Page 1

USER INSTRUCTIONS

T-series Thrust Bearing Pot

Installation

Operation

Thrust bearing pots for vertical wet pit pumps

PCN=26999907 01-2013 (E). Original instructions.

Maintenance

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

CONTENTS

Page

1 INTRODUCTION AND SAFETY ....................... 3

1.1 General ....................................................... 3

1.2 CE marking and approvals ........................... 3

1.3 Disclaimer ................................................... 3

1.4 Copyright ..................................................... 3

1.5 Duty conditions ............................................ 3

1.6 Safety .......................................................... 4

2 TRANSPORT AND STORAGE ......................... 6

2.1 Consignment receipt and unpacking ............ 7

2.2 Handling ...................................................... 7

2.3 Lifting .......................................................... 7

2.4 Storage ....................................................... 7

2.5 Recycling and end of product life ................. 7

3 DESCRIPTION ................................................. 7

3.1 Configurations ............................................. 7

3.2 Name nomenclature .................................... 7

3.3 Design of major parts ................................... 7

3.4 Performance and operating limits ................. 8

4 INSTALLATION .............................................. 10

4.1 Thrust bearing pot installation .................... 10

4.2 Optional Bearing Gard™ installation .......... 10

4.3 Optional Lifeseal™ installation ................... 11

4.4 Thrust bearing pot installation with optional

Bearing Gard™/Lifeseal™ sealing ............. 11

4.5 Pump vertical axial play adjustment ........... 12

4.6 Lubrication and cooling requirements ......... 12

4.7 Motor stand and flexible coupling ............... 12

6 MAINTENANCE ............................................. 13

6.1 General ..................................................... 13

6.2 Maintenance schedule ............................... 14

6.3 Spare parts ................................................ 14

6.4 Tools required ............................................ 15

6.5 Fastener torques ....................................... 15

6.6 Disassembly .............................................. 15

6.7 Examination of parts .................................. 15

6.8 Assembly ................................................... 15

7 FAULTS; CAUSES AND REMEDIES .............. 18

8 PARTS LISTS AND DRAWINGS ..................... 19

8.1 7000s series .............................................. 19

8.2 7000s + 6000s series ................................. 20

8.3 29000s + 22000s series ............................. 21

8.4 7000s + 6000s series with Bearing Gard™

seal and Lifeseal™ .................................... 22

8.5 General arrangement drawing .................... 23

9 CERTIFICATION ............................................ 23

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS ...................................................... 23

10.1 Supplementary User Instruction manuals ... 23

10.2 Change notes ............................................ 23

10.3 Additional sources of information ............... 23

Page

5 COMMISSIONING, START-UP, OPERATION

AND SHUTDOWN .......................................... 12

5.1 Pre-commissioning procedure ................... 12

5.2 Lubrication ................................................. 13

Page 2 of 24 flowserve.com

Page 3

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

1 INTRODUCTION AND SAFETY

1.1 General

These Instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilising sophisticated quality techniques and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted

use. Operating the product in compliance with

these instructions is important to help ensure

reliability in service and avoid risks. The

instructions may not take into account local

regulations; ensure such regulations are observed

by all, including those installing the product.

Always coordinate repair activity with operations

personnel, and follow all plant safety requirements

and applicable safety and health laws and

regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety, noted in the

instructions, have been met. Failure to follow

and apply the present user instructions is

considered to be misuse. Personal injury,

product damage, delay or failure caused by

misuse are not covered by the Flowserve

warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment,

Electromagnetic Compatibility (EMC), Pressure

Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory

provision of technical documents and safety

instructions. Where applicable this document

incorporates information relevant to these Directives

and Approvals.

To confirm the Approvals applying and if the product

is CE marked, check the serial number plate

markings and the Certification. (See section 9,

Certification.)

1.3 Disclaimer

Information in these User Instructions is

believed to be complete and reliable. However,

in spite of all of the efforts of Flowserve

Corporation to provide comprehensive

instructions, good engineering and safety

practice should always be used.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality Assurance

organisations. Genuine parts and accessories have

been designed, tested and incorporated into the

products to help ensure their continued product

quality and performance in use. As Flowserve cannot

test parts and accessories sourced from other

vendors the incorrect incorporation of such parts and

accessories may adversely affect the performance

and safety features of the products. The failure to

properly select, install or use authorised Flowserve

parts and accessories is considered to be misuse.

Damage or failure caused by misuse is not covered

by the Flowserve warranty. In addition, any

modification of Flowserve products or removal of

original components may impair the safety of these

products in their use.

1.4 Copyright

All rights reserved. No part of these instructions

may be reproduced, stored in a retrieval system or

transmitted in any form or by any means without

prior permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been

sent separately to the Purchaser. A copy should be

kept with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

Page 3 of 24 flowserve.com

Page 4

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

product for the application intended, contact

Flowserve for advice, quoting the serial

number.

If the conditions of service on your purchase order are

going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user

seeks the written agreement of Flowserve before start

up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction

would cause hazards. The specific safety markings

are:

This symbol indicates electrical

safety instructions where non-compliance will

involve a high risk to personal safety or the loss of

life.

This symbol indicates safety instructions

where non-compliance would affect personal safety

and could result in loss of life.

This symbol indicates “hazardous and toxic

fluid” safety instructions where non-compliance

would affect personal safety and could result in loss

of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in

safety instructions where non-compliance in the

hazardous area would cause the risk of an

explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the

hazardous area would cause the risk of an

explosion.

This sign is not a safety symbol but

indicates an important instruction in the assembly

process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the

manufacturer/supplier to provide applicable

training.

Always coordinate repair activity with operations

and health and safety personnel, and follow all

plant safety requirements and applicable safety and

health laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For

products used in potentially explosive

atmospheres section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

GUARDS MUST NOT BE REMOVED WHILE

THE UNIT IS OPERATIONAL

DRAIN THE UNIT AND ISOLATE

PIPEWORK BEFORE DISMANTLING THE UNIT

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted.)

When a unit has experienced temperatures over

250 ºC (482 ºF), partial decomposition of fluoro-

elastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and

equipment is required when handling these

components. To lift heavy pieces above 25 kg (55

lb) use a crane appropriate for the mass and in

accordance with current local regulations.

THERMAL SHOCK

Rapid changes in the temperature of the liquid

within the unit can cause thermal shock, which can

result in damage or breakage of components and

should be avoided.

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators and

persons entering the immediate area action must

be taken to avoid accidental contact. If complete

protection is not possible, the machine access must

Page 4 of 24 flowserve.com

Page 5

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

be limited to maintenance staff only, with clear

visual warnings and indicators to those entering the

immediate area. Note: bearing housings must not

be insulated and drive motors and bearings may be

hot.

If the temperature is greater than 80 ºC (175 ºF)

or below -5 ºC (23 ºF) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate siting of the pump, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive, strict safety procedures

must be applied.

ENSURE CORRECT

LUBRICATION

(See section 5, Commissioning, startup, operation

and shutdown.)

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent build up of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the unit to avoid hazard

The following instructions for pump units when

installed in potentially explosive atmospheres must be

followed to help ensure explosion protection. For

ATEX, both electrical and non-electrical equipment

must meet the requirements of European Directive

94/9/EC. Always observe the regional legal Ex

requirements eg Ex electrical items outside the EU

may be required certified to other than ATEX eg

IECEx, UL.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of

the specific atmosphere in which they are to be

installed.

Where Flowserve has supplied only the bare shaft

pump unit, the Ex rating applies only to the pump

unit. The party responsible for assembling the ATEX

pump set shall select the coupling, driver and any

additional equipment, with the necessary CE

Certificate/ Declaration of Conformity establishing it

is suitable for the area in which it is to be installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so,

for pumps sets with a VFD, the ATEX Certification for

the motor must state that it is covers the situation

where electrical supply is from the VFD. This particular

requirement still applies even if the VFD is in a safe

area.

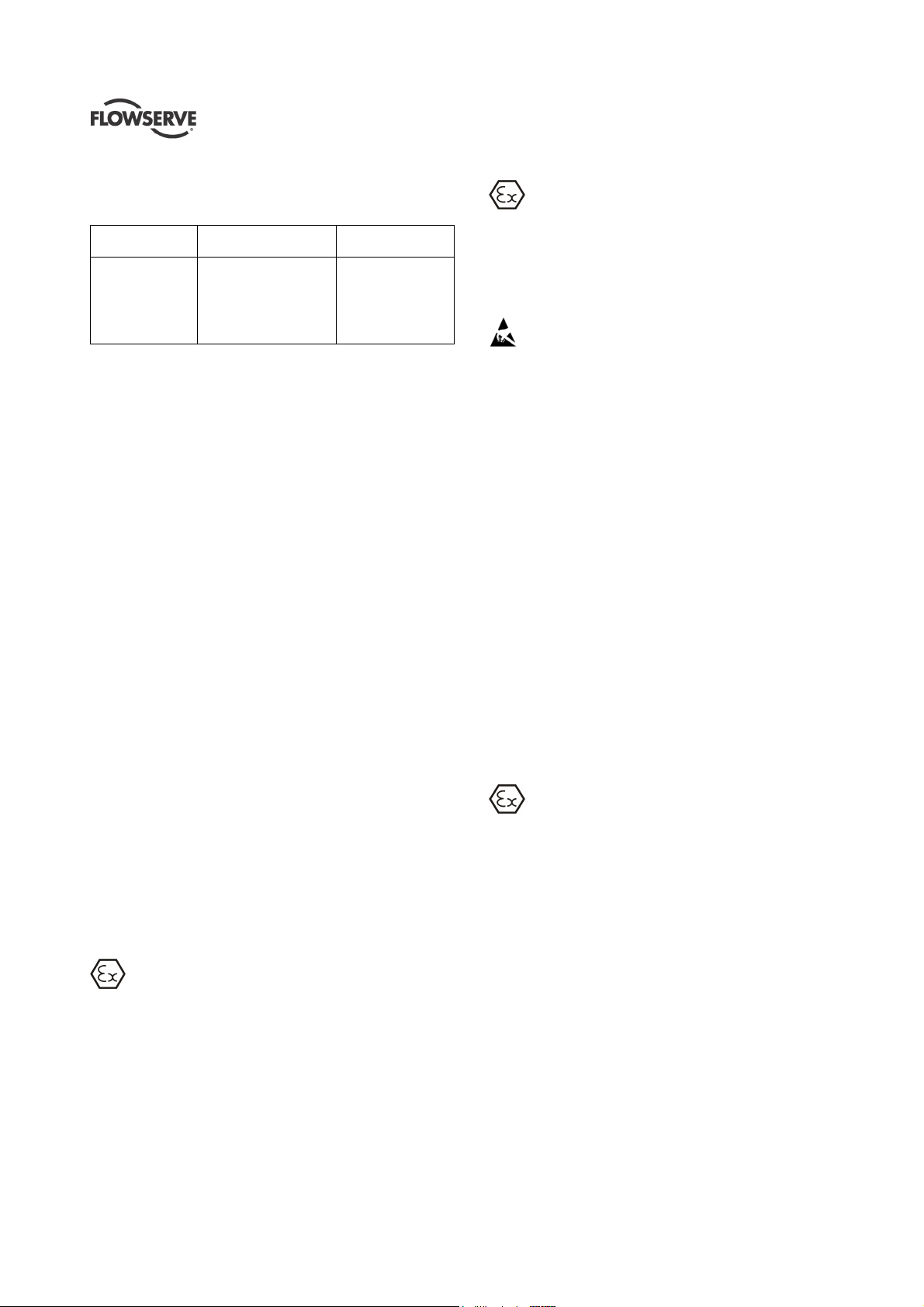

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump unit

will be engraved on the nameplate.

II 2 GD c IIC 135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with EN13463-5)

Gas Group

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

Maximum surface temperature (Temperature

Class)

(see section 1.6.4.3.)

1.6.4.3 Avoiding excessive surface

temperatures

ENSURE THE EQUIPMENT

TEMPERATURE CLASS IS SUITABLE FOR THE

HAZARD ZONE

Units have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are

based on a maximum ambient of 40 ºC (104 ºF);

refer to Flowserve for higher ambient temperatures.

The surface temperature on the unit is influenced

by the temperature of the liquid handled. The

Page 5 of 24 flowserve.com

Page 6

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Temperature class

maximum permissible liquid temperature depends

on the temperature class and must not exceed the

values in the table that follows.

to EN13463-1

T6

T5

T4

T3

T2

T1

* The table only takes the ATEX temperature class into consideration.

Unit design or material, as well as component design or material,

may further limit the maximum working temperature of the liquid.

Maximum surface

temperature permitted

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperature limit of

liquid handled *

65 °C (149 °F) *

80 °C (176 °F) *

115 °C (239 °F)

180 °C (356 °F)

275 °C (527 °F)

400 °C (752 °F)

The temperature rise at the seals and bearings and

due to the minimum permitted flow rate is taken

into account in the temperatures stated.

The responsibility for compliance with the

specified maximum liquid temperature is with

the plant operator.

Temperature classification “Tx” is used when the

liquid temperature varies and the unit could be

installed in different hazarous atmospheres. In this

case the user is responsible for ensuring that the

unit surface temperature does not exceed that

permitted in the particular hazardous atmosphere.

If an explosive atmosphere exists during the

installation, do not attempt to check the direction of

rotation by starting the unit unfilled. Even a short

run time may give a high temperature resulting

from contact between rotating and stationary

components.

Avoid mechanical, hydraulic or electrical overload

by using motor overload trips, temperature monitor

or a power monitor and make routine vibration

monitoring checks.

In dirty or dusty environments, make regular

checks and remove dirt from areas around close

clearances, bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE THE UNIT IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

It is essential to make sure that seal chambers,

auxiliary shaft seal systems and any heating and

cooling systems are properly filled.

1.6.4.5 Preventing sparks

To prevent a potential hazard from

mechanical contact, the coupling guard must be

non-sparking.

To avoid the potential hazard from random induced

current generating a spark, the baseplate must be

properly grounded.

Avoid electrostatic charge: do not rub non-

metallic surfaces with a dry cloth; ensure cloth is

damp.

For ATEX applications the coupling must be selected

to comply with 94/9/EC. Correct coupling alignment

must be maintained.

Additional requirement for metallic pumps on

non-metallic baseplates

When metallic components are fitted on a nonmetallic base they must be individually earthed.

1.6.4.6 Preventing leakage

Bursting of liquid containing parts due to freezing

must be avoided by draining or protecting the unit

and ancillary systems.

Where there is the potential hazard of a loss of a

seal barrier fluid or external flush, the fluid must be

monitored.

If leakage of liquid to atmosphere can result in a

hazard, install a liquid detection device.

1.6.4.7 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED

TO AVOID POTENTIAL HAZARDS WHICH GIVE

A RISK OF EXPLOSION

The responsibility for compliance with

maintenance instructions is with the plant

operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions. Where

there is a risk from such tools or materials,

maintenance must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (See section 6,

Maintenance.)

Page 6 of 24 flowserve.com

Page 7

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and

unpacking

Immediately after receipt of the equipment it must

be checked against the delivery/shipping

documents for its completeness and that there has

been no damage in transportation. Any shortage

and/or damage must be reported immediately to

Flowserve Pump Division and must be received in

writing within one month of receipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as

well as when ordering spare parts or further

accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their

size and construction.

2.3 Lifting

A crane must be used for all pump sets and

components in excess of 25 kg (55 lb.). Fully

trained personnel must carry out lifting, in

accordance with local regulations.

Before lifting the driver alone, refer to the

manufacturer’s instructions.

2.4 Storage

Store the unit in a clean, dry

location away from vibration. Leave protective

covers and plugs in place to keep dirt and other

foreign material out of the unit. Turn shaft at

intervals to prevent brinelling of the bearings and

the seal faces, if fitted, from sticking.

The unit may be stored as above for up to 6

months. Consult Flowserve for preservative

actions when a longer storage period is needed.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local requirements. If the

product contains substances that are harmful to the

environment, these should be removed and

disposed of in accordance with current regulations.

This also includes the liquids and/or gases that

may be used in the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the

current regulations at all times.

3 DESCRIPTION

3.1 Configurations

These instructions cover only rolling element type

bearing thrust pots, without fan cooling, with

different rolling element bearing sizes available as

shown in the drawings. (See section 8.)

Thrust bearing pots are designed for vertical

centrifugal pumps driven by solid shaft electric

motor which have very limited capacity for taking

the pump vertical thrusts without a thrust bearing

pot fitted to the pump.

Installation is between the pump discharge head

and the motor/pump coupling. Sufficient room

should be provided between the pump discharge

head and the driver, normally by a driver stool, to

allow the necessary span for the installation of the

thrust bearing pot and the pump/motor coupling.

Pump hydraulic thrusts, producing energy, are not

transmitted to the pump foundation but are

converted into heat that is absorbed by the

lubrication oil for the bearings.

3.2 Name nomenclature

The thrust bearing pot size will be on the General

Arrangement drawing for the pump.

3.3 Design of major parts

3.3.1 Bearing housing

The bearing housing [3200] allows the installation

in the pump and takes the bearings themselves. It

acts as the sump for the lubrication oil for the

bearings and the larger sizes incorporate an

integral water cooling jacket that must be used to

allow adequate cooling of the bearings lubrication

oil where fitted with a cooling jacket. The bearing

housing incorporates ports to allow the internal

Page 7 of 24 flowserve.com

Page 8

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Load capacity

Max. torque

Dynamic (C)

Static (C

0

)

kN

(lbf (x1 000))

rpm mm (in.)

kNm (

lbf•ft (x

1 000))

kN

recirculation of the oil lubrication and includes an oil

level gage to check the lubricant oil level.

3.3.2 Bearings

The bearings [3010 and 3011] are hydrodynamic

rolling element type ball or roller bearings sized to

absorb the pump vertical thrust and pump rotor

weight from the centering sleeve [2470].

The thrust bearing [3010] absorbs the pump

hydraulic down thrust and the pump rotor weight.

The line bearing [3011] guides the rotating

components and absorbs the pump up-thrust

produced at start-up in most vertical pumps.

3.3.3 Centering sleeve

The centering sleeve [2470] connects mechanically

with an axial setting adjusting nut [2909], the pump

rotor and the bearings.

3.4 Performance and operating limits

3.4.1 Load capacity

Size Description

3.3.4 Bearing cover

The Bearing cover [3260] and upper bearing

housing [3210] provide sealing to the bearing

housing [3200] against the atmosphere.

It incorporates the oil filling connection and holds

the line bearing [3011] in position.

3.3.5 Thrust axial setting adjusting nut

The axial setting control adjusting nut [2909]

connects mechanically with the centering sleeve

[2470], the pump rotor and the bearings. This

allows control of the pump rotor axial regulation

play.

3.3.6 Accessories

Accessories may be fitted when specified.

Fan cooling is not available for these designs of

thrust bearing pot as a default; available designs

for special requirements or applications must be

consulted with Flowserve representative.

Max. speed Max. shaft dia

(11 – 13 % Cr. Shaft)

7211B

7218B 106 (23.8) 73.5 (16.5) 4 000 57.2 (2.25) 3.48 (2.57)

7318B 156 (35.1) 114 (25.6) 3 570 57.2 (2.25) 3.48 (2.57)

7322B 225 (50.6) 193 (43.4) 2 850 69.9 (2.75) 6.90 (5.09)

7211B + 6013

7218B + 6020 106 (23.8) 73.5 (16.5) 4 000 57.2 (2.25) 3.48 (2.57)

7318B + 6022 156 (35.1) 114 (25.6) 3 570 57.2 (2.25) 3.48 (2.57)

7322B + 6028 225 (50.6) 193 (43.4) 2 850 69.9 (2.75) 6.90 (5.09)

29417 + 22217

29420 + 22220 863 (194) 1 250 (281) 1 600 69.9 (2.75) 6.90 (5.09)

29424 + 22224 1 170 (263) 1 760 (395) 1 300 76.2 (3.0) 9.60 (7.08)

Single row angular

contact bearing

Single row angular

contact and radial

ball bearing

Spherical thrust

and spherical

roller bearing

46.2 (10.4) 28.5 (6.4) 6 450 31.8 (1.25) 0.29 (0.21)

46.2 (10.4) 28.5 (6.4) 6 060 31.8 (1.25) 0.29 (0.21)

633 (142) 900 (202) 1 900 57.2 (2.25) 3.48 (2.57)

3.4.2 Maximum down thrust

Max. instant

Size

7211B

7218B 12.4 (2.8) 13.2 (2.9) 15.6 (3.5) 16.6 (3.7) 17.9 (4) 19.7 (4.4) 40 (88)

7318B 18.2 (4.1) 19.4 (4.3) 23.0 (5.2) 24.4 (5.5) 26.3 (5.9) 29 (6.5) 48 (106)

7322B 28.0 (6.3) 33.2 (7.4) 35.2 (7.9) 38 (8.5) 41.8 (9.4) 50 (132)

7211B + 6013

7218B + 6020 12.4 (2.8) 13.2 (2.9) 15.6 (3.5) 16.6 (3.7) 17.9 (4) 19.7 (4.4) 58 (128)

7318B + 6022 18.2 (4.1) 19.4 (4.3) 23.0 (5.2) 24.4 (5.5) 26.3 (5.9) 29 (6.5) 67 (148)

7322B + 6028

29417 + 22217

29420 + 22220

29424 + 22224

up-thrust

(lbf ( x1000))

N/A

13.5 (3.0)

37.4 (8.4)

3 500 2 900 1 750 1 460 1 170 880 kg (lb)

5.4 (1.2) 5.7 (1.3) 6.8 (1.5) 7.2 (1.6) 7.8 (1.8) 8.6 (1.9) 20 (44)

5.4 (1.2) 5.7 (1.3) 6.8 (1.5) 7.2 (1.6) 7.8 (1.8) 8.6 (1.9) 22 (49)

Max down thrust for L

kN (lbf (x1 000)) @ rpm

28.0 (6.3) 33.2 (7.4) 35.2 (7.9) 38 (8.5) 41.8 (9.4) 110 (243)

68 (15) 72 (16) 77 (17) 84 (19) 86 (190)

= 16 000 hours

10h

98 (22) 105 (23) 114 (26) 276 (608)

142 (32) 155 (35) 276 (608)

Nett

weight

Page 8 of 24 flowserve.com

Page 9

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

3.4.3 Down-thrust ratings

3.4.3.1 7000s and 7000s + 6000s series

Axial load (kN)

12

10

8

6

4

2

0

800 1600 2400 3200 4000 4800 5600 6400

8k 16k 25k 50k (Hours L10 life)

Axial load (kN)

30

25

20

15

10

5

0

500 1000 1500 2000 2500 3000 3500 4000

8k 16k 25k 50k (Hours L10 life)

Axial load (kN)

50

40

30

20

10

0

600 1200 1800 2400 3000 3600

8k 16k 25k 50k (Hours L10 life)

Axial load (kN)

70

60

50

40

30

20

10

0

500 1000 1500 2000 2500 3000

8k 16k 25k 50k (Hours L10 life)

7211B (C = 46.2kN)

7218B (C = 106kN)

7318B (C = 156kN)

7322B (C = 225kN)

lbf (x1 000)

Speed (rpm)

lbf (x1000)

Speed (rpm)

lbf x1 000

Speed (rpm)

(lbf (x1 000))

Speed (rpm)

3.4.3.2 29000s + 22000s series

Axial load (kN)

2.5

2

1.5

1

0.5

0

6

5

4

3

2

1

0

200

150

100

50

0

200 400 600 800 1000 1200 1400 1600 1800

8k 16k 25k 50k (Hours L10 life)

Axial load (kN)

250

200

150

100

50

0

200 400 600 800 1000 1200 1400 1600

8k 16k 25k 50k (Hours L10 life)

29417 (C = 633kN)

29420 (C = 863kN)

Axial load (kN)

300

10

8

6

4

2

0

250

200

150

100

50

0

200 400 600 800 1000 1200

8k 16k 25k 50k (Hours L10 life)

29424 (C = 1 170kN)

14

12

10

8

6

4

2

0

(lbf x1 000)

Speed (rpm)

(lbf ( x1 000))

Speed (rpm)

(lbf x1 000)

Speed (rpm)

40

30

20

10

0

50

40

30

20

10

0

60

50

40

30

20

10

0

Page 9 of 24 flowserve.com

Page 10

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4, Products used in

potentially explosive atmospheres.

4.1 Thrust bearing pot installation

Pots are either delivered to the customer fully

assembled except for the oil/cooling piping

extension, or pre-installed in the pump.

Before installation remove all items from the pump

discharge head.

a) Remove any debris and thoroughly clean the

surface receiving the pot with solvent. Apply a

thin film of mineral oil to the surface.

b) Remove the screws [6570.2] from the pot, the

adjusting nut [2909] and the oil flinger, oil

thrower [2540].

c) Remove the key [6700.1] from the pump shaft.

Thoroughly clean, with solvent if necessary, the

exposed surface of the shaft and apply a thin

film of mineral oil to it.

d) Install the pot and the rest of the assembly in

the pump. Take care not to damage the pump

shaft during the pot installation and to properly

match the alignment fits of the pump and pot.

e) Rotate the pot assembly on its receiving

surface to match up the holding holes.

f) Install the key [6700.1]. The keyway position is

reached by turning the centering sleeve [2470].

g) Re-install the pot holding bolts.

h) Re-install the oil flinger, oil thrower [2540].

i) Re-install the adjusting nut [2909].

j) Regulate the pump rotor axial play by turning,

as necessary, the adjusting nut [2909].

k) Re-install the screws [6570.2].

l) Re-install the items removed from the

discharge head and the pot piping extensions.

Use Heldite or similar proprietary pipe thread

sealant to seal the piping extensions, where

customer practices permit PTFE based pipe

sealants or PTFE tape these can also be

utilized.

m) Fill the pot with lubricant up to the required

level. Open the vent plug [6521] while filling.

4.2 Optional Bearing Gard™

installation

4.2.1 Preparation before installation

a) Remove the oil seal from the housing.

b) Check to ensure the housing bore is free from

contaminants, nicks and burrs or sharp edges.

c) Check the shaft and remove any burrs or sharp

edges on the shaft keyway and trademark

stamps on the shaft.

d) Thoroughly clean the shaft and housing bore.

e) Concentricity of the housing bore to the shaft is

to be maintained within 0.13 mm (0.005 in.)

TIR.

4.2.2 Bearing Gard™ installation

a) Do not disassemble the Bearing Gard™

[4330.2]: it is designed to be installed as a unit.

b) Lubricate the O-rings, the shaft and housing

bore with the lubricant provided.

c) Align the Bearing Gard™ [4330.2] in the

housing so the drain slot is located on the

bottom.

d) Install the Bearing Gard™ [4330.2].

Original-style Bearing Gard™ and Metallic

Bearing Gard™ ll. Use an arbour press to

push on the outer portion of the stator. Do not

use a hammer.

Non-metallic Bearing Gard™ ll. Install using

hand pressure only.

For 7000s and 7000s + 6000s series

the oil level is the centre of the oil level sight

glass; for 29000s + 22000s series the oil level

is indicated in the sectional drawing.

n) Check the oil level before operation. Also,

when specified, check that the piping system is

ready to provide proper cooling to the pot.

Page 10 of 24 flowserve.com

Metallic Bearing Gard™ II

Page 11

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

4.3.2 Lifeseal™ installation

Non-metallic Bearing Gard™ ll

e) During installation, simply discard any O-ring

material pinched or sheared by the bore. Make

sure the face is perpendicular to the shaft.

f) Once a Bearing Gard™ is in place you may

remove and plug the bearing housing vent.

Bearing Gard™ is self-venting and will not

allow pressure build up in the housing.

Plugging the bearing housing vent will reduce

the entry of contamination into the housing.

g) Refill the bearing housing to the correct oil

level.

4.2.3 General tolerance information

Shaft tolerance: ± 0.05 mm (± 0.002 in.)

Axial run-out: ± 0.075 mm (± 0.003 in.)

Bore tolerance: ± 0.025 mm (± 0.001 in.)

Radial run-out: ± 0.13 mm (± 0.005 in.)

4.3 Optional Lifeseal™ installation

4.3.1 Preparation before installation

a) Check to ensure the housing bore is free from

contaminants, nicks and burrs or sharp edges.

b) Check the shaft and remove any burrs or sharp

edges that may damage the rotary O-ring as

the Lifeseal™ [4330.1] slides over the shaft.

c) Concentricity of the housing bore to the shaft is

to be maintained within 0.13 mm (0.005 in.)

T.I.R.

a) Using the water-soluble lubricant provided,

lubricate the stationary unit outside diameter

O-ring and the rotary unit inside diameter Oring.

b) Slide the Lifeseal™ [4330.1] along the shaft

and evenly press the unit into the housing bore

until the shoulder on the stationary unit bottoms

out on the face of the housing. During

installation, simply discard any O-ring material

pinched or sheared by the bore. Make sure the

face is perpendicular to the shaft.

c) Evenly tighten the six set screws in the rotary

unit to secure the seal to the shaft.

d) Remove the bronze setting clips and clip bolts

from the Lifeseal™ [4330.1].

4.3.3 General tolerance information

Shaft tolerance: ± 0.05 mm (± 0.002 in.)

Axial run-out: ± 0.075 mm (± 0.003 in.)

Bore tolerance: ± 0.025 mm (± 0.001 in.)

Radial run-out: ± 0.13 mm (± 0.005 in.)

4.4 Thrust bearing pot installation

with optional Bearing

Gard™/Lifeseal™ sealing

Pots are either delivered to the customer fully

assembled except for the oil/cooling piping

extension, or pre-installed in the pump.

Before installation remove all items from the pump

discharge head.

a) Remove any debris and thoroughly clean the

surface receiving the pot and the exposed

Page 11 of 24 flowserve.com

Page 12

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

surfaces of the shaft with solvent. Check to

ensure the shaft is free from contaminants,

nicks and burrs, or any sharp edges. If

necessary remove them.

b) Remove the screws [6570.2] from the pot and

remove the adjusting nut [2909].

c) Remove the key [6700.1] from the pump shaft.

d) Apply a thin film of mineral oil to the shaft

exposed area and the pot mounting surface.

e) Rest the pot assembly in the pump taking

special care not to damage the pump shaft, the

Lifeseal™ [4330.1] and the Bearing Gard™

[4330.2] during the pot installation and to

properly match the pump and pot alignment

fits.

f) Rotate the pot assembly on its receiving

surface to match up the holding holes.

g) Install the key [6700.1]. The keyway position is

reached by turning the centering sleeve [2470].

h) Re-install the pot holding bolts.

i) Re-install the adjusting nut [2909].

j) Regulate the pump rotor axial play by turning

the adjusting nut [2909] as necessary.

k) Re-install the screws [6570.2].

l) Tighten the Lifeseal™ [4330.1] rotary unit set

screws and remove the setting clips and bolts.

(See section 4.3.2, Lifeseal™ installation.)

m) Re-install the items removed from the

discharge head and the pot piping extension.

Use Heldite or similar proprietary pipe thread

sealant to seal the piping extensions, where

customer practices permit PTFE based pipe

sealants or PTFE tape these can also be

utilized..

n) Fill the pot with lubricant up to the required

level.

on the axial hydraulic thrust or force that tends to

elongate the shaft. It is also dependent on the

shaft diameter. The adjustment figure is indicated

in the pump User Instruction manual.

Adjustment is performed, once the pump and motor

are completely installed, by tightening or loosening

the adjusting nuts [2909] of the thrust bearing pot.

Further adjustment details are provided in the

pump User Instruction manual. Also refer to the

lubrication table in section 5.1.

4.6 Lubrication and cooling

requirements

Refer to the lubrication chart in section 5.2.

4.7 Motor stand and flexible coupling

After the thrust pot installation, install the motor

stand, the flexible coupling and the driver.

5 COMMISSIONING, START-UP,

OPERATION AND SHUTDOWN

These operations must be carried

out by fully qualified personnel.

5.1 Pre-commissioning procedure

5.1.1 Lubrication

Determine the mode of lubrication of the unit, eg

grease, oil, product lubrication etc.

For oil lubricated units, fill the bearing

housing with correct grade of oil to the correct level, ie

sight glass or constant level oiler bottle.

For 7000s and 7000s + 6000s series

the oil level is the centre of the oil level sight

glass; for 29000s + 22000s series the oil level

is indicated in the sectional drawing.

o) Check the oil level before operation. Also,

when specified, check that the piping system is

ready to provide proper cooling to the pot

4.5 Pump vertical axial play

adjustment

The pump vertical axial play adjustment depends

on the length of the shaft, which, in turn, depends

Page 12 of 24 flowserve.com

When fitted with a constant level oiler, the bearing

housing should be filled by unscrewing or hinging

back the transparent bottle and filling the bottle with

oil.

Page 13

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

-

1

80 (

176) 22 32 46 68

60 (

140) 15 22

80 (

176) 46 68

60 (

140) 22 32

80 (

176) 46

5.2 Lubrication

Size Description Cooling data

7211

7218 0.35 (0.74)

7318 0.6 (1.27)

7322 0.9 (0.90)

7211 & 6013

7218 & 6020 1.0 (2.1)

7318 & 6022 0.9 (1.90)

7322 & 6028 1.3 (2.75)

29417 + 22217

29420 + 22220

29424 + 22224

Single row

angular contact

bearing

Single row

angular contact

and radial ball

bearings

Spherical roller

thrust and

spherical roller

bearings

Not applicable

Maximum

Pressure

3.0 barg

(43 psig)

Temperature

30 ºC

(86 ºF)

Flow

0.25 m3/h

(1.10 Usgpm)

Oil pan nominal

capacity

Litre (US pint)

0.13 (0.26)

0.35 (0.74)

1.2 (2.54)

5.75 (12.2)

Lubrication data

Oil temp

º C (º F)

60 (140) 22 32 46

70 (158) 32 46 68

80 (176) 32 46 68 100

60 (140) 15 22 32

70 (158) 22 32 46

80 (176) 32 46 68

60 (140) 15 22 32

70 (158) 15 22 32 46

80 (176) 22 32 46 68 68

60 (140)

70 (158) 15 22 32

80 (176) 22 32 46

60 (140) 22 32 46

70 (158) 32 46 68

80 (176) 32 46 68 100

60 (140) 15 22 32

70 (158) 22 32 46

80 (176) 32 46 68

60 (140) 15 22 32

70 (158) 15 22 32 46

70 (158) 15 22 32

80 (176) 22 32 46

60 (140)

70 (158) 32 46

70 (158) 32 46

80 (176) 46 68

60 (140)

70 (158) 32

Oil requirements

3 600 3 000 1 800 1 500 1 200 1 000

Viscosity ISO VG @ min

15 22

22 32

22

• For oil changes a dewaxed mineral oil with anti-oxidants, corrosion protection and anti-foaming additives should be used.

• The first oil change should be after 100 hours operation. Subsequent oil changes after every 2 000 hours operation.

• Oil consumption is negligible.

6 MAINTENANCE

6.1 General

It is the plant operator's responsibility to

ensure that all maintenance, inspection and

assembly work is carried out by authorized and

qualified personnel who have adequately

familiarized themselves with the subject matter by

studying this manual in detail. (See also section

1.6.)

Any work on the machine must be performed when

it is at a standstill

On completion of work all guards and safety

devices must be re-installed and made operative

again.

Before restarting the machine, the relevant

instructions listed in section 5, Commissioning,

start up, operation and shut down must be

observed.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and the

exterior of the machine.

If platforms, stairs and guard rails are required for

maintenance, they must be placed for easy access

to areas where maintenance and inspection are to

be carried out. The positioning of these

accessories must not limit access or hinder the

lifting of the part to be serviced.

When air or compressed inert gas is used in the

maintenance process, the operator and anyone in

Page 13 of 24 flowserve.com

Page 14

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

the vicinity must be careful and have the

appropriate protection.

Do not spray air or compressed inert gas on skin.

Do not direct an air or gas jet towards other people.

Never use air or compressed inert gas to clean

clothes.

Before working on the unit, take measures to

prevent an uncontrolled start. Put a warning board

on the starting device with the words:

"Machine under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning board

on the fuse box or main switch with the words:

"Machine under repair: do not connect".

Never clean equipment with inflammable solvents

or carbon tetrachloride. Protect yourself against

toxic fumes when using cleaning agents.

6.2 Maintenance schedule

It is recommended that a maintenance plan

and schedule is adopted, in line with these User

Instructions, to include the following:

a) Any auxiliary systems installed must be

monitored, if necessary, to ensure they function

correctly.

b) Check for any leaks from gaskets and seals.

c) Check bearing lubricant level, and if the hours

run show a lubricant change is required.

d) Check vibration, noise level and surface

temperature at the bearings to confirm

satisfactory operation.

e) Check dirt and dust is removed from areas

around close clearances, bearing housings and

motors.

f) Check coupling alignment and re-align if

necessary.

Our specialist service personnel can help with

preventative maintenance records and provide

condition monitoring for temperature and vibration

to identify the onset of potential problems.

If any problems are found the following sequence

of actions should take place:

a) Refer to section 7, Faults; causes and

remedies, for fault diagnosis.

b) Ensure equipment complies with the

recommendations in this manual.

c) Contact Flowserve if the problem persists.

6.2.1 Routine inspection (daily/weekly)

The following checks should be

made and the appropriate action taken to remedy

any deviations:

a) Check operating behaviour. Ensure noise,

vibration and bearing temperatures are normal

b) Check the level and condition of oil lubricant.

c) Check any auxiliary supplies eg.

heating/cooling, if fitted, are functioning

correctly.

Refer to the manuals of any associated

equipment for routine checks needed.

6.2.2 Periodic inspection (six monthly)

a) The coupling should be checked for correct

alignment and worn driving elements.

Refer to the manuals of any associated

equipment for periodic checks needed.

6.2.3 Re-lubrication

Lubricant and bearing temperature analysis can be

useful in optimizing lubricant change intervals. In

general however, the following is recommended.

6.3 Spare parts

6.3.1 Ordering of spares

Flowserve keeps records of all pumps that have

been supplied. When ordering spares the following

information should be quoted.

1) Pump serial number.

2) Pump size.

3) Part name – taken from section 8.

4) Part number – taken from section 8.

5) Number of parts required.

The pump size and serial number are shown on the

pump nameplate.

To ensure continued satisfactory operation,

replacement parts to the original design

specification should be obtained from Flowserve.

Any change to the original design specification

(modification or use of a non-standard part) will

invalidate the pump’s safety certification.

6.3.2 Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re-treatment of

metallic surfaces (if necessary) with preservative is

recommended at 6 monthly intervals.

Page 14 of 24 flowserve.com

Page 15

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Tightening torques Nm (lbf•ft))

45 (

1.77) 970 (

720)

2 800

(2 000)

2 800

(2 000)

1 900

(1

400)

6.4 Tools required

Standard tools needed to maintain this pump

are follows.

• Open ended spanners / wrenches (standard

size range)

• Socket spanners / wrenches (standard size

range)

• Allen keys / wrenches

• Standard range of screw drivers

• Soft mallet

Other tools may be required depending

on the accessories/ special parts used per contract.

Flowserve in general is not obligated to ship the

tools with any pump shipped

6.5 Fastener torques

Diameter

mm (in.)

7 (0.28) 2 (2) 10 (7) 7 (5) 5 (4)

8 (0.31)

9 (0.35)

10 (0.39) 9 (6) 28 (21) 22 (16) 15 (11)

12 (0.47) 13 (10) 48 (35) 37 (27) 24 (18)

14 (0.55) 20 (14) 70 (50) 55 (40) 37 (27)

16 (0.63)

18 (0.71)

20 (0.79)

22 (0.87)

24 (0.94) 110 (80 378 (279) 293 (216) 195 (144)

27 (1.06) 160(120 580 (428) 452 (33) 299 (221)

30 (1.18) 260 (190) 920 (680) 710 (530) 470 (350)

33 (1.30) 360 (270) 1 300 (940) 1 000 (740) 660 (490)

36 (1.42) 480 (360) 1 700 (1 260) 1 340 (990) 890 (650)

39 (1.54) 580 (430) 2 080 (1 530) 1 600 (1 180) 1 070 (790)

42 (1.65) 800 (590) 2 200 (1 600) 2 200 (1 600) 1 400 (1 080)

48 (1.89) 1 400(1 000) 3 800 (2 800) 3 800 (2 800) 2 500 (1 800)

52 (2.05) 1 500 (1 100) 4 150 (3 000) 4 100 (3 000) 2 700 (2 000)

Carbon steel

5 (4) 19 (14) 15 (11) 10 (7)

40 (30) 142 (104) 110 (70) 70 (50)

67 (50) 238 (176) 183 (135) 122 (90)

High tensile

steel

Martensitic

stainless

steel

Austenic

stainless

steel

6.6 Disassembly

Refer to Safety (1.6) section before

dismantling the unit.

Before dismantling the Thrust

bearing pot for overhaul, ensure genuine Flowserve

replacement parts are available.

Refer to sectional drawings for part numbers and

identification. See section 8, Parts lists and drawings.

Disassembly is generally the reverse process to

those described below in section 6.8, Assembly.

6.7 Examination of parts

Used parts must be inspected

before assembly to ensure the unit will

subsequently run properly. In particular, fault

diagnosis is essential to enhance unit and plant

reliability.

6.8 Assembly

To assemble consult the sectional drawings. See

section 8, Parts lists and drawings.

Ensure threads, gasket and O-ring mating faces

are clean. Apply thread sealant to non-face sealing

pipe thread fittings.

In all cases and whenever an overhaul is made, the

pot will have to be assembled again. The

assembly procedures are described below.

6.8.1 Thrust bearing pot assembly - 7000s

series

a) Press the bearing [3010] onto the centering

sleeve [2470] using a hydraulic press.

b) Thoroughly clean the bearing housing [3200].

Install the oil retaining sleeve [3860]. Use an

oil and heat resistant sealing compound

(LOCTITE 641 or equivalent) to seal the

bearing housing [3200] and oil retaining sleeve

[3860].

c) Install the oil level sight glass [3858].

d) Install the washer [2905] and screws [6570.1a].

e) Install the assembly [3010 and 2470], from a)

above, into the bearing housing [3200]. Leave

some clearance between the bearing housing

[3200] and the outer race of the bearing [3010].

f) Apply mineral oil in the bearing cover groove

[3260]and install the felt ring [4320].

g) Install the assembly [3260 and 4320] from step

f) in the bearing housing [3200].

h) Install the holding screws [6570.1] in the

bearing housing/bearing cover.

i) Install the vent plug [6521].

Assembly of the pot is now completed. For

installation onto the pump proceed as in section 4,

Installation.

6.8.2 Thrust bearing pot assembly - 7000s

series with optional Bearing

Gard™/Lifeseal™ sealing

a) Press the bearing [3010] onto the centering

sleeve [2470] using a hydraulic press.

b) Install the oil level sight glass [3858].

c) Install the washer [2905] and screws [6570.1a].

Page 15 of 24 flowserve.com

Page 16

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

d) Install the assembly [3010 and 2470], from step

a), into the bearing housing [3200]. Leave

some clearance between the bearing housing

[3200] and the outer race of the bearing [3010].

e) Work the gasket [4590] by hand and install it

onto the bearing housing [3200]. Apply a thin

film of mineral oil on the gasket.

f) Install the bearing cover [3260]on the bearing

housing [3200].

g) Install the bearing housing/Bearing cover

holding screws [6570.1].

h) Install the Bearing Gard™ seal [4330.2] and

the Lifeseal™ [4330.1] as described in section

4.2 and 4.3.

Tightening of the Lifeseal™ [4330.1]

rotary unit set screws and removal of the

setting clips and bolts (see Lifeseal™

installation , section 4.3) must only be done

after the installation of the pot on the pump and

the regulation of the pump rotor, (see section

4.4).

i) Assemble the cooling water pipes [6552]. Use

Heldite or similar proprietary pipe thread

sealant to seal between the different

components.

j) Install the piping assembly from step i) in the

bearing housing [3200]. Use Heldite or similar

proprietary pipe thread sealant to seal the

assembly to the bearing housing [3200].

Depending on the motor stool

configuration, the installation is made at pot

assembly stage or after the pot and motor

stand installation onto the pump discharge

head.

Assembly of the pot is now completed. For

installation onto the pump proceed as in section 4.4,

Optional Bearing Gard™/Lifeseal™ installation.

6.8.3 Thrust bearing pot assembly - 7000s +

6000s series

a) Press the bearings [3010 and 3011] onto the

centering sleeve [2470] using a hydraulic

press.

b) Lock the thrust bearing [3010] in place with the

lock washer [6541] and bearing nut [3712].

c) Thoroughly clean the bearing housing [3200].

d) Install the oil retaining sleeve [3860]. Use an

oil and heat resistant sealing compound

(LOCTITE 641 or equivalent) to seal the

bearing housing [3200] and oil retaining sleeve

[3860].

e) Install the oil level sight glass [3858].

f) Install the bearing preload springs [2460] in the

bearing housing [3200].

g) Install the assembly [3010, 3011, 2470, 6541

and 3712], from a) and b) above, in the bearing

housing [3200]. Leave some clearance

between the bearing housing [3200] and the

outer race of the thrust bearing [3010].

h) Apply mineral oil in the bearing cover [3260]

groove and install the felt ring [4320]

i) Work the gasket [4590] by hand and install it

on the bearing housing [3200]. Apply a thin

film of mineral oil on the gasket.

j) Install the assembly [3260 and 4320] from step

h) onto the bearing housing [3200]. Pay

attention to the position of the gasket [4590]

and to the adjustment of the line bearing

[3011].

k) Install the holding screws [6570.1] in the

bearing housing/Bearing cover.

l) Install the vent plug [6521].

Assembly of the pot is now completed. For

installation onto the pump proceed as in section 4,

Installation.

6.8.4 Thrust bearing pot assembly - 7000s +

6000s series with optional Bearing

Gard™/Lifeseal™ sealing

a) Press the bearings [3010 and 3011] onto the

centering sleeve [2470] using a hydraulic

press.

b) Lock the thrust bearing [3010] in place with the

lock washer [6541] and bearing nut [3712].

c) Install the (3858) oil level sight glass [3858].

d) Install the bearing preload springs [4260] into

the bearing housing [3200].

e) Install the assembly [3010, 3011, 2470, 6541

and 3712], from steps a) and b) above, into the

bearing housing [3200]. Leave some

clearance between the bearing housing [3200]

and the outer race of the thrust bearing [3010].

f) Work the gasket [4590] by hand and install it

onto the bearing housing [3200]. Apply a thin

film of mineral oil to the gasket.

g) Install the bearing cover [3260]onto the bearing

housing [3200].

h) Install the bearing housing/Bearing cover

holding screws [6570.1].

i) Install the Bearing Gard™ seal [4330.2] and

the Lifeseal™ [4330.1] as described in section

4.2 and 4.3.

Tightening of the Lifeseal™ [4330.1]

rotary unit set screws and removal of the

setting clips and bolts (see Lifeseal™

installation , section 4.3) must only be done

Page 16 of 24 flowserve.com

Page 17

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

after the installation of the pot on the pump and

the regulation of the pump rotor, (see section

4.4).

j) Assemble the cooling water pipes [6552]. Use

Heldite or similar proprietary pipe thread

sealant to seal between the different

components.

k) Install the piping assembly from step j) in the

bearing housing [3200 ]. Use Heldite or similar

proprietary pipe thread sealant to seal the

assembly to the bearing housing [3200].

Depending on the motor stool

configuration, the installation is made at pot

assembly stage or after the pot and motor

stand installation onto the pump discharge

head.

Assembly of the pot is now completed. For

installation onto the pump proceed as in section 4.4,

Optional Bearing Gard™/Lifeseal™ installation.

6.8.5 Thrust bearing pot assembly - 29000s +

22000s series

a) Press the bearing [3011] and bearing inner

race [3010] onto the centering sleeve [2470]

using a hydraulic press.

b) Thoroughly clean the bearing housing [3200].

c) Install the oil retaining sleeve [3860]. Use an

oil and heat resistant sealing compound

(LOCTITE 641 or equivalent) to seal the

bearing housing [3200] and oil retaining sleeve

[3860].

d) Install the bearing preload springs [4260] into

the bearing housing [3200].

e) Install the outer race [3010] and rollers

assembly into the bearing housing [3200].

f) Install the assembly [3010, 3011 and 2470],

from a) above, in the bearing housing [3200].

g) Work the gasket [4590.1] by hand and install it

on the bearing housing [3200]. Apply a thin

film of mineral oil on the gasket.

h) Install the upper bearing housing [3210]. Pay

attention to the position of the gasket [4950.1]

and to the adjustment of the bearing [3011].

i) Install the holding screws [6570.1].

j) Work the gasket [4590.2] by hand and install it

on the upper bearing housing [3210]. Apply a

thin film of mineral oil on the gasket.

k) Install the housing cover [3260]. Pay attention

to the position of the gasket [1300a].

l) Install screws [6570.2].

m) Install the vent plug [6521].

Assembly of the pot is now completed. For

installation onto the pump proceed as in section 4,

Installation.

6.8.6 Thrust bearing pot assembly - 29000s +

22000s series with optional Bearing

Gard™/Lifeseal™ Sealing

a) Press the bearing [3011] and thrust bearing

inner race [3010] onto the centering sleeve

[2470] using a hydraulic press.

b) Thoroughly clean the bearing housing [3200].

c) Install the bearing preload springs [4260] in the

bearing housing [3200].

d) Install the outer race bearing [3010] and roller

assembly into the bearing housing [3200].

e) Install the assembly [3010, 3011 and 2470]

from step a) into the bearing housing [3200].

f) Work the gasket [4590.1] by hand and install it

on the bearing housing [3200]. Apply a thin

film of mineral oil on the gasket.

g) Install the upper bearing housing [3210]. Pay

attention to the position of the gasket [4590.1]

and to the adjustment of the bearing [3011].

h) Install the holding screws [6570.1].

i) Work the gasket [4590.2] by hand and install it

on the upper bearing housing. [3210] Apply a

thin film of mineral oil on the gasket.

j) Install the housing cover [3260]. Pay attention

to the position of the gasket [4590.2].

k) Install the Bearing Gard™ seal [4330.2] and

the Lifeseal™ [4330.1] as described in section

4.2 and 4.3.

Tightening of the Lifeseal™ [4330.1]

rotary unit set screws and removal of the

setting clips and bolts (see Lifeseal™

installation , section 4.3) must only be done

after the installation of the pot on the pump and

the regulation of the pump rotor, (see section

4.4).

l) Assemble the cooling water pipes [6552], pipe

reducer [2042] and oil level sight glass [3856].

Use Heldite or similar proprietary pipe thread

sealant to seal between the different

components.

m) Install the assembly [6552, 2042 and 3856]

from step l) in the bearing housing [3200 ]. Use

Heldite or similar proprietary pipe thread

sealant to seal the assembly to the bearing

housing [3200].

Depending on the motor stool

configuration, the installation is made at pot

assembly stage or after the pot and motor

stand installation onto the pump discharge

head

Assembly of the pot is now completed. For

installation onto the pump proceed as in section 4.4,

Installation.

Page 17 of 24 flowserve.com

Page 18

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Check and correct level after renewing

7 FAULTS; CAUSES AND REMEDIES

FAULT SYMPTOM

Be a ri n g s o v e rh e at in g

B e a ri n g s h a ve sh o r t li f e o r a r e d a ma g ed

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

POSSIBLE CAUSES POSSIBLE REMEDIES

⇓⇓⇓⇓

⇓⇓⇓⇓

A. SYSTEM TROUBLES

Incorrect oil level

Worn bearings

Water or foreign materials entering oil

Shaft running off center because of

worn bearings or misalignment.

damaged bearings

Replace bearings.

Conduct oil analysis and CONSULT

FLOWSERVE, if necessary

Check misalignment and correct if

necessary. If alignment satisfactory

check bearings for excessive wear

Check the flange connection and

Misalignment due to pipe strain

eliminate strains using method

permitted

Oil film too thin or too thick

Check correct oil viscosity used for the

temperature

Rotating part rubbing on stationary part

internally

Check and CONSULT FLOWSERVE, if

necessary

Impeller out of balance resulting in

vibration and or creating excessive

Check and CONSULT FLOWSERVE

loading to the thrust bearing

Page 18 of 24 flowserve.com

Page 19

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Item Description

2130 Pump top shaft

2909 Adjusting nut

3200 Bearing housing

3860

Oil retaining sleeve

6521 Vent plug

6569.2

Plug

6570.1

Screw

6570.3

Screw

6700.2

Key (Coupling)

8 PARTS LISTS AND DRAWINGS

8.1 7000s series

2470 Centering sleeve

2905 Washer

3010 Bearing

3260 Bearing cover

3858 Oil level sight glass

4320 Felt ring

6552 Cooling water pipe

6570.2 Screw

6700.1 Key

Drawing taken from X081145E

Page 19 of 24 flowserve.com

Page 20

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Item Description

2470 Centering sleeve

3010 Bearing

3200 Bearing housing

3712 Bearing nut

3860 Oil retaining sleeve

6521 Vent plug

6569.1

Plug

6570.1

Screw

8.2 7000s + 6000s series

2130 Top shaft

2540 Oil flinger, oil deflector

2905 Washer

2909 Adjusting nut

3011 Bearing

3260 Bearing cover

3858 Oil level sight glass

4260 Spring

4320 Felt ring

4590 Gasket

5652 Cooling water pipe

6541 Lock washer

6569.2 Plug

6570.2 Screw

6700.1 Key

6700.2 Key (coupling)

Drawing taken from X092052

Page 20 of 24 flowserve.com

Page 21

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Item Description

2470 Centerin

g sleeve

3210 Upper bearing housing

4590.1

Gasket

6521 Vent plug

6570.2

Screw

9028 Pipe reducer

Oil level

Normal

8.3 29000s + 22000s series

2130 Pump top shaft

2909 Adjusting nut

3010 Bearing

3011 Bearing

3200 Bearing housing

3260 Bearing cover

3856 Oil level sight glass

3860 Oil retaining sleeve

4260 Spring

4590.2 Gasket

6552 Cooling water pipe

6569.1 Plug

6569.2 Plug

6570.1 Screw

6570.3 Screw

6700.1 Key

6700.2 Key (coupling)

6810 Pin

Drawing taken from X092817

Size

29417 + 22217 55.5 (2.2)

29420 + 22220 60 (2.4)

29424 + 22224 65 (2.6)

mm (in.)

Page 21 of 24 flowserve.com

Page 22

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

Item Description

2909 Adjusting nut

3011 Bearing

3858 Oil level sight glass

4330.1

Lifeseal™

4590 Gasket

4610.2

O-

ring

6552 Cooling water pipe

8.4 7000s + 6000s series with Bearing Gard™ seal and Lifeseal™

2130 Pump top shaft

2470 Centering sleeve

2905 Washer

3010 Bearing

3200 Bearing housing

3260 Bearing cover

3712 Bearing nut

4260 Spring

4330.2 Bearing Gard™ seal

4610.1 O-ring

6541 Lock washer

6569.1 Plug

6569.2 Plug

6570.1 Screw

6570.2 Screw

6700.1 Key

6700.2 Key (Coupling)

Drawing taken from X100349

Page 22 of 24 flowserve.com

Page 23

USER INSTRUCTIONS T-SERIES THRUST BEARING POT ENGLISH 26999907 01-2013

8.5 General arrangement drawing

The typical general arrangement drawing and any

specific drawings required by the contract will be

sent to the Purchaser separately unless the

contract specifically calls for these to be included

into the User Instructions. If required, copies of

other drawings sent separately to the Purchaser

should be obtained from the Purchaser and

retained with these User Instructions.

9 CERTIFICATION

Certificates determined from the Contract

requirements are provided with these Instructions

where applicable. Examples are certificates for CE

marking, ATEX marking etc. If required, copies of

other certificates sent separately to the Purchaser

should be obtained from the Purchaser for retention

with these User Instructions.

10 OTHER RELEVANT

DOCUMENTATION AND MANUALS

10.1 Supplementary User Instruction

manuals

Supplementary instruction determined from the

contract requirements for inclusion into User

Instructions such as for a driver, instrumentation,

controller, sub-driver, seals, sealant system, mounting

component, etc. are included under this section. If

further copies of these are required they should be

obtained from the purchaser for retention with these

User Instructions.

Where any pre-printed set of User Instructions are

used, and satisfactory quality can be maintained

only by avoiding copying these, they are included

at the end of these User Instructions such as within

a standard clear polymer software protection

envelope.

10.2 Change notes

If any changes, agreed with Flowserve Pump

Division, are made to the product after its supply, a

record of the details should be maintained with

these User Instructions.

10.3 Additional sources of information

Reference 1:

Pump Handbook, 2nd edition, Igor J. Karassik et al,

McGraw-Hill Inc., New York, 1993.

Page 23 of 24 flowserve.com

Page 24

USER INSTRUCTIONS THRUST BEARING POT ENGLISH 26999907 01-2013

Your Flowserve factory contact:

Flowserve Spain S.L.

Avenida de Madrid 67

Arganda del Rey, Madrid, Spain 28500

Telephone +34 91 876 0750

Fax +34 91 871 5704

Flowserve Spain S.L.

Avenida Fuentemar 26-28

Coslada, Madrid, Spain 28023

Telephone +34 91 660 4600

Fax +34 91 674 0433

Flowserve Pump Division

5310 Taneytown Pike, PO Box 91

Taneytown, MD 21787-0091, USA

Telephone: +1 (410) 756 2602

Customer Service FAX: +1 (410) 756 2615

Parts inquiry/Order PH: +1 (800) 526 3569

Your local Flowserve representative:

Flowserve Pumps

Flowserve GB Limited

PO Box 17, Lowfield Works

Newark, Notts NG24 3EN

United Kingdom

Telephone (24 hours) +44 1636 494 600

Sales & Admin Fax +44 1636 705 991

Repair & Service Fax +44 1636 494 833

Email newarksales@flowserve.com

To find your local Flowserve representative

please use the Sales Support Locator System

found at www.flowserve.com

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

5215 North O’Connor Blvd.,

Suite 2300

Irving, Texas 75039-5421, USA

Telephone +1 972 443 6500

Fax +1 972 443 6800

Europe, Middle East, Africa

Flowserve FSG – Italy

Worthing S.r.l.

Via Rossini 90/92

20033 Desio (Milan), Italy

Telephone +39 0362 6121

Fax +39 0362 628 882

Latin America and Caribbean

Flowserve Corporation

6840 Wynnwood Lane

Houston, Texas 776541, USA

Telephone +1 713 803 4434

Fax +1 713 803 4497

Asia Pacific

Flowserve Pte. Ltd

10 Tuas Loop

Singapore 637345

Telephone +65 6771 0600

Fax +65 6862 2329

Loading...

Loading...