Page 1

1

Hygiene, Food and Beverage Valves

Series 191400

KMEIM9103-01 06.04

INDEX

1 Using FLOWSERVE valves, actuators and acces-

sories correctly

2 Unpacking

3 Technical data

4 Safety

5 Installation

6 Disassembly and assembly

7 Disassembly

8 Assembly

9 Commissioning

10 Maintenance

1 USING FLOWSERVE VALVES, ACTUATORS AND AC-

CESSORIES CORRECTLY

1.1 Using

The following instructions are designed to assist in

unpacking, installing and performing maintenance as

required on FLOWSERVE products. Product users and

maintenance personnel should thoroughly review this

bulletin prior to installing, operating or performing any

maintenance.

In most cases FLOWSERVE valves, actuators and ac-

cessories are designed for specific applications (e.g.

with regard to medium, pressure, temperature). For

this reason they should not be used in other applications without first contacting the manufacturer.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAUTION and

NOTE are used in these instructions to highlight par-

ticular dangers and/or to provide additional information

on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury

and/or substantial property damage will occur if proper

precautions are not taken.

WARNING: indicates that death, severe personal injury

and/or substantial property damage can occur if proper

precautions are not taken.

CAUTION: indicates that minor personal injury and/or

property damage can occur if proper precautions are

not taken.

NOTE: indicates and provides additional technical

information, which may not be very obvious even to

qualified personnel.

Compliance with other, not particularly emphasised

notes, with regard to transport, assembly, operation

and maintenance and with regard to technical documentation (e.g. in the operating instruction, product

documentation or on the product itself) is essential,

in order to avoid faults, which in themselves might

directly or indirectly cause severe personal injury or

property damage.

1.3 Protective clothing

FLOWSERVE products are often used in problematic

applications (e.g. extremely high pressures, dangerous, toxic or corrosive mediums). In particular valves

with bellows seals point to such applications. When

performing service, inspection or repair operations

always ensure, that the valve and actuator are depressurised and that the valve has been cleaned and is free

from harmful substances. In such cases pay particular

attention to personal protection (protective clothing,

gloves, glasses etc.).

1.4 Qualified personnel

Qualified personnel are people who, on account of their

training, experience and instruction and their knowledge of relevant standards, specifications, accident

prevention regulations and operating conditions, have

been authorised by those responsible for the safety of

the plant to perform the necessary work and who can

recognise and avoid possible dangers.

STOP!

Page 2

2

STOP!

1.5 Installation

DANGER: Before installation check the order-no, serial-

no. and/or the tag-no. to ensure that the valve/actuator

is correct for the intended application.

Do not insulate extensions that are provided for hot or

cold services.

Pipelines must be correctly aligned to ensure that the

valve is not fitted under tension.

Fire protection must be provided by the user.

1.6 Spare parts

Use only FLOWSERVE original spare parts. FLOWSERVE

cannot accept responsibility for any damages that

occur from using spare parts or fastening materials

from other manufactures. If FLOWSERVE products

(especially sealing materials) have been on store

for longer periods check these for corrosion or

deterioration before using these products. Fire

protection for FLOWSERVE products must be provided

by the end user.

1.7 Service / repair

To avoid possible injury to personnel or damage to

products, safety terms must be strictly adhered to.

Modifying this product, substituting nonfactory parts,

or using maintenance procedures other than outlined

in this instruction could drastically affect performance

and be hazardous to personnel and equipment, and may

void existing warranties. Between actuator and valve

there are moving parts. To avoid injury FLOWSERVE

provides pinch-point-protection in the form of cover

plates, especially where side-mounted positioners

are fitted. If these plates are removed for inspection,

service or repair special attention is required. After

completing work the cover plates must be refitted.

Apart from the operating instructions and the obligatory

accident prevention directives valid in the country of

use, all recognised regulations for safety and good

engineering practices must be followed.

WARNING: Before products are returned to FLOWSERVE

for repair or service FLOWSERVE must be provided

previously with a certificate which confirms that

the product has been decontaminated and is clean.

FLOWSERVE will not accept deliveries if a certificate

has not been provided (a form can be obtained from

FLOWSERVE).

1.8 Storage

In most cases FLOWSERVE products are manufactured

from stainless steel. Products not manufactured

from stainless steel are provided with an epoxy resin

coating. This means that FLOWSERVE products

are well protected from corrosion. Nevertheless

FLOWSERVE products must be stored adequately

in a clean, dry environment. Plastic caps are fitted

to protect the flange faces to prevent the ingress of

foreign materials. These caps should not be removed

until the valve is actually mounted into the system.

1.9 Valve and actuator variations

These instructions cannot claim to cover all details of

all possible product variations, nor in particular can

they provide information for every possible example of

installation, operation or maintenance. This means that

the instructions normally include only the directions to

be followed by qualified personal where the product

is being used for is defined purpose. If there are any

uncertainties in this respect particularly in the event

of missing product-related information, clarification

must be obtained via the appropriate FLOWSERVE

sales office.

2 UNPACKING

Each delivery includes a packing slip. When unpacking,

check all delivered valves and accessories using this

packing slip.

Report transport damage to the carrier immediately.

In case of discrepancies, contact your nearest

FLOWSERVE location.

Page 3

3

3 TECHNICAL DATA

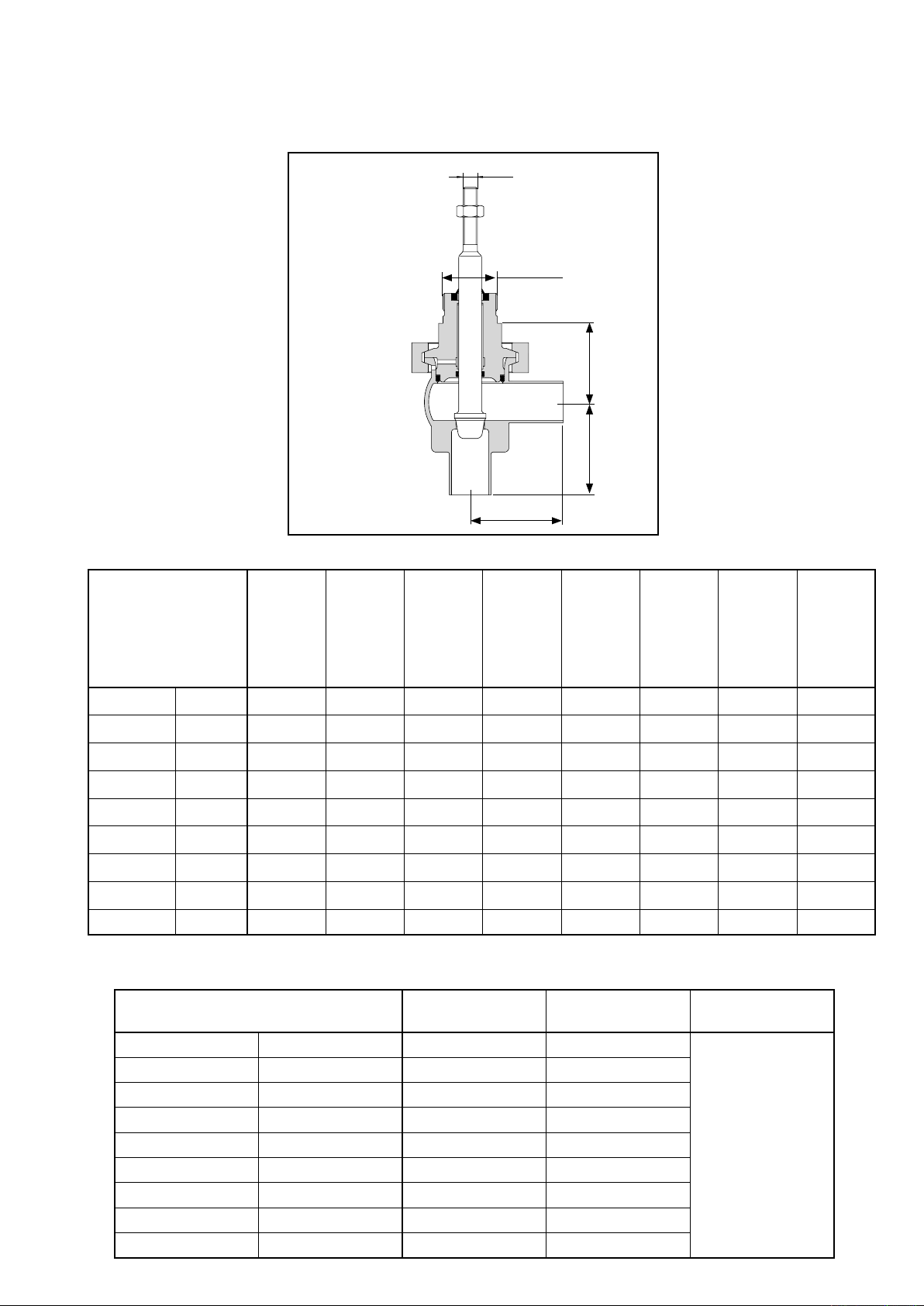

Fig. 1

M 10

A

A

F

M 38 x 1,5

a ↑

Valve size

Dim. A

DIN 11850

Weld ends

Dim. A

ISO 2037

BS 4825

Part 1

Weld ends

Dim. A

DIN EN

ISO 1127/

DIN 2463

Reihe 1

Weld ends

Dim. A

DIN 11851

Screwed

ends

Dim. A

11864

Form

GS-A

Screwed

ends

Dim. A

DIN 32676

Clamp

ends

Dim. A

ISO 2852

Clamp

ends

Dim. A

ASME

BPE-97

DN 10 - 15 ½"

60 60 60 80 78 77 - 80

DN 20 ¾"

60 60 60 83 80 77 - 80

DN 25 1"

65 65 65 93 90 85 85-NS25 -

DN 32 1¼"

70 70 70 101 99 90 - -

DN 40 1½"

75 75 75 107 105 95 95-NS38 -

DN 50 2

85 85 85 120 116 105 105-NS51 -

DN 65 2½"

100 100 100 140 136 128

120-NS63,5

-

DN 80 3"

110 110 110 155 152 138

128-NS76,1

-

DN 100 4"

120 120 120 173 169 148

140-NS101,6

-

Dimensions (mm) and weights (kg)

Valne size

Dimension F

191400

Dimension F

191700 und 800

Weight

without actuator

DN 10 - 15 ½"

56 81

Upon request

DN 20 ¾"

56 81

DN 25 1"

56 81

DN 32 1¼"

56 81

DN 40 1½"

63 82

DN 50 2

70 84

DN 65 2½"

77 105

DN 80 3"

90 109

DN 100 4"

100 115

b ⇒

Page 4

4

3.1 Application Control Valve

3.2 Pressure rating PN 25 ( depending on body

connection)

3.3 Temperature range 0 °C to 100 °C

3.4 Valve function

To ensure optimum valve function, observe the flow

direction from connection a to connection b.

3.4.1 Function: air-to-open – spring-to-close

Product flow direction a → b (see fig. 1)

Product flow direction closed by spring force.

3.4.2 Function: spring-to-open – air-to-close

Product flow direction a → b (see fig. 1)

Product flow direction closed by air force.

3.5 Material data

Seals in contact with the medium

Valve plug 1.4435

Operating temperature max. 100° C

Sterilisation temperature 130° C

Operating pressure max.25 bar

Seals not in contact with the medium

O-Rings Silicon

Stainless steels

In contact with the medium 1.4404 / 1.4435 (316L)

Not in contact with the medium 1.4301

3.6 CIP cleaning agents

Nitric acid 3% / Temperature 80° C

Soda lye 3% / Temperature 80° C

3.7 SIP sterilisation agents

Hot water / Temperature 130° C

Steam / Temperature 130° C

3.8 Surfaces

In contact with medium Ra ≤ 0,6 µm

Ra ≤ 0,5 µm Elec.-polished (opt.)

Ra ≤ 0,4 µm Elec.-polished (opt.)

Not in contact with medium Metal, turned bright

3.9 Valve connection piping

Installation position

Vertical, to ensure valve and line drain free.

3.10 Connection types

DIN 11850 series 2 (DN10 - 100) weld ends

ISO 2037 / BS 4825 weld ends

DIN EN ISO 1127 weld ends

DIN 11851 threaded connection

DIN 11864 Form A threaded connection

DIN 11864 Form A flange connection

DIN 2526 flange connection PN 10

DIN 32676 clamp connection

ISO 2852 clamp connection

3.11 Pipe connection

Separable (for disassembly).

3.12 Welding instruction

See welding instructions (sec. 5.4).

3.13 Installation

See assembly and disassembly instructions (sec. 6).

3.14 Electrical and pneumatic connections

Assemble after fitting the valve.

3.14.1 Electrical connections

WARNING: Electrical connections to be made by a

qualified electrician only.

• Observe valid VDE-EVU and other local regulations.

• Check operating voltage and amperage of specific

parts before connection.

3.15 Quality of supply air

Pressure 6 bar

Solid particles Particle size max. 5 mm (0.4inch)

Particle density max. 5 mg/m

3

(quality class 3)

Water content Dew point +2° C

(quality class 3)

Oil content Oil free, max. oil content

25 mg/m3 (quality class 3)

STOP!

Page 5

5

4 SAFETY

The valves described in this documentation are de-

signed and produced so that they do not present any

hazard for the operating and service personnel or for

the system, in which the valves are installed, when

handled properly observing all important instructions

and safety precautions.

All installation and removal work, performed within the

scope of maintenance or repair to the valves, should

be accomplished only by trained personnel. When

assembling or disassembling, observe the installation

instructions. Proceed precisely as specified in the installation and removal instructions to prevent severe

injury to the operating and service personnel.

The operator of the system is responsible for ensur-

ing that the installation, operating and maintenance

personnel assigned have the required qualifications.

The operator is also responsible for ensuring that the

personnel in question are familiar with the documentation and safety regulations.

The values listed in the chapter “Technical Data”, such

as pressure, temperature, installation locations, etc.,

should be observed under all circumstances.

All materials and sealing elements must be suitable for

these operating conditions and the media, with which

the valves come into contact. The system operator

is solely responsible for all risks and consequences

resulting from failure to observe these operating

parameters. Unauthorized modifications to the valves

have an effect on the intended application and are not

permissible.

In addition to these instructions, all local safety and

accident prevention regulations apply.

5 INSTALLATION

5.1 General Instructions

We urgently recommend having the installation

work accomplished by trained, expert personnel.

5.2 Delivery Status

The valves are tested at the factory and ready for in-

stallation when shipped. The valve can be connected

to the product line with weld ends or selected pipe

connections.

5.3 Installation Guidelines

5.3.1 Installation Space

Before starting installation determine and define the

connection axes. Take installation dimensions from

dimension drawings. Provide for space for operation

as well as service.

5.3.2 Installation

Do not subject to pressure or tension.

5.3.3 Installation Position

Vertical, to ensure that valve and line run empty.

5.4 Welding Guidelines

Range of application Welding between weld connections

and piping acc. to DIN 11850 Series 2

Welding procedure TIG (tungsten Inert gas welding)

Type of weld • Prepare weld acc to DIN 2559

(joint shape I / for I-welds)

• Welds conforming to EN 25817

⇒ evaluation group B (high)

butt weld I-joint acc. to DIN 8532

5.4.1 Welding in valves

Installation state Single-piece body

CAUTION: To prevent damage to sealing materials and

functioning parts, always weld the body in a disassembled state. Disassemble according to disassemble

instructions.

5.4.2 Preparation of weld

Cut off ends of pipe even and deburr. Adjust weld-

ing ends on housing so that they make radially and

axially level contact with the piping (centering tool).

Ensure that no gap is present at the welding ends

in contact with each other, because otherwise the

forming gas would flow out reducing the corrosion

resistance of the weld.

5.4.3 Welding

Connect forming gas. Tack 3-4 points. TIG welding,

manual or orbital (machine welding).

Page 6

6

5.4.4 Welding fillers

Filler match-up table

Material to Suitable welding filler

be welded 1.4316 1.4430 1.4440 1.4519

1.4301 x

1.4306 x

1.4401 x

1.4404 x

1.4435 x x x

1.4571 x x

5.4.5 Final treatment of weld

Interior area

Final treatment of weld not required. Surface quality

can be improved at accessible points by grinding.

Exterior areas

Final treatment process:

Pickling– brushing– grinding- polishing

5.5 Cleaning

Clean entire valve thoroughly before installing.

5.6 Installation

Install according to installation instructions.

6 DISASSEMBLY AND ASSEMBLY

(see fig. 2)

6.1 Installation

To remove the complete valve, separable connections

must be provided in the vicinity of the valve connections a and b.

We recommend following distances from the valve:

Product inlet (a) : 1 x diameter

Product outlet (b) : 6 x diameter

7 DISASSEMBLY

Please observe separate documentation for disas-

sembly of the actuator.

CAUTION:

Before disassembly:

depressurise the line to atmospheric pressure and

drain all fluid from the valve, close-off the supply air.

Valves with air-to-open actuators: tension the actua-

tor springs using top handwheel or by applying sup-

ply air under the membrane.

WARNING: Failure to do this will cause the valve bon-

net to spring-out when the clamp is released due to

the spring pressure acting between the plug and seat.

Observe electrical connection voltage, as necessary

switch off power supply.

7.1 Disconnect pneumatic and electrical feed lines.

7.2 On air-to-open / spring-to-close actuators tension

actuator springs.

7.3 Remove actuator

Remove the coupling between the actuator stem and

the plug stem (3). Loosen the slotted nut (M38x1.5)

on the valve bonnet (2) and remove the actuator.

7.4 Release the tension on actuator springs.

7.5 Loosen and remove the TC clamp (4).

7.6 Remove the bonnet assy (2) from the body (1).

CAUTION: To avoid damage to the O-ring (6) do not

turn the bonnet.

7.7 Pull the plug/stem (3) out of the bonnet (2).

7.8 Carefully remove the wiper (5).

7.9 Remove the O-Ring (7) which serves as the stem seal.

7.10 Remove the body O-Ring (6)

7.11 Remove the PTFE-guide (8) from the bonnet (2).

8 ASSEMBLY

Please observe separate documentation for assembly

of the actuator.

Before assembly:

Thoroughly clean all surfaces.

8.1 Place O-Ring (7) in the bonnet (2).

8.2 Place the wiper (5) in the bonnet (2).

8.3 Place the housing gasket O-Ring (6) in the shoulder

provided on the bonnet (2).

8.4 Insert the PTFE-guide (8) carefully in the bonnet (2)

and ensure it is seated correctly to prevent damage to

the guide.

8.5 Insert the plug/stem (3) into the bonnet (2) .

8.6 Place the bonnet assy. (2) on the body (1).

CAUTION: Insert the body straight. Ensure that the

O-Ring (6) is seated correctly in the groove in the bon-

net. To avoid damage to the O-ring (6) do not rotate

the bonnet.

8.7 Ensure that the bonnet is seated correctly on the body

without a gap between the two. Replace the TC clamp

(3) and tighten securely.

8.8 On air-to-open /spring-to-close apply supply pressure

to move actuator to half stroke.

WARNING: If the actuator is not moved to half stroke

the plug can contact the body when assembling and

damage the seating faces and/or the valve body.

8.9 Mount the actuator on the valve and secure with slotted nut (M38x1,5).

8.10 Attach the coupling between valve and actuator.

8.11 Release tension on the actuator springs.

8.12 Reconnect pneumatic and electrical feed lines and

prepare the valve for cleaning.

STOP!

STOP!

Page 7

7

Figure 2

9 COMMISSIONING

CAUTION: Ensure that no foreign particles are present

in the line system

9.1 Idle test

Operate valve once by actuating with compressed air,

while checking mechanical function of valve.

• TC clamp (4) seated tightly

• Check air pressure and air connections for leakage

• Check stroke path; valve spindle (3) should open

and close without jerking

Check function of the actuator based on documenta-

tion for actuator.

Clean system before operating with product for the

first time.

9.2 Test Run under Operating Conditions

Check sealing elements for leakage.

Replace defective seals as described in installation and

removal instructions.

Check mechanical functions (see idle test).

Check function of control drive (see idle test).

9.3 Initial Operation

Check valve function analog to test criteria for test run.

9.4 Malfunctions

Eliminate any malfunctions, which occur immediately

according to installation and removal instructions.

9.5 Malfunctions

Eliminate any malfunctions, which occur immediately

according to installation and removal instructions.

10 MAINTENANCE

Before maintenance

CAUTION:

Valves with air-to-open actuators: tension the actua-

tor springs using top handwheel or by applying supply air under the membrane.

Failure to do this will cause the valve bonnet to

spring-out when the clamp is released due to the

spring pressure acting between the plug and seat.

Observe electrical connection voltage, as necessary

switch off power supply.

Have repair work performed only by trained personnel

authorised by the operator.

Plug/stem (3)

Wiper (5)

PTFE-guide(8)

TC-clamp (4)

Bonnet (2)

O-Ring, body seal (6)

O-Ring, Stem seal (7)

Valve body (1)

Page 8

8

10.1 Inspection

FLOWSERVE valves do not require any special serv-

ice. However perform a visual check for leakage and

proper function between the maintenance intervals.

10.2 Maintenance

Maintenance intervals based on the actual operating

conditions can only be determined by the user/operator, because they depend on the following application

parameters:

• Operating time per day

• Switching intervals

• Type of product

Type of cleaning (CIP / SIP)

We recommend the following data as guide values:

• For liquids with solid constituents and tempera-

tures of 80° C to 100° C:

approx. every 3 – 6 months

• For liquids with solid constituents and tempera-

tures of approx. 60° C:

approx. every 12 months

• For liquids without solid constituents and tempera tures of max. 95° C:

approx. every 24 months

Intervals of 12 months are recommended for cleaning sys-

tems.

Naturally, the specified values assume that the sealing material is resistant to any chemicals used in cleaning.

All data subject to change without notice

©01.2003 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

Regional Headquarters

Flowserve EMA Flowserve America Flowserve Asia

Burrell Road, Hayward Heath 1350 N. Mt. Springs Prkwy. 12 Tuas Avenue 20

West Sussex, RH16 1TL Springville, UT 84663 638824

England USA Republic of Singapore

Telephone: +44 (0) 1444 314400 Telephone: +1 801 489 8611 Telephone: +65 862 3332

Facsimile: +44 (0) 144 3144401 Facsimile: +1 801 489 3719 Facsimile: +65 862 4940

Main Sales Offices EMA (Europe, Middle East, Africa)

Flowserve France Flowserve UK Flowserve Switzerland Flowserve Germany

7 Avenue de la Libération Station Road Allee du Quartz 1 Manderscheidtstr. 19

63300 Thiers Cedex Pershore, Worcestershire CH-2300 La-Chaux-de Fonds 45141 Essen

France England WR102BZ Switzerland Germany

Telephone: +33 (0) 4 73 80 42 66 Telephone: +44 (0) 1386 55 45 51 Telephone: +41 (0) 32 925 9700 Telephone: +49 (0) 201 8919 5

Facsimile: +33 (0) 4 73 80 14 24 Facsimile: +44 (0) 1386 55 49 68 Facsimile: +41 (0) 32 926 5422 Facsimile: +49 (0) 201 8919 662

Flowserve South Africa Flowserve Middle-East Flowserve Austria Flowserve Benelux

Units 1 and 2 C/O Saleh & Abdulaziz Abahsain Kasernengasse 6 Van Leeuwenhoekweg 6

26, Imvuba Road, Sebenza Ext 6 P.O. Box 209

Edenvale, Gauteng

Edenglen 1613 Al Khobar 31952 9500 Villach 3225 LX Hellevoetsluis

South Africa Saudi Arabia Austria The Netherlands

Telephone: +27 11 609 2094 Telephone: 9663 857 3442 Telephone: +43 (0) 424241 181-0 Telephone: +31 (0) 181 330044

Facsimile: +27 11 609 3735 Facsimile: 9663 859 5284 Facsimile: +43 (0) 424241 181 50/51 Facsimile: +31 (0) 181 330040

Flowserve Italy Flowserve Spain Flowserve Portugal Flowserve Scandinavia

Via Prealpi, 30 Luis Cabrera, 86-88 Av. Dr. Antunes Guimaraes, 1159 Gelbgjutaregatan

Cormano (Milano) E-28002 Madrid Porto 4100-082 58933 Linköping, Östergötland

Italy Spain Portugal Sweden

Telephone: +39 (0) 2663251 Telephone: +34 9 15 152 032 Telephone: +351 22 619 8770 Telephone: +46 13 316100

Facsimile: +39 (0) 26151863 Facsimile: +34 9 14 136 747 Facsimile: +351 22 619 7575 Facsimile: +46 13 136054

Flowserve Eastern Europe

12, av. du Québec

91965, Courtaboeuf Cedex

France

Telephone: +33 (0) 1 60 923 251

Facsimile: +33 (0) 1 60 923 299

Loading...

Loading...