Page 1

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

ARG Series Standard Actuator

Jackscrew Override

USER INSTRUCTIONS

Sandwich Gearbox Override

Hydraulic Override

FCD ACENIM0123-00 12/12

Installation

Operation

Maintenance

Experience In Motion

Worchester Controls

1

Page 2

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

STOP!

®

INDEX

1 Using Flowserve valves, actuators and acces-

sories correctly

2 Jackscrew Override

2.2 Install jackscrew override onto heavy duty DA

actuator

2.3 install jackscrew override onto existing heavy

duty SR actuator

2.4 Operation –Jackscrew Override

2.5 Automatic Operation

3 Gear Override

3.2 Retrofit Gear Override onto Existing ARG Actuator Installation

3.3 Mount a Preassembled Actuator

3.4 Operation

3.5 Restoring Automatic Operation

4 Hydraulic Override

4.2 Install hydraulic override onto existing heavy

duty Spring Return actuator

4.3 Operation –SR Override

4.4 Install hydraulic override on Standard DA

heavy duty actuator

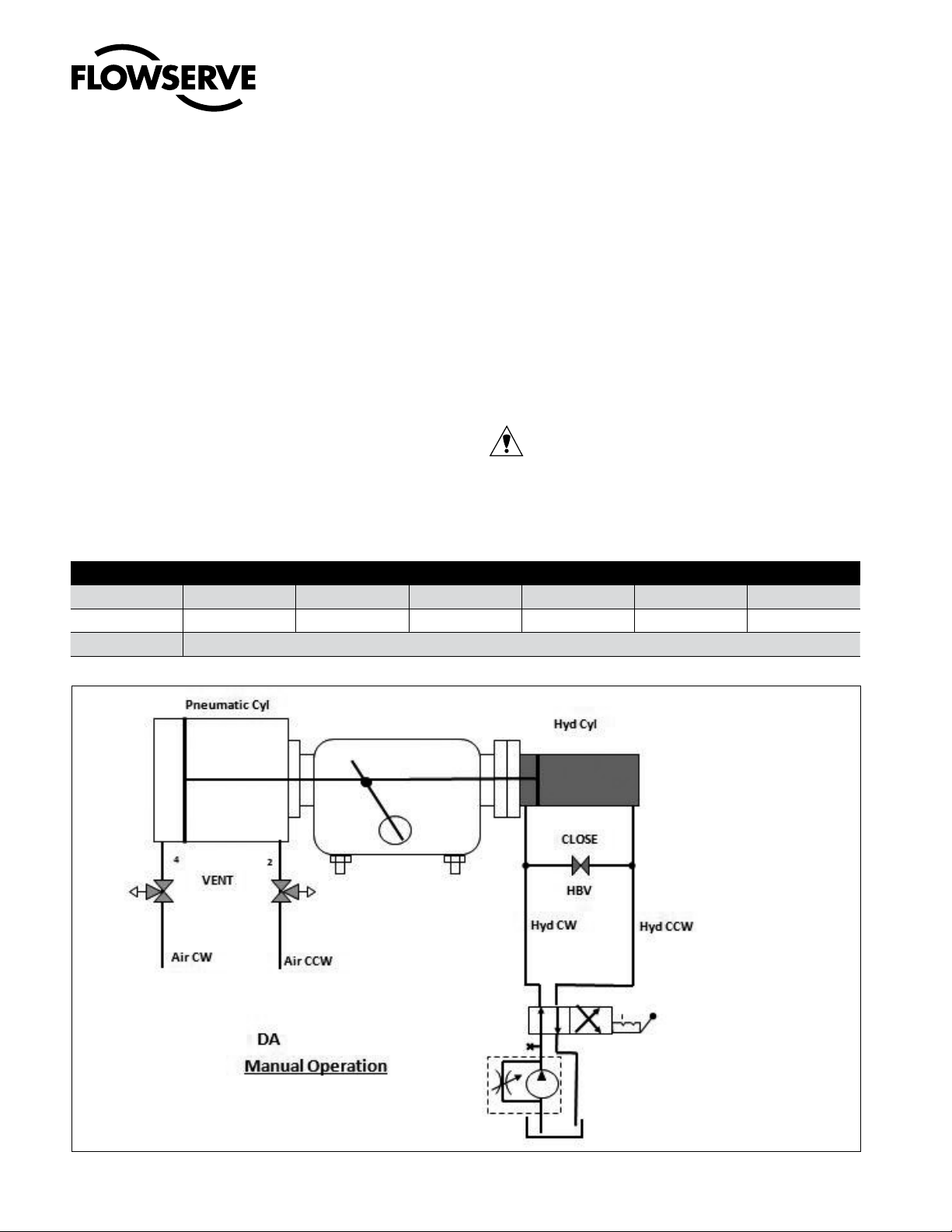

4.5 Operation –DA Override

1 Using Flowserve Valves, Actuators and Acces-

sories Correctly

1.1 General usage

The following instructions are designed to assist in

unpacking, installing and performing maintenance

as required on FLOWSERVE products. Product users and maintenance personnel should thoroughly

review this bulletin prior to installing, operating or

performing any maintenance.

In most cases FLOWSERVE valves, actuators and

accessories are designed for specific applications

with regard to medium, pressure and temperature.

For this reason they should not be used in other applications without first contacting the manufacturer.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAUTION

and NOTE are used in these instructions to highlight

particular dangers and/or to provide additional information on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury

and/or substantial property damage will occur if proper

precautions are not taken.

WARNING: indicates that death, severe personal

injury and/or substantial property damage can occur

if proper precautions are not taken.

CAUTION: indicates that minor personal injury and/

or property damage can occur if proper precautions

are not taken.

NOTE: indicates and provides additional technical

information, which may not be very obvious even to

qualified personnel.

Compliance with other, not particularly emphasised

notes, with regard to transport, assembly, operation

and maintenance and with regard to technical documentation (e.g. in the operating instruction, product

documentation or on the product itself) is essential,

in order to avoid faults, which in themselves might

directly or indirectly cause severe personal injury or

property damage.

1.3 Protective clothing

FLOWSERVE products are often used in problematic

applications (e.g. extremely high pressures, dangerous, toxic or corrosive mediums). In particular valves

with bellows seals point to such applications. When

performing service, inspection or repair operations

always ensure, that the valve and actuator are depressurised and that the valve has been cleaned and is free

from harmful substances. In such cases pay particular

attention to personal protection (protective clothing,

gloves, glasses etc.).

1.4 Qualified personnel

Qualified personnel are people who, on account of their

training, experience and instruction and their knowledge of relevant standards, specifications, accident

prevention regulations and operating conditions, have

been authorised by those responsible for the safety of

the plant to perform the necessary work and who can

recognise and avoid possible dangers.

2

Page 3

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

STOP!

®

1.5 Installation

DANGER: Before installation check the order-no.,

serial-no. and/or the tag-no. to ensure that the valve/

actuator is correct for the intended application.

Do not insulate extensions that are provided for hot

or cold services.

Pipelines must be correctly aligned to ensure that the

valve is not fitted under tension.

Fire protection must be provided by the user.

1.6 Spare parts

Use on l y FLOWS E R V E origin a l spare parts.

FLOWSERVE cannot accept responsibility for any

damages that occur from using spare parts or fastening materials from other manufactures. If FLOWSERVE

products (especially sealing materials) have been on

store for longer periods check these for corrosion or

deterioration before using these products. Fire protection for FLOWSERVE products must be provided by

the end user.

1.7 Service / repair

To avoid possible injury to personnel or damage to

products, safety terms must be strictly adhered to.

Modifying this product, substituting nonfactory parts,

or using maintenance procedures other than outlined

in this instruction could drastically affect performance

and be hazardous to personnel and equipment, and

may void existing warranties. Between actuator

and valve there are moving parts. To avoid injury

FLOWSERVE provides pinch-point-protection in the

form of cover plates, especially where side-mounted

positioners are fitted. If these plates are removed

for inspection, service or repair special attention is

required. After completing work the cover plates must

be refitted.

1.8 Storage

In most cases FLOWSERVE products are manufactured

from stainless steel. Products not manufactured from

stainless steel are provided with an epoxy resin

coating. This means that FLOWSERVE products

are well protected from corrosion. Nevertheless

FLOWSERVE products must be stored adequately

in a clean, dry environment. Plastic caps are fitted

to protect the flange faces to prevent the ingress of

foreign materials. These caps should not be removed

until the valve is actually mounted into the system.

1.9 Valve and actuator variations

These instructions cannot claim to cover all details of

all possible product variations, nor can they provide

information for every possible example of installation,

operation or maintenance. This means that the

instructions normally include only the directions to

be followed by qualified personal where the product

is being used for is defined purpose. If there are any

uncertainties in this respect particularly in the event

of missing product-related information, clarification

must be obtained via the appropriate FLOWSERVE

sales office.

1.10 Unpacking

Each delivery includes a packing slip. When unpacking,

check all delivered valves and accessories using this

packing slip.

Report transport damage to the carrier immediately.

In case of discrepancies, contact your nearest

FLOWSERVE location.

Apart from the operating instructions and the

obligatory accident prevention directives valid in the

country of use, all recognised regulations for safety

and good engineering practices must be followed.

WARNING: Before produ c ts ar e re t urned to

FLOWSERVE for repair or service FLOWSERVE must

be provided with a certificate which confirms that

the product has been decontaminated and is clean.

FLOWSERVE will not accept deliveries if a certificate

has not been provided (a form can be obtained from

FLOWSERVE).

3

Page 4

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

2 Heavy Duty Jackscrew Overrides

Jackscrew overrides on Worchester Controls heavy duty actuators provide economical, durable method for manually

operating the actuator. The jackscrews are either direct operating or bevel gearbox driven, to reduce operation effort. The

direct operation consists of a rotating screw, threading into

the nut which is fitted on the Torque module/ Spring module,

and the hand wheel directly turns the screw.

The bevel gearbox driven jackscrew, has an arrangement of

rotating nut and a rising screw. The higher thrust requirements for models bigger than 4000 Nm and for the stiffer

springs are met with this type of jackscrew design.

Jackscrews are available on models ARG1 through ARG5.

2.1 Installation

worchester Controls standard jackscrew overrides are provided as a complete integral component of the heavy duty

actuator. Override units are shipped with the jackscrew assembly mounted to the actuator and vent valves installed on

the pressure module. No additional customer installation is

required. Refer Worchester Controls Heavy Duty IOM (FCD

AXENIM0121) for instructions on installing Heavy Duty actuator into service.

end flange, locating the spigot in the Torque module.

2.2.4 Use the jackscrew mounting kit and the O-ring from

the DA cover.

2.2.5 Tighten the mounting stud nuts fully, with lock washers from the kit.

2.2.6 Fix the 3 way vent valves supplied in the kit, to both

ports of the pressure module and connect air supply

pressure lines to these valves.

2.2.7 Installation of pressure module side jackscrew requires replacement of std end plate of the pressure

module. Remove tie rod nuts and end plate, and fit in

the jackscrew assembly, supplied preassembled with

the suitable thrust base End Plate. Tighten the tie rod

nuts back on the pressure module. Fix the 3way valve

on the ports.

2.3 Install jackscrew override onto existing heavy

duty SR actuator (see Fig.: 2)

2.3.1 Disconnect air pressure and electrical power from actuator.

2.2 Install jackscrew override onto heavy duty DA

actuator (see Fig.: 1)

2.2.1 Disconnect air pressure and electrical power from actuator.

2.2.2 Remove the DA end cover plate.

2.2.3 Back off the jackscrew fully in the assembly and

mount the jackscrew assembly on the torque module

2.3.2 Remove the end cover plate on the Spring module, retaining the cover O-ring.

2.3.3 Tighten the mounting studs from the mounting kit with

thread lock compound into the spring module end

plate.

2.3.4 Back off the jackscrew fully in the assembly and mount

the jackscrew assembly on the spring module end

plate’s thrust base, locating the spigot in the spring

4

Fig.: 1 Install Jackscrew Override (DA)

Page 5

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

Fig.: 2 Install Jackscrew Override (SR)

module end plate.

2.3.5 Locate the jackscrew nut or the spool (for bevel gearbox jackscrews) into the studs and tighten the nuts

fully, with lock washers from the kit.

2.3.6 Fix a 3 way valve, to the pressure module’s rod end

side port and connect air supply pressure line to it, see

fig.

2.4 Operation –Jackscrew Override

2.4.1 To test / operate the override, turn the 3 way valves to

shut off air supply and vent the cylinder ports.

sure module would be required for this.

2.5 Automatic Operation

2.5.1 Operate hand wheel counterclockwise to completely

retract the jackscrews and lock the position with the

locknut on the jackscrew.

2.5.2 Turn the 3way valves on the pressure module to connect to air supply.

2.5.3 Operate actuator normally on supply pressure.

2.4.2 Turning the hand wheel clockwise advances the screw

into the torque / spring module for DA/SR models.

2.4.3 Resistance will be felt when the thrust head of the

jackscrew touches the guide block face in case of DA

actuator or on the Pull Rod hex end, in case of the SR

model.

2.4.4 Tightening the hand wheel further clockwise will cause

the guide block to move against the resistance from

the valve/ spring and effect the override function.

NOTE: In case of SR jackscrew, the spring constantly

loads the screw, and returns the actuator to fail safe

state when the jackscrew is retracted. But in case of

DA models, the jackscrew on torque module retracts

free of load and does not move the actuator in the

other direction. An additional jackscrew on the pres-

5

Page 6

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

3 Heavy Duty Gear Overrides

Gear overrides on Worchester Controls ARG series heavy duty

actuators are available for models ARG1 through ARG5 providing a convenient and safe method for manually operating the

actuator, in event of supply failure. These are declutchable for

efficient, automatic operation. The gear override consists of a

declutchable gearbox mounted below the actuator, and is positioned between the ARG series actuator and the valve/damper to

be actuated.

Any accessories, such as limit switches and positioners, are not

disturbed and continue to be mounted on the NAMUR mounting

drive, on top side of the actuator.

The gear override is designed for the full rated torque of the

actuator and has an identical ISO base and bolting patterned, as

the actuator.

NOTE: In the event that needs the actuator to be removed

from the valve for maintenance or repair, the gearbox

can be left mounted on the valve, to allow manual operation.

3.1 Installation

bore of the actuator, aligning the keys on the shaft to the

keyways in the Yoke bore. Declutch the manual gearbox

(see instructions on gear box to disengage lock pin and

disengage the worm shaft).

3.2.6 Seat the actuator fully on the override gearbox flange and

thread in the Nuts with Lock washers from the Mounting

Kit, from below the mounting flange. Torque the Nuts to

rated torque for the Nut size.

3.2.7 Now this assembly is mounted on the valve stem or on

the bracket and coupler shaft, the way the actuator was

seated.

3.2.8 Bolt up the Gear drive mounting with the fasteners removed from the actuator-valve mounting.

3.2.9 Fit the 3 way valves to pressure module, per schematic

(see Figs. on page 5).

NOTE: After mounting actuator to valve, the gear over-

ride travel stops must be set. First make sure that the

actuator travel stops are set correctly. Then set the

gear override travel stops to the same position.

Worchester Controls standard sandwich gear overrides are provided as a modular component of the heavy duty actuator. Gear

override units are shipped with the gear mounted to the actuator. The vent valves are installed on the pressure cylinder. No

additional customer installation is required. Refer Worchester

Controls Heavy Duty ARG series IOM (FCD ACENIM0121) for

instructions on installing Heavy Duty actuator into service.

3.2 Retrofit gear override onto existing ARG actuator installation

3.2.1 Disconnect air pressure and electrical power from actuator and dismount the actuator from valve/mounting

bracket.

3.2.2 Thread in fully, the studs from the Gear Override Mounting Kit, into the mounting base of the removed actuator.

3.2.3 Orient the manual override gear to the fail safe position

of the actuator, if actuator is spring return model, or else

bring both the actuator and the gear to the same position, say Clockwise end. Back off the gearbox’s travel

stops.

3.2.4 The coupler shaft is fitted into and supplied with the

gearbox. The coupler shaft bottoms out on the step/

circlip inside the gear bore, preventing it from sliding

through the gear bore.

3.2.5 Mount the actuator on to the coupler shaft, into the yoke

3.3 Mount a preassembled actuator- gear override

assembly on the valve, a mounting bracket and

a Coupler/ Adaptor shaft is required with the

mounting kit.

3.3.1 Fix the mounting bracket on to the valve with the fasteners from the mounting kit.

3.3.2 Locate the Coupler/Adaptor shaft supplied, on the valve

stem and lock to the stem.

3.3.3 Orient the actuator and the valve to same position, usually the fail safe condition of the actuator for SR/SO models and full clockwise end, for DA models.

3.3.4 Disengage the worm shaft from the worm wheel of the

override gearbox (see declutching instructions on the

override gearbox).Back off the override gearbox’s travel

stops.

3.3.5 Now mount the actuator-override gearbox assembly on

the coupler shaft, aligning the keys into the keyways in

the gear bore. Seat the actuator assembly on the bracket

and fasten with the mounting bolts.

3.3.6 Set the Actuator’s travel stops to the position required by

the valve.

3.3.7 Set the override gearbox’s travel stops to the same position as the actuator, and lock the setting.

6

Page 7

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

7

Page 8

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

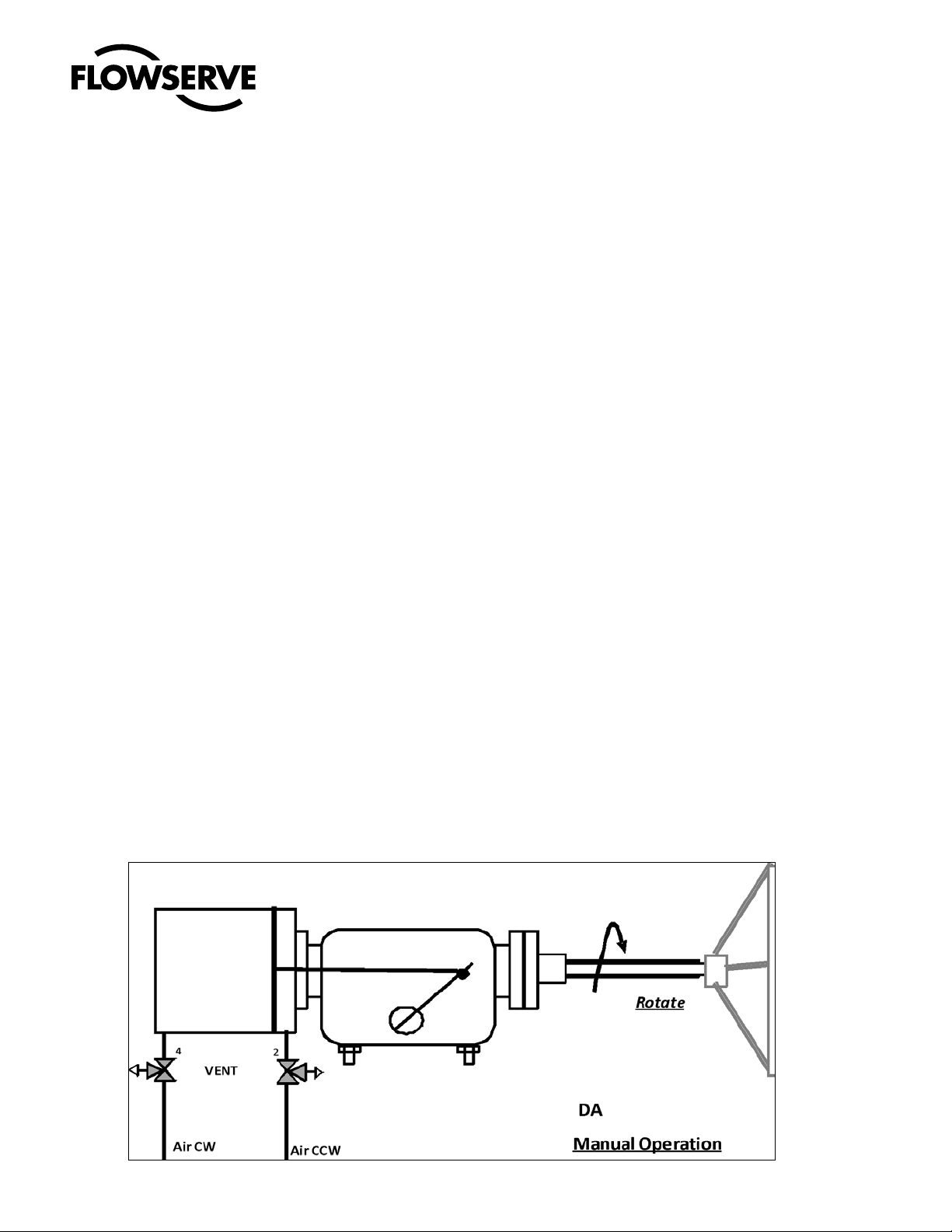

3.4 Operation

Manual Operation (In the absence of pneumatic pressure

only)

3.4.1 Turn the 3 way valves on the pressure module to vent the

cylinder ports to atmosphere. Ensure all vent valves are

in vent position. Number of these valves varies as per the

actuator type (DA/DD/SR).

3.4.2 Rotate the hand wheel on the manual override until the

position indicator on the manual override agrees with the

valve position.

4 Hydraulic Override

Hydraulic overrides on Worchester Controls heavy duty actuators provides a low effort, high thrust in compact sized

override, for manually operating the actuator. The hydraulic

overrides are single acting on the SR models and double

acting on the DA actuator for efficient, automatic operation.

These are available on models ARG3 through ARG8.

The hydraulic override consists of a power pack with hand

operated high pressure pump connected by SS tubing, to hydraulic cylinder, mounted on spring module on SR models

and on the torque module, on the DA models.

NOTE: The position indicator on the manual override

indicates actuator/valve position only when the hand

wheel is engaged. (Position indicator shows ‘SHUT’ in

full CW position and ‘OPEN’ in full CCW position)

3.4.3 Engage worm shaft by pulling out the lock pin and rotate the engage-disengage lever 90 degrees till the spring

loaded lock pin drops into the indexed position. Operate

hand wheel to turn the gear override. Follow instructions

on gearbox to engage the worm shaft.

3.4.4 Manually operate the actuator by turning the hand wheel.

See direction markings on the gearbox and turn the hand

wheel accordingly to open/shut the valve.

3.5 Restoring Automatic Operation

3.5.1 Operate hand wheel to desired valve position. This should

be fail safe position, for a spring return actuator.

3.5.2 Pull out the lock pin of the declutch mechanism, out of

locking position, and turn the lever to Disengage the

worm shaft from the wheel. Turn the lever until the lock

pin sits into the indexed position. It may be necessary to

rotate the hand wheel back & forth at the same time the

declutching handle is lifted, to relieve the load on the

declutching pin.

3.5.3 Turn the 3 way valves, on the pressure module ports to

connect cylinder ports to air supply pressure.

The hydraulic override provides adequate thrust to output the

rated torque on DA models, and required valve torque output

for the operation of SR models.

4.1 Installation

Worchester Controls standard hydraulic overrides are provided as a complete integral component of the heavy duty actuator. Hydraulic override is shipped with the cylinders mounted

to the actuator and bypass/vent valves installed on the pressure cylinders. The power pack is selected, factory fitted and

connected, as per the application. No additional customer

installation is required. See Worchester Controls Heavy Duty

IOM (FCD WCENIM0121) for instructions on installing Heavy

Duty actuator into service.

4.2 Install hydraulic override onto existing heavy

duty Spring Return actuator (see Fig.: 2)

4.2.1 Disconnect air pressure and electrical power from actuator.

4.2.2 Remove the end cover plate, retaining the O-ring on

the Spring Module end.

4.2.3 Thread in the studs (1), from the override mounting

kit, into the thrust base and insert the Hydraulic Cylinder into the Spring Module to mate the cylinder flange

inner face to the thrust base, keeping the air venting

plug to the top (see Fig.: 1 ).

3.5.4 Operate actuator normally with pneumatic pressure supply.

CAUTION! The gearbox override on a spring return ac-

tuator shall not be disengaged while the spring is under compression. Engagement and disengagement of

the worm shaft of the override gearbox should be done

only at the Fail Safe condition of the actuator.

8

Fig.: 1 Insert Hydraulic Cylinder

Page 9

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

Hydraulic Pressure Settings for SR Models, psi

Model

ARG3

ARG4

ARG5

ARG6

ARG7

ARG8

1 2 3 4 5 6 7 8

1550 2000 2400 2850 3000 3000 3000

1350 1580 1950 2200 2450 2900 3000 3000

1200 1680 2000 2300 2900 3000

1000 1550 1900 2200 2500 2800

1050 1750 2000 2350 2800 3000

1150 1800 2300 2700 2900 3000

Hydraulic MOP: 3000 psi

Fig.: 2 Install Hydraulic Override (SR)

4.2.4 Bolt up the cylinder flange on the thrust base of the

Spring Module using the using the lock washers and

nuts from override mounting kit.

4.2.5 Thread in the hydraulic connector into the cylinder port

and connect it to the power pack, as per the schematic.

4.2.6 Fit the 3 way valves supplied in the mounting kit, to the

pressure module’s ports, as per the schematic.

Spring Module

4.3 Operation –SR Override

4.3.1

To operate the override, turn the 3/2 way valve on pressure module to vent the cylinder port to atmosphere and

Close the pressure release valve, PRV (provided either

externally or integral with the hand pump). Operating the

Hand Pump on the power pack pushes the pull rod, compresses the spring and operates the valve.

4.2.7 Fill to level, hydraulic fluid (ISO 32 grade for general

application) in the power pack reservoir, in the full retracted position of the piston.

4.3.2

Opening the pressure release valve, PRV releases the hydraulic pressure and the spring returns the actuator to fail

safe state and the piston rod of override cylinder to retracted

position.

4.2.8 Verify the maximum hydraulic pressure setting for the

actuator model (refer table), close the pressure release

valve on the pump and operate the hydraulic pump to

start the ram movement. Lightly loosen the air vent

4.3.3 To restore normal Automatic operation, turn the PRV

to Open and switch the 3/2 way valve in position to

connect cylinder port to air supply pressure.

screw on the cylinder flange to bleed off air from the

hydraulic lines. The ram touches the Pull Rod’s end

face and pushes the pull rod, effecting the override.

4.2.9 Adjust the overload valve setting on the pump to ensure the pressure does not grossly exceed the Hydraulic pressure setting for the actuator, at the end of the

stroke when the stopper bolt gets loaded.

Piston rod/pull Rod Torque

Hex Size, A/F 18 18 24 30 36 46 65 85

Tightning

torque

ft Lb 30-35 35-45 50-60 60-75 75-85 100-140 175-200 200-240

kgm 4-5 4-5 7-8 8-10 10-12 13-19 24-28 28-33

4.4 Install hydraulic override on Standard DA heavy

duty actuator

4.4.1 Remove the DA cover plate from the torque module

and mount the DA hydraulic override cylinder assembly with the mounting kit and flange O-ring in the face

groove.

9

Page 10

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

4.4.2

Remove end cap of the hydraulic cylinder. With a suitable socket/tube spanner located on the hex head of the

hydraulic piston end, thread in and tighten the piston rod

into the threading of the Torque Module’s Guide Block.

Torque

to values, as for pull rod/ piston rod.

4.4.3 Put back the end cap, taking care not to damage the

cap seal, and tighten fully the tie rod nuts of the hydraulic cylinder.

4.4.4 Connect the ports of the hydraulic cylinder to the direction control valve on the hydraulic power pack. Refer schematic.

4.4.5 Check and ensure the Hydraulic pressure setting of

the pump does not exceed the MOP setting, refer table

below. Use the plugged port on the pressure line Tee,

to connect a suitable pressure gage.

4.5 Operation –DA Override

4.5.1 For Manual Override operation, turn the 3 way valves

on the pressure module to vent cylinder ports to atmosphere and Close the the hydraulic bypass valve,

HBV (if provided externally). Close the pressure release valve on the pump. Turn the lever on the 4 way

direction control valve on the power pack, to select

the direction of the actuator rotation and stroke the

hydraulic pump.

4.5.2 To restore Automatic operation, turn HBV to Open

position, turn the vent valves to connect the cylinder

ports to air supply pressure and open the pressure

release valve on the hand pump.

CAUTION! Over thrust by the hydraulic override may

cause actuator damage. Prevent damage and unsafe working, by adjusting the overload valve on the

pump to limit the hydraulic pressure, as shown in

the table.

Model

MOP, psi

Max. System Pr

DA Hydraulic Override Pressure for Rated Body torque

ARG3 ARG4 ARG5 ARG6 ARG7 ARG8

1860 2100 2050 1950 1950 2150

2500 psi

Fig.: 3 Install Hydraulic Override (DA)

10

Page 11

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

11

Page 12

Contact:

User Instructions ARG Series Standard Actuator - ACENIM0123-00 12/12

®

All data subject to change without notice

© ©12.2010 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser

or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot

provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/

user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate they are supplied for informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon.

Nothing contained herein is to be construed as a warranty or guarantee, expressed or implied, regarding any matter with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications,

dimensions and information contained herein are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

Flowserve Flow Control (UK) Ltd.

Burrell Road

Haywards Heath

West Sussex United Kingdom RH16 1TL

Phone:

+44 1444 314400

Fax:

+44 1444 314401

Flowserve Corporation

Flow Control Division

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: +931 432 4021

Fax: +931 432 5518

12

Flowserve Pte Ltd

No. 12 Tuas Avenue 20

Singapore 638824

Phone: +65 6879 8900

Fax: +65 6862 4940

Flowserve Flow Control Benelux BV

Rechtzaad 17

4703 RC Roosendaal NB

Netherlands

Phone: +31 165 598 800

Fax: +31 165 555 670

Flowserve Australia Pty Ltd

Flow Control Division

14 Dalmore Drive

Scoresby, Victoria 3179

Austrialia

Phone: +61 3 9759 3300

Fax: +61 3 9759 3301

Flowserve do Brasil Ltda

Rua Tocantins, 128 - Bairro Nova Gerti

São Caetano do Sul,

São Paulo 09580-130 Brazil

Phone: +5511 4231 6300

Fax: +5511 4231 6329 - 423

Unit 01\02\06\07 9F

China Fortune Tower

No. 1568, Century Avenue, Pudong

Shanghai China 200122

Phone: +86 21 38654800

Fax: +86 21 50811781

Flowserve Corporation

No. 35, Baiyu Road

Suzhou Industrial Park

Suzhou 215021, Jiangsu Province, PRC

Phone: +86-512-6288-1688

Fax: +86-512-6288-8737

Loading...

Loading...