Page 1

Tandem Rotary Actuators

GENERAL INFORMATION

The following instructions are designed to assist in

unpacking, installing and performing maintenance as

required on Valtek¨ tandem rotary actuators. Product

users and maintenance personnel should thoroughly

review this bulletin along with Installation, Operation,

Maintenance Instructions 10, Valdisk¨ Control Valves,

prior to installing, operating or performing any maintenance on the actuator. (additional features such as

handwheels, limit switches, fail-safe systems, etc).

This publication does not contain information on Valtek

positioners. Refer to the appropriate Installation, Operation, Maintenance Instructions for installing, maintaining, troubleshooting, calibrating, and operating these

accessaries.

To avoid possible injury to personnel or damage

to valve parts, WARNING and CAUTION notes

must be strictly adhered to. Modifying this product, substituting non-factory of inferior parts, or

using maintenance procedures other than outlined could drastically affect performance and be

hazardous to personnel and equipment.

Spare Parts

Valtek international recommends quality, factory-built

parts be used when servicing Valtek valves. In the USA

phone 1 800 99 SPARE for spare parts information.

Unpacking

Before unpacking the actuator, check the packing list

against the materials received. Lists describing the

actuator and accessories are included in each shipping

container.

1. When lifting the actuator from the shipping container,

position lifting straps to avoid damage to tubing and

mounted accessories. With tandem rotary actuators,

do not attach a lifting ring; instead, use lifting straps

through the yoke legs.

WARNING: When lifting the actuator with lifting

straps, be aware that the center of gravity may

not be at the lifting point. Therefore, support

must be given to prevent the actuator from rotat

ing. Failure to do so can cause serious injury to

personnel or damage to nearby equipment.

2. In the event of shipping damage, contact your shipper immediately.

3. Should any problem arise, contact your Valtek representative.

Installation

Prior to installation, make sure adequate overhead and

side clearance is provided to allow for proper removal

and maintenance of the actuator.

1. Connect air supply and instrument signal. Both connections are marked for the respective positioner

port. Since both cylinder and positioner are suitable

for 150 psi air supply, an air regulator is not required

unless the supply pressure exceeds 150 psi.

NOTE: In some cases, the air supply must be limited

to less than 150 psi. In this case, a sticker near the

upper cylinder air supply connection will indicate the

maximum pressure and an air regulator should be

installed to ensure the supply pressure does not

exceed this value.

2. Use the actuator to close the rotary valve tightly in

the seat before installing between the line flanges.

Do not allow actuator to open the valve until it is

properly bolted between the line flanges (see Maintenance Instructions 10).

CAUTION: Failure to do so may cause seat

misalignment and damage to the seat.

3. Installation of an air filter on the supply line is recommended.

4. Using a soap solution, make sure all air connections

are free of leaks.

5. Be sure mounting box is sealed on all possible

locations.

PREVENTATIVE MAINTENANCE

At least once every six months, check for proper operation by following the preventative maintenance steps

outlined below. These steps can be performed while the

actuator is in service and, in some cases, without

interrupting service. If an internal problem is suspected

with the actuator, refer to the ÒDisassembly and Reas-

-

semblyÓ section.

Rev. 5/89/5M/B Valtek No. 49064

May 1989

1

Page 2

1.

Examine the actuator for damage caused by corro-

sive fumes and process drippings.

2.

Clean the actuator and repaint areas of oxidation.

3.

If possible, operate the actuator and check for fullstroke operation. Observe the disc position indicator plate mounted on the transfer case: The disc

position indicator should change position in a

smooth, rotary fashion.

Unsteady movement of

the indicator suggests a possible internal valve or

actuator problem.

4.

After depressurizing the line and disconnecting the

air supply, remove the transfer case cover plate and

make sure the lever arm is securely fastened to the

shaft. The positioner follower arm should be correctly linked to the follower pin on the lever arm.

cover plate removed.

cover plate before operating the actuator will

cause damage to the shaft, since the cover plate

houses a shaft support bearing.

5. Replace transfer case cover plate and be sure all

mounted accessories (including the positioner),

brackets, and associated bolting are securely

fastened.

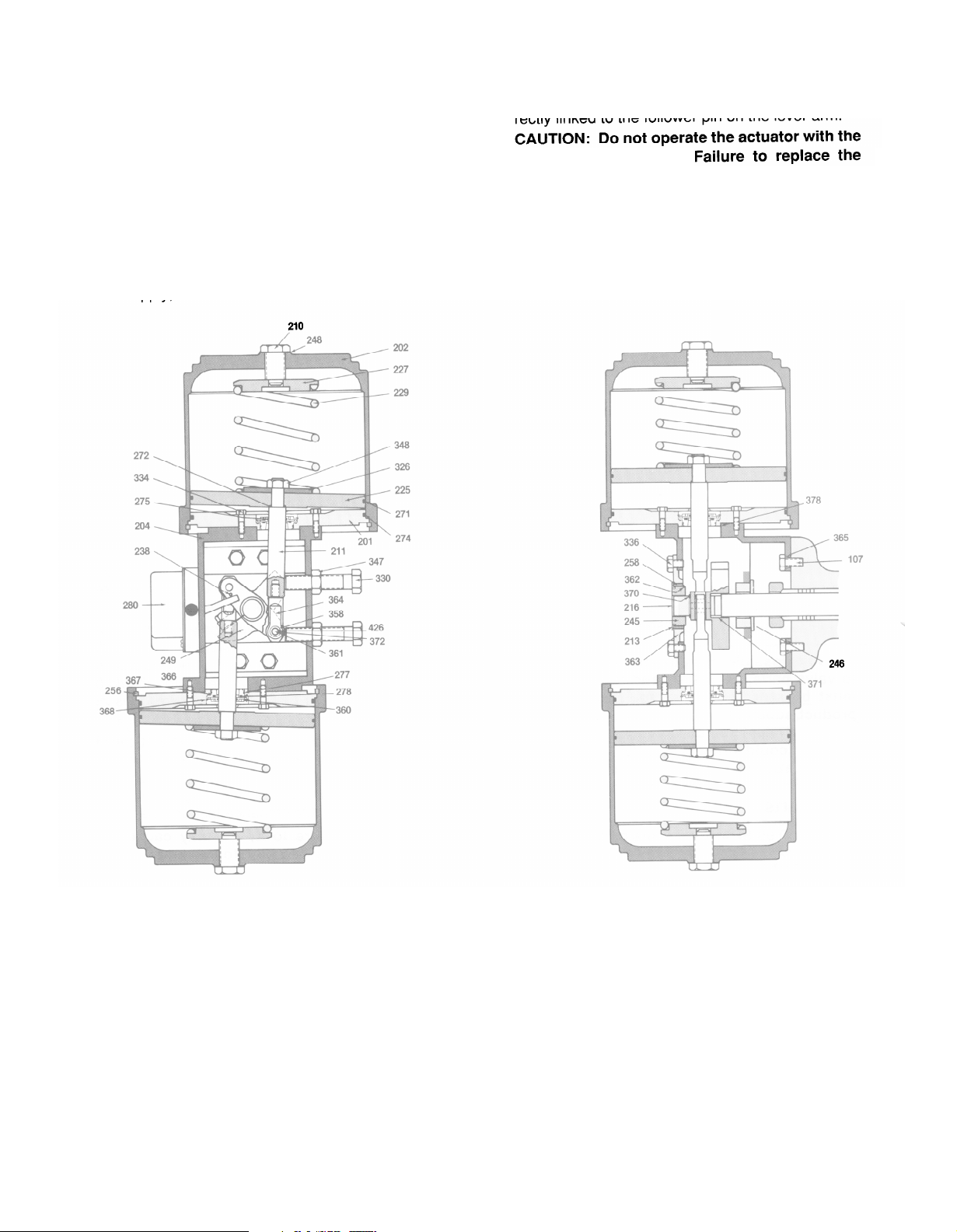

Sectioned View (Front)

Full Open or Closed

Parts List

107.

Body bolt

201. Yoke plate

202. Cylinder

204. Transfer case

210. Adjusting screw

211. Actuator stem

213. Stroke plate

216. Indicator plate

225. Piston

227. Spring button

229. Spring

238. Follower pin

Figure 1: 4-inch Stroke Tandem Actuator

245. Bearing

246. Yoke bushing

248. Adjusting screw gasket

249. Lever arm

256. Cylinder retaining ring

258. Cover plate bushing

261. Dust cover (not shown)

262. Flange cover (not shown)

271. Piston o-ring

272. Piston stem 0-ring

274. Cylinder O-ring

275. Actuator stem Wing

277. Base seal O-ring

278. Base slider O-ring

280. Positioner

326. Spring guide

330. Stroke stop bolt

334. Yoke plate bolts

336. Cover plate bolts

347. Stroke stop jam nut

348. Actuator stem locknut

358. Rod end bearing

360. Sliding seal top clamp

361. Pivot pin

362. Splined bearing snap-ring

363. Cover plate

Sectioned View (Side)

Mid-Stroke

364. Rod end

365. Doweled washer

366. Sliding seal collar

367. Base seal

368. Spiral retaining ring

370. Retaining ring

371. Shaft spacer

372. Flat washer

378. Gasket

426. Cotter pin

427. Bolt (not shown)

Page 3

6. If possible, check for correct fail-safe action. Position

the valve to mid-stroke and shut off the air supply or

disconnect the instrument signal. By observing the

indicator plate, the disc should either fail open, closed,

or in place, depending on the air failure action. If the

failure action does not operate correctly, refer to the

“Troubleshooting” section.

7. Spray soap solution around the cylinder retaining

ring, the adjusting screw, and actuator stem seal (this

should be done when the cover plate is removed) to

check for air leaks through the O-rings and adjusting

screw gaskets.

8. Check all air connections for leaks. Tighten or replace

any leaky lines.

9. Check positioner calibration by observing the gauges

and the disc position indicator plate. Make sure

positioner is calibrated to correct range. For the System 80 Positioner, push positioner cleanout plunger

several times to clear any possible restrictions.

10. When using an air filter, check and replace the

cartridge if necessary.

DISASSEMBLY AND REASSEMBLY

Removing Valve From Line

See Maintenance Instructions 10, Valdisk Control Valves,

for instructions for removing the tandem rotary valve from

the service line.

Disassembling the Actuator

Because of the tandem actuator design, it is necessary to

disassemble the actuator before removing the valve body

from the transfer case. Refer to Figure 1:

1. Disconnect all tubing from the actuator.

2. Relieve the spring compression from both cylinders

by removing both adjusting screws.

WARNING: Failure to do so may result in personal injury.

3. Using a screwdriver, remove the cylinder retaining

ring from the groove at the base of each cylinder.

4. Pull both cylinders off the transfer case and pistons.

NOTE: Substantial O-ring resistance may be felt.

WARNING: Do not use air pressure to remove

cylinder. Personal injury and damage to valve

parts may result.

5. Remove both spring buttons and springs.

6. Using each piston as a handwheel, turn each until the

actuator stem screws out of its rod end. Pull the

piston/actuator stem assembly out of transfer case.

CAUTION: Care must be taken not to damage the

sliding seal assembly or actuator stem O-ring

when removing the actuator stem.

7. If the piston, piston stem O-ring, or actuator stem is to

be replaced, remove the actuator stem locknut from

actuator stem and slide spring guide, piston O-ring

and piston off the actuator stem. If desired, the yoke

plates can be removed from the transfer case by

removing both sets of yoke plate bolts.

8. Remove the spiral snap-ring holding the sliding seal

assembly in place.

9. Remove the top clamp, sliding seal collar and base

seal. The base seal can usually be removed by hand

or by gently prying the inside lip of the seal upward.

WARNING: Do not scratch the top surface of the

base seal with a screw driver or sharp object.

Scratches can cause excessive wear and possible leakage.

10. Remove the transfer case cover plate.

11. Referring to the appropriate Maintenance Instructions, remove the positioner from the transfer case.

12. Remove the snap-ring from the shaft to allow the

lever arm to slide off. Slide the lever arm off the shaft.

NOTE: If the rod end bearing needs replacement,

remove the cotter pin and the pivot pin that holds the

rod end to the lever arm out of the lever arm. On the

200, and dual 200, a solid clevis pin with cotter pin

retainer is used.

13. Using a socket wrench and proper-length extension,

insert the wrench through the transfer case and

remove the four case bolts holding the transfer case

to the valve body.

14. Remove the transfer case from the valve body, being

careful not to damage the shaft.

NOTE: If the shaft bearing is to be replaced, push it

out with a press.

Reassembling the Actuator

To reassemble the actuator, refer again to Figure 1:

1. Clean and lubricate all internal parts. All O-rings

should be replaced and lubricated using a silicone

lubricant (Dow Corning 55M or equivalent). The bore

that houses the sliding seal assembly in the transfer

case must be smooth and clean.

2. Reassemble the sliding seal assembly by pushing

the base seal into the transfer case. Place the sliding

seal collar on top of the base seal so that the raised

portion of the sliding collar protrudes through the hole

in the top clamp.

3. Replace the top clamp and the spiral snap-ring.

CAUTION: Avoid pinching or twisting the diaphragm seal while clamping it down.

4. If the rod end bearings have been removed, press a

new bearing into each rod end. Reinstall each rod

end into the lever arm by inserting the pivot pin

through the lever arm and rod end bearing. Replace

the cotter pin in the hole of the pivot pin.

5. If the shaft bearing has been removed, press a new

bearing into the transfer case. When pressing shaft

bearings into the transfer case, the bearings may

have to be ground out to fit the shaft bearing.

6. Use a socket wrench and proper-length extension to

reinstall the four body bolts, attaching the transfer

case to the valve body.

3

Page 4

7. Position the lever arm on the shaft (as shown in

Figure 1) and tighten the linkage bolt securely.

8. Reinstall the positioner, making sure the positioner

follower arm rides underneath the follower pin pressed

into the lever arm.

9. If the yoke plates have been removed, reinstall them

with both sets of yoke plate bolts. If necessary, install

a new piston stem O-ring, piston and spring guide

onto each actuator stem and secure each with the

actuator stem locknut.

10. Being careful not to damage the sliding seal assemblies; reinstall both actuator stems through the transfer case until they engage the threaded rod ends.

Turn the piston until the actuator stem and rod end

threads are firmly engaged.

11. Bolt the transfer case cover plate to transfer case.

12. Install both springs and spring buttons.

13. Replace the piston and cylinder O-rings.

14. Slide cylinder down over piston and transfer case.

CAUTION: The cylinder must be perpendicular

with the piston when sliding it over the piston

O-ring. If this is not done, the O-ring could be

damaged.

15. Reinsert both cylinder retaining rings by feeding

each (a little at a time) into the groove in the cylinder.

16. Center the hole in both spring buttons directly under

the adjusting screw hole in the cylinders. Install both

adjusting screws and tighten only enough to provide

an air seal with the gaskets. Do not overtighten.

17. Reconnect the tubing.

Adjusting the External Stroke Stops

After disassembly and reassembly, it may be necessary to

readjust the external stroke stops to avoid unnecessary

overstressing of the shaft on the body disc stop (disc stop

is a safety device designed to protect the seat). The

external stroke stops can be adjusted while the valve is in

line; however, there must be no line pressure on the disc.

To adjust the external stroke stops, proceed as follows:

1. If the valve is out of the line, screw the stroke stop bolts

out far enough to allow the disc to touch the disc stop

in the closed position. If the valve is installed in the line,

cycle the valve to the closed position with very low air

pressure (10 - 15 psi). At this point, the disc should be

resting on the disc stop.

CAUTION: Overstressing the shaft can occur if

full operating torque is applied to the disc stop.

2. Screw the stroke stop in clockwise (as viewed from the

end) until resistance is felt. By turning stroke stop an

additional 1/8 -turn, disc should be just off disc stop.

3. Cycle valve open. Adjust the other stroke stop until

disc is 90 degrees from the closed position.

4. Cycle the valve several times to make sure position

indicator returns to the same position with each cycle.

5. Tighten the stroke stop jam nuts.

REVERSING THE ACTUATOR ACTION

The Valdisk transfer case for the tandem actuator is

designed for one failure mode only. Should a different

failure mode be required, contact factory for a different

transfer case.

Troubleshooting Tandem Rotary Actuators

Failure Probable Cause Corrective Action

Actuator moves to failure 1. Failure of an actuator stem O-ring 1. Replace actuator stem O-ring

position, bleeding from 2. Failure of a sliding seal assembly 2. Replace sliding seal assembly

transfer case

Jerky shaft rotation 1. Improper adjustment of lever on shaft causing 1. Readjust lever arm

arm to contact transfer case

2. Worn piston O-ring allowing piston to gall on 2. Replace O-ring; if galling has occurred, replace all

cylinder wall damaged parts

3. Cylinder wall not lubricated 3. Lubricate cylinder wall with silicone lubricant

4. Worn actuator stem O-ring causing actuator 4. Replace O-ring; if actuator stem is galled, replace it

stem to gall on stem collar

5. Valve bearings may have been damaged 5. Replace bearings according to Maintenance Bulletin 10

Excessive leakage 1. Improper adjustment of external stroke stops 1. See “Adjusting the External Stroke Stops” section

through seat 2. Seat damage 2. See Maintenance Bulletin 10 to replace seat ring

Actuator operates, 1. Broken rod end or pivot pin 1. Replace rod end

shaft does not rotate 2. Broken rod end bearing 2. Replace rod end bearing

Valtek International is represented by factory-trained manufacturer representatives throughout the world.

Valtek International Headquarters–Springville, UT 84663

Phone 801 489 8611 Fax 801 489 3719

Valtek Baton Rouge – Baton Rouge, LA 70809

Phone 504 751 9880 Fax 504 755 0728

Valtek Beaumont – Beaumont, TX 77705

Phone 409 842 0087 Fax 409 842 4444

Valtek Corpus Christi – Corpus Christi, TX 78408

Phone 512 289 6911 Fax 512 289 6917

Valtek Houston – Deer Park, TX 77536

Phone 713 479 9500 Fax 713 479 8511

Valtek Philadelphia – Boothwyn, PA 19061

Phone 215 497 8600 Fax 215 497 6680

Valtek Controls Ltd. – Edmonton, Alberta T6P 1K6

Phone 403 449 4850 Fax 403 449 4851

Valtek Australia Pty. Ltd. – Scoresby, Victoria 3179

Phone 3 764 8522 Fax 3 764 0013

Valtek Engineering Ltd. – Pershore, England WR10 2BZ

Phone 386 554 551 Fax 386 554 968

Kämmer Valves Inc. – Pittsburgh, PA 15205

Phone 412 787 8803 Fax 412 787 1944

Kämmer Ventile GmbH – Essen, Germany

Phone 201 29407 0 Fax 201 29407 62

Valtek-Sereg Vannes S.A. – Paris, France

Phone 64 47 21 00 Fax 64 47 20 94

Valtek Sulamericana Ltda. – Sao Paulo 09940, Brazil

Phone 11 745 1011 Fax 11 745 2477

Valtek India Ltd. – Ahmedabad, India

Phone 272 813319 Fax 91 22 623 1055

Durco Valtek Pte. Ltd. – Singapore 2263

Phone 862 3332 Fax 862 2800

Yokogawa•Kitz •Valtek – Tokyo 141, Japan

Phone 03 5434 5963 Fax 03 5434 5930

Valtek Nederland BV – IJssel, Holland

Phone 10 458 6388 Fax 10 442 1255

C

S

E

L

I

T

R

E

ISO

9000

E

C

T

L

O

F

I

E

D

S

N

O

I

T

A

C

© 1994, Valtek Incorporated, a subsidiary of The Duriron Company, Inc.

4

Valtek is a registered trademark of Valtek Incorporated.

Loading...

Loading...