G

w/gum bush

Pan head truss screw

Nameplate

Part name

Part No.

VCS-48

FCS-48

FCS-48

S04137

S04136

139668

S02753

S91239

S02461

J50002

FGS-48

FGS-48

FGS-48

FGS-48

S02495

S02494

PSH-6W

FSH-41

ASH

57

AT2453

S90045

S50360

S60099

FUTABA CORPORATION

Makuhari

Overseas Marketing & Sales Radio Control Systems

Phone: (043)296-5119 Facsimile: (043)296-5124

Techno

Garden

Bidg.,

B6F

1-3

Nakase,

Mihama-ku,

FUTABA CORPORATION OF AMERICA

4 Studebaker, Irvine California 92718, U.S.A.

Phone:714-455-9888

Telex:

23-0691227

Facsimile:

Chiba

714-455-9899

261-01,

Japan

Loading...

Loading...