Page 1

USER INSTRUCTIONS

Limitorque L120-190 through L120-2000

FCD LMENIM1203-00 – 10/11

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

2

Page 3

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Contents

1 Introduction 5

1.1 Purpose 5

1.2 User Safety 5

2 Product Capabilities and Features 6

3 Initial Inspection and Storage Instructions 7

3.1 Product Identification 7

3.2 Inspection and Recording 8

3.3 Storage Procedures 8

3.3.1 Short-Term Storage (less than 1 year) 8

4 Actuator Weights 10

5 Installation Instructions 11

5.1 Safety Precautions 11

5.2 Safety Practices 12

5.3 Actuator Preparation 12

5.3.1 Mounting Base 13

5.3.2 Stem Acceptance 13

5.4 Double Torque Switch 13

5.4.1 Setting Torque Switch 14

5.4.2 Balancing Torque Switch 15

5.4.3 Torque Switch Terminal Connections 15

5.5 Geared Limit Switch – Rotor Type 16

5.5.1 Setting Limit Switch 16

5.5.2 Combination of Contacts 19

5.6 Position Indication 19

5.6.1 Local Position Indication 19

5.6.2 Remote Position Indication 20

5.6.3 Calibrating Position Transmitter PT20SD 20

6 Operation 21

6.1 Electrical Start-Up 21

6.1.1 Typical Wiring Diagram 22

6.2 Manual Operation 22

6.3 Motor Operation 23

6.4 Torque and Travel Limiting 23

7 Maintenance 24

7.1 Lubrication 24

7.1.1 Lubrication Inspection 24

7.1.2 Factory Lubricant 25

8 Disassembly and Reassembly 26

8.1 L120-190, -420, and -800 26

8.1.1 To Replace Stem Nut Only 26

8.1.2 L120-190, 420, 800 Disassembly 27

8.1.3 Reassembling Actuator Sizes L120-190, -420 and -800 28

8.1.4 Gaskets 29

8.2 L120-2000 38

8.2.1 Drive 2 Disassembly (Thrust Housing Only) 38

8.2.2 Drive 1 Disassembly (Torque Housing) 38

8.2.3 Drive 1 (Torque Housing) Reassembly 40

8.2.4 Drive 2 (Thrust Housing Only) Reassembly 42

3

flowserve.com

Page 4

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

9 Standard Wiring Diagrams 49

10 Troubleshooting 52

11 How to Order Parts 53

12 Regulatory Information 54

Figures

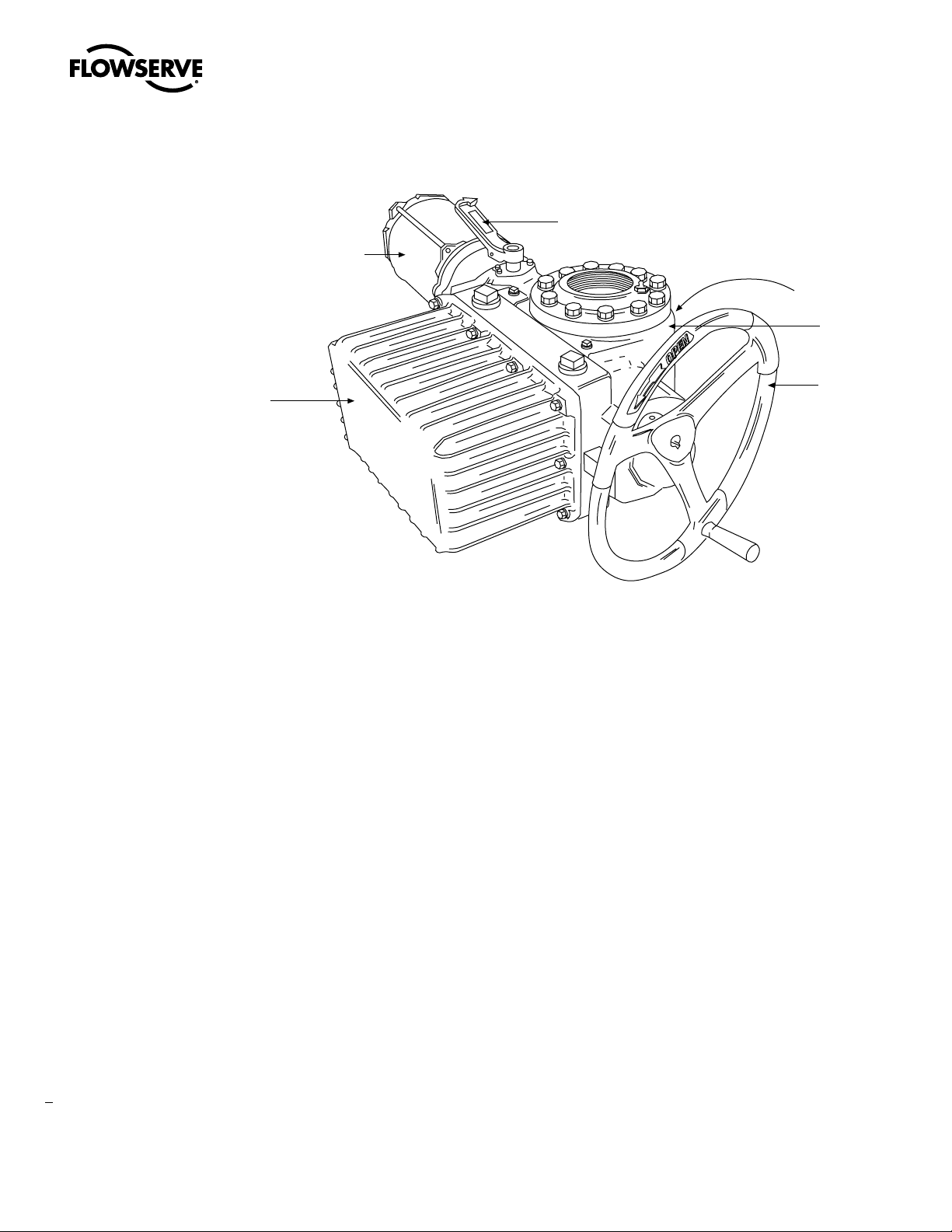

Figure 3.1 – L120-190 through 2000 8

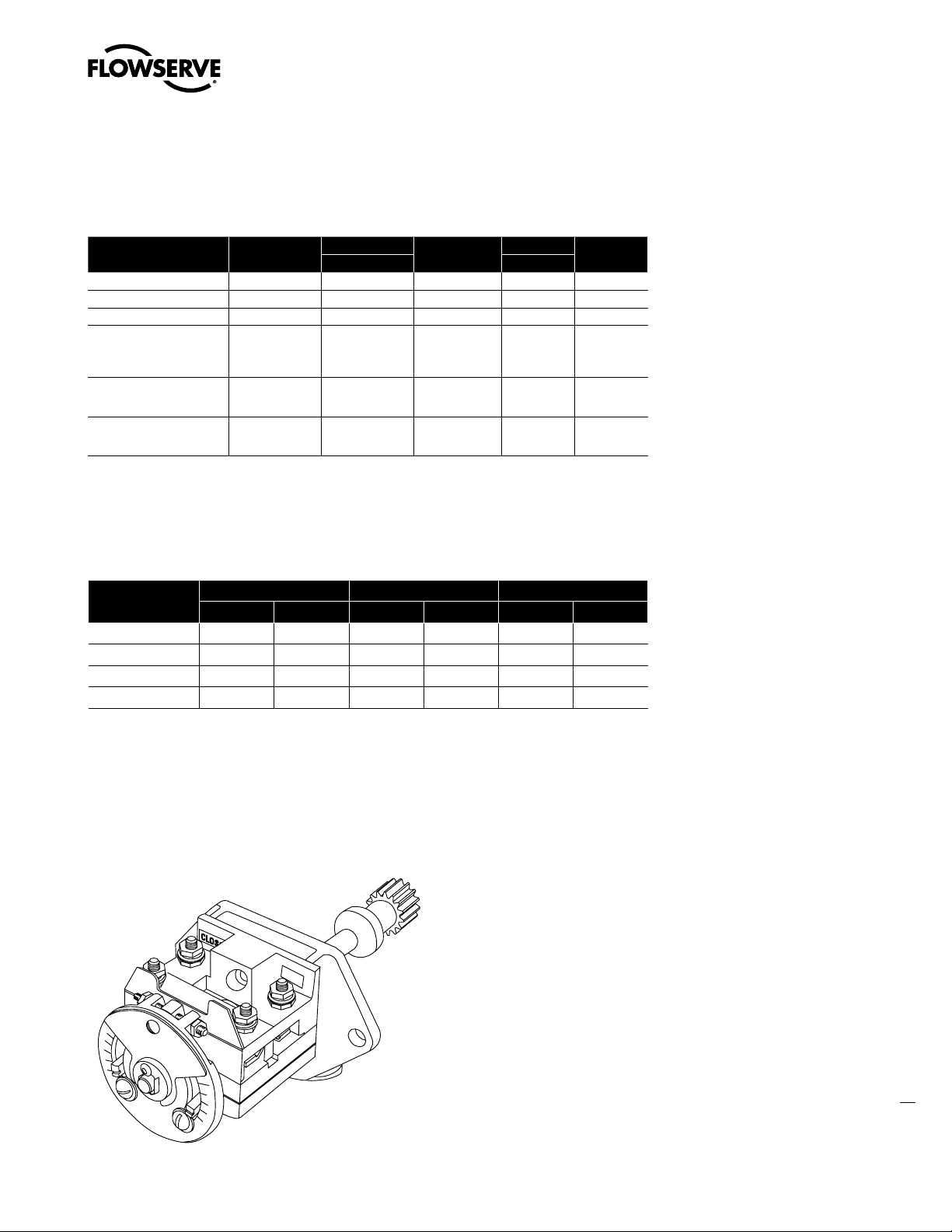

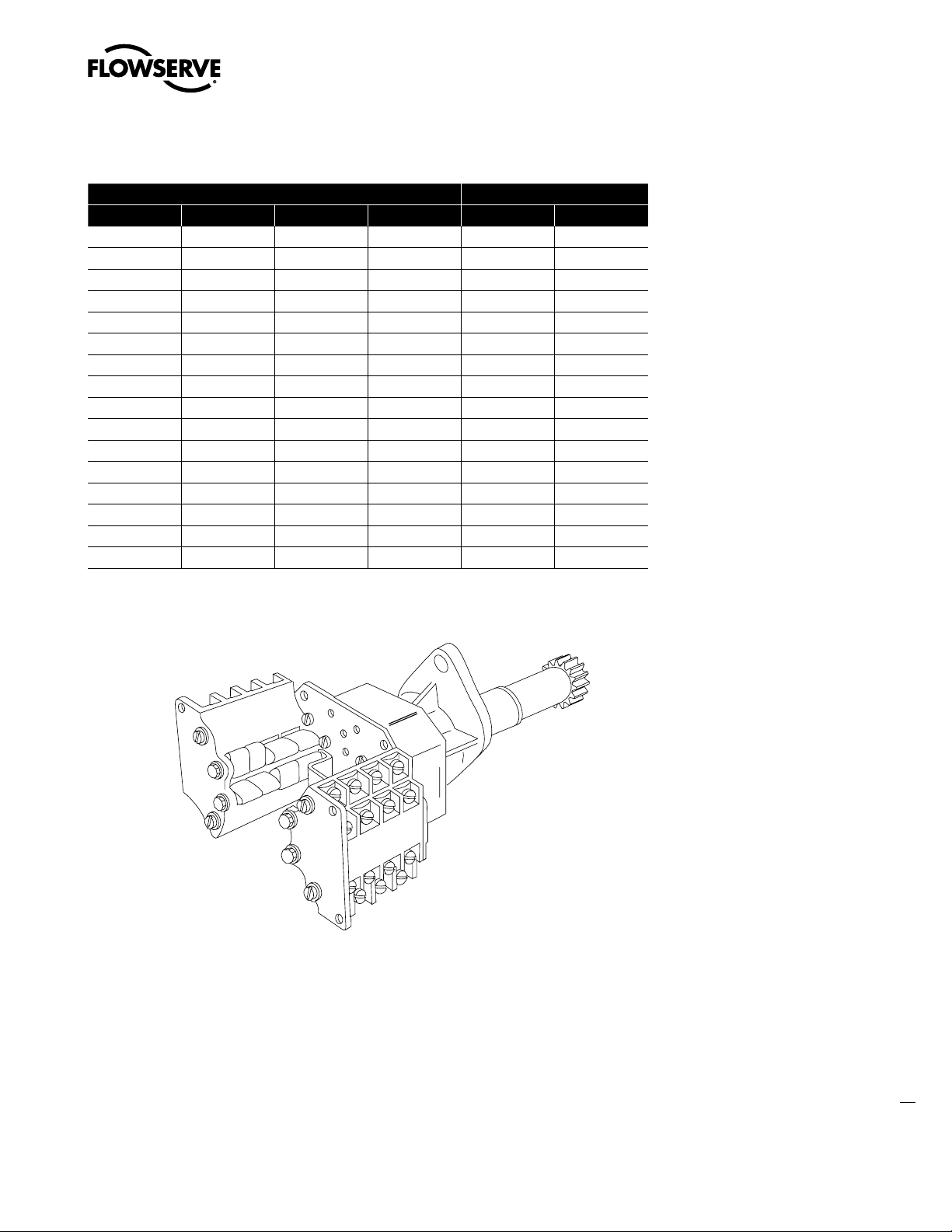

Figure 5.1 – Double Torque Switch 13

Figure 5.2 – Setting Torque Switch 14

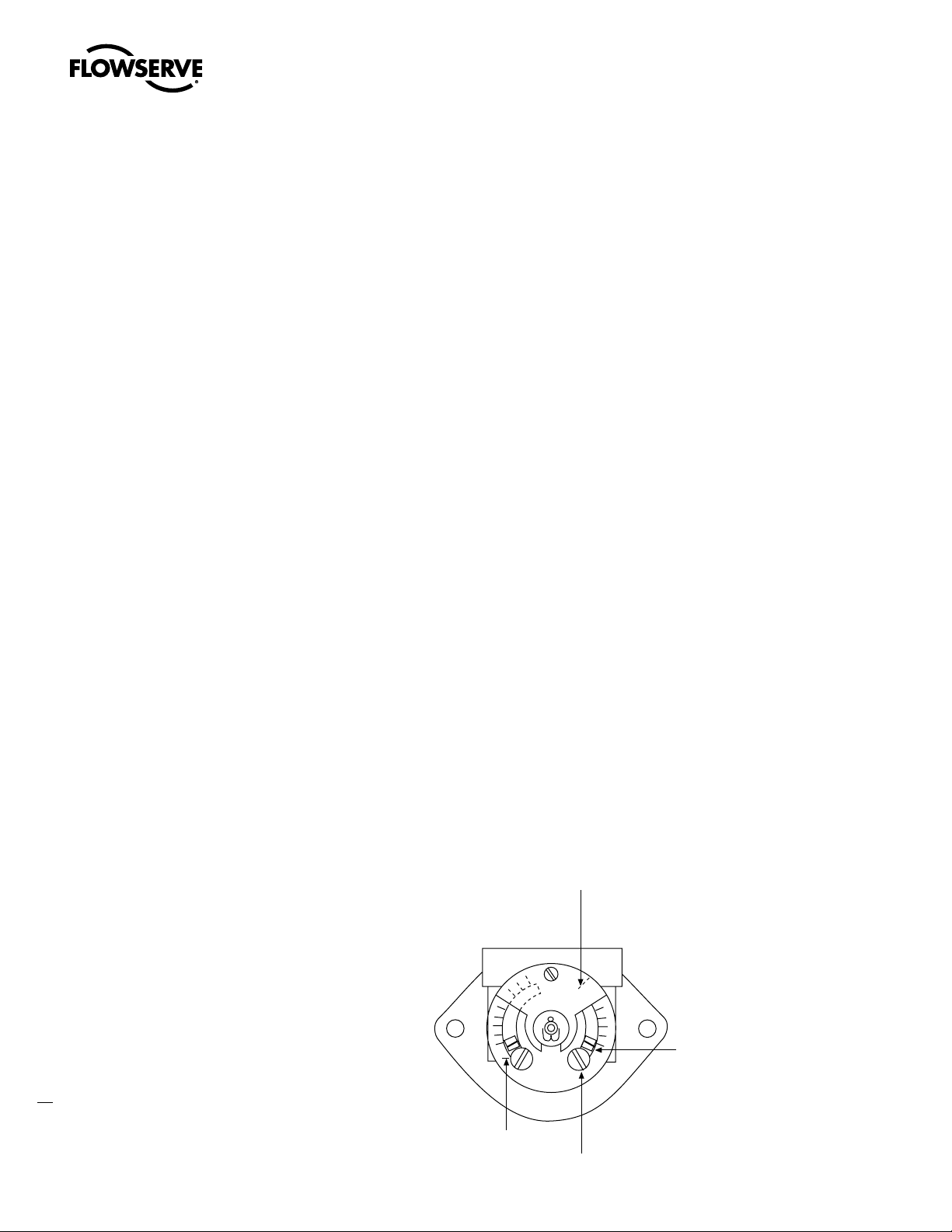

Figure 5.3 – Ring Tongue Terminal 15

Figure 5.4 – Geared Limit Switch 17

Figure 5.5 – Setting Geared Limit Switch 18

Figure 5.6 – Position Indicators 19

Figure 5.7 – Typical Connection for a 1000 ohm Potentiometer 20

Figure 8.1 – L120-190 and -420 Drive Sleeve Side View (Refer to Table 8.1 for parts list) 30

Figure 8.2 – L120-190 and -420 Worm Shaft Side View (Refer to Table 8.1 for parts list) 31

Figure 8.3 – L120-190 and -420 Top View (Refer to Table 8.1 for parts list) 32

Figure 8.4 – L120-800 Drive Sleeve Side View (Refer to Table 8.1 for parts list) 33

Figure 8.5 – L120-800 Worm Shaft Side View (Refer to Table 8.1 for parts list) 34

Figure 8.6 – L120-800 Top View (Refer to Table 8.1 for parts list) 35

Figure 8.7 – L120-2000 Drive Sleeve Side View (Torque Base) (Refer to Table 8.2 for parts list) 43

Figure 8.8 – L120-2000 Top View (Refer to Table 8.2 for parts list) 44

Figure 8.9 – L120-2000 Side View (Refer to Table 8.2 for parts list) 45

Figure 8.10 – L120-2000 Exploded View 46

Figure 9.1 – Wiring Diagram – No Controls 49

Figure 9.2 – Wiring Diagram – Integral Controls 50

Figure 9.3 – Wiring Diagram – NCU 51

Tables

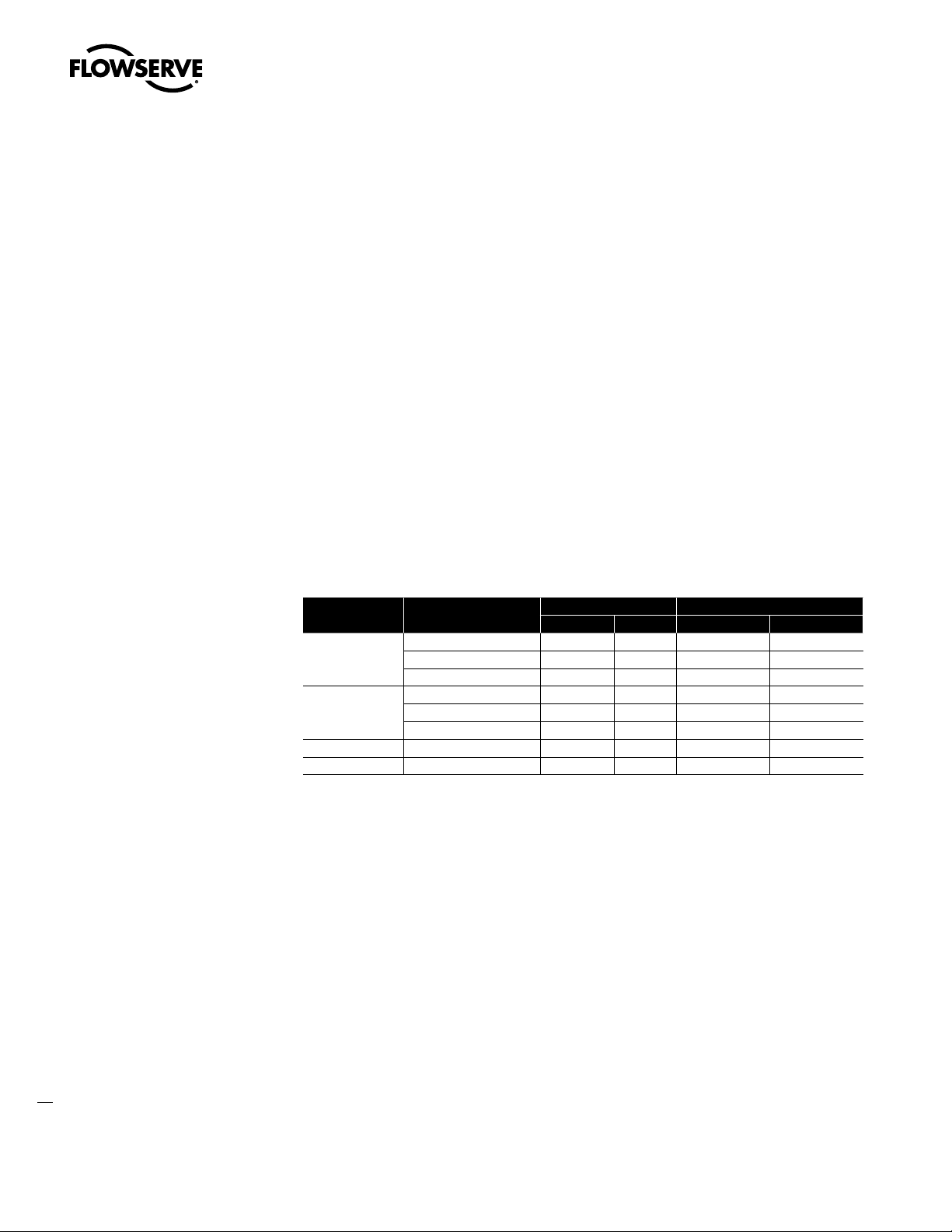

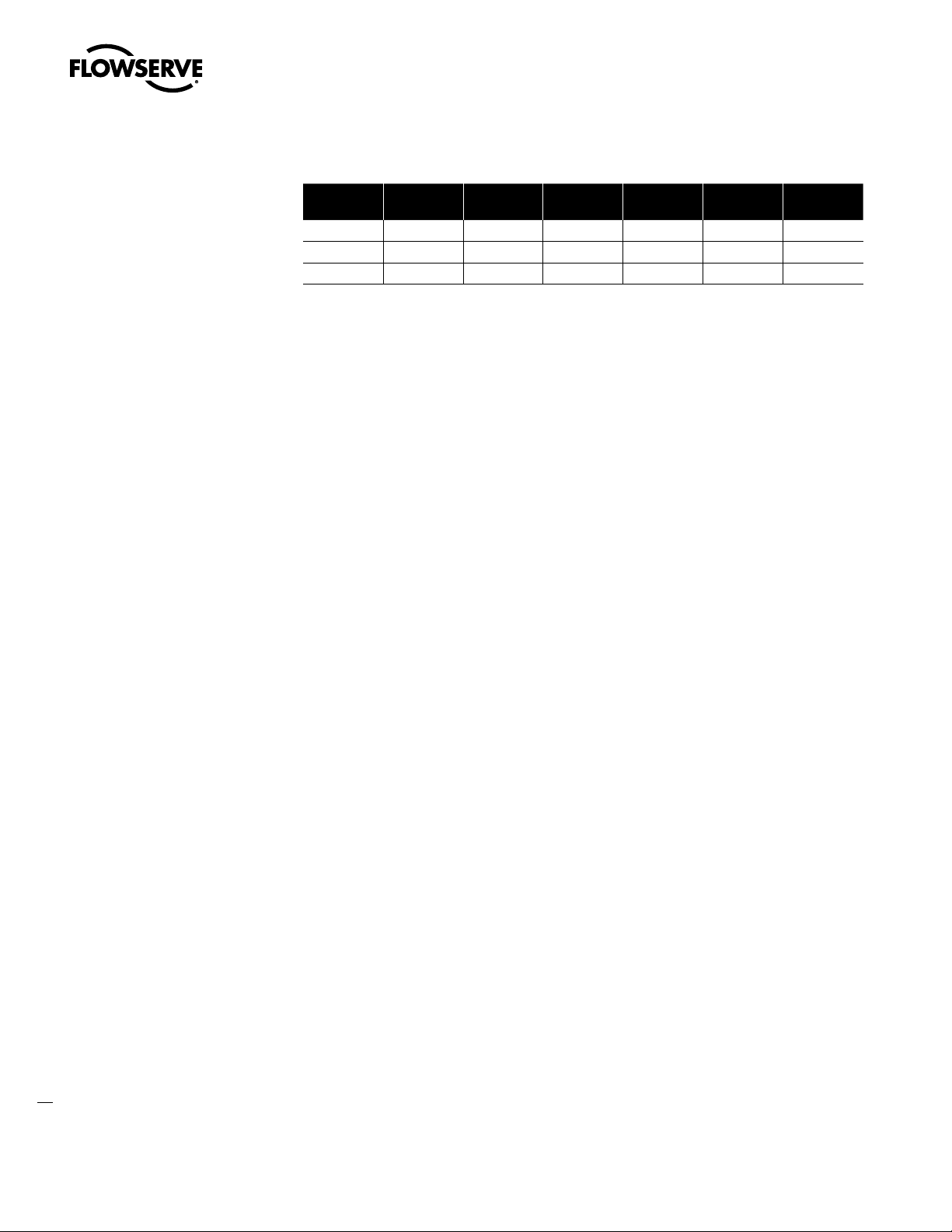

Table 4.1 – Actuator Weights 10

Table 5.1 – Mounting Base Dimensions 13

Table 5.2 – Maximum Stem Acceptance 13

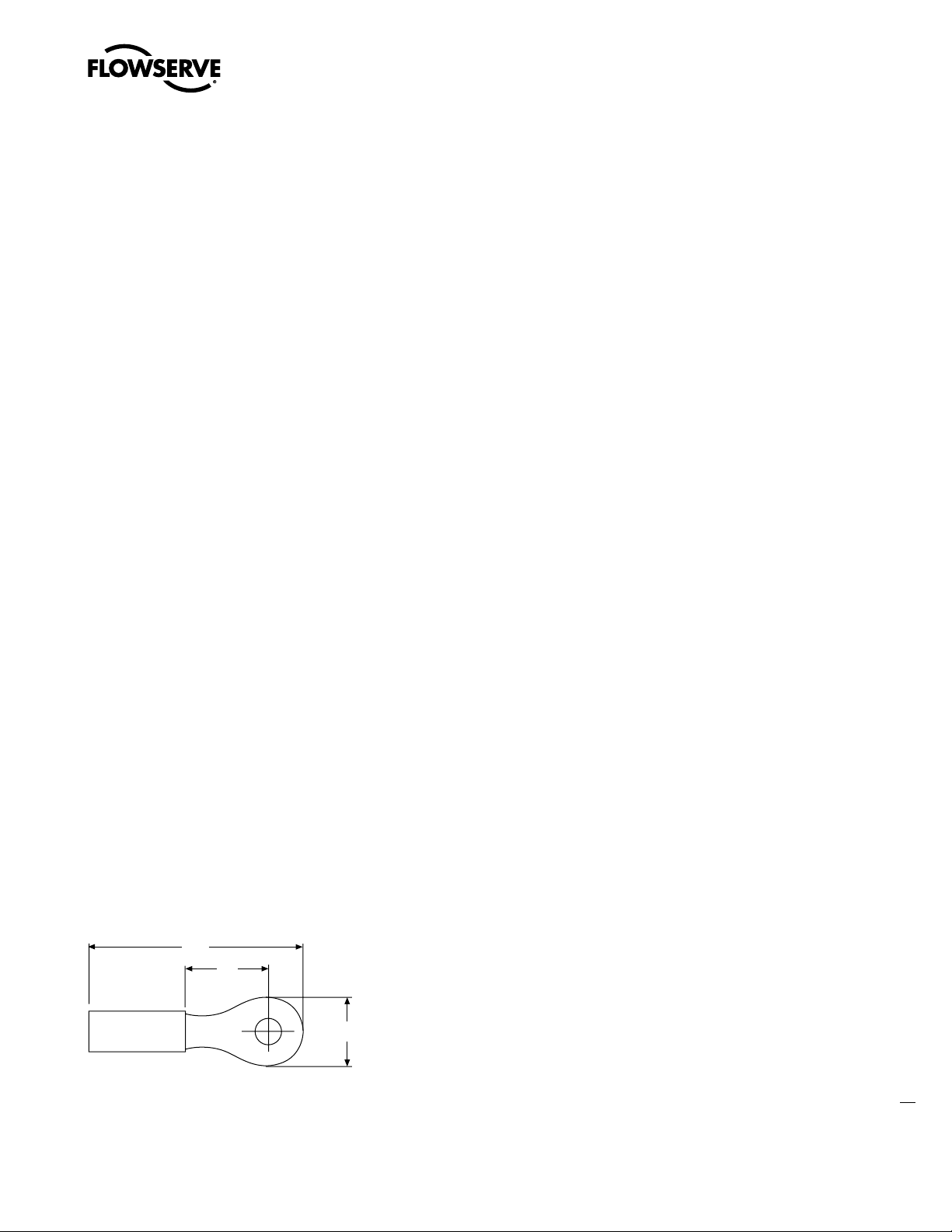

Table 5.3 – Terminal Dimensions By Cable Size 16

Table 5.4 – Maximum Drive Sleeve Turns 17

Table 7.1 – Lubricant Weights 25

Table 8.1 – L120-190, -420 and -800 typical parts list 36

Table 8.2 – L120-2000 typical parts list 47

4

Page 5

1

Limitorque

Introduction

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

1.1 Purpose

This Installation and Maintenance Manual explains how to install and maintain L120-190 through -2000

actuators. Information on installation, disassembly, reassembly, lubrication, and parts is provided.

1.2 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury

and damage to the equipment. The user must read and be familiar with these instructions before

attempting installation, operation, or maintenance. Failure to observe these precautions could result in

serious bodily injury, damage to the equipment, warranty void, or operational difficulty.

Safety notices are presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow

warning notices could result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in

personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the actuator’s installation and

operation.

flowserve.com

5

Page 6

2

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Product Capabilities and Features

L120 Series actuators operate without modification in any rising or non-rising stem application for

linear-action valves.

The actuators meet rigid safety requirements and are available in weatherproof, explosionproof, and

submersible configurations.

The actuators are compatible with a wide range of control options from stand-alone actuators with local

control stations to open standards-based DDC-100 networks with up to 250 actuators.

The actuators are designed with integral control packages including plug-in interconnect boards that

increase control functionality for stand-alone or networked actuators.

Torque overload protection is provided in both directions of travel.

6

Page 7

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Initial Inspection

and Storage Instructions

3

c WARNING: Read this Installation and Maintenance Manual carefully and completely before

attempting to store the actuator. Be aware of the electrical hazards.

3.1 Product Identification

The actuator nameplate is located on the back of the actuator opposite the limit switch controls

compartment. The nameplate contains the following information:

• Limitorque name

• Point of manufacture

• Actuator size

The motor nameplate is located on the motor. The nameplate contains the following information:

• ID number

• Run torque

• RPM

• Full load amps

• Insulation class

• Space heater size

• Service Factor

• Cycles

• Ambient temperature

• Start torque

• Order number

• Serial number

• Customer tagging

• Enclosure type

• Volts

• Locked rotor amps

• Duty

• Horsepower

• Phase

• Motor code

• Connection diagram

flowserve.com

7

Page 8

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Figure 3.1 – L120-190 through 2000

Motor

Declutch

Lever

Actuator Nameplate

(hidden)

Housing

Limit Switch

and Controls

Compartment

Handwheel

3.2 Inspection and Recording

Upon receipt of the actuator, inspect the condition of the equipment and record nameplate information.

1. Carefully remove actuator from shipping carton or skid. Thoroughly examine the equipment for

any physical damage that may have occurred during shipment. If damaged, immediately report the

damage to the transport company.

2. Record the actuator nameplate information for future reference, i.e., ordering parts, obtaining

further information.

3.3 Storage Procedures

NOTE: The following are our recommended storage procedures to retain maximum product integrity

during short-term storage. Failure to comply with recommended procedures will void the warranty. For

longer-term storage, contact Limitorque for procedures and recommendations.

3.3.1 Short-Term Storage (less than 1 year)

Actuators are not weatherproof until properly installed on the valve or prepared for storage.

Store actuators in a clean, dry, protected warehouse away from excessive vibration and rapid tempera-

8

ture changes. If the actuators must be stored outside, they must be stored off the ground, high enough

to prevent them from being immersed in water or buried by snow.

Page 9

Limitorque

1. Position the actuator in storage with motor and switch compartment horizontal.

2. Connect the space heaters (if supplied) or place desiccant in the switch compartment.

3. Connect space heaters if actuator is to be stored in a damp place.

4. Replace all plastic caps or plugs with pipe plugs and ensure that all covers are tight.

5. If the actuator is mounted on a valve and the stem protrudes from the actuator, a suitable stem

cover must be provided.

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

flowserve.com

9

Page 10

4

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Actuator Weights

The approximate L120 actuator weights are provided below:

Table 4.1 – Actuator Weights

Actuator Size Control Types

3

NCU

3

L120-190

L120-420

L120-800 NCU

L120-2000 NCU

Note 1: Torque Only

Note 2: Torque and Thrust

Note 3: NCU = No Controls Actuator

BIC = Basic Integral Controls

UEC = Universal Electronic Controller

BIC

UEC/Clamshell

3

NCU

3

BIC

UEC/Clamshell

3

3

Drive 1 Weight Side HW Drive 2 Weight Side HW

lb. kg lb. kg

520 192 520 192

3

3

586 217 586 217

586 217 586 217

1065 394 1065 394

1130 418 1130 418

1220 451 1220 451

1

1270

1

2500

471

925

1

1

1700

3300

2

2

629

1221

2

2

10

Page 11

5

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Installation Instructions

5.1 Safety Precautions

c WARNING: Read this Installation and Maintenance Manual carefully and completely before

attempting to install, operate, or troubleshoot the Limitorque actuator.

c WARNING: Be aware of electrical hazards. Turn off incoming power before working on the

actuator and before opening the switch compartment.

c WARNING: Potential HIGH PRESSURE vessel — be aware of high-pressure hazards associated

with the attached valve or other actuated device when installing or performing maintenance

on the actuator. Do not remove the actuator mounting bolts from the valve or actuated device

unless the valve or device stem is secured or there is no pressure in the line.

c WARNING: For maintenance and/or disassembly of the actuator while installed on the valve,

ensure that the actuator is not under thrust or torque load. If the valve must be left in service,

the valve stem must be locked in such a way as to prevent any movement of the valve stem.

c WARNING: Do not attempt to remove the spring cartridge cap, housing cover, or stem nut

locknut from the actuator while the valve or actuated device is under load.

c WARNING: Do not manually operate the actuator with devices other than the installed hand-

wheel and declutch lever. Using force beyond the ratings of the actuator and/or using additive

force devices such as cheater bars, wheel wrenches, pipe wrenches, or other devices on the

actuator handwheel or declutch lever may cause serious personal injury and/or damage to the

actuator and valve.

c WARNING: Do not exceed any design limitations or make modifications to this equipment

without first consulting Limitorque.

11

flowserve.com

Page 12

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

c WARNING: Actuators equipped with electrical devices (motors, controls) requiring field wiring

must be wired and checked for proper operation by a qualified tradesman.

c WARNING: Use of the product must be suspended any time it fails to operate properly.

a CAUTION: Do not use oversized motor overload heaters. Instead, look for the cause of the

overload.

a CAUTION: Do not operate the valve under motor operation without first setting or checking the

limit switch setting and motor direction.

a CAUTION: Do not force the declutch lever into the motor operation position. The lever returns to

this position automatically when the motor is energized.

a CAUTION: Do not depress the declutch lever during motor operation to stop valve travel.

a CAUTION: Do not use replacement parts that are not genuine Flowserve Limitorque parts, as

serious personal injury and/or damage to the actuator and valve may result.

a CAUTION: Do not lift actuator/gearbox or actuator/valve combinations with only the eye bolts in

the L120 actuator. These eye bolts are designed for lifting the L120 actuator only.

a CAUTION: Do not lift the actuator by handwheel.

5.2 Safety Practices

The following check points should be performed to maintain safe operation of the L120 actuator:

• Eye bolts are designed for lifting only the actuator and not associated gearboxes or valves.

• Mount motor on a horizontal plane, if possible. Preferably, keep the motor or limit switch compartment from hanging down. This prevents head of grease from being against motor or switch seals.

• Keep the switch compartment clean and dry.

• Keep the valve stem clean and lubricated.

• Set up periodic operating schedules for infrequently used valves.

• Verify that all actuator wiring is in accordance with the applicable wiring diagram.

• Carefully check for correct motor rotation direction. If the motor is driving the valve in the wrong

direction, interchange any two leads on the three-phase motor or switch the armature leads on DC

motors.

• Use a protective stem cover. Check valve stem travel and clearance before mounting covers on rising

stem valves.

• Verify that a locking nut tightly secures the stem nut and that the top thread of the lock nut is crimped

and staked in two places.

• For the DC motor, keep the armature clean and periodically check brushes for proper contact and wear.

12

5.3 Actuator Preparation

NOTE: Replace all molded plastic conduit and top protectors (installed for shipping purposes only) with

pipe plugs when installation wiring is complete.

Page 13

Limitorque

OPEN

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

5.3.1 Mounting Base

The mounting hole sizes and quantities are as detailed in Table 5.1, below:

Table 5.1 – Mounting Base Dimensions

Actuator Size

L120-190 8 ¾–10 x 1.13 M20 x 2.5 x 32 11.75 298 mm

L120-420 8

L120-800 (Torque Only) 8 ¾–10 x 1.63 N/A 17.0 N/A

L120-800 (Thrust Only) 8 1.25–7 x 2.0 N/A 16 N/A

Mounting Holes Tap Size

Quantity MSS MSS

7

⁄8–9 x 1.75 N/A 14.0 N/A

ISO

Bolt Circle

ISO

L120-2000 (Torque Only)

L120-2000 (Thrust Only) 12 1-½–6 x 3.0 N/A 18.0 N/A

16

1–8 x 2.0 N/A 23.5 N/A

5.3.2 Stem Acceptance

The maximum stem acceptance is provided in Table 5.2, below:

Table 5.2 – Maximum Stem Acceptance

Actuator size

L120-190 3.5 89 2.875 73 ¾ x ¼ 20 x 12

L120-420 5 127 4.25 108 1 x ¾ 28 x 16

L120-800 5 127 7 178 1 x ¾ 32 x 18

L120-2000 6.25 159 8.00 203 1¼ x

NOTE: For complete mounting dimensions, see sales brochure LMENBR1200.

Drive 2 Tapped Drive 1 Bore Drive 1 Key

inch mm inch mm inch mm

7

⁄8 40 x 22

5.4 Double Torque Switch

The torque switch is designed to protect the actuator in open and close directions.

Figure 5.1 – Double Torque Switch

NOTE: See Caution and Note on following page.

13

flowserve.com

Page 14

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

a CAUTION: Disconnect all incoming power before opening limit switch compartment or working

on the torque switch.

• Do not use abrasive cloth to clean the contacts on the torque switch.

• Do not torque-seat 90° operation valves or run them against the stops. This may cause damage

to the valve.

NOTE: If the actuator has “torqued out,” release torque buildup by operating the actuator manually in

opposite direction ½ to 1 turn of the output drive sleeve.

NOTE: Torque switch contacts are rated 600 volts, in accordance with NEMA ICS-2.

5.4.1 Setting Torque Switch

The torque switch was set at the factory according to customer-supplied information regarding necessary torque or thrust output provided at the time of the order. However, if the torque switch is newly

installed or the setting needs to be adjusted, follow the procedure below:

a CAUTION: A maximum stop setting plate is provided on most actuators. Do not remove this

plate. Do not exceed the setting indicated by this plate without contacting Limitorque.

• Installing or adjusting the torque switch with the operator in a “loaded” condition will result in a

loss of torque protection.

Item letters correspond to Figure 5.2.

1. Place the L120 actuator in manual mode.

2. Release the load on the wormshaft spring pack. Put operator in manual mode and operate in

opposite direction until switch is in neutral position.

3. For open and close directions, loosen Screw (A) and move Pointer (B) to desired position. A higher

number indicates a high torque and/or thrust output.

4. Tighten Screw (A).

5. Operate the valve electrically to seat the valve and to ensure tight shutoff.

Figure 5.2 – Setting Torque Switch

Maximum Stop

Setting Plate

14

B

Torque Switch Dial

A

Page 15

Limitorque

A

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

5.4.2 Balancing Torque Switch

Item letters correspond to Figure 5.2.

1. Place the actuator in manual mode.

2. Remove the load from the wormshaft spring pack.

NOTE: If the actuator has “torqued out,” release torque buildup by operating the actuator manually in

opposite direction ½ to 1 turn.

3. Note the open and close torque switch settings prior to re-installing the torque switch.

4. Loosen Screws (A) and position both Pointers (B) at the #1 setting; tighten Screws (A).

5. Mount the torque switch and tighten the mounting screws. Verify that both contact pointers are

touching the arms. The interface between the pointers and the arm is found beneath the torque

switch dial. If the pointers and the arms are not in contact, the clearance on the open and close

torque switches should be equal. If not equal, the torque switch needs to be balanced. (See Step 7.)

6. If the pointers and arms are in contact on both sides of the switch, manually rotate the torque

switch dial clockwise and counter-clockwise to determine if there is equal backlash in both directions of rotation. If there is not equal backlash in both directions, the torque switch needs to be

balanced. (See Step 7.)

7. Loosen both hex nuts.

8. Back out one setscrew and tighten the other setscrew until there is equal backlash in both directions

of rotation of the dial, or equal clearance between the pointers and arms.

9. Tighten the hex nuts and return the torque switch to its original settings.

a CAUTION: The balancing screws should not be touched except during the balancing procedure.

The switch is now balanced and ready for the pointers to be returned to their original settings.

5.4.3 Torque Switch Terminal Connections

Wiring connections to the L120 geared limit switch, torque switch, and marathon terminal strips are to

be made using ring-tongue terminals as shown below:

Figure 5.3 – Ring Tongue Terminal

C

B

See Table 5.3, next page

15

flowserve.com

Page 16

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Table 5.3 – Terminal Dimensions By Cable Size

AWG Screw Hole Insulation

22-16 #10 Vinyl 18RA-10 .97 .31 .27

18-14 #10 Vinyl 14RB-10 .97 .31 .27

12-10 #10 Vinyl 14RC-10 1.06 .31 .27

Terminals are to be crimped using Thomas & Betts crimping tool WT111M.

Thomas &

Betts P/N

A B C

5.5 Geared Limit Switch – Rotor Type

a CAUTION: The geared limit switch is not preset at the factory and must be adjusted after the

actuator has been mounted on associated equipment.

NOTE: Limit switch contacts are rated 600 volts, in accordance with NEMA ICS-2

• Disconnect all incoming power to the actuator prior to opening the limit switch compartment and

adjusting the switch.

• Consult the relevant wiring diagram for limit switch contact development. All L120 actuators are

supplied with 16-contact limit switches - four switches on each of the four rotors. Two rotors are

used for end-of-travel indication. The remaining two rotors may be adjusted for any intermediate

point-of-travel.

• Do not use abrasive cloth to clean the contacts on the limit switch.

• Do not attempt to repair gearing in the limit switch. Replace entire gear frame assembly if necessary.

16

5.5.1 Setting Limit Switch

The maximum number of drive sleeve turns available is a funtion of actuator size, worm gear ratio,

and type of switch. See Table 5.4. The Intermediate Shaft shown in Figure 5.5 may take a considerable

number of turns before rotor trip occurs.

c WARNING: Potential Explosion Hazard. Do not use a variable speed electric drill for setting the

limit switch in an explosive environment.

a CAUTION: When setting the limit switch rotor segments (cams) using a variable speed electric

drill, do not run drill at speeds higher than 200 RPM. Operating the drill at high speeds can

damage the gearing within the limit switch.

Page 17

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Table 5.4 – Maximum Drive Sleeve Turns

Limit Switch Gearing PIC Gearing

Actuator Size W.G. Ratio 4-Gear 5-Gear PIC or R/I (270) RVDT(90)

L120-190 13.3:1 3110 31100 13706 4569

33:1 1250 12500 5521 1837

60:1 690 6900 3037 1012

85:1 N/A N/A N/A N/A

L120-420 10.33:1 N/A N/A N/A N/A

16:1 3300 33000 11405 3797

41:1 1280 12800 4445 1481

57:1 910 9100 3195 1065

80:1 N/A N/A N/A N/A

L120-800 12.67:1 N/A N/A N/A N/A

19:1 2850 28500 9586 3195

49:1 1050 10500 3720 1240

58:1 N/A N/A N/A N/A

86:1 N/A N/A N/A N/A

L120-2000 43:1 1210 12100 4234 1413

71:1 740 7400 2566 855

Figure 5.4 – Geared Limit Switch

Set the limit switch as shown on the following page. All item letters and piece numbers refer to Figure 5.5.

flowserve.com

17

Page 18

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Assembly

Figure 5.5 – Setting Geared Limit Switch

Contact Plunger

Rotor Cam

Intermediate Shaft

Contact Open

8

7

Contact Close

3

Clutch

Screw

4

9

2

A

Close

Open

B

Clutch Screw

5

Piece Quantity Description

C

INT - 1 INT - 2

D

1 1 Gear Frame Assembly

6

2 2 8-Switch Contact Block

3 12 Rotor Segment (short)

4 4 Rotor Shaft

5 4 Machine Screw

6 4 Flat Washer

7 4 Lock Washer

8 8 Hex Nut

9 4 Rotor Segments (long)

18

1

Unless otherwise noted part numbers refer to Figure 5.5.

1. Open the Limit Switch Compartment Cover (piece #200-1 of Figure 8.3 for L120-190 and -420,

Figure 8.6 for L120-800, and Figure 8.7 for L120-2000).

2. Put the actuator into manual operation. Use the handwheel to operate the valve in the “open”

direction. While operating the valve, note the direction of rotation of the Intermediate Shaft

corresponding to the rotor or rotors to be set.

3. When the valve is fully open, close it one turn of the handwheel to allow for coast of moving parts.

4. Push in the Clutch Screw and turn one-quarter turn. The rod will latch in this depressed position.

5. Refer to the applicable wiring diagram for contact development. The limit switch contact is closed

when the rotor is engaged with the plunger. If the rotor to be set has not turned 90° to operate

the plunger, turn the intermediate shaft in the same direction as noted in Step No. 2 until the rotor

clearly trips the switches. This rotor is now set correctly.

6. If the intermediate position rotors 1 and 2 are also to be set at any desired position, repeat the

setting operation in steps 1 through 5 above.

7. Before moving the valve, depress and turn the Clutch Screw counterclockwise one-quarter turn to

the spring-released position. Insert a screwdriver into the intermediate shafts to ensure that they are

loaded in position and will not rotate.

Page 19

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

NOTE: The cross-slotted shafts A, B, C, and D have been designed for use with a No. 2 Phillips

screwdriver shank chucked into a variable speed reversible electrical drill. Do not run drill at speeds

higher than 200 RPM (see previous CAUTION on page 16).

a CAUTION: Do not operate the valve when the Clutch Screw is in a fully depressed position. Loss

of contact setting will occur and the setting rod will be damaged.

8. Operate the valve by handwheel to the fully “close” position; reverse direction by one turn of the

handwheel to allow for coast of moving parts.

9. Set the other rotors by following steps 1 through 7.

10. Secure the Limit Switch Compartment Cover (piece #200-1 of Figure 8.3 for L120-190 and -420,

Figure 8.6 for L120-800, and Figure 8.7 for L120-2000).

NOTE: For actuators having captive bolts, pull-down torque must not exceed 30 ft lbs.

5.5.2 Combination of Contacts

Refer to Figure 5.5.

The rotor segments can be separated and rotated through 90° to give various combinations of normally

open or normally closed contacts to each rotor.

1. Remove Nuts (piece #8) and Fillister Head Machine Screws (piece #5) for a total of two fasteners on

each side of the switch.

2. Remove complete contact assembly from the back plate.

3. Rearrange cams on the camshaft to produce the required combination of contacts.

4. Replace contact assembly on back-plate (ensuring the registers fit correctly) and secure with the

machine screws and nuts.

5.6 Position Indication

5.6.1 Local Position Indication

The local dial position indicator is factory-built per the application. The position indicator can only be

adjusted when mounted on the valve.

Figure 5.6 – Position Indicators

MID-TRAVEL

CLOSE

OPEN

50

25

75

0

PERCENT

O PEN

100

NOTE: See the setting procedure on the following page.

19

flowserve.com

Page 20

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

1000 ohms

To set the local position indicator:

1. Disconnect all incoming power and remove Limit Switch Compartment Cover (piece #200-1 of

Figure 8.3 for L120-190, -420 and -800, and Figure 8.7 for L120-2000).

2. Using the handwheel place the valve in the fully “close” position.

3. Loosen the round head machine screw which holds the pointer in place; move the pointer to the “O”

position, and re-tighten the screw.

The indicator is now set.

NOTE: The end-of-travel rotors of the geared limit switch activate “flip-flop” type indicators. This type of

indicator will require no further setting after the geared limit switch has been adjusted.

5.6.2 Remote Position Indication

The remote position indicator is a Limitorque digital position indicator. This indicator is a digital LED

display module that displays valve position in 1% increments. The readout accepts inputs from signals

of 4-20 mA, 0-2 V, or a 1000 ohm feedback potentiometer (mounted on the MDPI). The readout is

accurate to 1% +/- 1 digit.

5.6.3 Calibrating Position Transmitter PT20SD

1. Position the actuator to mid-travel value at 50% position.

2. Disconnect the potentiometer wiring harness from the PT20SD board and measure the resistance

from each end connection to the center connection on the potentiometer.

3. Set the potentiometer to the correct resistance reading. Loosen the setscrew that retains the spur

gear on the potentiometer shaft and rotate the shaft until a reading of 500 ohms is achieved.

4. Tighten the setscrew and reconnect the wiring harness to the PT20SD.

5. Run the actuator fully CLOSED.

6. Calibrate ZERO position by adjusting the zero potentiometer until a 4mA output signal is read at

terminal +Ve and -Ve.

7. Run the actuator fully OPEN.

8. Calibrate SPAN position by adjusting the span potentiometer until a 20mA output signal is read at

terminals +Ve and -Ve.

9. Repeat steps 5 through 8 and fine-tune as necessary.

Figure 5.7 – Typical Connection for a 1000 ohm Potentiometer

20

Gearing

Receiver

+

-

Customer Equipment

DC Power

Suppl y

-

+

Page 21

6

Limitorque

Operation

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

c WARNING: See Sections 5.1 and 5.2 Safety Precautions and Safety Practices.

c WARNING: Do not manually operate the actuator with devices other than the installed

Handwheel and Declutch Lever. Using force beyond the ratings of the actuator and/or using

additive force devices such as cheater bars, wheel wrenches, pipe wrenches or other devices on

the actuator Handwheel or Declutch Lever may cause serious personal injury and/or damage to

the actuator or valve.

a CAUTION: Do not motor-operate the valve without first setting or checking the limit switch

setting and motor direction. If the valve closes when the open button is pushed, the motor may

need to be electrically reversed.

• Do not force the declutch lever into hand operation. If the clutch does not easily engage, rotate

handwheel slowly while operating the declutch lever.

• Do not force the declutch lever into motor operation position. Lever returns to this position automatically when motor is energized.

• Do not run “plug” type valve against stop.

• Do not alternately start/stop the motor to open or close a valve that is too tight for normal operation.

6.1 Electrical Start-Up

1. Verify that the actuator has been correctly lubricated. This is particularly important if the actuator

has been in long-term storage.

2. Verify that the geared limit switch has been correctly set per Section 5.5.1, Setting Limit Switch.

3. If the valve stem is not visible, remove the stem cover or handwheel cover plate to observe the

output direction of the drive sleeve.

4. Engage manual operation and hand crank the valve well away from end-of-travel positions.

5. Turn on power supply and push the “open” button on the pushbutton station.

21

flowserve.com

Page 22

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

6. Check output rotation:

• If phase rotation is correct, the valve should begin to open.

• If valve begins to CLOSE, STOP IMMEDIATELY. Incorrect phase rotation will lead to serious

damage if the valve seats.

NOTE: For UEC only – if incorrect rotation, select opposite direction with dipswitch.

7. Correct the phase rotation one of two ways:

• switch any two of the three power leads for three-phase power, or

• reverse the armature leads for DC power.

The actuator should operate correctly and will be stopped at the end-of-travel positions by torque or

limit switch functions.

Premature stopping may be caused by incorrect limit switch or torque switch settings or obstructions in

the valve.

6.1.1 Typical Wiring Diagram

Figures 9.1 through 9.4 are representations of typical applications and may not be applicable to

your specific actuator. Please refer to the wiring diagram supplied with your actuator to confirm the

actual equipment supplied. Check www.limitorque.com for the latest diagram revisions and/or related

diagrams.

22

6.2 Manual Operation

Piece numbers refer to Figures 8.1, 8.2, and 8.3 for L120-190 and -420, Figures 8.4, 8.5, and 8.6 for

L120-800, and Figures 8.7 - 8.10 for L120-2000.

The actuator has a handwheel for manual operation. The actuator may be manually operated any time

the motor is not engaged.

Manually operate as follows:

1. Move the Declutch Lever (piece #10, #11) in the direction of the arrow until it latches into place. Do

not force the lever.

2. If the lever will not latch, rotate the Handwheel (piece #5) while turning the declutch lever and the

lever will latch in place.

When the declutch lever is turned, it rotates a Cam which causes the Clutch Fork (piece #42-1) to move

the Worm Shaft Clutch (piece #33) axially along the worm shaft against the force of a Clutch Spring

(piece #45, #46). This disengages the mating lugs on the Worm Shaft Gear (piece #32) and the clutch,

and engages the clutch with the Handwheel Gear (piece #17, #9). The Clutch Trippers (piece # 34-A

and 34-B) maintain this position and latch onto the worm shaft gear. Turning the Handwheel (piece #5)

rotates the Handwheel Shaft (piece #18) and the Handwheel Pinion. The handwheel pinion then drives

the Handwheel Gear (piece #8, #9) which in turn drives the clutch. The clutch then drives the actuator in

the same manner as in motor operation.

When the motor is energized, the motor pinion will turn the worm shaft gear. Tripper cams mounted

on the worm shaft gear cause the trippers to release the clutch. The Clutch Fork (piece #42-1) is then

forced, under spring pressure, to return the clutch to the motor operation position.

NOTE: The shift from manual operation to motor operation is automatic and does not require external

positioning of the declutch shaft.

Page 23

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

6.3 Motor Operation

The actuator is always available for motor operation whenever the motor is energized.

a CAUTION: Do not force the declutch lever into motor operation. Lever will automatically return

to motor operation when the motor is energized.

Reset the travel limit switches prior to motor operation if the actuator has been dismantled or removed

from the valve. Piece numbers refer to Figures 8.1, 8.2, and 8.3 for L120-190 and -420, and Figures 8.4,

8.5, and 8.6 for L120-800.

In motor operation, the Motor Pinion (piece #31) drives the Worm Shaft Gear (piece #32), which drives

the Worm Shaft Clutch (piece #33) through the clutch lugs on both the worm shaft gear and the clutch.

The Worm Shaft (piece #17) is driven by splines on the OD of the worm shaft and on the ID of the

clutch. The worm shaft is splined to the Worm (piece #30-1) which drives the Worm Gear (piece #13).

Two lugs on the worm gear are engaged by matching grooves in the Drive Sleeve (piece #8). This

arrangement provides the no-lost-motion mode of operation and allows the worm gear to turn the

drive sleeve. The worm gear lugs may also be oriented outside the grooves to give the lost-motion

or hammerblow effect. The Stem Nut (piece #12) is rotated by internal splines on the ID of the drive

sleeve and external splines on the OD of the stem nut. This causes a threaded stem to translate in a

threaded stem nut and a keyed shaft to rotate in a keyed stem nut. Thrust is absorbed by Bearings

(piece #40, #41, #14, and #67 ) located at the top and bottom of the drive sleeve.

6.4 Torque and Travel Limiting

Unless otherwise stated, piece numbers refer to Figures 8.1, 8.2, and 8.3 for L120-190 and -420, and

Figures 8.4, 8.5, and 8.6 for L120-800.

The Geared Limit Switch (piece #305 of Figure 8.6) is driven directly by the worm shaft gear through the

limit switch pinion. Thus, the limit switch is directly connected to the output of the actuator and, once

properly set, remains in step with the valve position regardless of the electric or manual operation of the

actuator.

As the actuator increases torque, the worm and the Torque Spring Cartridge Assembly

(composed of piece #'s 16-1 through 16-8) move axially along the worm shaft, compressing the disk

spring packs. The torque spring assembly is calibrated such that a finite spring compression relates to

a finite output torque. Axial worm movement causes movement of the bearing cartridge that is geared

to the Torque Switch (piece #300). The torque switch is graduated and adjustable so it may be set to

interrupt power to the motor at a predetermined output torque level.

flowserve.com

23

Page 24

7

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Maintenance

7.1 Lubrication

The L120 series actuators have a totally sealed gear case, factory-lubricated with grease. The gear case

can be mounted in any position.

a CAUTION: When the actuator is mounted in an upside-down orientation, the worm may not be

completely immersed in lubricant. Check lubricant levels before operating the actuator.

No seal can remain absolutely tight at all times. Therefore, it is not unusual to find a very small amount

of weeping around shaft seals—especially during long periods of idleness such as storage. Using

grease minimizes this condition as much as possible. If a small amount of lubricant is weeping at

start-up, remove it with a clean cloth. Once the equipment is operating on a regular basis, the weeping

should stop.

7.1.1 Lubrication Inspection

Inspect Limitorque L120 series actuators for correct lubrication prior to operating—particularly

following a long storage period.

Each application has its own effect on the actuator. The frequency of these inspections should be based

on the application and the operating experience. The following lubrication inspection schedule is recommended until operating experience indicates otherwise.

For Gear Case, inspect lubrication every 18 months or 500 cycles, whichever occurs first.

24

During an inspection, consider the following:

• Quantity – Ensure there is enough lubricant so that the Worm and the Worm Gear are totally

immersed in grease regardless of the position.

• Quality – Inspect lubricant for dirt, water or other foreign matter. If any one of these is found:

1. Flush the actuator with a commercial degreaser/cleaner such as Exxon Varsol #18. This

degreaser/cleaner is not corrosive and does not affect the seal materials.

2. Repack the actuator with fresh lubricant, allowing room for grease thermal expansion.

Page 25

Limitorque

• Consistency – Ensure the lubricant is fluid approximating a standard NLGI-0 grade consistency or

less. Thinners such as Amoco WAYTAC #31 oil may be added provided the volume of thinner does

not exceed 20% of the total lubricant.

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

7.1.2 Factory Lubricant

Gear Case

• The L120-190 through 2000 is factory-lubricated with an NLGI Grade 00 lithium-base grease, suitable

for temperatures from 0°F to 225°F (-18°C to 107°C).

Geared Limit Switch

• Mobil 28 (No Substitute)

Table 7.1 – Lubricant Weights

Actuator Size lb. kg

L120-190 15 5.6

L120-420 50 18.7

L120-800 Drive 1 71 26.5

L120-800 Drive 2 75 28

L120-2000 Drive 1 65 24.3

L120-2000 Drive 2 72 26.9

Minimum Lubricant Qualities Required

The standard lubricants used by Limitorque have been proven to be extremely reliable over years of

service. Limitorque does not recommend a particular lubricant substitute for the standard lubricants;

however, Limitorque does require the following lubricant qualities as a minimum.

a CAUTION: Do not mix lubricants of a different base chemical. Mixing lubricant bases may cause

lubricant properties to be ineffective.

The lubricant must:

• Contain an “EP” additive.

• Be suitable for the temperature range intended.

• Be water and heat-resistant and non-separating.

• Not create more than 8% swell in Buna N or Viton.

• Not contain any grit, abrasive, or fillers.

• Comply with a slump-prefer NLGI-00 grade.

• Not be corrosive to steel gears, ball, or roller bearings.

• Have a dropping point above 316°F (158°C) for temperature ranges of 0°F to 225°F (-18°C to 107°C).

flowserve.com

25

Page 26

8

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Disassembly and Reassembly

c WARNING: See sections 5.1 and 5.2 Safety Precautions and Safety Practices prior to

disassembly.

c WARNING: Potential High Pressure Vessel. Before removing or disassembling your actuator,

ensure that the valve or other actuated device is isolated and is not under pressure.

a CAUTION: Turn off all power services before attempting to perform service on the actuator.

NOTE: Remove the actuator from the valve for complex work. Minor work, such as replacing geared

limit switch, torque switch or motor, may be readily performed while the actuator is still on the valve.

8.1 L120-190, -420, and -800

c WARNING: See sections 5.1 and 5.2 Safety Precautions and Safety Practices prior to

disassembly.

NOTE: The disassembly of the actuator L120–190 will be used as a general example. Always refer

to the parts drawing when disassembling. Be certain to keep all parts clean and free from dirt after

disassembly.

NOTE: Unless otherwise noted, piece numbers refer to Figures 8.1, 8.2 and 8.3 for L120-190 and -420,

and Figures 8.4, 8.5 and 8.6 for L120-800.

26

8.1.1 To Replace Stem Nut Only

c WARNING: Do not remove Locknut (piece #39) with actuator under load or with valve under

pressure. See Warning on Step No. 11 of Section 8.1.2 L120-190, 420, 800 Disassembly.

NOTE: If the valve must be left in service while the stem nut is replaced, the valve stem must be locked

in such a way as to prevent any movement of the valve stem.

Page 27

Limitorque

Piece numbers refer to Figures 8.1, 8.2 and 8.3 for L120-190 and -420, and Figures 8.4, 8.5 and 8.6 for L120-800.

If the Stem Nut (piece #12) is to be removed from the assembled actuator, remove the Lock Nut (piece #39) and

lift out top of nut.

1. The Lock Nut (piece #39) is staked in two places. Locate the stakes and spot with a drill.

2. Clean all metal particles and remove.

3. If the actuator is mounted on a valve having a threaded stem, and removal of the stem nut is required,

perform Step No.1 and rotate the handwheel to close the valve.

4. The stem nut will rise up the threaded valve stem. When the stem nut splines are free from the drive sleeve,

rotate the stem nut by hand the remaining length of the valve stem.

5. Replace if necessary.

6. Install the new stem nut with the lock nut.

7. Stake the top threads of the lock nut in two places.

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

8.1.2 L120-190, 420, 800 Disassembly

Piece numbers refer to Figures 8.1, 8.2 and 8.3 for L120-190 and -420, and Figures 8.4, 8.5 and 8.6 for L120-800.

1. Turn off power to the actuator.

2. Open or remove electrical Compartment Cover (piece #200-1).

3. Disconnect all electrical leads from the Torque Switch (piece #300) and Geared Limit Switch (piece #305).

Ensure that all leads and terminals are clearly marked to facilitate reassembly.

4. Remove two screws holding limit switch and one holding torque switch. Remove both items.

5. Remove four bolts holding Motor (piece #124) and three bolts holding conduit Nipple Flange (piece #26).

Remove motor, drawing motor leads through the conduit opening.

6. Replace Motor Pinion (piece #31). The motor pinion is keyed to the motor shaft and held there with a

setscrew and lockwire to retain the pinion in its proper position. The motor pinion should be shouldered on

the motor shaft.

7. Remove Handwheel (piece #5) by loosening setscrew. Handwheel can then be pulled from Handwheel Shaft

(piece #18).

8. Remove Declutch Lever Subassembly (piece #11) by removing Extension Spring (piece #48), Retaining Ring

(piece #53-4), Declutch Link (piece #10), and two hex head cap screws holding the subassembly in place.

Remove subassembly.

9. Remove Spring Cartridge Cap (piece #4).

10. Remove Worm and Torque Spring Subassembly (piece #13, #30-1) completely. Temporarily replace the

handwheel and then rotate in the close direction to cause the worm to screw out of engagement with worm

gear and cause the torque spring cartridge to emerge from Housing (piece #1). See Step No. 21 to further

disassemble the cartridge.

11. Remove Housing Cover (piece #3).

c WARNING: Do not remove if a thrust load is on the actuator or if the valve is under pressure and not fully

open, as personal injury may result.

27

flowserve.com

Page 28

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

12. Lift complete drive sleeve assembly from actuator housing. The drive sleeve assembly consists

of Lock Nut (piece #39), Stem Nut (piece #12), Drive Sleeve (piece #8), Upper Thrust Bearings

(piece #40, #67), Worm Gear (piece #13), Worm Gear Spacer (piece #36) and Lower Thrust Bearing

(piece #14). The drive sleeve assembly may be further dismantled if required by pressing off Lower

Drive Sleeve Bearing (piece #41).

13. Remove Retaining Ring (piece #53-1), Split Ring Retainer (piece #27) and Conduit Nipple

(piece #26). Pull the Worm Shaft Clutch Gear (piece #32) from the worm shaft.

14. Spread clutch trippers with a tool to shift actuator into motor operation.

c WARNING: Do not use hands as spring forces could result in personal injury.

15. Remove bolts holding Declutch Housing (piece #2) to Housing (piece #1). Remove clutch housing,

Trippers (piece #34-A and #34-B), and Clutch Fork Assembly (piece #42-1). Worm Shaft Clutch

(piece #33) will slide off worm shaft when removing clutch housing.

16. Slide Clutch Spring (piece #45) off worm shaft toward motor end.

17. Remove Elastic Stop Nut (piece #16-7). Pull Handwheel Spur Gear (piece #9) that is keyed to Shaft

(piece #17).

18. Remove bolts holding WS Bearing Cap (piece #7) and slide cap off wormshaft. Remove Handwheel

Clutch Pinion (piece #20) from bearing cap by removing Retaining Ring (piece #53-3). Be careful

not to lose Handwheel Pinion Spring (piece #47) and Spring Ring (piece #49).

19. Remove Handwheel shaft: tap on the motor end of the shaft to free Ball Bearing (piece #52-1) from

housing. Handwheel shaft will break free from Ball Bearing (piece #52-6). Remove handwheel shaft

from housing.

20. Withdraw handwheel shaft from handwheel end of housing.

21. To disassemble worm assembly further (removed in Step No. 10), remove Elastic Stop Nut

(piece #16-7), noting the number of turns to remove.

22. Remove Thrust Washers (piece #16-2), Limit Sleeve (piece #16-5), and Belleville Disc Springs

(piece #16-3 and #16-4). Note the orientation of the discs for reassembly later.

23. Remove Retaining Ring (piece #53-4).

24. The Bearing Cartridge (piece #16-1) and Worm Subassembly (piece #30-1) can now be withdrawn.

25. Remove the Ball Bearing (piece #52-7), locate setscrew in bearing locknut and remove setscrew

and Locknut (piece #44-1).

8.1.3 Reassembling Actuator Sizes L120-190, -420 and -800

1. Follow the disassembly instruction for Actuator Sizes 190, 420, and 800 in the reverse order and

follow the gasketing instructions below.

28

2. Stack Belleville disc, thrust washers, and spacers that were removed in the exact order as they were

removed.

3. Re-install Elastic Stop Nut (piece #16-7) with the same number of turns used to remove.

4. For the Worm Shaft Clutch (piece #33), install the clutch with smaller set of lugs first to engage with

lugs on Handwheel Clutch Pinion (piece #20).

Page 29

Limitorque

5. For worm, rotate Worm Shaft Clutch (piece #33) to engage splines on worm shaft. Place actuator

in manual operation, replace Declutch Lever Subassembly (piece #11), and handwheel temporarily;

rotate handwheel in opposite direction used to remove worm.

6. When re-installing the Motor Pinion (piece #31), ensure it fits tightly on the motor shaft (preferably

a light press fit).

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

8.1.4 Gaskets

All gaskets, except the housing cover gaskets, are 1⁄32" thick Anchorite. The housing cover gaskets

vary in thickness. Determine the correct size as follows:

1. Clean both housing cover and main housing gasketed surface.

2. Install actuator drive sleeve assembly complete with bearings.

3. Install housing cover and measure the gap between the housing cover and the main housing.

4. Add 10% to the measurement. Use the closest nominal gasket thickness or combination available.

flowserve.com

29

Page 30

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Figure 8.1 – L120-190 and -420 Drive Sleeve Side View (Refer to Table 8.1 for parts list)

61 60

61-1

64 66

63 65

55-1

3 56-3

39

54-4

55-2

55-5

38

1 54-3 12

55-11

30

37

40

67

8

54-7

Drawing 01-608-0115-4

13

364114

Page 31

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Figure 8.2 – L120-190-and 420 Worm Shaft Side View (Refer to Table 8.1 for parts list)

58 48 56-5 31 55-10

56-13 11 56-7 19 10 42-1

54-9 50 56-6 56-18 56-8 54-1 55-9

55-6

55-7

43 54-8

53-4

56-12

56-10

46 57

56-14

29

9

52-6

52-1

56-9 54-6 53-753-8 18

54-2 16-3 16-2 16-5 16-1 52-7 53-252-8 35 20 47 49 45 33 2 51 27 32 23 28 53-11730-130-2

55-3

4

53-5

44-2

55-4 16-7 16-6 16-4 44-1 56-15 53-3 54-1 52-3 56-11 52-37

5

Drawing 01-608-0116-4

182

31

flowserve.com

Page 32

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

124

34-A

42-5

42-4

56-21

56-20

56-23

54-5

200-2

200-3

300

204

310

305

34-B 15

56-19

26

70-1

70

71

70-2

200-1

Drawing 01-608-0117-4

Figure 8.3 – L120-190 and -420 Top View (Refer to Table 8.1 for parts list)

32

Page 33

Limitorque

Figure 8.4 – L120-800 Drive Sleeve Side View (Refer to Table 8.1 for parts list)

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

1 54-3 8 12 14

3

56-3

54-7

Drawing 01-608-0138-4

40

13

54-4

33

flowserve.com

Page 34

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

55-7

Figure 8.5 – L120-800 Worm Shaft Side View (Refer to Table 8.1 for parts list)

56-5

10

48

56-6

115055-8

56-20

54-1

55-9

55-10

58

56-11

31

56-8

28

53-1

23

32 51 52-3

52-3

2

45 33

56-13 54-9 42-1 34

19 56-7 54-1

54-8

43

55-6

53-4

29

56-12

56-2

9

34

52-6 56-15

53-7 69

1 18 56-10

16-2 16-3 16-1 44-1 16-8 30-1 52-8 7 47 49 20

56-9 54-6 52-1 54-2

44-2 16-5 16-2 44-2 52-7 30-2 17 56-15 53-3

4 44-1

5

56-14

182

Drawing 01-608-0136-4

Page 35

Limitorque

Figure 8.6 – L120-800 Top View (Refer to Table 8.1 for parts list)

55-3

55-4

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

56-23

54-5

6-1

6-2

300

70

56-18

56-2156-25 56-25

56-19

34

34

42-4

42-5

26

15

70-1

68

71

70-2

35

Drawing 01-608-0137-4

flowserve.com

305 310 204 6

Page 36

36

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Table 8.1 – L120-190, -420 and -800 typical parts list

Piece No. Quantity Description Piece No. Quantity Description

1 1 Housing 38 1 Seal Retainer Plate

2 1 Declutch Housing 39 1 Lock Nut

3 1 Housing Cover 40 1 Upper Thrust Bearing Cup

4 1 Spring Cartridge Cap 41 1 Lower Thrust Bearing Cone

5 1 Handwheel 42-1 1 Declutch Fork

6 1 Limit Switch Compartment Cover (L120-800 only) 42-4 2 Fork Roller (L120-420, 800)

6-1 1 Hex Head Cap Screw (L120-800 only) 42-5 2 Fork Roller Pin (L120-420, 800)

6-2 1 Lockwasher (L120-800 only) 43 1 Declutch Lever Plate

7 1 Worm Shaft Bearing Cap (L120-420, 800) 44-1 1 Lock Nut

8 1 Drive Sleeve (2 pc) 44-2 1 Set Screw

9 1 Handwheel Spur Gear 45 1 Clutch Spring

10 1 Declutch Link 46 1 Handwheel Shaft Spacer

11 1 Declutch Lever 47 1 Handwheel Pinion Spring

12 1 Stem Nut 48 1 Extension Spring

13 1 Worm Gear 49 1 Spring Ring

14 1 Lower Thrust Bearing Cup 50 1 Declutch Lever Nameplate

15 1 Fork Pivot Pin (L120-420, 800) 51 1 Worm Shaft Gear Cam Pin

16-1 1 Bearing Cartridge 52-1 1 Ball Bearing (L120-190)

16-2 various Thrust Washer 52-1 1 Bushing (L120-420, 800)

16-3 various Belleville Spring 52-3 2 Motor Clutch Gear Bushing

16-4 various Belleville Spring 52-6 1 Ball Bearing

16-5 1 Torque Limit Sleeve 52-7 1 Ball Bearing

16-6 1 Torque Limit Sleeve 52-8 2 Ball Bearing

16-7 1 Elastic Stop Nut (L120-190 only) 53-1 1 Retaining Ring

16-8 1 Bearing Cartridge Stem (L120-420, 800) 53-2 1 Retaining Ring

17 1 Worm Shaft 53-3 1 Retaining Ring

18 1 Handwheel Shaft 53-4 1 Retaining Ring

19 1 Declutch Shaft 53-5 1 Retaining Ring

20 1 Handwheel Clutch Pinion 53-7 1 Retaining Ring

23 1 Split Ring 53-8 1 Retaining Ring (L120-190 only)

26 1 Motor Conduit Nipple 54-1 2 Declutch Housing Gasket

27 1 Split Ring Retainer 54-2 1 Spring Cartridge Cap Gasket

28 1 Lock Nut 54-3 1 Quad Ring

29 1 Worm Bushing 54-4 1 Quad Ring

30-1 1 Worm 54-5 1 O-Ring

31 1 Motor Pinion 54-6 1 O-Ring (L120-190)

32 1 Worm Shaft Gear 54-6 1 Oil Seal (L120-420, 800)

33 1 Worm Shaft Clutch 54-7 1 O-Ring (L120-190)

34-A 1 Clutch Tripper #1 54-7 1 Gasket (L120-420, 800)

34-B 1 Clutch Tripper #2 54-8 1 O-Ring

35 1 Spring Spacer 54-9 1 Chekseal

36 1 Worm Gear Spacer 55-1 12 Hex Head Cap Screw

37 1 Housing Cover Shim Set 55-2 12 Lockwasher

Page 37

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Table 8.1 Continued – L120-190, -420 and -800 typical parts list

Piece No. Quantity Description Piece No. Quantity Description

55-3 7 Hex Head Cap Screw 56-23 1 Pipe Plug

55-4 various Lockwasher 56-25 2 Dowel Pin (L120-420, 800)

55-5 2 Socket Head Cap Screw 57 1 O-Ring Spacer (L120-190)

55-6 various Hex Head Cap Screw (L120-190, 420) 58 1 Tripper Spring

55-7 various Lockwasher 60 1 Terminal Bracket

55-8 2 Drive Screw 61 2 Terminal Strip

55-9 4 Hex Head Cap Screw 61-1 2 Kulka Insulator Strip

55-10 4 Lockwasher 63 2 Fil HD Mach Screw

55-11 2 Lockwasher (L120-190) 64 2 Lockwasher

56-2 various Pipe Plug 65 8 RD HD Mach Screw

56-3 1 Grease Fitting 66 8 Lockwasher

56-5 1 Clevis Pin 67 1 Upper Thrust Bearing Cone

56-6 1 Key 68 2 Fork Spacer (L120-420, 800)

56-7 1 Key 69 1 Handwheel Bearing Cap (L120-420, 800)

56-8 1 Key 70 1 Hinge

56-9 1 Socket Head Set Screw 70-1 various Hex Head Cap Screw

56-10 1 Key 70-2 various Lockwasher

56-11 1 Flat Washer (L120-190) 71 1 Hinge Standard Compartment

56-11 1 Socket Head Set Screw (L120-420, 800) 124 1 Motor

56-12 1 Flat Washer 182 1 Handwheel Spinner Kit

56-13 1 Socket Head Set Screw 200-1 1 Limit Switch Compartment Cover (L120-190, 420)

56-14 1 Key 200-2 various Hex Head Cap Screw (L120-190, 420)

56-15 various Socket Head Cap Screw 200-3 various Lockwasher (L120-190, 420)

56-18 various Socket Head Cap Screw 204 1 M.D.P.I. Sight Glass

56-19 1 Socket Head Set Screw 300 1 Torque Switch

56-20 4 Socket Head Set Screw 305 1 Geared Limit Switch

56-21 4 Lockwasher 310 1 Mechanical Dial Position Indicator

flowserve.com

37

Page 38

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

8.2 L120-2000

c WARNING: See sections 5.1 and 5.2 Safety Precautions and Safety Practices.

NOTE: The L120-2000 Drive 2 is a thrust-type actuator consisting of an L120-2000 Drive 1 torque-type

actuator mounted on a thrust bearing assembly. For torque-only actuators see Section 8.2.2, Drive 1

Disassembly (Torque Housing).

NOTE: Piece numbers refer to Figures 8.7 - 8.10.

8.2.1 Drive 2 Disassembly (Thrust Housing Only)

c WARNING: Before proceeding, ensure that the actuator is not under load and that the valve is

not under pressure. If so, the valve must be in fully open position.

Remove Drive Sleeve Locknut (piece #130):

1. Rotate handwheel to close valve, causing the Stem Nut (piece #127) to rise up threaded valve stem

until the stem nut splines are free of Drive Sleeve (piece #126).

2. Rotate stem nut by hand for the remaining length of the valve stem and remove.

Remove Thrust Adapter (piece #125):

NOTE: If disassembly of thrust adapter assembly is not required, continue to Section 8.2.2, Drive 1

(Torque Actuator), Step No. 1.

1. Remove Seal Retainer Plate (piece #129) and Oil Seal (piece #54-6).

2. Loosen setscrew and remove Thrust Bearing Cartridge (piece #128) from the Thrust Adapter

Housing (piece #125).

3. Remove Upper Bearing Roller Assembly (piece #131).

4. Lift Thrust Drive Sleeve (piece #126) out of Thrust Adapter Housing (piece #125).

5. Remove Lower Bearing Roller Assembly (piece #131).

8.2.2 Drive 1 Disassembly (Torque Housing)

1. Remove Limit Switch Compartment (piece #200-1).

2. Disconnect motor leads, Torque Switch (piece #301) leads, and Geared Limit Switch (piece #305)

leads.

NOTE: Ensure leads are labeled for reassembly.

38

3. Remove screws holding Limit Switch and holding Torque Switch. Remove both items.

4. Remove bolts holding Motor.

5. Remove Motor Adapter (piece #22) and Motor Adapter Gasket (piece #105). Remove motor gear

shims from the motor adapter bearing bores and store in a safe place.

6. Remove Intermediate Pinion (piece #32-1) and the Drive Shaft Gear (piece #32-2).

7. Remove torque switch and geared limit switch.

Page 39

Limitorque

8. Using lifting eyebolts, remove Housing Cover (piece #3), Drive Sleeve (piece #8), and Worm Gear

(piece #13).

9. Remove Handwheel Washer (piece #88). Pull off Handwheel (piece #5) and Handwheel Clutch

(piece #83) from Handwheel Shaft (piece #18).

10. Remove Worm Shaft End Cap (piece #4) and Declutch Housing Cover (piece #86).

11. Remove Declutch Assembly:

A. Remove Declutch Lever Stop (piece #93), Tripper Spring (piece #58), Clutch Trippers

(piece #34-A and #34-B) and Roll Pin (piece #19-7).

B. Loosen setscrews on Declutch Lever (piece #11) and Hallowell Collar (piece #56-8). Remove

declutch lever, Declutch Shaft and Cap (piece #95), and slide Declutch Shaft (piece #19-1) out

through bottom of actuator.

C. Remove Declutch Lever (piece #11), and other Declutch Shaft-Mounted Components

(piece #19-2, #91, #92, and #56-8).

D. Remove Handwheel Shaft and Pinion (piece #18).

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

12. Remove Drive Shaft (piece #77) and Flexible Jaw Clutch (piece #82-1) as integral assembly.

Remove Gear Clutch Spacer (piece #78), Sliding Gear Clutch (piece #33), and Clutch Compression

Spring (piece #46).

13. Remove Splined Insert (piece #87) using jack screws. Remove Spirolox Ring (piece #53-3) and

Handwheel Gear (piece #9).

14. Remove Gear Mounting Bracket (piece #84) using jack screws, Bearing (piece #52-7), and Bearing

Adapter (piece #79).

15. Pull Hollow Drive Shaft (piece #17) toward declutch end and remove Spirolox Ring (piece #53-8).

16. Remove Declutch Housing (piece #2).

17. Remove Hollow Drive Shaft (piece #17):

A. Push hollow drive shaft toward motor end. Loosen setscrew and remove Bearing Locknut

(piece #80-1) – hold hollow drive shaft using adjustable spanner on splines.

B. Remove Bearing (piece #52 -8) by pushing hollow drive shaft toward declutch end.

C. Remove Gear Limit Thread Collar (piece #76) and key.

D. Remove hollow drive shaft from declutch end of actuator.

18. Loosen setscrew in Cartridge Stem Locking Nut (piece #16-10) and replace Declutch Housing

(piece #2) with two screws to compress torque spring.

19. Remove Locking Nut (piece #16-10).

a CAUTION: Declutch Housing is under spring load.

20. Remove Declutch Housing (piece #2):

A. Pull Bearing Cartridge Stem (piece #16-8) out partially.

B. Remove Thrust Washers (piece #16-2), Torque Limit Sleeve (piece #16-5) and Springs

(piece #16-3).

39

flowserve.com

Page 40

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

21. Remove bearing cartridge/worm assembly from actuator. To disassemble further:

A. Loosen two setscrews on Bearing Cartridge Cap (piece #16-1), and unscrew Bearing Cartridge

Stem (piece #16-8).

B. Slide bearing cartridge cap off toward worm threads.

C. Loosen setscrew and remove Bearing Locknut (piece #44-1).

D. Press off two Bearings (piece #73).

8.2.3 Drive 1 (Torque Housing) Reassembly

1. Press two Bearings (piece #73) onto worm. It may be necessary to apply heat to the bearings.

Ensure that the bearing spacer is installed.

2. Install Bearing Lock Nut (piece #44-1) and tighten screw.

3. Apply head to Bearing Cartridge Cap (piece #16-1) and drop on bearing from worm end. Ensure that

cartridge cap seats on bearing.

4. Install bearing cartridge/worm assembly in housing.

5. Replace the following in the order listed:

A. Thrust Washer (piece #16-2)

B. Belleville Springs (piece #16-3)

C. Torque Limit Sleeve (piece #16-5)

D. Thrust Washer (piece #16-2)

Ensure flat side of thrust washer is against springs.

6. Thread Cartridge Stem Nut (piece #16-10) onto Bearing Cartridge Stem (piece #16-8) by hand.

7. Slide bearing cartridge/worm assembly into housing.

8. Install Hollow Drive Shaft (piece #17).

9. Install Gear Limit Threaded Collar (piece #76) and key on motor end of hollow drive shaft with

threaded end toward worm.

10. Slide Bearing (piece #52-8) onto shaft.

11. Thread Bearing Locknut (piece #81-1) on shaft and tighten setscrew. Hold Drive Shaft using adjustable spanner on splines.

12. Re-install motor as follows:

A. Push Hollow Drive Shaft (piece #17) to declutch and install Bearing Spacer (piece #101).

40

B. Install motor gearing by meshing Drive Shaft Gear (piece #32-2) and Intermediate Pinion

(piece #32-1) and pressing combined assembly into housing bores.

C. Install motor gear shims in motor adapter bearing bores and install Motor Adapter Gasket

(piece #105) and Motor Adapter (piece #22). Tap adapter to ensure bearings seat.

D. Check intermediate pinion and shaft for proper shims.

E. Install motor.

Page 41

Limitorque

13. Re-install declutch housing as follows:

A. Install Spirolox Ring (piece #53-8) on Hollow Drive Shaft (piece #17).

B. Install Declutch Housing (piece #2) using two screws only to compress Belleville Spring Set

(piece #16-3).

C. Using two screws, thread Cartridge Stem Nut (piece #16-10) on Bearing Cartridge Stem

(piece #16-8) until nut is snug against Thrust Washer (piece #16-2).

D. Re-install declutch housing.

14. Install Bearing Mounting Bracket Assembly (piece #84, 79, and 52-7).

15. Install Handwheel Gear (piece #9) and Spirolox Ring (piece #53-8).

16. Install Splined Insert (piece #87), Spring Washer (piece #49) and Clutch Compression Spring

(piece #46).

17. Install Sliding Gear Clutch (piece #33) onto Hollow Drive Shaft Splines (piece #17).

18. Install Drive Shaft (piece #77), ensuring that Gear Clutch Spacer (piece #78) is in place. Align

splines on drive shaft and drive shaft gear and push drive shaft into actuator from declutch end.

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

19. Mount Bearing (piece #52-6 and #52-1) on Handwheel Shaft and Pinion (piece #18) and install

assembly into actuator.

20. Install Declutch Shaft (piece #19-1) and Torsion Spring (piece #94) into Declutch Cap (piece #95).

21. Install declutch shaft assembly through bottom of Declutch Housing (piece #2). Declutch shaft

assembly consists of:

• Declutch Shaft

• Declutch Shaft Washers (piece #91, 3 pieces)

• Torsion Spring

• Declutch Fork (piece #42-1)

• Declutch Cap

• Declutch Spacer (piece #92)

• Declutch Lever Drum (piece #19-3)

• Hallowell Collar (piece #56-8)

• Declutch Arm (piece #19-2)

NOTE: Declutch shaft must be installed with key seat facing right side of the declutch housing when

viewed from declutch end of actuator.

22. Fasten declutch cap.

23. Insert Roll Pin (piece #19-7) through declutch arm and shaft.

24. Ensure that declutch shaft bears against declutch cap, push collar against top of housing, and

tighten collar setscrew.

25. Ensure that Oil Seal (piece #54-8) is in place.

26. Install Declutch Lever (piece #11) and tighten setscrew.

27. Rotate declutch lever clockwise, hold in position, and install Declutch Lever Stop (piece #93).

41

flowserve.com

Page 42

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

28. Install Clutch Tripper (piece #34-A, 34-B) and Tripper Spring (piece #58).

29. Install Declutch Housing Cover (piece #3) and Declutch Cover Gasket (piece #54-11).

30. Ensure that Handwheel Oil Seal (piece #54-8) is in place.

31. Install Worm Shaft End Cap (piece #4) and Worm Shaft End Cap Gaskets (piece #54-2).

NOTE: Ensure that the same number of gaskets is installed as were removed during disassembly.

Thickness of gaskets must be sufficient to prevent end cap from bearing on drive shaft.

32. Install Worm Gear (piece #13).

33. Install Torque Drive Sleeve (piece #8) and Drive Sleeve Thrust Bearing (piece #40).

34. Apply fresh, clean lubricant in actuator housing. For quantity see Section 7.1, Lubrication.

35. Install Housing Cover Gasket (piece #54-7) and Housing Cover (piece #3).

36. Install Handwheel Clutch (piece #83), Handwheel (piece #5), and Handwheel Washer (piece #88) on

Handwheel Shaft and Pinion (piece #18).

37. Install Torque Switch (piece #301) and Geared Limit Switch (piece #305).

38. Connect motor leads and leads to torque switch and geared limit switch.

8.2.4 Drive 2 (Thrust Housing Only) Reassembly

1. If Thrust Adapter Assembly (piece #125) is not disassembled, go to Step No. 7.

NOTE: Thrust bearing races should be pressed on Thrust Drive Sleeve (piece #126), in Thrust

Adapter Housing (piece #125), and Thrust Bearing Cartridge (piece #128) prior to beginning

assembly procedure.

2. Install Lower Bearing Roller Assembly (piece #131) in Thrust Adapter Housing (piece #125).

3. Install short end of Thrust Drive Sleeve (piece #126) into Thrust Adapter Housing (piece #125).

4. Install Upper Bearing Roller Assembly (piece #131) on the Thrust Drive Sleeve (piece #126).

5. Install Thrust Bearing Cartridge (piece #128), thread tight, or until drag is felt on thrust drive sleeve

and tighten screw.

6. Install Oil Seal (piece #54-6) and Seal Retainer Plate (piece #129).

7. Lift actuator or turn upside down. Install Housing Thrust Adapter Assembly (piece #125). Ensure

that Thrust Drive Sleeve O-Ring (piece #134) is in place.

8. Install Stem Nut (piece #127).

9. Install Drive Sleeve Locknut (piece #130) and crimp or stake the top threads to two places.

42

c WARNING: Drive sleeve locknut has left-hand threads and must be rotated counterclockwise.

Page 43

Limitorque

Figure 8.7 – L120-2000 Drive Sleeve Side View (Refer to Table 8.2 for parts list)

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Drawing 01-608-0141-4_2of3

43

flowserve.com

Page 44

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Drawing 01-413-0036-4

Figure 8.8 -L120-2000 Top View (Refer to Table 8.2 for parts list)

5

88

82-2

4

54-2

82-3

80-1

82-7

82-4

182

83

54-6

52-1

56-13

86

54-11

11

18

52-6

2

54-1

44-1

41

73

52-1

82-1

82-6

78

33

87

53-3

85 89

46

952-7

49

84

79

53-8

16-10

16-2

16-3

16-8

16-1

16-5

16-2

30-2

30-1

44

305 200-1

52-8

81-1

81-2

101

70

31-2

17

76

56-7

32-1

32-1

31-2

52-9

Drawing 01-413-0036-4

52-8

Motor

77

22

162

105

Page 45

Limitorque

Figure 8.9 – L120-2000 Side View (Refer to Table 8.2 for parts list)

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Drawing 01-608-0141-4_3of3

45

flowserve.com

Page 46

Figure 8.10 - L120-2000 Exploded View

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

46

Drawing 08-408-0002-4

Page 47

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Table 8.2 - L120-2000 typical parts list

Piece No. Quantity Description Piece No. Quantity Description

1 1 Housing 50 1 Declutch Lever Nameplate

2 1 Declutch Housing 52-1 1 Ball Bearing

3 1 Housing Cover 52-6 1 Handwheel Shaft Bearing

4 1 Worm Shaft End Cap 52-7 1 Ball Bearing

5 1 Handwheel 52-8 1 Ball Bearing

8 1 Drive Sleeve 52-9 1 Ball Bearing

9 1 Handwheel Gear 53-3 1 Spirolox Ring

11 1 Declutch Lever 53-8 1 Spirolox Ring

13 1 Worm Gear 53-9 1 Retaining Ring

14 1 Bearing Cup 54-1 1 Declutch Housing Gasket

16-1 1 Bearing Cartridge Cap 54-2 2 Worm Shaft End Cap Gasket

16-2 2 Thrust Washer 54-3 1 Quad Ring

16-3 various Belleville Spring 54-5 1 O-Ring

16-5 1 Torque Limit Sleeve 54-6 1 Oil Seal

16-8 1 Bearing Cartridge Stem 54-7 3 Housing Cover Gasket

16-10 1 Cartridge Stem Locking Nut 54-8 1 Oil Seal

17 1 Hollow Drive Shaft 54-10 1 Declutch Cap Gasket

18 1 Handwheel Shaft and Pinion 54-11 1 Declutch Cover Gasket

19-1 1 Declutch Shaft 55-1 1 Hex Head Cap Screw

19-2 1 Declutch Arm 55-2 1 Lockwasher

19-3 1 Declutch Shaft Drum 55-3 1 Welsh Plug

19-5 1 Groove Pin 55-4 1 Soc Head Set Screw

19-6 1 Roll Pin 55-5 1 Lockwasher

19-7 1 Roll Pin 55-6 1 Soc Head Set Screw

22 1 Motor Adapter 55-7 1 Lockwasher

30-1 1 Worm 55-8 1 Soc Head Set Screw

30-2 1 Worm Bushing 55-9 1 Lockwasher

31-1 1 Motor Pinion 55-10 1 Jam Nut

31-2 1 Intermediate Gear 55-11 1 Flat Head Mach Screw

32-1 1 Intermediate Pinion 55-12 1 Soc Head Set Screw

32-2 1 Output Worm Shaft Gear 55-14 1 Lockwasher

33 1 Sliding Gear Clutch 55-15 1 Drive Screw

34-A 1 Clutch Tripper 56-5 1 Grease Fitting

34-B 1 Clutch Tripper 56-7 1 Key

36 1 Worm Gear Spacer 56-8 1 Hallowel Collar

37 1 Shim Set Bearing 56-9 1 Soc Head Set Screw

40 1 Bearing Cup 56-10 1 Lockwasher

41 1 Bearing Cone 56-12 1 Soc Head Set Screw

42-1 1 Declutch Fork 56-13 2 Tripper Bolt

42-4 1 Fork Roller 56-15 1 Key

42-5 1 Roller Pinion 56-16 1 Key

44-1 1 Bearing Locknut 56-17 1 Soc Head Set Screw

46 1 Clutch Compression Spring 56-20 1 Soc Head Set Screw

49 1 Spring Washer 56-21 1 Soc Head Set Screw

47

flowserve.com

Page 48

Limitorque® L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Table 8.2 Continued - L120-2000 typical parts list

Piece No. Quantity Description Piece No. Quantity Description

58 1 Tripper Spring 102 1 Gear Insert

70 1 Hinge 103 1 Split Ring

70-1 1 Hex Head Cap Screw 104 1 Retaining Ring

70-2 1 Lockwasher 105 1 Motor Adaptor Gasket

73 2 Bearing Cup 106 1 Hex Head Cap Screw

76 1 Gear Limit Threaded Collar 107 1 Lockwasher

77 1 Solid Drive Shaft 114 1 Hex Head Cap Screw

78 1 Gear Clutch Spacer 122 1 Thrust Drive Sleeve

79 1 Bearing Adapter 125 1 Thrust Adapter Housing

80-1 1 Bearing Locknut 126 1 Thrust Drive Sleeve

81-1 1 Bearing Locknut 127 1 Stem Nut

81-2 1 Bearing Locknut 128 1 Bearing Cartridge

82-1 1 Flexible Jaw Clutch Housing 129 1 Seal Retainer Plate

82-2 1 Motor Clutch Gear Cam Pin 130 1 Drive Sleeve Locknut

82-3 1 Flexible Jaw Clutch Sleeve 131 1 Bearing Roller Assembly

82-4 1 Nylon Insert 132 1 Oil Seal

82-5 1 Nylon Insert 133 1 Grease Fitting

82-6 6 Clutch Sleeve Insert 134 1 O-Ring

82-7 1 Flexible Jaw Clutch Collar 135 1 Housing Thrust Adapter Gasket

83 1 Handwheel Clutch 136 1 Hex Head Cap Screw

84 1 Gear Mounting Bracket 137 1 Lockwasher

85 1 Handwheel Gear Bushing 138 1 Soc Head Set Screw

86 1 Declutch Housing Cover 139 1 Soc Head Set Screw

87 1 Splined Insert 140 1 Seal Retainer Sleeve

88 1 Handwheel Washer 141 1 Lockwasher

89 1 Handwheel Gear Spacer 162 1 Motor Adapter Gasket

90 1 Stop Stud 182 1 Handwheel Spinner Kit

91 3 Declutch Shaft Washer 200-1 1 Limit Switch Compartment Cover

92 1 Declutch Shaft Spacer 200-2 1 Hex Head Cap Screw

93 1 Declutch Lever Stop 200-3 1 Lockwasher

94 1 Torsion Spring 301 1 Torque Switch

95 1 Declutch Cap 305 1 Geared Limit Switch

101 1 Bearing Spacer

48

Page 49

9

Limitorque

®

L120-190 through L120-2000 FCD LMENIM1203-00 – 10/11

Standard Wiring Diagrams

Figure 9.1 – Wiring Diagram – No Controls

00000

0 30 0

INDICATION

OPEN CIRCUIT

CLOSE CIRCUIT

HEATERS

VALVE POSITION

A B

0

0

0

T1

T2

T3

22

CL1

4

8

H

(4)

(8) (8C)

FULLY

CLOSED

4

(4C)

8

MOTOR

TH.OL

7

(7C)

(7)

3

(3)

(3C)

18

18 18C

(18C)

(18)

(5)

5

17

17

(17)

(17C)

(1

1

JUMPER

SEE NOTE#4

COMP HTR

MTR HTR

FUNCTION

BY-PASS CIR

SPARE

INDICATION

OPEN LIMIT

BY-PASS CIR

SPARE

INDICATION

CLOSE LIMIT

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

CL2

7C

3C

(5C)

17C

(1C)

H2

105161A

THERMAL OVERLOAD CONTACTS

.VALVE SHOWN IN FULL OPEN POSITION

LIMIT SWITCH CONTACT DEVELOPMENT

ROTOR

FULLY

OPEN

CONTACT

1

2

OPEN

3

4

5

6

CLOSE

7

8

9

0

1

INT.1

11

12

13

14

INT.2

15

16