Page 1

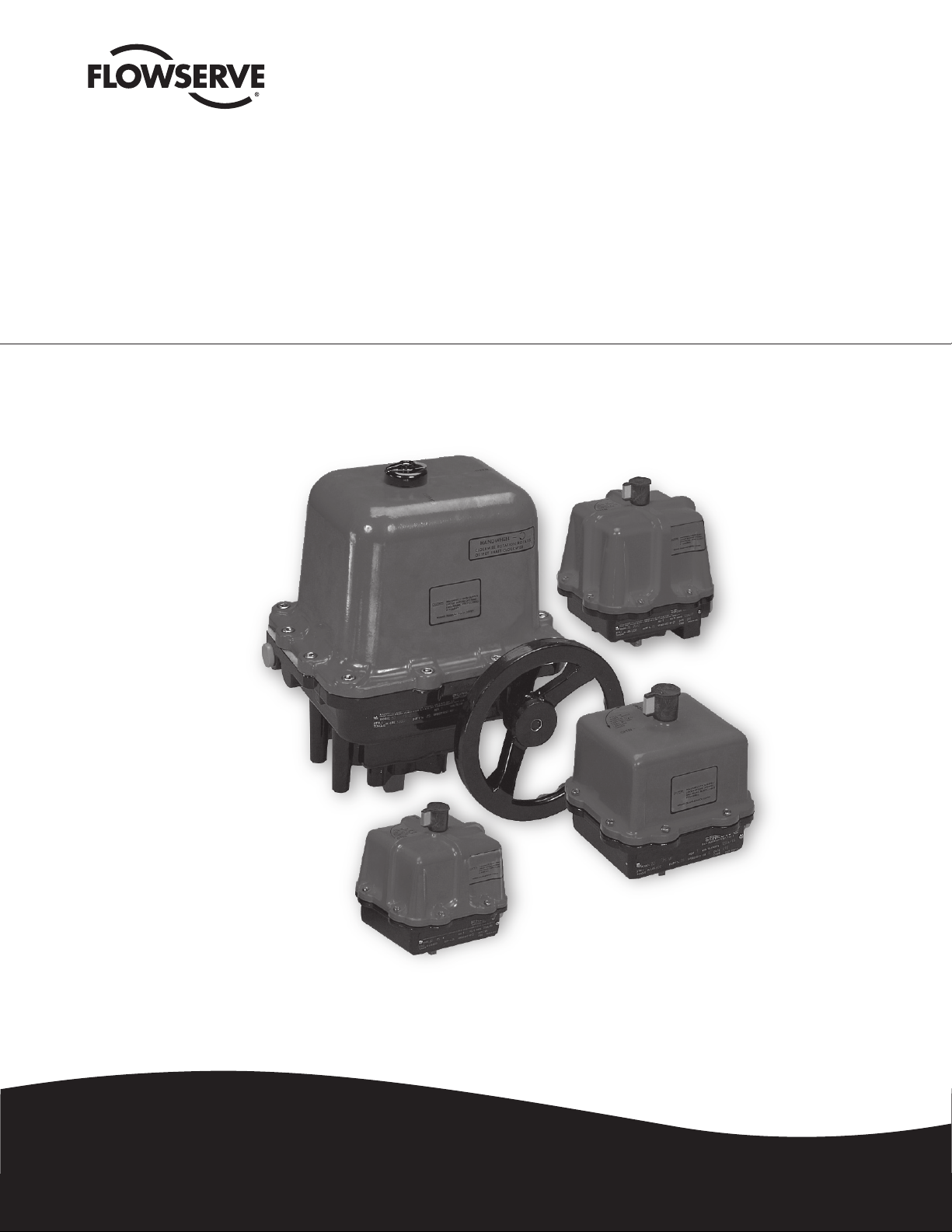

USER INSTRUCTIONS

L75 Series Electric Actuator

Modbus RTU Electronic Positioner

FCD LMAIM7502-00 – 07/05

Installation

Operation

Maintenance

Experience In Motion

Page 2

Page 3

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Contents

Introduction 4

Principles of Operation 4

General Environmental Information 4

Mechanical Installation 5

Electrical Connections 5

Adjustment of Switch Cams 7

Board Indicators 7

Termination Resistors 7

Configuration 8

Modbus Address Selection 8

Baud Rate Selection 8

Two-Wire or Four-Wire Bus Selection 8

Modbus Functions 8

Modbus RTU Message Format 9

Reception of Invalid Commands 13

Reception of Commands with Illegal Fields 14

Modbus Exception Responses 14

Troubleshooting 15

flowserve.com

3

Page 4

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Introduction

The Modbus RTU electronic positioner utilizes the RTU (Remote Terminal Unit) transmission mode to

communicate on standard Modbus networks. The mode and other serial parameters (baud, parity, stop

bits, etc.) must be configured the same for all devices on a Modbus network.

Principles of Operation

The Flowserve Modbus RTU Interface Card is a valve automation and control product that uses the

Modbus communication protocol to operate and monitor position as well as provide predictive and

preventative maintenance functions.

When power is first applied to the board, the motor drive circuits are inactive and the valve will remain

in its current position. A valve position is maintained until a Modbus movement command is received.

Modbus functions are viewed as commands and are available to start or stop movement in a particular

direction, to read the status of the end-of-travel limit switches, and to read the status of the motor drive

circuits. If all three indicator LEDs blink simultaneously when power is first applied, the Modbus address

is not correct and the actuator will not operate. Refer to Modbus Address Selection in the Configuration

section to correct the problem.

Using a Modbus command, the valve shaft can be rotated either clockwise (CW) or counterclockwise

(CCW). A movement command will cause rotation in a specified direction. Valve movement will continue

until either the end-of-travel limit switch opens, or a stop command is received. In full open/close applications, the stop command is not needed. In other applications, the valve can be stopped in mid-travel

by issuing a stop command before the end-of-travel limit switch opens.

It is not possible to command movement in both CW and CCW directions simultaneously. If this is

attempted, the last positioning command will remain in effect. If a command is issued to move in a

direction opposite to the current direction of movement, the actuator will stop movement in the current

direction, delay for one second, and then begin moving in the specified direction (i.e. a stop command

is not needed to change directions).

General Environmental Information

The L75 Modbus RTU Electronic Positioner is sensitive to electrical noise on communication and power

supply lines. The positioner can also be affected by radiated electrical noise. For best positioner operation, the electrical noise level should be as low as possible. Follow the wiring guidelines in this manual

carefully.

Shielded, twisted-pair wire is recommended for the communication cable. If shielded, twisted-pair wire

is not available, non-shielded twisted pair cable is the next best alternative to prevent susceptibility to

electrical noise. Unshielded, non-twisted cable is not recommended.

4

Page 5

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Flowserve recommends an indoor storage environment suitable for human occupancy if the product

must be stored prior to installation. Do not store the positioner in any of the following conditions:

Where exposure to relative humidity is greater than 85%.

1.

Where acid or alkali fumes are present.

2.

Where ultraviolet or other radiation is above normal background conditions.

3.

Where temperatures are above 120°C or are below -40°C

4.

Within 50 feet of any source of ozone.

5.

Operating solid-state electronic equipment near or beyond its high temperature ratings is the primary

cause for most failures. It is very important to consider factors that affect this product’s operating

temperature. Operating an electronic device at or below its low temperature rating may result in

inoperability. Proper operation usually resumes when rated operating temperatures are established.

Low-temperature problems can be easily cured by addition of a thermostatically controlled heater to the

actuator housing.

Flowserve has manufactured this product using moisture-proofing and fungicidal coatings. The coatings

provide added protection against the affects of high humidity. Where relative humidity is consistently

80% to 90% and the ambient temperature is subject to large variations, a heater/thermostat option

should be installed in the actuator housing. The heater should not increase the internal temperature

beyond the rated operating temperature.

Table 1: Electronic Printed Circuit Board Specifications

Power requirements

8345 / 8354 Modbus RTU Interface Card 120 VAC – 50 mA max.

8336 / 8366 Modbus RTU Interface Card 240 VAC – 25 mA max

Device Modbus

Firmware Revision 5/6/00

Transmission Speed 9.6 or 19.2 Kbaud maximum

Temperature

Operational -40°F to 150°F (-40°C to 65°C)

Storage -40°F to 250°F (-40°C to 120°C)

Mechanical Installation

Installation is best performed at the factory using brackets and mounting hardware designed for

the purpose. Factory-trained individuals must perform installation and calibration in any event. Field

upgrade of a non-Modbus unit to Modbus unit is possible with the proper hardware and training.

Electrical Connections

CAUTION: To prevent ignition of hazardous atmospheres, keep cover bolts tight while circuits

a

are live. Disconnect supply circuit before opening.

Entry into the actuator housing is made through one of the NPT conduit entries. Electrical data connections are made to a captive screw cage terminal strip located on the Modbus RTU board. Electrical

power (120 VAC) and limit switch connections are made to the actuator terminal strip.

5

flowserve.com

Page 6

PCB

REDBLK

J2 J1

W8

BLK

W8

BLK

W9

RED

RED

W9

VIEW SHOWING J1,J2 WIRES

FOR 240VAC USAGE

RESISTOR

USAGE

R22,R24

R22,R23,R24,R25

R22,R24

R22,R23,R24,R25

240VAC

25/30

NO YES

240VAC

10/23

NO YES

115VAC

25/30

YES NO

NOYES

10/23

115VAC

08366

08336

08354

08345

WIRES

W8 & W9

JUMPERS

J1 & J2

SIZE

ACTUATOR

PART NO.

VOLTAGE

INPUT

CAUTION:

BOARD

BEFORE REPLACING

REMOVE POWER

PROTECTIVE COVER

DO NOT REMOVE

HIGH VOLTAGE

CAUTION:

(W5) RED

(W6) GRA

(W7) ORN

SW1

LD2

LD1

TP1

SW2

LD4LD3 LD5

T1

GRA

2

BRN

4

BLK RED

3

CCW C

RED

WHT

1

J1

REDBLK

J2

CCW

CW

MSD

A

485 BUS TO MODBUS

SHLD

CCW

W/BORN

Z Y B

TB1

4W

2-WIRE OPERATION

2W

JUMPER 2W FOR

4W

2W

GND

SEL BAUD RATE

COMMSW3SW4

9600

19.2K

NODE ADDRESS

LSD

(W4) BLK

(W3) RED

(W2) BRN

(W1) WHT

XXXXX

PART NUMBER LABEL PER

LISTING IN SHEET 3 TABLE

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

CAUTION: Be sure to observe correct polarity of the power connections or damage to the

a

printed circuit board will occur!

Figure 1: Modbus RTU Board

6

Page 7

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Adjustment of Switch Cams

1. Loosen captive cover screws and remove lid, turning slightly while lifting.

2. Place the actuator in the CW position and apply voltage to the Modbus RTU Interface Card.

3. Loosen the CW cam set screw.

4. Adjust the cam associated CW limit switch clockwise until the CW LED is illuminated.

5. Tighten the cam set screw for the CW cam.

6. Place the actuator in the CCW position.

7. Loosen the CCW cam set screw.

8. Adjust the cam associated CCW limit switch rotate counter-clockwise until the CCW LED is

illuminated.

9. Tighten the cam set screw for the CCW cam.

10. Cycle the actuator to insure that each LED is illuminated at the appropriate time. Some minor

readjustment might be necessary.

11. Clean base, lid flanges, and replace lid on base.

NOTE: Make sure wires are not caught between flanges

12. Tighten captive screws.

Board Indicators

The Modbus RTU Interface Board contains several LED indicators that are helpful when initially configuring the device or when troubleshooting. Refer to figure one for the locations of the indicators.

CW The CW LED illuminates to indicate motor circuits are being driven to cause movement in the

CW direction. The LED will stay on during valve movement and will remain on until a stop movement

command is received.

CCW The CCW LED illuminates to indicate motor circuits are being driven to cause movement in the

CCW direction. The LED will stay on during valve movement and will remain on until a stop movement

command is received.

SW3 The SW3 LED illuminates when the CW limit switch is activated (closed) with the valve in the full

CW position.

SW4 The SW4 LED illuminates when the CCW limit switch is activated (closed) with the valve in the

full CCW position.

COMM The COMM LED illuminates whenever the actuator is receiving or transmitting a message. The

COMM LED will blink when any message is received - even if the message is for another actuator.

Termination Resistors

Termination resistors are not required at master or slave units.

7

flowserve.com

Page 8

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

MSD

Configuration

The data link layer of communication conforms to the Modbus RTU specification. Slaves (actuators)

reply on the bus only in response to a valid command from the master control unit addressed to the

actuator. Each actuator has an address selected with switches on the actuator board. An actuator can

have any address from 1 to 247. (Modbus address 0 is reserved for broadcast messages). The address

is specified using two hexadecimal rotary switches. If an illegal address is set in the switches, the

actuator will not respond to any commands.

Modbus Address Selection

The Modbus address may be between 1 and 247 (decimal) or 01 and F7 hexadecimal. Address 0 is used

for broadcast messages only. Two on-board, rotary hexadecimal switches are used to set the address.

Remember the addresses on the switch must be specified in hexadecimal—not decimal. Be sure the

address is correctly set on the switches. If an invalid address is set, the SW3, SW4 and COMM LEDs

will blink simultaneously and the unit will not be operational.

Figure 2: Node Address

Baud Rate Selection

Communication data rate is jumper-selectable as either 9600 bits per second or 19,200 bits per second.

Other communication parameters are fixed at no parity, 8 data bits, and 1 stop bit. Set the baud rate by

positioning the jumper as required for the appropriate transmission rate.

Two-Wire or Four-Wire Bus Selection

The RS-485 Modbus bus can be set to operate in either a two-wire or four-wire configuration. Set the

on-board jumpers as required for the desired configuration. Be sure that both jumpers are set for the

desired configuration. In either case, termination resistors are not required at segment ends.

Modbus Functions

The actuator supports the Modbus RTU protocol only. The actuator supports the following Modbus

functions:

Function Code Function Name Description

1 Read coil status State of motion control

2 Read input status State of limit switches

3 Read holding register State of actuator operation

8

5 Force single coil Starts/Stops actuator

6 Preset single register Starts/Stops actuator

Page 9

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Modbus functions are seen as commands to the positioner. Hereafter in this manual, they will be called

commands. A summary of commands to cause specific valve movement are shown in the table below:

Action Modbus Function (code) Coil/Reg. # (address) Data

CW Force single coil (05) Coil 1 (0000H) FF00 (hex)

Stop CW Force single coil (05) Coil 1 (0000H) 0000 (hex)

CCW Force single coil (05) Coil 2 (0001H) FF00 (hex)

Stop CCW Force single coil (05) Coil 2 (0001H) 0000 (hex)

CW Preset single reg. (06) Register 40,001 256 (dec)

Stop Preset single reg. (06) Register 40,001 512 (dec)

CCW Preset single reg. (06) Register 40,001 768 (dec)

Modbus RTU Message Format

Field Name Example

Actuator Address 05 (actuator 45)

Function 01 (Read Coil Status)

Starting Address (High) 00

Starting Address (Low) 00 (coil 1)

Number of Points (High) 00

Number of Points (Low) 01 (return 1 status)

CRC Error Check (LS byte) FC

CRC Error Check (MS byte) 4E

NOTE: The least significant byte of the 16-bit CRC value is sent first before the most significant byte.

Each message consists of the bytes mentioned above sent consecutively with less than a 1-½-character

time gap between bytes. Messages are considered completed when the actuator sees a time gap greater

than 1-½ characters.

Read Coil Status Command (01)

This command reads the ON or OFF state of the specified coil (i.e. motion control circuit). Coil 1

represents the CW motion control circuit; coil 2 represents the CCW motion control circuit. The Modbus

message can have a starting address of 0 or 1 (for coil 1 or 2, respectively). The number of points can

be either 1 or 2 when coil 1 is specified and should be 1 if coil 2 is specified. Requesting more than

2 points with coil 1 or more than 1 point with coil 2 will result in an error response. Regardless the

number of points requested, only one data byte will be returned. Broadcast is not supported.

Example: “Read the status of the CW motion control circuit (coil 1) on actuator #5”

Field Name Example

Actuator Address 05

Function (Read Coil Status) 01

Starting Address (High) 00

Starting Address (Low) 00

Number of Points (High) 00

Number of Points (Low) 01

CRC Error Check (LS byte) FC

CRC Error Check (MS byte) 4E

9

The bytes sent (in hex) to the actuator in the above example would be: 05, 01, 00, 00, 00, 01, FC, 4E

flowserve.com

Page 10

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Response to a Read Coil Status Command

A response to a correct reception of the command would have the data field set to either 00 (not driving

in the specified direction) or 01 (actively driving in the specified direction). The example response below

shows the CW motion control circuit is actively driving the valve in the CW direction.

Field Name Example

Actuator Address 05

Function (Read Coil Status) 01

Byte Count 01

Data 01

CRC Error Check (LS byte) 91

CRC Error Check (MS byte) 78

The bytes sent (in hex) to the master in the above example would be: 05,01,01,01.91,78

If coil 1 (CW) is specified and 2 points are requested, the data is packed into one byte of data where coil

1 (CW) status is bit 0 and coil 2 (CCW) status is bit 1 of the byte. If coil 2 (CCW) status is requested,

only one point can be specified and is returned in bit 0.

Data Byte When 2 Coil Statuses are Read

7 6 5 4 3 2 1 0 Status

0 0 0 0 0 0 0 0 Valve is not being driven in either direction.

0 0 0 0 0 0 0 1 Valve is being driven in the CW direction.

0 0 0 0 0 0 1 0 Valve is being driven in the CCW direction.

0 0 0 0 0 0 1 1 This status value is not possible.

10

Read Input Status Command (02)

This command reads the state of one or both end-of-travel limit switches. The CW limit switch detects

end-of-travel in the clockwise direction and is at register location 10001; the CCW limit switch detects

end-of-travel in the counterclockwise direction and is at register location 10002. Both locations can be

requested by reading two register locations starting at location 10001 or the locations can be requested

separately. Broadcast is not supported.

Example: “Read the status of both limit switches on actuator #5”

Field Name Example

Actuator Address 05

Function (Read Input Status) 02

Starting Address (High) 00

Starting Address (Low) 00

Number of Points (High) 00

Number of Points (Low) 02

CRC Error Check (LS byte) F8

CRC Error Check (MS byte) 4F

The bytes sent (in hex) to the actuator in the above example would be: 05, 02, 00, 00, 00, 02, F8, 4F

Page 11

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Response to a Read Input Status Command

Because two points were requested, bit 0 in the data field is the state of the CCW limit switch and bit 1

is the state of the CW limit switch (see the table below). For either bit, a 1 means the switch is activated

(closed) and a 0 means the switch is deactivated (open). In the example below, only the CW limit switch

is activated.

Field Name Example

Actuator Address Returned 05

Function (Read Input Status) 02

Byte Count 01

Data 02

CRC Error Check (LS byte) 21

CRC Error Check (MS byte) 79

The bytes returned (in hex) to the master in the above example would be: 05, 02, 01, 02, 21, 79

Data Byte When Two Limit Switch Statuses are Read

7 6 5 4 3 2 1 0 status

0 0 Both CW and CCW limit switches are OFF

0 1 CCW limit switch is ON, CW limit switch is OFF

1 0 CW limit switch is ON, CCW limit switch is OFF

1 1 If the actuator has been properly calibrated, this

state will never be returned since both switches

should not be on at the same time.

Read Holding Register Command (03)

This command reads the state of both end-of-travel limit switches, as well as actuator motion. The CW

limit switch detects end-of-travel in the clockwise direction and is at register location 40,009 (bit 0) and

40,012 (bit 5); the CCW limit switch detects end-of-travel in the counterclockwise direction and is at

register location 40,009 (bit 1) or 40,012 (bit 3); the stopped motion holding register is 40,009 (bit 2);

the CW motion holding register is 40,009 (bit 3); the CCW motion holding register is 40,009 (bit 4). All

register bit locations must be requested simultaneously by reading each register entirely. Broadcast is

not supported.

Example: “Read holding register 40, 012 for CW and CCW limit switch statuses of actuator #1”

Field Name Example

Actuator Address 01

Function (Read Coil Status) 03

Starting Address (High) 00

Starting Address (Low) 0B

Number of Points (High) 00

Number of Points (Low) 01

CRC Error Check (LS byte) F5

CRC Error Check (MS byte) C8

The bytes sent (in hex) to the actuator in the above example would be: 01, 03, 00, 0B, 00, 01, F5, C8

11

flowserve.com

Page 12

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Response to a Read Holding Register Command

Because 1 register was requested, bit 3 in the data field is the state of the CCW limit switch and bit 5 is

the state of the CW limit switch. For either bit, a 1 means the switch is activated (closed) and a 0 means

the switch is de-activated (open). In the example below, the low data byte is read as 00001000 since

only the CCW limit switch is activated.

Field Name Example

Actuator Address Returned 01

Function (Read Input Status) 03

Byte Count 02

Data Hi 00

Data Lo 08

CRC Error Check (LS byte) B9

CRC Error Check (MS byte) 82

The bytes returned (in hex) to the master in the above example would be: 01, 03, 02, 00, 08, B9, 82

Force Single Coil Command (05)

12

This command sets the state of a specific motion control circuit. Coil 1 is the CW motion control

circuit; coil 2 is the CCW motion control circuit. A force data of FF00 will either start or continue valve

movement; a force data of 0000 will stop valve movement. Other data values will return an exception

response. Only coil 1 and coil 2 are supported. Broadcast is not supported.

Example: “Direct actuator #5 to travel in the CW direction”

Field Name Example

Actuator Address 05

Function (Force Single Coil) 05

Coil Address (High) 00

Coil Address (Low) 00

Force Data (High) FF

Force Data (Low) 00

CRC Error Check (LS byte) 8D

CRC Error Check (MS byte) BE

The bytes sent (in hex) to the actuator in the above example would be: 05, 05, 00, 00, FF, 00, 8D, BE

Response to a Force Single Coil Command

The normal response is an echo of the original command, returned after the coil has been forced.

Field Name Example

Actuator Address 05

Function (Force Single Coil) 05

Coil Address (High) 00

Coil Address (Low) 00

Force Data (High) FF

Force Data (Low) 00

CRC Error Check (LS byte) 8D

CRC Error Check (MS byte) BE

The bytes sent (in hex) back to the master in the above example would be: 05, 05, 00, 00, FF, 00, 8D, BE

Page 13

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Preset Single Register Command (06)

This command sets the state of a specific motion control circuit by writing values to register 40,001.

By writing a value of 256 (dec) to the register, the CCW motion control circuit is activated. By writing a

value of 512 (dec) to the register, both the CCW and CW motion control circuits are deactivated. Finally,

writing a value of 768 (dec) to register 40,001 initiates the CW motion control circuit. Other data values

will return an exception response. Broadcast is not supported.

Example: “Direct actuator #1 to stop operation in either the CW or CCW direction”

Field Name Example

Actuator Address 01

Function (Force Single Coil) 06

Coil Address (High) 00

Coil Address (Low) 00

Force Data (High) 02

Force Data (Low) 00

CRC Error Check (LS byte) 88

CRC Error Check (MS byte) AA

The bytes sent (in hex) to the actuator in the above example would be: 01, 06, 00, 00, 02, 00, 88, AA

Response to a Preset Single Register Command

The normal response is an echo of the original command, returned after the register value is written.

Field Name Example

Actuator Address 01

Function (Force Single Coil) 06

Coil Address (High) 00

Coil Address (Low) 00

Force Data (High) 02

Force Data (Low) 00

CRC Error Check (LS byte) 88

CRC Error Check (MS byte) AA

The bytes sent (in hex) back to the master in the above example would be: 01, 06, 00, 00, 02, 00, 88, AA

Reception of Invalid Commands

A Modbus command is considered invalid if any of the following conditions is true:

The computed CRC value does not match the CRC in the received message.

1.

The message is not addressed to the actuator.

2.

The message is a broadcast message.

3.

In any of the above situations, the actuator will discard the invalid message and no error response will

be returned. The master should detect a timeout and reissue the command.

Reception of Commands with Illegal Fields

If a command is received with a field containing an illegal value, the actuator will reply with an Exception

Response (see the Modbus Exception Responses section below). No exception response will be given if

13

flowserve.com

Page 14

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

the message was broadcast—the command will not be executed. A command contains an illegal field if

any of the following conditions is true:

The message contains a coil address other than 1 or 2.

1.

The message contains a register address other than locations 10001 (coil 1) or 10002 (coil 2).

2.

The message contains force coil data other than 0000 or FF00 hex.

3.

The message contains an incorrect number of points.

4.

The message contains an unimplemented function code.

5.

The message contains a read holding register address other than 40,004 – 40,013

6.

The message contains a register preset value other than 256, 512, or 768 (dec).

7.

Modbus Exception Responses

Exception responses are given when the actuator receives a command message with at least one field

containing an illegal value. In an exception response, the actuator returns the function code byte with

the most significant bit set followed by an exception code byte.

The following exception codes are supported:

Exception

Code

01 Illegal Function The function code received in the query is not supported by the actuator.

02 Illegal Data Address

03 Illegal Data Value

Name Meaning

The data address (register or coil address) received is not an allowable

address for the actuator.

A value contained in a data field that is not an allowable value for the

actuator. This could include the request of more data points than are allowed

or forced coil data of other than 0000 or FF00 hex.

An exception response message contains the address of the actuator, the function in error, an error code

from the table above and the CRC bytes. The Error Function is the function code byte with the most

significant bit set. The fields of an exception message are shown below:

Command issued by host:

Field Name Example

Actuator Address 05

Function (Read Coil Status) 01

Starting Address (High) 00

Starting Address (Low) 06 (Illegal Address)

Number of Points (High) 00

Number of Points (Low) 01

CRC Error Check (LS byte) 1C

CRC Error Check (MS byte) 4F

Response from the actuator:

Field Name Example

Actuator Address 05

Error Function (Read Coil Status) 81

Exception Code (Illegal Data Address) 02

CRC Error Check (LS byte) 80

CRC Error Check (MS byte) 50

14

Page 15

L75 Series Electric Actuator — Modbus RTU FCD LMAIM7502-00 – 07/05

Troubleshooting

The following troubleshooting guide is given to help determine causes of some common problems.

Symptom Things to Check

When power is applied, all three

indicator LEDs blink and the

actuator will not operate properly.

Actuator does not respond to

any Modbus commands. The

COMM LED does NOT blink when

commands are sent.

Actuator does not respond to any

Modbus commands. The COMM

LED blinks when commands are

sent. No exception response is

received.

The COMM LED blinks even when a

Modbus command is not sent.

The actuator accepts Modbus

commands, but does not move in a

specified direction.

The actuator responds with an

exception response.

After a movement command is sent,

the valve moves but a subsequent

status read does not indicate the

valve in the desired position.

The Modbus address is not correctly entered on the address

1

switches. Refer to Modbus Address Selection section to correct the

problem.

1 Be sure power is applied to the actuator.

2 Be sure the Modbus baud rate and wire configuration is correctly set.

Check that communications wires are correctly connected.

3

1 Check that the message is sent to the address of the actuator.

Ensure data cables are not located near sources of noise. Use

shielded, twisted-pair cable if possible.

2

Ensure data cables are not located near sources of noise. Use

1

shielded, twisted-pair cable if possible.

Check the actuator wiring to the motors. Check for loose or broken

1

wires.

If wiring appears intact, check the LED for the direction specified.

If it is ON after the command is issued, either the motor wire is

2

disconnected, or the actuator board needs replacing. If the LED is

OFF, replace the actuator board.

Read the error code received and determine the problem using the

1

Exception Responses table.

The valve may not be done moving when the read status command

1

is issued. Delay before reading the status to give the valve time to

move.

Ensure the limit switches are correctly set for the end-of-travel. See

2

the Installation Manual for details.

flowserve.com

15

Page 16

FCD LMAIM7502-00 Printed in USA.

To find your local Flowserve representative:

For more information about Flowserve Corporation, visit

www.flowserve.com or call USA 1 800 225 6989

United States

Flowserve Corporation

Flow Control

Limitorque Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone 434 528 4400

Fax 434 845 9736

United Kingdom

Limitorque

Abex Road

Newbury

Berkshire, RG14 5EY

England

Phone 44-1-635-46999

Fax 44-1-635-36034

Japan

Limitorque Nippon Gear Co., Ltd.

Asahi-Seimei Bldg. 4th Floor

1-11-11 Kita-Saiwai, Nishi-Ku

Yokohama-Shi, (220-0004)

Japan

Phone 81-45-326-2065

Fax 81-45-320-5962

India

Limitorque India, Ltd.

15/4, Mile Stone

Mathura Road

Faridabad - 121002

India

Phone 91-129-2276586, 2276836

Fax 91-129-2277135

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should

read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in

connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2005 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Australia

Flowserve Australia, Pty. Ltd.

14 Dalmore Drive

Scoresby, Victoria 3179

Australia

Phone 61 3 9759 3300

Fax 61 3 9759 3301

Singapore

Limitorque Asia, Pte., Ltd.

12, Tuas Avenue 20.

Singapore 638824

Phone 65-6868-4628

Fax 65-6862-4940

Loading...

Loading...