Fluke MPG1 WITH RPM4, MPG1 WITH PG7302 INSTALLATION

Interconnection Kit

For MPG1 with RPM4 or PG7302

P/N 402265

Instruction Sheet

INTERCONNECTION KIT FOR MPG1 WITH

RPM4 OR PG7302, P/N 402265, INCLUDES:

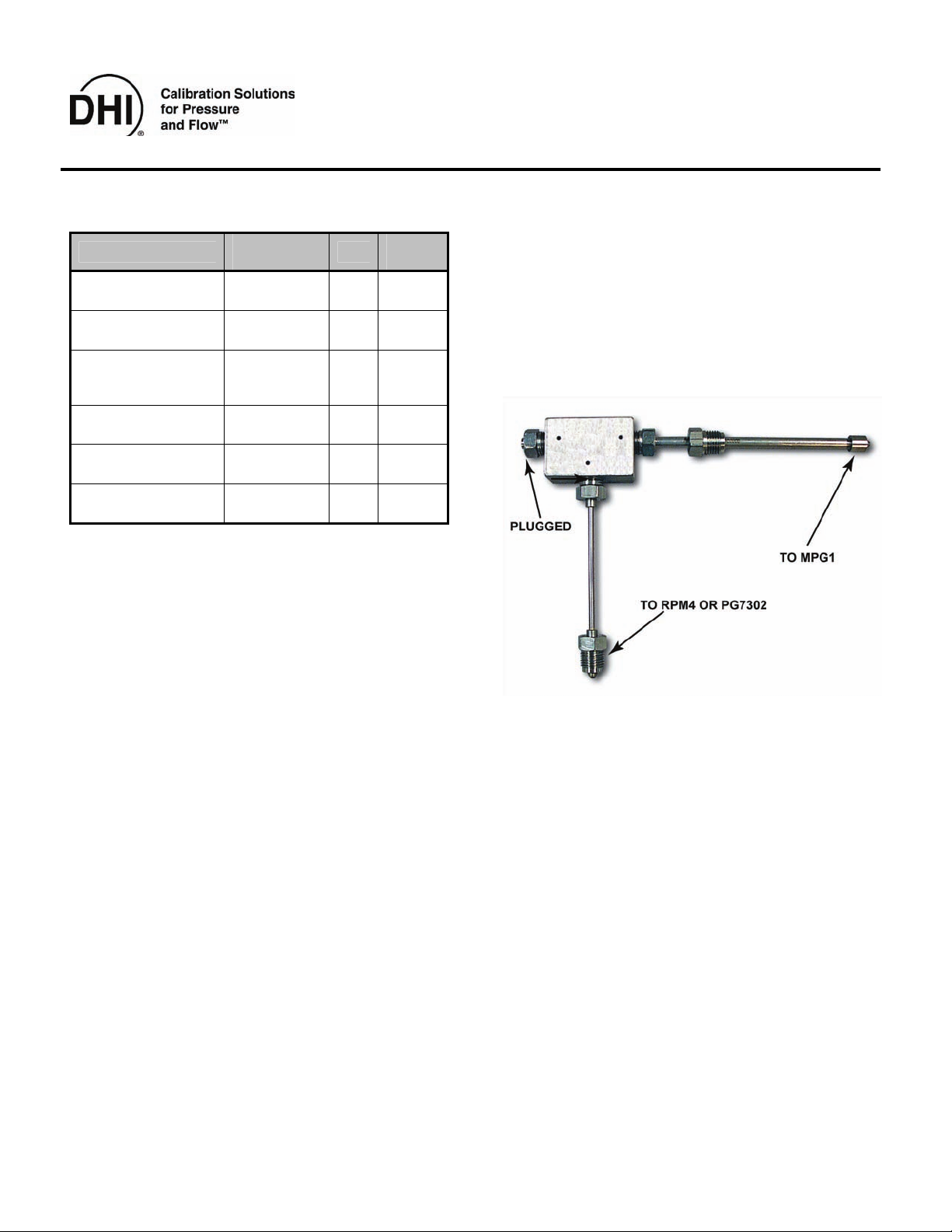

DESCRIPTION

Nipple, 6 in.

(152 mm), DH500

Nipple, 12 in.

(305 mm), DH500

Nipple, 5 in. x 1/8 in.

(127 mm x 3 mm),

DH500 tips

Tee DH500 400 MPa

Plug DH500/DH700 700 MPa

Adaptor, DH500F x

1/8 i n . (3 mm) N P TM

PRESSURE

RATING

500 MPa

(72 500 psi)

500 MPa

(72 500 psi)

200 MPa

(30 000 psi)

(60 000 psi)

(100 000 psi)

200 MPa

(30 000 psi)

QTY

1 103975

1 103976

2 123019

1 100291

1 100285

2 102819

PART

NO.

INTRODUCTION

This kit provides the tubing and fittings necessary to

connect an MPG1 pressure controller to either an

RPM4 reference pressure monitor or to a PG7302

piston gauge, and also to a device under test. This

document contains instructions for connecting the

fittings and tubing.

INSTALLATION OF INTERCONNECTIONS

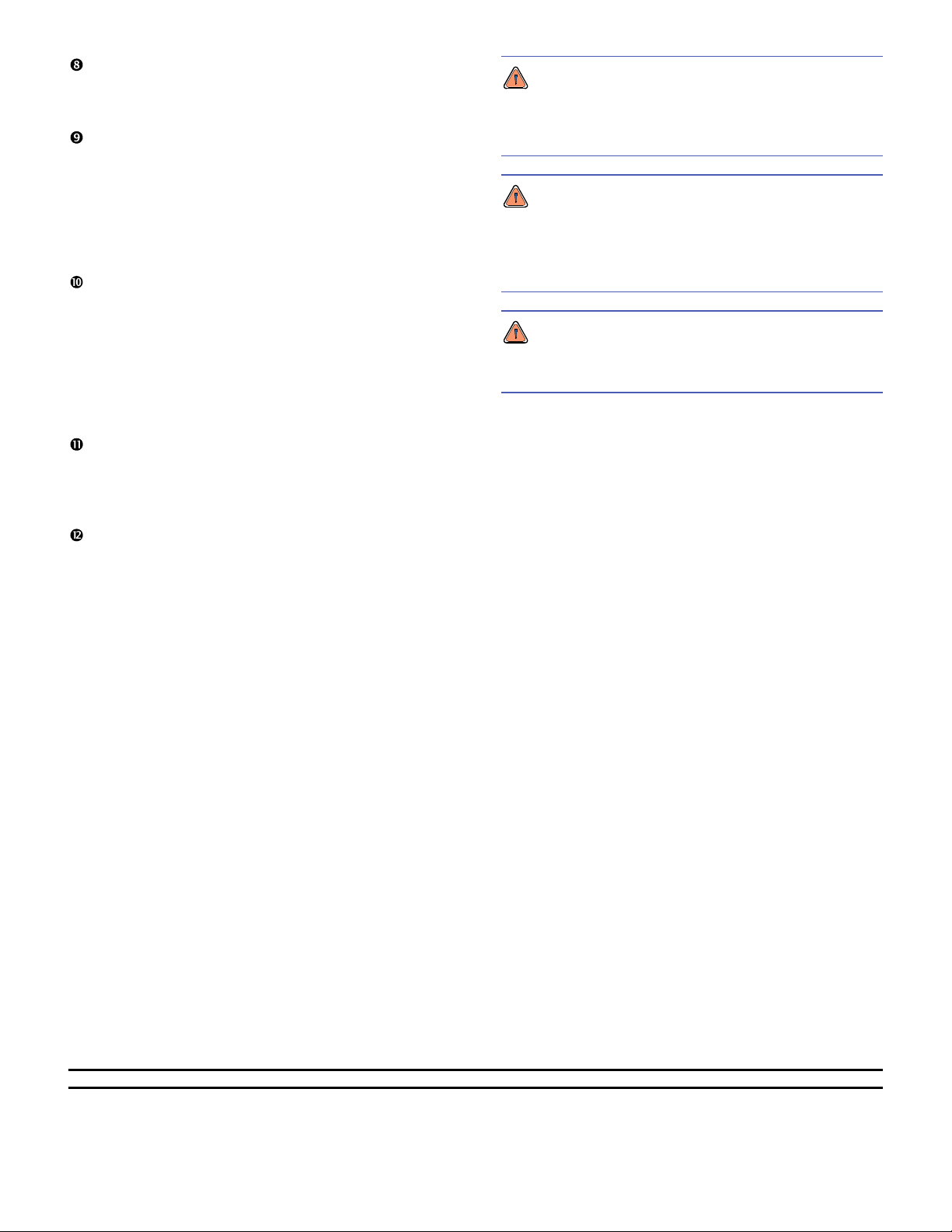

q Install nipples into three way tee: Install the 5 in.

nipple into the center port of the three way tee.

Install either the 6 in. or 12 in. nipple into either of the

end ports on the three way tee as shown in Figure 1.

Tighten the nipples with a 5/8 in. wrench or crescent

wrench. The thick nipple on the right connects to the

MPG1. The thin nipple in the center of the plug

connects to the RPM4 or to the PG7601. In Figure 1

the left port is currently plugged, but the remaining

thin 5 in. nipple can go in the left port and connect to

the DUT.

Figure 1: Two nipples installed in 3-way tee.

n Remove Plugs from MPG1 and RPM4 or

PG7302: Unscrew the glands from the test ports

of the MPG1 and RPM4 or PG7302. Remove the

collar and plug from inside each gland. There

should be two plastic plugs and one stainless steel

plug. The plastic plugs will not be used. Keep the

stainless steel plug.

o Install glands and collars onto flexible 5 in.

nipples: Slide a gland over a nipple so that the

threads of the gland face outward. Next, screw a

collar onto the nipple by turning it to the LEFT.

Allow two nipple threads to show between the

collar and nipple tip.

a RPM4 – Install glands and collars onto the 6 in.

p

nipple.

b PG7302 – Install glands and collars onto the

p

12 in. nipple.

r Optional: Extend the front feet on RPM4: The front

feet of the RPM4 can be extended so that the RPM4

is inclined for easier reading and display access.

s RPM4 A70M or less - install NPT adaptor into

RPM4. RPM4s that have ranges of 70 MPa

(10 000 psi) or less have 1/8 in. NPTF test ports.

These ports require the use of one of the DH500F

by 1/8 in. NPTM adaptors. Wrap Teflon

®

thread

tape around the NPT threads of the adaptor three

times, and install the adaptor into the RPM4.

t Install the free end of the center nipple into

RPM4 or PG7302: The center, thin, 5 in. nipple

should be inserted into the test port of the RPM4 or

PG7302. Screw in the gland loosely by hand. The

nipple can be bent slightly to ensure that nipple

enters straight into the test port. Do not tighten the

gland in the RPM4 or PG7302 yet, since it will be

tightened when the system is primed.

Install the 6 in. or 12 in. nipple into the MPG1.

Screw in the glands loosely by hand. Tighten the

gland with a 5/8 in. wrench or crescent wrench.

Install a DH500M to 1/8” NPT male adaptor in

the DUT if necessary: The 1/8 in. NPT male

adaptor can be used to connect the remaining thin

5 in. nipple to DUTs with 1/8 in NPT female ports.

If you intend to use the adaptor, wrap Teflon

®

thread tape around the NPT threads three times

and install it into the DUT.

Install the Device Under Test (DUT). The DUT

will be connected to the test line with the

remaining thin 5 in. nipple. This nipple can be

installed either in the 3-way tee, or in the port on

top of the MPG1. The tube can be slightly bent if

necessary. Install the nipple in the desired

location. Tighten the gland in the tee or MPG1, but

do not tighten the gland that connects to the DUT.

Plug the open test port: There is an open test port

either on the top of the MPG1, or on the 3-way tee.

Insert the stainless steel plug into a gland. Insert the

plug and gland into the open port. Do not tighten.

The maximum operating pressure of the variable volume is

100 MPa (15 000 psi) in MPG1-100M and 200 MPa (30 000 psi)

in MPG1-200M. Do not generate pressure greater than the

maximum operating pressure.

High pressure fluids are potentially hazardous. Energy

stored in pressurized fluids can be released unexpectedly and with

extreme force. High pressure systems should be assembled and

operated only by personnel who have been instructed in proper

safety practices.

ALWAYS use external tubing and fittings rated for

pressures equal to or greater than the maximum pressure which

MPG1 will be used to generate.

Prime the system, tighten fittings: Pump fluid

through the nipples by using the MPG1. See the

appropriate section of the MPG1 Operation and

Maintenance Manual for this procedure. Make

sure that all air is purged from the test lines.

There are 3 loose fittings: one on the DUT, one on

the RPM4 or PG7302, and the other on the plug.

Tighten each of the loose fittings when oil without

bubbles begins to flow through it.

Document 560080b 070208

DH Instruments, Inc.

4765 East Beautiful Lane

Phoenix AZ 85044-5318

USA

Tel 602.431.9100

Fax 602.431.9559

dhi@dhinstruments.com

www.dhinstruments.com

Loading...

Loading...