Page 1

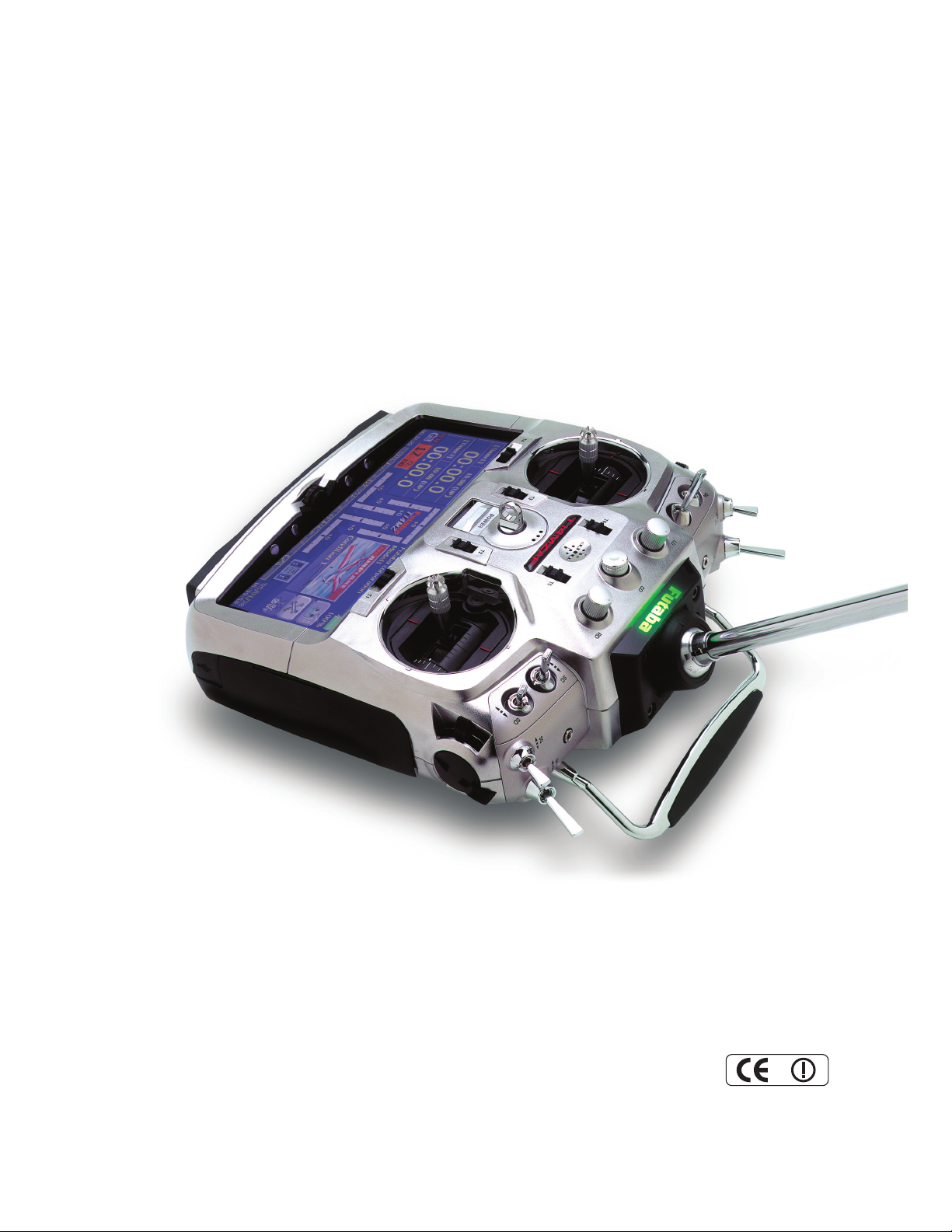

14MZ

14 CHANNEL RADIO CONTROL SYSTEM

PCMG3/PCM1024/FM selectable

INSTRUCTION MANUAL

Entire Contents © Copyright 2005

1M23N14802

Page 2

TABLE OF CONTENTS

INTRODUCTION .............................................. 4

●Support and Service ......................................... 4

●Application, Export, and Modifi cation ...........5

●Defi nitions of Symbols ...................................... 6

●Safety Precautions (do not operate without

reading) ............................................................. 6

BEFORE USE .....................................................9

●Features of 14MZ ............................................. 9

●Contents and technical specifi cations ........... 11

●Accessories ....................................................... 12

●Transmitter controls ....................................... 13

Cautions on handling antenna .......................... 13

LED monitor .................................................... 14

Switch reallocation (SA-SH) ........................... 14

Volume (LD, CD, RD) ..................................... 15

Slide Lever (LST, LS, RS, RST) ...................... 15

Digital trim (T1-T6) ......................................... 16

Touch panel/Rotary key/Direct key ................. 16

Stick Adjustment .............................................. 17

CF card CFDP32M ..........................................18

Connector/Plug ................................................. 19

USB port

Attachment and detachment of the battery ...... 20

RF module MZ-FM .......................................... 21

Toolbox ............................................................ 21

●Receiver nomenclature ................................... 22

●Safety precautions when installing receiver and

servos ............................................................... 23

BASIC OPERATION ....................................... 24

●Battery Charging ............................................ 24

How to charge the Lithium Ion Battery ...........24

How to charge the Ni-Cd Battery ..................... 24

●How to turn On/OFF the transmitter ........... 25

When turning on ............................................... 25

When turning off .............................................. 25

How to reset ..................................................... 26

●How to change the frequency/How to set the

receiver's ID .................................................... 26

(*This port is for factory use only.) .................

19

●In case of using PCM1024, PPM receivers ... 27

●Registration of the user's name ..................... 27

●Home screen .................................................... 28

●Music play back .............................................. 29

FUNCTIONS OF SYSTEM MENU ................ 30

Trainer .............................................................. 31

Display ............................................................. 33

Date & Time ..................................................... 34

User Name ........................................................ 35

Switch ............................................................... 36

HW Reverse ..................................................... 37

Information ...................................................... 38

MODEL BASIC SETTING PROCEDURE ... 39

●Airplane/glider basic setting procedure ........ 39

●Helicopter basic setting procedure ................ 41

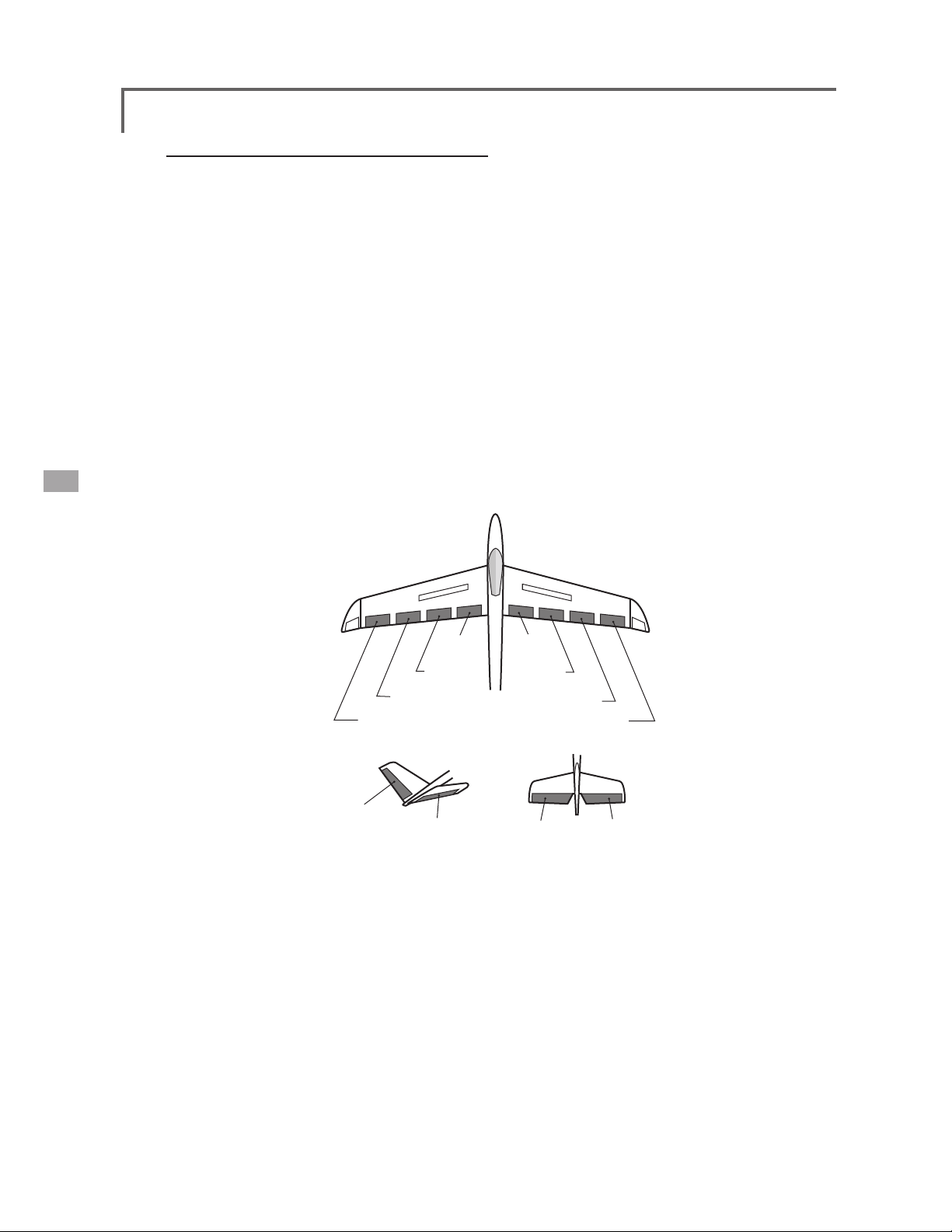

●Receiver and servos connection ..................... 45

●Servo connection by model type .................... 46

FUNCTIONS OF LINKAGE MENU .............50

(Common Functions)

Linkage Menu functions table .......................... 50

Servo Monitor .................................................. 51

Model Select .................................................... 52

Model Type ...................................................... 53

Picture .............................................................. 55

Sound ............................................................... 56

Frequency ......................................................... 58

Function ........................................................... 59

Sub-Trim .......................................................... 61

Servo Reverse .................................................. 62

Fail Safe ...........................................................63

End Point (ATV) .............................................. 64

Throttle Cut (Airplane/helicopter only) ........... 65

Idle Down (Airplane/helicopter only) .............. 66

Swash (Helicopter only) ................................... 67

Timer ................................................................ 69

Dial Monitor ..................................................... 70

Data Reset ........................................................ 71

TABLE OF CONTENTS

<

2

>

Page 3

FUNCTIONS OF MODEL MENU

●Common Functions ........................................72

Servo Monitor (Linkage Menu 51)

Condition Select ............................................... 73

Condition Hold ................................................. 74

AFR (D/R) ........................................................ 75

Program Mix .................................................... 77

Fuel Mixture ..................................................... 79

●Airplane/Glider/EP Glider Functions ........... 80

Model Menu functions list ............................... 80

AIL Differential ................................................ 82

Flap Setting ...................................................... 83

AIL to Camber FLP .......................................... 84

AIL to Brake FLP ............................................. 85

AIL to RUD ...................................................... 86

Airbrake to ELE ............................................... 87

RUD to AIL ...................................................... 88

Camber Mix .....................................................89

ELE to Camber ................................................. 91

Camber FLP to ELE ......................................... 92

Butterfl y ...........................................................95

Trim Mix 1/2 .................................................... 95

Airbrake ........................................................... 97

Gyro ................................................................. 99

V-tail ............................................................... 100

Ailevator ......................................................... 101

Winglet ........................................................... 102

Motor .............................................................. 103

RUD to ELE ................................................... 104

Snap Roll ........................................................ 105

Multi Engine .................................................. 106

●Helicopter Functions .................................... 107

Model Menu functions list ............................. 107

PIT Curve ....................................................... 108

THR Curve ..................................................... 111

Acceleration ................................................... 113

Throttle Hold .................................................. 114

Swash Mix ...................................................... 115

Throttle Mix ................................................... 116

PIT -> Needle ................................................. 117

PIT -> RUD .................................................... 118

Gyro ............................................................... 119

Governor ........................................................ 120

●Common Operations used in function setup

screen ............................................................. 121

TABLE OF CONTENTS

<

>

3

Page 4

INTRODUCTION

Thank you for purchasing the Futaba® 14MZ series digital proportional R/C system. In order for you to make the best use

of your system and to fly safely, please read this manual carefully. If you have any difficulties while using your system,

please consult the manual, our online Frequently Asked Questions (on the web pages referenced below), your hobby dealer, or the Futaba Service Center.

Due to unforeseen changes in production procedures, the information contained in this manual is subject to change without

notice.

Support and Service: It is recommended to have your Futaba equipment serviced annually during your hobby’s “off season”

to ensure safe operation.

IN NORTH AMERICA

Please feel free to contact the Futaba Service Center for assistance in operation, use and programming. Please be sure to

regularly visit the 14MZ Frequently Asked Questions web site at http://www.futaba-rc.com/faq/faq/index.html. This page

includes extensive programming, use, set up and safety information on the 14MZ radio system and is updated regularly. Any

technical updates and US manual corrections will be available on this web page. If you do not find the answers to your questions there, please see the end of our F.A.Q. area for information on contacting us via email for the most rapid and convenient response.

Don’t have Internet access? Internet access is available at no charge at most public libraries, schools, and other public

resources. We find internet support to be a fabulous reference for many modelers as items can be printed and saved for

future reference, and can be accessed at any hour of the day, night, weekend or holiday. If you do not wish to access the

internet for information, however, don’t worry. Our support teams are available Monday through Friday 8-5 Central time to

assist you.

OUTSIDE NORTH AMERICA

Please contact your Futaba importer in your region of the world to assist you with any questions, problems or service needs.

Please recognize that all information in this manual, and all support availability, is based upon the systems sold in North

America only. Products purchased elsewhere may vary. Always contact your region’s support center for assistance.

FOR SERVICE ONLY

Futaba Service Center

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Phone: 217-398-0007

www.hobbyservices.com

FOR SUPPORT

(PROGRAMMING AND USER QUESTIONS)

Please start here for answers to most questions:

www.futaba-rc.com

FACSIMILE: 217-398-7721

PHONE: 217-398-8970 option 2

Page 5

Application, Export, and Modification

1. This product is suitable for model airplane, surface or 50 MHz (license required) use, if on the correct frequency. It is

not intended for use in any application other than the control of models for hobby and recreational purposes. The product is subject to regulations of the FCC and is restricted under United States law to such purposes.

2. Exportation precautions:

(a) When this product is exported from the country of manufacture, its use is to be approved by the laws governing the

country of destination which govern devices that emit radio frequencies. If this product is then re-exported to other countries, it may be subject to restrictions on such export. Prior approval of the appropriate government authorities may be

required. If you have purchased this product from an exporter outside your own country and not the authorized Futaba distributor in your country, please contact the seller immediately to determine if such export regulations have been met.

(b) Use of this product with other than models may be restricted by Export and Trade Control Regulations, and an application for export approval must be submitted. In the US, use of 72MHz (aircraft only), 75MHz (ground models only) and

27MHz (both) frequency bands are strictly regulated by the FCC. This equipment must not be utilized to operate equipment other than radio controlled models. Similarly, other frequencies (except 50MHz, for HAM operators) must not be

used to operate models.

3. Modification, adjustment, and replacement of parts: Futaba is not responsible for unauthorized modification, adjust-

ment, and replacement of parts on this product. Any such changes may void the warranty.

The Following Statement Applies to the Receiver (for U.S.A.)

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesirable operation.

The RBRC

™

SEAL on the nickel-cadmium battery contained in Futaba products indicates that Futaba

Corporation of America is voluntarily participating in an industry-wide program to collect and recycle these

batteries at the end of their useful lives, when taken out of service within the United States. The RBRC program provides a convenient alternative to placing used nickel-cadmium batteries into the trash or municipal

waste system, which is illegal in most areas.

You may contact your local recycling center for information on where to return the spent battery. Please call 1-800-8-BATTERY for information on battery recycling in your area. Futaba Corporation of America’s involvement in this program is

part of it’s’ commitment to protecting our environment and conserving natural resources.

NOTE: Our instruction manuals encourage our customers to return spent batteries to a local recycling center in order to

keep a healthy environment. RBRC is a trademark of the Rechargeable Battery Recycling Corporation.

Page 6

Definitions of Symbols

Pay special attention to safety where indicated by the following symbols.

DANGER – Procedures which may lead to dangerous conditions and cause death/serious injury if not carried out

properly.

WARNING – Procedures which may lead to a dangerous condition or cause death or serious injury to the user if

not carried out properly, or procedures where the probability of superficial injury or physical damage is high.

CAUTION – Procedures where the possibility of serious injury to the user is small, but there is a danger of injury,

or physical damage, if not carried out properly.

= Prohibited = Mandatory

Warning: Always keep electrical components away from small children.

FLYING SAFETY

To ensure the safety of yourself and others, please observe the following precautions:

Have regular maintenance performed. Although your 14MZ protects the model memories with non-volatile

EEPROM memory (which does not require periodic replacement) and not a battery, it still should have regular

checkups. We recommend sending your system to the Futaba Service Center annually during your non-flying

season for a complete checkup and service.

Use the Fail-Safe safety feature to set the throttle to low-idle In case of signal loss or RX battery failure.

Engine power will be automatically reduced to help limit personal or property damage. Refer to the Failsafe

Setting Procedure listed in the index.

Receiver Ni-Cd Battery

Charge the batteries! (See Charging the batteries listed in the index for details.) Always recharge the receiver

batteries for at least 8 hours before each flying session. A low battery will soon die, causing loss of control and a

crash. When you begin your flying session, reset your timer, and during the session pay attention to the duration

of usage.

CAUTION: The initial charge on new NiCd receiver batteries should be done for 15 hours using the slow-charger

that came with the radio system. This will “condition” the batteries so that the next charge may be done using the

fast-charger of your choice. If the initial charge is done with a fast-charger the batteries may not reach their full capacity and you may be flying with batteries that are only partially charged.

Where to Fly

We recommend that you fly at a recognized model airplane flying field. You can f ind model clubs and fields by asking your

nearest hobby dealer, or in the US by contacting the Academy of Model Aeronautics. You can also contact the national

Academy of Model Aeronautics (AMA), which has more than 2,500 chartered clubs across the country. Through any one

of them, instructor training programs and insured newcomer training are available. Contact the AMA at the address or

toll-free phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tel. (800) 435-9262

Fax (765) 741-0057

or via the Internet at http:\\www.modelaircraft.org

Page 7

Lithium-ION Battery Safety and Handling instructions

It is important to understand the operating characteristics of lithium-ion (Li-Ion) batteries. Always read the specifications

printed on the label of your Li-Ion battery and charger prior to use. Failure to follow the proceeding precautions can

quickly result in severe, permanent damage to the batteries and its surroundings and possibly result in a FIRE!

IMPORTANT PRECAUTIONS

Do not attempt to disassemble Li-Ion packs or cells.

Do not allow Li-Ion cells to come in contact with moisture or water at any time.

Always provide adequate ventilation around Li-Ion batteries during charge, discharge, while in use, and during

storage.

Do not leave a Li-Ion battery unattended at any time while being charged or discharged.

Do not attempt to charge Li-Ion batteries with a charger that is NOT designed for Li-Ion batteries, as permanent

damage to the battery and charger could result.

Always charge Li-Ion batteries in a fireproof location. Do not charge or discharge Li-Ion batteries on carpet, a

cluttered workbench, near paper, plastic, vinyl, leather or wood, or inside an R/C model or full sized automobile!

Monitor the charge area with a smoke or fire alarm, and have a lithium-approved “ABC type” fire extinguisher

available at all times.

Do not charge Li-Ion batteries at currents greater than the “1C” rating of the battery (“C” equals the rated capacity of the

battery).

Do not allow Li-Ion cells to overheat at any time! Cells which reach greater than 140 degrees Fahrenheit (60oC)

should be placed in a fireproof location.

It is normal for the batteries to become warm during charging, but if the charger or battery becomes excessively hot

disconnect the battery from the charger immediately!! Always inspect a battery which has previously overheated for

potential damage, and do not re-use if you suspect it has been damaged in any way.

Do not use a Li-Ion battery if you suspect physical damage has occurred to the pack. Carefully inspect the battery

for even the smallest of dents, cracks, splits, punctures or damage to the wiring and connectors. DO NOT allow the

battery’s internal electrolyte to get into eyes or on skin—wash affected areas immediately if they come in contact with

the electrolyte. If in doubt, place the battery in a fire-proof location for at least 30 minutes.

Do not store batteries near an open flame or heater.

Do not discharge Li-Ion batteries at currents which exceed the discharge current rating of the battery.

Always store Li-Ion cells/packs in a secure location away from children.

Compact Flash (CF) Card Handling Instructions

Follow these precautions when handling the CF card included in your 14MZ transmitter.

IMPORTANT! The Lithium-Ion (Li-Ion) batteries included in the 14MZ transmitter are not to be confused with

Lithium-Polymer (LiPo) batteries, or any other type of rechargeable battery (including NiCd’s and NiMH’s). Li-Ion

batteries require special charging criteria different than other rechargeable batteries. Use only the Futaba lithium ion

transmitter charger included with this set for, or other chargers approved by Futaba to charge the Li-Ion batteries in

the 14MZ transmitter.

Never remove the CF card or turn off power while

entering data.

Never store the CF card where it may be subject to

strong static electricity or magnetic fields.

Do not expose the CF card to direct sunlight, excessive

humidity or corrosive environments.

Do not expose the CF card to dirt, moisture, water or

fluids of any kind.

Always hold the CF card by the edges during installation and removal.

Be certain to insert the CF card in the correct direction.

Page 8

AT THE FLYING FIELD

Always pay particular attention to the flying fields’ rules, as well as the presence and location of spectators, the wind

direction, and any obstacles on the field. Be very careful flying in areas near power lines, tall buildings, or communication

facilities as there may be radio interference in their vicinity. If you must fly away from a club field, be sure there are no other

modelers flying within a three-to-five-mile range, or you may lose control of your aircraft or cause someone else to lose control.

Before flying, be sure that the frequency you intend to fly with is not in use, and secure any frequency control

device (pin, tag, etc.) for that frequency before turning on your transmitter. It is never possible to fly two or more models on the same frequency at the same time. Even though there are different types of modulation (AM, FM, PCM), only

one model may be flown on a single frequency at any one time.

Stop flying long before your batteries become low on charge. Do not rely on your radio’s low-battery warning systems, which are intended only as a precaution, to tell you when to recharge. Always check your transmitter and

receiver batteries prior to each flight.

To prevent possible damage to your radio gear, turn the power switches on and off in the proper sequence:

1. Set the throttle stick to the idle position, or otherwise disarm your motor/engine.

2. Fully extend the transmitter antenna.

3. Turn on the transmitter power and allow your transmitter to reach its home screen.

4. Confirm the proper model memory has been selected.

5. Turn on your receiver power.

6. Test all controls. If a servo operates abnormally, don’t attempt to fly until you determine the cause of the problem. (For

PCM systems only: Test to ensure that the Failsafe settings are correct by waiting at least 2 minutes after adjusting then,

turning the transmitter off and confirming the proper surface/throttle movements. Turn the transmitter back on.)

7. Start your engine.

9. After flying, bring your throttle stick to idle position, engage any kill switches or otherwise disarm your

motor/engine.

10. Turn off receiver power.

11. Turn off transmitter power.

If you do not turn on your system in this order, you may damage your servos or control surfaces, flood your engine, or in

the case of electric-powered or gasoline-powered models, the engine may unexpectedly turn on and cause a severe injury.

While you are getting ready to fly, if you place your transmitter on the ground, be sure that the wind won’t tip

it over. If it is knocked over, the throttle stick may be accidentally moved, causing the engine to speed up. Also, dam-

age to your transmitter may occur.

Before taxiing, be sure to extend the transmitter antenna to its’ full length. A collapsed antenna will reduce your

flying range and cause a loss of control. It is a good idea to avoid pointing the transmitter antenna directly at the model,

since the signal is weakest in that direction.

Don’t fly in the rain! Water or moisture may enter the transmitter through the antenna or stick openings and cause

erratic operation or loss of control. If you must fly in wet weather during a contest, be sure to cover your transmitter

with a waterproof barrier. Never fly if lightning is expected.

Never turn the transmitter off during flight! Switching the transmitter off and on during flight will very likely cause

a crash because of the time required for the transmitter to "reboot" and become fully functional.

8. Complete a full range check.

Page 9

BEFORE USE

FEATURES

PCMG3 (PCM Generation 3)

PCMG3 has a 40% faster response than current PCM1024. The resolution is 2048, which is double

the current PCM1024. It can operate up to 14 Channels. The multi-level modulation technology has been

implemented for the R/C industry to achieve the highest performance available today.

WindowsCE

T14MZ utilizes the world famous Microsoft WindowsCE, which offers outstanding dependability and

valuable resources.

Color LCD

T14MZ has a HVGA (640x240 pixels) wide screen full color LCD. It has a backlight and the screen is

manufactured of a transfl ective construction which enables both indoor and outdoor visibility.

Music Play

T14MZ can playback WMA (Windows Media Audio) fi les on a CF-Card. You can enjoy music by the

internal speaker or stereo headphone from the earphone jack, and you can assign switches to start/stop your

music. You can download the WMA fi les of your own music from your PC.

Voice Recording

You can record your own voice by internal microphone and then play back commands to be assigned to

certain switches. Recording time is 3 seconds maximum and 24 voice fi les can be stored.

Picture Image Pasting

You can paste picture image fi les (168x80 pixels) taken by digital camera to the model screen. Enabling

you to download any image you like on your home screen.

Compact Flash

The model data and music fi les, voice fi les, picture image fi les are stored to Compact fl ash (CF) card.

The memory size is 32 MB. Futaba prepares industrial rating CF cards.

WFSS (Wireless Frequency Setting System)

The construction of both transmitter (T14MZ) and receiver (R5014) are a frequency synthesizer system.

Editing

The touch panel and rotary encoder editing system will allow you to edit your model in the manner that

is easiest and most functional for you.

Functions

The internal dual processors operate the many 14MZ FEATURE functions and optimize the response

time. Most of the mixing functions are operated by curves which give you more precise settings.

<Before Use>

9

Page 10

Stick

Each axis is supported by dual ball bearings. This allows for fi ner and more precise operation, the new

potentiometers also offer longer life.

Replaceable switches

You can replace 8 of the toggle switches on the right and left shoulder, with optional switches (two

position, three position, and momentary etc.).

Li-ion battery

T14MZ is operated by 7.4V/2,200 mAh Lithium-Ion battery.

R5014DPS

The R5014DPS is a small 14CH synthesized receiver with high sensitivity and selectability.

<Before Use>

10

Page 11

Contents and Technical Specifi cations

(Specifi cations and ratings are subject to change without notice.)

Your 14MZAP or 14MZHP (packaged with a 14-channel PCM-G3 receiver) includes the following components:

• T14MZ Transmitter, including RF module (MZ-DDS)

• R5014 Receiver

• CFDP32M Data-Pack (CF card)

• LT2F2200 Li-ion battery & LBC-1D5 Charger

• NR4F1500 Ni-Cd battery & 110V wall charger (North

America)

• Switch harness/Aileron extension cord/Y-harness/DSC

cord

• Tool Box (includes special jig for adjustment)

• Neck strap

• Frequency Flag

The set contents depend on the type of set.

Transmitter T14MZAP/HP

Operating system: 2-stick, 14 channels, PCM-G3,

synthesizer system

Transmitting frequency: US only 72 or 50 MHz bands

Modulation: PCM-G3, PCM1024, or FM/PPM

switchable.

Power supply: 7.4V LT2F2200 Li-ion battery

Current drain: 1 ampere maximum (RF power on and

back light on) 700mA average

Receiver R5014DPS

(PCM-G3, Synthesizer, Dual conversion)

Receiving frequency: US only 72 or 50 MHz bands

Intermediate freq.: 10.7 MHz & 450 kHz

Power requirement: 4.8 V Ni-Cd battery

Current drain: 75 mA

Size: 52x37.5x16.5 mm

Weight: 33 g.

Channels: 14

Suggested Servos for use with your 14MZ

Servo S9154 (Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 63.9 oz.-in. (4.6 kg-cm) at 4.8V

Operating speed: 0.14 sec/60 at 4.8V

Size: 1.87 x 1.06 x 0.97 in. (47.5 x 27.0 x 25.3 mm)

Weight: 1.87 oz. (53 g)

Servo S9151 (Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 131.9 oz.-in. (9.5 kg-cm) at 4.8V

Operating speed: 0.19 sec/60 at 4.8V

Size: 1.57 x 0.79 x 1.44 in. (40.0 x 20.0 x 36.6 mm)

Weight: 1.79 oz. (50 g)

Servo S9250 (Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 76.4 oz.-in. (5.5 kg-cm) at 4.8V

Operating speed: 0.11 sec/60 at 4.8V

Size: 1.59 x 0.79 x 1.48 in. (40.5 x 20.0 x 37.5 mm)

Weight: 1.90 oz. (54 g)

Servo S9255 (Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 125.0 oz.-in. (9.0 kg-cm) at 4.8V

Operating speed: 0.16 sec/60 at 4.8V

Size: 1.57 x 0.79 x 1.44 in. (40.0 x 20.0 x 36.6 mm)

Weight: 1.94 oz. (55 g)

<Before Use>

11

Page 12

The following additional accessories are available from your dealer. Refer to a Futaba catalog for

more information:

• Compact Flash Memory card - CFDP 32M Data-Pack increases your model, music file, voice file,

and picture image fi le storage capability, and allows you to transfer model settings to another T14MZ

transmitter.

• LT2F2200 Transmitter battery pack - the (2200mAh) transmitter Li-ion battery pack may be easily

exchanged with a fresh one to provide enough capacity for extended fl ying sessions.

• Trainer cord - the optional training cord may be used to help a beginning pilot learn to fly easily by

placing the instructor on a separate transmitter. Note that the T14MZ transmitter may be connected to

another T14MZ system, as well as to any other models of Futaba transmitters. The T14MZ transmitter

uses the newer “Micro” rectangular type cord plug. Both Micro- to-Micro and Micro-to-round plug style

trainer cords are available.

• Neckstrap - a neckstrap may be connected to your T14MZ system to make it easier to handle and improve

your fl ying precision since your hands won’t need to support the transmitter’s weight.

• Y-harnesses, servo extensions, etc - Genuine Futaba extensions and Y-harnesses, including a heavy-duty

version with heavier wire, are available to aid in your larger model and other installations.

• Gyros - a variety of genuine Futaba gyros are available for your aircraft or helicopter needs.

• Governor (GV1) - for helicopter use. Automatically adjusts throttle servo position to maintain a constant

head speed regardless of blade pitch, load, weather, etc.

• DSC Cord - allows setup and testing without transmitting. With your Transmitter and Receiver off, plug

cord into trainer port then, into the receiver Battery/DSC (B/C) slot. All programming and setup may be

done in this manner without transmitting.

• Receivers - various models of Futaba receivers may be purchased for use in other models. (Receivers for

PCM-G3, PCM1024, or FM/PPM types are available.)

<Before Use>

12

Page 13

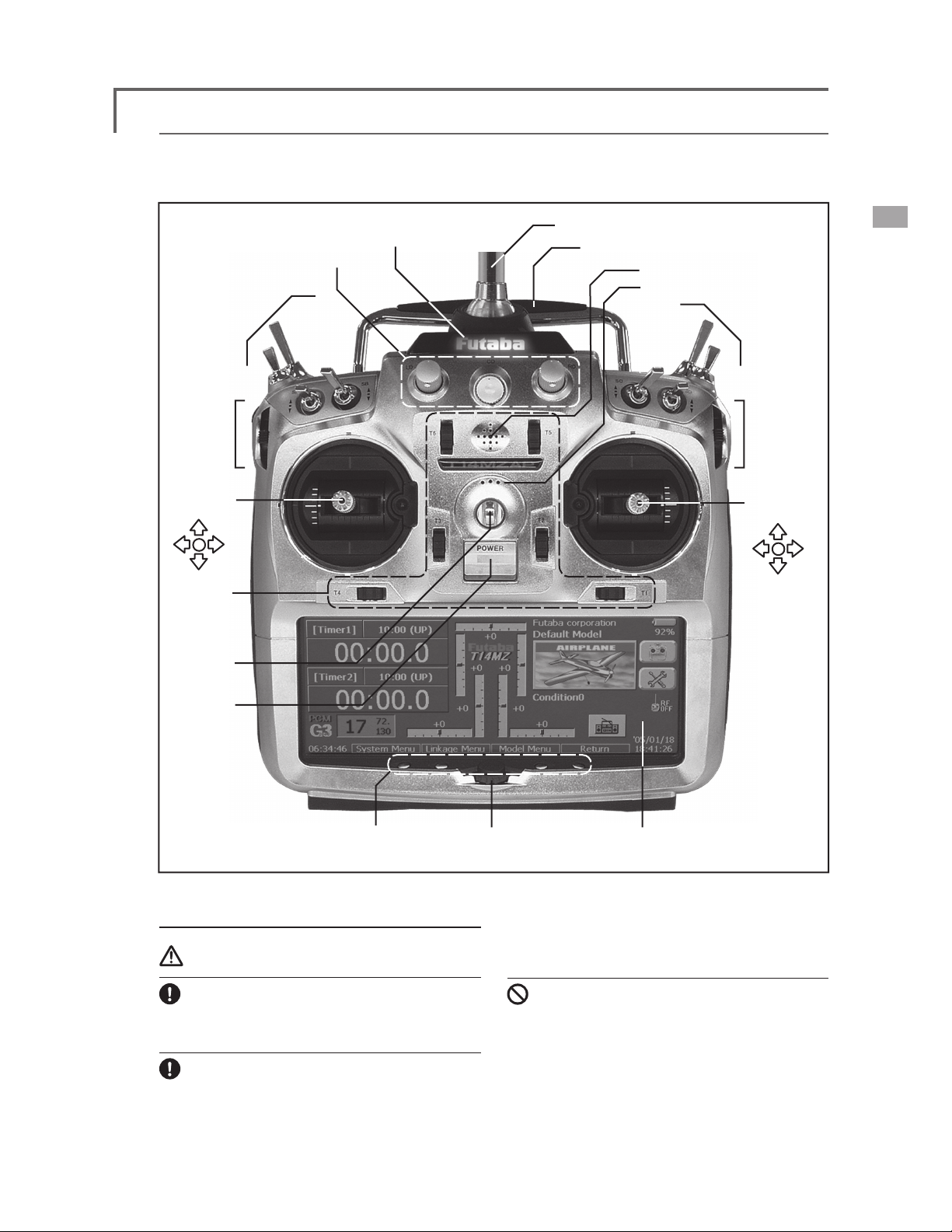

Transmitter controls

●Switch Block

(SA,SB,SE,SF)

●Slide

Lever

(LS,LST)

●Stick

(J3)

(J4)

●Digital

Trim

(T1-T6)

●Hook

(LD,CD,RD)

●Volume

●Monitor LED

●Antenna

●Carring Bar

●Speaker

●Microphone

●Switch Block

(SC,SD,SG,SH)

●Slide Lever

(RST,RS)

●Stick

(J2)

(J1)

●Power

Switch

●Direct Key ●Rotary Key ●LCD Display (Touch Panel)

(S1-S4)

Cautions on handling antenna

WARNING

Be sure to attach the antenna before operation.

*Antenna is stored in the antenna storage box in the trans-

mitter.

Extend the antenna to the full extent, and make

sure that the antenna is securely locked before

operation.

Never hold the antenna alone.

*Hold the carrying bar, otherwise the main body can be

damaged.

<Before Use>

13

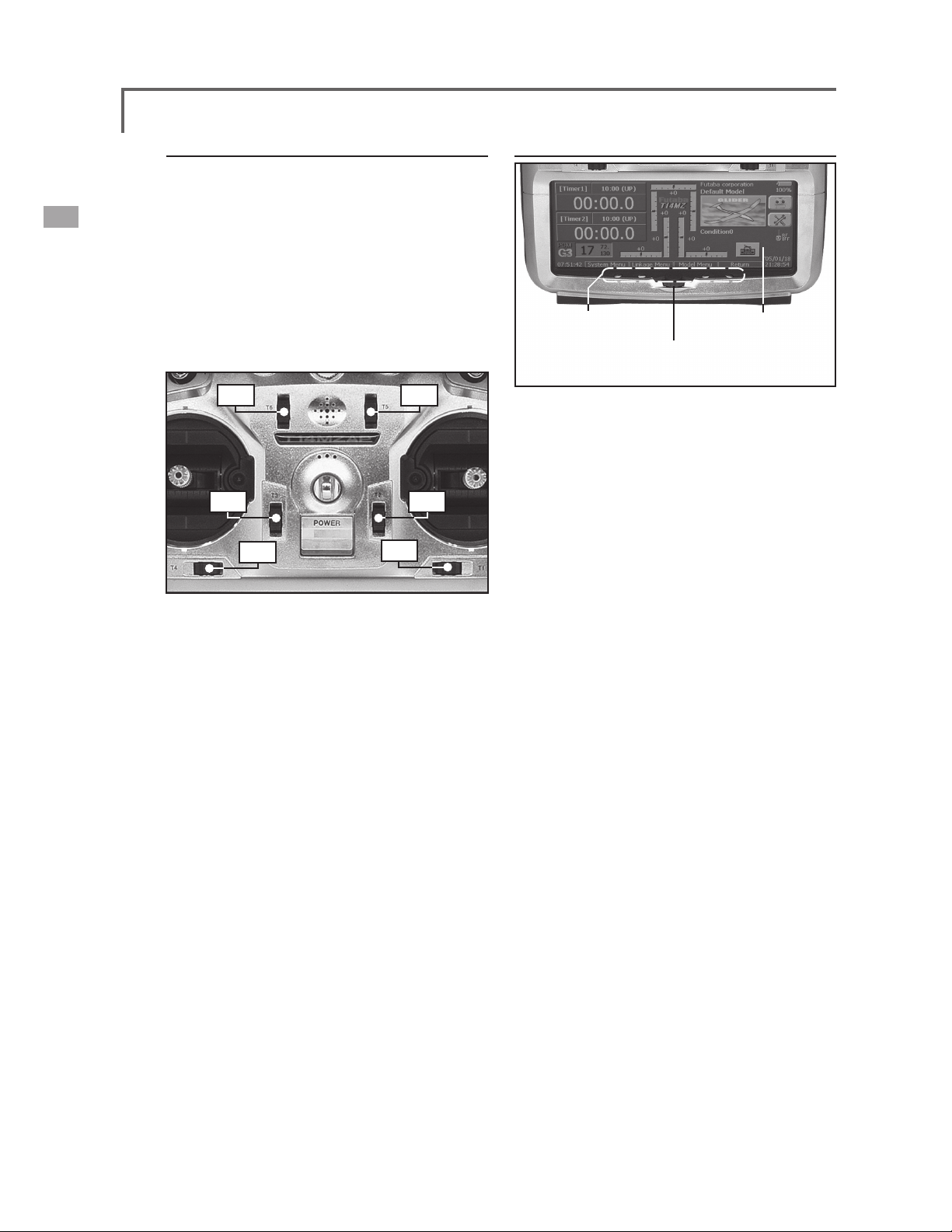

Page 14

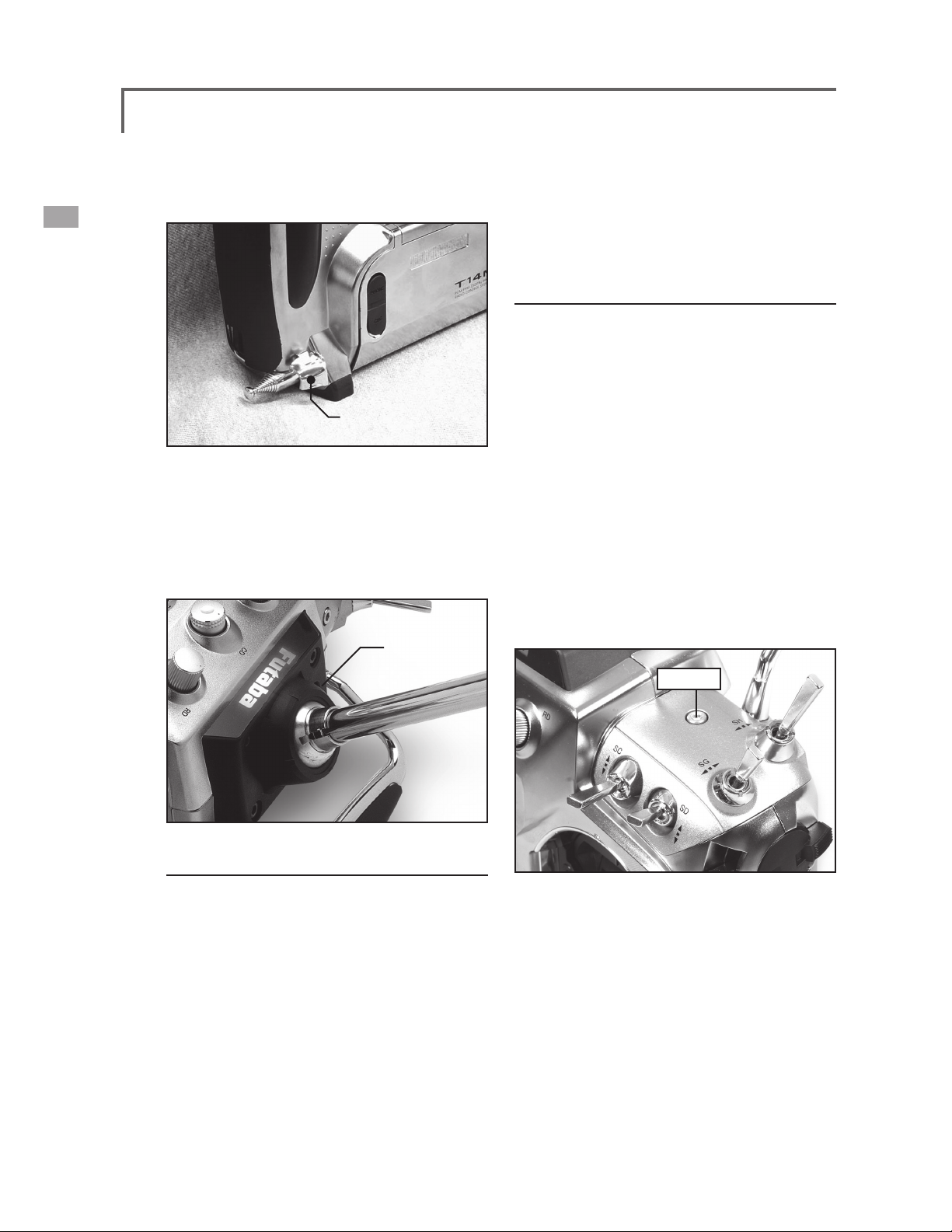

•Antenna storage

When you store the transmitter in the carrying

case, detach the antenna and store it in the antenna

compartment in the transmitter.

●Antenna Compartment

Cover

•Angle adjustment of the antenna

You can change the angle of the antenna, as

you like. Use 2.5mm hexagonal wrench to turn

counterclockwise to release the screw on the left

of the antenna holder, and change the angle of the

antenna, as you like, then retighten.

• The FUTABA logo blinks red slowly when you

attach the RF module that is different from

the setting.

• Under the normal usage (, that is, radio wave

is being emitted), the FUTABA logo turns on

green.

Switch reallocation

You can reallocate the toggle switches on the

shoulders of the transmitter, as you like.

(Default settings)

• SA : 3 positions; Alternate; Short lever

• SB : 3 positions; Alternate; Long lever

• SC : 3 positions; Alternate; Long lever

• SD : 3 positions; Alternate; Short lever

• SE : 3 positions; Alternate; Short lever

• SF : 2 positions; Alternate; Long lever

• SG : 2 positions; Alternate; Short lever

• SH : 2 positions; Momentary; Long lever

*You can choose switch and set the ON-direction in the

setting screen of the mixing functions.

●Screw

LED monitor

The color of the FUTABA logo mark shows the

status of the transmitter.

(LED Display)

• When you turn on the transmitter, FUTABA

logo shows different colors, and then the

color stays constantly pink. The FUTABA

logo blinks green very rapidly while internal

processing is carried out after the power is

turned on. Once the internal processing is

over, the logo turns to pink color.

• The FUTABA logo turns on blue when you

use DSC cable, or when no is selected for

transmit. when the trainer function is set at

student's side.

•When you change switches:

●Screw

To relocate switches;

1. Make sure your transmitter is off, and use the

attached 2.5mm hexagonal wrench (inside

stylus) to turn the screw counter-clockwise on

the switch block and detach the block.

<Before Use>

14

Page 15

●Projection

Slide Lever

2. Disconnect the connectors of switches you

want to change.

3. Use the attached jig (inside stylus) to turn the

face nuts counterclockwise, this will detach

the switches.

4. To re-attach, use the face nuts to attach

switches from other positions or optional

switches to the switch block.

5. Connect your connectors.

6. Insert the switch block so that it fi ts correctly

into the body of the transmitter (as shown in

the picture) and use the hexagonal wrench

to tighten the screws.

Volume

●Locked state

●LS

●LST

●LS

LST (Left), RST (right):

Outside levers

LS (Left), RS (right):

Inside levers: Each lever has two ends, one in

front and the other on the back.

*It sounds when the lever comes to the center.

*You can check the lever position on the dial-monitor screen

in the linkage menu.

*You can select a slide lever and set the movement direction

on the setting screen of mixing functions.

Volume LD, CD, and RD:

If you push the volume to the bottom, the volume

will stay there. If you push the volume again, the

lock will be released and become operative again.

This volume is digital type (rotary encoder). This

volume works as both a volume and a push-switch.

*T14MZ beeps when the volume knob reaches center.

*You can check the volume position on the Dial Monitor

screen in the Linkage menu.

*You can use each setting screen of the mixing functions to

select volumes and defi ne the direction of its movement.

<Before Use>

15

Page 16

Digital trim

This transmitter is equipped with digital trims.

Each time you press a trim button, the trim position

moves one step. If you continue pressing it, the trim

position starts to move faster. In addition, when

the trim position returns to the center, the tone will

change. You can always monitor trim positions by

graphics on the screen. To change the trim rate,

you must activate this through the function menu,

within the linkage menu. Touch the trim button and

you will access another screen which enables you

to change the trim percentages.

Touch Panel/ Rotary Key/ Direct Key

●Direct Key

(S1-S4)

●Rotary Key

●LCD Display

(Touch Panel)

●T6 ●T5

●T3 ●T2

●T4

Note: The trim positions you have set will be stored in the

non-volatile memory and will remain there.

●T1

Touch panel, rotary keys and direct keys are used

for entering data.

Touch Panel

Touch the panel with your fi nger or the attached

stylus pen, which is also used as a toolbox, to enter

data.

*Plastic film is attached on the glass of the touch panel.

Please be careful so that you don't scratch the touch panel

with something hard, such as metal and sand sticking on

the surface. And don't push the touch panel too hard and

don't give any physical shock to the surface.Although you

may find some air bubbles under the plastic panel due to

environmental changes such as temperature, it is not a

defect.

Rotary key

In addition to touch panel, you can select items

by rotating the rotary keys to the left or to the right.

Direct key

You can directly call your favorite functions or

menu screens.

(The default setting at the factory)

S1: System menu

S2: Linkage menu

S3: Model menu

S4: Return

<Before Use>

16

[How to change assignment of the direct key]

1. Open the screen you want to call. Then push

S1 and S4 keys simultaneously. (You will see

the direct key setting screen.)

2. Select the direct key.

Page 17

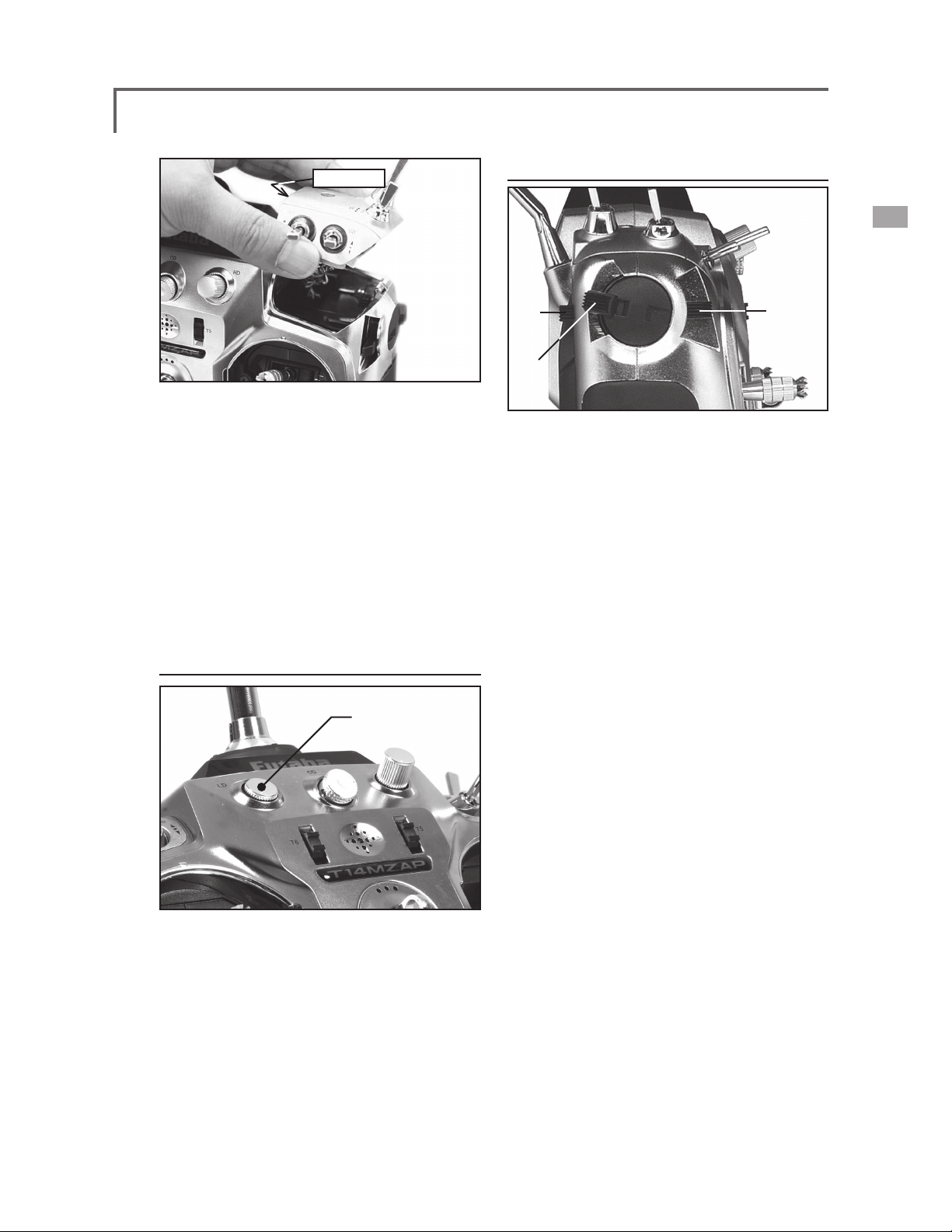

Stick Adjustment

Adjustment of the stick lever angle

You can make fine adjustments to the angle of

a stick lever either inwards or outwards from the

center stick position.

●Screw

Adjustment of Stick Lever Tension

You can adjust the tension of stick-levers.

●Retaining Force (J2)

(Mode 1)

●Stick

Tension

(J1)

(Mode 1/2)

●Stick Tension(J2)

(Mode 2)

●Stick Tension(J3)

(Mode 1)

●Retaining

Force (J3)

(Mode 2)

●Stick Tension(J4)

(Mode 1/2)

[Adjustment of tension]

Use the attached 1.5mm hexagonal wrench

(inside stylus) to turn the screw clockwise to adjust

the stick outwards, or counter-clockwise to tilt it

inward.

Note: The screw will fall out if you turn the screw counter-

clockwise too far.

Adjustment of the lever length

You can adjust the length of stick levers, as you

like. It is recommended to adjust the length of the

sticks in line with your hand size.

Lever Head

A

Lever Head

B

[How to adjust the length]

1. Hold the lever head "B" and turn the lever

head "A" counter-clockwise, the lock will be

released.

2. Turn the lever-head "A" clockwise as you hold

the lever-head "B" after placing it as you like.

Adjustment of Throttle Stick (Ratchet System)

You can also choose either airplane ratchet

system or helicopter-touch.

1. Open the dust protection cap on the back

of the transmitter that is covering the hole for

throttle stick adjustment.

2. Use the attached 1.5mm hexagonal wrench

(inside stylus) to turn the adjustment screw

and set it as you prefer. Turning the screw

clockwise increases the tension.

For airplanes: Adjust the screw on the left.

For helicopters: Adjust the screw on the right.

In changing the setting from airplane to

helicopter (or heli to airplane);

1. Turn the screw counter-clockwise until the

throttle stick moves freely, and turn the screw

clockwise to adjust it to the tension you

prefer.

*This transmitter has two ratchet plates, one for airplane and

the other one for helicopter. If you tighten both screws, you

won't able to achieve the adjustment that you need because

of the overlap of those two adjustments.

*If you want to change the setting from airplane to helicopter

(or from helicopter to airplane), turn counterclockwise until

the throttle stick moves freely. Then turn the screw for the

helicopter until you get the tension force you like.

<Before Use>

17

Page 18

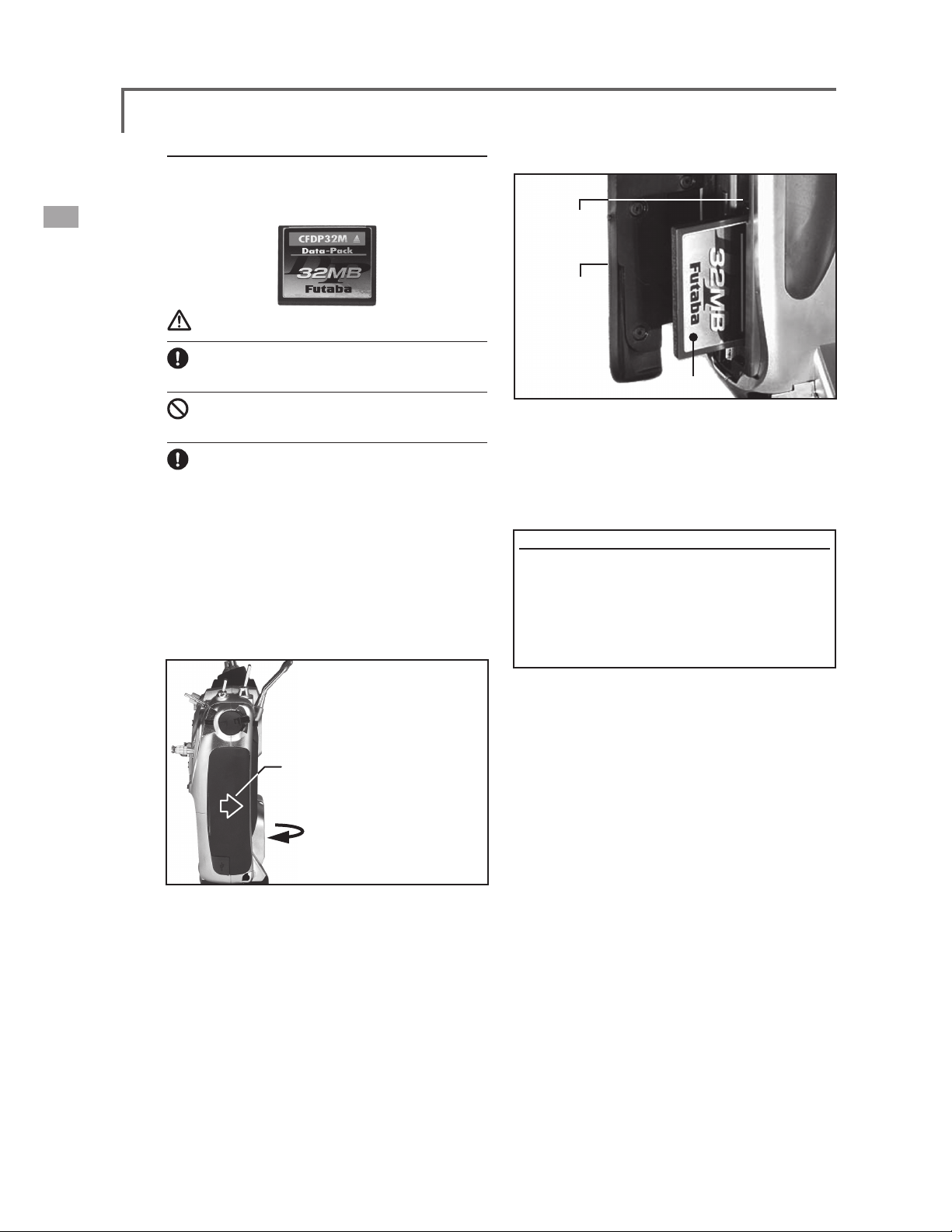

CF Card CFDP32M

CF (Compact Flash) card can store various fi les,

such as model data, music, sound and pictures. Its

memory size is 32MB.

Warning

Be sure to turn off the power to the transmitter

before inserting or removing the CF card.

As the CF card is a precision device, do not use

excessive force when inserting.

Be sure to use only Futaba's original CF card,

CFDP32M, for the T14MZ transmitter.

* Futaba does not recommend any CF cards other than

Futaba's original CF cards.

Set-up of CF card / Removal of CF card

1. Turn off the power to the transmitter.

2. Slide the card cover on the right side of the

transmitter back, and pull open the cover

towards you.

2. Close the card cover and slide it to the

original position.

●Eject

Button

●Side

Cover

●CF Card

Read data from a PC

Saving music and image files edited by a PC

into the CF card, you can use those files on your

T14MZ transmitter. Equipment for reading and

writing CF cards are available at most electronics

stores.

[Important]

Before saving data from the PC, insert the CF

card into the transmitter and turn on the power. To

save a fi le from the PC, copy the fi le to a folder

by fi le type, which are automatically written.

●BMP: Picture fi le ●WAV: Audio fi le

●WMA: Music fi le ●MODEL: Model data

1. Slide backward the side cover

of the transmitter.

2. Then, pull it toward you.

3. Inserting the card: Turn the CF card so that

the name seal faces to the back of the

transmitter. Then slide the card into the slot

until the card touches bottom.

4. Press the card cover back and then slide it

toward you to close it.

Removal of CF card:

1. Push the eject button and then take out the

CF card.

*Use only CF card reader/writer that complies with CFA

(CompactFlashTM Association) standard.

Stored data

The life of the CF card is limited due to the use

of Flash memory. When you have a problem of

saving or reading data such as picture data after a

long period of use, please get a new CF card.

*We do not have the responsibility of compensating any

failure or damage to the data stored in the memory card no

matter what the reason is. Be sure to keep the backup of

your important data in your CF card.

*

No necessity for backup;

are using nonvolatile memory devices so that the data stored

in those will not be destroyed even without a backup battery.

The clock for the transmitter depends on the Lithium battery.

T14MZ transmitters and CF cards

<Before Use>

18

Page 19

Connector/Plug

Battery Charge

Audio plug (PHONE)

Connecting a stereo headphone to this plug, you

can enjoy music fi les stored in the CF card.

Connector for battery charger (CHG)

This is the connector for charging the Lithium

Ion battery LT2F2200 that is installed in the

transmitter. Do not use any other chargers except

CR-2500 that is for 12V application to charge the

LT2F2200 battery through this connector.

●DSC/Trainer●Audio/

Danger

Connector for trainer function (TRAINER)

When you use trainer function, connect the

optional trainer cable between the transmitters for

teacher and student.

*You can set the trainer function on the Trainer Function

screen in the system menu.

Connector for DSC function (DSC)

You can operate the transmitter without

transmitting radio waves by connecting the

transmitter and the receiver to the DSC cable.

*Please refer to the section "Connection between Receiver/

Servo"

Do not connect any other chargers except

CR-2500 to this charging connector.

*If you take out the Lithium Ion battery LT2F2200 from the

transmitter, you can use the attached charger LBC-1D5 for

charging the battery.

USB port (Transmitter right side)

*This is for factory use only.

<Before Use>

19

Page 20

Installing and Removing of the battery

LT2F2200 for the transmitter

Attachment of the battery

1. Hook one of your fi ngers in the slit formed by

the transmitter’s main body and the battery

cover on the bottom of the transmitter, and

then pull up the cover to release the lock.

You can now open the cover in the direction

of the arrow.

2. Move the slide lever to the right end, and

then install the battery in the holder.

●Move the slide lever to the far right.

3. Push the battery to the left with your fi nger.

Removing of the battery

Note: If you detach the battery while the

power is on, the data you have set will not be

saved.

1. Hook one of your fingers in the slit formed

by the transmitter’s main body and the

battery cover on the back and bottom of

the transmitter, and then pull up the cover

to release the lock. You can now open the

cover in the direction of the arrow.

2. Slide the slide lever to the right while pressing

it, the battery will be released.

Warning

Be careful to not drop the battery.

Never take out the battery from the T14MZ

transmitter while the LED monitor is blinking

yellow after turning off the power the T14MZ

transmitter.

* Internal devices such as memories may have been de-

stroyed.

* If there is any problem, the message "Backup Error" will

be shown the next time when you turn on the power of the

transmitter. Do not use the transmitter as it is, send it back

for a check to the Futaba Service Center.

4. Close and lock the battery cover until you

<Before Use>

20

hear a snapping sound.

Page 21

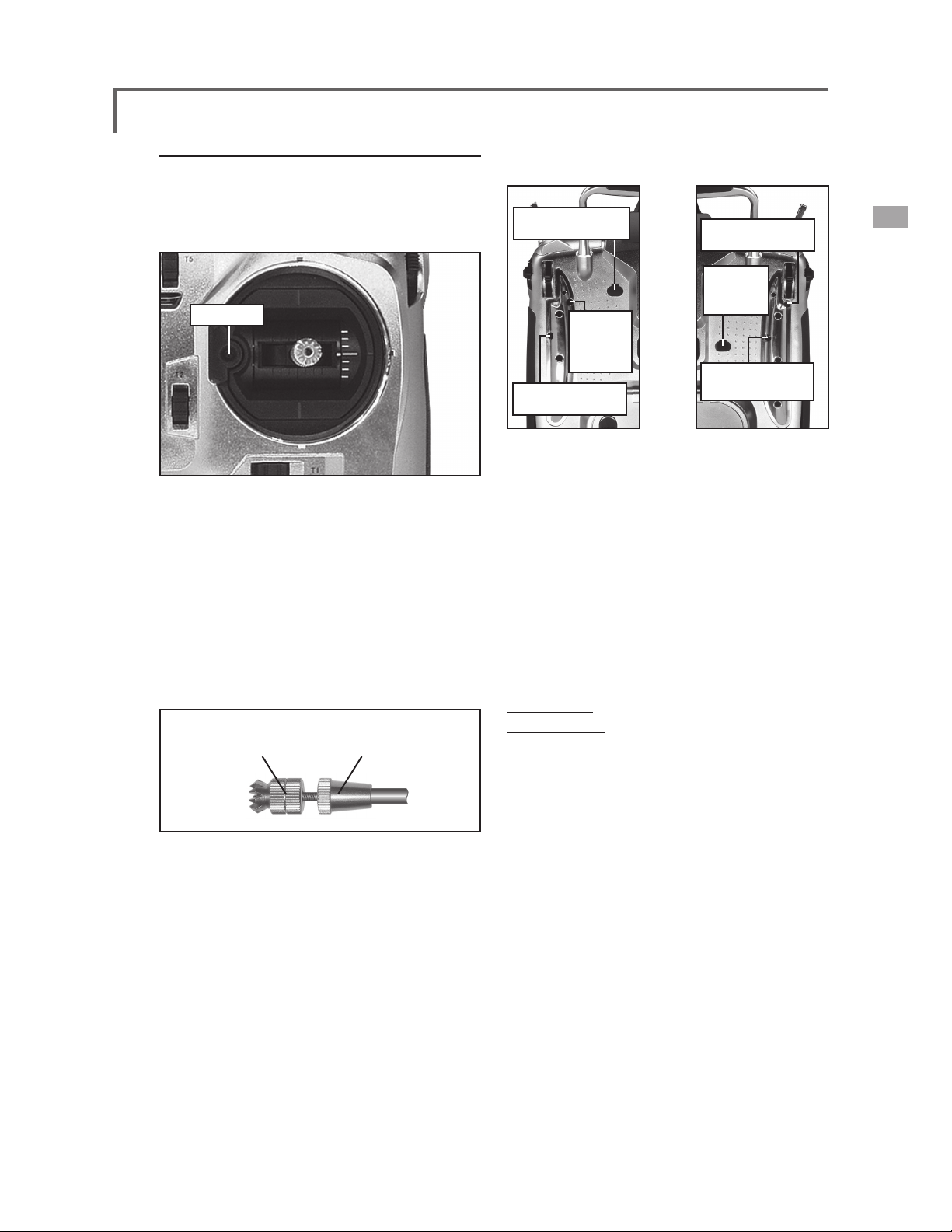

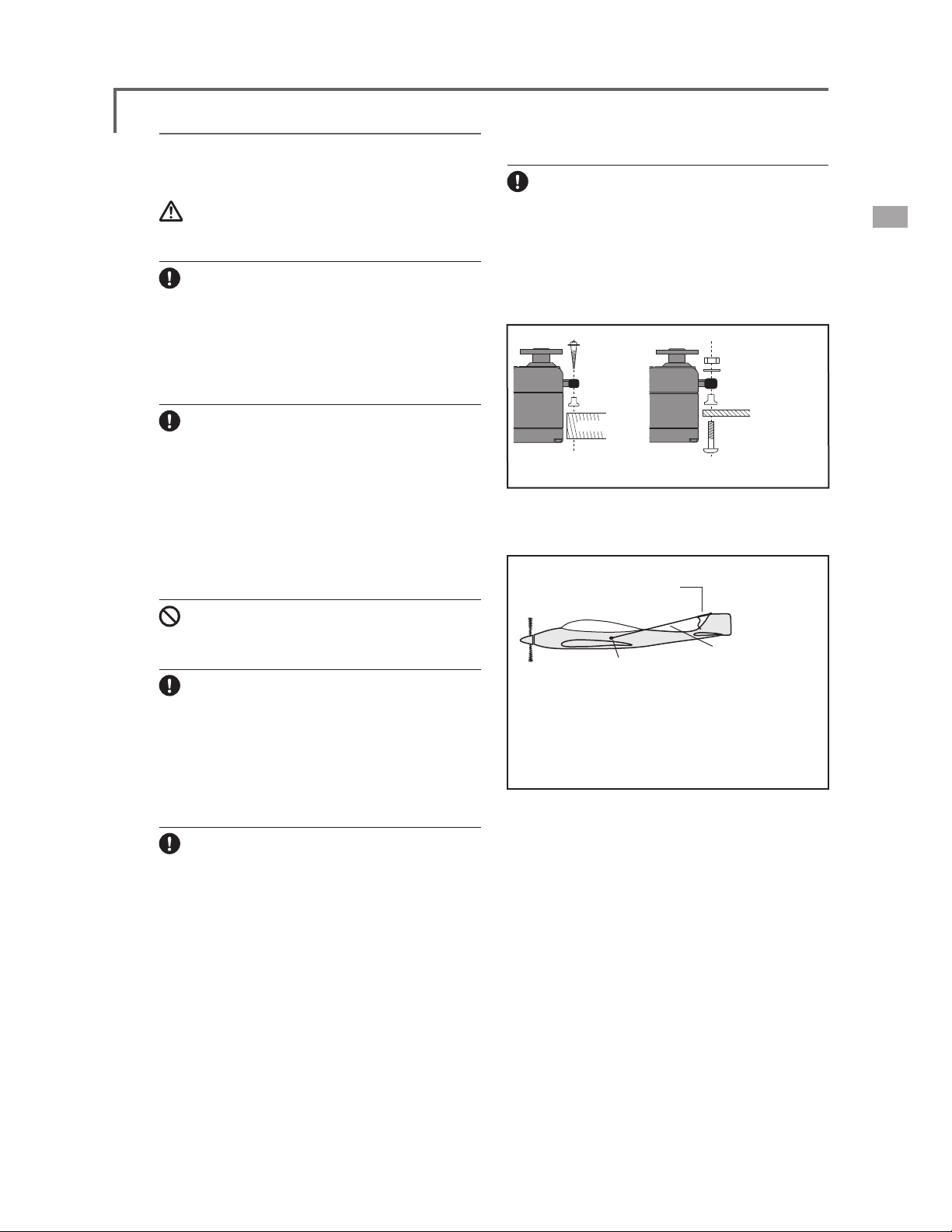

RF module MZ-FM

Toolbox

●Tool for removing

decoration nuts

●Rubber Cap

Caution

Be sure to turn off the power of the transmitter

before you attach or detach the module.

●Connector

Detachment of the RF module

Pull the module straight while you are pushing

inward the projections on both sides of the module.

●Hex. Wrench (1.5mm and 2.5mm)

You can use the toolbox contained in the set for

various adjustment of the transmitter.

Hexagonal wrench (1.5mm and 2.5mm)

These wrenches are for adjustment of sticks,

replacement of the switches and adjustment of the

antenna.

Tool for removing decoration nuts

This is for replacement of switches.

Stylus pen

Rubber cap is attached on the tip of the toolbox.

You may use this tool as a stylus pen for operating

touch panel. This stylus pen can let you do more

precise operation than fingers without damaging

the surface.

*There is a connector above and under the module

respectively. So, you might fi nd diffi culty in pulling out the

module if the module is tilted.

Attachment of the RF module

Insert the module with care so that the connecter

pins of the transmitter won't be bent.

●You may use this tool

as a stylus pen.

<Before Use>

21

Page 22

Receiver nomenclature

●Antenna

●Connectors

●DG1

●Monitor LED

●CH1〜12

●DG2

●B/C

Before using the receiver, be sure to read the

precautions listed in the following pages.

Receiver R5014DPS

Connector

"1 through 12": outputs for the channels 1 through 12

"DG1", "DG2": outputs of DG1 and DG2 channels

"B/C": connector for the power and DSC.

LED Monitor

This monitor is used to check the frequency of

the receiver.

<Before Use>

22

Page 23

Safety precautions when you install

Rubber

grommet

Brass eyelet

Wood screw

Servo mount

2.3-2.6mm nut

washer

Rubber

grommet

Brass eyelet

Servo mount

2.3-2.6mm screw

(Helicopter)(Airplane/Glider)

receiver and servos

Warning

Connecting connectors

Be sure to insert the connector until it stops at

the deepest point.

*If a connecter comes out during the fl ight due to some

reasons such as vibration, your aircraft will crash.

How to protect the receiver from vibration and

water

Wrap the receiver with something soft such

as foam rubber to avoid vibration. If there is

a chance of getting wet, put the receiver in a

waterproof bag or balloon to avoid water.

*Strong physical shock or water infi ltration may damage

the receiver and let the receiver malfunction to crash your

aircraft.

Mounting servos

Use a vibration-proof rubber (such as rubber

grommet) under a servo when mounting the

servo on a servo mount. And be sure that the

servo cases do not touch directly to the metal

parts such as servo mount.

*If a servo case is in direct contact with the airframe, the

vibration of the airframe directly travels to and may damage

the servo.

Internal antenna mounting (Airplanes)

Receiver's antenna

Never cut the receiver's antenna. Do not bind

the receiver's antenna with the cables for

servos.

Locate the receiver's antenna as far as possible

from metals such as frames.

*Cutting or binding the receiver's antenna will reduce the

radio reception sensitivity and the fl ight area, causing the

crash.

Servos throw

Adjust your system so that pushrods will not

bind or sag when operating the servos to the

full extent.

*If excessive force is continuously applied to a servo, your

aircraft may crash because the servo would be damaged

and the battery would be consumed rapidly.

●Use rubber band to stretch

antenna and then fix it.

Antenna

アンテナ

●Use a rubber bushing to the position where

antenna is coming out from the airframe so

that the antenna won't be cut due to the

friction.

●Use rubber band to stretch antenna and then

fix it.Make a knot inside of the airframe so that

the antenna will not fall out.

Mounting the power switch

When mounting a power switch to an airframe,

make a rectangular hole that is a little larger than

the total stroke of the switch so that you can turn

ON/OFF without binding.

Avoid mounting the switch where it can be

covered by engine oil and dust. In general, it is

recommended to mount the power switch on the

side of the fuselage that is opposite the muffl er.

<Before Use>

23

Page 24

BASIC OPERATION

Battery Charging

Before charging batteries, read the "Cautions for

handling battery and battery charger" in the section

"For your safety".

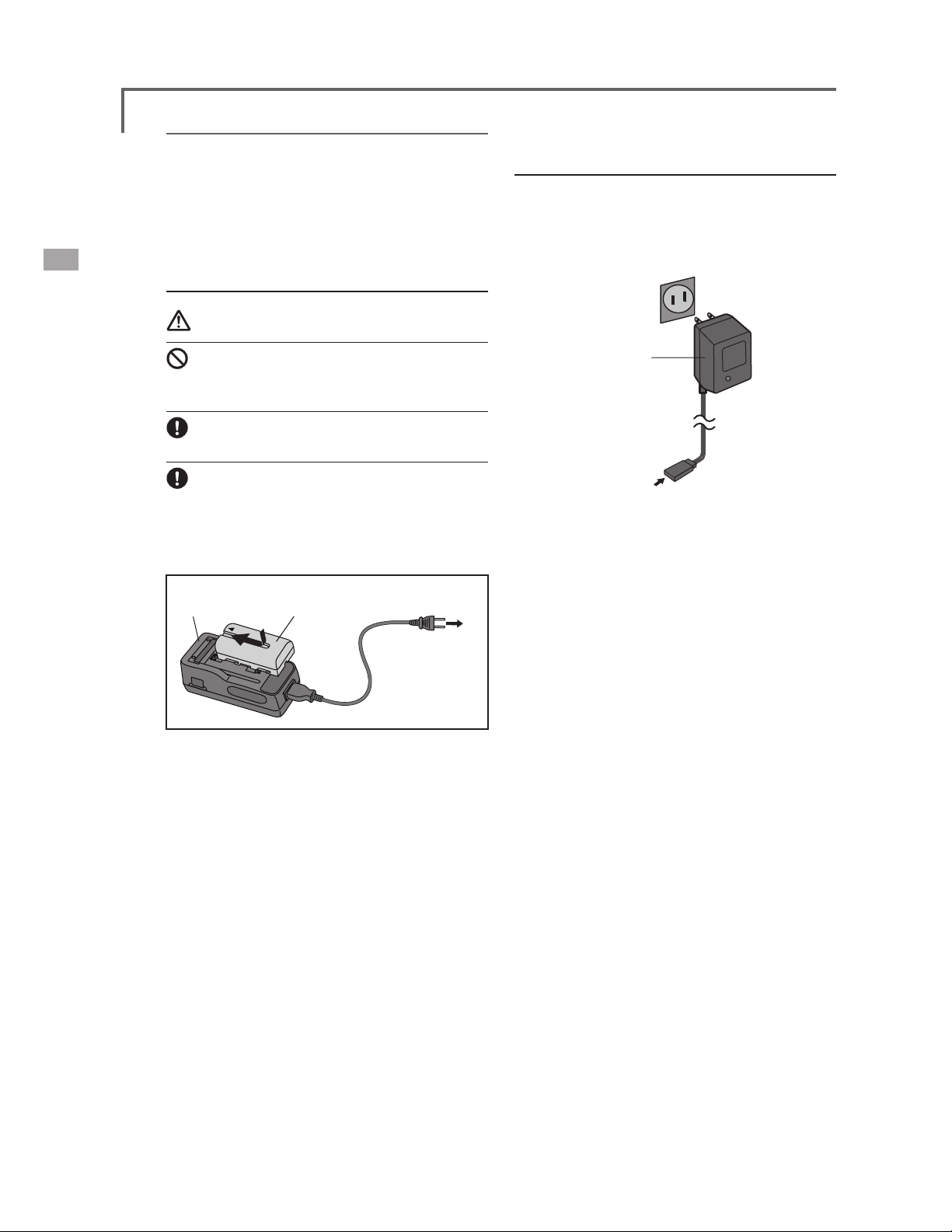

How to charge the Lithium Ion battery

LT2F2200 for the transmitter

Danger

The Lithium-Ion battery LT2F2200 is only for

your T14MZ. Do not use this battery for other

equipment.

Be sure to use the battery charger LBC-1D5 to

charge the battery.

To charge the battery while installed in the

transmitter, use the optional battery charger

CR-2500 for 12V.

[Method of charging battery]

●Special Charger

LBC-1D5

1. Connect the power cable to the charger.

2. Connect the power cable of the charger to

the wall socket (AC outlet).

* The power lamp turns on.

3. Mount the battery and then slide the battery

in the direction shown in the fi gure until you

hear a locking sound.

*The charge-lamp turns on and charging starts.

4. When the charge-lamp turns off, charging

has been completed.

*Be sure to remove the power cable from the wall socket

after using a battery charger.

*It takes about two and a half hours for charging the battery

pack that has been used fully. However, the charging time

may vary depending on the surrounding air temperature and

the condition of the battery pack.

*The charge LED blinks (error) if the battery is improperly

mounted or the battery itself is a defective product. In this

case, remount the battery or use another battery.

*If you mount a charged battery, the charge lamp will turn on

for several seconds, but it will turn off later.

●Li-ion Battery

LT2F2200

to AC Outlet

How to charge the Ni-Cd battery NR4F1500 for

the receiver

Use the battery charger FBC-32A that is included

in the set.

[Method of charging battery]

AC Outlet

●Special Charger

FBC-32A

●Ni-Cd Battery

NR4F1500

1. Connect the power cable of the charger to

the wall socket (AC outlet).

2. Connect the connector to the NiCd battery.

*Confi rm that the charging indicator, LED lamp, is on.

3. Remove the battery after 15 hours.

*Battery charging will not automatically stop. Remove the

battery from the charger and remove the charger from the

wall socket.

*It is recommended to reactivate the battery by cycling

several times if the battery has not been used for a long

period.

*In case of NiCd battery, you may fi nd the poor performance

of the battery if you have used the battery only for a short

period or if you repeat charging while the battery is not fully

discharged. It is recommended to discharge the battery to the

recommended level after your usage. It is also recommended

to charge the battery just before your usage.

<Basic Operation>

24

Page 25

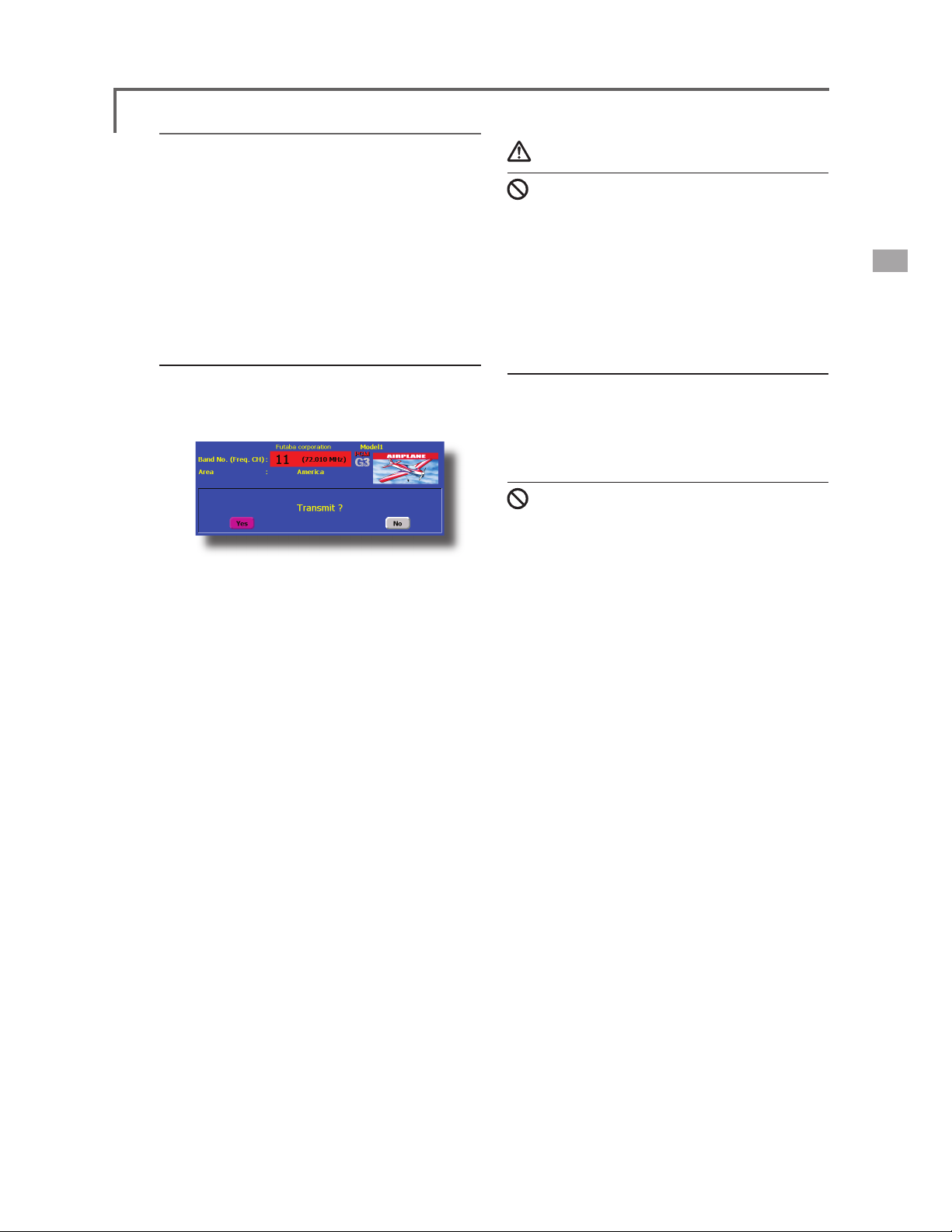

How to turn ON/OFF the power of the

transmitter

Windows® CE is installed as a built-in operating

system in the T14MZ transmitter. Compared to the

conventional system, the T14MZ takes extra time

for internal processing when it is turned on/off.

For safety reasons, the radio will be emmiting

only after you push the confi rmation button when

turning on the power. Please follow the instructions

for turning on/off the transmitter.

Warning

Once you turn on the power, never shut off the

power switch until the power becomes stable

(or until the fi rst screen shows up). If you turn

off the power switch while the transmitter is

going through the initialization process, the

data could be damaged. Note: The start-up time

may be a little bit slower when the CF card

is installed compared to when the card is not.

When turning on the power of the transmitter

1. Turn on the power switch of the transmitter.

*After initialization of the transmitter is over, the frequency

confirmation screen pops up, and LED monitor turns on

pink.

2. Check the frequency shown on the screen. If

it is OK, then click the button "YES".

*LED monitor turns to green and the transmitter begins to

emit radio waves.

*If you push the button "NO", then the transmitter will not

emit radio waves.

Then, you will see the home screen and you

will be able to set conditions.

Start-up time; The time required for initializing

the internal circuit of the transmitter varies between

the previous time you turned off the transmitter

and the time you will turned on the power. There

are two “start up” modes for your transmitter, see

below:

How to stop the transmitter

Turn off the power switch of the transmitter. The

internal circuit of the transmitter starts the shut

down process including saving the set-up data. The

LED will blink yellow while the transmitter is in

the shutdown process.

Once you turn off the power, never operate the

power switch until the power shutdown process

is fully completed. If you turn on the power

switch again while the transmitter is still in the

process of power shutdown, the data could be

damaged.

As the internal circuit of the transmitter stays on the

standby mode for 4 hours after turning off the

power, some part of the circuit is consuming

current. When you turn on the power during

this period, the power starts in “Hot mode”. But

if more than four hours pass after shutting down

the power, the power supply will completely

shut down the internal circuit. When you turn

on the power after this point, the power starts in

“Cold start mode”.

Cold start;

If you turn on the transmitter more than four

hours after you last turned it off, the mode is “Cold

start”. “Cold start” is normal for the first initial

power up of the day. It will take about 30 seconds

to be ready for use, as it takes time to initialize the

internal circuit of the transmitter.

Hot start;

If you turn on the transmitter less than four hours

after you last turned it off, the mode is “Hot start”.

Since initialization has been partly completed, the

transmitter will be ready to use in several seconds.

“Hot start” takes place usually at a second fl ight or

later fl ight in the day.

<Basic Operation>

25

Page 26

●Reset Button

How to reset software

If the screen freezes for some reason and you

cannot edit, the transmitter power supply is not shut

off even if you turn OFF the power switch. You will

need to use the reset button or remove the battery

and reinsert it again. In this case, the power restarts

in “Cold mode”. Even though the screen freezes,

all the other functions for radio control operation

remain operative.

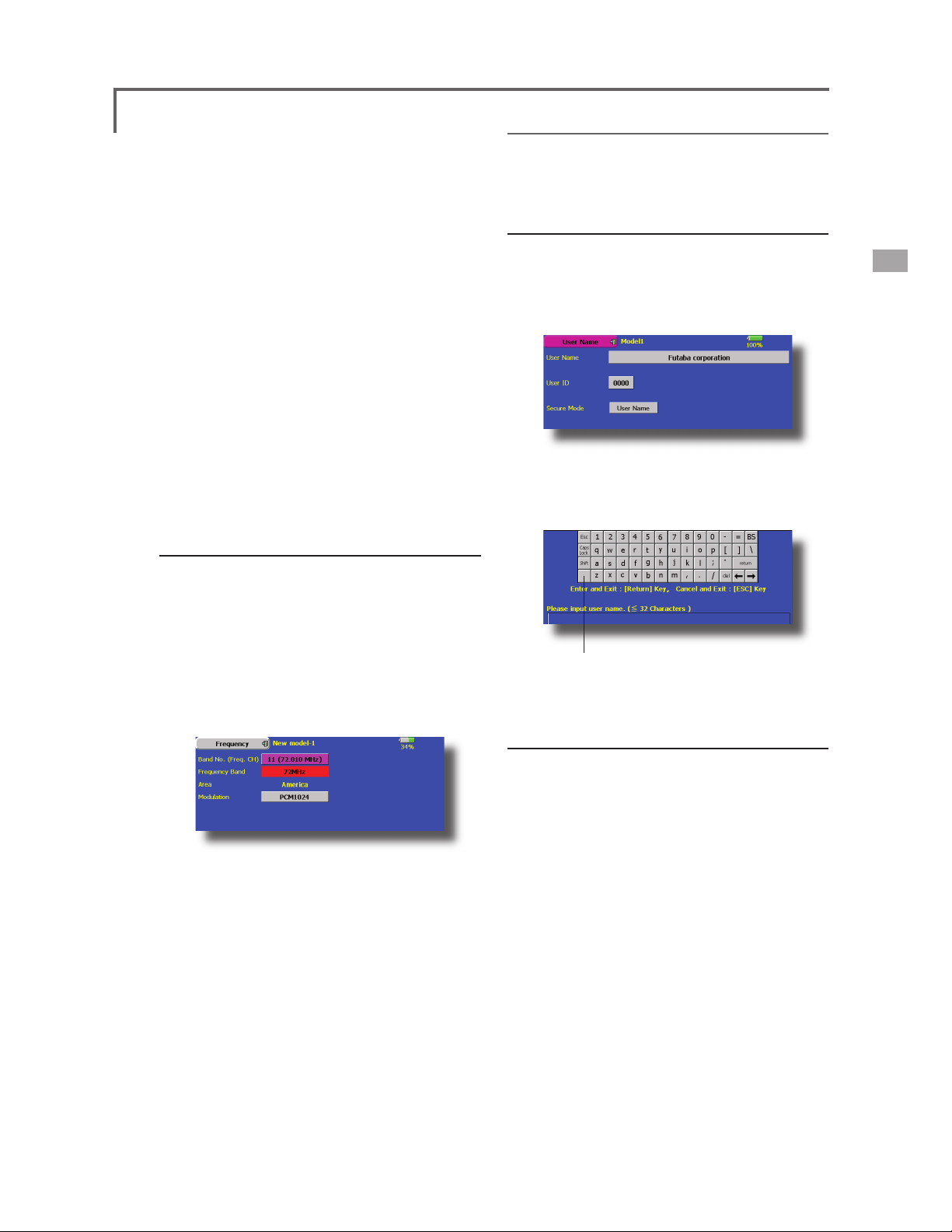

How to change the frequency/How to set ID

The T14MZ system has employed the frequency

synthesizer scheme. The T14MZ transmitter will

set the frequency of the R5014DPS (PCMG3

receiver) by the wireless data transmission. When

you are using a new PCMG3 receiver and changing

the frequency, set ID or frequency by the following

instructions.

In case of using PCMG3 receivers

*Make sure that PCM-G3 is set as a modulation scheme.

Then change the frequency by the following instruction.

How to change the frequency

1. Turn on the power of the transmitter.

2. Push the area that shows the frequency in

the home screen or push the "Frequency"

button in the Linkage menu. Then the

Frequency Set screen will pop up.

3. Push the "Receiver ID" button. Then ID

inputting screen for receiver will pop up.

Input the eight-digit ID code attached to the

receiver's case. Push the "Yes" button after

confi rming the ID.

*Use the "BS" button to move back digit by digit for

correction if you made a mistake. If you want to stop

changing ID code halfway, push "Return" button to return to

the previous screen.

*Once you set the ID code for a receiver, you don't have to set

the ID code again as long as you change the receiver itself.

*When you need to use two receivers for a large size aircraft,

you need to enter different ID codes to those receivers

respectively.

4. Push the "Band NO. (Frequency)" button if

you need to change the frequency. Then

you will see frequencies on the screen. Select

the frequency you want use. Push the button

"Yes" after confi rmation. Then you will see the

"Confi rmation of the change" box.

*If you have changed the module prior to turning on the

power, confi rmation screen will pop up to ask you whether

you want to change the frequency. Push the button "Yes" to

change the frequency.

5. If the frequency is correct, push the button

"Yes". Then you will see the message

"Transmitting the frequency data". It takes a

certain time to send the new frequency data

to the receiver with a sound. (If you need to

resend the data, push the "Resend" button.)

6. Turn on the power of the receiver while the

<Basic Operation>

26

Page 27

new frequency data is displayed. When

the frequency setting for the receiver is

completed, the LED monitor of the receiver

blinks once and the 1CH servo shuttles three

times across the neutral position.

*A very low power, whose frequency is different from that

of the channel frequency, is used to set the frequency of the

receiver. The reachable distance of the radio is designed to

be within several feet. Therefore, put the transmitter and the

receiver as close as possible when setting the frequency of

the receiver.

* If the receiver can not load the new data

due to environmental reasons, connect the

transmitter and the receiver directly by the

DSC cable. And do the procedure 6 and 7.

*LED monitor will blink on and off if the receiver's ID code

is wrong. Then move back to the Receiver ID Set screen and

restart the receiver's ID setting from the beginning.

7. Push the button "End" when the frequency

setting is completed. Then turn off the power

of the transmitter following the instructions

shown on the screen. You will be able to

use the new frequency after you turn on the

power again.

In case of using PCM1024, PPM receivers

*Make sure that PCM1024 or PPM is set as a modulation

scheme. Then change the frequency by the following

instruction.

Registration of the user's name

T14MZ transmitter can register user's name.

How to register user's name

1. Turn on the power of the transmitter.

2. Push the area of the user's name shown on

the home screen or the "user's name" in the

linkage menu. Then the User's Name Set

screen will pop up.

3. Push the user's name. Then the keyboard will

pop up. You can use up to 32 characters

as a user's name. Use the keyboard on the

screen to enter user's name.

How to change the frequency

1. Turn on the power of the transmitter.

2. Push the area that shows the frequency in

the home screen or push the "Frequency"

button in the Linkage menu. Then the

Frequency Set screen will pop up.

3. Push the "Band NO. (Frequency)" button if

you need to change the frequency. Then

you will see frequencies on the screen. Select

the frequency you want use. Push the button

"Yes" after confi rmation. Then you will see the

"Confi rmation of the change" box.

*If you have changed the module prior to turning on the

power, confi rmation screen will pop up to ask you whether

you want to change the frequency. Push the button "Yes" to

change the frequency.

4. If the frequency is correct, push the button

"Yes". Turn off the power of the transmitter

following the instructions shown on the

screen. You will be able to use the new

frequency after you turn on the power again.

space key

4. Push "Return" key to return to the previous

screen after entering the user's name.

(If you want to protect the user's name)

If you don't want anybody else to change your

user's name, set your ID in the following way.

*Please be aware that you will not able to change user's name

if you forget your password.

1. Make sure that the security mode is "User's

name", and then push the User ID button.

2. Enter your password, using keyboard on the

screen.

You will need to enter your password for

changing the user's name from the next time

you turn on the power of the transmitter.

*Even if you enter the same character, your password will be

identified differently depending on whether you are using

"Transform" mode or "Direct" mode for inputting.

<Basic Operation>

27

Page 28

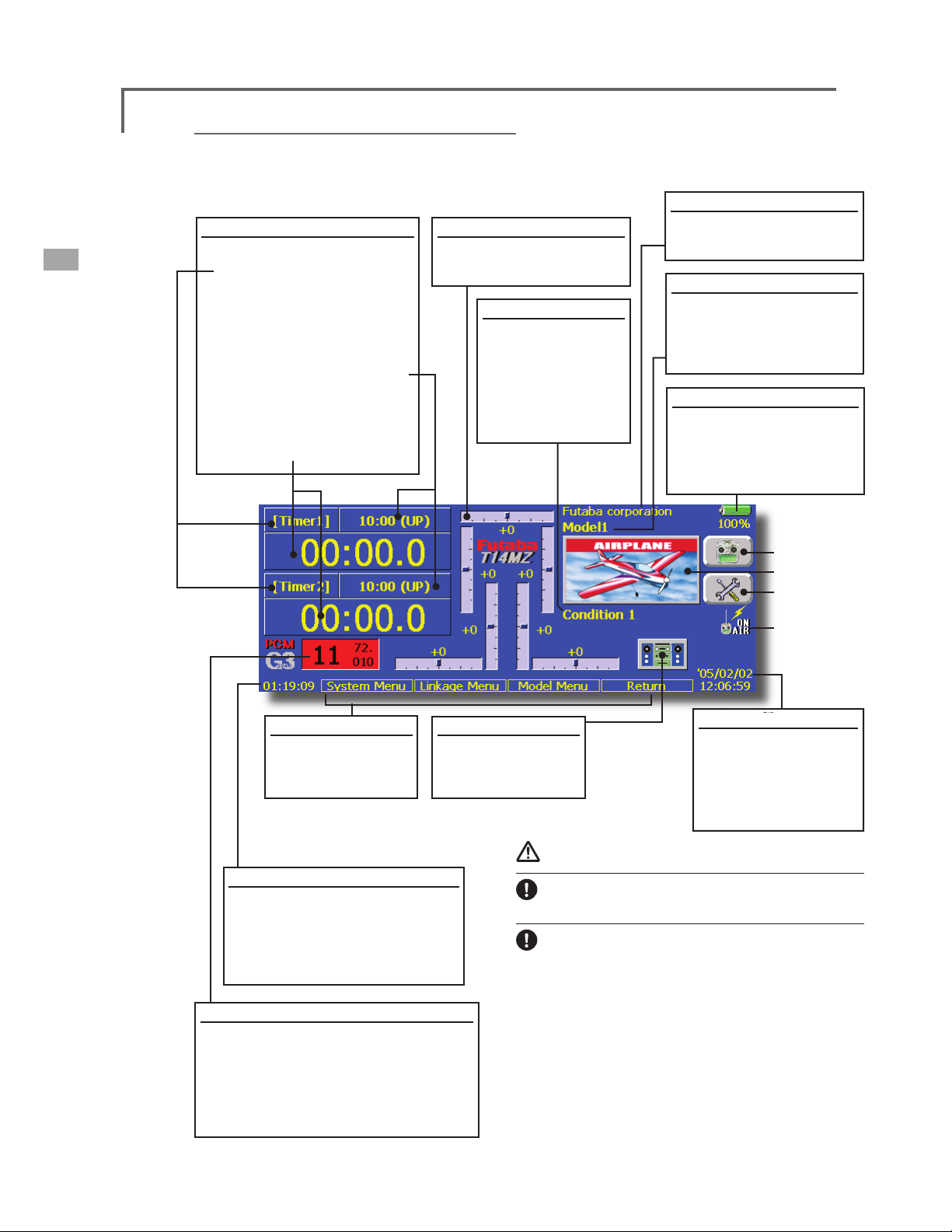

Home screen

Here is the home screen and its descriptions. Use your fi nger or included stylus pen to operate the touch

screen.

Timer

• To call the setting screen

Push [Timer1] or [Timer2] to

call the timer setting screen.

• To display and reset the

setting

Time and mode (UP/DN)

are displayed here. Push this

area for resetting the timer.

• To display, start and stop the

timer

Timer is displayed here. Push

this area to start/stop the

timer.

Digital trim (T1 to T6, CD)

Push this area to call the

Dial Monitor screen.

Condition

The condition name

that is currently used

is displayed here.

• Push this area to

call the Condition

Select screen.

User's Name Setting screen.

currently used is displayed here.

• Push this area to call the

•When the remaining

User's name

Push this area to call the

Model Name

The model name that is

Model Select screen.

Battery Indicator

battery reaches 30%,

the alarm will beep.

Land your aircraft

immediately.

(Menu Button)

●System

●Model

●Linkage

Direct buttons

Select and push one

of the direct buttons to

call its setting screen.

Music playback

• Push this button

to call the Music

Playback screen.

System timer/Reset

• This shows the accumulated

time up to now since the latest

reset.

(Hour):(Minute):(Second)

Push this area to reset the timer.

Modulation mode/Frequency

Modulation mode is displayed here.

(PCM-G3/PC M1024/PPM)

• Band number and frequency are

displayed here.

• Push the frequency displaying area to

call the Frequency Set screen.

●RF Indicator

Clock

This shows the today's

date and the current time.

• Push this area for the

Date & Time Setting

screen.

Warning

Be sure to confirm the model name before flying

your aircraft.

Check the remaining battery as often as possible

and try to charge the battery earlier. If the battery

alarm makes a sound and its warning symbol is

displayed, land your aircraft immediately.

Although you may notice the flickering of the numbers on the

LCD screen, this is not an abnormal, because the LCD screen is

frequently refreshing those even if those numbers are unchanged.

You can adjust the LCD contrast and the backlight brightness,

and can change the duration time to turn off the backlight and

color of the background by the screen setting in the system menu.

<Basic Operation>

28

Page 29

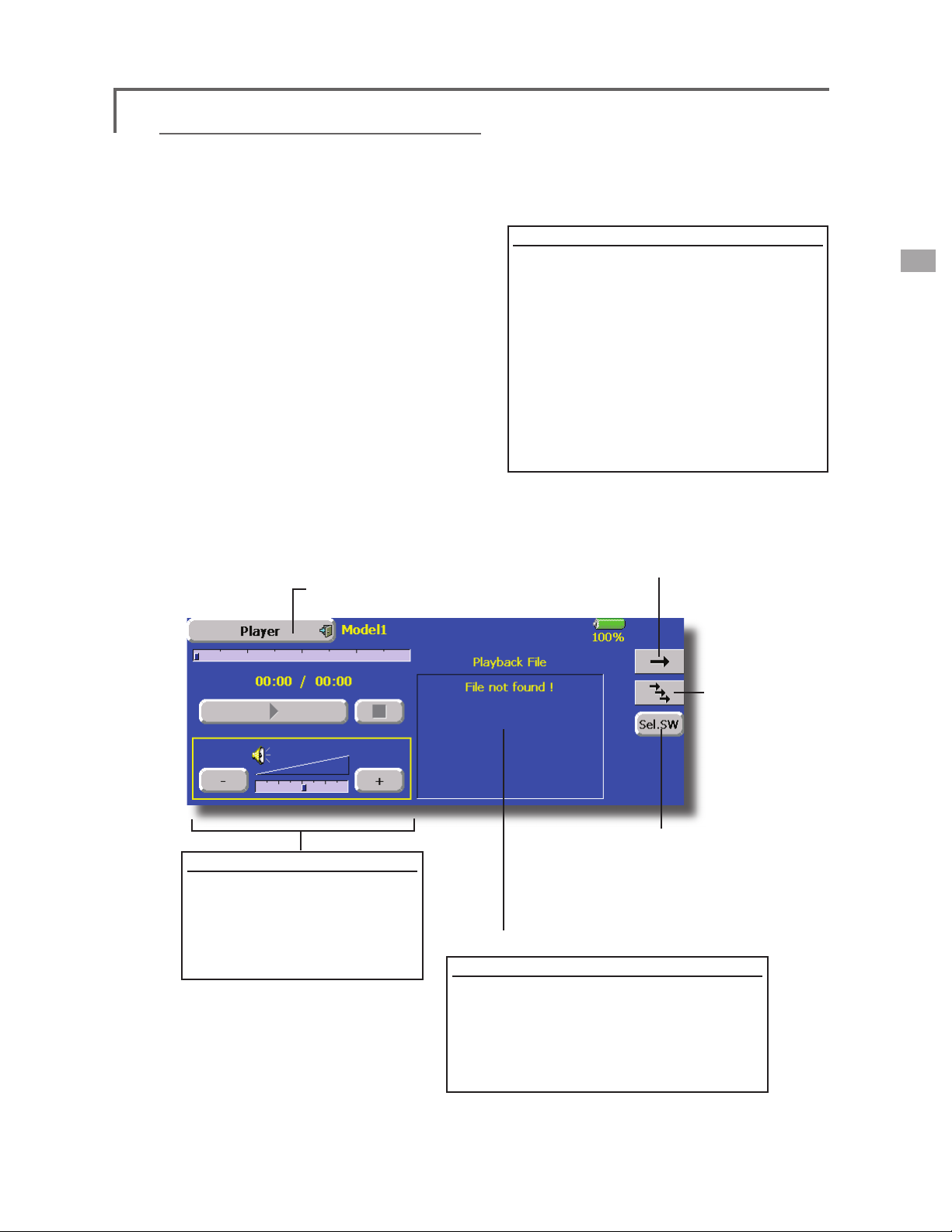

Music playback

The T14MZ transmitter can play back the ".wma" music fi les stored in the CF (Compact Flash) card.

You can listen to them through the built-in speaker or a headphone by the earphone plug.

*First, store music fi les from your PC into the WMA folder

on the CF card, and then insert the CF card into your

transmitter to play back music fi les on the transmitter.

• Push the Music Playback button on the home

screen to call the following set-up screen.

• Return to the home screen

[Important notice]

Before downloading fi les from your PC into the

CF card, insert the CF card into the transmitter

and turn on the power of the transmitter. Then

the following folders will be automatically

created in the CF card. When you download fi les

from you PC, copy and paste the fi les into their

corresponding fi les.

• BMP : picture fi les

• WMA : music fi les

• WAV : sound fi les

• MODEL : model data fi les

• Button to select either One-time

Playback or Repeat Playback

Buttons for music playback

• You can playback any music

files listed on the right side of

the screen.

• If you adjust the volume here, it

adjusts not only music playback

but also other applications.

•Button to

select either

One Music

Playback or

Multiple Music

Playback

• SW selection button

Push this button to call the SW

select screen and choose the

Music playback switch.

(Refer to the description in the

end of this manual)

(Playback fi le list)

To playback

• All the music fi les saved in the CF card will

be shown here.

1. Push the file name to select the music file

you want to hear.

2. Use the buttons on the left to playback or

stop the music.

<Basic Operation>

29

Page 30

SYSTEM MENU

The System Menu sets up functions of the

transmitter, this does not set up any model data.

● When the System Menu button is touched,

the menu shown below is called. Call the

setup screen by pressing the function you

want to set up.

●Return to Home screen

System Menu functions table

[Trainer]: Starts and sets the trainer system.

[Display]: Display adjustment and auto power off setting.

[Date & Time]: Sets the date and time (system clock setting) and resets the timer.

[User Name]: User name registration and ID Pin number.

[Switch]: Toggle switch type setting (Set when the switch is replaced.)

[H/W Reverse]: Reverses the direction of operation of the sticks, switches, trim levers, knobs, etc.

[Information]: Displays the program version, CF card information, and product ID.

<Functions of System Menu>

30

Page 31

Trainer

Trainer system starting and setting

The Trainer function makes it possible for the

NOTE: This trainer system can be used in the

instructor to choose which functions and channels

are to be used for instruction, making it possible to

1. In the T14MZ transmitter and a conventional

match the training ability to the student's skill level.

Two transmitters must be connected by an optional

Trainer Cord, and the Instructorsʼ transmitter

should be programmed for trainer operation, as

2. When the T14MZ is used as the Teacher,

described below.

When the Instructor activates the trainer switch,

the student has control of the aircraft (if MIX or

FUNC mode is turned on, the Instructor can make

corrections while the student has control). When

the switch is released the Instructor regains control.

This is very useful if the student gets the aircraft

3. Be sure that all channels work correctly in

into an undesirable situation.

● Touch the [Trainer] button at the System Menu to

call the setup screen shown below.

●Return to System Menu

following manner;

transmitter, if the channel order is different. It

is necessary to match the channel order in

the Linkage Menu when connecting it with

other than a T14MZ.

set the modulation mode of the student’

s transmitter to PPM. If being used as the

student, set the T14MZ to the modulation

mode specifi ed by the Instructors’ transmitter.

When the Instructors’ transmitter is a T14MZ,

T9Z, T9C or T7C transmitter, it should be

switched to PPM mode.

both transmitters before fl ying.

Corresponding types of transmitters:

T4VF, T6YG, T6YFK, T6X, T6EX, T7U, T7C, T8U,

T9C, T9Z, T14MZ

Non-corresponding types of transmitters:

T6VA, T6DA

(The display screen is an example. The screen depends on the model type.)

Teacher mode

1. Set "Teacher/Student" button to "Teacher".

2. Change "ACT/INH" button from "INH" to "OFF"

or "ON".

3. Set "12CH/8CH" to "12CH" when the student is

using T14MZ. Otherwise set it to "8CH".

4. Call up the Switch Setting screen by touching

"Switch". Then set the desired switch and on/

off direction.

5. Select the switch mode. If you select "NORM",

the trainer function will be turned on or off

by a switch position. If you select "ALT", ON

and OFF of the trainer function switches

alternatively every time the switch is turned

on. This means the student side can be

operated without holding the switch lever.

6. The Instructor side selects the channel

for control. Three operating modes are

available.

"NORM" mode (Normal mode);

Student side has no control of mixes and

settings in Teachers radio..

"MIX" mode;

Student has full advantage of all setting in

Teachers radio, plus Teacher has the option

to change any setting while Student has

control.

"FUNC" mode (Function mode);

Student has control of mixes and rate settings

of Teachers radio.

[Notes]

1. In the teacher mode, the trainer function

display does not come on as long as the

student's transmitter is not receiving signals

from the teacher's transmitter (when the

student's transmitter is not connected).

<Functions of System Menu>

31

Page 32

Student mode

1. Set "Teacher/ Student" button to "Student".

2. Change "ACT/INH" button from "INH" to "OFF"

or "ON".

3. Set "12CH/8CH" to "12CH" when the Instructor

is using the T14MZ. Otherwise set it to "8CH".

Note: In "student mode", only the teacher

side can turn on and off the power of the

student's transmitter. Keep the power switch

always at off position. Note: In "teacher

mode", the trainer function won’t be turned

on unless the Instructors' transmitter receives

signals from the student's transmitter. Be sure

●The setup screen for the student mode is

shown below.

●Return to System Menu

to confirm this after connecting your trainer

cable.

<Functions of System Menu>

32

Page 33

Display

LCD screen adjustment and auto power off setting

The following LCD screen adjustments and auto

power off setting are possible:

● Contrast adjustment

● Auto power off time setting

● Backlighting brightness adjustment

● Background color change

● Touch panel screen position correction

● Touch the [Display] button in the System Menu to

call the setup screen shown below.

●Return to System Menu

LCD contrast adjustment

1. Adjust the LCD contrast with the left and right

side buttons.

*When the right side button is pressed, the LCD contrast

decreases. When the left side button is pressed, the LCD

contrast increases.

Auto power off time setting

1. Adjust the auto power off time with the left

and right side buttons.

*When the time the transmitter is inactive exceeds the set

time, the power is turned off automatically. This time can be

set up to 1 hour in 10 minutes increments. The auto power

off function can also be deactivated.

Backlighting brightness adjustment

1. Adjust the backlighting brightness with the

left and right side buttons.

*When the right side button is touched, the backlighting

becomes brighter. When the left side button is touched, the

backlighting becomes darker.

Backlight power-off time

You can set a time period to turn off the LCD