Fluke PG7302 V2.07, PG7102 V2.07, PG7202 V2.07, PG7601 V2.07 Operation and Maintenance Manua

PG7000™ PISTON GAUGES

PG7102™, PG7202™,

PG7302™, PG7601™

(Ver. 2.07a through 2.07g) Operation and Maintenance Manual

© 1998-2008 DH Instruments, a Fluke Company

PG7000™ OPERATION AND MAINTENANCE MANUAL

High-pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases can be released unexpectedly and with extreme force. High-pressure systems should be assembled and operated only by personnel who have been instructed in proper safety practices.

High-pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases can be released unexpectedly and with extreme force. High-pressure systems should be assembled and operated only by personnel who have been instructed in proper safety practices.

© 1998 - 2008 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments 4765 East Beautiful Lane Phoenix Arizona 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty, expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not constitute an endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, PG7000, PG7102, PG7202, PG7302, PG7601, CalTool and COMPASS are trademarks, registered and otherwise, of DH Instruments, a Fluke Company.

Swagelok is a registered trademark of the Swagelok Company.

Krytox is a registered trademark of the Dupont de Nemours Company.

Products described in this manual are manufactured under international patents and one or more of the following U.S. patents: 6,701,791, 5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

Document No. 550099p 080123

Printed in the USA

© 1998-2008 DH Instruments, a Fluke Company

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS ............................................................... |

I |

|||

TABLES .................................................................................. |

|

V |

||

FIGURES ................................................................................ |

|

VI |

||

ABOUT THIS MANUAL ............................................................ |

VII |

|||

1. |

INTRODUCTION ................................................................. |

1 |

||

|

1.1 |

PRODUCT OVERVIEW............................................................................................................................ |

1 |

|

|

1.2 |

SPECIFICATIONS.................................................................................................................................... |

2 |

|

|

|

1.2.1 |

GENERAL SPECIFICATIONS ....................................................................................................................... |

2 |

|

|

1.2.1.1 |

EMBEDDED FEATURES........................................................................................................................... |

3 |

|

|

1.2.1.2 |

AMBIENT AND INSTRUMENT CONDITION MEASUREMENTS.............................................................. |

4 |

|

|

1.2.2 |

PISTON-CYLINDER MODULES.................................................................................................................... |

5 |

|

|

1.2.2.1 |

PC-7100/7600 ............................................................................................................................................ |

5 |

|

|

1.2.2.2 |

PC-7200 ..................................................................................................................................................... |

6 |

|

|

1.2.2.3 |

PC-7300 ..................................................................................................................................................... |

7 |

|

|

1.2.3 |

MASS SETS................................................................................................................................................... |

8 |

|

|

1.2.4 |

PRESSURE MEASUREMENTS .................................................................................................................... |

8 |

|

|

1.2.4.1 |

PC-7100/7600 ............................................................................................................................................ |

8 |

|

|

1.2.4.2 |

PC-7200 ..................................................................................................................................................... |

9 |

|

|

1.2.4.3 |

PC-7300 ................................................................................................................................................... |

10 |

|

1.3 TERMINAL AND PLATFORM FRONT AND REAR PANELS ............................................................... |

11 |

||

|

|

1.3.1 TERMINAL FRONT AND REAR PANELS .................................................................................................. |

11 |

|

|

|

1.3.1.1 |

PG TERMINAL FRONT PANEL............................................................................................................... |

11 |

|

|

1.3.1.2 |

PG TERMINAL REAR PANEL ................................................................................................................. |

12 |

|

|

1.3.2 |

PLATFORM REAR PANELS ....................................................................................................................... |

12 |

2. |

INSTALLATION ................................................................ |

13 |

||

|

2.1 |

UNPACKING AND INSPECTION........................................................................................................... |

13 |

|

|

|

2.1.1 |

REMOVING FROM PACKAGING................................................................................................................ |

13 |

|

|

2.1.1.1 |

PLATFORM.............................................................................................................................................. |

13 |

|

|

2.1.1.2 |

MASS SET ............................................................................................................................................... |

13 |

|

|

2.1.1.3 |

PISTON-CYLINDER MODULE(S) ........................................................................................................... |

14 |

|

|

2.1.1.4 |

AUTOMATED MASS HANDLER ............................................................................................................. |

14 |

|

|

2.1.2 |

INSPECTING CONTENTS........................................................................................................................... |

14 |

|

|

2.1.2.1 |

PLATFORM.............................................................................................................................................. |

14 |

|

|

2.1.2.2 |

MASS SET ............................................................................................................................................... |

19 |

|

|

2.1.2.3 |

PISTON-CYLINDER MODULE(S) ........................................................................................................... |

21 |

|

2.2 |

SITE REQUIREMENTS.......................................................................................................................... |

22 |

|

|

2.3 |

SETUP.................................................................................................................................................... |

|

23 |

|

|

2.3.1 |

PREPARING FOR OPERATION ................................................................................................................. |

23 |

|

|

2.3.1.1 |

SETTING UP THE PLATFORM ............................................................................................................... |

23 |

|

|

2.3.1.2 |

SYSTEM PRESSURE INTERCONNECTIONS ....................................................................................... |

24 |

|

|

2.3.1.3 |

SETTING UP A MASS SET ..................................................................................................................... |

24 |

|

|

2.3.2 INSTALLING A PISTON-CYLINDER MODULE INTO THE PLATFORM.................................................... |

25 |

|

|

|

2.3.3 SWITCHING A PG7202 BETWEEN GAS OPERATION AND OIL OPERATION ....................................... |

27 |

|

|

2.4 POWER UP AND VERIFICATION ......................................................................................................... |

28 |

||

|

|

2.4.1 |

POWER UP.................................................................................................................................................. |

28 |

2.4.2CHECK THAT ON-BOARD PISTON-CYLINDER MODULE AND MASS SET INFORMATION ARE

|

CORRECT.................................................................................................................................................... |

29 |

2.4.3 |

SET LOCAL GRAVITY VALUE ................................................................................................................... |

29 |

2.4.4 |

SETUP PRESSURE EQUATION VARIABLE INPUT SOURCES ..................................................... |

29 |

Page I |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

2.4.5 |

CHECK PROPER OPERATION OF AMBIENT CONDITION MEASUREMENTS ...................................... |

29 |

2.4.6 |

APPLY PRESSURE TO THE PISTON-CYLINDER MODULE .................................................................... |

30 |

2.4.7 |

CHECK PROPER BEHAVIOR OF MOTORIZED PISTON ROTATION (IF PRESENT).............................. |

30 |

2.4.8 |

CHECK PROPER OPERATION OF PISTON BEHAVIOR MEASUREMENTS........................................... |

31 |

2.4.8.1 |

VERIFY VACUUM REFERENCE (PG7601 ONLY) ................................................................................. |

31 |

2.4.9 |

CHECK AUTOMATED PRESSURE GENERATION (IF PRESENT) .................................................... |

32 |

2.4.10 |

CHECK/SET SECURITY LEVEL................................................................................................................. |

32 |

2.4.11 |

ADDITIONAL PRECAUTIONS TO TAKE BEFORE MAKING PRESSURE MEASUREMENTS ................ |

32 |

2.5 SHORT TERM STORAGE ..................................................................................................................... |

33 |

|

3. GENERAL OPERATION ..................................................... |

35 |

3.1 FUNDAMENTAL OPERATING PRINCIPLES........................................................................................ |

35 |

3.1.1GAS OPERATED, LIQUID LUBRICATED PISTON-CYLINDER OPERATING PRINCIPLE

|

|

(PG7202) .................................................................................................................................................... |

36 |

||||

3.2 |

KEYPAD LAYOUT AND PROTOCOL ................................................................................................... |

37 |

|||||

3.3 |

SOUNDS ................................................................................................................................................ |

38 |

|||||

3.4 |

PRESSURE READY/NOT READY INDICATION................................................................................... |

38 |

|||||

|

3.4.1 |

PISTON POSITION READY/NOT READY .................................................................................................. |

39 |

||||

|

3.4.2 |

PISTON ROTATION READY/NOT READY................................................................................................. |

39 |

||||

|

3.4.3 |

VACUUM REFERENCE READY/NOT READY (PG7601 ONLY) ..................................................... |

40 |

||||

3.5 |

PISTON POSITION ................................................................................................................................ |

41 |

|||||

3.6 |

MASS LOADING PROTOCOL............................................................................................................... |

42 |

|||||

3.7 |

MAIN RUN SCREEN.............................................................................................................................. |

45 |

|||||

3.8 |

GENERAL FUNCTION/MENU FLOW CHART ...................................................................................... |

46 |

|||||

3.9 |

DIRECT FUNCTION KEYS .................................................................................................................... |

47 |

|||||

|

3.9.1 |

DIRECT FUNCTION KEYS SUMMARY ...................................................................................................... |

47 |

||||

|

3.9.2 |

[P-C]............................................................................................................................................................. |

48 |

||||

|

3.9.3 |

[UNIT]........................................................................................................................................................... |

49 |

||||

|

3.9.3.1 |

|

CUSTOMIZING PRESSURE UNITS AVAILABLE UNDER THE UNIT FUNCTION ................................ |

50 |

|||

|

3.9.4 |

[MODE] ........................................................................................................................................................ |

52 |

||||

|

3.9.4.1 |

|

DIFFERENTIAL MEASUREMENT MODE (PG7601 ONLY) ........................................................ |

53 |

|||

|

3.9.4.2 |

|

HIGH LINE DIFFERENTIAL MEASUREMENT MODE (PG7102, PG7302 AND PG7202 ONLY)........... |

60 |

|||

|

3.9.5 |

[SYSTEM] .................................................................................................................................................... |

72 |

||||

|

3.9.5.1 |

|

FIRST SYSTEM RUN SCREEN .............................................................................................................. |

73 |

|||

|

3.9.5.2 |

|

SECOND SYSTEM RUN SCREEN ......................................................................................................... |

73 |

|||

|

3.9.6 |

[AMBIENT]................................................................................................................................................... |

74 |

||||

|

3.9.7 |

[HEAD] ......................................................................................................................................................... |

75 |

||||

|

3.9.8 |

[ROTATE]..................................................................................................................................................... |

77 |

||||

|

3.9.8.1 |

|

<2PRE-DECEL>....................................................................................................................................... |

79 |

|||

|

3.9.9 |

[GEN] (OPTIONAL)...................................................................................................................................... |

79 |

||||

|

3.9.9.1 |

|

<2TARGET>............................................................................................................................................. |

81 |

|||

|

3.9.9.2 |

|

<3RAISE> ................................................................................................................................................ |

82 |

|||

|

3.9.9.3 |

|

<4UL>....................................................................................................................................................... |

82 |

|||

|

3.9.9.4 |

|

<5TOL> .................................................................................................................................................... |

82 |

|||

|

3.9.9.5 |

|

<6REFLOAT>........................................................................................................................................... |

83 |

|||

|

3.9.9.6 |

|

<7VOL>.................................................................................................................................................... |

83 |

|||

|

3.9.10 |

[RES]............................................................................................................................................................ |

84 |

||||

|

3.9.11 |

[ENTER/SET P] FROM RUN SCREEN ....................................................................................................... |

85 |

||||

|

3.9.11.1 |

|

[ENTER/SET P] IN PRESSURE TO MASS MODE ................................................................................. |

86 |

|||

|

3.9.11.2 |

|

[ENTER/SET P] IN MASS TO PRESSURE MODE ................................................................................. |

88 |

|||

|

3.9.11.3 COMMANDS FOR ZERO PRESSURE, ENDING A TEST ..................................................... |

89 |

|||||

|

3.9.12 |

[P OR M] ...................................................................................................................................................... |

89 |

||||

|

3.9.13 |

[ |

|

] AND [ |

|

], [←] |

90 |

|

|

|

|||||

|

|

|

|||||

3.10 |

[SETUP] MENU...................................................................................................................................... |

91 |

|||||

|

3.10.1 |

<1SELECT> ................................................................................................................................................. |

93 |

||||

|

3.10.2 |

<2VIEW> ...................................................................................................................................................... |

93 |

||||

|

3.10.3 |

<3EDIT> ....................................................................................................................................................... |

94 |

||||

3.11 |

[SPECIAL] MENU .................................................................................................................................. |

96 |

|||||

|

3.11.1 |

<1PC/MS>.................................................................................................................................................... |

97 |

||||

|

3.11.1.1 |

|

CREATE PISTON-CYLINDER MODULE................................................................................................. |

98 |

|||

|

3.11.1.2 |

|

EDIT PISTON-CYLINDER MODULE ..................................................................................................... |

101 |

|||

|

3.11.1.3 |

|

VIEW PISTON-CYLINDER MODULE .................................................................................................... |

101 |

|||

|

3.11.1.4 |

|

DELETE PISTON-CYLINDER MODULE ............................................................................................... |

102 |

|||

|

3.11.1.5 SELECT THE ACTIVE PISTON-CYLINDER MODULE ......................................................................... |

102 |

|||||

|

3.11.1.6 |

|

ADD MASS SET..................................................................................................................................... |

102 |

|||

© 1998-2008 DH Instruments, a Fluke Company |

Page II |

|

|

TABLE OF CONTENTS |

|

|

3.11.1.7 |

EDIT MASS SET.................................................................................................................................... |

107 |

|

3.11.1.8 |

VIEW MASS SET................................................................................................................................... |

107 |

|

3.11.1.9 |

DELETE MASS SET .............................................................................................................................. |

107 |

|

3.11.1.10 |

SELECT MASS SET .............................................................................................................................. |

108 |

|

3.11.1.11 |

ADD MASS LOADING BELL.................................................................................................................. |

108 |

|

3.11.1.12 |

EDIT MASS LOADING BELL ................................................................................................................. |

110 |

|

3.11.1.13 |

VIEW MASS LOADING BELL................................................................................................................ |

110 |

|

3.11.1.14 |

DELETE MASS LOADING BELL ........................................................................................................... |

110 |

|

3.11.1.15 |

SELECT MASS LOADING BELL ........................................................................................................... |

111 |

|

3.11.2 |

<2PRESU>................................................................................................................................................. |

111 |

|

3.11.3 |

<3HEAD> ................................................................................................................................................... |

111 |

|

3.11.3.1 |

<3HEAD>, <1FLUID>............................................................................................................................. |

112 |

|

3.11.3.2 |

<3HEAD>, <2UNIT>............................................................................................................................... |

112 |

|

3.11.3.3 |

<3HEAD>, <3ATM> ............................................................................................................................... |

113 |

|

3.11.3.4 |

<3HEAD>, <4PISTON>.......................................................................................................................... |

113 |

|

3.11.4 |

<4PREFS> ................................................................................................................................................. |

114 |

|

3.11.4.1 |

<4PREFS>, <1SCRSVR>...................................................................................................................... |

114 |

|

3.11.4.2 |

<4PREFS>, <2SOUND>........................................................................................................................ |

114 |

|

3.11.4.3 |

<4PREFS>, <3TIME> ............................................................................................................................ |

115 |

|

3.11.4.4 |

<4PREFS>, <4ID> ................................................................................................................................. |

115 |

|

3.11.4.5 |

<4PREFS>, <5LEVEL>.......................................................................................................................... |

116 |

|

3.11.5 |

<5REMOTE>.............................................................................................................................................. |

118 |

|

3.11.5.1 |

COM1, COM2 AND COM3 (RS232) ...................................................................................................... |

119 |

|

3.11.5.2 |

IEEE-488................................................................................................................................................ |

119 |

|

3.11.5.3 |

RS232 SELF TEST ................................................................................................................................ |

120 |

|

3.11.5.4 |

EXTERNAL BAROMETER (RPM) COMMUNICATIONS (COM2)......................................................... |

120 |

|

3.11.5.5 |

EXTERNAL VACUUM GAUGE COMMUNICATIONS (COM2) (PG7601 ONLY) .................................. |

122 |

|

3.11.6 |

<6GL> ........................................................................................................................................................ |

124 |

|

3.11.7 |

<7CAL> ...................................................................................................................................................... |

125 |

|

3.11.8 |

<8AMH> ..................................................................................................................................................... |

125 |

|

3.11.8.1 |

<2CONTROL>, <1UP/DOWN> .............................................................................................................. |

126 |

|

3.11.8.2 |

<2CONTROL>, <2DISCREET> ............................................................................................................. |

126 |

|

3.11.8.3 |

<2CONTROL>, <3LOADALL> ............................................................................................................... |

127 |

|

3.11.8.4 |

<2CONTROL>, <4UNLOADALL> .......................................................................................................... |

127 |

|

3.11.9 |

<9RESET> ................................................................................................................................................. |

127 |

|

3.11.9.1 |

<9RESET>, <1SETS> ........................................................................................................................... |

128 |

|

3.11.9.2 |

<9RESET>, <2UNITS> .......................................................................................................................... |

128 |

|

3.11.9.3 |

<9RESET>, <3COM>............................................................................................................................. |

129 |

|

3.11.9.4 |

<9RESET>, <4CAL>.............................................................................................................................. |

129 |

|

3.11.9.5 |

<9RESET>, <5SETUPS> ...................................................................................................................... |

130 |

|

3.11.9.6 |

<9RESET>, <6ALL> .............................................................................................................................. |

130 |

4. REMOTE OPERATION ...................................................... |

131 |

||

4.1 |

OVERVIEW .......................................................................................................................................... |

131 |

|

4.2 |

INTERFACING ..................................................................................................................................... |

131 |

|

|

4.2.1 |

RS232 INTERFACE ................................................................................................................................... |

131 |

|

4.2.1.1 |

COM1 ..................................................................................................................................................... |

132 |

|

4.2.1.2 |

COM2 AND COM3 ................................................................................................................................. |

132 |

|

4.2.2 |

IEEE-488 (GPIB)........................................................................................................................................ |

133 |

4.3 |

COMMANDS ........................................................................................................................................ |

133 |

|

|

4.3.1 |

COMMAND SYNTAX ................................................................................................................................. |

133 |

|

4.3.2 |

COMMAND SUMMARY ............................................................................................................................. |

134 |

|

4.3.3 |

ERROR MESSAGES ................................................................................................................................. |

136 |

|

4.3.3.1 |

AMH ERRORS ....................................................................................................................................... |

137 |

|

4.3.4 |

COMMAND DESCRIPTIONS..................................................................................................................... |

137 |

|

4.3.4.1 |

IEEE STD. 488.2 COMMON AND STATUS COMMANDS ..................................................... |

137 |

|

4.3.4.2 |

PG7000 COMMANDS............................................................................................................................ |

139 |

4.4 |

STATUS SYSTEM................................................................................................................................ |

166 |

|

|

4.4.1 |

STATUS REPORTING SYSTEM ............................................................................................................... |

166 |

|

4.4.1.1 |

STATUS BYTE REGISTER ................................................................................................................... |

166 |

|

4.4.1.2 |

STANDARD EVENT REGISTER ........................................................................................................... |

167 |

4.5 HIGH LINE DIFFERENTIAL MODE PROGRAMMING EXAMPLES.................................................... |

168 |

||

4.5.1RECOMMENDED SEQUENCE FOR A HOST PROGRAM TO REMOTELY SET A NEW HIGH LINE

PRESSURE AND ENABLE HIGH LINE DIFFERENTIAL MODE.............................................................. |

168 |

4.5.2RECOMMENDED SEQUENCE FOR A HOST PROGRAM TO REMOTELY ENABLE HIGH LINE

DIFFERENTIAL MODE USING THE LAST LINE PRESSURE SETTING................................................. |

171 |

Page III |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION ........... |

173 |

||

5.1 |

INTRODUCTION .................................................................................................................................. |

173 |

|

5.2 |

PLATFORM.......................................................................................................................................... |

174 |

|

|

5.2.1 CALIBRATION/ADJUSTMENT OF ON-BOARD MEASUREMENT FUNCTIONS.................................... |

174 |

|

|

5.2.1.1 |

PRINCIPLES.......................................................................................................................................... |

174 |

|

5.2.1.2 |

BAROMETRIC PRESSURE SENSOR .................................................................................................. |

175 |

|

5.2.1.3 |

AMBIENT TEMPERATURE SENSOR ................................................................................................... |

175 |

|

5.2.1.4 |

RELATIVE HUMIDITY SENSOR ........................................................................................................... |

176 |

|

5.2.1.5 |

PISTON-CYLINDER MODULE TEMPERATURE SENSOR..................................................... |

176 |

|

5.2.1.6 |

REFERENCE VACUUM GAUGE (PG7601 ONLY) ............................................................................... |

178 |

|

5.2.2 |

PISTON POSITION DETECTION ADJUSTMENT..................................................................................... |

179 |

|

5.2.3 |

EMPTYING OIL RUN-OFF TRAY (PG7202 AND PG7302 ONLY)................................................. |

180 |

|

5.2.4 |

PURGE MOUNTING POST LIQUID RUN OFF (PG7202 ONLY) .............................................. |

180 |

|

5.2.5 |

DRIVE BELT REPLACEMENT.................................................................................................................. |

181 |

5.3 |

PISTON-CYLINDER MODULES.......................................................................................................... |

182 |

|

|

5.3.1 DISASSEMBLY, CLEANING AND MAINTENANCE ................................................................................. |

182 |

|

|

5.3.2 |

DISASSEMBLY AND REASSEMBLY ....................................................................................................... |

183 |

|

5.3.2.1 |

DISASSEMBLY AND REASSEMBLY OF GAS OPERATED, GAS LUBRICATED |

|

|

|

PISTON-CYLINDER MODULES (PC-7100/7600) ....................................................................... |

183 |

|

5.3.2.2 |

DISASSEMBLY AND REASSEMBLY OF GAS OPERATED, LIQUID LUBRICATED |

|

|

|

PISTON-CYLINDER MODULES (PC-7200) .......................................................................................... |

187 |

|

5.3.2.3 |

DISASSEMBLY AND REASSEMBLY OF OIL OPERATED, OIL LUBRICATED |

|

|

|

PISTON-CYLINDER MODULES (PC-7300) .......................................................................................... |

189 |

5.3.3FILLING OR EMPTYING GAS OPERATED, LIQUID LUBRICATED PISTON-CYLINDER MODULE

|

|

|

RESERVOIR WITH LIQUID ....................................................................................................................... |

191 |

|

|

5.3.4 |

CLEANING PISTON-CYLINDERS............................................................................................................. |

192 |

|

|

5.3.5 |

LUBRICATING PISTON-CYLINDER MODULES ...................................................................................... |

194 |

|

|

5.3.6 |

RECALIBRATION ...................................................................................................................................... |

198 |

|

|

5.3.6.1 |

UPDATING PISTON-CYLINDER MODULE FILES................................................................................ |

198 |

|

5.4 |

MASS SETS......................................................................................................................................... |

198 |

|

|

|

5.4.1 |

CLEANING................................................................................................................................................. |

198 |

|

|

5.4.2 |

RECALIBRATION ...................................................................................................................................... |

198 |

|

|

5.4.2.1 |

UPDATING MASS SET FILES............................................................................................................... |

198 |

|

5.5 |

RELOADING EMBEDDED SOFTWARE INTO PG7000 FLASH MEMORY........................................ |

199 |

|

|

5.6 |

DISASSEMBLY AND REASSEMBLY OF PG7000 ............................................................................. |

199 |

|

|

|

5.6.1 |

PLATFORM................................................................................................................................................ |

199 |

|

|

5.6.2 |

TERMINAL ................................................................................................................................................. |

199 |

|

|

5.6.3 AMH AUTOMATED MASS HANDLER REMOVAL ................................................................................... |

199 |

|

6. |

TROUBLESHOOTING ....................................................... |

201 |

||

|

6.1 |

OVERVIEW .......................................................................................................................................... |

201 |

|

7. |

APPENDIX ...................................................................... |

205 |

||

|

7.1 |

CONVERSION OF NUMERICAL VALUES.......................................................................................... |

205 |

|

|

|

7.1.1 |

PRESSURE................................................................................................................................................ |

205 |

|

7.2 |

DEFINED PRESSURE CALCULATIONS ............................................................................................ |

205 |

|

|

|

7.2.1 PG7102, PG7202 AND PG7302 ................................................................................................................ |

207 |

|

|

|

7.2.2 |

PG7601 ...................................................................................................................................................... |

208 |

|

|

7.2.3 |

FLUID HEADS ........................................................................................................................................... |

209 |

|

|

7.2.3.1 |

FLUID HEAD COMPONENTS ............................................................................................................... |

209 |

|

|

7.2.3.2 |

OVERALL FLUID HEAD CORRECTION ............................................................................................... |

210 |

|

7.3 |

GLOSSARY.......................................................................................................................................... |

211 |

|

|

7.4 |

WARRANTY STATEMENT .................................................................................................................. |

213 |

|

© 1998-2008 DH Instruments, a Fluke Company |

Page IV |

TABLES AND FIGURES

TABLES |

|

|

Table 1. |

PG7102 Parts List........................................................................................................................ |

15 |

Table 2. |

PG7202 Parts List........................................................................................................................ |

16 |

Table 3. |

PG7302 Parts List........................................................................................................................ |

17 |

Table 4. |

PG7601 Parts List........................................................................................................................ |

18 |

Table 5. |

Manual Mass Set Parts List (excluding 80 and 100 kg) .............................................................. |

19 |

Table 6. Manual Mass Set Parts List (80 and 100 kg)............................................................................... |

19 |

|

Table 7. AMH-38 Mass Set Parts List........................................................................................................ |

19 |

|

Table 8. AMH-100 Mass Set Parts List...................................................................................................... |

19 |

|

Table 9. Mass Set Compositions ............................................................................................................... |

20 |

|

Table 10. |

Mass Set Compatibility .............................................................................................................. |

20 |

Table 11. |

PC-7100/7600 Piston-Cylinder Modules Parts List ................................................................... |

21 |

Table 12. |

PC-7200 Piston-Cylinder Modules Parts List ............................................................................ |

21 |

Table 13. PC-7300 Piston-Cylinder Modules Parts List ........................................................................... |

22 |

|

Table 14. Summary of PG7000 Direct Function Key Operations .............................................................. |

47 |

|

Table 15. |

Pressure Units of Measure Available......................................................................................... |

51 |

Table 16. |

Valve Settings for Setting Differential Mode Static Pressure..................................................... |

56 |

Table 17. |

Valve Settings to Apply PG7000 Pressure to the RPM for Differential Mode Offsetting........... |

57 |

Table 18. |

Valve Settings for Operating in Differential Mode...................................................................... |

59 |

Table 19. SETUP File Choices, Factory Preferred Choice and Normal Value.......................................... |

92 |

|

Table 20. |

Security Levels - Functions NOT Executed Per Function/Level.............................................. |

117 |

Table 21. COM1, COM2 and COM3 Available Settings.......................................................................... |

119 |

|

Table 22. COM1 DB-9F Pin Designation................................................................................................. |

132 |

|

Table 23. COM2 and COM3 DB-9M Pin Designation ............................................................................. |

132 |

|

Table 24. Command Summary ................................................................................................................ |

134 |

|

Table 25. Error Messages........................................................................................................................ |

136 |

|

Table 26. |

Status Byte Register ................................................................................................................ |

166 |

Table 27. |

Standard Event Register.......................................................................................................... |

167 |

Table 28. |

Mounting Post Wire Colors, Description and Location ............................................................ |

178 |

Table 29. |

PG7000 Troubleshooting Checklist ......................................................................................... |

201 |

Table 30. Pressure Unit of Measure Conversions................................................................................... |

205 |

|

Table 31. |

PG7000 Defined Pressure Calculation Variables.................................................................... |

206 |

Table 32. |

DHI Authorized Service Providers ........................................................................................... |

213 |

Page V |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

FIGURES |

|

|

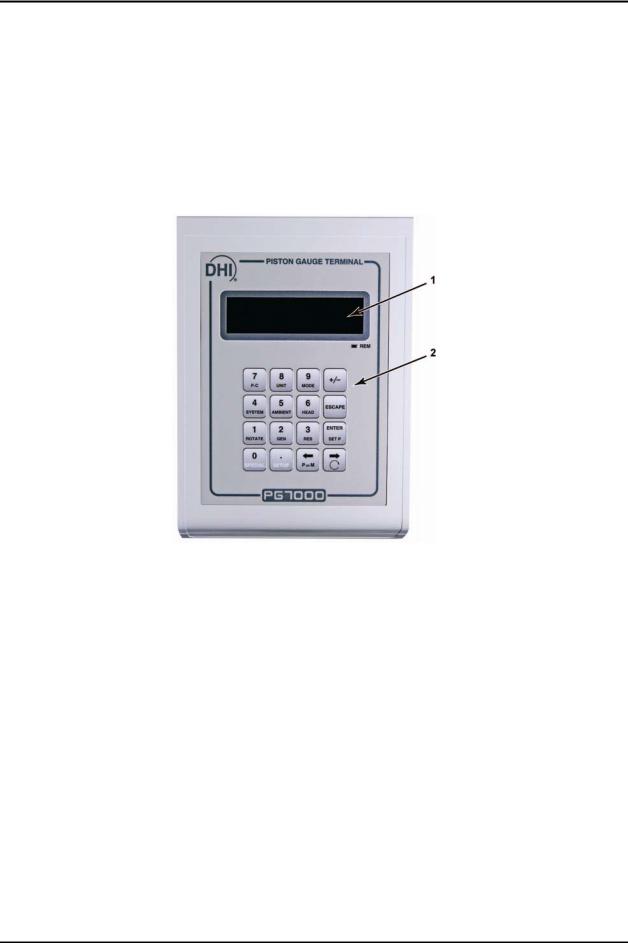

Figure 1. |

PG Terminal Front Panel ............................................................................................................ |

11 |

Figure 2. PG Terminal Rear Panel............................................................................................................. |

12 |

|

Figure 3. PG Platform Rear Panel ............................................................................................................. |

12 |

|

Figure 4. |

Piston-Cylinder Module Installation ............................................................................................ |

26 |

Figure 5. |

Piston Gauge Operating Principle .............................................................................................. |

35 |

Figure 6. |

Gas Operated, Liquid Lubricated Piston-Cylinder (PC-7200) Operating Principle ................... |

37 |

Figure 7. PG7000 Keypad Layout.............................................................................................................. |

37 |

|

Figure 8. |

Piston Stroke and Zones ............................................................................................................ |

41 |

Figure 9. Run Screen Flow Chart .............................................................................................................. |

46 |

|

Figure 10. |

Differential Mode Controller Schematic.................................................................................... |

55 |

Figure 11. |

High Line Differential Mode Schematic .................................................................................... |

63 |

Figure 12. |

Status Byte Register ............................................................................................................... |

166 |

Figure 13. PG7202 Mounting Post Drain................................................................................................. |

181 |

|

Figure 14. 10 and 20 kPa/kg Gas Piston-Cylinder Module (Expanded View) ......................................... |

184 |

|

Figure 15. |

10 kPa/kg Piston Insertion Tool.............................................................................................. |

185 |

Figure 16. |

Gas Piston-Cylinder Module Sleeve Nut Tool ........................................................................ |

185 |

Figure 17. 50, 100 and 200 kPa/kg Gas Piston-Cylinder Modules (Expanded View) ............................. |

186 |

|

Figure 18. |

Gas Operated, Liquid Lubricated Piston-Cylinder Module (Expanded View) ....................... |

188 |

Figure 19. |

Oil Piston-Cylinder Module (Expanded View) ........................................................................ |

190 |

Figure 20. |

Filling Gas Operated, Liquid Lubricated Piston-Cylinder Module Reservoir (PC-7200) ....... |

192 |

Figure 21. Gas Operated, Gas Lubricated Piston-Cylinder Module Lubrication Chart ............................ |

195 |

|

Figure 22. |

Gas Operated, Liquid Lubricated Piston-Cylinder Module Lubrication Chart ........................ |

196 |

Figure 23. |

Oil Operated Piston-Cylinder Module Lubrication Chart ........................................................ |

197 |

© 1998-2008 DH Instruments, a Fluke Company |

Page VI |

ABOUT THIS MANUAL

ABOUT THIS MANUAL

This manual provides the user with the information necessary to operate various PG7000 Piston Gauges. It also includes a great deal of additional information provided to help you optimize PG7000 use and take full advantage of its many features and functions.

This manual covers four PG7000 models: PG7102, PG7202, PG7302 and PG7601. The four models have many features and characteristics in common as well as individual differences. When discussing features that are common to all four models, they are referred to collectively as PG7000. When providing information pertaining to a specific model, that model is referred to by its specific model number.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure. All first time PG7000 users should read Sections 1 and 2. Section 3 provides a comprehensive description of general PG7000 operating principles. Section 4 covers remote communication with an external computer. Section 5 provides maintenance and calibration information. Section 6 is a quick troubleshooting guide. Use the information in Section 6 to troubleshoot unexpected PG7000 behavior based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to PG7000s. The Glossary (see Section 7) is useful as a quick reference for the definition of specific words and expressions as they are used in this manual.

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 2.3 TO SET UP YOUR PG7000. THEN GO TO SECTION 2.4. THIS WILL GET YOU RUNNING QUICKLY WITH MINIMAL RISK OF CAUSING DAMAGE TO YOURSELF OR YOUR PG7000. THEN… WHEN YOU HAVE QUESTIONS OR START TO WONDER ABOUT ALL THE GREAT FEATURES YOU MIGHT BE MISSING, GET INTO THE MANUAL!

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 2.3 TO SET UP YOUR PG7000. THEN GO TO SECTION 2.4. THIS WILL GET YOU RUNNING QUICKLY WITH MINIMAL RISK OF CAUSING DAMAGE TO YOURSELF OR YOUR PG7000. THEN… WHEN YOU HAVE QUESTIONS OR START TO WONDER ABOUT ALL THE GREAT FEATURES YOU MIGHT BE MISSING, GET INTO THE MANUAL!

Manual Conventions

(CAUTION) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and additional explanations.

(NOTE) is used throughout the manual to identify operating and applications advice and additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates PG7000 screen displays (e.g., <1yes>)

Page VII |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

NOTES

© 1998-2008 DH Instruments, a Fluke Company |

Page VIII |

1. INTRODUCTION

1.INTRODUCTION

1.1PRODUCT OVERVIEW

PG7000 Piston Gauges are reference level pressure standards that operate on the piston gauge principle. Pressure is defined by balancing it against the force exerted by a known mass accelerated by gravity on the effective area of a piston-cylinder.

A PG7000 piston gauge consists of the PG7000 Platform, one or several piston-cylinder modules, a mass set. An automated mass handling system is available. A PG7000 system normally also includes the means to generate and adjust pressures and to interconnect the system components and a device being calibrated or tested. The pressure generation component can be manual or automated. COMPASS® for Pressure software may also be included to assist in executing test sequences, acquiring test data and producing test reports.

There are four PG7000 Platforms: PG7102, PG7202, PG7302 and PG7601. These have a common PG7000 presentation and features. They are distinguished by their normal operating medium (oil and/or gas) and the capability to define pressures relative to a vacuum reference.

•PG7102 - Gas operated with gas lubricated piston-cylinder modules (PC-7100/7600 modules)

-Maximum pressure is 11 MPa (1 600 psi)

-Does not support definition of pressure against a vacuum reference

•PG7202 - Gas operated, liquid lubricated piston-cylinder modules (PC-7200 modules)

-Oil operated piston-cylinder modules (PC-7300 modules)

-Maximum pressure is 110 MPa (16 000 psi) when operated with a PC-7200 module

-Maximum pressure is 200 MPa (30 000 psi) when operated with a PC-7300 module

-Does not support definition of pressure against a vacuum reference

•PG7302 - Oil operated (PC-7300 modules)

-Maximum pressure is 500 MPa (72 500 psi)

•PG7601 - Gas operated, gas lubricated piston-cylinder modules (PC-7100/7600 modules)

-Maximum pressure is 7 MPa (1 000 psi)

-Supports definition of pressure against a vacuum reference

PG7000 platforms, piston-cylinder modules, mass sets and mass handling systems are designed to maximize metrological performance and ease of operation. They include many features that enhance the fundamental precision and stability of pressure measurements as well as simplifying use and reducing operator influence on the measurements. Extensive monitoring and controlling capability and advanced local and remote user interfaces are integrated into PG7000 Platforms.

Operator interaction with PG7000 and its extensive capabilities and peripherals is accomplished through a single display and keypad on the PG Terminal or from a computer via a single standard RS232 or IEEE-488 interface.

Page 1 |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2SPECIFICATIONS

1.2.1 |

GENERAL SPECIFICATIONS |

|||

Power Requirements |

85 to 264 VAC, 50/60 Hz, 22 VA max. consumption. |

|||

Operating Temperature Range |

15 to 35 °C |

|

||

Operating Humidity Range |

5 to 95% R.H., non-condensing |

|||

Weight |

|

|

|

|

Instrument platform with no mass loaded. |

|

|

|

|

|

PG7102 |

13 kg (29 lb) |

|

|

|

PG7202 |

13 kg (29 lb) |

|

|

|

PG7302 |

13 kg (29 lb) |

|

|

|

PG7601 |

17 kg (37 lb) |

|

|

|

PG Terminal |

1.4 kg (3 lb) |

|

|

Dimensions |

|

|

|

|

|

Instrument Platform |

36 cm H x 40 cm W x 35 cm D (14.5 in. x 15.8 in. x 13.8 in.) |

||

|

|

(Height: Top of mounting post with piston-cylinder module installed |

||

|

|

for PG7102/PG7202/PG7302; top of bell jar for PG7601.) |

||

|

PG Terminal |

12 cm H x 15 cm W x 20 cm D (4.7 in. H x 5.9 in. W x 7.9 in. D) |

||

Microprocessors |

|

|

|

|

|

Instrument Platform |

Motorola 68302 |

||

|

PG Terminal |

Hitachi 64180 |

|

|

Communication Ports |

|

|

|

|

|

RS232 |

COM1: Host computer |

||

|

|

COM2: External barometer or vacuum gauge (PG7601) and pass |

||

|

IEEE-488 |

through communications |

||

|

COM3: Automated pressure generator/controller Host computer |

|||

|

|

|||

Overall Pressure Ranges |

|

|

|

|

Actual range depends on piston-cylinder |

|

|

|

|

and mass set selection |

|

|

|

|

|

PG7102 |

Gauge: |

|

5 kPa to 11 MPa (0.7 to 1 600 psi) |

|

|

Absolute: |

|

105 kPa to 11 MPa (15 to 1 600 psi) |

|

|

Differential: |

DP + static pressure < 11 MPa (1 600 psi) |

|

|

PG7202 |

Gauge (gas): |

100 kPa to 110 MPa (15 to 16 000 psi) |

|

|

|

Absolute (gas):200 kPa to 110 MPa (30 to 16 000 psi) |

||

|

|

Gauge (oil): (PG7302 module): 1 to 200 MPa (150 to 30 000 psi) |

||

|

|

Absolute (oil): (PG7302 module) 1.1 to 200 MPa (165 to 30 000 psi) |

||

|

|

Differential: |

DP + static pressure < 110 MPa (16 000 psi) |

|

|

|

PC-7200 can be operated in oil up to 200 MPa (30 000 psi) |

||

|

|

when used with PC-7300 oil operated piston-cylinders. |

||

|

PG7302 |

Gauge: |

|

20 kPa to 500 MPa (3 to 75 000 psi) |

|

|

Absolute: |

|

120 kPa to 500 MPa (20 to 75 000 psi) |

|

PG7601 |

Gauge: |

|

4 kPa to 7 MPa (0.6 to 1 000 psi) |

|

|

Absolute: |

|

7 kPa to 7 MPa (0.7 to 1 000 psi) |

|

|

Differential: |

- 90 to 350 kPa (-13 to 50 psi) at |

|

|

|

|

|

15 to 200 kPaa (2 to 30 psia) static pressure |

Operating Media |

|

|

|

|

|

PG7102 |

Gas: |

air, helium, nitrogen |

|

|

PG7202 |

Gas: |

any non-corrosive |

|

|

|

Oil: |

Di2-EthylHexyl Sebacate (synthetic oil) |

|

|

PG7302 |

Oil: |

Di2-EthylHexyl Sebacate (synthetic oil) |

|

|

PG7601 |

Gas: |

air, helium, nitrogen |

|

© 1998-2008 DH Instruments, a Fluke Company |

Page 2 |

1. INTRODUCTION

Maximum Mass Load

PG7102 100 kg, while not exceeding 11 MPa (1 600 psi)

PG7202 100 kg, while not exceeding 110 MPa (16 000 psi) when operated with PC-7200 piston-cylinder modules or 200 MPa (30 000 psi) when operated with PC-7300 piston-cylinder modules

PG7302 |

100 kg |

|

|

|

|

|

|

PG7601 |

38 kg |

|

|

|

|

|

|

Pressure Connections |

|

|

|

|

|

|

|

PG7102 |

Test port: |

DH200 |

|

|

|

|

|

PG7202 |

Test port: |

DH500 |

|

|

|

|

|

|

Drain port: |

DH500 |

|

|

|

|

|

PG7302 |

Test port: |

DH500 |

|

|

|

|

|

PG7601 |

Test port: |

DH200 |

|

|

|

|

|

|

Bell Jar Vent Port: |

DH200 |

|

|

|

|

|

|

Vacuum Reference |

|

|

|

|

|

|

|

Pump Down Port: |

KF25 (KF40 available on optional AMH |

|

||||

|

|

|

automated mass handler) |

|

|

|

|

|

External Vacuum Port: Optional KF25 on bell jar (KF40 available |

|

|||||

|

|

|

on optional AMH automated mass handler) |

||||

|

DH200 |

and |

DH500 are gland and collar |

type |

fittings |

for |

|

|

1/4 in. (6.35 mm) coned and |

left hand |

threaded tubes. |

||||

|

DH200 is |

equivalent to AE |

SF250C, |

HIP |

LF4, |

etc. |

|

DH500 is equivalent to AE F250C, HIP HF4, etc.

CE Conformance |

Available, must be specified. |

1.2.1.1 EMBEDDED FEATURES

•Local control with 2 x 20 vacuum fluorescent display and 4 x 4 function driven keypad.

•Real time (1 second update rate) display and measurement of ambient (pressure, temperature, humidity) and instrument (piston-cylinder temperature, piston position, piston drop rate, piston rotation rate, piston rotation decay rate, reference vacuum) conditions.

•Real time (1 second update rate) mass-to-pressure and pressure-to-mass calculations taking into consideration all environmental and operational variables.

•Full gas and liquid fluid head corrections including DUT head correction and piston position head correction.

•Adjustable mass loading resolution (0.01 g to 0.1 kg).

•Audible prompts of instrument status (piston movement, Ready/Not Ready indication) with override capability.

•Integrated automated mass handling option (AMH-38 or AMH-100).

•Interfacing and automatic exploitation of external barometer via RS232.

•Interfacing and automatic exploitation of any external vacuum gauge via RS232 (PG7601 only).

•Automated differential mode to define low differential pressures at various static pressures between vacuum and two atmospheres.

•Automated high line differential mode to define differential pressure at high line pressure.

Page 3 |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

•Storage and one step activation of metrological data on up to 18 piston-cylinder modules, (3) mass sets and (3) mass loading bells.

•Continuous pressure Ready/Not Ready indication based on measured conditions.

•Motorized, intelligent piston drive system based measured rotation rate with operator alert and manual override (motorization optional on PG7102 and PG7302).

•Integrated automated pressure control with standard DHI pressure controllers.

•Full RS232 and IEEE-488 communications with multi-level commands to set and read all instrument functions.

1.2.1.2 AMBIENT AND INSTRUMENT CONDITION MEASUREMENTS

Temperature |

Ambient |

Piston Cylinder Module |

Range |

0 to 40 o C |

0 to 40 oC |

Resolution |

0.1 |

0.01 |

Measurement Uncertainty |

± 1 |

± 0.1 |

Barometric Pressure |

|

|

with Internal Sensor |

|

|

Range |

70 to 110 kPa |

|

Resolution |

10 Pa |

|

Measurement Uncertainty |

± 140 Pa |

|

|

Barometric pressure can also be read automatically with any |

|

|

RS232 device such as a DHI RPM. |

|

Relative Humidity |

|

|

Range |

5 to 95 % RH |

|

Resolution |

1 % RH |

|

Measurement Uncertainty |

± 10 % RH |

|

Piston Position |

|

|

Range |

± 4.5 mm |

|

Resolution |

0.1 mm |

|

Measurement Uncertainty |

± 0.2 mm |

|

Piston Rotation |

|

|

(Rate and deceleration) |

|

|

Range |

2 to 99 rpm |

|

Resolution |

1 rpm |

|

Vacuum |

|

|

(PG7601 only) |

|

|

Range |

0 to 20 Pa |

|

Resolution |

0.01 Pa |

|

Measurement Uncertainty |

± 0.1 Pa or 10 % of reading, whichever is greater |

|

© 1998-2008 DH Instruments, a Fluke Company |

Page 4 |

1. INTRODUCTION

1.2.2 PISTON-CYLINDER MODULES

All piston-cylinders are integrated modules including mounting hardware delivered in individual shipping and storage bullet cases.

1.2.2.1 PC-7100/7600

Gas operated, gas lubricated piston-cylinder characteristics. Used in PG7102 and PG7601 platforms.

PC-7100/7600-10, TC

PC-7100/7600-10-L

Operation |

Gas operated, gas lubricated |

Piston Material |

Tungsten carbide |

Cylinder Material |

Tungsten carbide |

Nominal Diameter |

35 mm |

Nominal Area |

1 000 mm2 |

Mounting System |

Simple free deformation |

PC-7100/7600-20 |

|

Operation |

Gas operated, gas lubricated |

Piston Material |

Tungsten carbide |

Cylinder Material |

Tungsten carbide |

Nominal Diameter |

25 mm |

Nominal Area |

500 mm2 |

Mounting System |

Simple free deformation |

PC-7100/7600-50 |

|

Operation |

Gas operated, gas lubricated |

Piston Material |

Tungsten carbide |

Cylinder Material |

Tungsten carbide |

Nominal Diameter |

16 mm |

Nominal Area |

200 mm2 |

Mounting system |

Negative free deformation |

PC-7100/7600-100 |

|

Operation |

Gas operated, gas lubricated |

Piston Material |

Tungsten carbide |

Cylinder Material |

Tungsten carbide |

Nominal Diameter |

11 mm |

Nominal Area |

98 mm2 |

Mounting System |

Negative free deformation |

PC-7100/7600-200 |

|

Operation |

Gas operated, gas lubricated |

Piston Material |

Tungsten carbide |

Cylinder Material |

Tungsten carbide |

Nominal Diameter |

8 mm |

Nominal Area |

50 mm2 |

Mounting System |

Negative free deformation |

Page 5 |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.2.2 PC-7200

Gas operated, liquid lubricated piston-cylinder module characteristics. Used in PG7202 platform.

Though not recommended for day-to-day operation, PC-7200 modules can also be filled completely with oil and operated with oil as the test medium (see Section 2.3.3).

Though not recommended for day-to-day operation, PC-7200 modules can also be filled completely with oil and operated with oil as the test medium (see Section 2.3.3).

PC-7200-100 |

|

Operation |

Gas operated, liquid lubricated |

Lubricating Liquid |

Synturion 6 (Krytox® optional) |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

11.2 mm |

Nominal Area |

98.1 mm2 |

Mounting System |

Negative free deformation |

PC-7200-200 |

|

Operation |

Gas operated, liquid lubricated |

Lubricating Liquid |

Synturion 6 (Krytox® optional) |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

7.9 mm |

Nominal Area |

49.0 mm2 |

Mounting System |

Negative free deformation |

PC-7200-500 |

|

Operation |

Gas operated, liquid lubricated |

Lubricating Liquid |

Di-2-ethylhexyl Sebacate (Krytox® optional) |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

5.0 mm |

Nominal Area |

19.6 mm2 |

Mounting System |

Negative free deformation |

PC-7200-1 |

|

Operation |

Gas operated, liquid lubricated |

Lubricating Liquid |

Di-2-ethylhexyl Sebacate (Krytox® optional) |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

3.5 mm |

Nominal Area |

9.8 mm2 |

Mounting System |

Negative free deformation |

PC-7200-2 |

|

Operation |

Gas operated, liquid lubricated |

Lubricating Liquid |

Di-2-ethylhexyl Sebacate (Krytox® optional) |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

2.5 mm |

Nominal Area |

4.9 mm2 |

Mounting System |

Negative free deformation |

© 1998-2008 DH Instruments, a Fluke Company |

Page 6 |

1. INTRODUCTION

1.2.2.3 PC-7300

Oil operated, oil lubricated piston-cylinder module characteristics. Used in PG7302 and PG7202 platforms (1 MPa/kg and higher only in PG7202).

PC-7300 modules PC-7300-1, -2 and -5 may also be used in a PG7202 platform.

PC-7300 modules PC-7300-1, -2 and -5 may also be used in a PG7202 platform.

PC-7300-100 |

|

Operation |

Oil operated, oil lubricated |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

11.2 mm |

Nominal Area |

98.1 mm2 |

Mounting System |

Simple free deformation |

PC-7300-200 |

|

Operation |

Oil operated, oil lubricated |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

7.9 mm |

Nominal Area |

49.0 mm2 |

Mounting System |

Simple free deformation |

PC-7300-500 |

|

Operation |

Oil operated, oil lubricated |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

5.0 mm |

Nominal Area |

19.6 mm2 |

Mounting System |

Simple free deformation |

PC-7300-1 |

|

Operation |

Oil operated, oil lubricated |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

3.5 mm |

Nominal Area |

9.8 mm2 |

Mounting System |

Simple free deformation |

PC-7300-2 |

|

Operation |

Oil operated, oil lubricated |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

2.5 mm |

Nominal Area |

4.9 mm2 |

Mounting System |

Simple free deformation |

PC-7300-5 |

|

Operation |

Oil operated, oil lubricated |

Piston and Cylinder Material |

Tungsten carbide |

Nominal Diameter |

1.6 mm |

Nominal Area |

2.0 mm2 |

Mounting System |

Simple free deformation |

Page 7 |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.3 MASS SETS

All masses are delivered in molded, reusable, transit cases with custom inserts.

Masses > 50g |

|

Material |

304L non-magnetic stainless steel |

Finish |

Electropolished |

Adjustment Tolerance |

± 20 ppm of nominal value (manual mass sets, AMH |

|

automated mass handler mass sets do not have fixed |

|

adjustment tolerances) |

Uncertainty of Measured Values |

± 5 ppm or 1 mg, whichever is greater |

Masses < 50g |

± 1 mg |

Masses designated “tare” are delivered without reported measured values and are intended only for use on the “tare” PG7000 in high line differential pressure measurement mode.

Masses designated “tare” are delivered without reported measured values and are intended only for use on the “tare” PG7000 in high line differential pressure measurement mode.

1.2.4 PRESSURE MEASUREMENTS

1.2.4.1 PC-7100/7600

For uncertainty in piston-cylinder effective area and typical measurement uncertainty in pressure defined by the piston gauge, see the piston-cylinder calibration report and current revision of DHI Technical Note 7920TN01.

For uncertainty in piston-cylinder effective area and typical measurement uncertainty in pressure defined by the piston gauge, see the piston-cylinder calibration report and current revision of DHI Technical Note 7920TN01.

PC-7100/7600-10

PC-7100/7600-10-L

Sensitivity1 |

0.02 Pa + 0.5 ppm |

Reproducibility2 |

± 2 ppm |

Typical Drop Rate (35 kg) |

0.2 mm/min |

PC-7100/7600-20 |

|

Sensitivity1 |

0.04 Pa + 0.5 ppm |

Reproducibility2 |

± 2 ppm |

Typical Drop Rate (35 kg) |

0.3 mm/min |

PC-7100/7600-50 |

|

Sensitivity1 |

0.1 Pa + 0.5 ppm |

Reproducibility2 |

± 2 ppm |

Typical Drop Rate (35 kg) |

0.5 mm/min |

PC-7100/7600-100 |

|

Sensitivity1 |

0.2 Pa + 0.5 ppm |

Reproducibility2 |

± 3 ppm |

Typical Drop Rate (35 kg) |

0.7 mm/min |

PC-7100/7600-200 |

|

Sensitivity1 |

0.4 Pa + 0.5 ppm |

Reproducibility2 |

± 3 ppm |

Typical Drop Rate (35 kg) |

1.0 mm/min |

1Sensitivity: The smallest variation in input detectable in output.

2Reproducibility: Combined long term stability of piston-cylinder effective area and masses.

© 1998-2008 DH Instruments, a Fluke Company |

Page 8 |

1. INTRODUCTION

Piston-cylinder modules designated “tare” are delivered without reported values and are intended only for use on the “tare” PG7000 in high line differential pressure measurement mode.

Piston-cylinder modules designated “tare” are delivered without reported values and are intended only for use on the “tare” PG7000 in high line differential pressure measurement mode.

1.2.4.2 PC-7200

For uncertainty in piston-cylinder effective area and typical measurement uncertainty in pressure defined by the piston gauge, see the piston-cylinder calibration report and current revision of DHI Technical Note 7920TN01.

For uncertainty in piston-cylinder effective area and typical measurement uncertainty in pressure defined by the piston gauge, see the piston-cylinder calibration report and current revision of DHI Technical Note 7920TN01.

PC-7200-100 |

|

Sensitivity1 |

2 Pa + 1 ppm |

Reproducibility2 |

± 5 ppm |

Typical Drop Rate (50 kg) |

0.10 mm/min |

PC-7200-200 |

|

Sensitivity1 |

4 Pa + 1 ppm |

Reproducibility2 |

± 5 ppm |

Typical Drop Rate (50 kg) |

0.15 mm/min |

PC-7200-500 |

|

Sensitivity1 |

10 Pa + 1 ppm |

Reproducibility2 |

± 5 ppm |

Typical Drop Rate (50 kg) |

0.20 mm/min |

PC-7200-1 |

|

Sensitivity1 |

20 Pa + 1 ppm |

Reproducibility2 |

± 5 ppm |

Typical Drop Rate (50 kg) |

0.25 mm/min |

PC-7200-2 |

|

Sensitivity1 |

40 Pa + 1 ppm |

Reproducibility2 |

± 5 ppm |

Typical Drop Rate (50 kg) |

0.50 mm/min |

1Sensitivity: The smallest variation in input detectable in output.

2Reproducibility: Combined long term stability of piston-cylinder effective area and masses.

Page 9 |

© 1998-2008 DH Instruments, a Fluke Company |

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.4.3 PC-7300

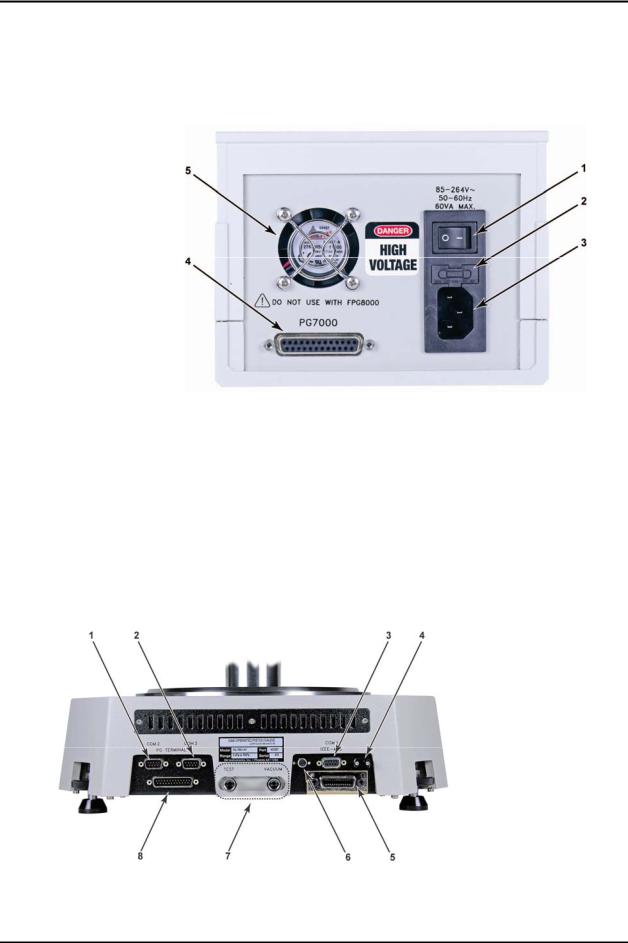

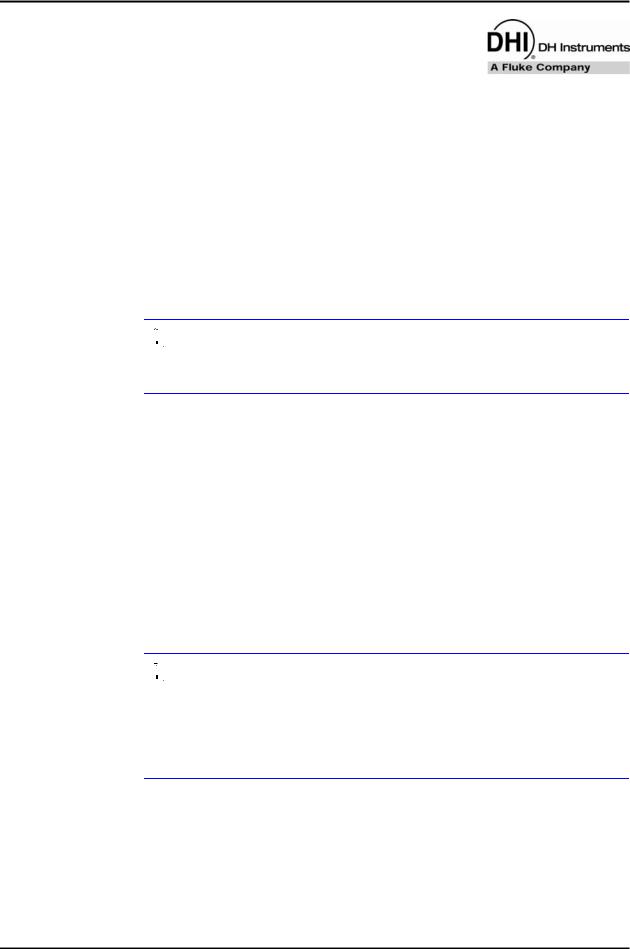

For uncertainty in piston-cylinder effective area and typical measurement uncertainty in pressure defined by the piston gauge, see the piston-cylinder calibration report and current revision of DHI Technical Note 7920TN01.