Page 1

Anchor Darling Swing Check

Installation

INSTRUCTION MANUAL

Sizes 2-1/2” through 24”

FCD ADENIM0013-00

Operation

Maintenance

Page 2

Swing Check Valves FCD ADENIM0013-00

REVISION RECORD

Revision Section Description Date

- All Original Issue 09/18/2003

1

Page 3

TABLE OF CONTENTS

1.0

VALVE DESCRIPTION Page

1.1 Recommended Uses .................................................5

1.2 Principles of Operation .............................................. 5

1.3 Design Features ...................................................... 6

1.3.1 Bonnet Seals ............................................... 6

1.3.2 Disc Assembly and Seats............................7

1.3.3 Seat ...................................................... 8

2.0

CARE OF VALVE PRIOR TO INSTALLATION

2.1 Receiving Inspection..................................................8

Swing Check Valves FCD ADENIM0013-00

2.2 Handling .................................................................. 9

2.3 Storage .................................................................. 9

3.0

INSTALLATION INSTRUCTIONS

3.1 Rigging .....................................................................9

3.2 Cleaning ..................................................................... 9

3.3 Installing Valve In Line............................................... 9

4.0

VALVE MAINTENANCE

4.1 Inspection ....................................................... 10

4.2 Cleaning ....................................................... 10

4.3 Bolt Torquing ........................................................ 10

4.4 Refinish Sealing Surfaces........................................10

2

Page 4

TABLE OF CONTENTS

5.0

DISASSEMBLY Page

5.1 Flanged Bonnet Valves.......................................................... 11

5.1.1 Bonnet .................................................................. 11

5.1.2 Disc Assembly......................................................... 13

5.1.2.1 Configuration A ......................................... 13

5.1.2.1.1 Pipe Plug Seal Cover .............. 14

5.1.2.1.2 Pressure Seal Cover ............... 15

5.1.2.1.3 Blind Cover Flange.................. 15

5.1.2.2 Configuration B ...................................... 16

5.1.2.3 Configuration C ...................................... 17

Swing Check Valves FCD ADENIM0013-00

5.1.2.4 Disc/Hinge Assembly ................................ 18

5.2 Pressure Seal Bonnet Valves ................................................ 19

5.2.1 Bonnet .................................................................. 19

5.2.2 Disc Assembly......................................................... 19

6.0

ASSEMBLY

6.1 Flanged Bonnet Valves.......................................................... 21

6.1.1 Disc Assembly......................................................... 21

6.1.1.1 Disc/Hinge Connection.............................. 21

6.1.1.2 Hinge Mounting ......................................... 22

6.1.1.2.1 Pin Mounted in Body Wall ......... 22

6.1.1.2.2 Bracket Pin on Bonnet .............. 24

6.1.1.2.3 Bracket Pin in Body................... 25

6.1.2 Bonnet ..................................................................... 26

6.2 Pressure Seal Bonnet Valves ................................................ 27

6.2.1 Disc Assembly......................................................... 27

6.2.2 Bonnet ..................................................................... 28

3

Page 5

Swing Check Valves FCD ADENIM0013-00

4

Page 6

Swing Check Valves FCD ADENIM0013-00

1.0 VALVE DESCRIPTION

1.1 Recommended Uses

Anchor/Darling Swing Check Valves are designed to prevent the reversal of flow in a piping system. While they

may hold pressure in the reverse direction, they are not intended for use as isolation valves without special

provisions e.g. elastomeric seats. A reliable seal across the disc can be expected if the reverse flow or

differential pressure is large. However, when the differential pressure is low, difficulty may be encountered in

obtaining a tight seal without special features being added to the valve. If the system operation requires sealing

against a low pressure, Anchor/Darling should be consulted.

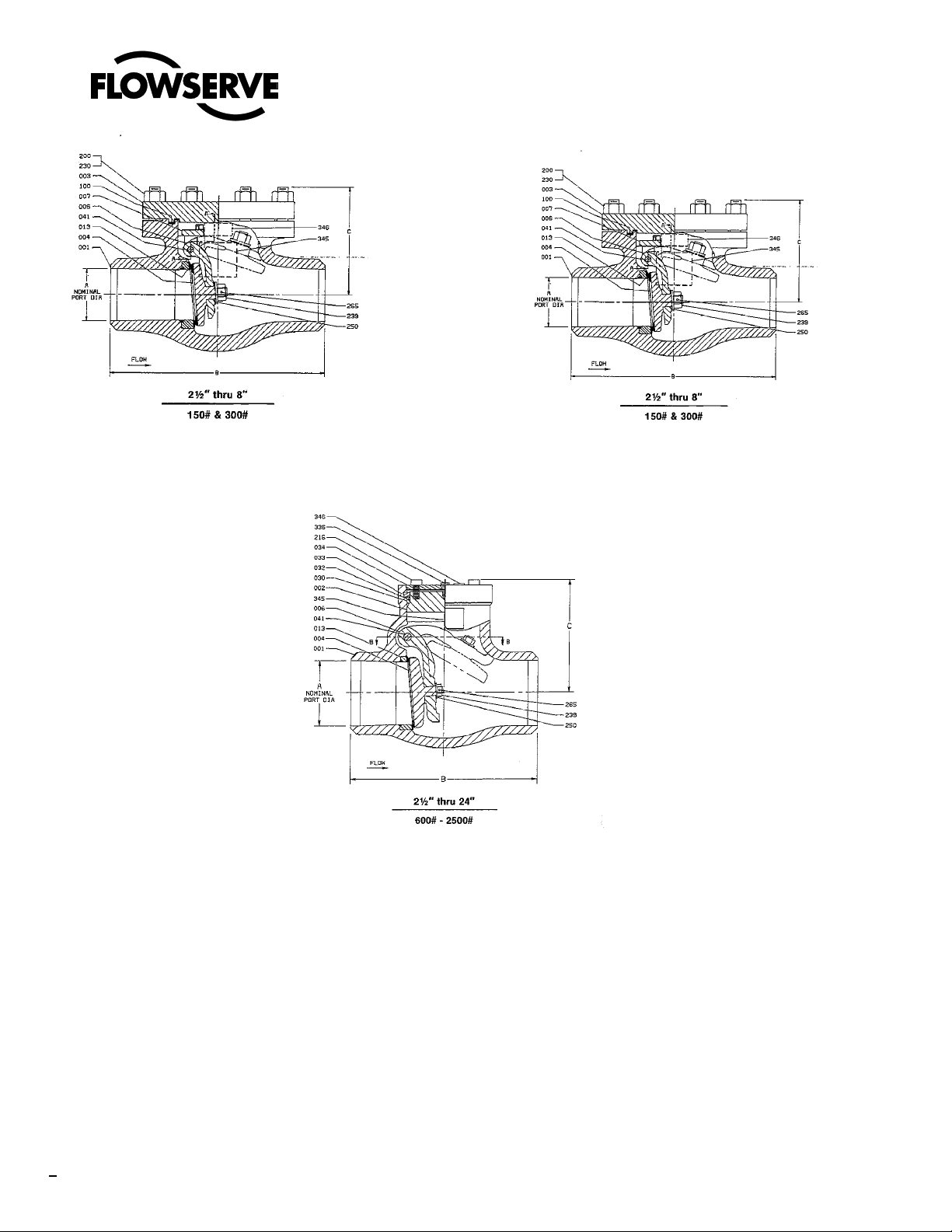

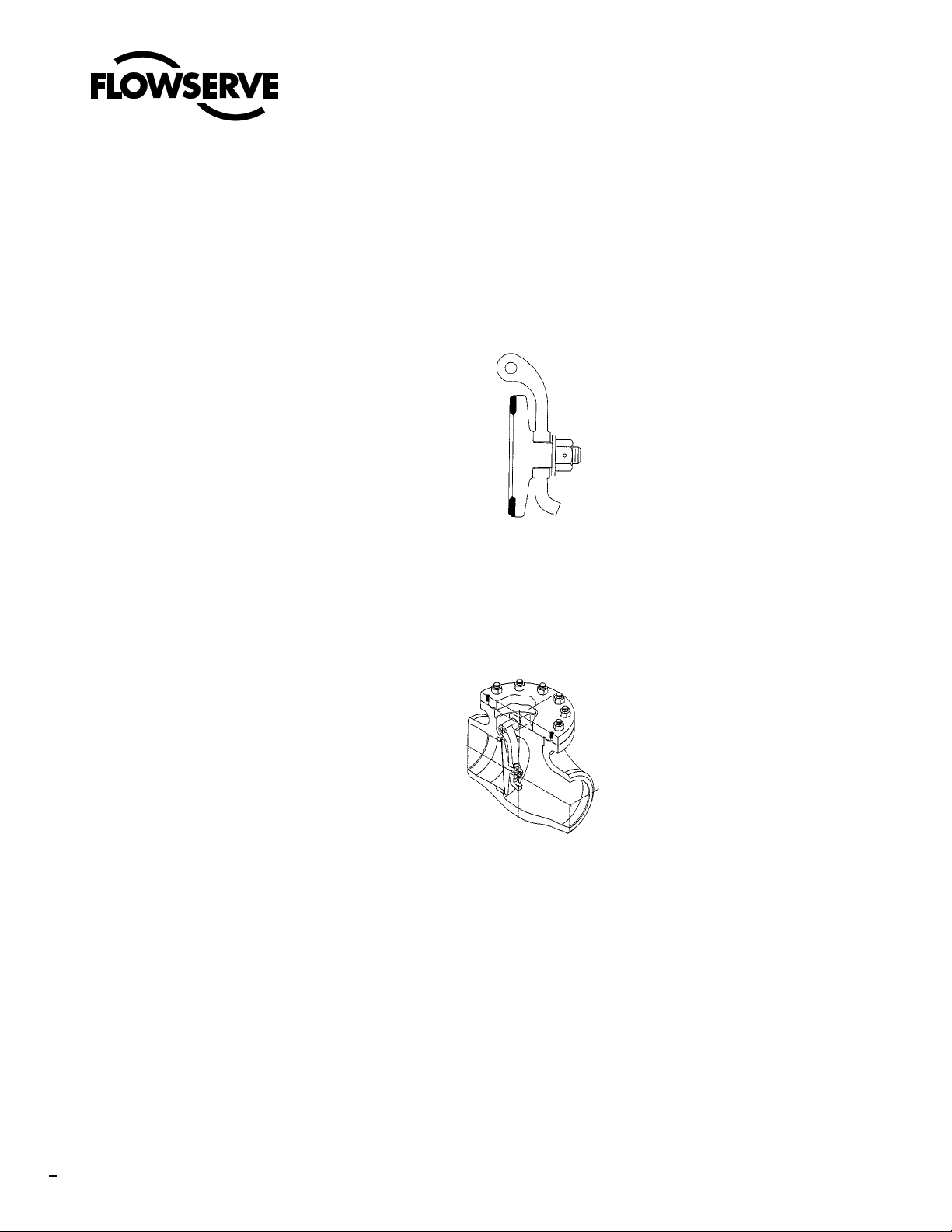

1.2 Principles of Operation (Fig. 1)

The principle parts of a swing check valve are the body, bonnet, disc and hinge assembly. The body and bonnet

contain the fluid within the system. The disc is mounted on a hinge arm which rotates about a shaft positioned

above the seat in the body neck. Flow in the normal direction creates a force on the disc which causes it and the

hinge to rotate about the shaft. With increasing flow the disc assembly is rotated further from the seat up into the

body neck. In the full open position a stop on the back of the hinge contacts the body. This positions the major

portion of the assembly out of the flow stream and permits unobstructed fluid flow through the valve. Upon the

cessation of forward flow or reversal of flow direction, the force holding the disc assembly open is no longer

present, whereupon the weight of the assembly combined with the reverse flow causes the disc to return to the

seat. Any seal obtained between the disc and the seat results solely from the difference in pressure across the

disc. Hence, the difficulty in maintaining a tight seal at low pressures.

Figure 1

5

Page 7

Swing Check Valves FCD ADENIM0013-00

1.0 VALVE DESCRIPTION

1.3 Design Features

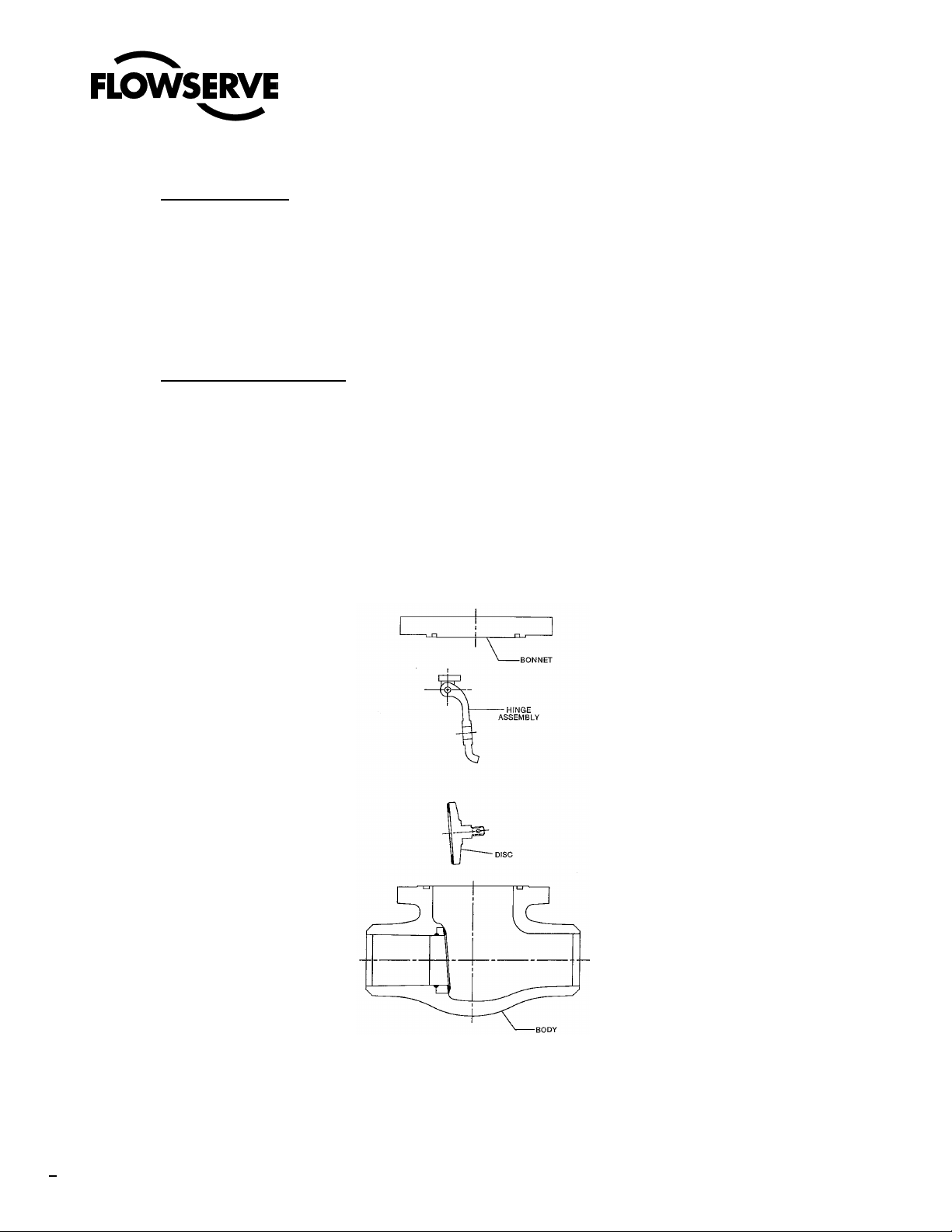

1.3.1 Bonnet Seals

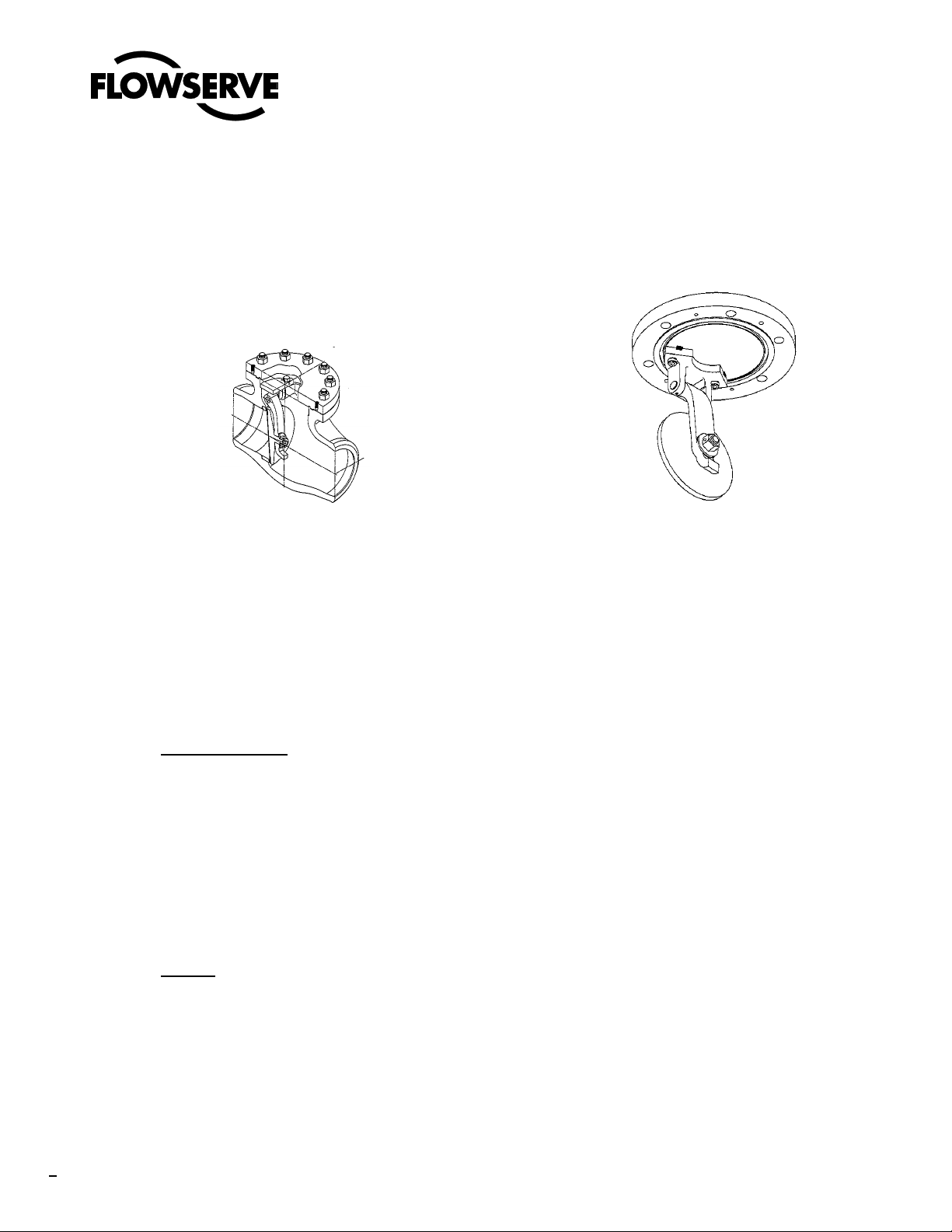

Anchor/Darling swing check valves are supplied with two basic types of body/bonnet closures; bolted

bonnet or pressure seal. The bolted bonnet closure (Fig. 2) is a bolted flange tongue and groove joint

with a gasket generally comprised of spiral-wound stainless steel and asbestos filler. The seal

depends upon the bolt preload to maintain sufficient compressive force on the gasket.

Pressure seal type closures (Fig. 3) utilize a tapered soft metal ring gasket for sealing. The gasket is

contained within the body neck bore by a retaining ring. The tapered inner surface of the gasket bears

against a mating angular surface on the valve bonnet. Under internal pressure, the bonnet is forced

against the pressure seal gasket, wedging it against the body neck wall. A slight interference angle

produces a line contact and high sealing pressure. The greater the valve pressure, the tighter the

metal-to-metal seal. No bolting is required to maintain the seal although the bonnet is initially drawn

into contact with the pressure seal by cap screws.

(Continued)

Figure 2 Figure 3

6

Page 8

Swing Check Valves FCD ADENIM0013-00

1.0 VALVE DESCRIPTION

1.3.2 Disc Assembly

The disc assembly (Fig. 4) consists of a flat faced disc tapering back to an integral disc pin. The

threaded pin (and disc), loosely mounted in a hole in the bottom of the hinge arm, is held in place by a

heavy nut that is drilled and pinned. The flexible disc-hinge connection permits the disc to completely

contact the seat even if there is minor seat face movement. The hinge arm rotates about the hinge pin

and has a stop on its tail below the disc pin hole. The stop contacts the body in the fully open position

and prevents damaging impact forces from reaching the disc.

Three methods of supporting the hinge pin in the body have been used. Where shaft penetration of the

body is acceptable (Fig. 5) or desirable, the pin is supported in journals that are integrally cast in the

body neck above the seat ring. One journal is drilled through the body wall to permit insertion of the

pin. In this design, the body penetration is sealed by a spiral wound gasket and a blind flange.

(Continued)

Figure 4

7

Figure 5

Page 9

Swing Check Valves FCD ADENIM0013-00

1.0 VALVE DESCRIPTION

1.3.2 Disc Assembly (continued)

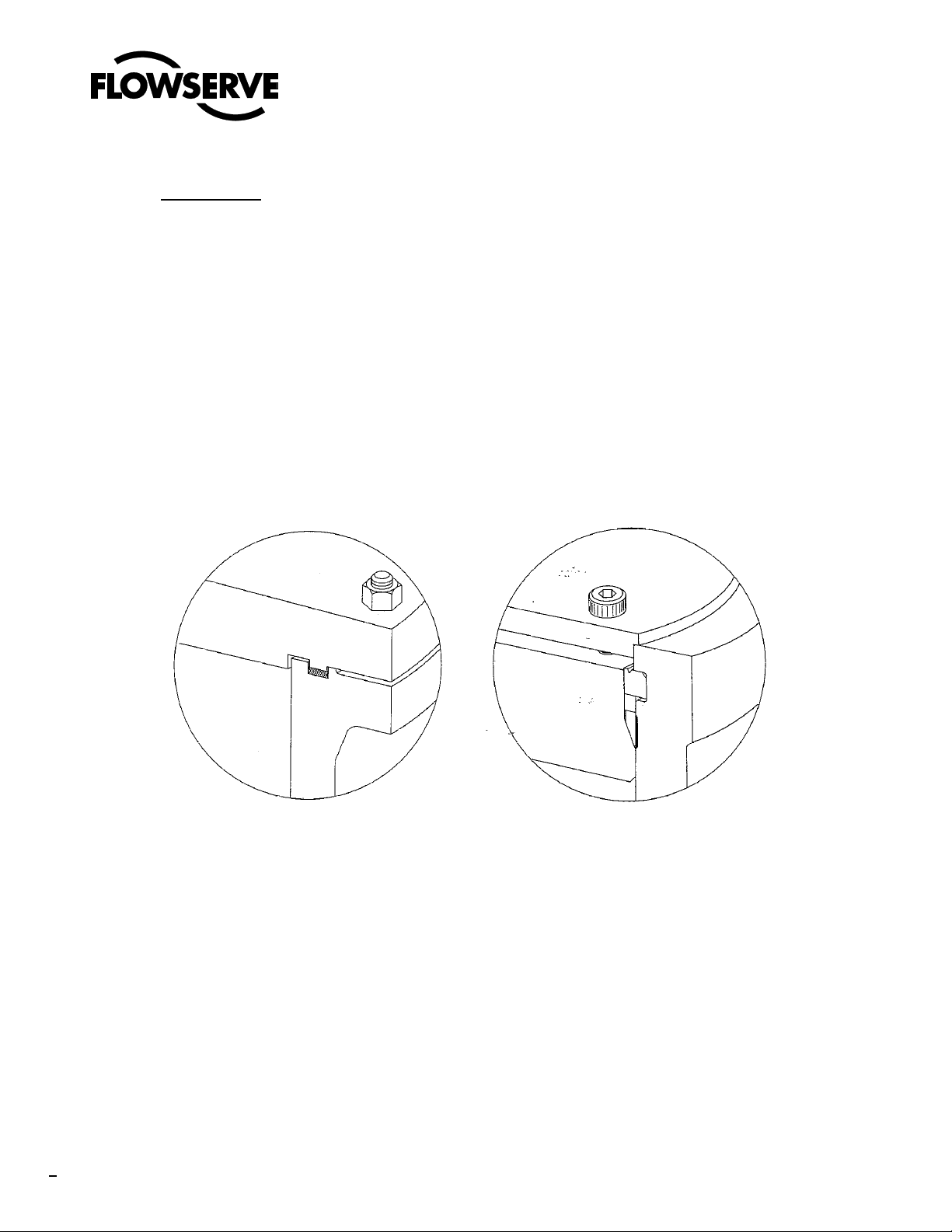

In an alternate arrangement (Fig. 6) the pin is supported in a bracket that mounts on two pads located

above the seat ring. The pin and hinge fit down between the pads and are captured by them. In a third

configuration (Fig. 7), the pin is supported in a bracket attached to the bonnet.

Figure 6 Figure 7

1.3.3 Seat

The seat ring is set into a machined recess in the body port which supports and retains the ring. A seal

weld is provided between the body and the ring. This weld is for sealing only and is not structural. The

seat ring is replaceable.

(Continued)

2.0 CARE OF VALVE PRIOR TO INSTALLATION

2.1 Receiving Inspection

Upon receipt of the valve, thoroughly inspect it for shipping damage. As a minimum, the following items should

be checked:

1. Missing or loose bolting?

2. End covers in place?

3. Is valve securely fastened to shipping skid?

4. Abrasion - damaged paint?

5. Are spare parts shipped with valve and secure?

2.2 Handling

Anchor/Darling valves are shipped strapped to wooden skids designed to be moved by forklift. It is

recommended that when being handled prior to installation, the valve be kept on its skids and a forklift truck be

used for moving. If an overhead crane is used, care must be exercised to center the load. The slings should not

lift the valve by the wooden skid structure alone, but must pass under the valve.

8

Page 10

Swing Check Valves FCD ADENIM0013-00

2.0 CARE OF VALVE PRIOR TO INSTALLATION

2.3 Storage

Store valves on their shipping skids in a clean and dry area protected from the weather.

3.0 INSTALLATION INSTRUCTIONS

3.1 Rigging

When lifting the valve for installation in the line, it is important that slings of adequate size be used. The capacity

of the sling must exceed the weight of the valve. Slings should pass under the valve body. Block carefully to

prevent damage or abrasion of component parts and finishes.

3.2 Cleaning

Prior to installation remove the valve end covers and inspect for cleanliness. If any sign of foreign matter is

observed

in the valve internals, open the valve and place it on its side and flush thoroughly with water. Steam or air may

be used if water is not available but exercise caution that the high velocity does not drive debris into clearance

spaces.

3.3 Installing Valve In-line

The pipe must be properly supported and aligned with the valve. Seat leakage in valves is frequently caused by

seat misalignment resulting from excessive end movements introduced in the cold springing of the connecting

pipe. Check valves, with their automatic operation, must be installed with the flow in the proper direction. The

arrow on body should point in the normal flow direction, I.e., the direction in which flow is desired. Swing check

valves can be installed in both horizontal and vertical lines. However, in vertical lines the normal flow must be

upward and the checked flow downward. In all installations the valve must be oriented such that the hinge pin is

horizontal.

(Continued)

4.0 VALVE MAINTENANCE

Anchor/Darling Valves are designed to be essentially maintenance free pieces of equipment. When used in the proper

application and operated correctly they will provide reliable operation for many years. Some other maintenance

recommendations are included in the following sections for information.

9

Page 11

Swing Check Valves FCD ADENIM0013-00

4.0 VALVE MAINTENANCE

4.1 Inspection

The most important aspect of valve maintenance is periodic inspection. The early detection of a malfunction

can, in many cases, prevent a minor defect from becoming a major problem. It is very important that leakage

from any of the major seals (disc/seat, body-bonnet) be addressed immediately. The smallest weepage can

quickly become a major problem if it is not treated promptly. Some other areas that should be included in a

periodic inspection program are:

1. Cleaning: Pressure Seal Area and Body-Bonnet Studs

2. Bolting: Body-Bonnet and Hinge Pin Cover

4.2 Cleaning

The frequency and extent of cleaning will depend on the valves' location and service conditions. Do not allow

water or dirt to collect in the body neck bore area above the pressure seal of pressure seal valves. The build up

of corrosion or extraneous material may interfere with removal of the bonnet. For the same reason, excessive

rust should not be allowed to build-up on the body-bonnet bolting of bolted bonnet valves.

4.3 Bolt Torquing

At regular intervals, not more than six months, check the tightness of all bolting. Bolted bonnet valves should

have the body-bonnet bolting torqued to the valves shown in Table 2.

4.4 Refinishing Sealing Surfaces

Minor discontinuities in both the disc and seat sealing surfaces, which may cause leakage, can, in many cases,

be removed by lapping. Major defects such as cracks or deep gouges will generally require replacement of the

part.

(NOTE: Lapping is a polishing process in which a sealing surface is ground with an abrasive held in place by a

special fixture. The abrasive is commonly found in paste form or bonded to a paper backing. Detailed

instructions on the use of lapping abrasives and fixtures, normally supplied with such equipment, should be

adhered to). In addition to the following lapping materials manufacturers' recommendations, the following

precaution should be observed. Anchor/Darling swing check valves are supplied with a crowned sealing

surface on the seat in order to provide precise seat width and tight sealing. Lapping of the seat will cause the

sealing band width to be significantly increased.

Subsequent to all seat refinishing operations, the seat width must be checked against dimensions supplied in

Table 1 and reduced if necessary. Failure to do so may create leakage problems, particularly at low pressures.

(Continued)

10

Page 12

Swing Check Valves FCD ADENIM0013-00

4.0 VALVE MAINTENANCE

4.4 Refinishing Sealing Surfaces (Continued)

Seat Ring

Swing Check

For 150# and 300#

F = 3/32”

(Continued)

Hardfacing

NOMINAL SEAT WIDTH

Valve Size

2-1/2 .090 .090 .125

3 .090 .090 .125

4 .090 .090 .156

6 .125 .125 .187

8 .125 .156 .218

10 .156 .156 .250

12 .156 .187 .250

14 .156 .187 .250

16 .187 .218 .281

18 .187 .218 .312

20 .187 .218 .312

22 .187 .218 .312

24 .187 .218 .312

600# 900# 1500#

TABLE 1

F

5.0 DISASSEMBLY

By carefully following these instructions, any Anchor/Darling valve can be easily disassembled and reassembled. If

problems are encountered with equipment, Anchor/Darling Field Service should be contacted. The use of improper tools

or methods may cause severe damage to the valve and may void the warranty. Prior to attempting disassembly of a

particular valve, refer to the specific assembly drawing for the valve.

5.1 Flanged Bonnet Valves

5.1.1 Bonnet (Fig. 8)

Remove the nuts (230) from the bonnet studs (200). Although it is not imperative, it may be helpful to

loosen the nuts in a criss-cross pattern (Fig. 18). With the nuts removed, the bonnet can be lifted off

the body. Tapped holes are provided in the top of larger bonnets to accept eyebolts. The bonnets on

these valves are most easily raised using slings attached to the eyebolts. (NOTE: Some older

Anchor/Darling swing check valves were designed with the disc assembly attached to the bonnet (See

5.1.2.2). With this design care should be taken in raising the bonnet so that the disc is not damaged.)

With the bonnet removed, the old gasket (100) should be lifted out of its groove. Be careful not to

damage the gasket sealing surface.

11

Page 13

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

(Continued)

FIGURE 8

12

Page 14

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

5.1.2 Disc Assembly

Three methods of supporting the disc assembly in the body have been used by Anchor/Darling.

A. Hinge rotates on pin inserted through body wall (Fig. 9).

B. Hinge rotates on pin mounted in bracket hung from bonnet (Fig. 14).

C. Hinge rotates on pin supported in bracket mounted on pads above seat ring (Fig 15).

(Fig. 15) is the design currently supplied by Anchor/Darling.

5.1.2.1 Configuration A (Figure 9)

(Continued)

Removal of the disc assembly in this design, necessitates withdrawing the hinge pin (5) from

side of body. The hinge pin is retained in the body by one of three methods. The hinge pin

cover in each of the designs is used to seal the penetration of the body.

A. Pipe plug threaded into body and sealed by either an asbestos or spiral wound gasket.

B. Pressure seal joint.

C. Blind flange attached to body by studs and sealed with a spiral wound gasket or seal

welded.

Prior to withdrawing the hinge pin in this configuration, make sure the hinge/disc assembly is

properly supported either by hand or with slings and that the weight of the assembly is not on

the hinge pin.

FIGURE 9

13

Page 15

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

(Continued)

5.1.2.1.1 Pipe Plug Seal Cover (Fig 10 & 11)

In this design the cover (5A) is removed by unthreading the plug out of the body. In

some smaller valves, the plug may be an integral part of hinge pin (5) and its

removal will as well withdraw the pin. In larger valves, the plug is a separate part

and can be removed by itself. Where a separate plug is provided, a roll pin (58),

inserted into the ends of both the plug and the hinge pin, serves to prevent hinge pin

rotation. Care must be taken during disassembly not to misplace it.

FIGURE 10

FIGURE 11

14

Page 16

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

(Continued)

5.1.2.1.2 Pressure Seal Cover (Fig 12)

In this design, the hinge pin cover (10) holds a metal gasket (6A) against the hinge

pin bonnet (2A) by studs threaded into the body. As with the pipe plug design, in

small valves the bonnet may be an integral part of the hinge pin (5). To remove the

cover, unthread the nuts (8A) off the studs (8). The cover can then be removed. The

gasket and bonnet are most easily removed as one unit. The bonnet is provided

with a tapped hole in the end. If the hinge pin cover has not been disassembled for

a long period of time the gasket and bonnet may stick in the body. Prior to

attempting removal, lubricate the area well with penetrating oil. Although the hole in

the bonnet is intended for an eye bolt, if the bonnet is extremely tight a slide

hammer may be attached to the bonnet to free it. In withdrawing the bonnet/gasket it

is important to pull on the assembly squarely. If the bonnet/gasket becomes cocked,

removal can be quite difficult. Once the bonnet and gasket are removed, the hinge

pin can be withdrawn.

FIGURE 12

5.1.2.1.3 Blind Flange Cover (Fig 13)

In this design the cover (037) is held against a spiral wound gasket (101) by nuts on

studs threaded into the body. The cover can be removed after the cover nuts (229)

are unthreaded off the studs. A roll pin (263) inserted into the cover and the end of

the hinge pin (039) is used to prevent rotation of the hinge pin. Care must be taken

during disassembly to avoid misplacing it. With the cover off, the hinge pin can be

withdrawn. A tapped hole is provided in the end of the hinge pin to facilitate

withdrawal.

FIGURE 13

15

Page 17

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

5.1.2.2 Configuration (Fig. 14)

(Continued)

In this configuration, the disc assembly is attached to the bonnet and will come out of the

body along with it. Once free of the body, the bonnet can be laid down with disc assembly

upmost. To remove the disc/hinge assembly, loosen the staked-setscrew(220) that holds the

hinge pin (041) in the hinge support bracket (007). With the disc/hinge assembly properly

supported the pin can be withdrawn.

(NOTE: The hinge support bracket mounting position on the bonnet is critical. Removal of the

bracket should not be attempted unless the bracket is damaged beyond further use. If

replacement of the bracket is required, an Anchor/Darling Field Service Engineer should be

contacted for assistance.)

FIGURE 14

16

Page 18

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

5.1.2.3 Configuration C (Fig. 15)

(Continued)

In this configuration, the disc assembly is mounted on pads in the body and held in place by

hex head bolts. To remove the assembly, bend back the tabs on the tab lock washers (251)

and unthread the hex head bolts (289). The hinge support (007) can now be raised. The

hinge pin (041) is held in place by two retaining rings (245). Once the disc assembly is safely

supported, the retaining rings can be removed and the pin withdrawn. A pin (257) is used to

prevent rotation of pin in the bracket. Care should be taken not to misplace it.

FIGURE 15

17

Page 19

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

5.1.2.4 Disc/Hinge Assembly (Fig. 16)

(Continued)

The disc (004) in all Anchor/Darling swing check valves is attached to the hinge by means of

a disc in (an integral part of the disc) which is inserted into a hole in the lower portion of the

hinge. It is held in place by a disc nut (239 or 4B) and a disc washer (250 or 4A) threaded on

the disc pin. The nut is locked by either a lock wire or a disc nut pin (265 or 4C). The disc can

be removed from the hinge by removing the disc nut pin, the disc nut and the disc washer, in

that order. The disc can then be separated from the hinge.

FIGURE 16

18

Page 20

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

5.2 Pressure Seal Bonnet Valves (Fig 17)

5.2.1 Bonnet

A. Unbolt the capscrews (bonnet) (216) and remove the bonnet retainer (034). Set aside for use later.

B. Tap Ule 150nnet sharply to break the seal between it and the pressure seal gasket (030).The

bonnet will drop downward against its stop, uncovering the retaining ring (gasket) (033).

C. The retaining ring (gasket) (033) is comprised of four segments, one of which has a small drilled

hole. Remove this piece first. The groove in the top of the retaining ring gasket permits the use of a

pry bar or screwdriver in removing the segments. In some cases, it may be necessary to loosen the

segments by tapping with a hammer or bar.

D. The bonnet is now ready for removal from the body. The tight clearances between the body bonnet

and gasket, necessary for a reliable seal, require that the' bonnet be withdrawn squarely 'from the neck

bore. The slightest cocking of the bonnet during withdrawal can cause it to bind. Therefore, it is

recommended prior to removal, that the squareness of bonnet and gasket with respect to the body be

checked. This is most easily accomplished by measuring the distance between the top of the gasket

and top of the body neck. If the gasket is not square, it should be tapped with a brass rod until it is.

With large bonnets i(is a good idea as well to periodically check the squareness of bonnet as it 'is

being withdrawn. Binding any time during withdrawal indicates the bonnet has cocked. Further efforts

to force the, bonnet will generally make the situation worse. At the first sign of binding, stop and check

the squareness of the bonnet.

E. The preferred method of lifting the bonnet is by using slings attached to an eyebolt threaded into the

tapped hole in its center.

F. Following the above procedure will, in most cases, result in removal of the bonnet with little difficulty.

However, certain circumstances, such as installation of the valve in other than a horizontal orientation,

may cause complications. If greater difficulty is encountered, an Anchor/Darling service engineer

should be consulted. Excessive force which may damage critical surfaces should be avoided.

G. It is not normally recommended that the pressure seal gasket be reused. However, if a spare

gasket is not available, mark the gasket, bonnet and body prior to removal so that the gasket may be

reinstalled in its original orientation.

5.2.2 Disc Assembly

Anchor/Darling pressure seal swing check valves have been supplied with disc support configurations

as described in sections 5.1.2.1 and 5.1.2.3. Refer to these sections and section 5.1.2.4 for

disassembly procedures.

(Continued)

19

Page 21

Swing Check Valves FCD ADENIM0013-00

5.0 DISASSEMBLY

(Continued)

20

FIGURE 17

Page 22

6.0 ASSEMBLY

Before starting the reassembly of the valve, all parts should be thoroughly cleaned and inspected. All foreign material

should be removed from any area of the valve. However, there are certain critical areas that must be free of dirt, weld

spatter, filings, etc. These include the following:

1. Disc and seat sealing surfaces

2. Bonnet 00 (on pressure seal valves)

3. Body neck 10 (on pressure seal valves)

4. Gasket tongue (on flanged bonnets)

5. Gasket groove (on flanged bodies)

6. Bonnet studs and nuts

7. Hinge pin

8. Hinge pin cover gasket groove in body

9. Hinge pin cover

10. Pressure seal gasket

The above areas must also be free of any nicks, scratches, gouges, etc. Any damage in these areas must be repaired.

Any questions about the acceptability of any surface condition should be discussed with a service engineer prior to using

the part.

6.1 Flanged Bonnet Valves

6.1.1 Disc Assembly

6.1.1.1 Disc/Hinge Connection (Fig. 16)

The disc (004) is attached to the hinge (006) by inserting the pin on the back of the disc

through the hole in the lower end of the hinge. The disc washer (250 or 4A) and the disc nut

(239 or 4B) are then threaded on the pin. With the disc nut tight on the pin, there should be

freedom of movement between the disc and the hinge. If the disc if tightly connected, back off

the disc nut one turn.

If the valve is being reassembled with the original parts, the correct position of the nut can be

determined by aligning the disc nut pin holes in the nut and the disc pin. If new parts are

being used, the hole for the disc nut pin must be drilled through the nut and disc pin. Once

the nut is positioned properly, the disc nut pin (265) should then be inserted into the hole and

the ends peened over.

Swing Check Valves FCD ADENIM0013-00

FIGURE 16

21

Page 23

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

(Continued)

6.1.1.2 Hinge Mounting

6.1.1.2.1 Pin Mounted in Body Wall (Figs. 9-13)

Pin Mounted in Body Wall (Figs. 9·13). The disc assembly should be lowered into

the body and supported either by hand or with a sling. With the pin (039, 041, 5)

partially inserted through the body wall, align the hinge assembly with the pin and

push the pin through the hinge, into the journal on the opposite body wall.

Depending on the type of hinge cover supplied it may be necessary to affix a roll pin

(58) between the end of the hinge pin and the cover, plug or bonnet (037, 10, SA).

With the plug type cover (Fig. 11) in which the plug is an integral part of the pin the

gasket should be placed on the plug prior to insertion of the pin. If the plug is

separate, the gasket and the roll pin should be affixed and the plug screwed into the

body. Where a spiral wound gasket is used, care must be taken to correctly

compress the gasket. The plug should be tightened until the proper compressed

gasket thickness is achieved.

Where a pressure seal bonnet has been supplied, the pin (5) and bonnet (2A) or

integral pin/bonnet should be inserted. The gasket can then be inserted into the

bore until it contacts the bonnet. With the above in position the cover (10) is fitted on

to the studs (11) and pushed up against the gasket. Using a criss cross pattern the

nuts should be torqued to the valves shown in Table (2). Where a blind flange cover

is used, the gasket (101) and roll pin (263) should be affixed and the cover (037)

placed over the studs (208). After the nuts (229) have been threaded on to the

studs, they should be torqued to the values listed in Table 2.

FIGURE 9

22

Page 24

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

(Continued)

6.1.1.2.1 Pin Mounted in Body Wall (Figs. 9-13)(Continued)

FIGURE 10

FIGURE 11

FIGURE 12

FIGURE 13

23

Page 25

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

(Continued)

6.1.1.2.2 Pin Mounted in Bracket on Bonnet (Fig 14)

Where a pressure seal bonnet has been supplied, the pin (5) and bonnet (2A) or

integral pin/bonnet should be inserted. The gasket can then be inserted into the

bore until it contacts the bonnet. With the above in position the cover (10) is fitted on

to the studs (11) and pushed up against the gasket. Using a criss cross pattern the

nuts should be torqued to

the vaives shown in Table (2). Where a blind flange cover is used, the gasket (101)

and roll pin (263) should be affixed and the cover (037) placed over the studs (208).

After the nuts (229) have been threaded on to the studs, they should be torqued to

the values listed in Table 2.

24

FIGURE 14

Page 26

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

(Continued)

6.1.1.2.3 Pin Mounted on Bracket in Body (Fig 15)

With the hinge assembly supported, the hinge support (007) should be placed over

the hinge end and the hinge pin (041) (with the retaining pin (257) in place) inserted

into position. Prior to installing the assembly in the body, position the two spring

pins (258) on the pads in the body. The assembly can now be lowered over the

pins into position on the pads. Put a washer (Tab Lock) (251) on each hinge support

bolt (289), insert them through the hinge support bracket into the body and tighten.

Once they are in place, the tabs on the lock washer should be bent over.

FIGURE 15

25

Page 27

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

6.1.2 Bonnet

(Continued)

Prior to lowering the cap (003) into position, a new gasket (100) should be placed in the gasket groove

on the body flange. The bonnet can then be lowered into place. On valves where the hinge is attached

to the bonnet, care should be taken to insure that the disc is aligned correctly with the seat. This is

accomplished by lining up the dowel pin with the holes in the body and bonnet. With the bonnet in

place, the studs (200) and nuts (230) can be installed. Prior to installation the studs and nuts should be

cleaned and thoroughly lubricated with a high quality lubricant. Any nuts or studs with damaged

threads should be replaced. It is very important that the body·bonnet bolting be torqued to specific

values in accordance with the procedure listed below. The torque values are shown in Table 2 for

various diameter studs and materials. The nuts should be tightened evenly using a crisscross pattern

similar to the one shown in Fig. 18. Tighten all of the nuts to 1/3 of the recommended value initially.

Then repeat the sequence raising the torque to 2/3 of full torque. Finally, torque all the nuts to the

recommended value following the criss-cross pattern. It is essential that the flange faces remain

parallel and all the bolting has uniform tension. Failure to achieve this may cause gasket weepage

when the joint is subjected to operating pressures and temperatures.

FIGURE 18

26

Page 28

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

The following torque values are provided for guidance in filed work. These maximum torque values

*Nominal torque values are 20% less than these values.

6.2 Pressure Seal Bonnet Valves

6.2.1 Disc – Hinge Assembly

(Continued)

MAXIMUM TORQUES FOR FIELD SERVICE (Ft. Lb.)

provide for a range of friction coefficients without damage to the designated bolting material.

Stud Size

5/16 -18 11 6.5 12 13 15

3/8 – 16 20 12 20 23 26

7/16 – 14 30 19 30 36 44

½ - 13 45 28 50 55 67

9/16 – 12 70 40 70 80 -

5/8 – 11 90 56 100 110 130

¾ - 10 165 100 165 195 230

7/8 – 9 270 160 280 310 375

1 – 8 400 240 420 470 560

1 1/8 - 8 600 350 600 690 800

1 ¼ - 8 800 500 850 970 1140

1 3/8 – 8 1100 675 1200 1320 1500

1 ½ - 8 1500 900 1600 1750 1970

1 5/8 – 8 1900 1150 2000 2250 -

1 ¾ - 8 2400 1450 2500 2850 3100

1 7/8 – 8 3000 1800 3200 3500 -

2 – 8 3700 2200 3900 4300 4600

2 1/8 – 8 4400 2650 4700 5200 -

2 ¼ - 8 5300 3200 5600 6200 6900

2 ½ - 8 7400 4400 8000 8600 9400

2 ¾ - 8 8700 5900 10400 11600 12800

3 – 8 11400 7800 13000 15200 16900

The disc assembly procedure in a pressure seal valve is identical to the one for flanged bonnet valves

included in section 6.1.1. Refer to it for instructions.

A193

B7 & B16

A193

B8 &B8M

TABLE 2

A453

660

A564

630

A574

27

Page 29

Swing Check Valves FCD ADENIM0013-00

6.0 ASSEMBLY

6.2.2 Bonnet

(Continued)

Once the hinge - disc assembly is in place, the bonnet (002) can be inserted into the neck. Care must

be taken in lowering the bonnet. It is again very important to keep the bonnet from cocking, as it is

lowered into the body. If it does bind, the bonnet must be straightened before insertion can continue.

Measuring from the bonnet bolting surface to the top of the body is the simplest way to detect cocking.

With the bonnet resting on the counterbore in the neck, a new gasket (030) and the spacer ring (032)

can be inserted. In that the gasket may also cock, it must be inserted with care. Once these are in

place, the four-piece gasket retainer (033) can be put into place. It is important to remember that the

piece with the drilled hole must be positioned last. If the valve is installed in other than a horizontal

position, it may be necessary to orient or hold the retainer such that the pieces stay in place until the

bonnet is moved into its raised position. Prior to installing the bonnet retainer, the pipe plug (336)

should be removed. A threaded rod, long enough to extend from the top of the bonnet above the body

neck should be inserted into the tapped hole in the center of the bonnet. The bonnet retainer (034)

can now be lowered over the top of the rod and set into position. Using the threaded rod the bonnet

can be raised into its position and the bonnet capscrews (216) inserted through the retainer and

threaded into their holes in the bonnet. By turning each capscrew a couple of turns, proceeding to the

adjacent capscrew, turning it and then repeating this around the bolt circle, the bonnet will be raised

squarely until it is firmly in contact with the gasket. Note that while the capscrews need not be torqued

to a specific value to maintain a tight seal at system pressures, they should be tightened with wrench

to insure good gasket-body-bonnet seal contact before the full pressure is reached.

FIGURE 17

28

Page 30

United Stat

es

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform

To find your

local Flowserve representative:

Flowserve Corporation

Flow Control Division

1900 S. Saunders Street

Raleigh, NC 27603

Phone: (919) 832-0525

Fax: (919) 831-3369

FDC ADENIM0013-00 Printed in USA.

For more information about Flowserve Corporation, visit

www.flowserve.com or call USA 1 800 225 6989

its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous

applications under a wide variety of industrial service conditions. Although Flowserve can provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve

products. The purchaser/user should read and understand the (INSERT OFFICIAL USER INSTRUCTION TITLE) instructions included with the product, and train its employees

and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered

certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained

herein are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its

worldwide operations or offices.

© 2006 Flowserve Corporation, Irving, Texas USA. Flowserve is a registered trademark of Flowserve Corporation

Loading...

Loading...