Fluke VT Mobile User Manual

VT MOBILE

Gas Flow Analyzer

Operators Manual

February 2006

© 2006 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship for one full year from the date of original purchase. During the warranty period, we will repair or, at our option, replace at no charge a product that proves to be defective, provided you return the product, shipping prepaid, to Fluke Biomedical. This warranty does not apply if the product has been damaged by accident or misuse or as the result of service or modification by other than Fluke Biomedical. IN NO EVENT SHALL FLUKE BIOMEDICAL BE LIABLE FOR CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items bearing a distinct serial number tag) are covered under this one–year warranty. PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT COVERED UNDER THE WARRANTY. Items such as cables and nonserialized modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state, province to province, or country to country. This warranty is limited to repairing the instrument to Fluke Biomedical’s specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other than Fluke Biomedical, please be advised that the original warranty covering your product becomes void when the tamper-resistant Quality Seal is removed or broken without proper factory authorization. We strongly recommend, therefore, that you send your instrument to Fluke Biomedical for factory service and calibration, especially during the original warranty period.

Notices

All Rights Reserved

Copyright 2006, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in service training programs and other technical publications. If you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop unpacking the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800-648-7942 or 1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical condition but does not operate within specifications, or if there are any other problems not caused by shipping damage, please contact Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number tag) are eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases, auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of original purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and the product must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not eligible for credit return and will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products returned in excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for damage and/or missing parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return an instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments or instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at 1-800-648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, goto www.flukebiomedical.com/service or

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-800-850-4606

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it was shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST). Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The VT MOBILE is manufactured in Everett, WA, U.S.A.

|

Symbols |

|

|

|

|

Symbol |

Description |

|

|

|

|

W |

See Operators Manual. |

|

|

|

|

P |

Manufacturer’s declaration of product compliance with applicable |

|

|

EU directives |

|

) |

CSA Listing mark |

|

|

|

|

" |

Battery Eliminator input |

|

12V DC F |

|

|

|

|

|

~ |

Do not mix with solid waste stream. Dispose of using a qualified |

|

recycler or hazardous material handler. |

||

|

||

M9V NEDA 1604A |

9-volt battery |

|

|

||

6F22 006P |

|

‚Flow Port

f |

Pressure Port |

|

|

|

Temperature and Relative Humidity Port |

|

|

|

Oxygen Sensor Port |

"Battery Eliminator Port

'Miniature RS232 Port

WXWarning. Read before using Analyzer.

To avoid personal injury, follow these guidelines:

Do not use the VT MOBILE in any manner not specified in the Operator’s Manual. Otherwise, the protection provided by this product may be impaired.

When measuring oxygen, always keep all components of test setup well away from open flame or other combustion-starting devices.

Use in well-ventilated space. Be aware that a gas defined with VT for Windows software as ‘User’ may be unknown while using the VT MOBILE.

For high pressure measurements, always turn off gas source before connection or disconnection of VT MOBILE. Be aware that there is no pressure indication on the VT MOBILE screen when VT for Windows software is in control.

•Always press power off on the VT MOBILE and unplug the battery eliminator before cleaning the outer surface.

•Inspect the product, if the instrument appears damaged or appears to operate in a manner not specified in the manual, DO NOT CONTINUE USE. Return the product for service.

•Avoid spilling liquids on the analyzer; fluid seepage into internal components creates corrosion and a potential shock hazard. Do not operate the instrument if internal components are exposed to fluid.

•Do not open this product. There are no user replaceable parts.

WCaution

The VT MOBILE should be calibrated annually. Only qualified technical personnel should perform troubleshooting and service procedures on the VT MOBILE.

Do not expose the system to temperature extremes. Ambient operating temperatures should remain between 10 and 40 °C. System performance may be adversely affected if temperatures fluctuate above or below this range.

Clean only with a damp, lint-free cloth, using a mild detergent, and wipe down gently.

Table of Contents

Chapter |

Title |

Page |

1 |

Introducing the VT MOBILE................................................................ |

1-1 |

|

Introduction........................................................................................................ |

1-1 |

|

Operation, Storage, and Maintenance................................................................ |

1-1 |

|

Features.............................................................................................................. |

1-2 |

|

About This Manual ............................................................................................ |

1-2 |

2 |

Preparing for Operation...................................................................... |

2-1 |

|

Unpacking the VT MOBILE ............................................................................. |

2-1 |

|

Powering Up ...................................................................................................... |

2-3 |

|

Using the Tilt Bail.............................................................................................. |

2-3 |

|

Using the Keys................................................................................................... |

2-4 |

|

Selecting the Operating Mode ........................................................................... |

2-4 |

|

Setting Up .......................................................................................................... |

2-5 |

|

Selecting the Gas Type.................................................................................. |

2-5 |

|

Gas Temperature and Relative Humidity ...................................................... |

2-5 |

|

Selecting the Correction Mode...................................................................... |

2-5 |

|

Setting the Breath Detect Threshold.............................................................. |

2-6 |

|

Setting Zero Warn ON or OFF ...................................................................... |

2-6 |

|

Setting the Time ............................................................................................ |

2-7 |

|

Setting the Date ............................................................................................. |

2-7 |

|

Selecting the Date Format ............................................................................. |

2-8 |

|

Setting the Contrast ....................................................................................... |

2-8 |

|

Checking Version and Serial Numbers ......................................................... |

2-8 |

|

Connecting the Analyzer ................................................................................... |

2-8 |

|

High-Flow Connection .................................................................................. |

2-9 |

|

Low-Flow Connection................................................................................... |

2-9 |

|

High-Pressure Connection............................................................................. |

2-9 |

|

Low-Pressure Connection ............................................................................. |

2-9 |

|

Ventilator Test Connections .......................................................................... |

2-10 |

3 |

Using the VT MOBILE.......................................................................... |

3-1 |

|

Understanding the Controls and Indicators........................................................ |

3-1 |

|

Screens............................................................................................................... |

3-4 |

|

Ventilator Parameters Screens....................................................................... |

3-4 |

i

VT MOBILE

Operators Manual

|

|

Waveform Screens......................................................................................... |

3-6 |

|

|

Other Measurements Screens ........................................................................ |

3-9 |

|

|

Special Functions Screens ............................................................................. |

3-10 |

|

Using Trend Test ............................................................................................... |

3-12 |

|

|

Making Measurements....................................................................................... |

3-14 |

|

|

Working with Memory ...................................................................................... |

3-14 |

|

|

Printing .............................................................................................................. |

3-14 |

|

|

Making a Measurement More Accurate ............................................................ |

3-14 |

|

|

|

Warm-up and Zeroing ................................................................................... |

3-14 |

|

|

Oxygen Sensor............................................................................................... |

3-16 |

|

|

Verifying Oxygen Sensor Calibration ........................................................... |

3-16 |

|

|

Calibrating the Oxygen Sensor...................................................................... |

3-16 |

|

|

Using the Temperature and Relative Humidity Sensor ................................. |

3-17 |

|

|

Checking Barometric Pressure ...................................................................... |

3-18 |

|

|

Changing Barometric Pressure Units ............................................................ |

3-19 |

|

Viewing Demo Data .......................................................................................... |

3-19 |

|

|

Accessing Help .................................................................................................. |

3-19 |

|

4 |

Checking Ventilator Parameters ........................................................ |

4-1 |

|

|

Introduction........................................................................................................ |

4-1 |

|

|

Checking Ventilator Parameters ........................................................................ |

4-1 |

|

|

Understanding the Parameters ........................................................................... |

4-3 |

|

5 |

Measuring Pressure ............................................................................ |

5-1 |

|

|

Introduction........................................................................................................ |

5-1 |

|

|

Measuring Low Pressure ................................................................................... |

5-2 |

|

|

Measuring High Pressure................................................................................... |

5-3 |

|

|

Measuring Airway Pressure............................................................................... |

5-5 |

|

6 |

Measuring Flow and Volume.............................................................. |

6-1 |

|

|

Introduction........................................................................................................ |

6-1 |

|

|

|

Gas Settings................................................................................................... |

6-1 |

|

|

Balance Gas Settings ..................................................................................... |

6-1 |

|

|

Correction Modes .......................................................................................... |

6-2 |

|

|

Flow Zeroing ................................................................................................. |

6-2 |

|

Measuring Low Flow......................................................................................... |

6-3 |

|

|

Measuring High Flow ........................................................................................ |

6-4 |

|

|

Measuring Volume ............................................................................................ |

6-5 |

|

7 |

Maintaining and Troubleshooting the VT MOBILE........................... |

7-1 |

|

|

Introduction........................................................................................................ |

7-1 |

|

|

Calibration and Service...................................................................................... |

7-1 |

|

|

Battery................................................................................................................ |

7-1 |

|

|

Cleaning............................................................................................................. |

7-2 |

|

|

Verifying Oxygen Sensor Calibration ............................................................... |

7-2 |

|

|

Replacing the Oxygen Sensor............................................................................ |

7-3 |

|

|

Calibrating the Oxygen Sensor .......................................................................... |

7-3 |

|

|

Troubleshooting ................................................................................................. |

7-4 |

|

Appendices |

|

||

|

A |

VT for Windows.......................................................................................... |

A-1 |

|

B |

Specifications .............................................................................................. |

B-1 |

ii

List of Tables

Table |

Title |

Page |

1-1. |

VT MOBILE Versions........................................................................................... |

1-1 |

2-1. |

Standard Accessories ............................................................................................. |

2-2 |

2-2. |

Optional Accessories.............................................................................................. |

2-2 |

2-3. |

Gas Types............................................................................................................... |

2-5 |

2-4. |

Correction Modes................................................................................................... |

2-6 |

3-1. |

Controls and Indicators .......................................................................................... |

3-2 |

3-2. |

Ventilator Parameters............................................................................................. |

3-4 |

4-1. |

Ventilator Parameters............................................................................................. |

4-3 |

7-1. |

Troubleshooting the Analyzer................................................................................ |

7-4 |

iii

VT MOBILE

Operators Manual

iv

List of Figures

Figure |

Title |

Page |

2-1. |

Key Available Accessories..................................................................................... |

2-3 |

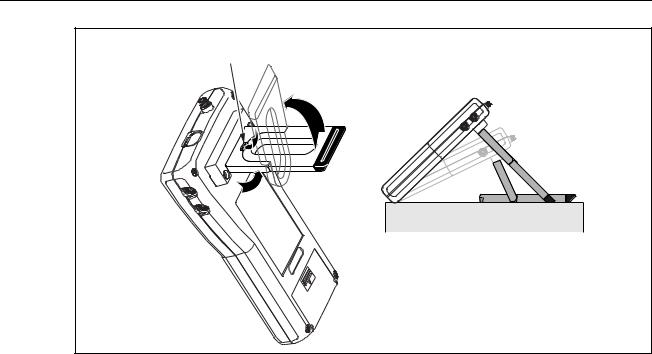

2-2. VT MOBILE Tilt Bail............................................................................................ |

2-4 |

|

2-3. |

Low-Pressure/High-Flow/Low-Flow Connection.................................................. |

2-8 |

2-4. |

High-Pressure Connection...................................................................................... |

2-9 |

2-5. |

Ventilator Test Connections................................................................................... |

2-10 |

3-1. |

Controls and Indicators .......................................................................................... |

3-1 |

3-2. Flow Sensors and Pressure Adapters Disconnected............................................... |

3-15 |

|

3-3. Flow Sensors and Pressure Adapters Connected ................................................... |

3-15 |

|

3-4. |

Oxygen Sensor Calibration .................................................................................... |

3-17 |

3-5. Measuring Temperature and Relative Humidity .................................................... |

3-18 |

|

4-1. |

Ventilator Connections........................................................................................... |

4-2 |

4-2. |

Accessing Calculated Parameters........................................................................... |

4-4 |

4-3. |

Accessing Other Parameters................................................................................... |

4-4 |

5-1. |

Measuring Low Pressure........................................................................................ |

5-2 |

5-2. |

Accessing Low-Pressure Measurements................................................................ |

5-3 |

5-3. |

Measuring High Pressure ....................................................................................... |

5-4 |

5-4. |

Accessing High-Pressure Measurements ............................................................... |

5-4 |

5-5. Accessing Airway Pressure Measurements............................................................ |

5-5 |

|

6-1. |

Measuring Low Flow ............................................................................................. |

6-3 |

6-2. |

Accessing Low-Flow Measurements ..................................................................... |

6-4 |

6-3. |

Measuring High Flow ............................................................................................ |

6-5 |

6-4. |

Accessing High-Flow Measurements..................................................................... |

6-5 |

7-1. |

Changing the Battery.............................................................................................. |

7-2 |

7-2. |

Oxygen Sensor Calibration .................................................................................... |

7-3 |

v

VT MOBILE

Operators Manual

vi

Chapter 1

Introducing the VT MOBILE

Introduction

This Operators Manual provides complete operating instructions for the Fluke Biomedical VT MOBILE Gas Flow Analyzer (hereafter referred to as the Analyzer.) Seven language options support the available factory-set versions of the Analyzer. The overlay language identifies these.

The Analyzer is a general-purpose, portable gas flow analyzer with special modes designed specifically for testing mechanical patient ventilators. The Analyzer measures bi-directional flow in both high and low ranges as well as highand low-pressure ranges. The Analyzer is not for use in the patient environment. Table 1-1 identifies Analyzer language versions.

The Analyzer measures the basic signals of pressure, flow, and oxygen. From these basic signals, the Analyzer computes other parameters. The Analyzer obtains volume from the integration, or summation, of the flow signal over a period of time.

Table 1-1. VT MOBILE Versions

Version |

Language Overlay |

|

|

VT MOBILE US |

English |

VT MOBILE FRA |

French |

VT MOBILE DEU |

German |

VT MOBILE ITAL |

Italian |

VT MOBILE SPAN |

Spanish |

VT MOBILE JPN |

Japanese |

VT MOBILE CHI |

Chinese |

Operation, Storage, and Maintenance

Operate the Analyzer in a dry area within temperature limits of 10 °C to 40 °C. The maximum operating relative humidity at temperatures up to 31 °C is 80 % noncondensing, decreasing linearly to 50 % non-condensing at 40 °C.

Store the Analyzer at a temperature of -25 °C to 50 °C and at a non-condensing relative humidity of 0 to 95 %.

The battery is the only user-serviceable part in the Analyzer. For safety reasons, only an experienced technician should perform maintenance requiring other internal access.

1-1

VT MOBILE

Operators Manual

Features

Features include:

•Percent Oxygen Measurement. An oxygen sensor measures the oxygen percent of the gas in series with the highor low-flow channel of the Analyzer. Maxtec oxygen sensor distributed by Fluke Biomedical.

•Breath Parameters. The Analyzer measures 16 parameters on each detected breath. These parameters include tidal volume, minute volume, inspiratory and expiratory pressures, etc.

•Selectable Units. The Analyzer allows you to select the desired units for each of the measured signals. For example, pressures can be displayed in mmHg, kPa, bar, mbar, atm, inH2O, inHg, cmH2O or mmHg.

•Gas Type. Select the gas type from a pre-defined list, or, using the VT for Windows software, specify a user-defined gas.

•Trend Testing. The Analyzer provides an automated test to see if a predetermined parameter deviates from limits you set.

•Evaluations/Troubleshooting. Use the Analyzer for pre-purchase evaluations of ventilators, incoming and routine performance verification, and troubleshooting clinical problems, as well as teaching principles of mechanical ventilation.

•Computer Control, Data Logging, and Printing. A miniature RS232 serial port allows connection to a personal computer for external Analyzer control, data logging of test results, and printing. The Analyzer is compatible with Fluke Biomedical’s VT for Windows PC software (version 2.01.00 or higher.)

•Lung Simulator. The Analyzer operates with or without a test lung attached. Use the optional Fluke Biomedical ACCU LUNG as a test lung with integrated airway restrictors that assist you in evaluating intermittent errors.

About This Manual

This manual provides a complete description of the Analyzer and its applications. The manual contains information for beginners as well as experts in mechanical ventilator evaluation and separate measurement of pressure, flow, and volume.

Chapters are as follows:

•Chapter 1: Introducing the VT MOBILE. An introduction to the Analyzer

•Chapter 2: Preparing for Operation. Unpacking and setting up the Analyzer

•Chapter 3: Using the VT MOBILE. How to use the keys and interpret the screens

•Chapter 4: Checking Ventilator Parameters. How to access and interpret the 16 ventilator parameters

•Chapter 5: Measuring Pressure. How to measure high and low pressure

•Chapter 6: Measuring Flow and Volume. How to measure high and low flow and derive volume

•Chapter 7: Maintaining and Troubleshooting the VT MOBILE. How to perform maintenance and routine troubleshooting

•Appendix A: VT for Windows PC Software

•Appendix B: Specifications

1-2

Chapter 2

Preparing for Operation

Unpacking the VT MOBILE

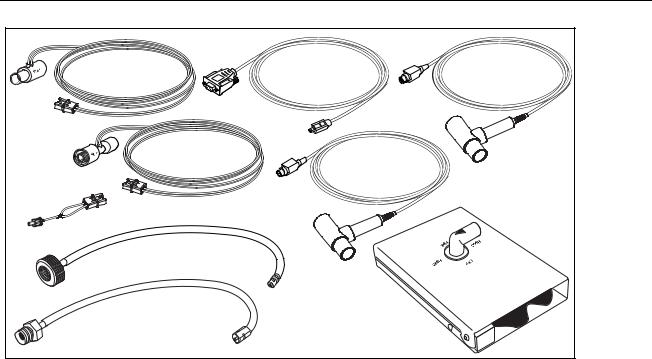

Before unpacking the Analyzer, visually inspect the shipping box for damage. If no damage is evident, unpack the Analyzer and its accessories from the shipping carton. Table 2-1 lists the standard accessories included in the box. Save the foam inserts and shipping box. You must use the original packing materials when shipping the Analyzer for service or re-calibration. If the original shipping carton and packing materials are not available, call a Fluke Biomedical service representative for assistance.

Identify accessories for your Analyzer with the aid of Tables 2-1, 2-2 and Figure 2-1. Check for missing parts. Carefully inspect the unit for damage such as cracks, dents, or bent parts. If items are missing or any physical damage is apparent, call Fluke Biomedical for assistance. For information on ways to contact Fluke Biomedical, see the section in this manual called “Support.” Also, notify the carrier if the damage appears to be the result of a shipping mishap.

2-1

VT MOBILE

Operators Manual

Table 2-1. Standard Accessories

Item |

Part Number |

|

|

Accessory Kit |

2548405 |

High-Flow Sensor |

2438334 |

High-Pressure Adapter (Luer to Male Nut/Nipple D.I.S.S. Oxygen) |

2548303 |

Low-Pressure Adapter |

2454175 |

Oxygen Sensor |

2448801 |

Oxygen Sensor Cable 6 ‘ |

2448051 |

‘T’, 15 mm ID, 22 mm ID, 15 mm ID end |

2457028 |

VT MOBILE RS232 Cable, 6’ |

2075257 |

9 VDC Battery (Alkaline) |

614487 |

Battery Eliminator |

2547455 |

Soft Carrying Case |

2523995 |

Information Packet: Getting Started Manual; Quick Reference Card; CD |

|

with Quick Reference Card, Getting Started Manual, Operators Manual, VT |

2544926 |

for Windows (V2.01.00 +) |

|

Table 2-2. Optional Accessories |

|

|

|

Item |

Part No. |

|

|

Low-Flow Sensor |

2438352 |

High-Pressure Adapter (Luer to Female D.I.S.S. Oxygen) |

2548315 |

Temperature and RH Sensor Assembly |

2541622 |

Serial Communications Cable (RS232) DB9F to miniature RS232, 6’ |

2075257 |

Power Adapter, Universal (USA and International) |

2118212 |

ACCU LUNG Portable, Precision Test Lung |

2387318 |

2-2

Preparing for Operation 2

Powering Up

High-Flow |

|

RS232 |

Temperature/RH |

Sensor |

|

Cable |

|

|

Sensor |

||

|

|

|

|

|

Low-Flow |

|

|

|

Sensor |

|

Oxygen |

|

|

|

|

|

|

|

Sensor |

Low-Pressure |

|

|

|

Adapter |

|

|

|

|

|

|

ACCU LUNG |

|

High-Pressure |

|

|

|

Adapters |

|

|

|

|

|

ede03f.eps |

Figure 2-1. Key Available Accessories

Powering Up

1.Press the Power key (H) to power on the Analyzer. The Analyzer displays the power up screen for several seconds.

2.The Analyzer then prompts you for the zeroing procedure. Place the Analyzer on a flat surface, and, if necessary, disconnect flow and pressure sensors.

W Warning

Make sure pressure is set to zero before disconnecting the High-Pressure Adapter. Exposure to high pressure could cause personal injury.

3.Press G (Ok). The Analyzer now performs the zeroing procedure. After several seconds, the Tidal Volume screen appears and the Analyzer is ready for use. If you have pressed R to initiate the zero procedure, the Analyzer returns to the previous screen displayed.

Note

If the Analyzer encounters a power problem (such as a backwards battery), thermal overload devices interrupt normal operation. Repair the problem, wait several seconds, and resume normal operation.

Using the Tilt Bail

As shown in Figure 2-2, you can use the Analyzer in flat or elevated positions. Do not use the Analyzer by hand or during transport.

2-3

VT MOBILE

Operators Manual

RELEASE

HERE

edg21f.eps

Figure 2-2. VT MOBILE Tilt Bail

Using the Keys

Press each key firmly; the Analyzer responds to a recognized key press with a beep. Generally, you can exit one function by selecting another function. Press the Band Cnavigation keys to cycle through multiple functions accessed from one key. Relevant functions for the two softkeys (Fand G) appear in the display immediately above these keys. When text entry is necessary, quickly press a key to cycle through the characters it accesses. Pause to accept the present character and move to the next entry. Think of text entry as text messaging, as you would encounter on a cell phone.

Note

If the Zero warning screen appears at any time, follow on-screen directions and then press G; the interrupted function will continue automatically after the zeroing procedure.

Selecting the Operating Mode

Local Mode is the default setting upon powering up the Analyzer. In Local Mode, select functions by pressing keys on the front panel.

To change modes from Local to Remote, first connect the serial cable to both the PC and the miniature RS-232 serial port on the Analyzer. Launch VT for Windows software (version 2.01.00 or higher) to activate Remote Mode.

If VT for Windows has remote control, the following appears on the Analyzer display screen:

No Graphics Available, While Communications Are Active

Normal local key presses have no effect. Press G(Cancel) to regain local control.

2-4

Preparing for Operation 2

Setting Up

Setting Up

Press Dto access Analyzer settings. (Press Gto return to the measurement screen.)

Selecting the Gas Type

Ensure that you have selected the gas or gas mixture you will be using, as the gas density will be different for each gas type and mixture. The Analyzer uses this information to improve the accuracy of the flow calculations. Failure to enter the correct value will cause the flow and volume calculations to be in error.

Select the gas type by pressing DÆ EÆ EÆ Bor C Æ E. Available selections are: Air, O2, Heliox, CO2, N2, N2O, N2O/O2 (N2O balance O2), He/O2 (He balance O2), N2/O2 (N2 balance O2), and User. Refer to Table 2-3 for descriptions of gas types. Only the VT for Windows software can identify a ‘User’ gas.

|

Table 2-3. Gas Types |

|

|

Gas |

Description |

|

|

Air |

Standard room air |

|

|

O2 |

100% Oxygen |

|

|

Heliox |

30% Oxygen and 70% Helium blend |

|

|

CO2 |

100% Carbon Dioxide |

|

|

N2 |

100% Nitrogen |

|

|

N2O |

100% Nitrous Oxide |

|

|

N20 bal O2 |

Measured Oxygen balance Nitrous Oxide |

|

|

He bal O2 |

Measured Oxygen balance Helium |

|

|

N2 bal O2 |

Measured Oxygen balance Nitrogen |

|

|

User |

User selects custom gas mixture. This option requires the VT for Windows PC software. |

|

|

Gas Temperature and Relative Humidity

These parameters are not really settings, but are available when the optional Temperature and Relative Humidity Sensor is connected. The Analyzer measures the gas flowing through the sensor and uses this information to improve the accuracy of the flow measurements. All temperatures are in degrees Celsius.

Selecting the Correction Mode

This setting calculates the flow volume of the air flowing through the high or low-flow ports. Ensure that the correction mode setting matches the one used by the ventilator or anesthesia machine manufacturer for their display of flow and volume measurements. If the correction mode is unknown, select “ATP” (Ambient Temperature and Pressure).

Refer to Table 2-4 for descriptions of the correction modes.

The Analyzer can operate with a correction mode of ATP, STPD21, BTPS, or STPD0. Select the mode as follows:

1.Press DÆ E Æ C(to ‘Corr Mode’)

2.Press E Æ C (to select mode)

3.Press Eto activate your selection.

2-5

VT MOBILE

Operators Manual

|

|

Table 2-4. Correction Modes |

|

|

|

|

|

Mode |

Name |

Description |

|

|

|

|

|

ATP |

Ambient Temperature |

The Analyzer corrects the flow rate (and therefore, volume) such that the |

|

|

and Pressure |

reported flow equals the flow if the gas temperature and pressure are at |

|

|

|

ambient (room) temperature and pressure. |

|

|

|

|

|

BTPS |

Body Temperature and |

The Analyzer corrects the flow rate (and therefore, volume) such that the |

|

|

Pressure Saturated |

reported flow equals the flow if the gas temperature and pressure were |

|

|

with water vapor |

changed to body conditions (37 °C and ambient pressure). Further, the |

|

|

|

Analyzer compensates the flow to add the amount of water vapor as if to |

|

|

|

make the gas fully saturated (i.e. 100% relative humidity). In this |

|

|

|

correction, the Analyzer uses the relative humidity reading to determine |

|

|

|

the amount of water vapor that would need to be added. |

|

|

|

|

|

STPD0 |

Standard Temperature |

The Analyzer corrects the flow rate (and therefore, volume) such that the |

|

|

and Pressure Dry, |

reported flow equals the flow if the gas temperature and pressure were |

|

|

0 °C |

changed to standard conditions (0 °C and 760 mmHg). Further, the |

|

|

|

Analyzer compensates the flow to subtract the amount of water vapor as |

|

|

|

if the gas was dry (i.e. 0% relative humidity). In this correction, the |

|

|

|

Analyzer uses the relative humidity reading to determine the amount of |

|

|

|

water vapor that would need to be subtracted. |

|

|

|

|

|

STPD21 |

Standard Temperature |

The Analyzer corrects the flow rate (and therefore, volume) such that the |

|

|

and Pressure Dry, |

reported flow equals the flow if the gas temperature and pressure were |

|

|

21 °C |

changed to standard conditions (21°C and 760 mmHg). Further, the |

|

|

|

Analyzer compensates the flow to subtract the amount of water vapor as |

|

|

|

if the gas was dry (i.e. 0% relative humidity). In this correction, the |

|

|

|

Analyzer uses the relative humidity reading to determine the amount of |

|

|

|

water vapor that would need to be subtracted. |

|

|

|

|

|

Setting the Breath Detect Threshold

The Analyzer breath detection algorithm uses a flow rate threshold that the inspiratory flow must cross to trigger a change in the breath phase. Higher flow rate thresholds yield less sensitive breath detection. Lower thresholds yield more sensitive breath detection.

The default setting of 2.00 lpm is usually appropriate for the ventilators and anesthesia machines being tested. This setting tells the Analyzer how to divide the delivered flow into breaths. If necessary, adjust the Breath Detect Threshold up or down until the breath rate reported on the Analyzer Timing display matches the ventilator breath rate.

Set the threshold as follows:

1.Press DÆ E Æ C(to ‘BD Thresh’).

2.Press E Æ C or B(to change threshold in increments of 0.25). You can also use text entry to enter a new value directly.

3.Press Eto activate your selection.

Setting Zero Warn ON or OFF

You need to "zero" (or calibrate) the pressure and differential pressure (flow) sensors in the Analyzer to a zero reference. This “zero” reminder function can be set to occur automatically at pre-determined intervals or only when you request the function by pressing R. The Zero Warn is helpful in reminding you to stop and zero the transducers from time-to-time during operation. This is especially important during the 40-minute warm-up to full stability. The Analyzer does not calculate breath parameters for any breath in which a zero occurs. For this reason, it may be desirable to turn off automatic zeroing for a short while during a critical test.

2-6

Preparing for Operation 2

Setting Up

The Analyzer Zero Warn is set to ON at the factory to remind you to zero out any offset in the Flow measurements. The Zero Warn screen reminds you at power on, after the first five minutes, and then after each 30-minute period. After the power-on zero warning, you can choose to Zero or Cancel when the reminder appears; either action returns the Analyzer to the same function.

W Caution

Setting Zero Warn to OFF may result in introduction of offset into the Flow and Volume measurements and cause errors in the assessment of those measurements against the medical device under test specification. Fluke Biomedical strongly recommends that you leave Zero Warn ON.

Turn this warning on or off using the following procedure:

1.Press DÆ E Æ C(to ‘Zero Warn’).

2.Press E Æ C (to select ON or OFF).

3.Press E to activate your selection.

Setting the Time

You can set hours and minutes. Enter the time in the HHMM or HMM format, where HH or H is the hours in 12-hour format and MM is the minutes (00 through 59).

To set the time, follow these steps:

1. Press DÆ C Æ E Æ C Æ E to access the time setting screen.

2.Enter the hour (HH or H) with the text entry keys.

3.Press G.

3.Enter the minutes (MM) with the text entry keys.

4.Press Fto select P (PM) or A (AM).

5.Press E.

Setting the Date

To set the date, follow these steps:

1.Press DÆ C EÆ Æ Eto access the date setting screen.

2.Enter the month (MM) or day (DD), depending on the date format, with the text entry keys.

3.Press G.

4.Enter the day (DD) or month (MM) with the text entry keys.

5.Press G.

6.Enter the year (YYYY) with the text entry keys.

7.Press E.

The Analyzer displays the date with the following information:

•MM is the number between 1 and 12 corresponding to the month.

•DD is the number between 1 and 31 corresponding to the day of the month.

•YYYY is the year.

2-7

VT MOBILE

Operators Manual

Selecting the Date Format

The Analyzer uses either of the following date formats:

•M/D/Y

•D/M/Y

To change the format, follow these steps:

1.Press DÆ C Æ E Æ C Æ C Æ E

2.Press Cor C to select ‘M/D/Y’ or ‘D/M/Y’.

3.Press E to activate your choice.

4.Press Gto return to the active display screen.

Setting the Contrast

Use the following procedure to change the screen contrast:

1.Press AÆ CÆ E.

2.Highlight Contrast by scrolling down with C.

3.Press Eand adjust the contrast in either of the following ways:

•Press Bor Cto increment or decrement the contrast in steps of 10.

•Enter any contrast value directly using the text entry keys.

Checking Version and Serial Numbers

Press DÆ CÆ CÆ Eto check the version and serial numbers.

Connecting the Analyzer

Connect the Analyzer for flow and pressure measurements as shown in Figures 2-3 and 2-4.

edg23f.eps

Figure 2-3. Low-Pressure/High-Flow/Low-Flow Connection

2-8

Preparing for Operation 2

Connecting the Analyzer

edg22f.eps

Figure 2-4. High-Pressure Connection

High-Flow Connection

The High-Flow Sensor connects to the flow/low-pressure port on the top of the Analyzer. Connect the High-Flow Sensor in line using adapters from the Accessory Kit.

W Caution

Do not exceed a flow of 200 lpm through the high-flow port. Damage to the Analyzer could otherwise result.

Measure only dry gases using the high-flow port. Do not use this port to measure exhaled or artificially humidified gases.

Low-Flow Connection

The Low-Flow Sensor connects to the flow/low-pressure port on the top of the Analyzer. Connect the Low-Flow Sensor in line using adapters from the Accessory Kit.

W Caution

Do not exceed a flow of 35 lpm through the low-flow port. Damage to the Analyzer could otherwise result.

Measure only dry gases using the low-flow port. Do not use this port to measure exhaled or artificially humidified gases.

High-Pressure Connection

The High-Pressure Adapter connects to the high-pressure port on the top of the Analyzer. The connector mates to standard oxygen DISS fittings as used on oxygen supply hoses. Connectors are available with male or female fittings. Do not apply fluid to the highpressure port.

W Caution

Do not exceed a pressure of 125 psi at the high-pressure port.

Damage to the Analyzer could otherwise result.

Low-Pressure Connection

The Low-Pressure Adapter connects to the flow/low-pressure port on the top of the Analyzer. Do not apply fluid to the low-pressure port.

2-9

VT MOBILE

Operators Manual

W Caution

Do not exceed a pressure of 5 psi at the low-pressure port.

Damage to the Analyzer could otherwise result.

Ventilator Test Connections

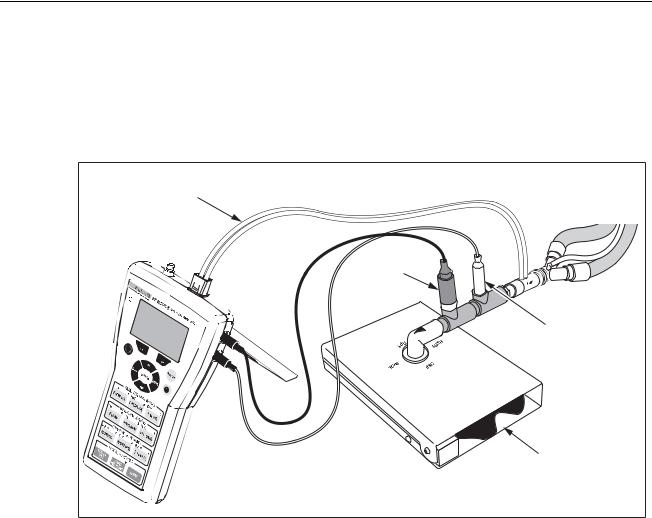

Ventilator testing involves multiple connections as shown in Figure 2-5.

High Flow Sensor |

To |

|

|

|

Ventilator |

|

Oxygen |

|

Sensor |

|

Temp./RH Sensor |

|

Fluke Biomedical |

|

ACCU LUNG |

|

ede06f.eps |

Figure 2-5. Ventilator Test Connections

2-10

Chapter 3

Using the VT MOBILE

Understanding the Controls and Indicators

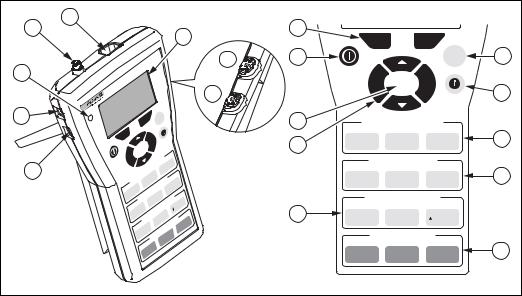

Figure 3-1 and Table 3-1 describe the controls and indicators.

|

4 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F1 |

|

|

F2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

ANALYZER |

|

|

|

|

|

|

7 |

18 |

|

|

|

|

Memory |

10 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

FLOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

GAS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

MOBILE |

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

Back |

ENTER |

|

Setup |

|

11 |

|

|

VT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2 |

|

|

|

|

|

|

|

|

|

ry |

|

|

|

|

|

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

F2 |

Memo |

|

|

|

|

|

_ , |

VENTILATOR PARAMETERS |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

ABC |

2 |

DEF |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

@ |

12 |

|||||

|

|

|

F1 |

|

|

|

|

|

|

|

|

|

|

|

|

16 |

FLOW/VOL |

PRESSURE |

TIMING |

|

|||

|

|

|

|

|

|

|

|

Setup |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

ENTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Back |

|

|

|

|

|

|

|

|

|

|

|

|

WAVEFORM SCREENS |

|

|

|||||

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

GHI |

4 |

JKL |

5 |

MNO |

6 |

|

|

1 |

|

|

|

|

|

|

PARAMETERS2 TIMING |

|

|

|

|

13 |

||||||||||

|

|

|

|

|

BC |

|

|

|

|

|

|

6 |

|

|

FLOW |

PRESSURE |

VOLUME |

||||||

|

|

|

|

VENTILATOR1 |

|

|

NO |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

PRESSURE |

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

_,@ |

/VOL |

|

|

SCREENS5 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

VOLUME |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

FLOW |

|

|

|

L |

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

WAVEFORMJ |

|

|

|

Z |

|

2 |

|

|

OTHER MEASUREMENTS |

|

|

||||||

|

|

|

|

|

|

4 |

PRESSURE |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

XY |

|

O |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

W |

|

RH |

|

PQRS |

7 |

TUV |

8 |

WXYZ |

9 |

|

||||

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

% |

|

|

|

|||||||||

|

|

|

|

GHI |

FLOW |

|

|

MEASUREMENTS |

|

|

|

15 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

FLOW/VOL |

|

|

%RH O2 |

|

|||||||||

|

|

|

|

|

OTHER7 |

T V |

|

|

|

|

|

|

PRESSURE |

|

|||||||||

|

|

|

|

|

|

|

PRESSURE |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

S |

|

|

0 |

|

|

MORE |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

QR |

|

|

|

FUNCTIONS |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

P |

FLOW/VOL |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

SPECIAL ZERO |

|

|

|

|

|

|

SPECIAL FUNCTIONS |

|

|

||||||||

|

|

|

|

|

|

|

TREND |

SENSORS |

|

|

|

|

|

|

|

0 |

|

|

14 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TREND |

ZERO |

|

MORE |

|

|||||

|

|

|

|

|

|

|

|

TEST |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEST |

SENSORS |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ede01f.eps |

Figure 3-1. Controls and Indicators

3-1

VT MOBILE

Operators Manual

|

|

Table 3-1. Controls and Indicators |

|

|

|

|

|

No. |

Name |

|

Description/Use |

|

|

|

|

A |

Miniature RS-232 Serial |

Connect the RS-232 cable here (for use with VT for Windows |

|

|

Port |

|

software.) |

B |

Battery Eliminator |

|

Connect the battery eliminator here. Use the battery eliminator |

|

Connector |

|

whenever possible. |

C |

Battery Eliminator |

|

Glows green when the battery eliminator is supplying power to the |

|

Indicator |

|

Analyzer. Note that this power source cannot recharge the |

|

|

|

battery. |

D |

High-Pressure Connector |

Connect the High-Pressure Adapter here. The Analyzer makes |

|

|

|

|

high-pressure measurements from -2 to 100 psi. |

E |

Flow and Low-Pressure |

Insert one of three coded modular connectors here; the Analyzer |

|

|

Connector |

|

automatically detects the connector type. The Analyzer use the |

|

|

|

High-Flow Sensor to measure up to ± 150 lpm, the Low-Flow |

|

|

|

Sensor to measure up to ± 25 lpm, or the Low-Pressure Adapter |

|

|

|

to measure from -20 to 120 cmH2O. |

F |

Display Screen |

|

Shows measurement parameters and statistics (Min, Avg, and |

|

|

|

Max), waveforms, and setup selections. English only. |

G |

Oxygen Sensor Connector |

Connect the Oxygen Sensor here. The Analyzer makes O2 |

|

|

|

|

measurements from 0 to 100%. |

H |

Temperature, RH Sensor |

Connect the optional Temperature and Relative Humidity Sensor |

|

|

Connector |

|

here. |

I |

Softkeys |

|

Use F andGto access selections identified on the screen |

|

F |

G |

immediately above these keys. |

|

|

|

|

J |

Memory Key |

|

Press Jto save, view, or delete memory files. A memory file |

|

J |

|

contains data to reconstruct all aspects of a stored screen |

|

|

|

(reading, statistics, waveform, parameters, etc.) |

|

|

|

|

K |

Help Key |

|

Press Ito access context-sensitive help. If necessary, press |

|

I |

|

Bor Cto scroll through additional text. Press Ato return to |

|

|

the previous screen. |

|

|

|

|

|

|

|

|

|

L |

Ventilator Parameters |

Press K, L, or Mto display ventilator measurement |

|

|

Keys |

|

parameters. When text entry is required, press Ksuccessively |

|

K L M |

to cycle through 1 Æ - Æ @. Press Lto cycle through A Æ B |

|

|

|

|

Æ C Æ 2, and press Mto cycle through D Æ E Æ F Æ 3. |

|

|

|

|

3-2

|

|

|

|

|

Using the VT MOBILE |

3 |

|

|

|

|

|

|

Understanding the Controls and Indicators |

||

|

|

|

Table 3-1. Controls and Indicators (cont.) |

|

|||

|

|

|

|

|

|

|

|

|

No. |

|

Name |

|

Description/Use |

|

|

|

|

|

|

|

|

|

|

|

M |

Waveform Screens Keys |

|

Press N, L, or Oto display specific waveforms. |

|

|

|

|

|

N L O |

|

For any waveform, press F(Rescale) to optimize the |

|

|

|

|

|

|

|

|

display or press G(Units) to select new units of |

|

|

|

|

|

|

|

measurement. When text entry is required, press N |

|

|

|

|

|

|

|

successively to cycle through G Æ H Æ I Æ 4. Press Lto |

|

|

|

|

|

|

|

cycle through J Æ K Æ L Æ 5, and press Oto cycle |

|

|

|

|

|

|

|

through M Æ N Æ O Æ 6. |

|

|

|

N |

Other Measurements Keys |

|

Press Kto access direct readings and statistics of flow |

|

|

|

|

|

K |

L |

P |

and volume. Press Lfor readings and statistics of high or |

|

|

|

|

|

|

|

low pressure. Repeated presses of Pyield readings of |

|

|

|

|

|

|

|

O2 %, temperature, and relative humidity. When text entry is |

|

|

|

|

|

|

|

required, press Ksuccessively to cycle through P Æ Q Æ |

|

|

|

|

|

|

|

R Æ S Æ 7. Press Lto cycle through T Æ U Æ V Æ 8, |

|

|

|

|

|

|

|

and press Pto cycle through W Æ X Æ Y Æ Z Æ 9. |

|

|

|

|

Special Functions Keys |

|

Press Qto start new or review old trending data. Press |

|

|

|

|

O |

Q |

R |

S |

Rat any time to initiate the zeroing procedure or, when |

|

|

|

|

|

|

|

keypad entry is required, to enter 0. Press Sto access |

|

|

|

|

|

|

|

barometric pressure and battery readings. |

|

|

|

P |

Navigation Keys |

|

Press Ato exit specific screens (Setup, Memory, Help, |

|

|

|

|

|

|

AB CD |

|

More, etc.) |

|

|

|

|

|

|

|

Press Bor Cto cycle through specific screen |

|

|

|

|

|

|

|

selections (Setup, Memory, More, etc.) or to scroll through |

|

|

|

|

|

|

|

help text. Press Dto access system settings (Gas Type, |

|

|

|

|

|

|

|

Correction Mode, Breath Detect Threshold, Zero Warning, |

|

|

|

|

|

|

|

Date, Time, and version numbers.) |

|

|

|

Q |

Enter Key |

|

Press Eto activate a menu selection. |

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

Power Key |

|

Press and briefly hold this key to power on or power off the |

|

|

|

|

|

H |

|

|

Analyzer. |

|

|

|

|

|

|

|

|

|

|

3-3

VT MOBILE

Operators Manual

Screens

Ventilator Parameters Screens

The Analyzer calculates 16 parameters for every breath. You can display all parameters individually or most parameters in groups of four. Parameters update following every breath. Units of measure for breath parameters are fixed. Table 3-2 shows parameters and groupings, along with abbreviations and units of measurement.

Table 3-2. Ventilator Parameters

Parameter |

Units |

|

|

Inspiratory and Expiratory Tidal Volume (VT) |

ml |

|

|

Expiratory Minute Volume (MV) |

lpm |

|

|

Peak Inspiratory Flow (PIF) |

lpm |

|

|

Peak Expiratory Flow (PEF) |

lpm |

|

|

Peak Inspiratory Pressure (PIP) |

cmH2O |

|

|

Positive-End Expiratory Pressure (PEEP) |

cmH2O |

|

|

Mean Airway Pressure (MAP) |

cmH2O |

|

|

Inspiratory Pause Pressure (IPP) |

cmH2O |

|

|

Breath Rate (Rate) |

bpm |

|

|

Inspiratory Time (Ti) |

s |

|

|

Expiratory Time (Te) |

s |

|

|

Inspiratory, Expiratory Time (I:E) Ratio |

s:s |

|

|

Oxygen Concentration |

% O2 |

|

|

Temperature (optional) |

°C (selectable) |

|

|

Relative Humidity (optional) |

% RH |

|

|

Barometric Pressure |

mmHg (selectable) |

|

|

3-4

Using the VT MOBILE |

3 |

Screens |

Viewing a Single Parameter

To view single parameters, press K, L, or Mrepeatedly. If you are already viewing a multi-parameter screen, press G(Single). The following is an example of the PIP single parameter screen:

ede26s.bmp

Viewing a Group of Parameters

From an individual parameter screen, press G(All) to display the related screen of four parameters. The groups are Pressures, Vol/Flow, and Timing. The following is an example of the Pressures multi-parameter screen:

ede27s.bmp

Viewing All Parameters

You can view all 16 parameters on one screen when using the Analyzer connected to a PC running the VT for Windows software.

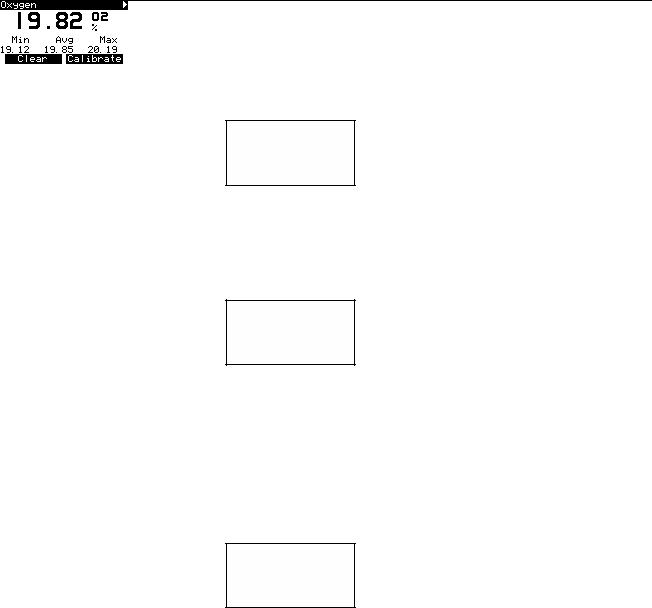

Oxygen Screen

Press Pto access the Oxygen Screen. The sample oxygen screen shown below displays the signal and statistics for the oxygen sensor.

ede28s.bmp

Press F(Clear) to reset the statistics and start a new reading.

Press G(Calibrate) to begin the calibration routine for the oxygen sensor; you will find complete instructions later in this chapter.

3-5

VT MOBILE

Operators Manual

Temperature Screen

Press Pas required to access the Temperature Screen (available when the optional Temperature and Relative Humidity Sensor is connected.) The sample temperature screen shown below represents the gas temperature as measured in series with the High-Flow or Low-Flow Sensor.

ede29s.bmp

Relative Humidity Screen

Press Pas required to access the Relative Humidity Screen (available when the optional Temperature and Relative Humidity Sensor is connected.) The sample relative humidity screen shown below represents the gas relative humidity as measured in series with the High-Flow or Low-Flow Sensor.

ede30s.bmp

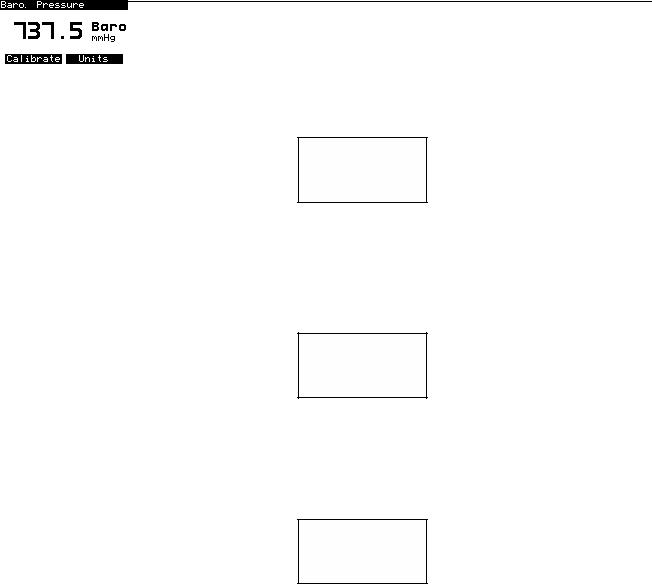

Barometric Pressure Screen

Press S Æ Eto access the Barometric Pressure Screen. The Analyzer continuously measures the barometric pressure using an internal sensor. A sample barometric pressure screen follows:

ede31s.bmp

Waveform Screens

You can access waveform representations of the reading by pressing keys in the WAVEFORM SCREENS section of the keypad. The Analyzer provides Flow, Pressure (high, low, and airway), and Volume waveform screens.

3-6

Loading...

Loading...