Page 1

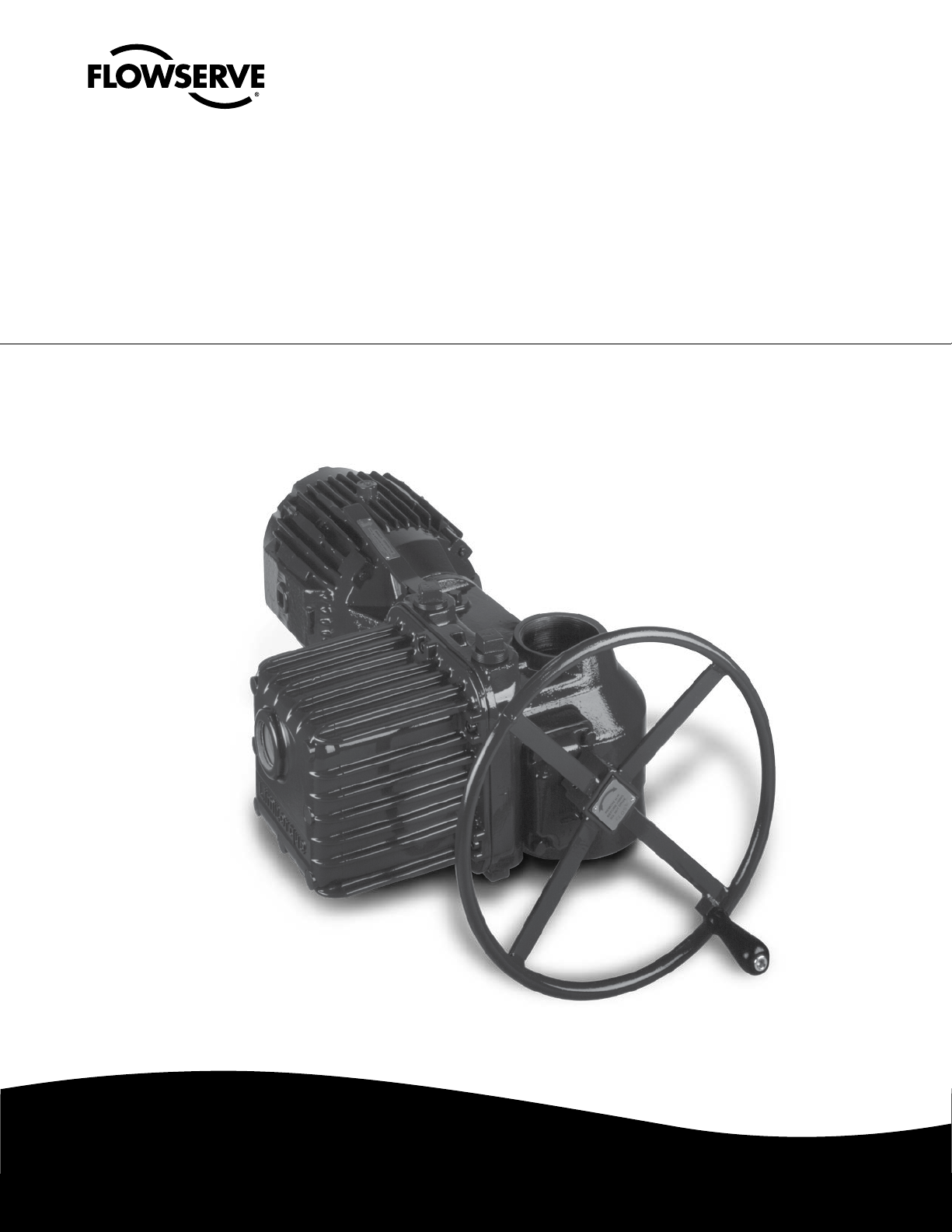

USER INSTRUCTIONS

Limitorque L120-85 Actuator

FCD LMENIM1202-00 – 11/05

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

L120-85 Actuator

Installation and Maintenance Manual

©2005 Copyright Flowserve Corporation. All rights reserved.

Printed in the United States of America.

Disclaimer

No part of this book shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, mechanical, photocopying,

recording, or otherwise without the written permission from Flowserve. While every precaution has been taken in the preparation of the

book, the publisher assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained herein.

This document is proprietary information of Flowserve furnished for customer use ONLY. No other uses are authorized without written

permission of Flowserve.

Flowserve reserves the right to make changes, without notice, to this document and the products it describes. Flowserve shall not be liable

for technical or editorial errors or omissions made herein; nor for incidental or consequential damages resulting from the furnishing, performance or use of this document.

This manual contains information that is correct to the best of Flowserve’s knowledge. It is intended to be a guide and should not be considered as a sole source of technical instruction, replacing good technical judgment, since all possible situations cannot be anticipated. If there

is any doubt as to exact installation, configuration, and/or use, please contact Flowserve at 1-800-225-6989.

The choice of system components is the responsibility of the buyer, and how they are used cannot be the liability of Flowserve Corporation.

However, Flowserve’s sales team and application engineers are always available to assist you in making your decision.

Belden® is a registered trademark of Belden, a division of Cooper Industries, Inc.

2

Page 3

Contents

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

1.1 Purpose 5

1.2 User Safety

2.1 Product Identification

2.2 Product Description

2.3 Product Features

4.1 Safety 1

4.2 Initial Actuator Preparation 1

4.2.1 Inspection and Recording 1

4.2.2 Short-Term Storage (less than one year) 1

4.3 Actuator Mounting 1

4.3.1 Torque Only Applications (Drive 1) 1

4.3.2 Torque and Thrust Applications

4.3.3 Mounting Bolts 1

4.3.4 Stem Cover for Rising Stem Applications 1

4.4 Verifying Motor Rotation Direction 1

4.4.1 Initial Electrical Connections 1

4.4.2 Motor rotation (phasing)

and OPEN/CLOSE pushbutton operation. 15

4.4.3 Three-Phase Motor 1

4.4.4 DC Motor 1

4.5 Limit Switch Settings 1

4.5.1 Basic Theory of Operation 1

4.5.2 Adjustment—General 1

4.5.3 Setting the OPEN Limit Switch 1

4.5.4 Setting the CLOSE Limit Switch 1

4.6 Torque Switch Setting and Wiring 1

4.6.1 Basic Theory of Operation 1

4.6.2 Setting the Torque Switch 1

4.6.3 Balancing the Torque Switch 1

(Drive 2) 12

4.6.4 Rewiring the Torque Switch

5

4.7 Position Indication 2

7

8

8

1

5.1 Description of Motor Operation 2

1

5.2 Description of Manual Operation 2

1

6.1 Lubrication 2

1

2

2

3

3

8.1 Handwheel Shaft Assembly and Shimming 3

4

8.2 Verifying Handwheel Operation 3

4

8.3 Thrust Base Assembly and Shimming 3

9.1 Typical Wiring Diagram 3

5

10.1 L120-85 Illustrated Parts Breakdown 4

5

10.2 L120-85 Parts List 4

5

6

7

7

8

9

9

9

9

for Non-Standard Drive Sleeve Rotation 20

4.7.1 Local Position Indication 2

4.7.2 Remote Position Indication 2

4.7.3 Setting the Potentiometer 2

6.1.1 Initial Inspection 2

6.1.2 Frequency 2

6.1.3 Routine Inspection 2

6.1.4 Factory Lubricants 2

6.1.5 Minimum Lubricant Qualities Required 2

Three-phase with Control Package 3

0

0

1

2

3

3

5

5

5

5

5

6

1

3

3

7

7

0

5

flowserve.com

3

Page 4

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Figures

Figure 1: Limitorque L120-85 Actuator 8

Figure 2: L120-85 Torque Drive Nut and Retaining Ring Details 1

Figure 3: Thrust Base removal from an L120-85 1

Figure 4: L120-85 Torque Drive Nut orientation (Drive 1) 1

Figure 5: L120-85 Thrust Base Assembly orientation (Drive 2) 1

Figure 6: Electrical Compartment and Conduit Pipe Plug openings 1

Figure 7: Grounding Lug location 1

Figure 8: Limit Switch Rotor development 1

Figure 9: L120-85 Limit Switch Components 1

Figure 10: Limit Switch OPEN/CLOSED Rotor Cam orientation 1

Figure 11: Torque Switch Components 1

Figure 12: Reversing Torque Switch wiring 2

Figure 13: Aligning MDPI Pointer for Fully CLOSED Position 2

Figure 14: Remote Position Indicator Calibration Configuration 2

Figure 15: Potentiometer Calibration configuration 2

Figure 16: Loosening Potentiometer Assembly 2

Figure 17: Removing Clutch Pinion Assembly 2

Figure 18: Key components affected by Handwheel shimming 3

Figure 19: Cut-away view of L120-85 actuator

with Clutch Latch positioned on face of Clutch Bearing 3

Figure 20: Gap between Housing face and Handwheel Bushing

shown as dimension “A” 3

Figure 21: Shimming parts and their order of assembly 3

Figure 22: Shim location for gap “B” dimension/ 3

Figure 23 Three-phase with Control Package 3

Figure 24: Electrical Compartment 4

Figure 25: Motor and Motor Drive Components 4

Figure 26: Handwheel Shaft and Associated Components 4

Figure 27: Drive Sleeve Group 4

Figure 28: Thrust Base Group 4

Tables

Table 1: L120-85 Approximate Weight Chart 9

2

Table 2: Torque Drive Nut: Maximum Allowable

Bore and Key Sizes 1

2

Table 3: L120-85 Actuator/Mounting Base Tap Size 1

3

Table 4: Gap “A” shim thickness selection chart 3

4

Table 5: Gap “B” shim thickness selection chart 3

4

5

6

7

8

9

0

0

1

2

2

9

1

2

2

3

3

7

0

1

2

3

4

2

3

2

3

4

Page 5

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Introduction

1

1.1 Purpose

This Installation and Maintenance Manual explains how to install and

maintain the L120-85 actuator. Information is provided for installation, disassembly, reassembly, lubrication, and parts selection.

WARNING: Read this installation and maintenance man-

c

ual carefully and completely before storing, installing,

operating or troubleshooting your Flowserve Limitroque

actuator. Be aware of electrical hazards within the actuator and high-pressure hazards at the attached valve or

other device when installing or performing maintenance

on your L120-85 actuator.

1.2 User Safety

Safety notices in this manual detail precautions the user must take

to reduce the risk of personal injury and damage to the equipment.

The user must read and be familiar with these instructions before

attempting installation, operation, or maintenance. Failure to observe

these precautions could result in serious bodily injury, damage to the

equipment, voiding of the warranty, or operational difficulty.

Safety notices are presented in this manual in three forms:

WARNING: Refers to personal safety. Alerts the user to

c

potential danger. Failure to follow warning notices could

result in personal injury or death.

CAUTION: Directs the user’s attention to general precautions

a

that, if not followed, could result in personal injury and/or

equipment damage.

NOTE:

Highlights information critical to the user’s understanding of

the actuator’s installation and operation.

flowserve.com

5

Page 6

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

6

Page 7

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Product Capabilities and Features

2

2.1 Product Identification

The actuator unit nameplate is located on the back of the unit,

opposite the limit switch compartment. The nameplate contains the

following information:

• Product name

• Point of Manufacture

• Unit Size

• Order Number

• Serial Number

• Customer Tagging

• Certification Information

The motor nameplate is located on the motor. The nameplate contains the following information:

• Full Load Amps

• Insulation Class

• Horsepower

• Number of Phases

• Motor Code

• Connection Diagram

• Start Torque

• Enclosure Type

• Volts

• Locked Rotor Amps

• Duty Rating

• Service Factor

• ID Number

• Run Torque

• RPM

• Frequency

• Ambient Temperature

7

flowserve.com

Page 8

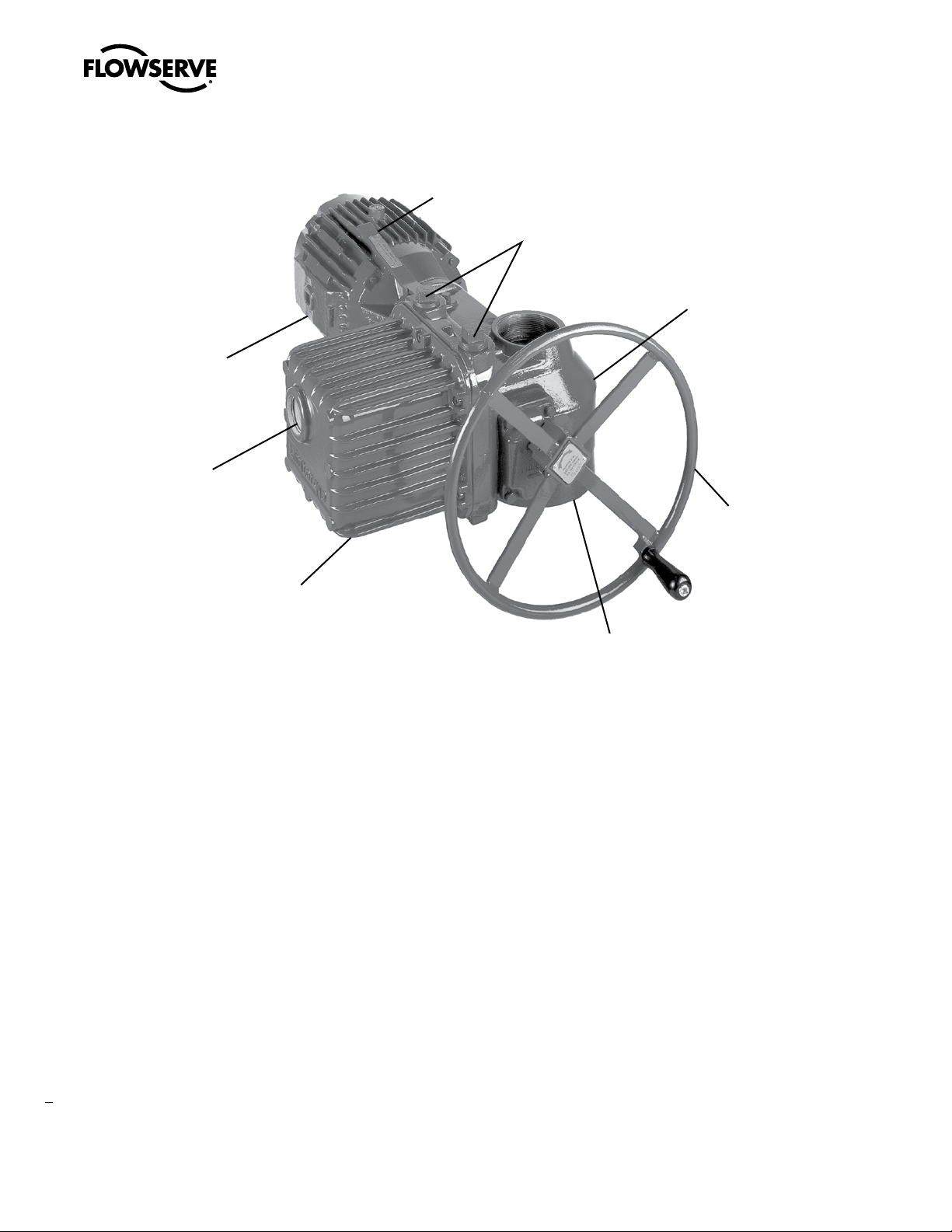

Thrust

Base

Handwheel

Electrical

Compartment

Cover

Conduit

Openings

(plugged; two additional openings

are supplied on the bottom of the

Electrical Compartment)

Housing

Declutch

Lever

Motor

Position

Indication

Window

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Figure 1: Limitorque L120-85 Actuator

2.2 Product Description

Your L120-85 actuator controls the opening and closing travel of

valves or other actuated devices. OPEN and CLOSED limits are

protected by Limit Switches and output torque is measured and

protected by the Torque Switches. As a result, all valves and other

actuated devices are protected from potential damage from overload,

improper seating and foreign obstructions.

Limitorque actuators may be mounted on any appropriately sized

valve in almost any position or location.

Microprocessor-based controls and monitoring devices are also

available for installation on your actuator. Contact your local Limitorque distributor or Limitorque sales office for further information.

2.3 Product Features

• Up to 850 ft-lb/1156 Nm torque capacity.

8

• Up to 45,000 lb./20250 kg thrust capacity.

• Up to 3.25"/76 mm threaded stem capacity.

• Up to 2.75"/70 mm bore capacity.

• Torque Only (Drive 1) or Torque and Thrust (Drive 2) actuators,

with removable ductile iron thrust base assembly.

• Torque unit can be removed from thrust base while valve position

is maintained.

• Standard cast iron gear case.

• All power gearing supported on anti-friction bearings.

• All gearing is alloy, heat-treated steel or bronze.

• Speed range of 24-192 RPM (60 Hz), 20-160 RPM (50 Hz).

• Declutch force independent of load on valve stem.

• Self-locking gearing available.

Page 9

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Unit Weight

3

The following table is an L120-85 representative weight chart. It

provides the weight of several components that may be incorporated

into a typical package. Use the chart as a guideline to estimate the

weight of your particular actuator package.

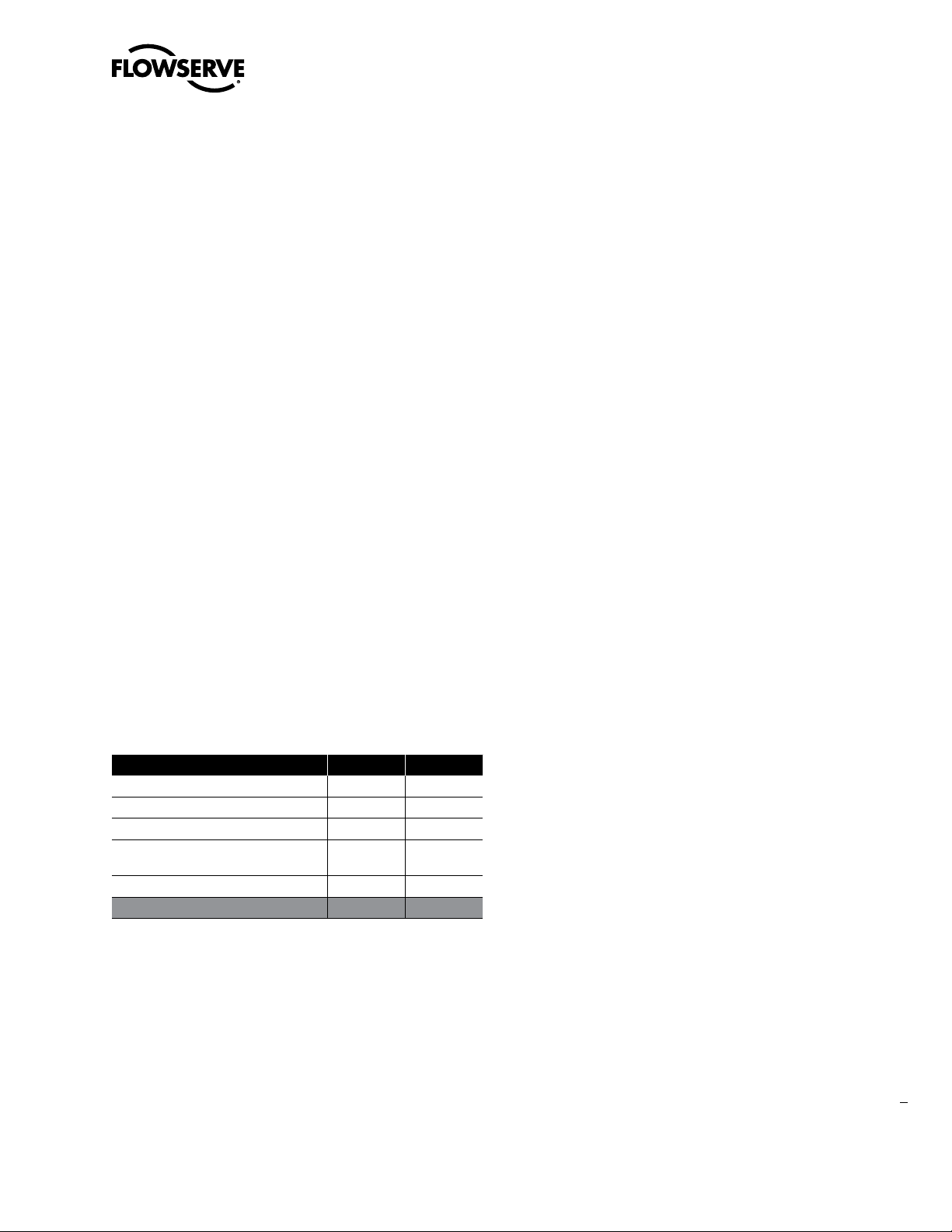

Table 1: L120-85 Approximate Weight Chart

Components lb. kg

L120-85 with 40 ft-lb 1700 RPM Motor 253 558

18" Handwheel 7 15

Handwheel Adapter 5 11

Minimum Integral Control

Package and Compartment

Thrust Base Assembly (Drive 2) 67 148

Total Weight 366 lb. 807 kg

34 75

flowserve.com

9

Page 10

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

10

Page 11

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Initial Preparation and Installation

4

4.1 Safety

WARNING: Read this Installation and Maintenance

c

Manual carefully and completely before attempting to

store, install, operate or troubleshoot your Limitorque

valve actuator. Be aware of electrical hazards within the

actuator and high pressure hazards of the attached valve

or other actuated device when installing or performing

maintenance on your L120-85 actuator.

4.2 Initial Actuator Preparation

4.2.1 Inspection and Recording

Upon receipt of the actuator, several steps should be initially followed to ensure condition of equipment and to establish proper

record keeping.

1. Carefully remove actuator from shipping carton or skid.

Thoroughly examine for any physical damage which may have

occurred during shipment. If you note any damage, immediately

report the damage to the transport company.

2. A nameplate with important information is attached to each

actuator. Record this information for future reference.

4.2.2 Short-Term Storage

(less than one year)

Units are not weatherproof until properly installed on the valve or

prepared for storage.

Store units in a clean, dry, protected warehouse away from excessive

vibration and rapid temperature changes. If the units must be stored

outside, they must be stored off the ground, high enough to prevent

them from being immersed in water or buried by snow.

1. Position the actuator in storage with motor and switch compart

ment horizontal.

2. Connect the internal heaters (if supplied) or place desiccant in

the switch compartment.

3. Replace all plastic caps or plugs with taped or doped pipe plugs

and ensure that all covers are tight.

4. If the actuator is mounted on a valve and the stem protrudes

from the unit, a suitable stem cover must be provided.

-

11

flowserve.com

Page 12

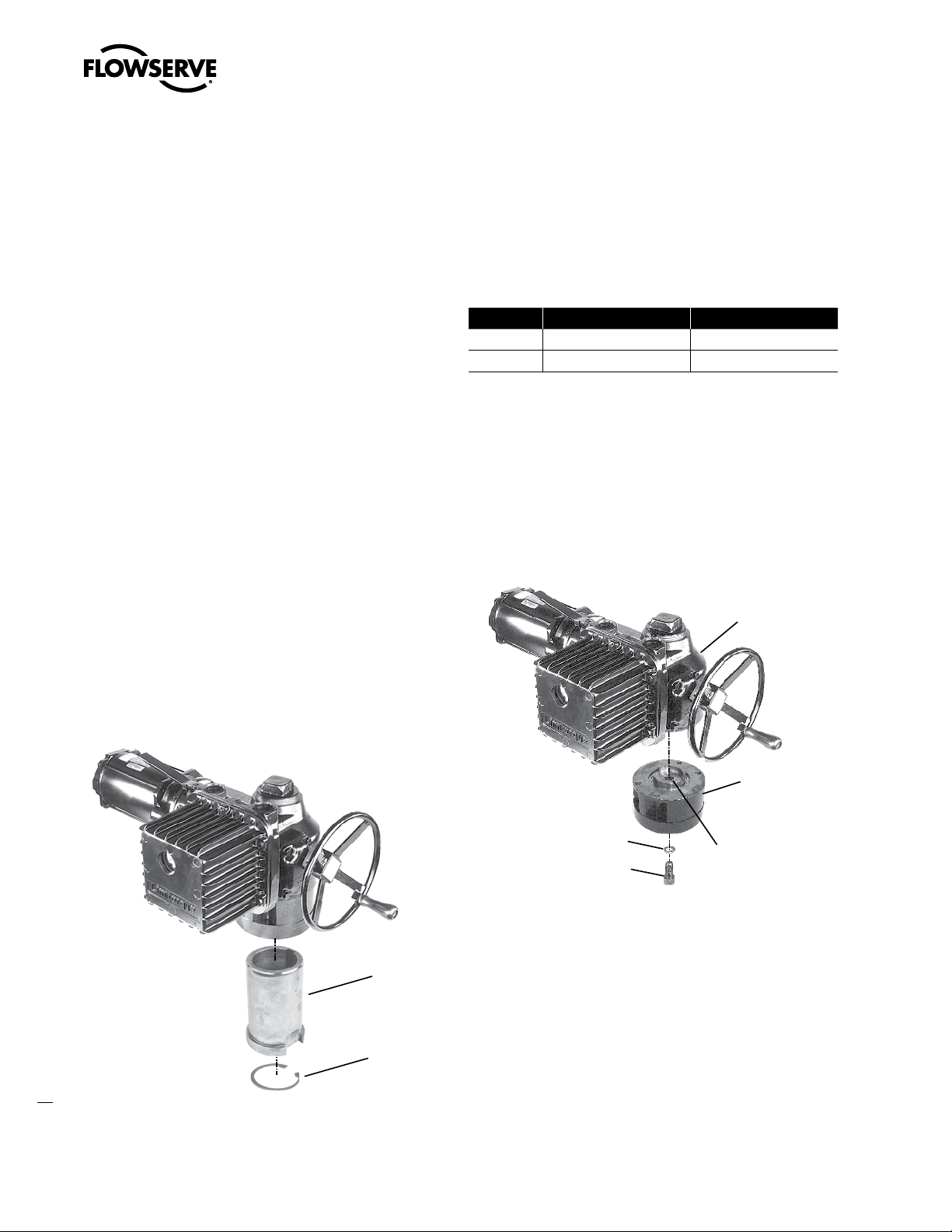

#95 Torque

Drive Nut

#98 Torque Nut

Retaining Ring

#111 Lockwasher

#110 Socket Head

Cap Screw

#100 Thrust Base

Housing

#1 Housing

#101 Thrust Base

Drive Sleeve

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

NOTE: If your unit incorporates a rising stem application, it may be

shipped with a plastic cap over the Drive Sleeve Housing. If so, in

order to store without possible corrosion occurring, install a pipe

plug or protective stem cover to protect the Drive Sleeve Housing.

NOTE: Failure to comply with recommended storage procedures

could cause the warranty to be voided. For long-term storage procedures, consult the Limitorque Customer Service Department.

4.3 Actuator Mounting

Your L120-85 is designed to perform actuation for torque only

applications (drive 1) or for torque and thrust applications (drive

2). If you are using a torque only configuration, before installing on

the valve or other actuated device, you will need to verify that the

Torque Drive Nut (piece 95) is properly bored and keyed to fit your

valve stem. If you are using a torque and thrust configuration, you

will need to verify that the Thrust Base Drive Sleeve (piece 101) is

properly threaded to fit your threaded valve stem. Use the following

procedures to check for proper fit of the Torque Drive Nut or the

Thrust Base Drive Sleeve.

A) If Torque Drive Nut has been bored and keywayed by supplier,

verify dimensions of keyway for proper compatibility with the

valve stem.

B) If Torque Drive Nut has not been bored and keywayed by sup

plier, it is provided solid (blank) to allow customer to custom

bore and key up to the maximum permissible sizes as listed:

Table 2: Torque Drive Nut: Maximum Allowable Bore and Key Sizes

Key Type Maximum Bore in. (mm) Maximum Key in. (mm)

Rectangle 2.750 (69.85) .625 x .4375 (20 x 12)

Square 2.625 (66.67) .625 x .625 (20 x 20)

4.3.2 Torque and Thrust Applications

(Drive 2) (Refer to Figure 28)

Remove Socket Head Cap Screw (piece 110) and Lockwasher (piece

111) that holds the Thrust Base Housing Assembly to the actuator

Housing (piece 1).

Figure 3: Thrust Base removal from an L120-85

12

4.3.1 Torque Only Applications (Drive 1)

(Refer to Figure 27)

Remove the Torque Nut Retaining Ring (piece 98) and Torque Drive

Nut (piece 95) from actuator.

Figure 2: L120-85 Torque Drive Nut and Retaining Ring Details

A) If the Thrust Base Drive Sleeve (piece 101) has been threaded by

supplier, verify thread compatibility with the threaded Valve Stem

by screwing Drive Sleeve onto the valve stem.

B) If Thrust Base Drive Sleeve (piece 101) has not been threaded by

supplier, it is provided solid (blank) to allow customer to custom

thread. Maximum threaded stem diameter is 3.25" (82.5 mm).

NOTE: If Thrust Base disassembly is required in order to thread

blank Thrust Base Drive Sleeve, remove Quad Rings (piece 107)

before removing Thrust Washer (piece 104) and Thrust Bearing

Page 13

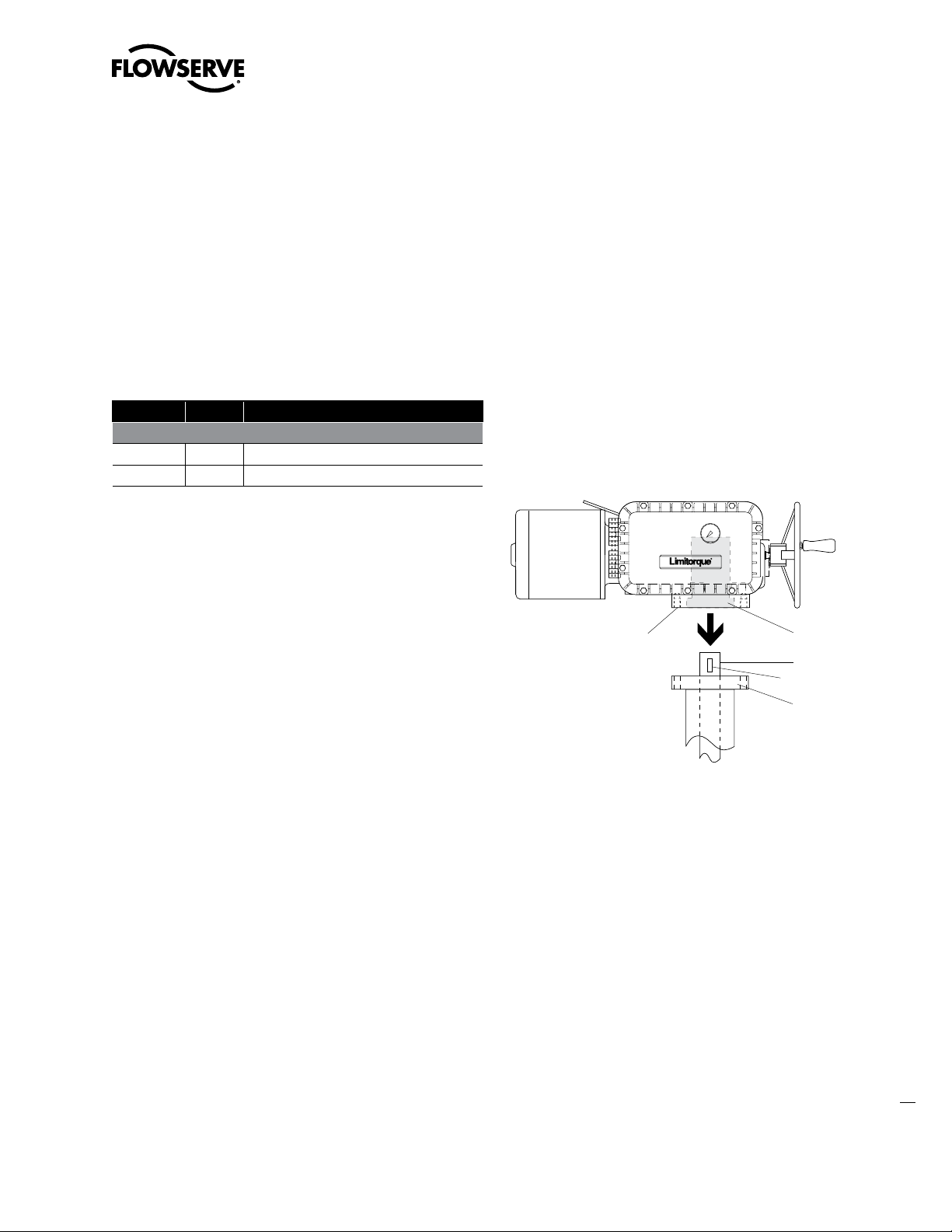

Drive 1

Actuator

Mounting

Base

Actuator

Mounting

Adapter

Valve

Stem

#95 Torque

Drive Nut

Key

Note: Key is shown for reference.

It may be in one of several other

orientations in reference to the

actuator.

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

(piece 103). This will prevent damaging the Quad Rings (piece 107).

For details refer to Section 10.1, Figure 28.

4.3.3 Mounting Bolts

Mount the L120-85 actuator on the Actuator Mounting Adapter

(Drive 1) or on the Thrust Base Assembly (Drive 2). High-strength

(minimum hex head SAE-Grade 5 or ISO Metric Class socket head

cap screws) 8.8 hex head or socket head cap screws with lockwashers are recommended. The quantity and thread size of the actuator

mounting taps are as follows:

Table 3: L120-85 Actuator/Mounting Base Tap Size

Unit Type Quantity Tap Size

Drive 1 and 2

English 4 ¾–10 Tap x 1.0 in. Deep*

Metric 4 M20 x 2.5 mm x 10 mm Deep*

*Complies with F16 IOS mounting flange criteria

NOTE: Limitorque has supplied four taps for the L120-85 English

and metric units. All four securing bolts are required to retain torque

and/or thrust reaction on these units.

Installation Overview

1. Applications

A. Torque Only Applications (Drive 1)

Mount Torque Drive Nut (piece 95) in the actuator with the

Torque Drive Nut axially aligned on the Drive Sleeve (piece

25) so that the bottom of the nut is positioned inside the

actuator Mounting Base. Secure Torque Drive Nut inside

Drive Sleeve (piece 25) with Retaining Ring (piece 98). Refer

to Figure 27.

B. Torque and Thrust Applications (Drive 2)

Screw the Thrust Base Assembly onto the Threaded Valve

Stem and secure the Thrust Base Assembly to the Actuator

Mounting Base using Socket Head Cap Screws (piece 110)

and Lockwashers (piece 111).

Figure 4: L120-85 Torque Drive Nut orientation (Drive 1)

4.3.4 Stem Cover for Rising Stem

a

a

a

Before putting your actuator into operational service, check the

height of your valve stem at the full OPEN position and mount a

suitable stem cover to protect the valve stems and to prevent water

entry into the actuator.

Applications

CAUTION: Selection and installation of a stem cover which is

too short will result in damage to the valve and/or actuator.

CAUTION: Be sure to complete each step of the installation

overview before electrically operating your actuator. If your

actuator is already mounted to a valve or other actuated

device from the manufacturer, verify that the actuator is

mounted according to the following overview. Failure to

follow the installation procedures could result in personal

injury or may allow the actuator to operate improperly and

could cause damage to your equipment.

CAUTION: Ensure Retaining Ring (piece 98) is properly

engaged in the Drive Sleeve (piece 25) to secure the Torque

Drive Nut (piece 95) in place. If the Torque Drive Nut is not

properly secured, it may fall from the bottom of the actuator

when removed from customer mounting adapters.

13

flowserve.com

Page 14

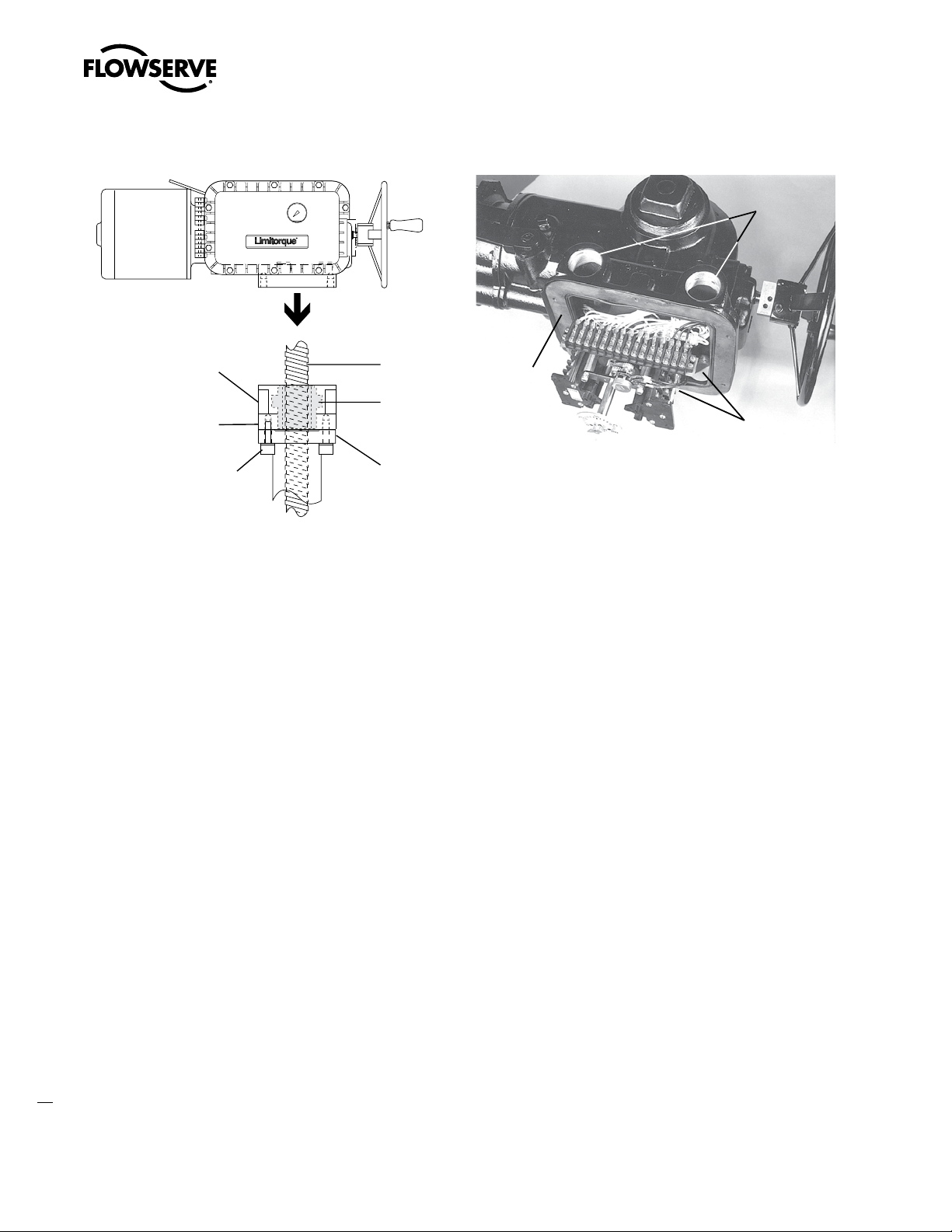

Drive 2 Actuator

Mounting Base

Actuator

Mounting

Adapter

Threaded

Valve Stem

#101 Thrust Base

(Drive Sleeve)

Thrust Base

Assembly

#110 Socket Head

Cap Screws

#111 Lockwashers

Conduit Pipe

Plug Locations

Conduit Pipe

Plug Locations

Electrical

Compartment

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Figure 5: L120-85 Thrust Base Assembly orientation (Drive 2)

4.4 Verifying Motor Rotation

Direction

4.4.1 Initial Electrical Connections

WARNING: Hazardous Voltage. No electrical power should

c

be connected until all wiring and Limit Switch adjustments have been completed. Once power is supplied to

unit, exercise caution if cover is not installed.

1. Open the Electrical Compartment Cover (piece 200-1) and

remove the Conduit Pipe Plugs from the opening(s) most conveniently located for your power leads and other cabling.

Figure 6: Electrical Compartment and Conduit Pipe Plug openings

2. Adjust the Limit Switches, MDPI (Mechanical Dial Position

Indicator) and Potentiometer following the procedures outlined

in Sections 4.5 and 4.7.

3. Ensure Torque Switch is set properly for your application. In

most cases, adjustments are not needed, but if changes are

required, see Section 4.6, “Torque Switch Settings and Wiring”.

4. Connect wiring to Terminal Strips provided on the actuator.

Refer to the wiring diagram supplied with your specific actuator.

“Fork-type” terminal connections are recommended.

5. Be sure any unused conduit entrances are plugged with metal

Conduit Pipe Plugs.

Notes:

a) Explosion-proof actuators require approved “sealing fittings”

installed in accordance with the National Electric Code.

b) Submersible actuators require approved “sealing fittings” in

order to prevent water entering the actuator.

6. Attach grounding wire to Grounding Lug (piece 14).

14

Page 15

Grounding Lug

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Figure 7: Grounding Lug location

7. Inspect actuator for proper lubrication. Refer to “Lubrication”

Section 6.1 for lubrication instructions.

8. Verify that Motor rotation is operating in the proper direction; the

Motor rotation will have a direct impact on the Limit Switch and

Torque Switch functions. Follow the procedure “Verifying Motor

Rotation Direction” in Sections 4.4.2, 4.4.3 and 4.4.4).

9. Close Electrical Compartment Cover (piece 200-1).

10. Unit is now ready for electrical operation. Continue to “Electrical

Start-up Procedure” in Section 5.3.

4.4.2 Motor rotation (phasing) and OPEN/

CLOSE pushbutton operation.

It is very important to check for correct motor rotation to ensure that

serious damage to your valve or other equipment does not occur.

If the actuator motor rotates in the wrong direction, damage could

occur by over-torquing equipment into a seated position.

Prior to being shipped from the factory, each actuator is inspected to

verify proper operation of the Torque and position Limit Switch and

to ensure that they function correctly (i.e. closes when the CLOSE

pushbutton is depressed, opens with the OPEN pushbutton, etc.).

These inspections are made with a properly phased power source

connected as described in the actuator manual.

CAUTION: To ensure proper operation and to prevent your

a

actuator or other actuated equipment from damage, verify

that your unit is properly connected to its power source.

NOTE: Your application may vary from the following standard wiring

configurations for Three-phase, Single-phase and DC motors. Refer

to your actuator wiring diagram for user-specific wiring configuration.

4.4.3 Three-Phase Motor

1. Using the Handwheel, move the valve to a midtravel position

(midtravel position allows electrical operation in the valve “safe”

area and keeps the OPEN and CLOSED Limit Switches from tripping while testing motor direction).

2. Be prepared to immediately remove power should the actuator

run the wrong way.

3. Test motor direction by momentarily pressing the OPEN push

button:

A) If the actuator moves toward CLOSED, immediately turn all

power OFF and reverse the motor leads T1 and T3.

NOTE: Refer to your actuator wiring diagram for user-specific wiring configuration.

B) If the actuator moves toward OPEN, the motor is wired

properly for the application.

-

4.4.4 DC Motor

1. Using the Handwheel, move the valve to a midtravel position

(midtravel position allows electrical operation in the valve “safe”

area and keeps the OPEN and CLOSED limit switches from tripping while testing motor direction).

2. Test motor direction by momentarily pressing the OPEN push

button:

A) If the actuator moves toward CLOSED, immediately turn all

power OFF and reverse the motor leads A1 and A2.

NOTE: Refer to your actuator wiring diagram for user specific wiring configuration.

B) If the actuator moves toward OPEN, the motor is wired

properly for the application.

-

4.5 Limit Switch Settings

The standard L120-85 Limit Switch has 16 contacts. The OPEN/

CLOSE Limit Switch (first eight contacts) has two Rotor Sets, one

for the OPEN position and one for the CLOSED position. Each Rotor

Set has four electrical contacts which can be arranged in any combination of normally OPEN and normally CLOSED. The SPARE Limit

Switch (second eight contacts) has two additional Rotor Sets with

four contacts each that can be set to operate anywhere between the

OPEN and CLOSE positions. These can be used to stop the valve in

mid-travel or to interlock with other equipment such as pumps, fans,

mixers, etc. Refer to Figure 8.

15

flowserve.com

Page 16

NOTES

1. Contact Open

2. Contact Closed

3. All limit switch trip points

are fully adjustable.

.

BY-PASS CIR.

IND LIGHT

OPEN LIMIT

BY-PASS CIR

IND LIGHT

CLOSE LIMIT

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

FULLY

OPEN

A

B

FULLY

CLOSED

VALVE SHOWN IN FULL OPEN POSITION

INDICATION

INDICATION

LIMIT SWITCH CONTACT DEVELOPMENT

VALVE POSITION

ROTOR

OPEN

CLOSE

INT.1

INT.2

FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CONTACT

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Figure 8: Limit Switch Rotor development

THE LIMIT SWITCH IS NOT PRESET at the Limitorque factory, and

must be set after mounting on the valve or other associated equipment. If your L120-85 actuator has been shipped already installed

on your equipment, your actuator should have the Limit Switch set

for your application. If your actuator is not already installed on your

equipment or needs resetting, use the following instructions to make

the appropriate settings.

The following instructions for setting the Limit Switches are based

on the typical orientation for most actuator applications (CCW

to OPEN and CW to CLOSE). Consult the applicable wiring

diagra located in the actuator Electrical Compartment for your specific Limit Switch development.

ing unseating, this momentary bypass is applied. The OPEN Rotor

actuates at the full OPEN position causing contact 1 to open as soon

as the valve moves in the close direction, thus returning the Torque

Switch function to the control circuit.

Contact 2

is normally used for a Remote Valve Position Indication

Lamp. As shown in Figure 8, the lamp will be turned ON when the

valve reaches the full OPEN position.

Contact 3

is for the Local Position Indication Lamp; included as part

of the actuator assembly when required. This switch turns the green

lamp/LED OFF in the full OPEN position, leaving the red lamp/LED

energized and indicating that the valve is OPEN.

Contact 4

is the OPEN Limit Switch which opens the control circuit

to de-energize the Motor at full OPEN position.

The CLOSE Rotor consists of contacts 5 through 8. This Rotor is set

to change state at the full CLOSE position. Switch functions are as

follows:

Contact 5

is the OPEN Torque Switch bypass. After the valve

has been tightly closed, it may stick when it is first opened which

would cause the Torque Switch Contacts to break. To momentarily

overcome this sticking, the OPEN Torque Switch is bypassed. This

OPEN Torque Switch bypass is part of the closed valve position

rotor so that as soon as the valve moves in the OPEN direction, the

bypass contact opens and the OPEN Torque Switch control function

is returned.

Contact 6

is normally used for a Remote Valve Position Indication

Lamp. As shown in Figure 8, the lamp will be turned ON when the

valve reaches the full CLOSE position.

Contact 7

is for the Local Position Indication Lamp; included as part

of the actuator assembly when required. This switch turns the red

lamp/LED OFF in the full CLOSE position, leaving the green lamp/LED

energized and indicating the valve is in the full CLOSE position.

16

4.5.1 Basic Theory of Operation

The Limit Switch (piece 305) is driven directly by the Worm Shaft

through the Limit Switch Pinion. Therefore, the Limit Switch is

directly connected to the output of the actuator. Once the Limit

Switch is properly set, it measures the position of the valve, or other

equipment, in the ELECTRIC or MANUAL operating modes.

The OPEN Rotor consists of contacts 1 through 4. These switches

are set to change state at the full OPEN position. The switch functions are as follows:

Contact 1

is the CLOSED Torque Switch bypass circuit. It’s purpose

is to allow the electric actuator to apply its full torque to unseat a

backseated valve. When a valve is manually backseated to prevent

packing leakage, it may stick momentarily when first operated. To

prevent the CLOSE Torque Switch from stopping the actuator dur-

Contact 8

is the CLOSE Limit Switch that opens the control circuit to

de-energize the Motor at full CLOSE position.

WARNING: Do not manually operate actuator with devices

c

other than installed Handwheel and Declutch Lever. Using

additive force devices (cheater bars, wheel wrenches,

pipe wrenches or other devices of this nature) on the

actuator Handwheel or Declutch Lever may cause serious

personal injury and/or damage to the actuator or valve.

WARNING: Hazardous Voltage. Make sure all power is

c

OFF before opening the Electrical Compartment Cover or

making the following settings.

Page 17

Gear Frame

Assembly

Intermediate Shafts

(A, B, C, and D)

Drive Pinion

Clutch Screw

Rotor Cams

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

4.5.2 Adjustment—General

Tools required:

• The cross-slotted Intermediate Shafts A, B, C and D have been

designed for use with a 6" No. 2 Phillips screw driver shank

chucked into a variable speed reversible electric drill. (See figure 9

for Limit Switch components).

• Phillips Head or Flat Head screwdriver.

WARNING: Potential Explosion Hazard. Do not use a vari-

c

able speed reversible electric drill for setting the Limit

Switch in an explosive environment.

CAUTION: When setting Limit Switch Rotor Cams using a

a

variable speed reversible electric drill, Do Not run drill at

speeds higher than 200 RPM. Operating drill at high speeds

can cause damage to gearing within the Limit Switch.

CAUTION: The Worm on the Worm Shaft Assembly is avail-

a

able in two different ratios 19:1 and 38:1. To avoid damage

to the gearing mechanisms, be sure you change the Limit

Switch Drive Pinion gear if the Worm gear ratio is changed.

NOTE: The Limit Switch is available with a 4 Gear Set or a 5 Gear

Set within the Gear Frame Assembly. The number of Gear Sets

built into your specific Limit Switch will determine the number

of maximum Drive Sleeve rotations required to go the full range

of the Limit Switch. A four Gear Set with 19:1 and 38:1 has a

maximum rotation of 902.25 Drive Sleeve rotations. A five Gear

Set with 19:1 and 38:1 has a maximum rotation of 9022.5 Drive

Sleeve rotations.

Figure 9: L120-85 Limit Switch Components

4.5.3 Setting the OPEN Limit Switch

1. De-engerize electrical circuit to the actuator.

2. Open Electrical Compartment Cover (piece 200-1).

3. Put the actuator into MANUAL operation by moving the Declutch

Lever in the direction of the arrow on the lever until the Declutch

Lever locks in place.

4. Turn the Handwheel CCW

OPEN position. While turning the Handwheel, note the direction

of the Intermediate Shaft that corresponds to the Open Rotor

Group. See figure 9.

NOTE: Most applications require turning the Handwheel CW to

obtain the full CLOSE position and CCW to obtain full OPEN

position. The actuator Drive Sleeve rotates in a CW direction

to the CLOSE position and CCW to the OPEN position. The

Limit Switch Intermediate Shafts rotate in a CCW direction

to the CLOSE position and CW to the OPEN position. If your

application is configured differently, keep in mind that the descriptions in this manual will describe rotation directions opposite of your

application.

5. Once the valve is fully OPEN, turn the Handwheel back toward

CLOSE approximately one full turn. This will allow for coasting

during motor operation.

CAUTION: Do not operate the actuator when the Clutch

a

Screw is in a fully depressed position; loss of the contact

setting will occur and the Setting Rod will be damaged.

CAUTION: For highly geared actuators, one turn of the

a

handwheel may not be sufficient to allow for coast of moving parts. Refer to valve manufacturer setting requirements

in these cases.

to move the valve to the full

6. Push in Clutch Screw and turn CW

latch in a depressed position.

7. Limit Switch Rotor Cams

A. If your Limit Switch Rotor Cams did not trip at the full

OPEN position point, turn the Intermediate Open Shaft in a

CW direction until the Open Limit Rotor Cam rotates

90° to make an OPEN contact (OPEN limit trip point = Rotor

Cam in a vertical orientation to make an OPEN contact);

see figure 10 for orientation. Once you have reached the

full OPEN position point, use the Handwheel to rotate the

Intermediate Shaft slowly in the CCW direction until

the Rotor just trips again.

B. If your Limit Switch Rotor Cams did trip before reaching

the full OPEN position point, leave the valve at the full OPEN

one quarter turn to

flowserve.com

17

Page 18

OPEN

Contact

CLOSED

Contact

Contact

Plunger

Rotor

Cams

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

position point and turn the Intermediate Open Shaft in a

CCW direction until the Rotor Cam rotates 90° to

make an OPEN contact (OPEN limit trip point = Rotor Cam

in a vertical orientation to make an OPEN contact). Once

you have reached the full OPEN position point, rotate the

Intermediate Shaft slowly in the CW direction until the

Rotor just trips again.

Figure 10: Limit Switch OPEN/CLOSED Rotor Cam orientation

4. Turn the Handwheel CW

CLOSED position. While turning the Handwheel, note the direction of the Intermediate Shaft that corresponds to the Closed

Rotor Group.

NOTE: Most applications require turning the Handwheel CW to

obtain the full CLOSE position and CCW to obtain full OPEN

position. The actuator Drive Sleeve rotates in a CW direction

to the CLOSE position and CCW to the OPEN position. The

Limit Switch Intermediate Shafts rotate in a CCW direction

to the CLOSE position and CW to the OPEN position. If your

application is configured differently, keep in mind that the descriptions in this manual will describe rotation directions opposite of your

application.

5. Once the valve is fully CLOSED, turn the Handwheel back toward

OPEN approximately one full turn. This will allow for coasting

during motor operation.

CAUTION: Do not operate the actuator when the Clutch

a

Screw is in a fully depressed position; loss of the

contact setting will occur and the Setting Rod will be

damaged.

to move the valve to the full

18

8. Before operating the actuator, depress and turn the Clutch Screw

CCW one-quarter turn to the spring release position.

Insert a screwdriver into each of the Intermediate Shafts and

“rock” them CW and CCW a few times to ensure all

the gearing is seated well.

4.5.4 Setting the CLOSE Limit Switch

1. De-engerize electrical circuit to the actuator.

2. Open Electrical Compartment Cover (piece 200-1).

3. Put the actuator into MANUAL operation by moving the Declutch

Lever in the direction of the arrow on the lever until the Declutch

Lever locks in place.

CAUTION: For highly geared actuators, one turn of

a

the handwheel may not be sufficient to allow for coast

of moving parts. Refer to valve manufacturer setting

requirements in these cases.

6. Push in Clutch Screw and turn CW

in a depressed position. See Figure 9 for Limit Switch nomenclature.

7. Limit Switch Rotor Cams

A. If your Limit Switch Rotor Cams did not trip at the full

CLOSE position point, turn the Intermediate Close Shaft

in a CCW direction until the Close Limit Rotor Cam

rotates 90° to make an OPEN contact (CLOSE limit trip

point = Rotor Cam in a vertical orientation to make an OPEN

contact). Once you have reached the full CLOSED position

point, rotate the Intermediate Shaft slowly in the CW

direction until the Rotor just trips again.

B. If your Limit Switch Rotor Cams did trip before reaching

the full CLOSE position point, leave the valve at the full

CLOSE position point and turn the Intermediate Close Shaft

in a CW direction until the Close Limit Rotor Cam

rotates 90° to make an OPEN contact (CLOSE limit trip

point = Rotor Cam in a vertical orientation to make an OPEN

contact). Once you have reached the full CLOSE position

point, rotate the Intermediate Shaft slowly in the CCW

direction until the Rotor just trips again.

one-quarter turn to latch

Page 19

ID Limiter

Plate (not shown)

#300-4 Torque Switch

Adjustment

Screws

#300-8 Balancing

Screws

Mounting

Screw Hole

Torque Arm

Red dot indicates

L120-85 Torque Switch

Typical OPEN

contact assembly

(18 & 18C)

#300-2 & 300-3

Index Arm

Typical CLOSE

contact assembly

(17 & 17C)

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

8. Before operating the actuator, depress and turn the Clutch Screw

CCW one quarter turn to the spring release position.

Insert a screwdriver into the Intermediate Shafts and “rock”

them CW and CCW a few times to ensure all the

gearing is seated well.

4.6 Torque Switch Setting

and Wiring

WARNING: Hazardous Voltage. Turn power OFF before

c

opening the Electrical Compartment Cover or making any

adjustments to the Torque Switch.

NOTE: Removal or modification of the Torque Switch Limiter Plate

will void the actuator warranty. Do not exceed the torque setting

indicated by the Torque Switch Limiter Plate without contacting the

Limitorque Customer Service Department.

The L120-85 unit is equipped with a double-acting Torque Switch

that has been factory preset according to the required torque value

provided by the valve manufacturer or other associated equipment

supplier. Further Torque Switch adjustment should not be required;

however, the Torque Switch may be reset from positions 1 through

5 (5 being the highest input torque requirement) by adjusting the

Torque Switch Adjustment Screws unless it is limited by the Limiter

Plate. See figure 11 for Torque Switch nomenclature.

4.6.1 Basic Theory of Operation

As torque is developed by the actuator, the Worm moves axially and

causes compression on the Spring Pack Assembly (components of

the Worm Shaft Assembly (piece 15)). The Spring Pack Assembly

is calibrated so that a given amount of spring compression equates

to a given amount of output torque. Axial Worm Shaft Assembly

movement causes the Torque Switch Shaft (piece 300-13) to move,

therefore engaging the Torque Switch measurement device. Once the

Torque Switch is properly set, it measures valve, or other equipment,

torque input in the ELECTRIC or MANUAL operating modes.

4.6.2 Setting the Torque Switch

CAUTION: Installing or adjusting the Torque Switch with the

a

actuator in a loaded condition will result in loss of torque

protection. Before adjusting or installing the Torque Switch,

place the actuator in MANUAL mode and turn the Handwheel in the direction necessary to release the torque load

on the Worm Shaft Assembly.

NOTE: If Torque Switch replacement is required, be sure to use an

L120-85 Torque Switch rather than replacing with an L120-10 thru

40 Torque Switch. The L120-85 Torque Switch Torque Arm is rotated

10° from the position of the Torque Arm on the L120-10 thru 40

Torque Switch (the red dot on the Torque Switch Shaft indicates an

L120-85 Torque Switch).

Figure 11: Torque Switch Components

1. Turn all power to the actuator OFF.

2. Loosen the Torque Switch Adjustment Screws (piece 300-4) on

the OPEN or CLOSED side of the Torque Switch.

3. Move Index Arm (piece 300-2 or piece 300-3) to desired torque

setting. The higher number indicates an increased torque and/or

thrust output requirement.

4. Tighten the Torque Switch Adjustment Screws (piece 300-4).

5. Turn power ON and operate the valve electrically to seat the valve

or other device and to ensure tight shut-off.

4.6.3 Balancing the Torque Switch

If the Torque Switch has been removed from the unit or if you are

installing a new Torque Switch, it must be rebalanced using the following procedure:

1. Ensure that the actuator is in MANUAL mode and the load is

removed from the Worm Shaft Assembly.

2. Make note of the current OPEN and CLOSED Torque Switch set

tings before reinstalling the Torque Switch.

3. Loosen Torque Switch Adjustment Screws (piece 300-4) and

position both Index Arms (piece 300-2) and (piece 300-3) at the

1 setting; tighten the Torque Switch Adjustment Screws. Make

sure the Index Marks are aligned. See figure 15.

4. Loosen Balancing Screws (piece 300-8) and install the Torque

Switch. When properly installed, the base of the Torque Switch

flowserve.com

-

19

Page 20

Typical CLOSE

contact assembly

(17 & 17C)

NOTE: 17C and 18C attach

to screws (not shown) on

the bottom of the switch.

#300-4 Torque Switch

Adjustment Screws

Typical OPEN

contact assembly

(18 & 18C)

18

18C

17

17C

#523 Round

Head

Machine

Screw

#522 MDPI

Pointer

MDPI

Dia

l

Plate

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

is flush against the Actuator Compartment and the hole for the

Mounting Screw is aligned. Install the Mounting Screw.

5. Tighten the Balancing Screws. The Torque Switch is now bal

anced and ready for Index Arm (piece 300-2 and piece 300-3) to

be returned to their original settings.

6. Follow your wiring diagram to connect Torque Switch wiring.

4.6.4 Rewiring the Torque Switch for

Non-Standard Drive Sleeve Rotation

CAUTION: Double check your wiring diagram to verify that

a

your Torque Switch is wired appropriately for your application. The Torque Switch will not protect your valve from

over-torque if you do not apply appropriate wiring for your

application.

L120-85 actuators are typically supplied with a CCW Drive

Sleeve rotation to open a valve. The two Torque Switches are marked

OPEN (CCW ) and CLOSE (CW ) based upon CCW

Drive Sleeve rotation to open the valve. The MDPI on the L120-85

is typically mounted for the full CCW rotation to indicate the

OPEN position (100%). If opposite drive sleeve rotation is required

(CCW to CLOSE a valve), the following torque switch modifications are required.

4. Remove the Mechanical Dial Position Indicator Plate and flip

over for indication of CCW rotation to the valve’s CLOSED

position. See figure 13 for MDPI Dial Plate.

5. Reverse the OPEN/CLOSE directional arrow on the Handwheel.

4.7 Position Indication

The MDPI is used to indicate the current position of the valve or

other actuated devices. Adjustments must be done after mounting

the actuator on the application. If your supplier has not set the MDPI

or your application has changed and requires resetting, use the following procedure to complete the MDPI settings.

WARNING: Hazardous Voltage. Turn power OFF before

c

opening the Electrical Compartment Cover, calibrating the

MDPI or installing the Remote Voltmeter Indicator.

4.7.1 Local Position Indication

1. Turn OFF all power to the actuator.

2. Manually position the valve in the fully CLOSED position.

3. Loosen the Round Head Machine Screw (piece 523) on the

MDPI Pointer (piece 522).

20

WARNING: Hazardous Voltage. Turn power OFF before

c

opening the Electrical Compartment Cover or making any

adjustments to the Torque Switch.

1. Turn power to the actuator OFF before changing Torque Switch

wiring.

2. Reverse the OPEN and CLOSE Torque Switch labels on the ID

Limiter Plate. See figure 11.

3. Interchange OPEN Torque Switch wires 18 and 18C with

CLOSED wires 17 and 17C (refer to your wiring diagram for

other Torque Switch wiring configurations).

Figure 12: Reversing Torque Switch wiring

Figure 13: Aligning MDPI Pointer for Fully CLOSED Position

4. Move the MDPI Pointer to the (CLOSED) position.

NOTE: If your application uses CW Handwheel rotation to

OPEN, flip the MDPI Plate over to properly orient the OPEN and

CLOSED position on the MDPI Plate.

5. Tighten the Round Head Machine Screw on the MDPI Pointer.

Page 21

P1 P2 P3

CLOSED

Valve Position

1

4

1

2

3

4

OPEN

LIMITORQUE CORPORATION

LYNCHBURG V A.

25 watt, 50 ohm Potentiometer

type Variable Resistor mounted

in a Limitorque Actuator Housing

10.00

Digital Multitester

Control voltage range

110 volts to 480 volts

175 watt, 2500 ohm

Adjustable Resistor

located adjacent to

Remote Position

Indicator for voltage

adjustment

Remote

Voltmeter

Indicator

Ohmmeter

for calibration

Adustable

Resistor Slider

Mounting

Surface

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

4.7.2 Remote Position Indication

NOTE: Typical voltmeter remote indicators furnished by Limitorque

are built to accept a maximum of 10 volts. In order to make voltmeter adjustments, you will need a separate voltmeter with a scale

suitable for the maximum incoming control voltage.

1. Mount the Adjustable Resistor as close as possible to the

Remote Voltmeter Indicator.

2. Turn power to actuator OFF and connect all wiring as shown in

Figure 14. For now, connect the wires leading to the Remote

Voltmeter Indicator to your test meter so you can conduct voltage readings during the setup.

3. Move the Adjustable Resistor Slider to the extreme opposite end

of the Resistor from the Power Connection.

4. Open the Electrical Compartment Cover (piece 200-1). Loosen

the Hex Head Retaining Nut at the base of the Potentiometer

Bracket and dis-engage the Spur Gear from the Potentiometer

Drive Gear. This will allow manual rotation of the Potentiometer

Assembly. See figure 14.

5. Manually position the valve in the fully CLOSED position. As

you are rotating the Handwheel to the CLOSED position, notice

the direction the Potentiometer Spur Gear would be turning the

Potentiometer Shaft/Wiper Arm inside the Potentiometer.

WARNING: Hazardous Voltage. Use extreme caution

c

if power is ON and Electrical Compartment Cover is

removed.

7. Turn power to the actuator ON. Your Test Meter should read “0”

or almost “0”. If not, go back through the above steps 1–7 to get

your Potentiometer calibrated to the proper end-of-travel.

8. Now manually position the valve in the fully OPEN position.

9. Move the Adjustable Resistor Slider toward the Power Connec

-

tion end until the Test Meter reads 10 volts.

10. Turn actuator power OFF, disconnect the Test Meter and connect

the leads to the Remote Voltmeter Indicator.

11. Turn actuator power ON. Your Remote Voltmeter Indicator

should read full OPEN.

12. Further adjustment may be necessary. If the Remote Voltmeter

Indicator reads less than full OPEN, carefully move the Adjustable Resistor Slider ahead being careful not to exceed the full

OPEN position on the Remote Voltmeter Indicator. If the Indicator reads more than “0” when the valve is CLOSED, repeat this

procedure.

13. When the Indicator properly shows valve position, lock the

Adjustable Resistor Slider in place.

6. When the valve is CLOSED, turn the Potentiometer Shaft to the

end-of-travel position that corresponds to the CLOSED position

of the Potentiometer. Carefully reposition the Potentiometer

Spur Gear onto the Potentiometer Shaft to re-engage with the

gear train. Re-tighten Hex Head Retaining Nut at the base of the

Potentiometer Bracket.

Figure 14: Remote Position Indicator Calibration Configuration

21

flowserve.com

Page 22

Pot Lead

End Connection

Pot Lead

Center Connection

Ohmmeter

Hex Head

Retaining Nut

Pontentiometer

Spur Gear

Pontentiometer

Drive Gear

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

4.7.3 Setting the Potentiometer

If your L120-85 actuator includes a Feedback Potentiometer supplied

for remote valve position indication, use an ohmmeter to calibrate

the position of the Potentiometer. Typically, the Potentiometer Spur

Gear is shipped from the factory dis-engaged from the Potentiometer Drive Gear. If your supplier has not re-engaged and calibrated

the Potentiometer, use the following procedure to complete the

Potentiometer setup.

WARNING: Hazardous Voltage. Turn power OFF before

c

opening the Electrical Compartment Cover or calibrating the Feedback Potentiometer. Use extreme caution if

power is ON and the Electrical Compartment is OPEN.

1. Turn all power to the actuator OFF.

2. Using the Handwheel, position the actuator to mid-travel (valve

at the 50% position).

3. Disconnect the Potentiometer Wiring Harness from the Intercon

nect Board or Terminal Strip.

4. Using an ohmmeter, verify that the potentiometer is in midtravel. The resistance from each End Connection to the Center

Connection should be half of the full resistance of the Potentiometer. Example: a 1000 ohm potentiometer should read

approximately 500 ohms from one of the End Connections to the

Center Connection. If the reading is not correct, proceed to step

5. If the reading is correct proceed to step 11.

Figure 15: Potentiometer Calibration configuration

Figure 16: Loosening Potentiometer Assembly

-

6. If the Potentiometer Spur Gear is not engaged with the Potentiometer Drive Gear continue to step 7.

7. Rotate the Potentiometer Spur Gear until the correct readings

are obtained as described in step 3.

8. Carefully reposition the Potentiometer Spur Gear to re-engage

with the gear train.

9. Re-tighten Hex Head Retaining Nut at the base of the Potentiom

eter Bracket.

-

22

5. If the Potentiometer Assembly is engaged with the Potentiometer Drive Gear: Loosen the Hex Head Retaining Nut at the base

of the Potentiometer Bracket and dis-engage the Spur Gear from

the Potentiometer Drive Gear. This will allow manual rotation of

the Potentiometer Spur Gear. Continue to step 7.

10. Recheck ohmmeter reading to assure Potentiometer adjustment

was not changed when Potentiometer was tightened to Potentiometer Bracket. If Potentiometer setting is not accurate, repeat

steps 5–9. If ohmmeter reading is accurate, proceed to step 11.

11. Disconnect the ohmmeter and reconnect the Potentiometer wir

ing to the Interconnect Board or Terminal Strip.

-

Page 23

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Operation

5

L120-85 actuators are always available for motor operation when

the motor is energized. Do not force the Declutch Lever into the

motor operation position. The Declutch Lever returns to motor

operation position automatically when the motor is energized.

NOTE: Refer to the Illustrated Parts Breakdown in Section 10.1 as

you step through the Description of Operation and the Assembly/

Disassembly procedures.

5.1 Description

of Motor Operation

In motor operation, the Motor Cam (piece 38) drives the Clutch

Assembly (piece 19-1, 2, and 3) which is splined on the outer

diameter and mates with the internal splines of the Clutch Pinion

Assembly (piece 18-1, 2 and 3). The helical gear teeth on the Clutch

Pinion (piece 18-1) mate with the Wormshaft Gear (piece 35) teeth.

The Clutch Pinion and Wormshaft Gear are always engaged. The

Wormshaft Gear is keyed to the Wormshaft (piece 15-1) which is

keyed to the Worm (piece 15-2). Rotation of the Wormshaft/ Worm

Assembly turns the Worm Gear (piece 21). Lugs on the Worm Gear

engage lugs on the outer diameter of the Drive Sleeve (piece 25).

Hammerblow or no lost motion is selected by the assembly arrangement of the Worm Gear and Drive Sleeve Lugs. Lugs at the base

of the Drive Sleeve can drive either a Torque Drive Nut (similar to

L120-10 through 40) or they can drive the lugs of the Thrust Stem

Nut contained in the type Drive 2 Thrust Base Assembly.

5.2 Description

of Manual Operation

WARNING: Do not manually operate actuator with devices

c

other than installed Handwheel and Declutch lever. Using

additive force devices (cheater bars, wheel wrenches,

pipe wrenches or other devices of this nature) on the

actuator Handwheel or Declutch Lever may cause serious

personal injury and/or damage to the actuator or valve.

The L120-85 actuator has a Handwheel (piece 29) for manual

operation. The unit can be manually operated any time the Motor is

not energized. To manually operate the L120- 85, push the Declutch

Lever (piece 9) in the direction of the arrow until it latches in place.

Pushing the Declutch Lever rotates the Declutch Shaft which is

23

flowserve.com

Page 24

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

keyed to the Declutch Link (piece 7-1). The Declutch Link engages

the Clutch Ball Bearing (piece 19-2) which disengages the Clutch

from the Motor Cam and engages the Handwheel Lugs (piece 3-1).

The Clutch Latches (piece 32) hold the Clutch Assembly in MANUAL

operation until the Motor is energized. Lobes on the Motor Cam

(piece 38) cause the Clutch Latches to release when the Motor is

energized. The spring-loaded Clutch (piece 19-1) reengages with

the lugs on the Motor Cam. The Declutch Lever will automatically

disengage when the Motor begins operating.

5.3 Electrical Start-up Procedure

1. Check that the actuator has been correctly lubricated. This is

particularly important if the actuator has been in long-term storage.

2. Ensure that the Limit Switch and Torque Switch have been

properly set.

3. If the valve stem is not visible, remove the Pipe Plug (piece 45)

to observe the output direction of the Drive Sleeve (piece 25).

4. Engage MANUAL operation and hand crank actuator well away

from the OPEN or CLOSED end-of-travel.

5. Turn power ON and push the OPEN button to electrically operate

the actuator.

6. Check output rotation; if Motor rotation (phase) is correct,

the valve will begin to open. If the valve begins to close,

Stop Immediately.

7. Correct the Motor rotation by following the procedure “Verifying

Motor Rotation Direction” in Section 4.4.

8. The actuator should operate correctly and will stop at the end of

travel by the Torque and Limit Switch functions.

9. Replace Pipe Plug (piece 45).

10 If your actuator configuration has a control package, consult you

specific controls package Installation and Maintenance Manual

for proper set-up and calibration.

24

Page 25

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Maintenance

6

6.1 Lubrication

6.1.1 Initial Inspection

NOTE: Before operating your actuator, inspect it for proper lubrication, (especially if it has been stored for a long period of time).

No seal can remain absolutely tight at all times; therefore, it is not

unusual to find a very small amount of weeping around shaft seals

— especially during long periods of idleness such as storage. Using

grease minimizes this condition as much as possible. If you find a

small amount of weeping at startup, remove it with a clean rag. Once

the equipment is operating, the weeping should stop.

6.1.2 Frequency

Base the frequency of lubrication inspections on historical data of

your installed equipment. Every actuator application has its own

effect on lubricants. Pattern lubricant inspections based on the

needs of your facility and its applications. The following schedule of

lubrication inspection should be followed until operating experience

indicates otherwise.

Gear Case:

— whichever occurs first.

Inspect lubrication every 18 months or 500 cycles

6.1.3 Routine Inspection

The three primary considerations in a lubrication inspection are:

1.

Quantity L120-85 operators are built to operate on the immersion principle. The primary concern in the amount of lubricant is

whether the “worm” is totally immersed in grease.

2.

Quality If dirt, water or other foreign matter are found during

lubrication inspection, the units should be flushed with a commercial degreaser/cleaner such as Exxon Varsol 18 which is not

corrosive and does not affect seal materials. Repack unit with

fresh lubricant allowing room for grease thermal expansion.

3.

Consistency Lubricant should be slightly fluid approximating

a standard NLGI-0 grade consistency or less. Thinners such as

Amoco WAYTAC 31 oil may be added provided the volume of

thinner does not exceed 20% of the total lubricant.

6.1.4 Factory Lubricants

Gear Case

• L120-85 is factory lubricated with an EP-0 lithium base grease,

suitable for temperatures from -20°F (-29°C) to + 250°F (+121°C).

Geared Limit Switch:

Exxon Beacon 325 (no substitute).

25

flowserve.com

Page 26

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

6.1.5 Minimum Lubricant Qualities Required

CAUTION: Do not mix lubricants of a different base chemi-

a

cal. Mixing lubricant bases may cause lubricant properties to

be ineffective.

The standard lubricants used by Limitorque have been proven

extremely reliable over years of service. We do not recommend a

particular lubricant substitute for our standard lubricants, but below

is a list of minimum lubricant qualities required by Limitorque:

• Should contain an “EP” additive.

• Must be suitable for the temperature range intended.

• Must be water and heat resistant and non-separating.

• Must not create more than 8% swell in Buna N or Viton.

• Must not contain any grit, abrasive or fillers.

• Must slump–prefer NLGI grade.

• Must not be corrosive to steel gears, ball or roller bearings.

• Dropping point must be above 316° F for temperature ranges of

-20°F (-29°C) to 150°F (66°C).

WARNING: Hazardous Voltage. Turn power OFF before

c

disassembling your L120-85 actuator.

WARNING: Potential high pressure vessel. Before removing

c

or disassembling your actuator, ensure that the valve or

other actuated device is isolated and is not under pressure.

NOTE: Minor service may be performed with the actuator mounted

on the valve or other actuated devices. Perform more complex

service with the actuator removed from the valve or other actuated

device.

NOTE: Review and familiarize yourself with the illustrated parts

breakdown prior to disassembly.

NOTE: Drive 2 units (Thrust only) will maintain the thrust of a valve

without the actuator mounted on the Thrust Base. Before removing

the actuator from the Thrust Base, ensure that all actuated devices

are secured to appropriate positions while actuator is removed from

the Thrust Base.

26

Page 27

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Disassembly

7

7.1 Removal From Valve

1. Rotate the Handwheel to the fully CLOSED position.

2. Drive 1 applications (Refer to illustrated parts breakdown)

a. Loosen and remove customer installed Mounting Screws

and Lock-washers that are holding the actuator to the

Mounting Adapter.

b. Remove Pipe Plug (piece 45) from top of actuator Housing

(piece 1).

c. Lift the actuator enough to loosen Key from the Drive Sleeve

(piece 25).

d. Remove Key from the Valve Stem and the Drive Sleeve

(piece 25).

e. Lift actuator completely off of the Mounting Adapter or

Thrust Base Assembly.

3. Drive 2 applications

b. Lift actuator completely off of the Mounting Adapter or

Thrust Base Assembly.

c. Disconnect Motor and remove control wiring (see next two

sections).

d. Drive 2 Only) Rotate the Thrust Base Assembly off the

threaded Valve Stem.

7.2 Open Electrical Compartment

and Disconnect Motor

1. Turn power to the actuator OFF.

2. Open or remove the Electrical Compartment Cover (piece 200-1)

by loosening pieces 200-2 and 200-3. Refer to illustrated parts

breakdown.

3. Disconnect motor leads from the Terminal Strip (Refer to your

wiring diagram to locate motor lead wiring numbers).

a. Loosen and remove Socket Head Cap Screws (piece 110)

and Lockwashers (piece 111) at the Mounting Base of

the actuator to remove the actuator from the Thrust Base

Assembly.

27

flowserve.com

Page 28

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

7.3 Remove Control Wiring

1. Slowly remove one of the Pipe Plugs (piece 50-24) to release

any air pressure built up within the actuator. Refer to illustrated

parts breakdown.

2. If unit has an Integral Assembly, remove all Integral Assembly

wiring that is connected to the Terminal Strip.

7.4 Remove Limit

and Torque Switch

1. Remove the M6 Hex Head Cap Screws and Lockwashers (piece

#s 305-47 and 48) from the base of the Limit Switch (piece

305).

2. Remove the M6 Socket Head Cap Screw and Lockwasher (piece

#s 300-20 and 21) from the base of the Torque Switch (piece

300).

3. Remove the Limit Switch (piece 305) and Torque Switch (piece

300) from the actuator with associated wiring intact.

1. Remove the M10 Hex Head Cap Screws and Lockwashers (piece

#s 50-3 and 50-4) to remove the Handwheel End Cap (piece 5).

2. Remove Handwheel Shaft Assembly comprised of (piece 2)

Handwheel Shaft, (piece 3-1) Handwheel Lug, (piece 3-2)

Spring, (piece 3-3) Roll Pin, (piece 4-1) Handwheel Bushing,

(piece 4-2) Handwheel Spacer, (piece 4-3) Retaining Ring, (piece

6-1) Handwheel Shims, (piece 6-2) Handwheel Shims, (piece

43) O-ring and (piece 44) O-ring (not shown).

7.8 Remove Declutch Lever

Assembly

1. Before removing the Declutch Lever Assembly (piece 9), loosen

Hex Head Screws and Lockwashers (piece #s 50-5 and 50-6)

and rotate the Declutch Lever Stop Plate (piece 11) in the

CW direction to free the Declutch Lever Assembly.

2. Remove Socket Head Shoulder Screws (piece 50-7) to remove

the Clutch Latch Assembly (piece 32) and Latch Spring (piece

33).

28

7.5 Remove Motor Assembly

1. Remove the M10 Hex Head Cap Screws and Lockwashers (piece

#s 50-3 and 50-4) to remove the Motor (piece 31-1).

2. Slide the Motor (piece 31-1) away from the actuator and pull the

motor leads through the conduit hole.

7.6 Remove Handwheel

Loosen Set Screw (piece 29-1A) from the Handwheel Hub Assembly

(piece 29-1) and remove Handwheel (piece 29-2) and Handwheel

Hub Assembly then remove Handwheel Shaft Key (piece 2-1) from

the Handwheel Shaft (piece 2).

7.7 Remove Handwheel Shaft

Assembly

NOTE: Before disassembling the Handwheel Shaft Assembly, make

note of the number of Handwheel Shims (piece #s 6-1 and 6-2)

that are used on each side of the Handwheel Bushing (piece 4-1).

This will allow reassembly of Handwheel Shims without need to remeasure gap between actuator Housing face (piece 1) and Bushing

(piece 4-1) for shimming requirements.

7.9 Remove Clutch Assembly

Remove Clutch Assembly comprised of (piece 19-1) Clutch,

(piece 19-2) Ball Bearing and (piece 19-3) Retaining Ring.

7.10 Remove Clutch Pinion

Assembly

1. Use a socket wrench extension or another bar device to exert

force against the face of the Clutch Pinion Assembly; this will

release some of the spring tension compressed behind the

Clutch Pinion Assembly by the Declutch Compression Spring

(piece 30). With some of the tension released from the Clutch

Pinion Assembly, use retaining ring pliers to remove Retaining

Ring (piece 41) that holds the Clutch Pinion Assembly in place.

2. Remove the Clutch Pinion Assembly (piece #s 18-1, 18-2, 18-3)

and the Declutch Compression Spring (piece 30).

Page 29

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Figure 17: Removing Clutch Pinion Assembly

replacement is necessary, contact your Limitorque authorized dealer

or the Limitorque Service Department for a complete Worm Shaft

Assembly replacement.

7.12 Remove and Disassemble

Thrust Base (if your unit

uses Drive 2)

1. Remove Socket Head Cap Screws (piece 110) and Lockwash-

ers (piece 111) to remove Thrust Base Assembly from actuator

Housing (piece 1).

NOTE: If reassembly of thrust base will use the same components, note quantity and location of shims.

2. After removing the Thrust Base Assembly from the actuator

Housing and the Mounting Base, remove the Socket Head Cap

Screw (piece 112) and Lockwasher (piece 113) to remove

the Thrust Base Housing (piece 100) from Thrust Base Plate

(piece 102). See page 55.

3. Remove the top Quad Ring (piece 107), then remove the Thrust

Bearing (piece 103) and Thrust Washers (piece 104).

7.11 Remove Worm Shaft

Assembly

1. Remove Flexloc Nut (piece 37) by holding Flange Nut (piece

15-10) (on opposite end of Worm Shaft Assembly) securely with

a wrench.

2. Remove Washer (piece 34) and Worm Shaft Gear (piece 35).

3. Push the Worm Shaft Assembly through the opposite end of the

actuator. The Worm Shaft Assembly is comprised of Worm Shaft

(piece 15-1), Worm (piece 15-2), Ball Bearing (piece 15-3), Ball

Bearing (piece 15-4), Disc Spring (piece 15-5-1), Spring Pack

Shim (piece 15-5-2), Disc Spring Spacer (piece 15-6), Disc

Spring Mandrel (piece 15-7), Bearing Adapter (piece 15-9),

Flange Nut (piece 15-10), Key (piece 15-11), Retaining Ring

(piece 15-12), Washer (piece 34), Worm Shaft Gear (piece 35),

Key (piece 36) and Flexloc Nut (piece 37).

NOTE: The Spring Pack is factory preloaded and should not be

disassembled from the Worm Shaft Assembly; if Spring Pack

NOTE: Removing the Quad Rings (piece 107) before removing

the Thrust Bearing (piece 103) and Thrust Washers (piece 104)

will prevent damaging the Quad Rings.

4. Lift the Drive Sleeve (piece 101) out of the Thrust Base Plate

(piece 102).

5. Pull the bottom Quad Ring (piece 107) off the Drive Sleeve, then

remove the Thrust Bearing (piece 103) and Thrust Washers

(piece 104).

NOTE: If installing a new Thrust Base or replacing components

within the Thrust Base, refer to L120-85 Thrust Base assembly in the

Assembly section.

7.13 Remove Drive Sleeve

1. Remove Socket Head Cap Screws (piece 50-1) and Lockwashers

(piece 50-2) to remove the Unit Base Plate (piece 27) from the

bottom of the actuator.

2. Remove the Retaining Ring (piece 22) and Ball Bearing (piece

16) from the Drive Sleeve (piece 25).

3. Remove the rest of the Drive Sleeve Assembly through the bot

tom of the actuator.

-

29

flowserve.com

Page 30

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

30

Page 31

8

Clutch Assembly

Clutch Pinion

Assembly

Handwheel Shaft

Assembly

Position of Latch for shimming

Handwheel Shaft

3-3

3-2

2-1

4-1

44

43

4-2

4-3

18-2

18-1

19-2

19-3

19-1

3-1

18-3

6-1

2-2

6-1

32-1

19-2

(qty. 1)

(qty. 5)

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

Assembly

Assembly should be conducted in the reverse order of the disassembly procedures noting the following points:

8.1 Handwheel Shaft Assembly

and Shimming

If you have disassembled the Clutch Latch Assembly (pieces 32-1,

32-2 and 33) or have replaced the Handwheel Shaft Assembly,

Figure 18: Key components affected by Handwheel shimming (Motor Cam not shown)

Clutch Pinion Assembly (piece 18), Clutch Assembly (piece 19) or

Motor Cam (piece 38) you need to re-shim the Handwheel Assembly

using the following procedure:

1. Remove the Retaining Ring (piece 4-3), Handwheel Spacer

(piece 4-2), Handwheel Shims (piece #s 6-1 and 6-2), Handwheel Bushing (piece 4-1), O-rings (piece #s 43 and 44) and

second group of Handwheel Shims (piece #s 6-1 and 6-2) from

the Handwheel Shaft Assembly. Refer to the Illustrated Parts

Breakdown for additional views.

31

flowserve.com

Page 32

#19-2 Clutch Bearing

Special tool used in

place of motor for

cut-away view only

#21-1 Clutch Latch

Shoulder on Handwheel

Shaft that positions shaft

when shimmed

#52 Handwheel

Shaft Washer

#2 Handwheel Shaft

#4-1 Handwheel Bushing

(without O-rings)

Dimension "A"

(Housing face

to Bushing)

#1 Housing face

(Handwheel end of

actuator)

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-00 – 11/05

2. Before shimming the Handwheel Assembly and to assure proper

Handwheel Lug (piece 3-1) engagement with the Clutch (piece

19-1), push the Declutch Lever into the MANUAL mode until

Latch 32-1 is engaged with Clutch Bearing (piece 19-2) as

shown in figures 18 and 19. Once Clutch is engaged, leave the

Declutch Lever in the declutch position during the shimming

procedure.

Figure 19: Cut-away view of L120-85 actuator with Clutch Latch

positioned on face of Clutch Bearing

Spring (piece 3-2) is compressed an additional amount due to forcing the Handwheel Shaft into the Housing the gap measurement will

be incorrect (see Figure 18).

Figure 20: Gap between Housing face and Handwheel Bushing

shown as dimension “A”

6. Select a shim thickness to satisfy the following chart

(each shim is .030"):

3. Now insert the Handwheel Shaft Assembly (piece #s 2, 3-1, 3-2

4. After Clutch Latch (piece 32-1) is positioned on the Clutch Bear

5. Once the Handwheel Shaft is installed and fully seated, use a

32

NOTE: When measuring the gap, verify that Spring (piece 3-2) is

at the “installed height” that is determined by the Handwheel Shaft

(piece 2), Handwheel Lugs (piece 3-1) and Roll Pin (piece 3-3). If

and 3-3) (without the parts of the Handwheel Shaft Assembly

removed in step 1) into the actuator (see figure 18). Assure the

Handwheel Lug (piece 3-1) is fully seated into the Clutch Assembly (piece 19) by rotating the Handwheel Shaft Assembly until

you feel it seat into engagement with the Clutch (piece 19-1).

ing (piece 19-2) as described in step 2 and the Handwheel Shaft

Assembly is inserted into the actuator Housing as described

in step 3, insert the Handwheel Shaft Washer (piece 52) (see

Figure 22) into the actuator Housing.

feeler gauge to measure the gap that is identified as Dimension

“A” in Figure 20. Dimension “A” must be within the range of

.000 to .180 inches (.00 mm to 4.57 mm) prior to shimming.

If dimension “A” is not within the range of .000 to .180 inches

(.00 mm to 4.57 mm), the assembly is incorrect and Steps 1

through 5 should be repeated.

Table 4: Gap “A” shim thickness selection chart

Shim Thickness for Gap “A”

Dimension “A”

Greater than Less than or equal to

0" 0 mm .030" 0.76 mm .03" 0.76 mm

.030" 0.76 mm .060" 1.52 mm .06" 1.52 mm

.060" 1.52 mm .090" 2.29 mm .09" 2.29 mm

.090" 2.29 mm .120" 3.05 mm .12" 3.05 mm

.120" 3.05 mm .150" 3.81 mm .15" 3.81 mm

.150" 3.81 mm .180" 4.57 mm .18" 4.57 mm

-

7. Install O-rings (piece 43 and 44) on Bushing (piece 4-1).

Nominal shim

thickness at gap “A”

Install the proper thickness of shims, based on step 6, on the

Handwheel Shaft (piece 2). The shims must rest on the major