Page 1

User Instructions

User

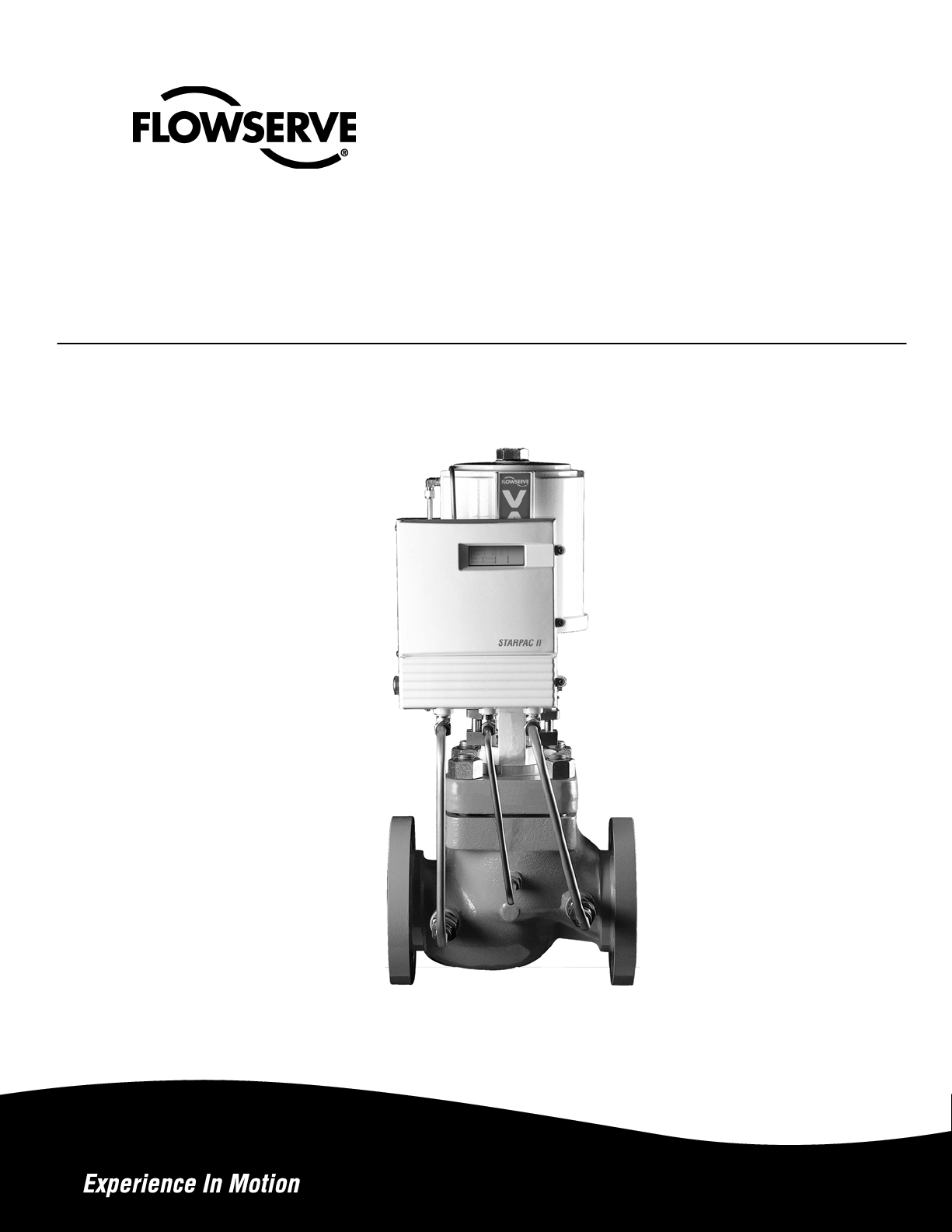

StarPac II

Control Valves

FCD VLAMN042-01

Interface

Manual

Page 2

Page 3

StarPac II User Interface

Manual

StarPac II User Interface Manual

Page 4

Page 5

Contents

OPERATION

Getting Started ……………..……………………….. 1

StarPac II Local Interface Structure & Operation .. 2

Initial Startup………..……………………………….. 3

Status Menu …………………………………………. 5

Tune Menu ………………....………………………... 9

Calibration Menu …………………………………... 12

Configuration Menu ……………………………….. 17

Changing or Viewing the Fluid Specification …… 25

Setting the Jumpers ………………………………. 26

Troubleshooting …………………………………… 26

APPENDICES

System Setup Checklist …………………………... 28

Detailed StarPac ll Register Map ………………... 29

Fluid Table …………………………………………. 50

StarPac Wiring and Grounding Guidelines …….. 51

INDEX 53

StarPac II User Interface Manual

Page 6

Page 7

Operation

Getting Started

This manual is designed to help you become familiar with, and

efficiently operate, the StarPac

While the information presented in this manual is believed to be

accurate, it is supplied for informative purposes only and should not

be considered to be certified or as a guarantee of satisfactory results

by reliance thereon. Specific instructions for the installation, wiring,

operation and maintenance of the StarPac II are contained in the

StarPac II manual (IOM 42). For information on Personal Computer

software, see the StarTalk for Windows™ Manual.

Because Flowserve is continually improving and upgrading its

product design, the specifications and information included herein

are subject to change without notice.

Flowserve will continue to provide its customers with the best

possible products and service available. Should you have any

questions about these provisions or about Flowserve products,

contact your local Flowserve representative or the Advanced Product

Development Group directly (801 489 2560). You can also access

Flowserve information via the internet HTTP: //www.flowserve.com.

®

II Intelligent Control System.

Restrictions

Copyright ©1996, Flowserve Corporation. All rights reserved. No part

of this manual may be reproduced in any form without the written

permission of the publisher. Due to product changes and periodic

review, the information contained in this manual is subject to change

without notice. All correspondence should be addressed to: Flowserve

Divisional Communication Group, Box 2200, Springville, Utah 84663-

0903.

This manual is not intended to be a replacement for the many manuals

already available for teaching and understanding instrumentation and

process control (such as the Instrument Society of America’s Instrument

Engineers Handbook, Revised Edition, 1982, etc.). A copy of one of these

manuals may prove valuable to the user in determining what StarPac II

parameters need to be set with respect to a particular application or

process.

StarPac II User Interface Manual

1

Page 8

C

g

C

g%C

StarPac II Local interface Structure & Operation

The StarPac II local user interface allows complete user access to

configure and calibrate a StarPac II Intelligent Control Valve

System. The interface consists of a Liquid Crystal Display (LCD)

and a membrane-covered keypad. The LCD is a 4 X 20 character

display with the top two lines user configured for normal operation,

or for displaying instructions or options during configuration. The

bottom two lines are used to indicate menu options that are

selected with the four function keys. To the right of the menu

options, on the bottom two lines, are two normally blank spaces

that indicate Alarm or Error conditions, indicated by a flashing “A”

and/or “E”. A flashing “T” on the right side of the display indicates

that the unit is in Test mode and will not respond to commands

until the unit is set to Manual or Auto mode in the T

The keyboard has three types of keys; the menu control keys (which

consist of the LAST OPTION, F1, F2, F3, and F4 keys); the alphanumeric keys; and the colored shift keys. The F1, F2, F3, and F4

keys refer to the menu options listed in the LCD of the interface. The

LAST OPTION key is used to move back through the menus. The

alpha-numeric keys are used to enter data requested in various

options. The red, blue and green shift keys are used to select the

corresponding colored letter on the alpha-numeric keypad.

UNE menu.

The various menu options have three basic forms. The first type is a

list that is scrolled through by using the F1 and F2 keys labeled

NEXT and PREVIOUS. The second type uses the F1 and F2 keys

to adjust a value up or down, and the third type uses the F1 and F2

keys to move the cursor to a position. The keypad is used to enter

characters. In all of the options, the F3 key is used to cancel the

operation. If the F3 key is pressed before the system returns to the

menu, then all variables are returned to their old values. The F4 key

is used to accept the current values in the display and continue.

al

i

t

o

fi

md

n-

Manu

Posn

Status

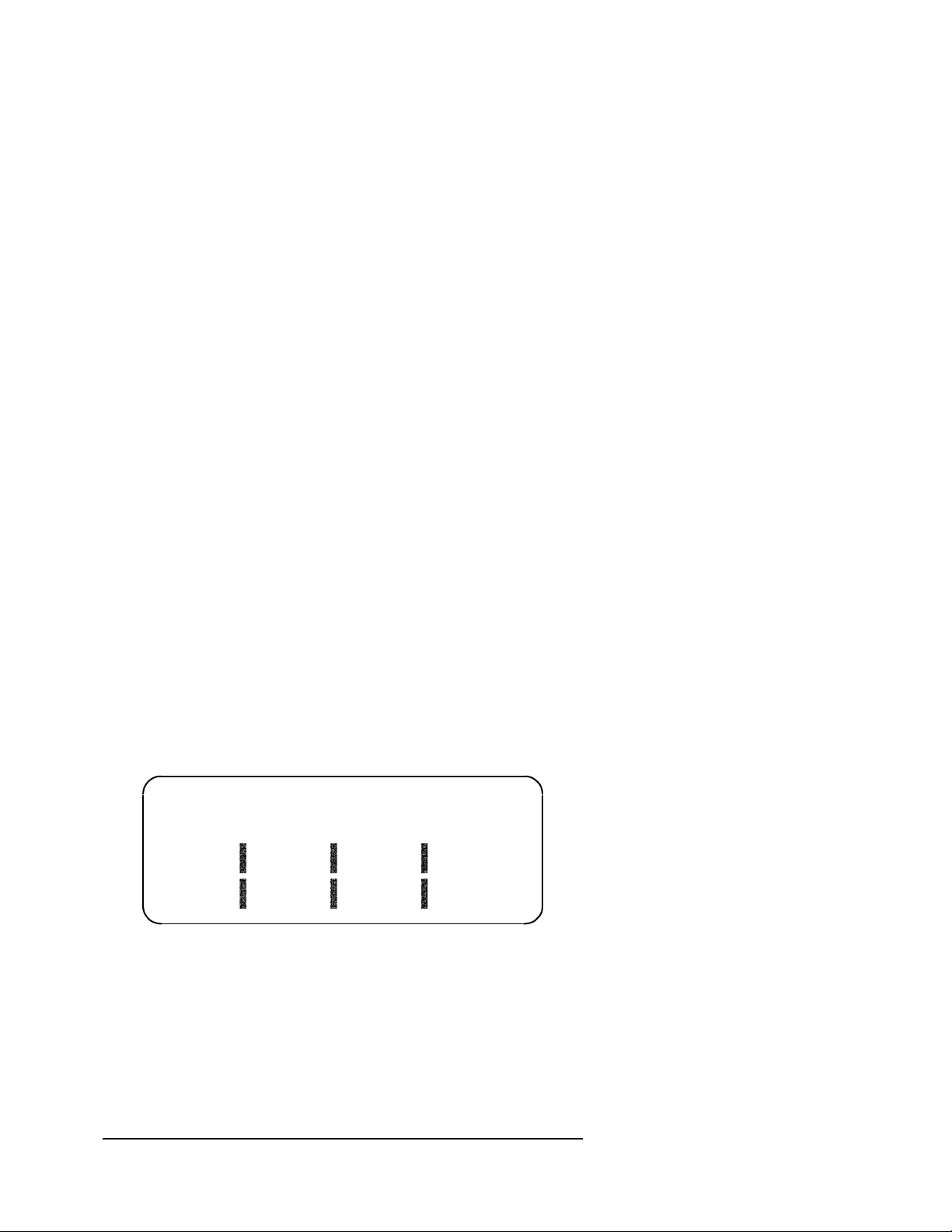

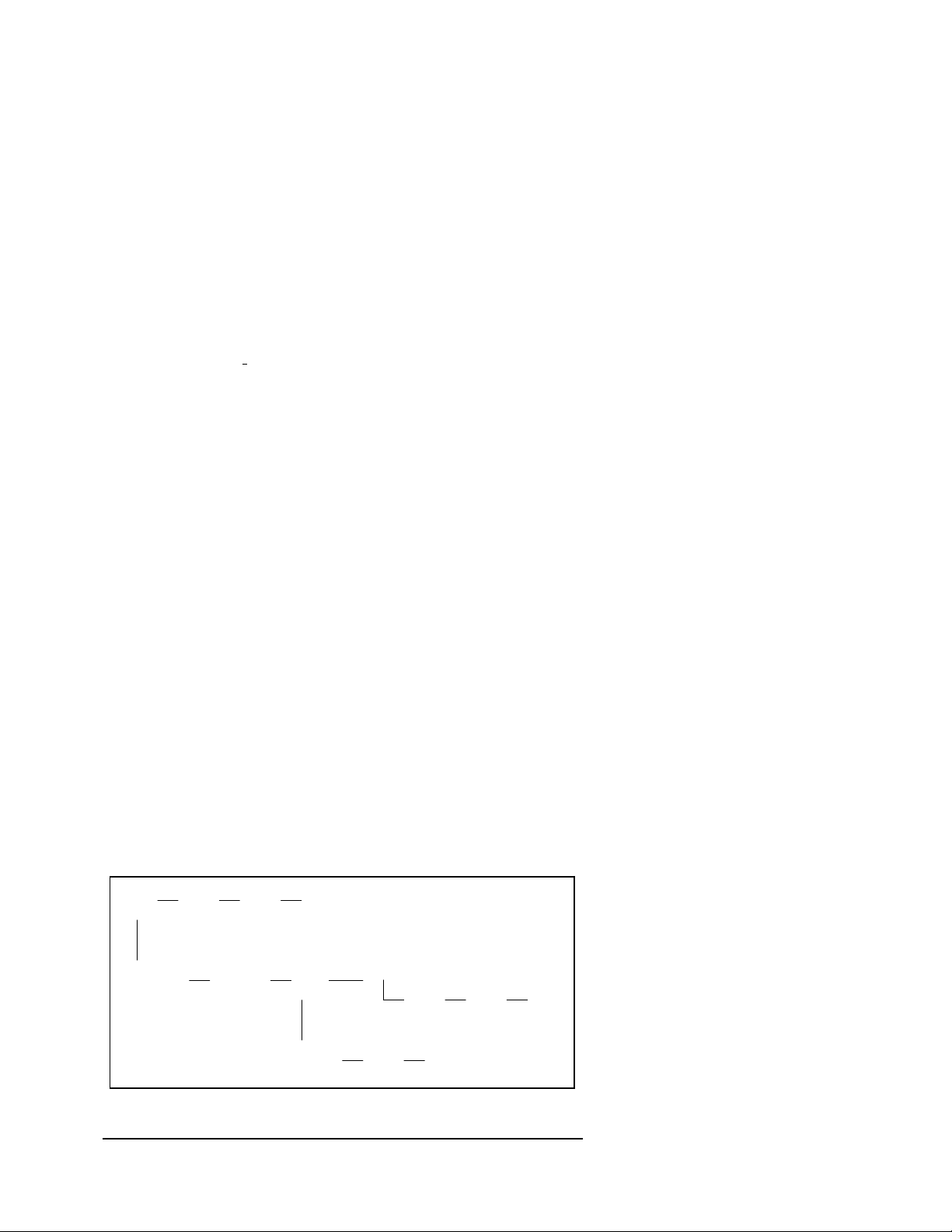

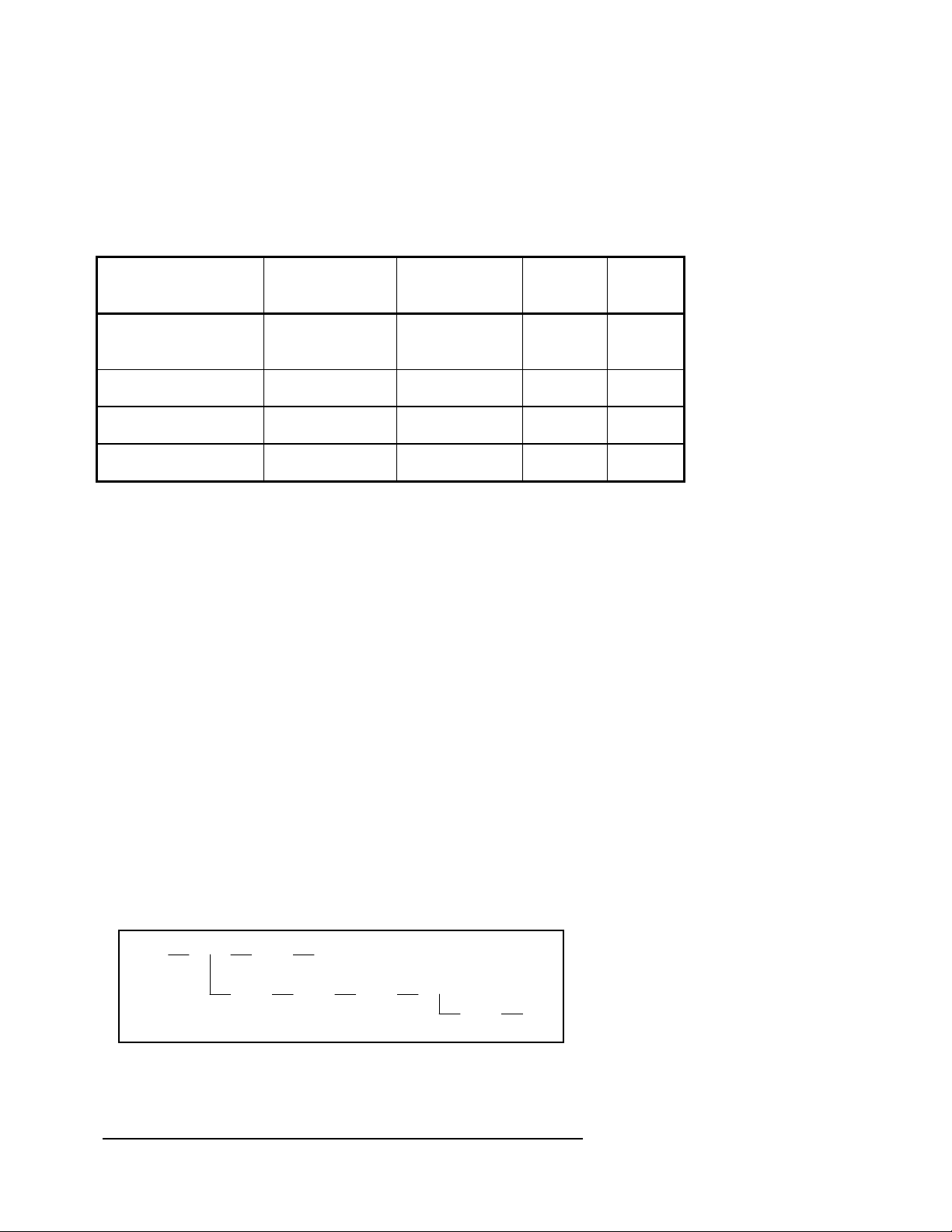

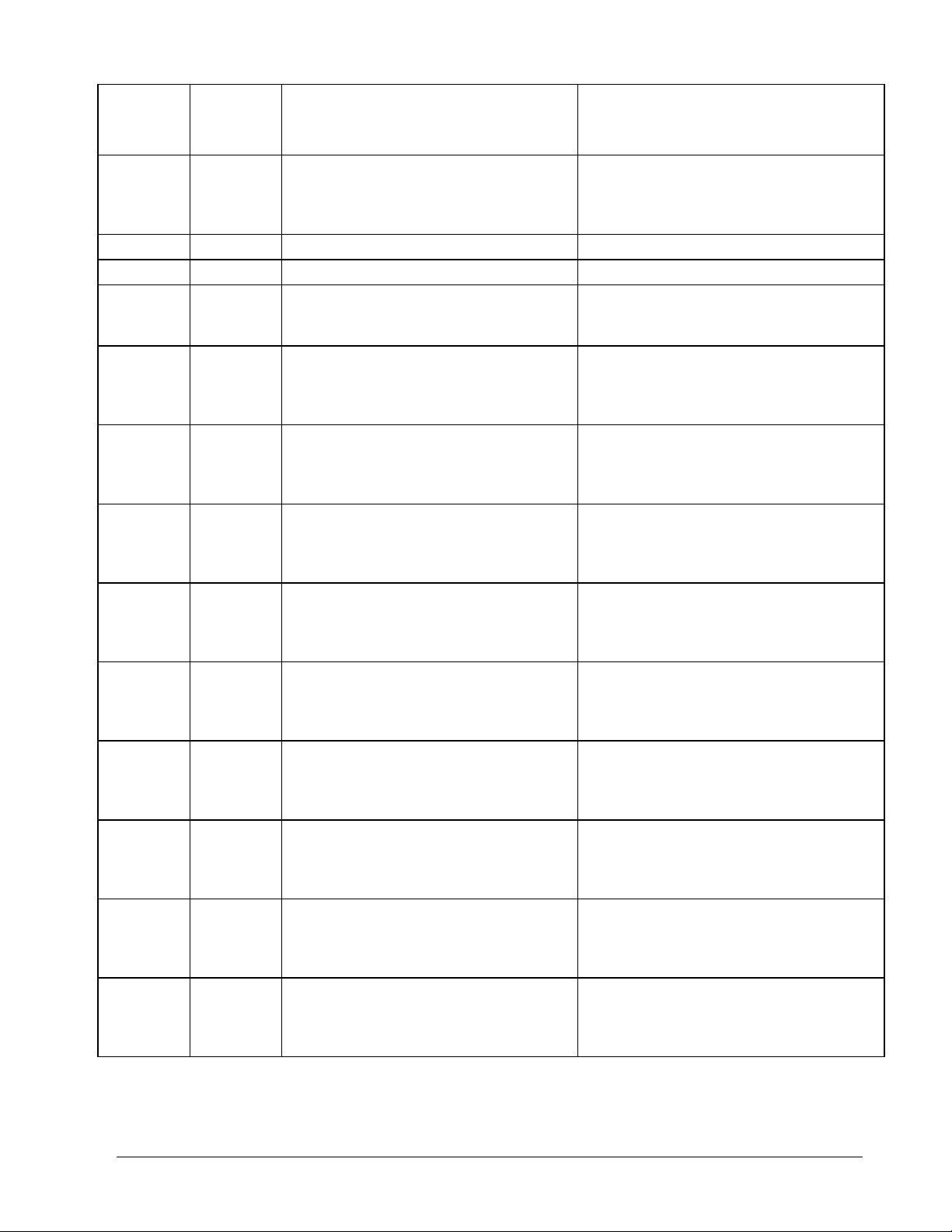

The HOME menu has selections of STATUS, TUNE, CALIBRATE, and

ONFIGURE. Each of these menus has several sub-menus. The

C

bottom two lines define the function keys that control the individual

menus. The top two lines in the display are user configurable and

may not look like Figure 1.

a

Mode-D

l

:

Tu

ne

.0056

br a

Figure 1 - Home Menu

The menus shown in the figures in this manual represent how the

information is laid out in the local display menu tree. The top row of

StarPac II User Interface Manual 2

Page 9

the figures shows the bottom two rows of the display. One of the

fields is in Bold type. Press the F key under this field to bring up the

choices shown on the bottom row. If you see the word ‘Next,’ then

push the F4 button to bring up the continuation of that row. To move

back up the menu tree, push the button labeled ‘Last Option’ to see

the preceding row.

Initial Startup

The StarPac II system is designed to interface with a variety of DCS

systems using analog, discrete, and digital communications.

Because of the processing power of the StarPac II system, a

separate 24 VDC power connection is required and connected to

terminals 16 (-) and 17 (+). This power supply should have a

minimum current capacity of 300 mA.

Before powering up the unit - Read the section “Setting the

System Jumpers” and set them according to the instructions and

particular application.

Powering up the unit on the bench - When the unit is first powered

up, the display will show the version number of the firmware for two

seconds before beginning operation. The StarPac II system sensors

are calibrated at the factory and the fluid data is entered as specified

on the order. However, due to the differing nature of installations,

the units and ranges of the analog and discrete I/O are not

configured at the factory.

The suggested process for setting up a new system on the bench is:

1. In the CONFIGURE menu, select the engineering units you will

be using.

2. If you will be using analog I/O signals, use the CONFIGURE

menu to set up the analog channels to indicate the proper

process variables and ranges you will be using. Note that

the StarPac II system treats gas flow and liquid flow as

different variables and they must each be specified correctly.

3. Connect the instrument air supply (40-150 psi) to the ¼-inch

NPT air supply port located on the back of the unit.

4. Use the STATUS menu and set the Row Two variable to

“valve position.”

5. Use the TUNE menu to put the unit in to Manual mode with a

digital command.

6. Using the “Command %” option in the TUNE menu, enter a 0

percent command and verify that the position follows to

within 0.5 percent.

Note: Command is a term with two meanings. For a

traditional control valve, the command is the signal a

controller sends to the I/P. position the stem. For the StarPac

II, this meaning refers to the signal sent to the positioning

module. When the StarPac II is in Manual mode, Command

also refers to the signal sent to the StarPac II via analog input

No. 1, a digital Modbus channel, or the front keypad. These

commands may differ due to the internal stroke calibration

and an inverted signal for air to close valves.

StarPac II User Interface Manual

3

Page 10

7. Using the Command % option in the T

percent command and verify that the position follows to

within 0.5 percent.

8. If the unit fails either of the tests above, perform a Stroke

calibration in the C

9. Use the STATUS menu and set the Row Two variable to be

“ISA upstream pressure.”

10. Verify that the unit is correctly indicating the ambient

pressure.

11. Use the S

“ISA downstream pressure.”

12. Verify that the unit is correctly indicating ambient pressure.

13. If the unit fails the above tests, re-zero the transducers using

the P1 & P2 option in the C

need to pressurize the sensors and verify the Span if the

calibration is suspect.

14. Use the S

“process temperature.”

15. Verify that the unit is correctly indicating ambient

temperature.

16. If the unit fails the above test, re-calibrate the transducer

using the thermocouple option in the C

calibration requires a Type-K thermocouple simulator or a

temperature bath.)

17. Use the CALIBRATE menu to check the analog channels that

you will be using.

18. Finally, use the TUNE menu to select the process variable

that you will be controlling and set the range.

TATUS menu and set the Row Two variable to be

TATUS menu and set the Row Two variable to be

ALIBRATE menu.

ALIBRATE menu. You may also

UNE menu, enter a 100

ALIBRATE menu. (This

Putting the Unit on line - After installing the unit, use the TUNE

menu to configure the setpoint signal to the proper source for your

DCS system. If you will be using the system in the Automatic mode,

adjust the Proportional-Integral-Derivative (PID) parameters so the

loop responds satisfactorily.

Backing up the system - When you have your unit calibrated and

working according to your needs, back up the configuration into the

safe memory area. This is done in the Save Backup choice in the

Tech option of the C

ONFIGURE menu.

StarPac II User Interface Manual 4

Page 11

r

/

A

Var

Var

g

A

V

g

Status Menu

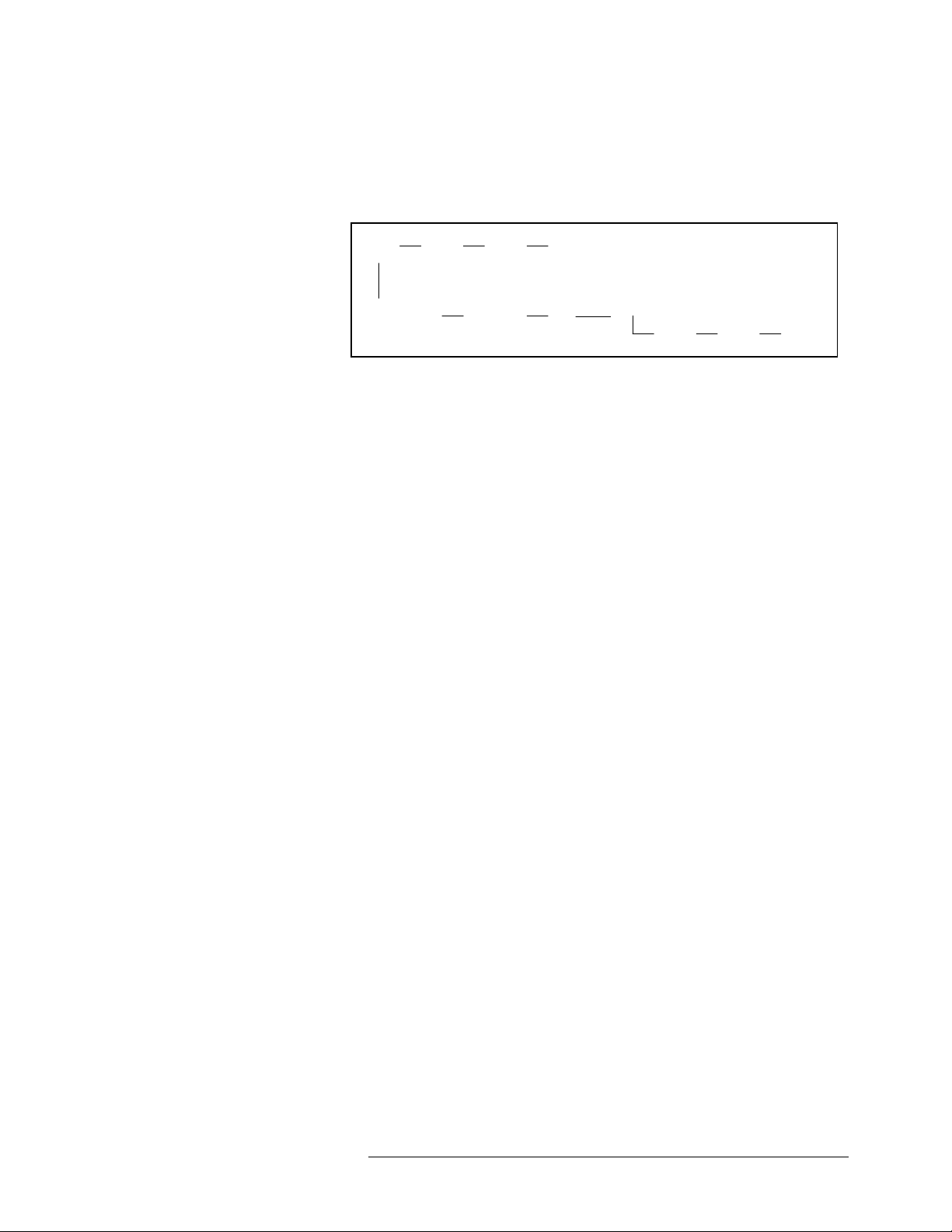

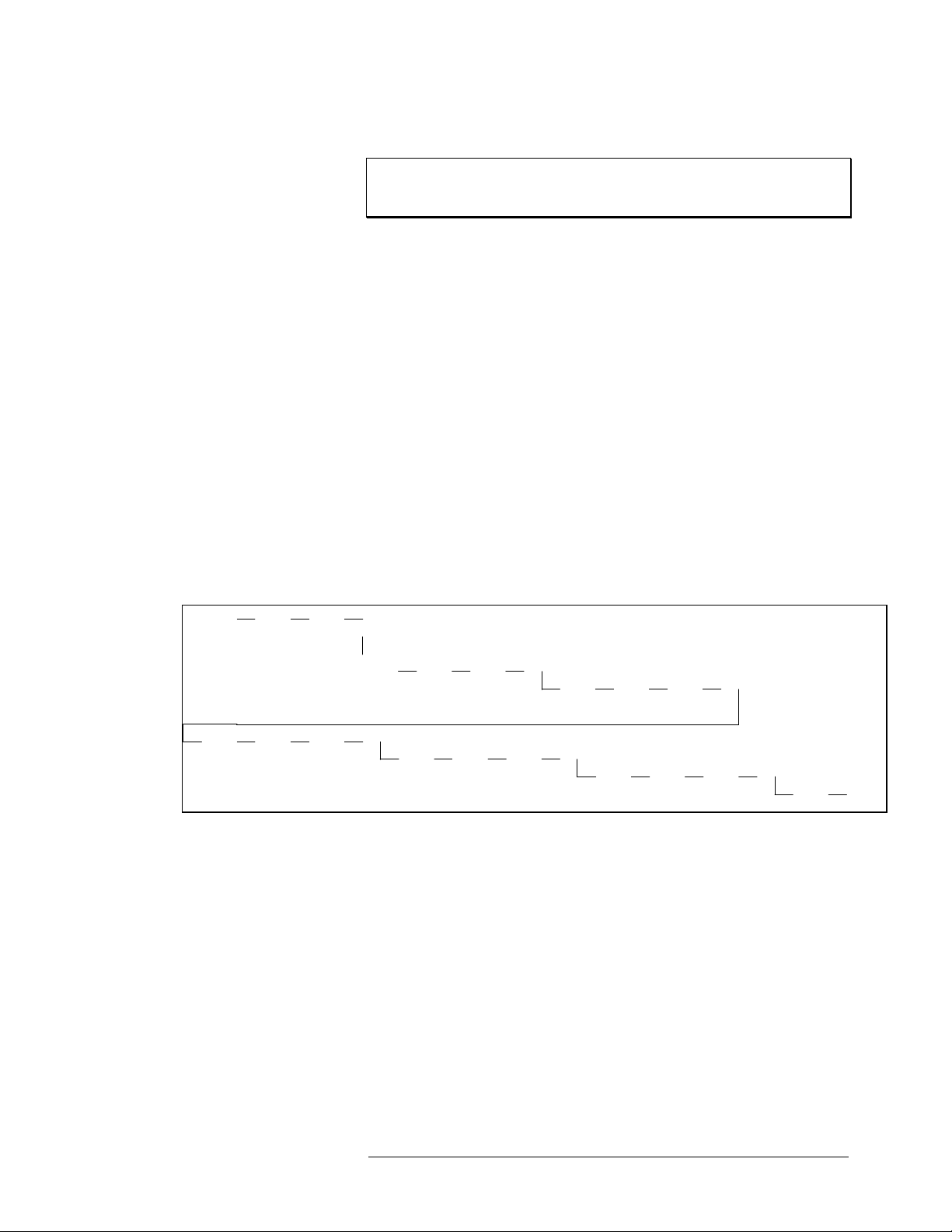

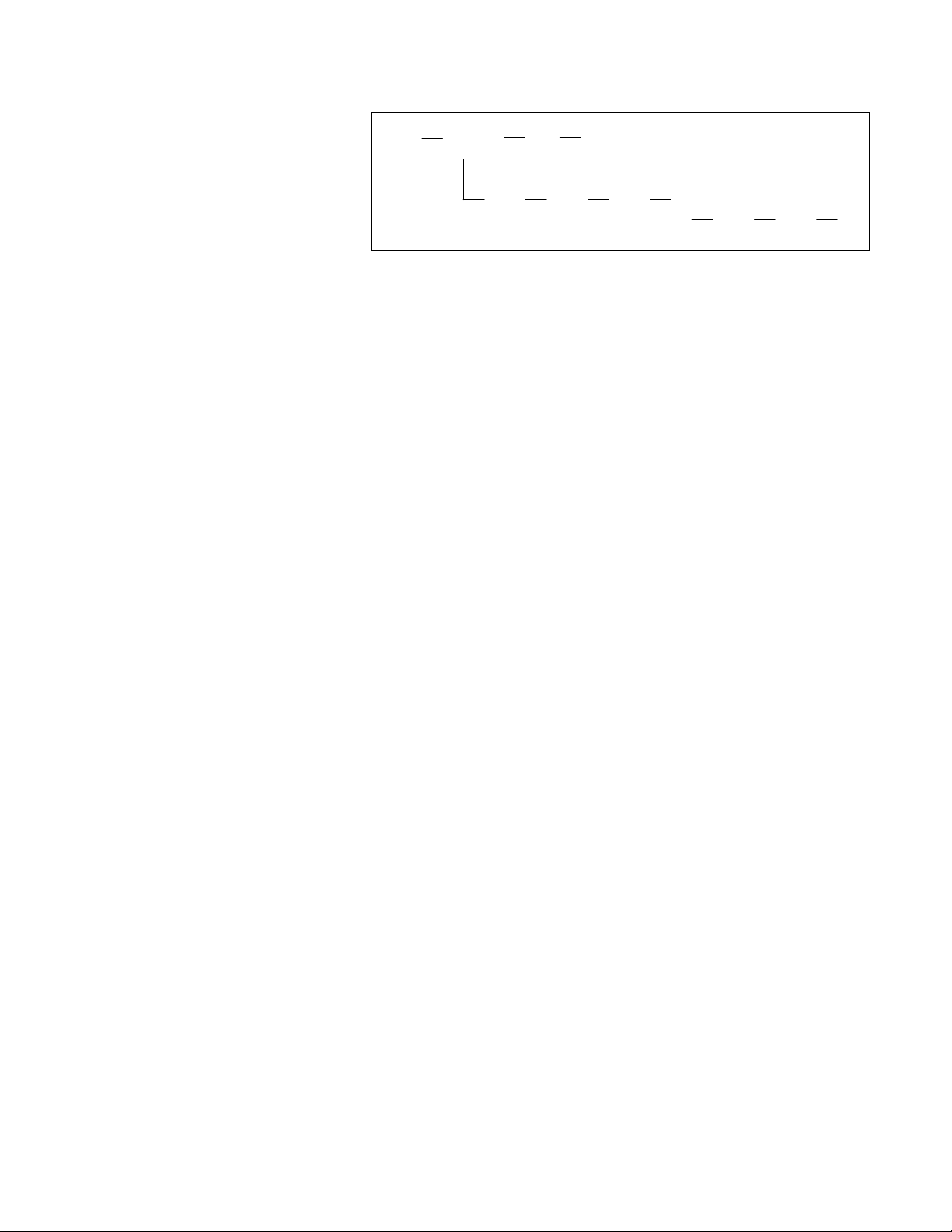

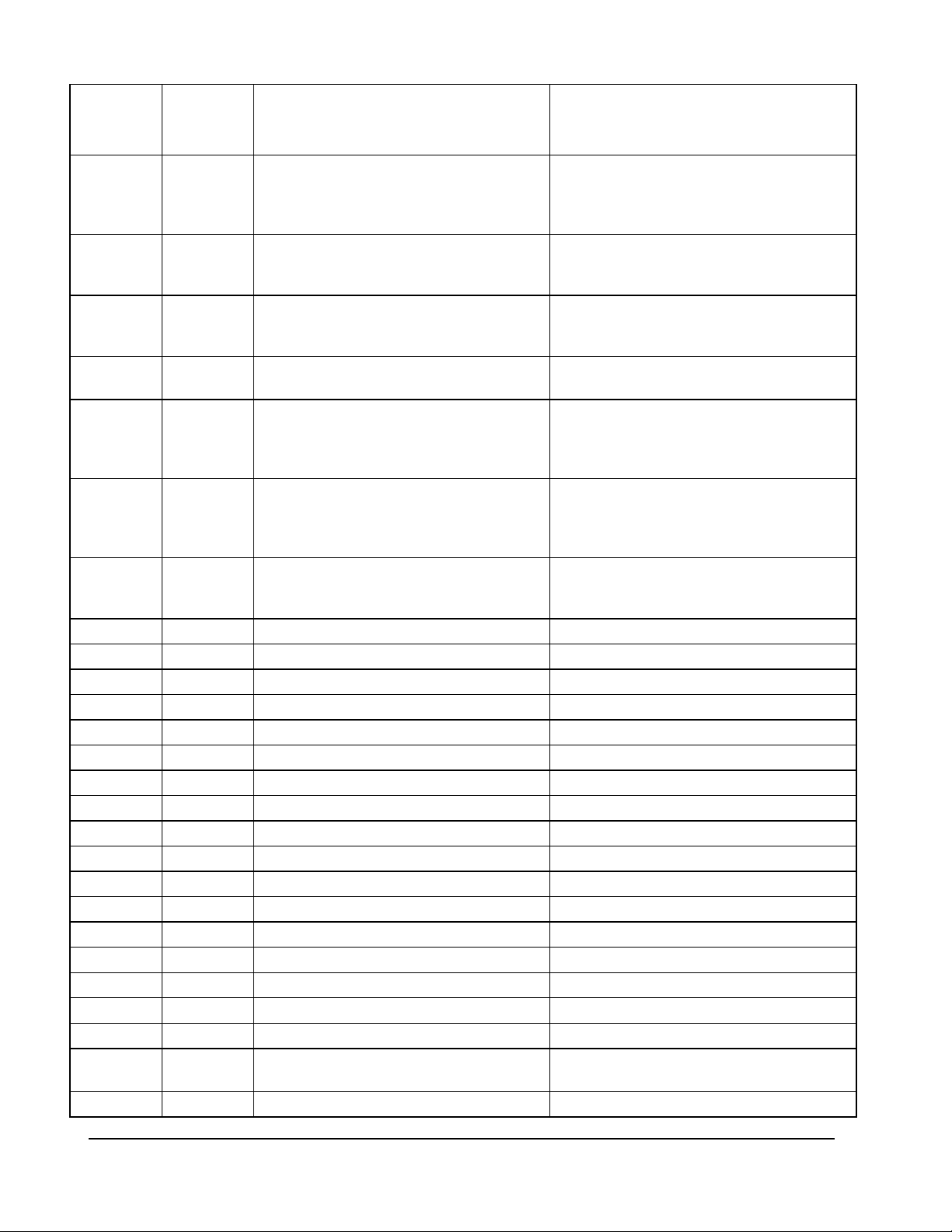

The STATUS menu is used to view information about the configuration

and operation of the system. Errors and alarms can also be viewed

from this menu. The S

Sta-

Tune Cal-

tus

Row1

Each option may have other menus or options to choose from.

Row 1 and Row 2 Var - Selects the information that will be

displayed on the first two rows of the display during normal

operation. Each selection has the same list of options except where

noted.

Mode/Status - Lists the operating mode and any current alarm

or trip conditions. (This option is only available on Row One.)

Scanning Display - Rotates automatically through a list that is

configured through the user interface. (This option is only

available on Row Two.)

Valve Position - Current valve position in percent open.

(Designated as “Posn” in the display.)

Valve Command - Current valve command in percent open.

(Designated as “Comnd” in the display.)

Liquid Flow - Current liquid flow rate in user-defined units.

(Designated as “FlowQ” in the display.)

Gas Flow - Current gas flow rate in user-defined units.

(Designated as “FlowW” in the display.)

ISA Up Stream Press - Current compensated upstream line

pressure in user-defined units. (Defined as two pipe diameters

upstream of the valve, designated as “P1isa” in the display.)

ISA Dn Stream Press - Current compensated downstream line

pressure in user-defined units. (Defined as six pipe diameters

downstream of the valve, designated as “P2isa” in the display.)

ISA Delta Pressure - Current differential pressure using the

pressure definitions above in user-defined units. (Designated as

“dPisa” in the display.)

Process Temperature - Current process temperature in userdefined units. (Designated as “Temp” in the display.)

Liquid Flow Totalizer - Totalized liquid flow in user-defined

units. (Designated as “TotlQ” in the display, the totalizer is reset

from the T

Gas Flow Totalizer - Totalized gas flow in user-defined units.

(Designated as “TotlW” in the display, the totalizer is reset from

the T

Row2

UNE menu.)

UNE menu.)

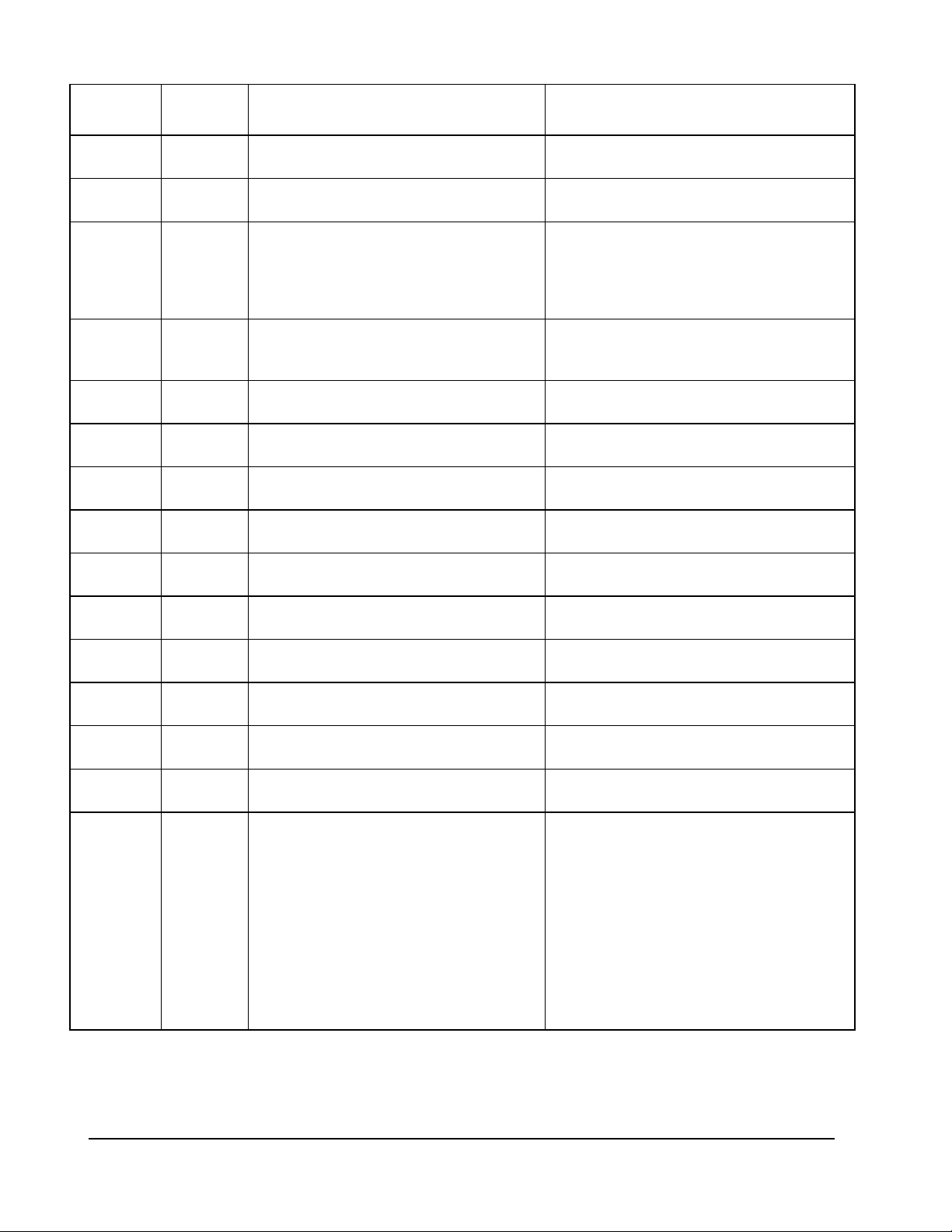

TATUS menu is arranged as shown in Figure 2.

Con-

brat

fi

Er

rlm

Next

lrm

Set

Figure 2: Status Menu

Sys

Info

iew

Re

StarPac II User Interface Manual

5

Page 12

r

r

g

A

g

Totalizer Time - Operating time since the totalizer was last

reset. (Designated as “TotTm” in the display.)

Valve Cv - Current valve CV at present valve position.

(Designated as “Cv” in the display.)

Setpoint (%) - Controller setpoint as a percent of the maximum.

(Designated as “SP” in the display. The process maximum is set

in the T

operation.)

Process Variable (%) - Process variable in percent of

maximum. (Designated as “PV” in the display. The process

maximum is set in the T

the controller operation.)

Setpoint (units

(Designated as “SP” in the display.)

PV (units) - Current process variable in user-defined units.

(Designated as “PV” in the display.)

fl - Current FL at present valve position. (Designated as “fl” in

the display.)

xt - Current X

the display.)

z - Current compressibility factor at existing process conditions.

(Designated as “z” in the display.)

Cylinder Top Press - Current pressure above the actuator

piston in user-defined units. (Designated as “Ptop” in the

display.)

Cylinder Bot Press - Current pressure below the actuator

piston in user-defined units. (Designated as “Pbot” in the

display.)

Time & Date - Current time and date of the internal clock.

Auxiliary 4-20 Input - Auxiliary input signal in percentage.

(Designated as “AuxIn” in the display.)

Flow State - Liquid non-choked, liquid choked, gas non-choked,

gas choked.

UNE menu with the process variable for the controller

UNE menu with the process variable for

) - Current controller setpoint in user units.

at present valve position. (Designated as “xt” in

T

Errors/Alarms allows the user to view any current errors and alarms

that are indicated by the flashing “A” and/or “E” on the right side of

the display. This option displays three menu choices (see next

page):

Status

StarPac II User Interface Manual 6

Row1

Va

Tune Cal-

brat

Row2

Va

Figure 3: Alarm / Errors Tree

Confi

/

Err

Arlm

Alrm

Next

Sensor

lrm

Set

Device

Sys

Info

View

Re

Page 13

Alarms - Allows the user to view any current alarms using the NEXT

or PREVIOUS function keys. Possible alarms are:

Setpoint Deviation - The controller is unable to maintain the

process at the current setpoint. (Sensitivity is adjusted using

StarTalk software.)

Positioner Deviation - The positioner is unable to maintain the

valve position at the current command. (Sensitivity is adjusted

using StarTalk software.)

Trip Condition - The unit is in a trip condition of either loss of

command, low supply air, or a low flow cutoff. Low flow is

determined when the pressure drop across the valve is less than

0.5% of the calibrated range of the pressure sensors. (Use the

Row 1 Variable M

ODE/STATUS menu selection to display the type

of trip.)

Override Condition - Indicates the controller is not currently

capable of doing any more to achieve the setpoint (or valve

position). This can be any of the trip conditions, or a mechanical

or software travel limit has been reached and the controller has

exceeded the 5 percent current limit.

Sensor Malfunction - One of the sensors has a suspect output.

(See sensor errors for detail.)

Device Malfunction - The electronics has an internal error.

(See device errors for detail.)

Sensor Errors - Allows the user to view any current sensor errors

using the NEXT or PREVIOUS

are:

function keys. Possible sensor errors

Upstream Pressure - The output of the upstream pressure

sensor is out of range.

Downstream Pressure - The output of the downstream

pressure sensor is out of range.

Cylinder Top Press - The output of the top actuator pressure

sensor is out of range.

Cylinder Bot Press - The output of the bottom actuator

pressure sensor is out of range.

Process Temperature - The output of the process temperature

sensor is out of range.

Ambient Temperature - The output of the ambient temperature

sensor is out of range.

Position Feedback - The output of the position feedback sensor

is out of range.

Device Errors - Allows the user to view any device errors using the

NEXT or PREVIOUS

function keys. Possible device errors are:

Watch Dog Timeout - The CPU had an interruption in the

execution cycle. This is sometimes caused by momentary

power interruptions. However, if it persists, this is a serious error

usually requiring hardware replacement. This error can only be

cleared by turning off the device and then turning it on again.

SRAM R/W Failure - The static RAM had an error. This is a

serious error usually requiring hardware replacement if it

StarPac II User Interface Manual

7

Page 14

persists. This error can only be cleared by turning off the device

and then turning it on again.

EPROM Checksum Error - Check the integrity of the firmware.

This error usually occurs when the firmware is changed and can

be cleared with an initialization. (This is done by holding down

the “0” on the keypad while powering up the unit.

Warning: An initialization will also reset the communication

parameters, password, and PID control parameters.

NVRAM R/W Failure - The non-volatile RAM had an error. This

is a serious error usually requiring hardware replacement if it

persists. This error can only be cleared by turning the device off

and then turning it on again.

Thermocouple Burnout - The thermocouple junction is open.

Check interface connections, thermocouple, and/or wire.

A/D Failure - One of the A/D converters is not working correctly.

If slowly cycling the power does not clear the error, then a

hardware replacement is necessary.

Vcc Out of Tolerance - An internal power supply is operating

out of tolerance.

V- Out of Tolerance - An internal power supply is operating out

of tolerance.

V+ Out of Tolerance - An internal power supply is operating out

of tolerance.

Illegal Pointer - One of the configurable arrays is using an

invalid register.

NVRAM Checksum Error - A value in the non-volatile RAM was

changed without resetting the checksum. Performing any write

function, such as a setpoint or command change should reset

the error. If the system behaves erratically after receiving an

error, the NVRAM may have been corrupted and you should

reload the factory configuration table from the disk provided

using the StarTalk for Windows software.

Divide by Zero - The StarPac II unit attempted an illegal math

operation due to bad calibration or configuration settings.

Reload the factory configuration table from the disk provided,

using StarTalk for Windows software.

Alarm Mask - Allows the user to enable or disable individual alarm

functions.

Setpoint Deviation - The controller is unable to maintain the

process at the current setpoint. (Sensitivity is adjusted using

StarTalk software.)

Positioner Deviation - The positioner is unable to maintain the

valve position at the current command. (Sensitivity is adjusted

using StarTalk software.)

Trip Condition - The unit is in a trip condition of either loss of

command, low supply air or a low flow cutoff. (Use the

ODE/STATUS menu selection to display the type of trip.)

M

StarPac II User Interface Manual 8

Page 15

g

p

p

Override Condition - Indicates the controller is currently not

capable doing any more to achieve the setpoint (or valve

position). This can be any of the trip conditions, or a mechanical

or software travel limit has been reached and the controller has

exceeded the 5 percent current limit.

Sensor Malfunction - One of the sensors has a suspect output.

(See sensor errors for detail.)

Device Malfunction - The electronics has an internal error.

(See device errors for detail.)

System Information - Allows the user to check the factory hardware

configuration for reference or spare parts. The following list shows

the items listed:

Valve Serial Number: Spring:

Trim Number: Spring Type:

Trim Characteristic: Air Action:

Trim Type: Electronics S/N:

Pressure Class: EPROM Version:

Valve Model: Sensor Rating:

Flow Direction: Sensor Drawing No.:

Body Size: P1 Serial Number:

Body Material: P2 Serial Number:

Packing Style: P1 Calibration Date:

Packing: P2 Calibration Date:

Gasket Material: Miscellaneous No. 1:

Actuator Size: Miscellaneous No. 2:

Status

Tune

Mode

View Registers - Allows the user to view any internal

integer or floating point Modbus register using the register

map provided (see appendix for a list of registers). String

registers cannot be viewed with this function.

Tune Menu

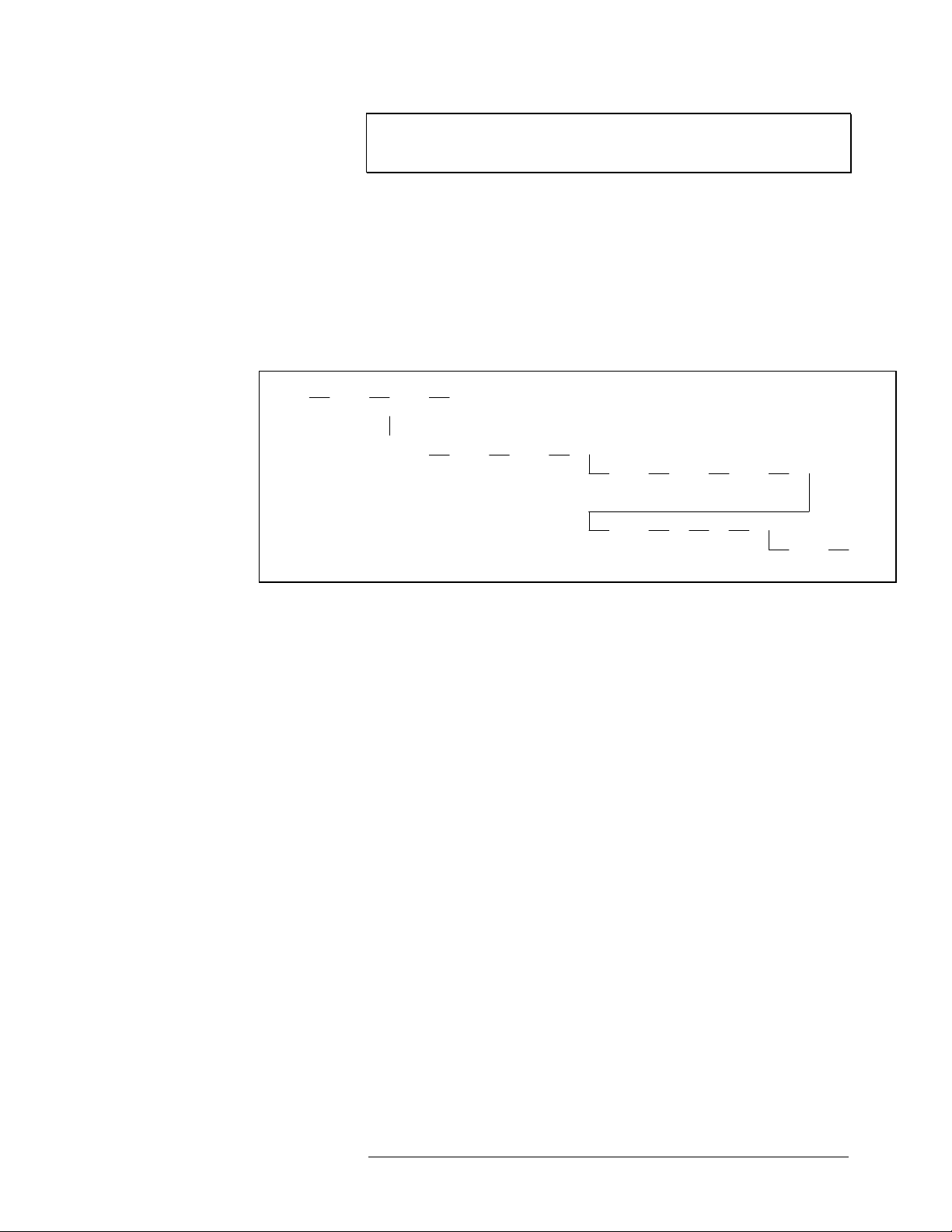

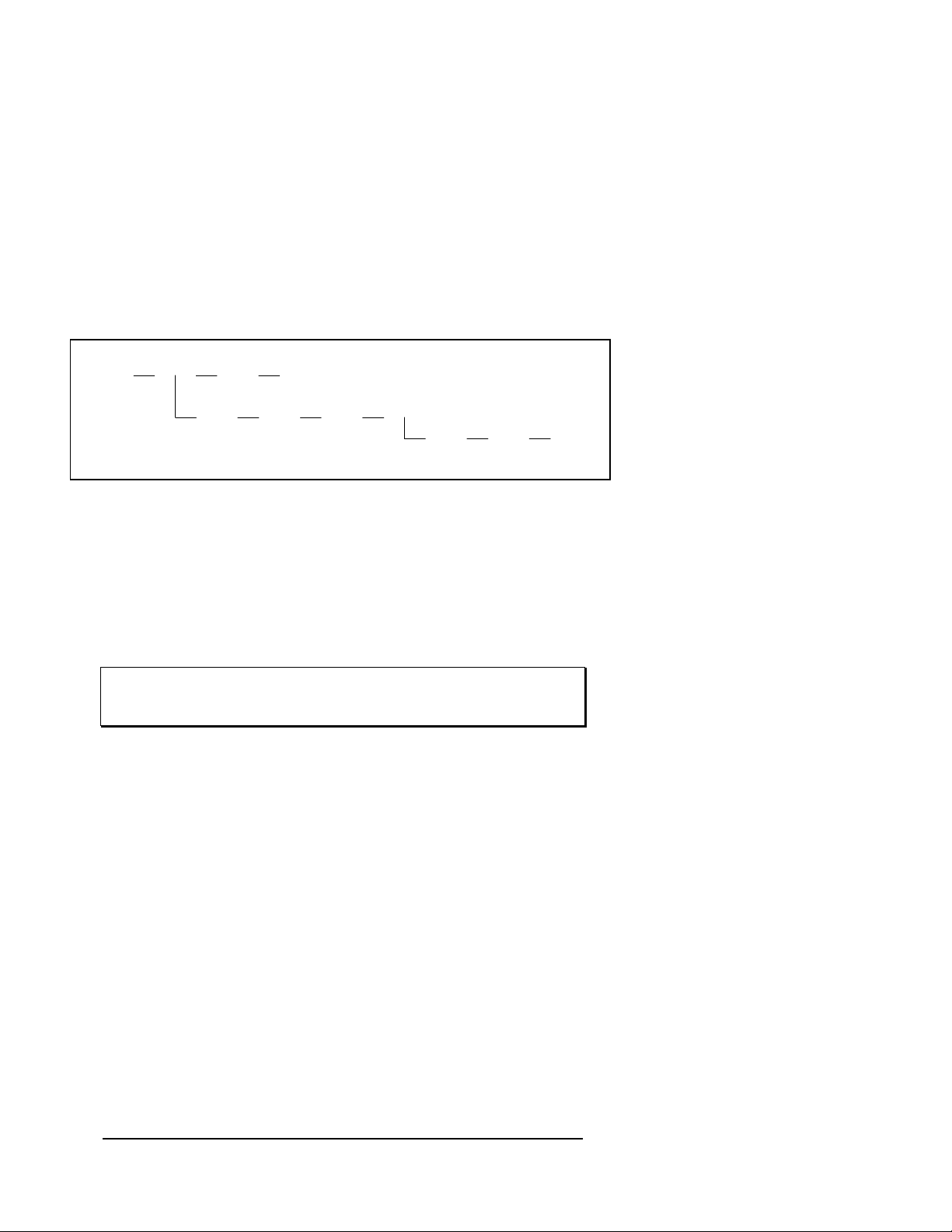

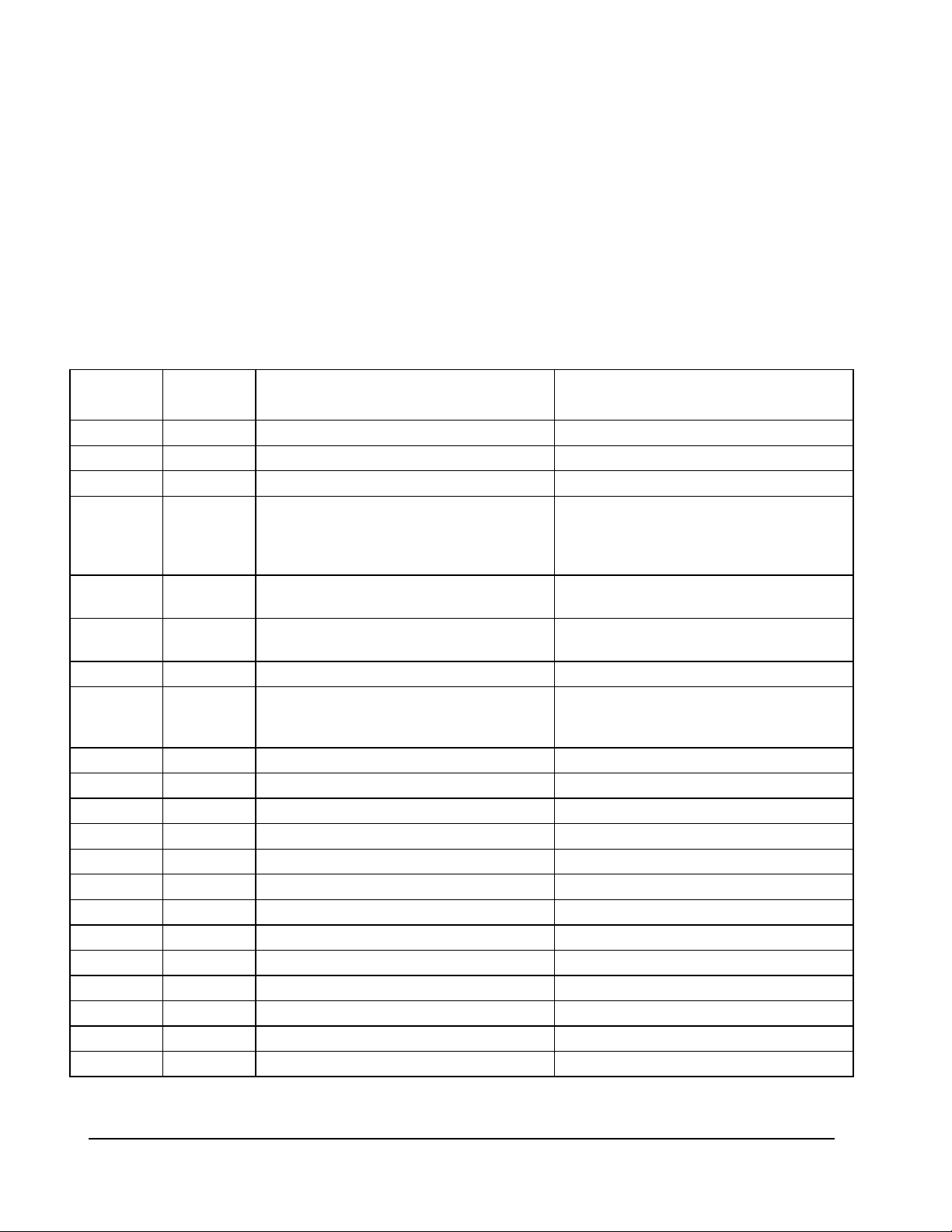

The T

UNE menu is used to view and configure the controller

variables and gains, change modes, and reset the totalizer. The

Calbrat

Set-

T

Mode - Has two options for defining the current mode and the

source of the mode.

Confi

nt

Command

Next

Pro

Band

Rset

Rate

Time

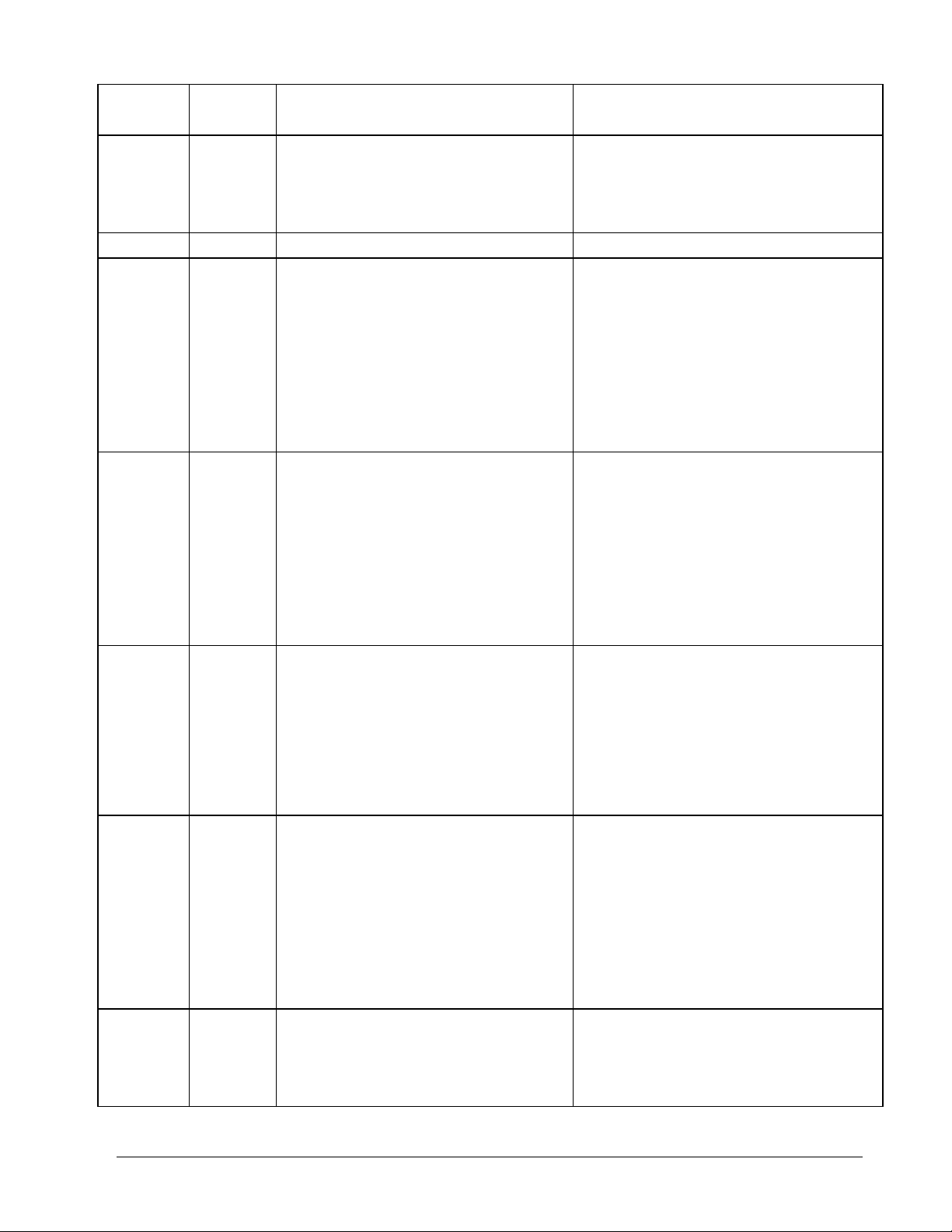

Figure 4: Tune Menu Tree

UNE menu is arranged as shown in Figure 4.

NextDer

PI

D

tn

PV

Slct

Ac

PV

Scal

Rset

Totl

StarPac II User Interface Manual

9

Page 16

Man/Auto - This option selects or changes the operating mode if

the mode source has been set to digital. If the mode source is

set to Remote or Discrete, the mode can only be changed using

the discrete input or the remote register. In Manual mode the

unit operates as a normal control valve, positioning the valve

according to its current command signal.

In Auto mode the unit will operate as a controller using the PID

settings, process variable, and control action currently defined

using a bumpless transfer algorithm. (Note that if the unit is

using an analog command source, the system will bump

because the 4-20 signal will change from indicating position

command to process setpoint.)

Test mode takes the unit off-line and the system DOES NOT

calculate pressures, temperatures, flow, or PID values; nor does

it support setpoints or any analog or digital commands. Test

mode is the beginning mode after an initialization and is used

during calibration. If power is lost during a calibration setup, the

unit will remain in Test mode and the mode will have to be reset.

If the unit is in Test mode, the letter “T” will flash on the right side

of the display.

Mode Source - This selects where the StarPac II unit will

receive the mode information. “Digital” indicates that the

keypad or the StarTalk software can be used to change the

mode. “Discrete” indicates that an external signal applied to

terminals 33 and 34 will be used to switch the unit between

Auto and Manual modes. The definition is fixed with an

energized state indicating Auto mode. Remote mode is used

when a host system such as a PLC or DCS is used to set the

mode via digital communications.

The difference between Remote and Digital is that if the

Setpoint/command is not refreshed within a given period, the

StarPac II will assume that the unit has lost communication with

the host and will go to a trip condition.

Setpoint - Provides four options used to change the setpoint and

configure the source of the setpoint.

Setpoint % - Allows the direct input of the controller setpoint as

a percentage of maximum, as setup with the process variable,

provided the unit is in the Auto mode with the digital setpoint

selected.

Setpoint User Units - Allows the direct input of the setpoint in

the configured engineering units, provided the unit is in Auto

mode with the digital setpoint selected.

Analog/Digital

will receive the setpoint information.

- This option selects where the StarPac II system

“Digital” indicates that the keypad or the StarTalk software can

be used to change the setpoint.

“Analog” prompts the StarPac II to use the 4-20 mA signal from

analog input No. 1 as the controller setpoint.

“Remote” is used when a host system such as a PLC or DCS is

used to write the setpoint to the unit digitally.

StarPac II User Interface Manual 10

Page 17

Remote Refresh Rate

- This option sets up a time-out on the

receipt of fresh setpoint data when set to operate with a remote

setpoint. If the setpoint is not refreshed within the time frame

entered in this field, the unit will go into a loss-of-command trip

as set up in the C

ONFIGURE menu. A value of “0” disables this

feature and makes the electronics think that the Mode source is

digital. Note that if the digital source is selected, the unit will

hold at the last setpoint indefinitely.

Command - Provides three options used to change the valve

position command and configure the source of the valve command.

Command % - Allows the direct input of the valve position

command as a percentage of valve travel. Zero percent is

closed and 100 percent is open--provided the unit is in Manual

mode with the digital command selected.

Analog/Digital - This option selects where the StarPac II system

will receive the valve position command information.

“Digital” indicates that the keypad or the StarTalk software can

be used to change the valve position command.

“Analog” prompts the StarPac II to use the 4-20 mA signal from

analog input No. 1 as the valve position command.

“Remote” is used when a host system such as a PLC or DCS is

used to write the valve position command to the unit digitally.

Remote Refresh Rate - This option sets up a “timeout” on the

receipt of fresh, valve-position command data when set to

operate with a remote command. If the valve position command

is not refreshed within the time frame entered in this field, the

unit will go into a loss of command trip (as set up in the

ONFIGURE menu). A value of “0” disables this feature. Note

C

that if the digital source is selected, the unit will hold at the last

valve position command indefinitely.

Proportional Band - Sets the proportional band for the controller.

Proportional Band = 100/gain or gain =100/prop. band. Since

proportional band is the inverse of gain, the larger the band value,

the smaller the controller gain.

Reset Rate - This is the integrator term in the PID controller,

referring to the action at which the rate of change of output is

proportional to the error input. “Reset” is the parameter that controls

how the integral control action affects the final control element. The

larger the value, the faster the system tries to eliminate the offset

error. Units are repeats/min.

Derivative Time - Sets the time on the derivative control action of

the PID controller. This time is the interval at which the rate action

advances the effect of the gain on the final control element. Units

are in seconds.

PID Action - This variable determines the response of the controller

to error. Reverse action will cause an air-to-open valve to begin to

close when the process variable is greater than the setpoint. Direct

action has the opposite effect. The following table gives some

guidelines for control action settings:

StarPac II User Interface Manual

11

Page 18

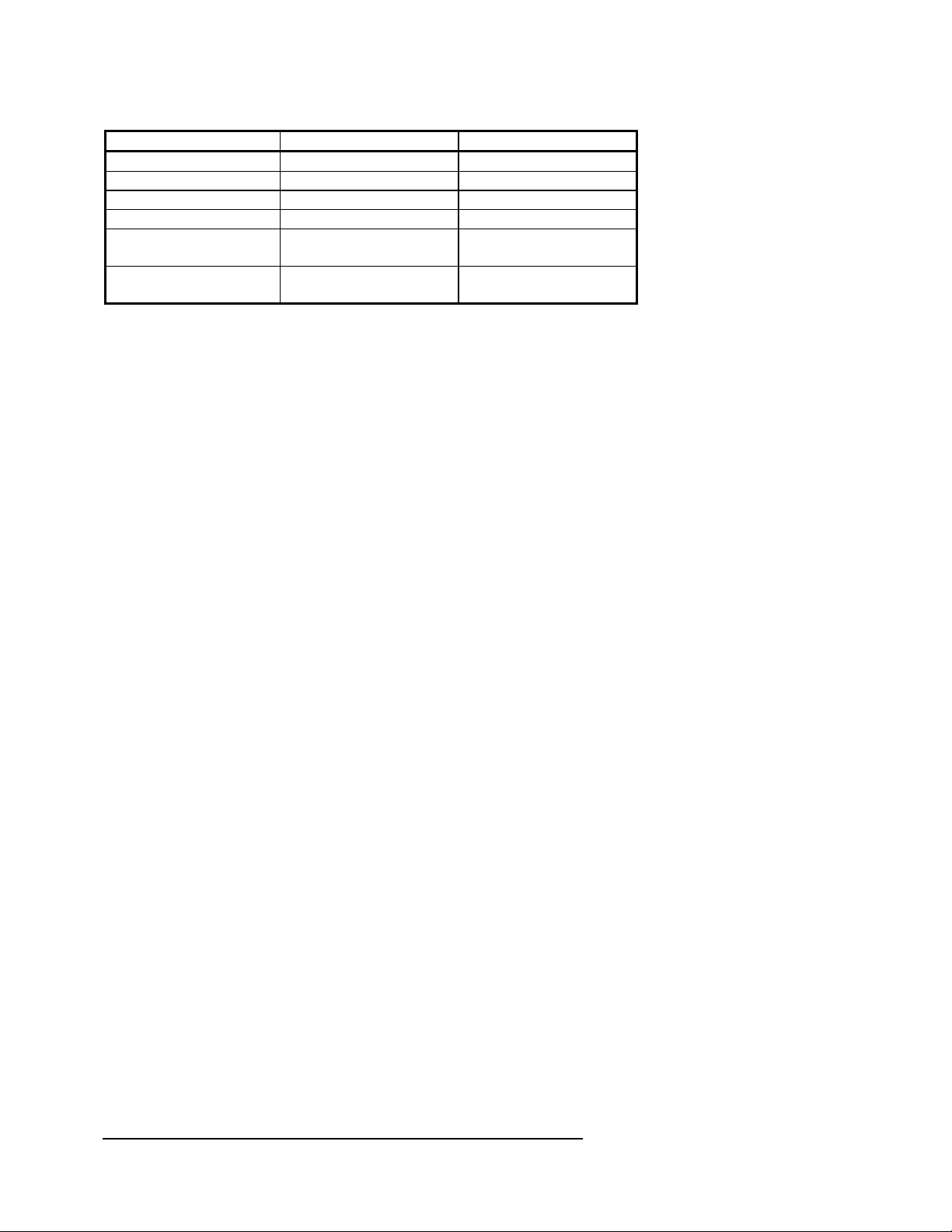

Process Variable Air-to-Open Valve Air-to-Close Valve

Flow Reverse Direct

Upstream Pressure Direct Reverse

Downstream Pressure Reverse Direct

Differential Pressure Direct Reverse

Process Temperature Depends on

installation

Auxiliary 4-20 input Depends on

installation

If the PID action is not set correctly, the controller will hold the valve

either full open or full closed and there will be no control.

Process Variable Select - Selects the process variable that will be

used to control the process.

Liquid Flow - Sets the system to control liquid flow. (If the flow

is gaseous, the system will read the liquid flow value as zero and

respond accordingly.)

ISA Up Stream Press - Sets the system to control using the

current compensated upstream line pressure. (Defined as two

pipe diameters upstream of the valve.)

Depends on

installation

Depends on

installation

ISA Dn Stream Press - Sets the system to control using the

current compensated downstream line pressure. (Defined as six

pipe diameters downstream of the valve.)

ISA Delta Pressure - Current differential pressure using the

pressure definitions above.

Process Temperature - Sets the system to control the process

temperature.

Gas Flow - Sets the system to control gaseous flow (if the flow

is liquid, the system will read the gas flow value as zero and

respond accordingly).

Auxiliary 4-20 Input - Sets the system to use a 4-20 mA signal

attached to Analog Input 2 as the process variable.

Process Variable Scaling - This option sets the full scale process

value that the controller will use in the PID algorithm, using the units

that have been selected in the C

Auxiliary, which is always in units of percent).

Reset Totalizer - Selecting this option resets the time and amount in

the flow totalizer to zero.

ONFIGURE menu (except for

Calibration

Menu

The CALIBRATE menu is used to calibrate the analog inputs and

outputs, process pressure and temperature sensors, as well as the

actuator position and pressure sensors. Before entering the

ALIBRATE menu, the display will indicate that the system will be

C

taken off-line and will ask the user to accept the condition.

StarPac II User Interface Manual 12

Page 19

g

Anlg

Anlg

Anlg

Anlg

p

WARNING: Taking the StarPac II unit off line may cause the

valve to stroke unexpectedly. Notify personnel working nearby

that the valve may stroke.

Status

While the C

will not respond to control signals. To put the unit back on line you

must press the LAST OPTION key until the display prompts you, and

then press ACCEPT. While you are in the C

letter “T” will flash on the right side of the display, indicating that the

unit is in Test mode. The unit may also change the valve position

during some of the calibration processes that could affect the

process if it is not properly isolated. The C

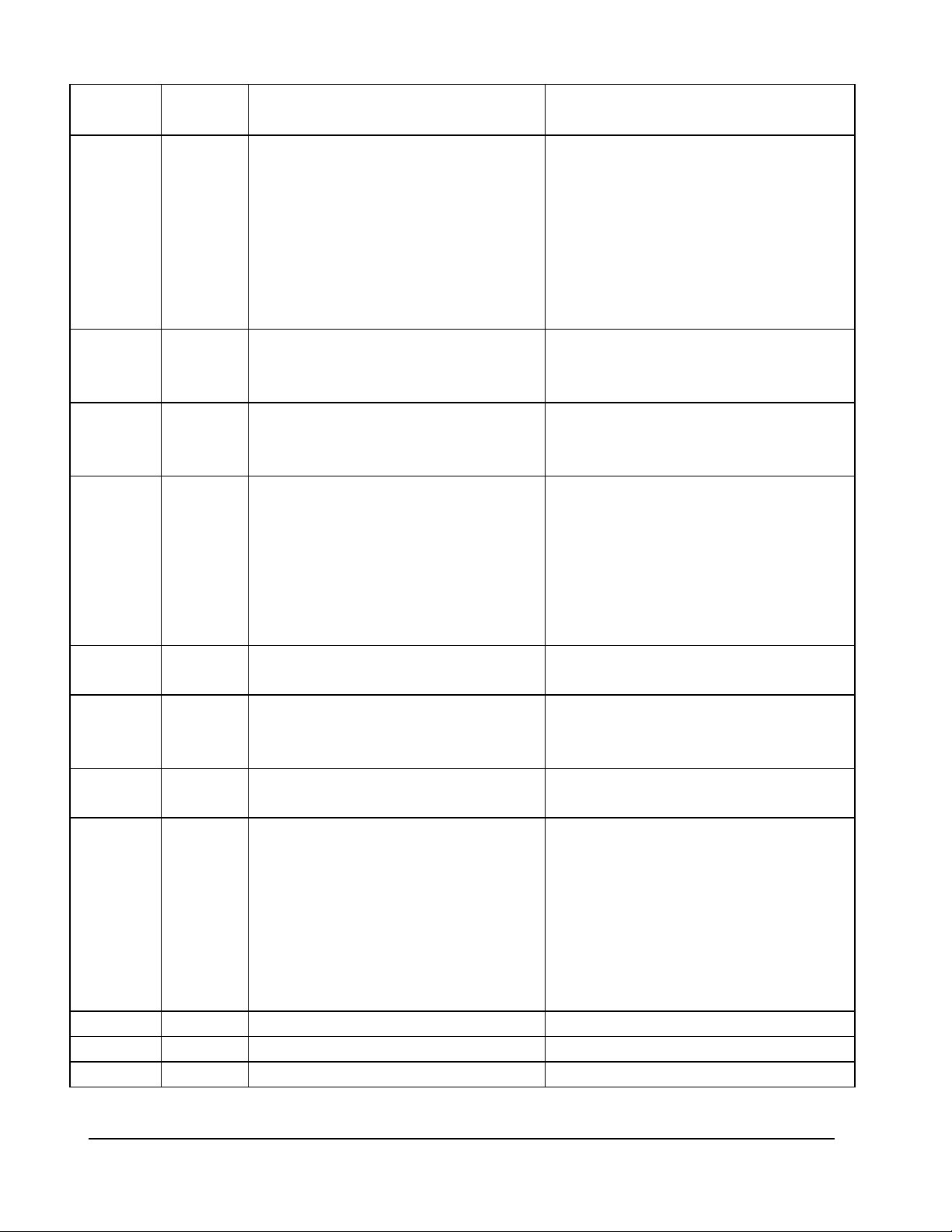

arranged as shown in Figure 5 below.

Tune

Calbrat

ALIBRATE menu is open, the system is in Test mode and

ALIBRATE menu, the

ALIBRATE menu is

Confi

Next

Out1

Out2

In1

In2

P1&

Actuatr

Stroke

NextP1 P2

P2

Figure 5: Calibration Menu Tree

Analog Out No. 1 - This option is used to calibrate the first analog

output of the StarPac II device. During the calibration procedure, a

reference milliamp meter should be connected to terminals 9(-) and

10(+) of the terminal block. The display will give instructions to use

the F1 and F2 keys to adjust the signal until the reference meter

reads 4 mA. When the 4 mA value has been accepted, you will be

prompted to set the 20 mA value. If the CANCEL key is pressed at

any time, all of the calibration values are returned to their original

value. The number shown at the end of the second line indicates the

raw D/A value that the unit is outputting, which is only used for

reference during calibration. Configuration of the variable and scaling

for the channel is performed in the C

ONFIGURE menu.

Next

Thrm

le

c

Psnr

Analog Out No. 2 - This option is used to calibrate the second

analog output of the StarPac II system. During the calibration

procedure a reference milliamp meter should be connected to

terminals 7(-) and 8(+) of the terminal block. The display will give

instructions to use the F1 and F2 keys to adjust the signal until the

reference meter reads 4 mA. When the 4 mA value has been

accepted, the user is then prompted to set the 20 mA value. If the

CANCEL key is pressed at any time, all of the calibration values will

be returned to their original value. The number shown at the end of

the second line indicates the raw D/A value that the unit is

outputting, which is only used for reference during calibration.

Configuration of the variable and scaling for the channel is

performed in the C

Analog In No. 1 - This option is used to calibrate the first analog

input of the StarPac II. During the calibration, a reference milliamp

StarPac II User Interface Manual

ONFIGURE menu.

13

Page 20

source should be connected to terminals 24(-) and 25(+) of the

terminal block. The display will give instructions to adjust the signal

until the reference meter reads 4 mA. When the 4 mA value has

been accepted, the user is then prompted to set the 20 mA value. If

the CANCEL key is pressed at any time, all of the calibration values

are returned to their original value. The number shown at the end of

the second line indicates the raw A/D value that the unit is receiving

and is only for reference during calibration. Configuration of the

variable and scaling for the channel is done in the T

UNE menu.

Analog In No. 2 - This option is used to calibrate the second analog

input of the StarPac II system. During the calibration, a reference

milliamp source should be connected to terminals 22(-) and 23(+) of

the terminal block. The display will give instructions to adjust the

signal until the reference meter reads 4 mA. When the 4 mA value

has been accepted, you are then prompted to set the 20 mA value.

If the CANCEL key is pressed at any time, all of the calibration

values are returned to their original value. The number shown at the

end of the second line indicates the raw A/D value that the unit is

receiving and is only for reference during calibration. Configuration

of the variable and scaling for the channel is done in the C

ONFIGURE

menu.

Actuator - This option calibrates the actuator pressure sensors in

the unit. The process requires that the valve stroke from full open to

full closed. Because the valve will change position during this

process you must confirm that you want to proceed. You will then be

prompted for the instrument air supply pressure to the unit. If the air

supply varies by more than 1 psi during the calibration, the test may

abort. Hence, a regulator may be required if the air supply is not

stable. The unit will then complete the calibration process by

stroking the valve open and closed over 30 to 60 seconds. Upon

successful completion, the display will momentarily flash the

message “Calibration Successful”.

Stroke - This option calibrates the position feedback sensor in the

unit. The process requires that the valve stroke from full open to full

closed. Because the valve will change position during this process

you must confirm that you want to proceed. You will then be

prompted for the valve type; linear or rotary. If the air supply varies

by more than 1 psi during the calibration, the test may abort. Hence,

a regulator may be required if the air supply is not stable. The unit

will then complete the calibration process by stroking the valve open

and closed over one to five minutes. Upon successful completion of

the process, the system will momentarily flash the message

“Calibration Successful”.

WARNING: Notify personnel working nearby that the valve will

stoke during this procedure; otherwise, serious injury may

occur.

P1 and P2 - This option simultaneously calibrates the process

pressure sensors in the unit and is the recommended sensor

calibration method. Because it calibrates both sensors at the same

time, this procedure automatically moves the valve’s stroke to midstroke. This calibration should always be done with the flow through

the valve blocked. If there is flow through the valve you must use

StarPac II User Interface Manual 14

Page 21

the individual calibration options. Because the valve will change

position during this process, you must confirm that you want to

proceed. You will then have three more menu options to set for

ERO, SPAN and SENSOR GAIN.

Z

Zero - Apply the atmospheric pressure or the minimum pressure

you want to use for your reference and press ACCEPT. The two

numbers on the right side of the display are register values that

indicate how steady the pressure is in the valve body. Next,

enter the actual pressure applied in the indicated engineering

units and press ACCEPT.

Span - Apply the maximum pressure you want to use for your

reference and press ACCEPT. The two numbers on the right

side of the display indicate how steady the pressure is in the

valve body. Next, enter the actual pressure applied in the

indicated engineering units and press ACCEPT.

Sensor Gain - This option configures the input amplifier range

for the installed sensors using the Up and Dn function keys.

Valtek’s standard sensors normally use the 39mV < out <

78mV selection. Normally, you should not have to change this

option. If you have questions, consult your Valtek

representative.

P1 - This option calibrates the upstream process pressure sensor in

the unit. You will then have two more menu options to set for Zero

and Span.

Zero - Apply the atmospheric pressure or the minimum pressure

you want to use for your reference and press ACCEPT. The

number on the right side of the display indicates how steady the

pressure is in the valve body. Next, enter the actual pressure

applied in the indicated engineering units and press ACCEPT.

Span - Apply the maximum pressure you want to use for your

reference and press ACCEPT. The numbers on the right side of

the display indicate how steady the pressure is in the valve body.

Next, enter the actual pressure applied in the indicated

engineering units and press ACCEPT.

P2 - This option calibrates the downstream process pressure sensor

in the unit. You will then have two more menu options to set for Zero

and Span.

Zero - Apply the atmospheric pressure or the minimum pressure

you want to use for your reference and press ACCEPT. The

number on the right side of the display indicates how steady the

pressure is in the valve body. Next, enter the actual pressure

applied in the indicated engineering units and press ACCEPT.

Span - Apply the maximum pressure you want to use for your

reference and press ACCEPT. The number on the right side of

the display indicates how steady the pressure is in the valve

body. Next, enter the actual pressure applied in the indicated

engineering units and press ACCEPT.

Thermocouple - This option is used to calibrate the Type-K

thermocouple temperature sensor in the unit. You will then have two

more menu options to set for Zero and Span. Normally this

calibration is done using a temperature controlled bath or a Type-K

StarPac II User Interface Manual

15

Page 22

thermocouple simulator connected to terminals 5 (yellow) and 6

(red).

Zero - Apply a signal equal to the minimum temperature you

want to use for your reference and press ACCEPT. The number

on the right side of the display indicates how steady the

temperature input is reading. Next enter the actual temperature

applied in the indicated engineering units and press ACCEPT.

Span - Apply a signal equal to the maximum temperature you

want to use for your reference and press ACCEPT. The number

on the right side of the display indicates how steady the

temperature input is reading. Next, enter the actual temperature

applied in the indicated engineering units and press ACCEPT.

Positioner - This option is used to set the control gains for the

positioner and also test for proper response.

Figure 6: Positioner Menu Tree

Default Gain - This option sets the default gain for the

positioner. Select the correct actuator size from the list using the

NEXT and PREVIOUS function keys on the menu. Default

selections exist for 25, 50, 100, and 200 square-inch actuators.

Edit Gain - This option allows you to change the gains from the

default value to customize the response of the system.

Proportional Gain - Controls the overall speed of response

of the system. Larger values will speed up the response of

the system.

Static Gain - Controls the response to steps of less than two

percent. Larger values will speed up the response of the

system to small steps (the effect of static gain is more

evident on larger actuators).

Error Gain - This is a dynamic gain variable that increases

the gain with error size to speed the response in larger

actuators. Note that smaller values increase the gain.

Step Test - Allows you to monitor the response of the system to

any step size that you input after pressing the function key. (Be

aware that this operation will cause the valve to stroke.) The

system reports the overshoot and rise time (Tr) for each step.

Pressing ACCEPT will continue to stoke the system up and

down and report on the response for each step. To quit the

positioner tuning press CANCEL.

Open Loop- This test is a diagnostic test to check the

mechanical operation of the postioner module. During this test

StarPac II User Interface Manual 16

Page 23

the valve is forced to full open and full closed by driving the

positioner output to its maximum and minimum values.

WARNING: Notify personnel working nearby that the valve will

stroke during this procedure; otherwise, serious injury may

occur.

Status

Soft

Lmts

Tune

Unit Tag

Calbrat

Name

Configuration

Menu

The CONFIGURE menu is used to set up the variables and scaling for

the analog inputs and outputs, actuator configuration, air supply and

trip limits, units, tagname, communications, LCD controls, and

individual register editing and viewing. Before entering the

ALIBRATE menu, the display will indicate that the system will be

C

taken off-line and ask you to accept that condition. While the

ONFIGURE menu is open, the system is in Test mode and will not

C

respond to control signals. To put the unit back on line, press the

LAST OPTION key until the display asks, “do you want to put the

unit back on line,” and press ACCEPT. When you are in the

ALIBRATE menu, a flashing “T” on the right side of the display will

C

indicate that the unit is in Test mode. Certain functions may cause

valve position to change unexpectedly that could affect the process if

the unit is not properly isolated. The C

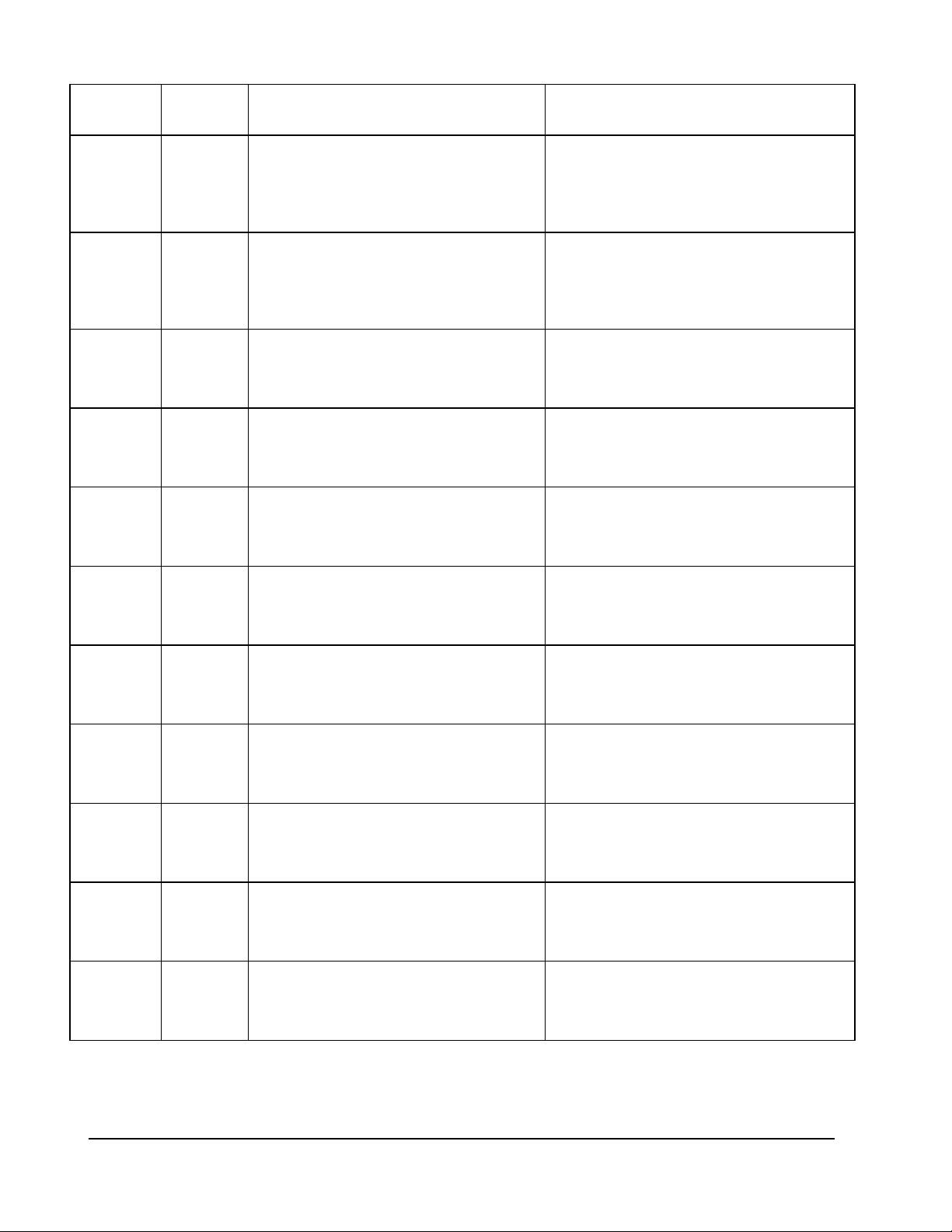

ONFIGURE menu is arranged

as shown in Figure 7.

Config

Anlg

Out1

Next

Out2

Pass

Word

Anlg

Cmd

Comm

Port

NextAnlg

LCD

Cont

Anlg

In2

Next

Air

Actn

LCD

BkLt

Low

Air

Tech

Next

Data

Log

Next

Time

Set

Figure 7: Configuration Menu Tree

Puls

Out

Analog Out 1 - This option configures the first analog output

channel. Select a variable from the list using the NEXT and

PREVIOUS function keys on the menu. You will then be asked for a

full scale output value in your selected user units. (This is the

process value that corresponds to 20 mA.) The last step is to enter

the offset or Zero output value in your selected user units. (This is

the process value that corresponds to 4 mA.) Available output

variables are:

Valve Position - Current valve position.

Liquid Flow - Current liquid flow rate.

ISA Up Stream Press - Current compensated upstream line

pressure (defined as two pipe diameters upstream of the valve).

StarPac II User Interface Manual

17

Page 24

ISA Dn Stream Press - Current compensated downstream line

pressure (defined as six pipe diameters downstream of the

valve).

ISA Delta Pressure - Current differential pressure using the

pressure definitions above.

Process Temperature - Current process temperature.

Gas Flow - Current gaseous flow rate.

Auxiliary 4-20 Input - Re-transmits the 4-20 mA signal from

analog in No. 2.

Register Number - Allows the selection of any internal register

value as an output. If a string register is selected, zero will be

displayed in the data field.

Analog Out 2 - This option configures the second analog output

channel. Select a variable from the list using the NEXT and

PREVIOUS function keys on the menu. You will then be asked for a

full scale output value in your selected user units. (This is the

process value that corresponds to 20 mA.) The last step is to enter

the offset or zero output value in your selected user units. (This is

the process value that corresponds to 4 mA.) Available output

variables are:

Valve Position - Current valve position.

Liquid Flow - Current liquid flow rate.

ISA Up Stream Press - Current compensated upstream line

pressure (defined as two pipe diameters upstream of the valve).

ISA Dn Stream Press - Current compensated downstream line

pressure (defined as six pipe diameters downstream of the

valve).

ISA Delta Pressure - Current differential pressure using the

pressure definitions above.

Process Temperature - Current process temperature.

Gas Flow - Current gaseous flow rate.

Auxiliary 4-20 Input - Re-transmits the 4-20 mA signal from

analog in No. 2.

Analog Command - This option sets up the first analog input

(analog No. 1) in the StarPac II system. This analog channel is

reserved as a control input. The signal is used either as a valve

position command, if the StarPac II is in Manual mode, or as the

controller setpoint if the StarPac II is in Auto mode. (The source of

the command or setpoint is selected in the T

UNE menu after it has

been configured here.) When this option is selected you are first

prompted for the interpretation of the analog signal. The signal can

be interpreted as Normal (4-20 mA = 0-100%), which means that 4

mA will indicate the 0 percent signal, or as Reverse (4-20 mA = 1000%), which then interprets 20 mA as the 0 percent signal.

Next, you are prompted for the hold time (in seconds) that you want

the system to hold the last command if the 4-20 mA signal should be

lost (defined as having the signal drop below 3 mA). The last prompt

requests a ramp rate that the system will use to fail the valve if the

signal has been lost and the hold time has expired. A negative value

will ramp the valve closed at the selected rate, and a positive value

StarPac II User Interface Manual 18

Page 25

will open the valve at the selected rate. (Note that this value may be

set different from the spring failure of the actuator.)

Analog In 2 - This option sets up the second analog input in the

StarPac II system. This input can be used as an external input that

is used with the internal PID controller, or as an external sensor input

for the StarPac II to use in its internal operation. If you wish to use

the input as a controller input, you must select the NOT

CONNECTED option since the scaling for the PID input is done in

UNE menu with the Process variable selection. If you want to

the T

feed an external variable into the StarPac II, select the variable from

the list using the NEXT and PREVIOUS function keys on the menu.

Next, you will be asked for a full scale input value in your userdefined units. (This is the process value that corresponds to the 100

percent signal.) The last step is to enter the offset or Zero input

value in your user-defined units. (This is the process value that

corresponds to the 0 percent signal). The available input variables

are:

Not Connected - Configures the StarPac II unit to ignore the

input as an internal variable, but the input may still be used as an

input to the controller that is configured with the process variable

selection in the T

UNE menu.

Process Temperature - Uses the value from the Auxiliary input

channel as the process temperature for all internal calculations

in place of the StarPac II sensor. The electronics assumes that

the Auxiliary input channel gets its signal from a temperature

transmitter.

Up Stream Pressure - Uses the signal from an external

pressure transmitter connected to the Auxiliary input channel as

the process pressure for all internal calculations in place of the

StarPac II sensor.

Down Stream Pressure - Uses an external pressure input as

the process pressure for all internal calculations in place of the

StarPac II sensor.

Valve Delta Pressure - Uses an external pressure input as the

process differential pressure for all internal calculations (in place

of the StarPac II differential pressure calculated by the difference

from the StarPac II internal pressure sensors). The most

common example is when a separate differential pressure

transmitter is used for cases when the application cannot

withstand pressure drops of at least ten percent of inlet

pressure.

Molecular Weight - Uses an external molecular weight input for

all internal calculations in place of the static value stored in the

StarPac II configuration.

Specific Gravity - Uses an external Specific Gravity input for all

internal calculations in place of the static value stored in the

StarPac II configuration.

Liquid Fudge Factor - This input allows you to make dynamic

adjustments to the liquid flow calculation based on the value of

the input.

Gas Fudge Factor - This input allows you to make dynamic

adjustments to the gaseous flow calculation based on the value

of the input.

StarPac II User Interface Manual

19

Page 26

g

q

p

A

Air Action - Used to set up the StarPac II for the configured actuator

failure mode. ATO (Air-to-Open) is normally used for fail-closed

valves, ATC (Air-to-Close) is normally used for fail-open valves. If

ATC is selected and you will be using an analog command source,

configure the analog command to reverse so that 4 mA equals the

100 percent position (open). The following table lists the possible

configurations:

Failure Mode Output 2

(bottom port) Is

Connected to:

Air loss, fail-closed:

Power loss, failclosed

Air loss, fail-closed;

Power loss, fail-open

Air loss, fail-open;

Power loss, fail-open

Air loss, fail-open;

Power loss, fail-close

actuator top actuator bottom above

actuator bottom actuator top above

actuator bottom actuator top below

actuator top actuator bottom below

Output 1 (top

port) Is

Connected to:

Spring

Failure

Position

piston

piston

piston

piston

Air

Action

ATO

ATC

ATC

ATO

Low Air - This option is used to set the trip parameters for low

supply air to the system, which is continuously monitoring the air

supply in the actuator. Using the actuator pressures, the StarPac II

can infer the supply pressure to within five to 10 psi. If the supply

pressure drops below the Low Air Trip Pressure then the positioner

will attempt to hold the valve for the time specified in the hold

parameter and then ramp to the spring failure position at the

specified Low Air Ramp Rate.

Softlimits - (Softlimits are stroke limits set and maintained by the

system’s electronics or software. These limits are only in effect

when the unit has power and is not in Test mode. When power has

failed or cut off to the StarPac II, the valve will fail to its mechanical

stops or limits.) This option allows you to set software limits on the

travel of the valve. These limits are active in Auto and Manual

modes, but they do not affect failure modes. Normally these limits

are set to -10 and 110 percent of travel so they do not affect valve

operation.

Units -The StarPac II system has individually configurable units for

Process Pressure, Liquid flow, Gas flow, Process temperature, and

actuator pressure. Units for each type of process variable are set in

the Unit menu. (See Figure 8)

NextSoft

Li

Flow

Gas

Flow

Next

Proc

Tem

ct

Pres

Lmts

Unit

Ta

Name

Proc

Pres

Figure 8: Units Menu

StarPac II User Interface Manual 20

Page 27

Process Pressure - This option sets the process pressure

engineering units for the StarPac II system. Use the NEXT and

PREVIOUS function keys to select units from the following list:

PSIG - Pounds per square-inch gauge

PSIA - Pounds per square-inch absolute

kPa G - Kilopascals gauge

kPa A - Kilopascals absolute

kgscmG - Kilograms per square-centimeter gauge

kgscmA - Kilograms per square-centimeter absolute

Bar G - Bar gauge

Bar A - Bar absolute

Liquid Flow - Sets the liquid flow engineering units for the

StarPac II system. Use the NEXT and PREVIOUS function keys

to select units from the following list:

Usgpm - US gallons per minute

l/m - Liters per minute

lbs/hr - Pounds per hour

kg/hr - Kilograms per hour

cm3/hr - Cubic centimeters per hour

bbl/dy - Barrels per day (42 gal/bbl)

Ukgpm - Imperial gallons per minute

CUSTOM - Allows you to create your own custom units by

first entering a multiplier that will operate on the StarPac

native liquid flow units which are Gallons/Minute to create

your new units. Next, select the time base that relates to

your flow rate of seconds, minutes, hours, or days for the

totalizer to use. Then enter the name for the units you want

to display. The name is limited to six characters. Lastly,

enter the name that you want the totalizer to display for the

totalized units.

Gas Flow - Sets the gaseous flow engineering units for the

StarPac II system. Use the NEXT and PREVIOUS function keys

to select units from the following list:

lbs/hr - Pounds per hour

kg/hr - Kilograms per hour

SCFH - Standard cubic feet per hour

MSCFD - Million standard cubic feet per day

SCFM - Standard cubic feet per minute

SCMH - Standard cubic meters per hour

CUSTOM - Allows you to create your own custom units by

first entering a multiplier that will operate on the StarPac

native gas flow units which are Pounds/Hour to create your

new units. Next you select the time base that relates to your

flow rate of seconds, minutes, hours, or days for the totalizer

to use. Next enter the name for the units you want to

display. The name is limited to six characters. Last enter

StarPac II User Interface Manual

21

Page 28

the name that you want the totalizer to display for the

totalized units.

Process Temperature - Sets the process temperature

engineering units for the StarPac II system. Use the NEXT and

PREVIOUS function keys to select units from the following list:

ºC - Degrees Celsius

ºF - Degrees Fahrenheit

ºR - Degrees Rankine

ºK - Degrees Kelvin

Actuator Pressure - Sets the actuator pressure engineering

units for the StarPac II system. Use the NEXT and PREVIOUS

function keys to select units from the following list:

PSIG - Pounds per square-inch gauge

PSIA - Pounds per square-inch absolute

kPa G - Kilopascals gauge

kPa A - Kilopascals absolute

kgscmG - Kilograms per square-centimeter gauge

kgscmA - Kilograms per square-centimeter absolute

Bar G - Bar gauge

Bar A - Bar absolute

Tag Name - This option allows the user to enter a tagname that will

be used as an identifier for the unit on a Modbus network.

Password - This option sets up a password to control access to the

local interface. Access to the T

UNE, CALIBRATE, and CONFIGURE

menus is allowed only with the password after the password has

been enabled. The S

TATUS menu is still accessible even when the

password is enabled. To enable the password, press F1 and enter

the password. The default password is “1234.” (If the system is

initialized by pressing the “0” while powering up the unit, the

password will be reset to “1234.” Note that control and

communication parameters will also be reset with an initialize.) To

disable the password, press F2. To change the password, select F3

and enter the old password, then enter the new password. Note that

when entering a new password the characters are visible on the

screen for verification.

Communication Settings - This option configures the

communication settings for the Modbus communications ports on the

StarPac II system. Both COMM port A and COMM port B use the

same settings--they cannot be set independently. The

communication settings are set in the C

OMM PORT menu (Figure 9).

StarPac II User Interface Manual 22

Page 29

A

y

A

y

Pass

Word

Address - This option sets the Modbus address of the StarPac II

system. Both the A and B COMM ports have the same address;

therefore, they cannot be hooked together on the same network

and must be connected to different networks. The default

address for a StarPac II is “1” after an initialization. Use the Up

or Dn function keys to select the proper address.

Baud Rate - This option sets the Baud Rate for the Modbus

communications. Available Baud Rate settings are: 1200, 2400,

9600, 19200, 31250, 38400, and 57600. The default setting is

19200 Baud after an initialization. Use the Up or Dn function

keys to select the desired Baud Rate.

Parity - This option sets the Parity for the Modbus

communications. Available Parity settings are: None, Even, and

Odd. The default setting is Odd after an initialization. Use the

NEXT or PREVIOUS function keys to select the proper Parity.

Comm

Port

LCD

Cont

ddr

ess

Figure 9: Comm Port Menu

Baud

Rate

Next

Parit

Next

RTU/

ASCI

Port

ccsTXDl

RTU / ASCII - This option sets the communication mode for the

Modbus communications. Available communications mode

settings are: ASCII and RTU. The default setting is RTU after an

initialization. Use the NEXT or PREVIOUS function keys to

select the proper communication mode.

Port Access - This option allows you to control the priority of the

communication ports. A port may be configured so that it can

only be used for monitoring by a remote device. Use the NEXT

and PREVIOUS function keys to select the access from the

following list:

A - R/W B - R/W - Both ports allow read/write access

A - R/W B - RO - “A” port allows read/write access; “B” port

is read only.

A - RO B - R/W - “A” port is read only; “B” port allows

read/write access.

Transmit Delay - This setting controls the time that the

StarPac II system will wait before answering a Modbus request.

The 3.5 character setting provides the best performance for most

systems. Available transmit delays are: 3.5 characters, 50

millisecond, 75 millisecond, 100 millisecond, 150 millisecond,

250 millisecond, 500 millisecond, and 1 second.

LCD Contrast - This option adjusts the viewing angle of the LCD.

Use the Up and Dn function keys to adjust the viewing angle.

StarPac II User Interface Manual

23

Page 30

V

g

g

g

p

p

LCD Backlight - Use this option to set the time that the backlight in

the LCD will stay on after the last pressed key. Available options

are: Always Off, 10 Seconds, 30 Seconds, 1 Minute, 5

Minutes, 15 Minutes, 1 Hour, and Always On. The LCD

backlight has a rated 5000 hour life; therefore, selecting the Always

On option may cause the display backlight to burn out prematurely.

Technician - This option allows you to view and manipulate internal

Modbus registers, backup a configuration in non-volatile RAM and

reset the system operation. These options are selected from the

ECHNICIAN menu. (See Figure 10 below.)

T

Edit

Re

Time

Set

Rset

SPac

Next

Save

Bku

Load

Bku

LCD

BkLt

Tech

Data

Lo

iew

Re

Figure 10: Technician Menu

View Register - This option allows you to view any integer or

floating point Modbus register. A register map is located in the

appendix. (String registers cannot be viewed with this function;

however, they can be viewed by using the StarTalk software.)

Edit Register - This option allows you to view and change any

read/write integer or floating point Modbus register. A register

map is located in the appendix.

Caution: Changing register values will affect the operation of

the system. String registers cannot be edited with this function.

You must use the StarTalk software to Edit string registers.

Reset StarPac II - This option will reset the system’s operation

(the same as powering up the unit) and will also reset some

error conditions while displaying the firmware revision on the

display.

Load

Dflt

Save Backup - This option will backup the current configuration

to a safe area in the non-volatile RAM. Valtek suggests that you

use this option before attempting to reconfigure your system to

ensure that you can restore the configuration should something

go wrong.

Load Backup - This option allows you to restore a known

configuration to the system by working registers from the backup

NVRAM.

Load Default - This option will overwrite the complete register

map in the StarPac II with default data. If you choose this option

all of the flow characterization data, configuration data and

calibration data will be lost. This option should only be used in

the rare case that the configuration of a system has become so

corrupt that all of the data will be re-entered from scratch. It is

StarPac II User Interface Manual 24

Page 31

recommended that you use the StarTalk for windows software to

reload your system information from the factory supplied disk.

Data Logger - This option sets the interval between data points on

the internal data logger. NOTE: You must use StarTalk software to

download a data logger file from the StarPac II.

Time Set - This option sets the internal StarPac II clock. The

internal clock is battery driven and keeps time whether the unit is

powered or not. Use the F1 and F2 function keys to select the field

to edit. Note that the time is in the 24 hour format and the date is the

mm/dd/yy format.

Pulse Relay Output - Configures the Pulse Out channel on the

StarPac II system for the process variable and scaling. First you

must select a variable from the list using the Next and Previous

function keys on the menu. Next you are asked for a full scale

output value in your selected user units. (This is the process value

that corresponds to the maximum frequency.) The last step is to

enter the offset or zero output value in your selected user units (this

is the process value that corresponds to 0 Hz). Available output

variables are the following:

Valve Position - Current valve position.

Liquid Flow - Current liquid flow rate.

ISA Up Stream Press - Current compensated upstream line

pressure (defined as two pipe diameters upstream of the valve).

ISA Dn Stream Press - Current compensated downstream line

pressure (defined as six pipe diameters downstream of the

valve).

ISA Delta Pressure - Current differential pressure using the

pressure definitions above.

Process Temperature - Current process temperature.

Gas Flow - Current gaseous flow rate.

Auxiliary 4-20 Input - Re-transmits the 4-20 mA signal from

analog in No. 2.

Register Number - Allows the selection of any internal register

value as an output.

Changing or Viewing the Fluid Specification

The StarPac II system must be configured for the exact fluid that you

have in your process. The factory configures the system with fluid

data for your system using the information supplied with the order.

Verify that the fluid data is correct for your process. The StarPac

system requires the following fluid data for accurate flow calculation:

Antoine’s A coefficient register 70329

Antoine’s B coefficient register 70331

Antoine’s C coefficient register 70333

Critical Pressure in psia register 70341

Critical Temperature in ºR register 70343

StarPac II User Interface Manual

25

Page 32

F

coefficient (=K/1.4) register 70345

K

Molecular Weight register 70347

Specific Gravity Reference temp in ºR register 70349

Specific Gravity at reference temp register 70351

Viscosity A register 70541

Viscosity B register 70543

The Antoine coefficients are used to calculate the vapor

pressure of the fluid at the temperature measured by the K

thermocouple in the StarPac according to the following equation:

B

VP A

=−

exp( )

TC

where VP is the vapor pressure in psia, T is the temperature in

°R, and A, B, and C are the Antoine coefficients.

Viscosity is calculated according to the following equation:

+

Visc A B T=* *exp

Where Visc is the fluid viscosity in centipoise, T is the process

temperature measured by the thermocouple in °F, and A and B

are the viscosity coefficients.

These registers can be checked using either the View option of the

TATUS menu or the View selection in the Tech option of the

S

ONFIGURE menu. They can be changed using the Edit selection in

C

the Tech option of the C

()

ONFIGURE menu.

Setting the Jumpers

The StarPac II system has several jumpers that are used to

configure the digital and discrete I/O. Two jumpers are on the

personality card (the small card in the lower right-hand side) and are

visible when the inner door is opened. The personality card must be

removed to change the discrete jumpers located on the board below

the personality card. To remove the personality card, remove the

four small screws that hold the card in place and gently remove it by

gripping the notch at the lower right-hand corner of the card.

RS- 485 Termination - On the personality card there are two

termination jumpers for the COMM A and B for the RS-485

communications. These jumpers should only be installed on the two

most remote devices on the network. Count the host computer as

any other device. For example, a single StarPac II system is

communicating with a host PC in the control room. The StarPac II

unit and the RS-485 driver in the host computer would each require

a termination jumper. Remove the termination jumpers in the

devices not considered to be the most remote. Using more than two

termination jumpers in a network may cause the RS-485

communications to fail.

Alarm Relay Setting - Under the personality card is a three position

jumper labeled “Relay.” This jumper, if set in the A-B position,

configures the relay to Normally-open operation. If set to the B-C

StarPac II User Interface Manual 26

Page 33

position, the jumper configures the relay to Normally-closed

operation.

Discrete Input Range Selection - Under the personality card are

two sets of three position jumpers labeled “DI1” and “DI2.” DI1

refers to discrete input No. 1 and DI2 to discrete input No. 2. In the

A-B position the input is set to trigger on 120V AC or DC. In the B-C

position the input is set to trigger on 24V AC or DC. These jumpers

must be moved in pairs for each individual relay, but each relay may

be setup differently.

Troubleshooting

If you experience problems with your system, check the following list

for some common solutions.

LCD blank and no system response - Check 24 VDC supply

polarity and capacity (>300 mA).

LCD Hard to view - In the C

for a better viewing angle.

LCD active, unit will not respond to position or control

commands, and the analog outputs do not change - Check

to see if the unit is in Test mode by looking for a flashing “T” on

the right side of the display. The unit will be in Test mode any

time you are in the C

ALIBRATE or CONFIGURE menu, use the LAST OPTION key

the C

ALIBRATE or CONFIGURE menu. If you are in

to move up to the top of the menu and exit from Test mode. If

that does not clear the flashing “T” from the display, go to the

UNE menu and use the mode command to put the system in

T

Auto or Manual mode. If the system displays a flashing “E” or

“A” on the left side of the display, check the cause of the error or

alarm using the ERR/ALRM option in the S

Alarm is a trip condition, then you can view the cause of the trip

by setting the ROW1 variable to show Mode/Status in the

TATUS menu.

S

System will not respond to discrete commands - Check

jumper selection to make sure the input is set to the proper

range and that the system is not in Test mode.

Pressure sensors appear to saturate prematurely - Check the

rating of the sensors in the system information option of the

TATUS menu to verify the rating (the rating is also etched on the

S

sensor). Check the sensor gain (set in the C

the P1 & P2 option (the standard range is 39 mV < out < 78

mV).

Stroke calibration aborts or hangs - Check the air supply and

make sure it is stable. A regulator may be required to stabilize

the air supply in some systems.

ONFIGURE menu adjust the contrast

TATUS menu. If the

ALIBRATE menu) in

StarPac II User Interface Manual

27

Page 34

Appendices

System Setup Checklist

A. Power

• (24) VDC power at least 300 mA.

• Polarity correct.

• Local display ON. If not, check power supply.

B. System Communications (if connected to a remote computer)

• RS-485 converter properly installed or attached to computer.

• Signal polarity correct.

• Modbus device address set in StarPac device; refer to StarPac Operation section.

• Start software; refer to software section.

• Configure communications in software and hardware to match. Refer to Initial Setup in The

StarTalk II portion of this manual and StarPac Operation section.

• Communications work. If not, recheck settings.

C. Calibration checks

• Air supply turned on.

• Check status screens to verify system calibration; refer to software section.

• Valve stroke calibration to remove installation and handling offsets; refer calibration section.

• Verify process sensor calibration; recalibrate if needed.

D. System Configuration; refer to engineering/configuration section for details

• Set or verify failure modes.

• Set or verify analog output.

• Set or verify command and mode source

• Set or verify stroke limits.

• Set or verify LCD display options.

• Check positioner response and set gain to control speed.

E. Automatic PID Operation; refer to Engineering/Tuning section

• Select process variable.

• Input full scale range.

• Set initial PID parameters.

• Begin Automatic mode and tune system.

F. Other Options; refer to Engineering section

• Set units.

• Reset totalizer.

• Set or verify tagname.

• Set and start Data Logger function.

• Collect and save installed signature, if desired.

G. Save Installed Configuration; refer to technician support section

• Save configuration.

• Make backup copy and archive.

StarPac II User Interface Manual 28

Page 35

Detailed StarPac ll Register Map

This reference will aid you in understanding the configuration of the StarPac ll register table. Registers are

described and notes are provided that give the range and more detailed information.

The StarPac ll register table consists of three different types of information: integers, IEEE floating point

numbers and strings. These types can have a read only (RO) access attribute or a read/write (RW) access

attribute. You can only read RO registers. Writing to a RO register will generate an exception error. You

can both read and write to RW registers.

The register numbering is as follows: a 30000 base indicates RO integers, a 40000 base indicates RW

integers, a 70000 base indicates floating point numbers, and a 50000 base indicates strings. For example,

a register number of 30003 indicates a RO integer.

Two contiguous integer registers make up a floating point register. You will get an exception response if

you try to access into the middle of a floating point register.

Registers making up bit fields follow the MSB/LSB (Most Significant Byte/Least Significant Byte) format.

Internally, Valtek calculates the StarPac ll variable numbers by taking the module of the register number

and 10,000 and subtracting 1. For example, register number 30001 would become variable number 0.

Integer Registers

Integer

Register