Fujifilm SonoSite X-Porte Service manual

Service Manual

i

Stand and Desktop Systems

ii

Legal Notices

Manufacturer

FUJIFILM SonoSite, Inc.

21919 30th Drive SE

Bothell, WA 98021-3904

USA

T: (888) 482-9449 or (425) 951-1200

F: (425) 951-1201

EC Authorized Representative

FujiFilm SonoSite B.V.

Joop Geesinkweg 140

1114 AB Amsterdam, The Netherlands

Australia Sponsor

FUJIFILM SonoSite Australasia Pty Ltd

114 Old Pittwater RD

Brookvale, New South Wales 2100, Australia

Caution:

SonoMB, SonoSite, Steep Needle Profiling, X-Porte, and the SonoSite logo are registered (in some jurisdictions) and unregistered trademarks

owned by FUJIFILM SonoSite, Inc. in various jurisdictions.

DICOM is the registered trademark of the National Electrical Manufacturers Association.

All other trademarks are the property of their respective owners.

Patents: US 8,216,146; US 8,213,467; US 8,147,408; US 8,137,278; US 8,088,071; US 8,066,642; US 8,052,606; US 7,819,807; US 7,804,970;

US 7,740,586; US 7,686,766; US 7,604,596; US 7,591,786; US 7,588,541; US 7,534,211; US 7,449,640; US 7,169,108; US 6,962,566; US

6,648,826; US 6,575,908; US 6,569,101; US 6,471,651; US 6,416,475; US 6,383,139; US 6,364,839; US 6,203,498; US 6,135,961; US

5,893,363 ; US 5,817,024; US 5,782,769; US 5,722,412; AU: 730822; AU: 727381; CA: 2,372,152; CA: 2,371,711; CN 98108973.9; CN:

98106133.8; CN: 97113678.5; DE: 69831698.3; DE: 69830539.6; DE: 69730563.5; DE: 602004027882.3; DE: 602004023816.3; DE:

60034670.6; DE: 60029777.2; EP: 1589878; EP: 1552792; EP: 1180971; EP: 0875203; EP: 0815793; EP 1180970; EP 0881492; ES: 2229318;

ES: 159878; ES: 1552792; ES: 0881492; FR: 158978; FR: 1552792; FR: 1180970; FR: 0881492; FR: 0875203; FR: 0815793; GB: 158978; GB:

1552792; GB: 1180971; GB: 1180970; GB: 0881492; GB: 0875203; GB: 0815793; IT: 1589878; IT: 1552792; IT: 0881492; IT: 0815793; JP:

4696150; KR: 532359; KR: 528102; NO: 326814; NO: 326202

Copyright © 2018 FUJIFILM SonoSite Inc, Inc. All rights reserved.

P16620-01

United States federal law restricts this device to sale by or on the order of a physician.

iii

iv

Table of Contents

Introduction ................................................................................. 1

Audience.................................................................................................................. 1

Contact Information ................................................................................................. 1

Terms and symbols ................................................................................................. 2

Labeling symbols ..................................................................................................... 2

Specifications .............................................................................. 3

Specifications........................................................................................................... 3

System Specifications ............................................................................................. 3

Electrical specifications ........................................................................................... 3

Environmental limits ................................................................................................ 4

Battery specifications............................................................................................... 4

Accessories and peripherals ................................................................................... 4

Safety .......................................................................................... 5

Electrical safety........................................................................................................ 5

Electrical safety classification .................................................................................. 7

Equipment safety ..................................................................................................... 7

DICOM standard...................................................................................................... 7

HIPAA standard....................................................................................................... 7

Transporting X-Porte Stand Systems ...................................................................... 7

System Overview ........................................................................ 9

About the System .................................................................................................... 9

Theory of Operation................................................................................................. 9

Description of Operating Modes.............................................................................. 10

Additional System Feature Performances............................................................... 12

Front End Overview................................................................................................. 13

X-Porte Front End Board......................................................................................... 14

PW Doppler Processing .......................................................................................... 15

CW Doppler Processing .......................................................................................... 16

Back End Overview ................................................................................................. 17

Control Subsystem .................................................................................................. 18

Power Supply and Control....................................................................................... 19

ECG Module............................................................................................................ 20

DICOM..................................................................................................................... 21

Troubleshooting .......................................................................... 23

X-Porte Desktop and Stand Versions Major Component Diagrams........................ 23

System and Subsystem Diagnosis .......................................................................... 23

System Repair ......................................................................................................... 24

Test Equipment........................................................................................................ 24

Failure (Assert) Codes............................................................................................. 24

Verifying a System Assert Code.............................................................................. 24

Clinical Monitor Display ........................................................................................... 25

DICOM..................................................................................................................... 26

SPMU ...................................................................................................................... 27

Touch Control Panel................................................................................................ 29

X-Porte Power-0 & Power-1 Procedural Steps........................................................ 29

v

Replacement Procedures............................................................ 33

Qualifying Service Personnel................................................................................... 34

Clinical Monitor Display ........................................................................................... 34

Required Parts......................................................................................................... 34

Required Tools ........................................................................................................ 34

Clinical Monitor Display Removal............................................................................ 34

Clinical Monitor Display Replacement..................................................................... 35

System (“Engine”).................................................................................................... 36

Required Part .......................................................................................................... 36

Required Tools ........................................................................................................ 36

System (“Engine”) Removal .................................................................................... 36

System (“Engine”) Replacement ............................................................................. 37

Clinical Monitor Stalk Cable..................................................................................... 37

Required Parts......................................................................................................... 37

Required Tools ........................................................................................................ 37

Clinical Monitor Stalk Cable Removal ..................................................................... 37

Clinical Monitor Stalk Cable Replacement .............................................................. 38

Touch Control Panel ................................................................................................ 38

Required Parts......................................................................................................... 38

Required Tools ........................................................................................................ 38

Control Panel Removal............................................................................................ 38

Control Panel Replacement..................................................................................... 40

Dock......................................................................................................................... 40

Required Part .......................................................................................................... 40

Required Tools ........................................................................................................ 40

Dock Removal ......................................................................................................... 40

Dock Replacement .................................................................................................. 41

Stand Power Management Unit (SPMU) ................................................................. 41

Required Part .......................................................................................................... 41

Required Tools ........................................................................................................ 41

Stand Power Management Unit (SPMU) Removal.................................................. 42

Stand Power Management Unit (SPMU) Replacement........................................... 45

Battery ..................................................................................................................... 46

Required Part .......................................................................................................... 46

Required Tools ........................................................................................................ 46

Battery Removal...................................................................................................... 46

Battery Replacement............................................................................................... 46

Triple Transducer Connect (TTC)............................................................................ 47

Required Part .......................................................................................................... 47

Required Tools ........................................................................................................ 47

Triple Transducer Connect (TTC) Removal ............................................................ 47

Triple Transducer Connect (TTC) Replacement ..................................................... 48

Optional Equipment - Stand System........................................................................ 49

PowerPark ............................................................................................................... 49

Required Part .......................................................................................................... 50

Required Tools ........................................................................................................ 50

PowerPark Stand Module Removal......................................................................... 50

PowerPark Stand Module Replacement.................................................................. 50

PowerPark Stand Module Removal (Alternate Method-Upright System)................ 50

PowerPark Stand Module Replacement (Alternate Method-Upright System)

Sony UP-D897MD Printer 50

Required Part .......................................................................................................... 51

Required Tools ........................................................................................................ 51

..... 50

vi

Sony UP-D897MD Printer Removal ........................................................................ 51

Sony UP-D897MD Printer Replacement ................................................................. 52

Maintenance................................................................................ 51

Periodic Maintenance .............................................................................................. 51

Cleaning and Disinfecting ........................................................................................ 51

Performance Testing................................................................... 53

Overview.................................................................................................................. 53

Recommend Test Equipment .................................................................................. 53

Setting Up Performance Tests................................................................................. 53

Basic Operational Tests........................................................................................... 54

2D Performance Tests............................................................................................. 54

2D Performance / Image Quality ............................................................................. 54

Axial Measurement Accuracy.................................................................................. 55

Lateral Measurement Accuracy............................................................................... 55

Penetration .............................................................................................................. 56

Additional Performance Tests.................................................................................. 56

Color Doppler (Color) .............................................................................................. 56

Color Power Doppler (CPD) .................................................................................... 57

M Mode Imaging...................................................................................................... 57

Tissue Harmonic Imaging........................................................................................ 57

Pulsed Wave (PW) Doppler Imaging....................................................................... 58

Continuous Wave (CW) Doppler Imaging ............................................................... 58

Image Quality Verification Test/Livescan ................................................................ 58

Printer...................................................................................................................... 59

Replacement Parts...................................................................... 61

Clinical Monitor ........................................................................................................ 62

Touch Control Panel ................................................................................................ 63

Dock......................................................................................................................... 64

“Ultrasound” Engine................................................................................................. 65

Stand Power Management Unit (SPMU & Batteries) .............................................. 66

Triple Transducer Connect (TTC)............................................................................ 67

Clinical Monitor Hardware........................................................................................ 68

Control Panel Hardware .......................................................................................... 68

Dock Hardware ........................................................................................................ 69

Stand Hardware Parts ............................................................................................. 69

Optional Equipment ................................................................................................. 70

PowerPark ............................................................................................................... 70

Sony UP-D897MD B&W Printer .............................................................................. 71

Desktop System Components ................................................................................. 72

EPS for Desktop System (Engine)........................................................................... 72

EPS for Desktop Clinical Monitor Display................................................................ 72

Other Desktop Components .................................................................................... 73

Ordering Replacement Parts ................................................................................... 73

Service Event Reporting ............................................................. 75

Service Event Report Form ..................................................................................... 76

Service Event Report Instructions ........................................................................... 77

Returning Products to FUJIFILM SonoSite.............................................................. 78

vii

Shipping Instructions ..............................................................................................78

viii

Chapter 1: Introduction

Before servicing the X-Porte Ultrasound System, please read this manual.

The ultrasound system has multiple configurations and feature sets. All are described in this service manual

but not every option may apply to your system. System features depend on your system configuration,

transducer, and exam type.

Refer to the X-Porte Product Information & Safety Guide (P14646) for additional information regarding

safety, system controls, operation, capabilities, and specifications.

Audience

The intended audience of this manual are properly trained field and in-house service personnel. The

ultrasound system operators are expected to be able to replace all the components of the Desktop version

and the System “Engine” attached to the Stand version. With technical support guidance, a basic knowledge

of hand tools, and the ability to handle about 20 lb (9.1 kg), the system operators are expected to replace

the touch Control Panel and Clinical Monitor display. The Stand Power Management Unit (SPMU) and

batteries in the Stand version will be serviced by qualified field service personnel. The batteries used are

sealed Lithium-ion type which requires no maintenance and are not serviceable. Expected life for these

batteries are between 3-6 years depending on system usage and configuration of the Stand system.

Contact Information

Questions and comments are encouraged. FUJIFILM SonoSite is interested in your feedback regarding the

system and user documentation. Please call FUJIFILM SonoSite at 888-482-9449 in the U.S. Outside the

U.S., call the nearest FUJIFILM SonoSite representative.

For technical support, please contact FUJIFILM SonoSite as follows:

FUJIFILM SonoSite Technical Support

Phone

(U.S. or Canada):

Phone

(Outside U.S. and

Canada):

Fax: 425-951-6700

E-mail: ffss-service@fujifilm.com

Web site: www.sonosite.com

Europe

Service

Center:

877-657-8118

425-951-1330

Or call your local representative.

FUJIFILM SonoSite - Amsterdam

Joop Geesinkweg 140

1114 AB Amsterdam

The Netherlands

Tel (Main): +31 20 751 2020

- English support: +44 14 6234 1151

- French support: +33 1 8288 0702

- German support: +49 69 8088 4030

- Italian support: +39 02 9475 3655

- Spanish support: +34 91 123 8451

Chapter 1: Introduction 1

FUJIFILM SonoSite Technical Support (Continued)

Asia

Service

Center:

Terms and symbols

The service manual follows these conventions:

•A WARN ING describes precautions necessary to prevent injury or loss of life.

•A Caution describes precautions necessary to protect the products.

• Numbered steps in procedures must be performed in order.

• Items in bulleted lists do not require performance in sequence.

Labeling symbols

Please refer to Chapter 4: Labeling Symbols found in the X-Porte Product Information & Safety Guide

(P14646)

e-mail:

ffss-apacme-service@fujifilm.com

Tel: +65 6380-5581

2 Chapter 1: Introduction

Chapter 2: Specifications

This chapter contains information regarding system specifications and accessory compatibility. The

information applies to the ultrasound system, transducers, accessories, and peripherals.

Specifications

System Specifications

Stand Dimensions:

• Length: 26.4 in. (67.1 cm)

• Width: 21.2 in. (53.8 cm)

• Height (max): 64 in. (162.6 cm)

• Height (min): 42.2 in. (107.2 cm)

• Height Adjustment: 9 in. (22.9 cm) travel

Touch Panel

• Capacitive Display Type

• Diagonal: 12.1 in. (30.7 cm)

• Multi-touch Gestures for System Controls

• Tilt Adjustment: 7.3 in. (18.5 cm)

• Side to Side Turning: +/- 90 degrees from center

Display (HD Monitor)

• Diagonal: 19 in. (48.3 cm)

• Screen Size: 1280 x 800

• Image Size: 800 x 600

• Monitor Tilt: 5° tilting forward from vertical, 20° tilting back from vertical

Electrical specifications

• Power Supply Input (Stand Version): 100-240V~ 6.0A Max, 50-60Hz

• Sony B/W Printer: 100-240V~ 1.5A-0.8A, 50-60Hz

• Power Supply Output 1 (Stand Version): 24 VDC, 11.5 A Max (Output not exceeding 275 watts)

• Power Supply Output 2 (Stand Version): 100-240V~ 3.0A - 1.5A, 50-60Hz

• Power Supply Input (Desktop Version): 100-240V~ 3.4A - 1.4A, 50-60Hz

• Power Supply Output (Desktop Version): 24 VDC, 6.25 A Max (Combined Output not exceeding 150

watts)

• Clinical Display Monitor Supply: 100-240V~ 2.7A, 50-60Hz

• Sony B/W Printer: 100-240V~ 1.5A-0.8A, 50-60Hz

• Batteries (Stand Version): 3 Lithium-ion batteries (385Wh total)

• Battery Use Time: 1.0 hour, 3 days on idle

• Battery Charge Time: 2.5 hours

• Battery Life: 3-6 years

Chapter 2: Specifications 3

Environmental limits

Note: The temperature, pressure, and humidity limits apply only to the ultrasound system, transducers,

and battery.

Operating

System and Transducer

10–40°C (50–104°F), 15–95% R.H.

700 to 1060hPa (0.7 to 1.05 ATM)

Shipping and Storage

System and Transducer

-35-65°C (-31-149°F), 15-95% R.H.

500 to 1060hPa (0.5 to 1.05 ATM)

Battery

-20–60°C (-4–140°F), 15–95% R.H. (For storage longer than 30 days, store at or below room temperature.)

500 to 1060hPa (0.5 to 1.05 ATM)

Battery specifications

The X-Porte stand uses three lithium-ion batteries that are charged and controlled by the Stand Power

Management Unit (SPMU) that can be switched off via three rocker type switches. These switches can be

accessed by lifting up from the stand bottom a black plastic door located under the left rear caster leg.

Run time is up to one hour (up to 3days on idle) depending on imaging mode and display brightness. This

chapter contains electrical, and clinical safety information required by regulatory agencies.

Accessories and peripherals

The system supports various accessories and peripherals. See the X-Porte Product Information & Safety

Guide (P14646) for a list of compatible products.

4 Chapter 2: Specifications

Chapter 3: Safety

This chapter contains electrical and clinical safety information required by regulatory agencies. The

information applies to the ultrasound system, transducers, accessories, and peripherals.

Electrical safety

This system meets EN60601-1, Class I/internally-powered equipment requirements and Type BF

(transducers) and Type CF (ECG leads) isolated patient-applied parts safety requirements.

This system complies with the applicable medical equipment requirements published in the Canadian

Standards Association (CSA), European Norm Harmonized Standards, and Underwriters Laboratories (UL)

safety standards.

For maximum safety observe the following warnings and cautions..

WARNING:

WARNING:

WARNING:

To avoid the risk of injury, do not operate the system in the presence of

flammable gasses or anesthetics. Explosion can result.

To avoid the risk of electrical shock or injury, do not open the system

enclosures. All internal adjustments and replacements, including battery

replacement, must be made by a qualified technician.

To avoid the risk of electrical shock:

• Use only properly grounded equipment. Shock hazards exist if the power

supply is not properly grounded. Grounding reliability can be achieved only

when equipment is connected to a receptacle marked “Hospital Only” or

“Hospital Grade” or equivalent. The grounding wire must not be removed or

defeated.

• This equipment must be connected only to supply mains with protective earth.

• Do not let any part of the system (including the bar code scanner, external

mouse, power supply, or power supply connector), except for the transducer

or ECG leads, touch the patient.

• Do not touch any of the following:

• The ungrounded signal input/output connectors on the back of the

ultrasound system

• The system battery contacts (Stand System Only)

• The system transducer connector when the transducer or Triple

Transducer Connect (TTC) is disconnected

• Any unused TTC transducer connector when the TTC is connected.

• Do not connect the system's power supply to an MPSO or extension cord.

• Before using the transducer, inspect the transducer face, housing, and cable.

Do not use the transducer if the transducer or cable is damaged.

• Always disconnect the power supply from the system before cleaning the

system.

• Do not use any transducer that has been immersed beyond the specified

cleaning or disinfection level. See “Cleaning and Disinfecting X-Porte

Products” P16529

• Use only accessories and peripherals recommended by FUJIFILM SonoSite,

including the power supply. Connection of accessories and peripherals not

recommended by FUJIFILM SonoSite could result in electrical shock. Contact

FUJIFILM SonoSite or your local representative for a list of accessories and

peripherals available from or recommended by FUJIFILM SonoSite.

Chapter 3: Safety 5

WARNING:

To avoid the risk of electrical shock and fire hazard:

• Inspect the power supply, AC power cords, cables, and plugs on a regular

basis. Ensure that they are not damaged.

• The power cord set that connects the power supply of the ultrasound system

or to mains power must only be used with the power supply, and cannot be

used to connect other devices to mains power.

WARNING:

WARNING:

WARNING:

WARNING:

Caution:

To avoid the risk of electrical shock, burn, or fire, use only AC power supplies

specified by FUJIFILM SonoSite.

To prevent injury to the operator/bystander, the transducer must be removed

from patient contact before the application of a high-voltage defibrillation pulse.

To avoid possible electrical shock or electromagnetic interference, verify proper

operation and compliance with relevant safety standards for all equipment

before clinical use. Connecting additional equipment to the ultrasound system

constitutes configuring a medical system. FUJIFILM SonoSite recommends

verifying that the system, all combinations of equipment, and accessories

connected to the ultrasound system comply with JACHO installation

requirements and/or safety standards such as AAMI-ES1, NFPA 99 OR IEC

Standard 60601-1-1 and electromagnetic compatibility standard IEC 60601-1-2

(Electromagnetic compatibility), and are certified according to IEC Standard

60950 (Information Technology Equipment (ITE) or IEC 60601-1.).

Due to the captive nature of the Stand version system batteries, any shipping

transport, service activities, or extended periods of non-operation with the

system unplugged from the AC wall source, will require that the battery

ON-OFF switch be set to the “•O” (OFF) position. Please refer to Figure 3.1 on

page 6.

Do not use the system if an error message appears on the display monitor:

note the error code; call FUJIFILM SonoSite or your local representative; turn

off the system by pressing and holding the power key until the system powers

down.

Caution:

To avoid increasing the system and transducer connector temperature, do not

block the airflow to the rear fans and ventilation holes around the bottom and

side perimeter of the Engine.

6 Chapter 3: Safety

Figure 3.1 Stand System Battery Switches & Transport Positioning

Access to the Stand battery switches can be gained by

lifting the black plastic panel and pulling outward. This

panel location is at the SPMU stand housing area near

the left rear caster leg.

Clinical Monitor display in the down (horizontal)

transport position.

Touch Control Panel in the down (horizontal)

transport position.

Battery

Switches

Stand collapsed

(lowest height)

for transport.

“•O”= OFF

Electrical safety classification

Equipment safety

Please refer to the X-Porte Product Information and Safety Guide (P14646) for the complete information

concerning all safety and standards applicable to the X-Porte Ultrasound System

DICOM standard

Please refer to the X-Porte Product Information and Safety Guide (P14646) for the complete information

concerning the DICOM standard applicable to the X-Porte Ultrasound System

HIPAA standard

Please refer to the X-Porte Product Information and Safety Guide (P14646) for the complete information

concerning HIPAA standard applicable to the X-Porte Ultrasound System

Transporting X-Porte Stand Systems

Please observe the prior Warnings and Cautions outlined in this chapter concerning the stand version

system for transport and servicing. Lower (collapse) the stand to the lowest height position, fold to the

horizontal position the Clinical Monitor display and touch Control Panel, and access the three battery

switches and ensure that all switches are in the “•O” (OFF) position. Many government agencies require

that no electronic equipment be shipped via air transport with live battery power attached to the equipment.

Refer to Figure 3.1 on page 6 as to how to position the system stand and disconnect the battery power for

transport and servicing.

Chapter 3: Safety 7

8 Chapter 3: Safety

Chapter 4: System Overview

About the System

The FUJIFILM SonoSite X-Porte high-resolution ultrasound system is a portable, full featured, general

purpose, software controlled, diagnostic ultrasound system using all digital architecture. The system is used

to acquire and display high-resolution, real-time ultrasound data in 2D, M Mode, Pulsed Wave (PW)

Doppler, Continuous Wave (CW) Doppler, Color Power Doppler (CPD), and color Doppler (Color) or in a

combination of these modes.

The system has an electrocardiography (ECG) display feature and supports a 3-lead ECG cable assembly

to collect data for M Mode and Doppler measurements. The system provides measurement capabilities for

anatomical structures and fetal biometry that provide information used for clinical diagnostic purposes. The

system has a PW and CW Doppler audio output feature, cine review, image zoom, labeling, biopsy,

measurements and calculations, image storage and review, printing, and recording capabilities.

The system includes optional Digital Imaging and Communications (DICOM) capabilities as well as general

computer communication capabilities to provide the acceptance, transfer, display, storage, and digital

processing of ultrasound images and loops. Security support is also provided to facilitate HIPAA

compliance.

The system displays the current output level in terms of one of two bioeffects indices (“Mechanical Index

[MI]” and “Thermal Index [TI]”) in accordance with the AIUM/NEMA Standard for Real Time Display of

Thermal and Mechanical Acoustic Output Indices on Diagnostic Ultrasound Equipment.

Theory of Operation

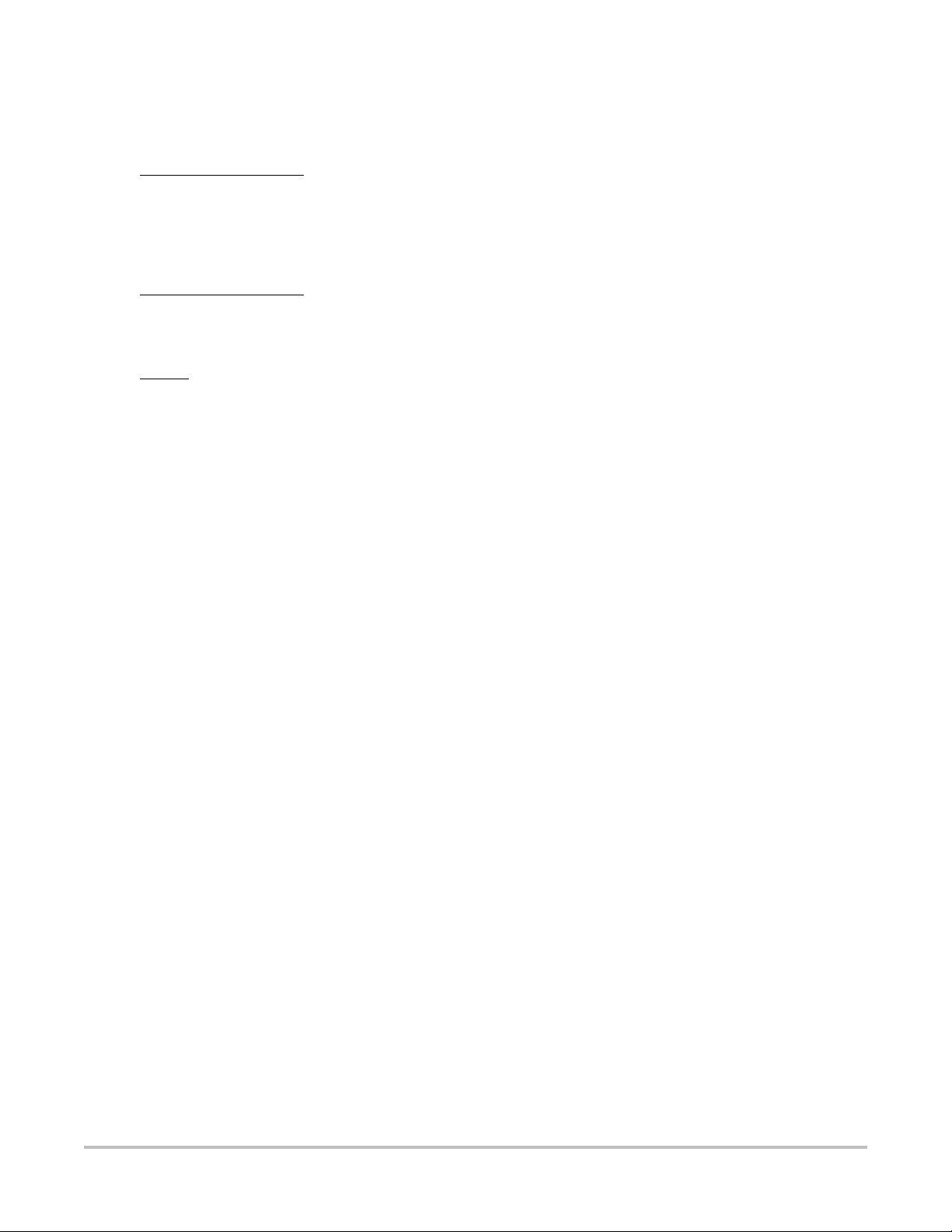

The X-Porte ultrasound system has seven (7) major functional groups:

• Transducer

• Acquisition Subsystem

• Processing Subsystem

• Display Subsystem

• Control Subsystem

• User Interface Subsystem

• Power Subsystem

The following block diagram shows the relationship of the functional groups.

Chapter 4: System Overview 9

Figure 4.1 Ultrasound System Functional Group

The Transducer elements convert the pulser voltage to acoustic energy during the transmit portion of the

ultrasound acquisition cycle. The elements convert the acoustic echo to voltage in the receive portion of the

acquisition. The voltage developed on the transducer elements is sensed by the acquisition subsystem. The

system transducers have 64 to 256 elements.

The Acquisition Subsystem consists of the beamformer and interface to the transducer. The beamformer

controls the timing of the transmit pulses to focus the acoustic beam. The beamformer amplifies the

low-level received echos and controls the receive focusing. The system beamformer transmits on up to 128

elements and receives on 64 elements.

The Processing Subsystem includes capabilities for interfacing with the beamformer and performing high

speed processing. The processing subsystem demodulates, filters, detects, and compresses the signal

supplied by the beamformer into display information.

The Display Subsystem converts the detected ultrasound data into picture elements (pixels). The software

user interface graphics are combined with the ultrasound information and converted to a video stream. The

external video port supports NTSC and PAL format.

The Control Subsystem consists of the central processing unit, program and video memory, permanent

image storage and retrieval memory, external communication interface ports, and connection to the user

interface keys. The control software includes the acoustic power and intensity software subsystem, power

group monitors, and a beamformer monitor. This software guarantees a level of patient safety by ensuring

the system is operating within acoustic power and intensity limits.

The User Interface Subsystem represents the software interface and form factor. The software interface

is the interaction between the user and the screen layout components. The form factor is the type of physical

buttons, location, and grouping of the buttons and the device size, shape, and weight. Dedicated controls

are for high usage activities and grouped according to the user workflow.

The Power Subsystem provides the system power and protects the hardware from destructive and/or

unsafe conditions by detecting failures in the system through hardware and software monitors. Detection of

a fault results in disabling of the pulser supply, and signaling of an error to the Control Group. The power

subsystem includes the batteries (quantity of three lithium-ion) and battery charging electronics.

Description of Operating Modes

2D Mode 2D mode is a two dimensional image of the amplitude of the echo signal. It is used for

location and measurement of anatomical structures and for spatial orientation during

operation of other modes. In 2D, a two-dimensional cross-section of a 3-dimensional

soft tissue structure such as the heart is displayed in real time. Ultrasound echoes of

different intensities are mapped to different gray scale or color values in the display.

The outline of the 2D cross-section may be a rectangle, parallelogram, trapezoid,

sector, or a full circle, depending on the particular transducer used. 2D mode can be

used in combination with any other modes.

MMode M Mode is also known as “T-M mode” or “time-motion” mode. It is used primarily for

cardiac measurements such as valve timing and septal wall thickness when accurate

timing information is required.

Ultrasound echoes of different intensities are mapped to different gray scale values in a

scrolling display. M Mode displays time motion information of the ultrasound data

derived from a stationary beam. Depth is arranged along the vertical axis with time

along the horizontal axis. M Mode can be used alone but is normally used in

conjunction with a 2D image for spatial reference. The 2D image has a graphical line

(M-line) superimposed on the 2D image indicating where the M Mode beam is located.

10 Chapter 4: System Overview

Color

Doppler

(Color)

In color Doppler, a real-time, two-dimensional cross-section of blood flow is displayed.

The 2D cross-section may be presented as a rectangle, parallelogram, trapezoid,

sector, or a full circle, depending on the particular transducer used.

The 2D cross-section is presented as a full color display, with various colors being used

to represent the velocity, both positive and negative, of the blood flow echoes. Often, to

provide spatial orientation, the full color blood flow cross-section is overlaid on top of

the gray scale cross-section of soft tissue structure (2D echo). For each pixel in the

overlay, the decision of whether to display VCD, gray scale (echo) information or a

blended combination is based on the relative strength of echoes from the soft-tissue

structures and from the red blood battery.

A high pass filter (wall filter) is used to remove the signals from stationary or slowly

moving structures. Tissue motion is discriminated from blood flow by assuming that

blood is moving faster than the surrounding tissue, although additional parameters may

also be used to enhance the discrimination. The remaining signal after wall filtering

may be averaged over time (persistence) to present a steady state image of blood flow

distribution. Variance information may also be displayed to provide information when

large variance is observed in the velocity information.

Color Power

Doppler

(CPD)

Continuous

Wave (CW)

Doppler

In CPD, a real-time two-dimensional cross-section of blood flow is displayed. The 2D

cross-section may be presented as a rectangle, parallelogram, trapezoid, sector, or a

full circle, depending on the particular transducer used.

The 2D cross-section is presented as a full color display, with various colors being used

to represent the power in blood flow echoes. Often, to provide spatial orientation, the

full color blood flow cross-section is overlaid on top of the gray scale cross-section of

soft tissue structure (2D echo). For each pixel in the overlay, the decision of whether to

display CPD, gray scale (echo) information or a blended combination is based on the

relative strength of echoes from the soft-tissue structures and from the red blood

battery.

A high pass filter (wall filter) is used to remove the signals from stationary or slowly

moving structures. Tissue motion is discriminated from blood flow by assuming that

blood is moving faster than the surrounding tissue, although additional parameters may

also be used to enhance the discrimination. The power in the remaining signal after

wall filtering may be averaged over time (persistence) to present a steady state image

of blood flow distribution.

CW provides a real-time representation of blood flow and is displayed as a

velocity-versus-time sweeping output. Velocity (or frequency) i

s presented as the

vertical axis with time along the horizontal axis. The magnitude of the detected signal is

represented as different gray scale values.

CW Doppler mode provides the clinician with the ability to obtain blood flow velocities

focused about a user specified focal region. A continuous transmit waveform of

ultrasound energy with a known frequency is transmitted and focused by the system;

on the receive side, the transducer receive echoes are continuously amplified, focused

about the focal region and converted to a base band quadrature signal. The signal is

analyzed by a quadrature phase detector that establishes two receive channels to

allow detection of flow direction. These two channels are then analyzed by a fast

complex Fourier transform (FFT) circuit to establish the spectrum of frequencies

present in the echoes. The data are displayed as spectrum frequencies with respect to

time.

CW can be used alone but is normally used in conjunction with a 2D image for spatial

reference. The 2D image has a graphical line (D-line) superimposed on the 2D image

indicating where the M-mode beam is located.

Chapter 4: System Overview 11

Pulsed Wave

(PW)

Doppler

PW provides a real-time representation of blood flow and is displayed as a

velocity-versus-time sweeping output. Velocity (or frequency) is presented as the

vertical axis with time along the horizontal axis. The magnitude of the detected signal is

represented as different gray scale values. The ultrasound data is derived from a single

area, the sample volume, on a stationary beam.

PW Doppler mode provides the clinician with the ability to obtain blood flow velocities

about a spatial sample volume. A burst of ultrasound with a known spectrum is

transmitted by the system; on the receive side, the transducer receive echoes are

amplified and range gated at the appropriate depth. The signal is analyzed by a

quadrature phase detector that establishes two receive channels to allow detection of

flow direction. These two channels are then analyzed by a fast complex Fourier

transform (FFT) circuit to establish the spectrum of frequencies present in the echoes.

The data are displayed as spectrum frequencies with respect to time.

PW can be used alone but is normally used in conjunction with a 2D image for spatial

reference. The 2D image has a graphical line (D-line) superimposed on the 2D image

indicating where the M-mode beam is located. The sample volume position (depth) and

size are also indicated on the D-Line.

Additional System Feature Performances

Broadband Imaging This ultrasound acquisition system uses high resolution broadband technology

in the transmit pulsers, transducer, and receivers. The receive path can capture

and process signals over a wide spectrum, from below 2.0 MHz to beyond 10

MHz. For each application, the transmit pulse is designed to produce an

appropriate bandwidth. For example, in 2D grayscale imaging, a wide band

pulse is used to support good axial resolution. For Doppler modes, a narrower

band pulse is used, which improves the spectral resolution of the detected

Doppler signal.

In addition to transmit pulse control, programmable digital signal processing is

used in the receive path to further refine the bandwidth used to produce the

final image. Digital filters are applied to the digitized received signal to limit and

shape the spectral bandwidth used to generate the displayed output.

Tissue Specific

Imaging

Biopsy Guidance The system can display a pair of biopsy guidelines that represent the

Measurement and

Calculation

Capabilities

In this feature, parameters for signal and image processing are optimized to

maximize the image quality or to obtain the best compromise of resolution and

penetration for different specific clinical applications. These parameters

include: the order of received filters, the bandwidth, the dynamic range, the

compression curve, the gain setting and parameters for compounding

frequency band, etc. For example, different system parameter setups are used

for abdominal or peritoneal scanning. This feature is for ease

operator by automatically setting up system control parameters rather than

manually adjusting settings for best performance.

anticipated path of the biopsy needle. The image of an anatomical target,

biopsy guidelines, a scan plane marker, and a biopsy needle are displayed to

assist in guiding the biopsy needle to the target. The system also provides

needle guidance for vascular access procedures. For additional information,

see the biopsy user guides.

The system offers a variety of measurements and calculations, specific to

exam type and transducer. A list of them, and author references, are in the

system user guide. Measurement accuracy is also discussed.

of use for the

12 Chapter 4: System Overview

Continuous Wave

Receive Section

X

T/R Sw

TGC Amplifier

A/D Delay

Weight

Pulser

Waveform

Delay

X

T/R Sw

TGC Amplifier

A/D Delay

Weight

Pulser

Waveform

Delay

Beamformed

Data

Transducer

Transmit Section

Control

Doppler Audio

Output

The system provides for audio output of the CW velocity information. This can

be presented as stereo information, with flow moving towards the transducer

on one channel and flow away on the other, or as a mono output with the single

audio output representing the summation of the flow directions.

Pulsed Wave

Doppler Audio

Output

Electrocardiograph

(ECG) Display

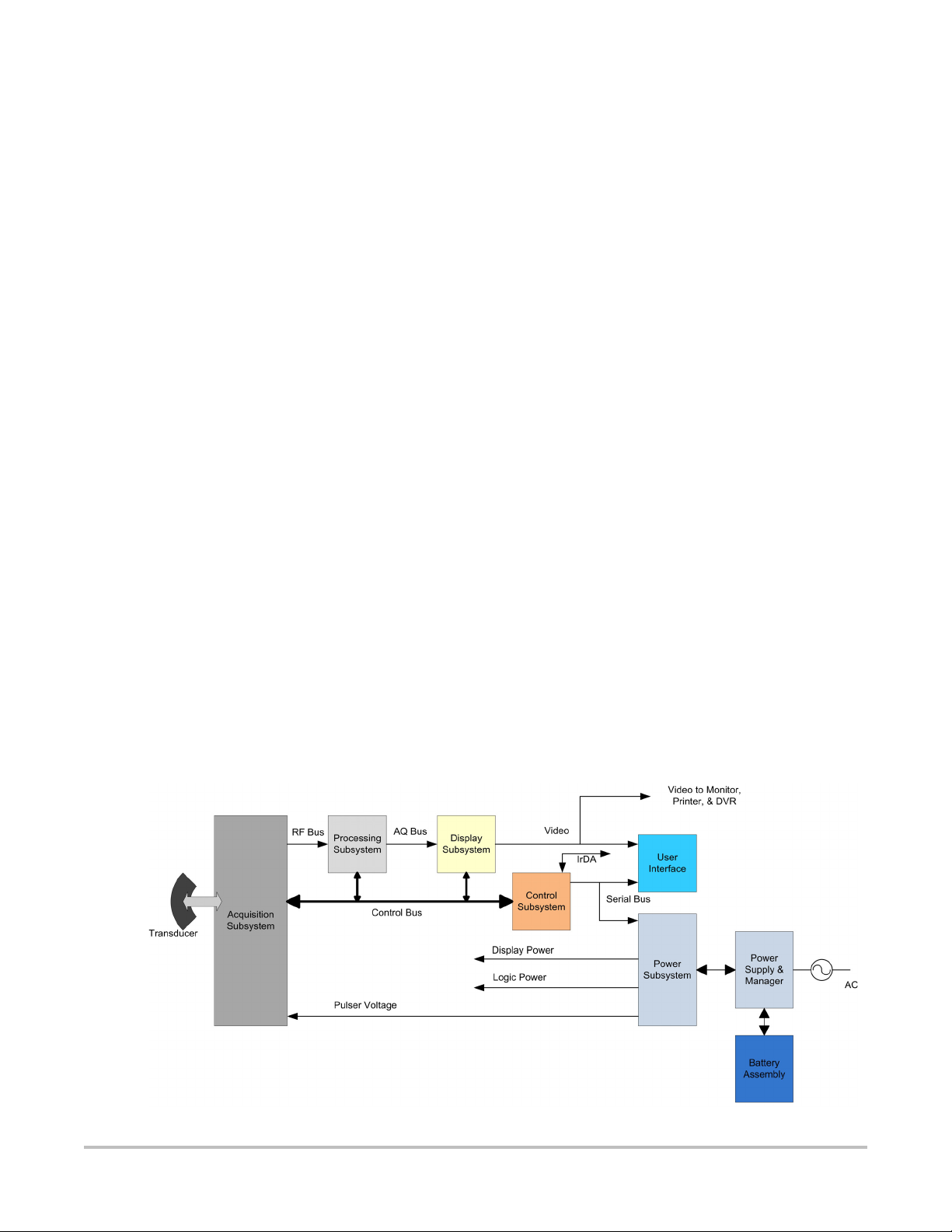

Front End Overview

The Front End is designed to support various imaging modalities such as 2D, M-Mode, Spectral Doppler

and Color Doppler. From the Front End's perspective, all modes can be grouped into a few basic types:

Single mode, simultaneous modes and triggered modes. All these modes are built from similar, basic

transmit and receive sequences controlled within the Front End. A generic top level block diagram of a

typical Front End is shown below in Figure 4.2 on page 13

The system provides for audio output of the PW velocity information. This can

be presented as stereo information, with flow moving towards the transducer

on one channel and flow away on the other, or as a mono output with the single

audio output representing the summation of the flow directions.

ECG is provided to measure the electrical signal generated by the heart. A

three lead interface: Right Arm (RA), Left Arm (LA) and Left Leg (LL), is

provided on the system.

The ECG signal is displayed as an amplitude-versus-time sweeping output.

Amplitude is presented on the vertical axis with time along the horizontal axis.

Figure 4.2 Generic Front End Block Diagram

The transmit section consists of a waveform generator, delay block, and high power high voltage driver to

excite the transducer element. Multiple elements are driven with delays determined by the time of flight in

the medium from the elements to the point in space where the beam is to be focused. The longer the time

of flight is to the focal point the smaller the delay is for a given transmit element to allow all to arrive at the

Chapter 4: System Overview 13

focal point at the same time. The number of elements driven is determined by element sensitivity off axis

and depth of field considerations. The waveform is selected to drive the transducer at a certain center

frequency, bandwidth, and power and is optimized for the given mode.

The receive section consists of a transmit/receive switch to protect the receiver from the transmit voltage, a

variable gain receiver to amplify and condition the return echoes, an A/D to digitize the data, a delay block

to focus the return signals and a weight block to scale the return echoes for each channel. All the signals

are then summed together to generate the beam-formed receive data. The analog gain varies with depth

to compensate for signal attenuation through the medium. The delays and weights are independent for

each channel. The delay and weight for the receive channel can typically be changed dynamically to keep

the receive beam in continuous focus. The delay is simply set by the time of flight in the medium from the

point of interest to the element, which starts at skin-line and proceeds to the deepest depth of interest.

The control section drives the data to the various data path elements on a line by line basis, controls the

timing of the transmit and receive sections and controls the tagged information and timing of the data to the

rest of the system.

X-Porte Front End Board

The X-Porte ultrasound system can be divide into two board section groups: Front End and Back End.

Below is the block diagram linking the necessary functional groups of an ultrasound system as they apply

to the X-Porte system. Please refer to Figure 4.3 on page 14

Figure 4.3 X-Porte Front End Board Block Diagram

14 Chapter 4: System Overview

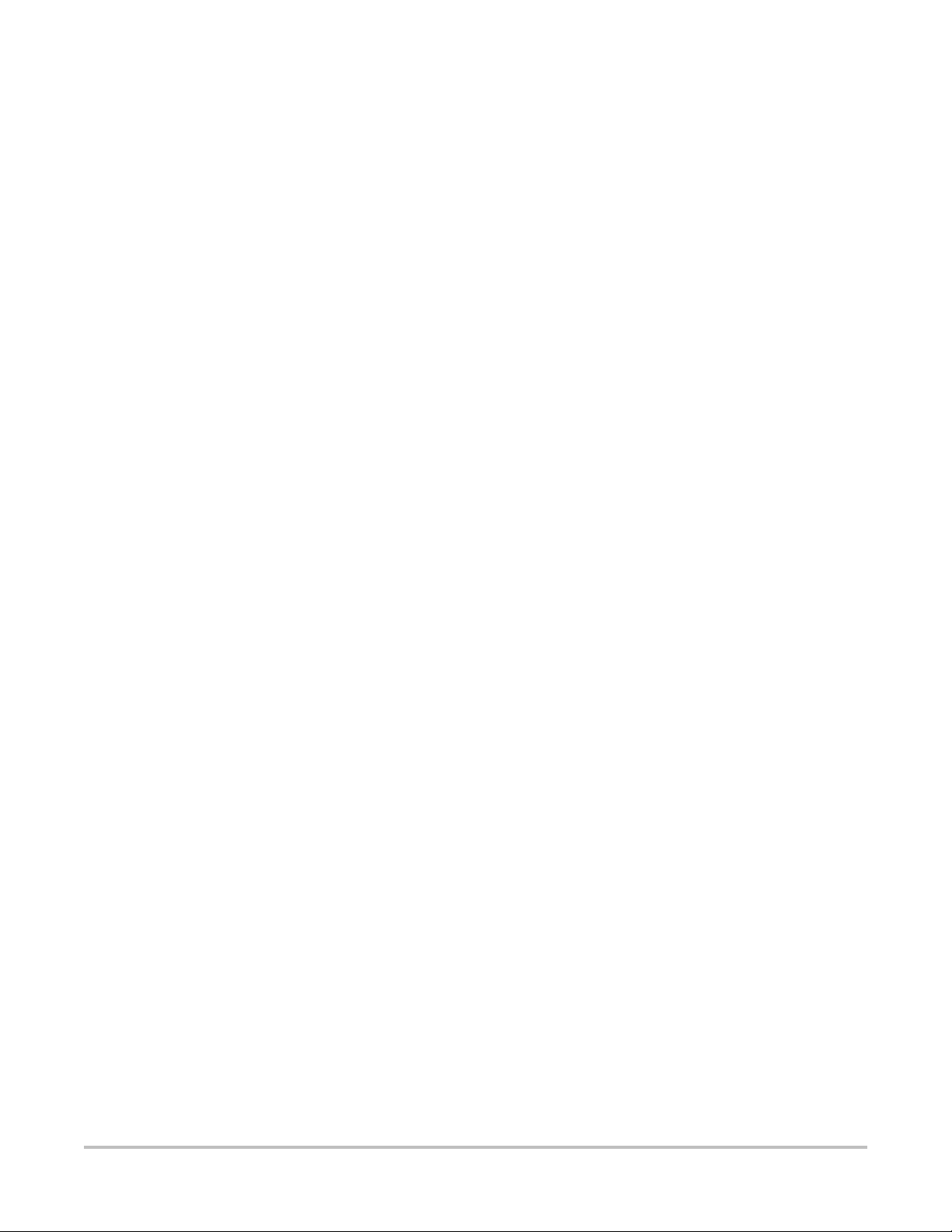

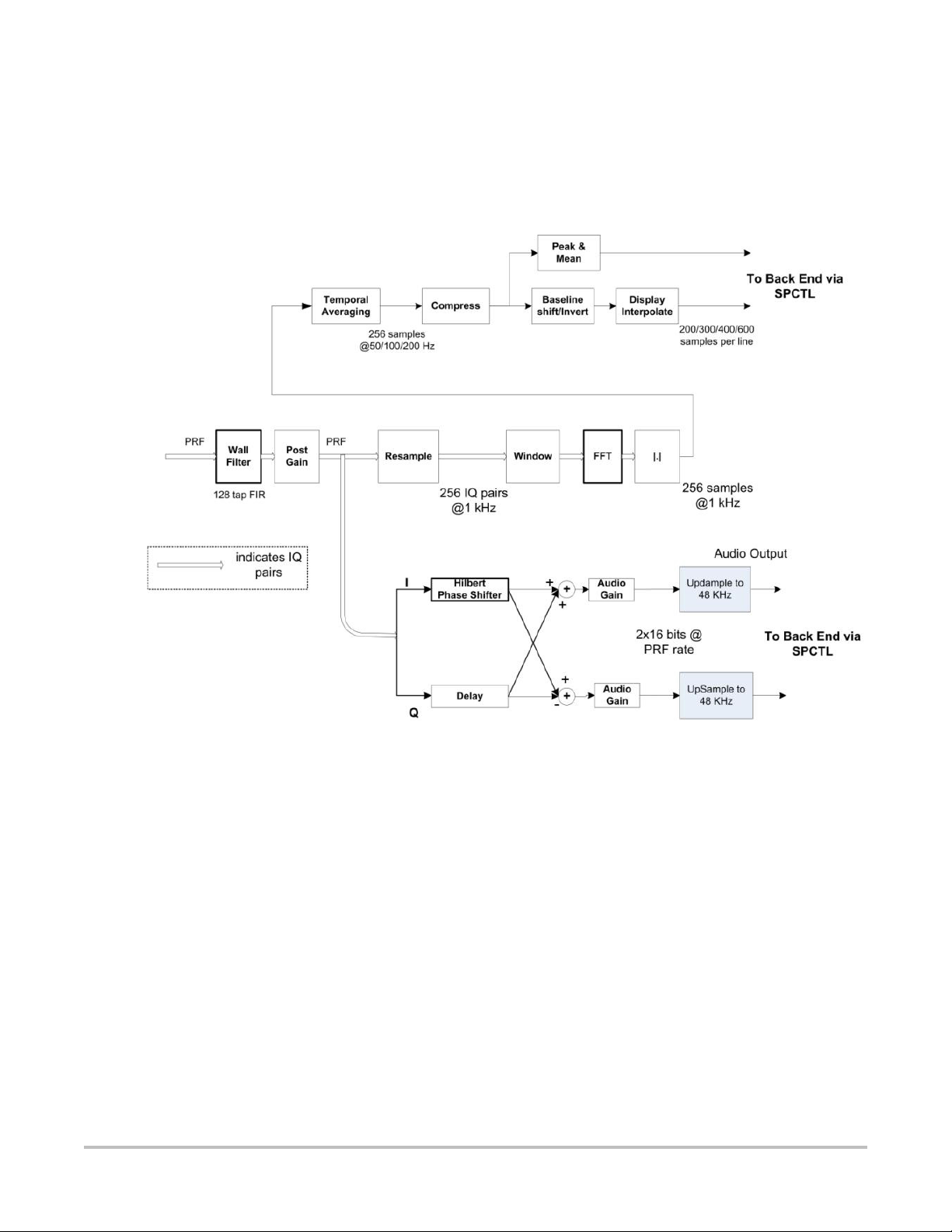

PW Doppler Processing

Doppler processing includes both audio processing which presents Doppler signal in the form of stereo

audio and spectral processing which generates data for display of Doppler spectrum in the form of a

scrolling spectrogram. Doppler power spectrum is estimated performing Discrete Fourier Transforms on

short, overlapped segments of wall filtered Doppler signal. Doppler audio data is generated from wall filtered

data by phase shifting the in-phase component. Refer to the PW Doppler Processing Function Block

Diagram Figure 4.4 on page 15

Figure 4.4 PW Doppler Processing Function Block Diagram

Chapter 4: System Overview 15

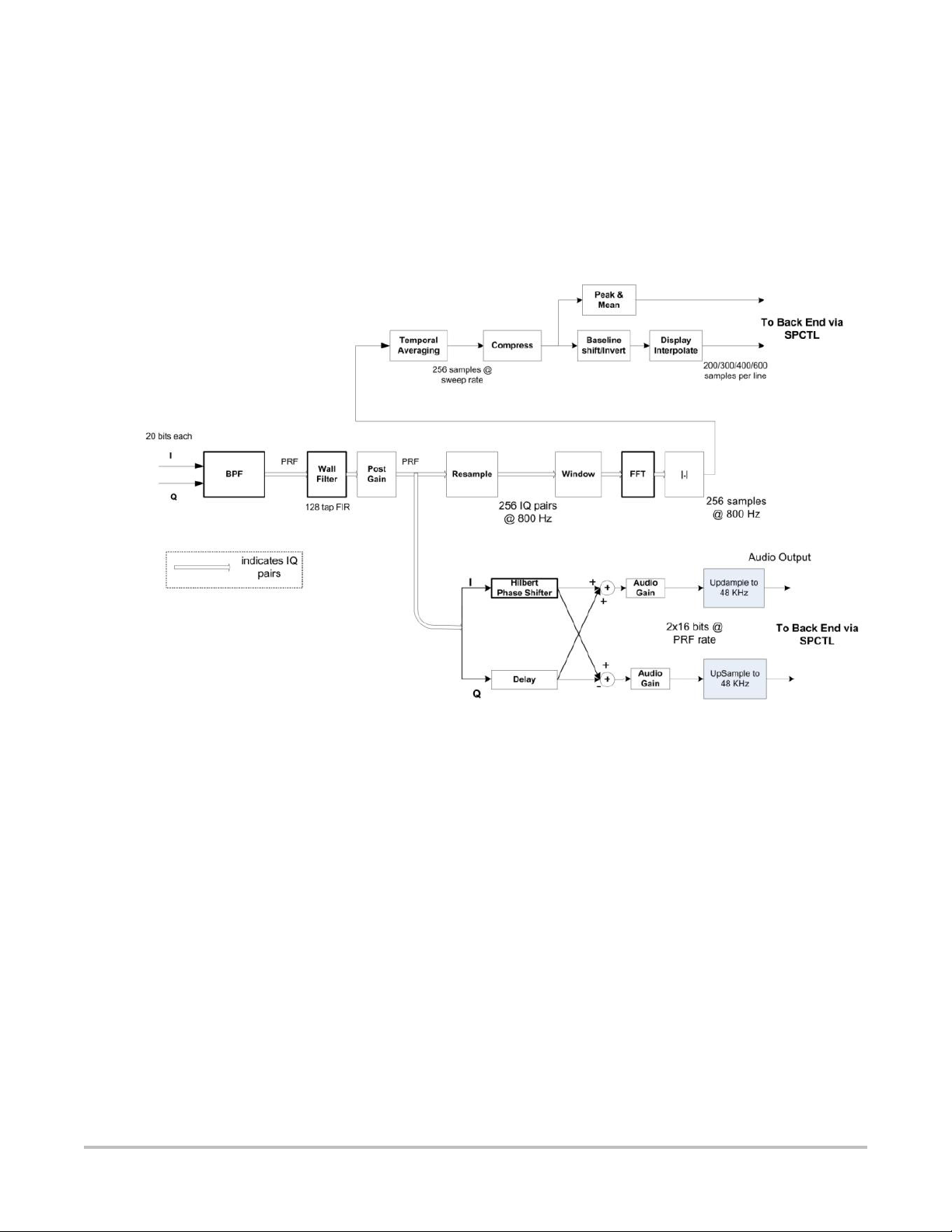

CW Doppler Processing

CW Doppler data will be presented to the signal processor as complex (I/Q) data from the analog front end

of the external DSP. The 20-bit data will be presented as consecutive samples at a data rate varying from

1.5 kHz to 64 kHz for the complex pair. Most of CW processing is similar to that of PW except for the QBP

function. In place of QBP will be a low pass decimating filter that operates on incoming I/Q data.

The Doppler Processing block must allow storage of 256 undetected I/Q pairs in to allow the system to

measure and correct for phase mismatch. Measuring and correcting will need to be accomplished in system

software. Refer to the CW Doppler Processing Function Block Diagram Figure 4.5 on page 16

Figure 4.5 CW Doppler Processing Function Block Diagram

16 Chapter 4: System Overview

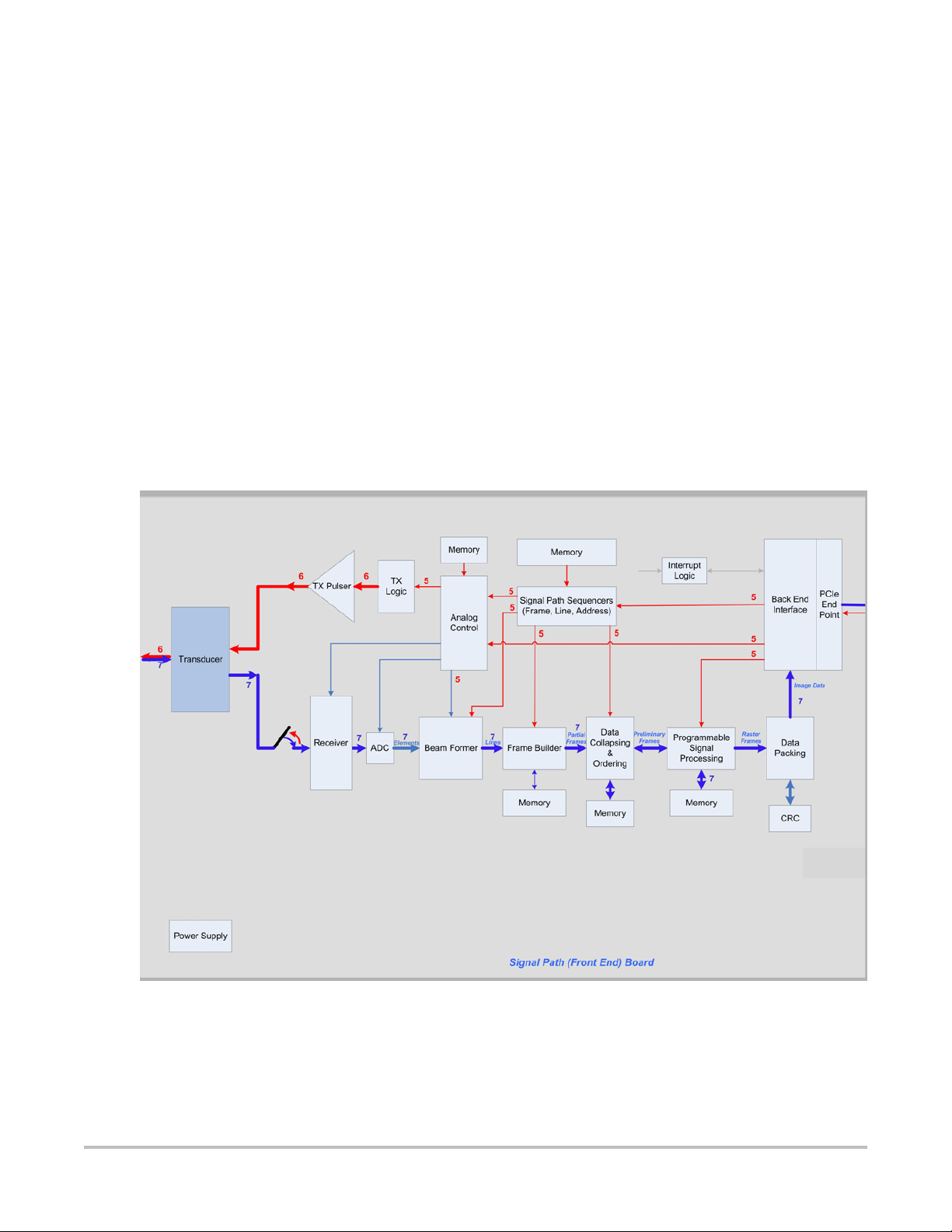

Back End Overview

The Back End subsystem is responsible for the conversion of raw acquisition data into a raster image ready

for display. The Back End subsystem also contains the video data path that supports generation of video

comprising of the ultrasound image as well as graphics annotation. Video generation of both standard

composite interlaced video and progressive scan video is supported. Most functionality is within the ASIC

but the memory resources for acquisition memory, and display memory are found in external memory

components. The conversion from PC type video to TV type video is also performed externally.

Control is received initially from the CPU to setup each functional block and afterward the hardware is

completely data driven. This control takes the form of programming setup registers inside the blocks and

setting up scan conversion tables. Each block provides temporary storage as required to buffer data and

keep their respective processing pipeline full and operating. Also note that the block diagrams show only

the data path, but each block is responsible for generating any necessary memory addresses for their

respective input data stream.

The X-Porte Back End subsystem is shown in Figure 4.6 on page 17.

Figure 4.6 X-Porte System Back End Subsystem Block Diagram

The Back End Subsystem performs processing encompassing three main data domains, acquisition data,

raster data, and video data. Support for acquisition data includes the input buffer, flash suppression, frame

average, and external ACQ memory. Cine buffer management is performed by the acquisition controller.

Conversion from acquisition data to raster data is performed by the graphics overlay, scan conversion system, sweeping system, and 3D system. Raster data is stored in an external DISPLAY memory. Also supporting raster operations is the graphics support block that provides acceleration hardware for pixel

operations from the CPU and graphics overlay system. The progressive video path includes buffers, priority logic, and LUTs.

Chapter 4: System Overview 17

Control Subsystem

LVDS (24 bit)

SDVO 720P

HDMI/DVI

transmitter

AD9889B or

equivalent

Display Control I/F

Display Control I/F

U

S

B

H

o

s

t

x

3

Control FPGA

Interrupts from the Front

End,and FPGA.

Processor

Audio Codec/

Amp

Hard IP Block in FPGA

Soft IP Block in FPGA

Ethernet

W

i

F

i

PCI Express

Video out

(

LVDS)

CH7308A LVDS(24 bit)

SATA

2

Configuration

FLASH/CPLD

Program

Control/Processor Section

Main Clinical display for

POC. If M2/S2 to Dock for

Aux Monitor with Audio

If M2/S2: Main Clinical display

If POC: Touch Screen

JTAG

GPIO

SATA 2

RJ45

Connector

(Debug only)

FE I/F Connector

Hirose:

(Debug only)

JTAG

Mini PCIe

(Debug Only)

PCI Express for WiFi

Video Buffer Ram

DDR3 1 GByte

GPIOs to Dock (TBD)

PCI Express for Dock

Dock Connector

SATA Connector

COMe Type 10

10/100/1G Ethernet

U

SB

H

o

s

t

Backlight enable and brightness

USB Host for Dock

Serial Port

Speakers

HDA

USB Type A

(x3)

SATA Boot

Device

Connector

Speakers

Switch

10

/

100

/

1

G

Ethernet

10/

100/

1G Ethernet

Switch

HDMI/DVI

receiver

TP401A or

equivalent

HDMI in

USB Module

USB

Line In

Audio Line In

24 bit Video to

VGA

ADV7123 or

Equivalent

Some GPIOs

tied to both

FPGA and

CPLD

SATA2

Serial Lite

(

x

4

)

,

WakeFromFE

,

FE

_

Detect

24

bit video

24

bit video

S/PDIF

S/PDIF

Note:

HDMI with

Audio

Headphones Headphones

Serial Port

I

2

C

USB Host for Touch Screen

The X-Porte Control Subsystem is shown in the figure below.

Figure 4.7 Control Subsystem Block Diagram

The core control subsystem contains the processor, the system bus, and the system memory resources of

RAM and solid state hard drives. These two solid state hard drive devices are responsible for the system

operating

system software, ultrasound program software, scanhead operation files, on-board training videos, and

storage for patient data (patient demographic information, images, and video clips)

18 Chapter 4: System Overview

The main operational solid state storage drive is a mSATA form factor device totalling 16 GB of storage

capacity. This device is responsible for handling the operational system software, the ultrasound program,

and the on-board training videos.

A secondary solid state storage drive of 80 GB with an 1.8 inch form factor is used to handle the scanhead

data files, other ultrasound system files, and 66 GB of storage capacity reserved for all patient data. It is

with these new solid state devices, the X-Porte architecture is similar to our past products utilizing CF and

SD storage cards, but with much improved data storage and throughput without the use of any mechanical

hard drive devices.

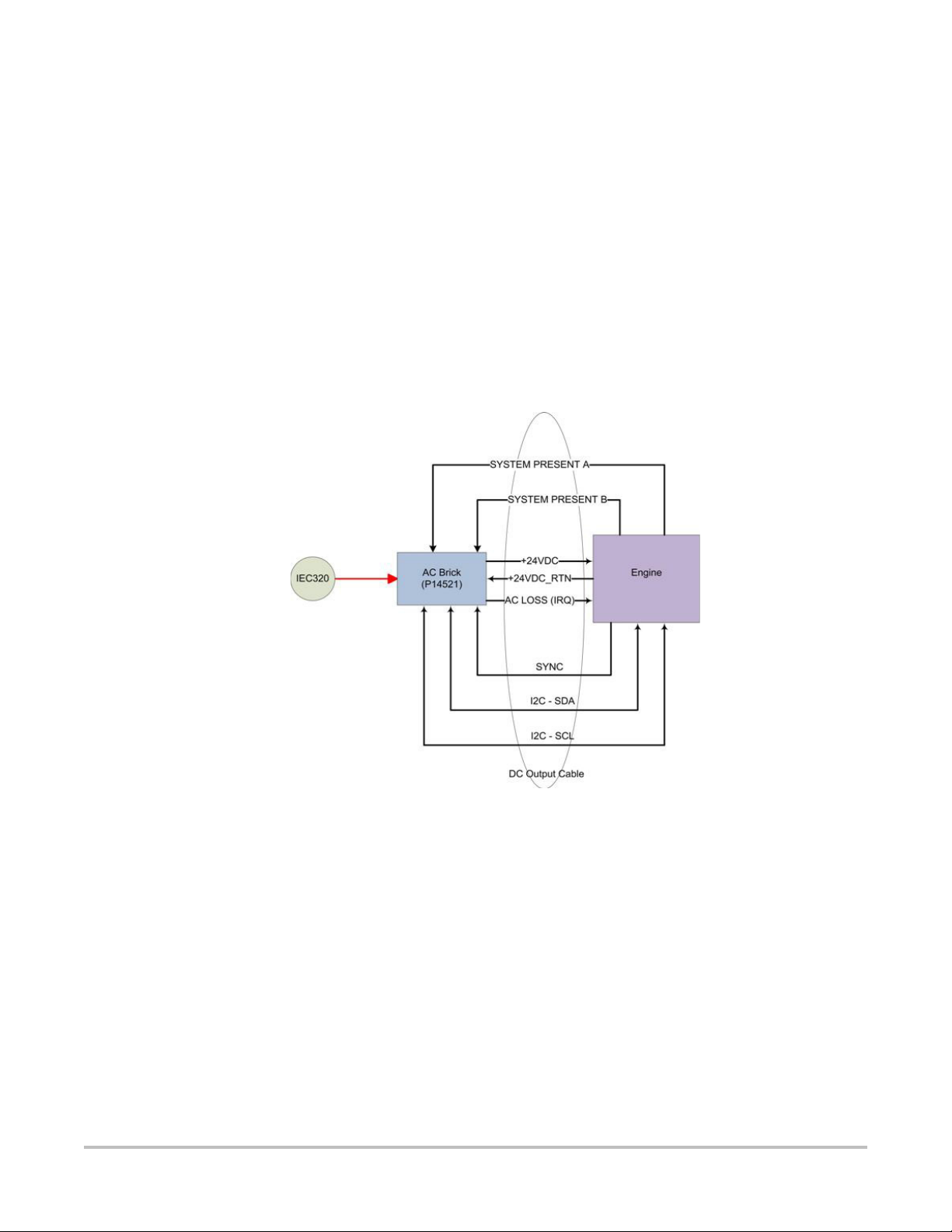

Power Supply and Control

The X-Porte ultrasound system utilizes one of two types of power supply arrangements depending on the

X-Porte system version, which are Desktop or Stand. The Desktop system uses two separate external

power supply (EPS) units. The 150 watt EPS supplies +24VDC to the main Ultrasound System Electronics

(Engine) and a separate 65 watt EPS is utilized to supply +24VDC for the Clinical Display Monitor. No

batteries can be utilized with this version of system. The electrical block diagram for the 150 watt EPS is

shown below in Figure 4.8 on page 19

Figure 4.8 Desktop External Power Supply (EPS)

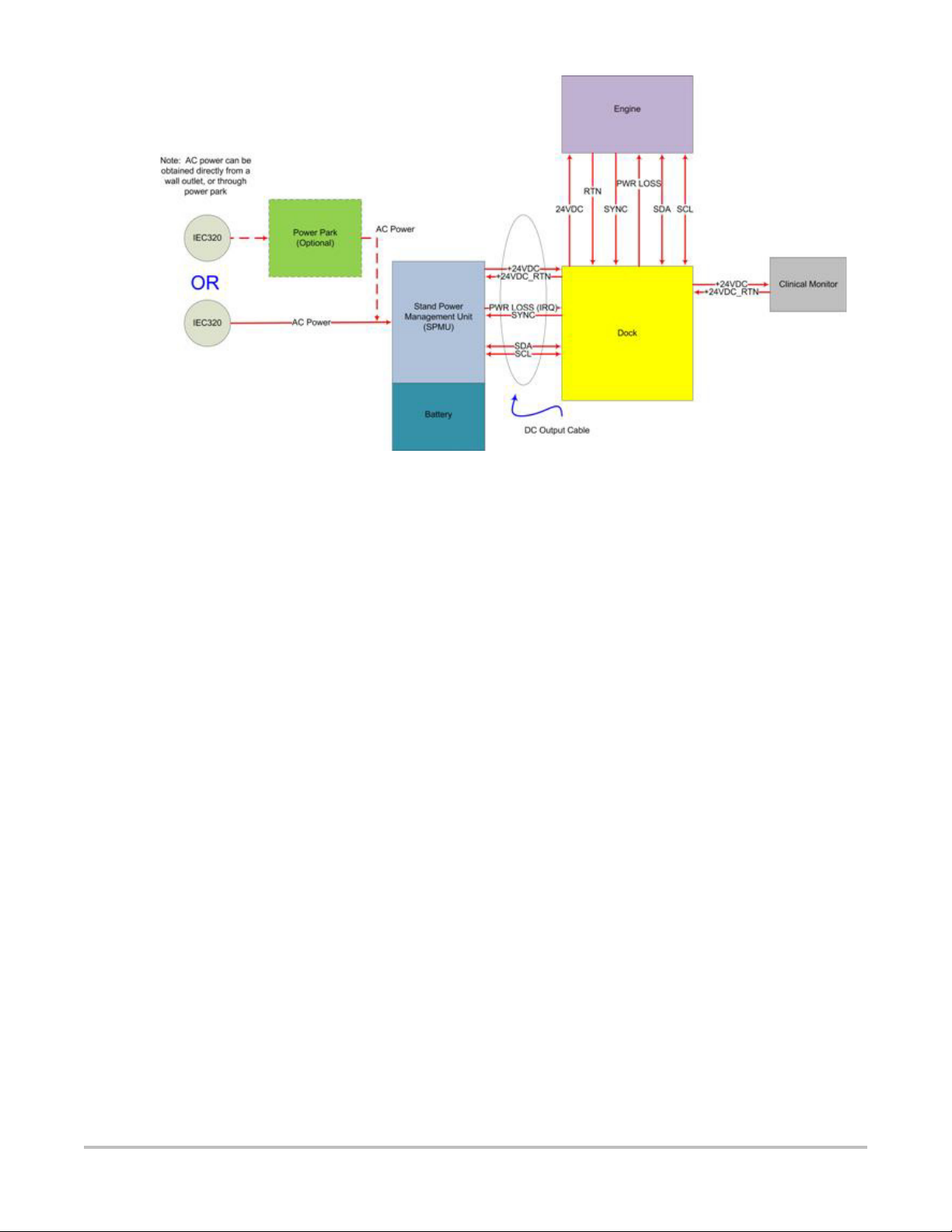

The Stand version X-Porte system utilizes a power supply/power control module mounted under the stand

base. This System Power Management Unit (SPMU) supplies the +24VDC power to the Engine and Clinical

Display Monitor. This SPMU is also the mounting point for the three lithium-ion batteries, charges the

batteries, and is responsible for switching the system from AC power to battery power when needed. Please

refer to Figure 4.9 on page 20

Chapter 4: System Overview 19

Figure 4.9 Stand Power Management Unit (SPMU)

ECG Module

The ECG module allows a representation of the heart electrical activity to be displayed in real time with

ultrasound images acquired and displayed on the system video display.

The ECG module interfaces to the patient through three (3) ECG leads: Right Arm ECG lead (RA), Left Arm

ECG lead (LA), and Left Leg ECG lead (LL). The ECG received signal from the ECG electrodes are isolated,

amplified, and filtered by the ECG module before it is sent to the system for further processing and display.

The ECG module and cable are an integrated assembly. The module receives power from the system.

Patient isolation is provided by the ECG module, allowing the connection and signals to the system to be

system-ground referenced. The isolation between the patient and the system meets the requirements of IEC

601-1 for Type CF equipment.

The ECG function accepts input from an external serial A/D and performs gain, filter, and DC Offset

functions. The resultant data is output at either the 200Hz sample rate or decimates the data by 2 or 4 and

outputs the data into acquisition memory. The data is assumed to be signed. An interrupt is provided that

will interrupt the processor after a set delay from the detected level and slope. A simple block diagram is

shown below in Figure 4.10 on page 21

20 Chapter 4: System Overview

Loading...

Loading...