Page 1

Installation, Operation, Maintenance Instructions

Sanitary and Hygiene Valves

Series 191 000

Series 191 600 Steam Barrier

Flow Control Division

Kammer Control Valves

1 GENERAL INFORMATION

These instructions are designed to support you when

unpacking, installing and performing maintenance

work on the valves. Users and maintenance personnel should carefully read these instructions before

installing, operating or performing maintenance

work. There is a separate set of instructions for accessories (special seat/plug fittings, diaphragm actuators, handwheels, special seats, etc.).

These instructions do not contain any information

on Kämmer positioners. For this, see corresponding instructions for the installation, maintenance,

troubleshooting, adjustment and operation of

Kämmer positioners.

To avoid damage or injury to personnel or equipment, always heed all warnings and instructions.

Unprofessional reconditioning, the use of foreign

replacement parts or the performance of other

maintenance steps than those described here, may

cause a loss of efficiency or lead to personnel injury or damage to parts, and render the warranty

void

1.1 UNPACKING

1.1.1 Each delivery includes a packing slip. When unpacking, check all delivered valves and accessories using this packing slip.

1.1.2 Report transport damage to the carrier immediately.

1.1.3 In case of discrepancies, contact your nearest dealer.

1.2 INSTALLATION

1.2.1 Clean tubing prior to installing.

1.2.2 If possible, install the valve in an upright position (actuator on top), to ease maintenance. An upright installation position is important with low-temperature

applications, in order to keep the distance between

the packing material and the medium as large as possible. The packing material then retains the ambient

temperature as much as possible.

Important: Do not insulate extension bonnets that

are provided for hot or cold services

1.2.3 Make sure that sufficient overhead clearance above

the actuator is maintained, to allow for disassembly

of plug from the valve body (see following table).

Actuator Clearance Actuator Clearance

size (mm) size (mm)

37/47 95 P2 140

38/48 140 P3 140

39/49 140 P4 140

39D/49D 140 P5 140

1.2.4 After installing, check direction of flow again.

1.2.5 If the valve is to be welded into the line, make sure

that the valve is shielded from excessive heat.

1.2.6 Connect supply pressure and signal lines. Control

valves can be supplied with a positioner. The end

connections for supply pressure and signal are clearly

marked. Actuator and positioner are suitable for max.

6 bar (87 psi) supply pressure. If the supply pressure exceeds the pressure specified on the nameplate, a pressure reducing station is required. If instrument air is not available, install an oil separator/

air filter in the air inlet line. All connections must be

free of leaks.

KMEIM9102-00 - 11.00

111.00

Page 2

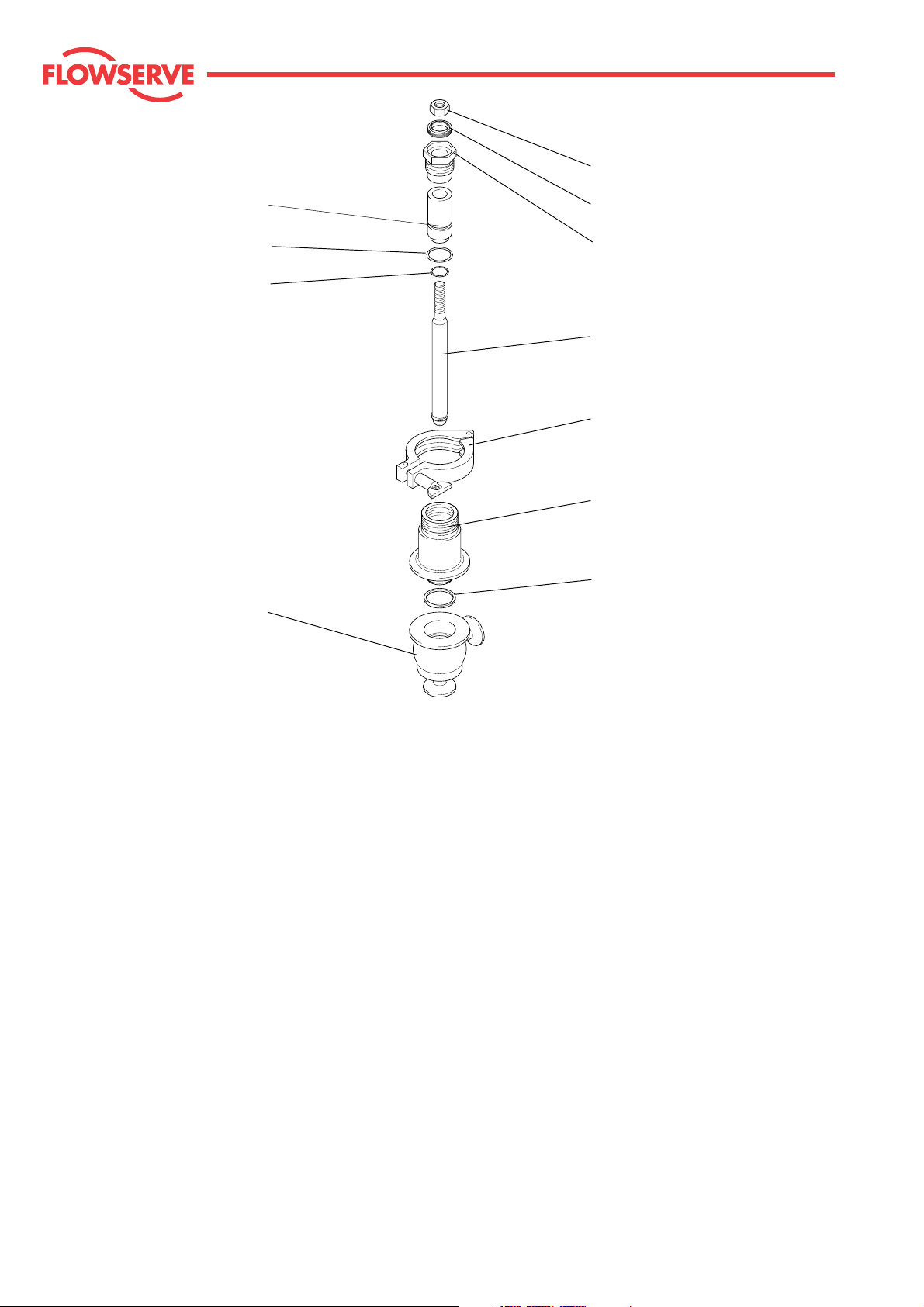

Nut

Flow Control Division

Kammer Control Valves

Guide bush

O-Ring

O-Ring

Body

Wiper ring

Packing follower

Plug

Clamp

Guide bush

O-Ring

Typical valve configuration

1.3 QUICK CHECK:

Before operating, check the valve as follows:

1.3.1 Open and close the valve, and observe the movement

of the actuator stem. The movement must be smooth

and linear.

1.3.2 Check for maximum stroke through change of signal

(for pneumatic positioners, 0.2 - 1.0 bar or corresponding split-range values; for IP positioners, 4-20

or 0-20 mA).

1.3.3 Check all air connections for leaks.

1.3.4 The packing follower must always be tight to ensure

that the packing kit (guide bush with O-Rings) functions correctly.

1.3.5 Check the wiper ring for damage.

1.3.6 Check fail-safe position. To do this, close supply pressure and observe whether the valve opens or closes

as prescribed.

Fig. 1

1.3.7 After use at fluctuating temperatures, re-tighten all

bolt connections and check for leaks.

2 MAINTENANCE

Check valves for correct functioning at regular intervals (at least once every 6 months) as follows. This

check can be made when installed and in many cases

without interrupting production. If internal defects are

suspected, see section on „Disassembly and Assembly of Valve“.

2.1 Examine gaskets for leaks and if necessary re-tighten

bolts (see Fig. 1).

2.2 Check valve for damage caused by corrosive residues

or corrosive vapours.

2.3 Clean valves and if necessary repaint.

2.4 Check that the packing follower is tight.

2 11.00

Page 3

Flow Control Division

Kammer Control Valves

2.5 If possible, open and close valve and check for maximum stroke and smooth movement of the plug stem.

Irregular movement of the plug stem may indicate

internal defects.

Note: With graphite packing, irregular movement of

the plug stem is normal.

IMPORTANT: Keep hands, hair, clothing, etc. away

from all moving parts. Failure to do so can lead to

serious injury.

2.7 Check all accessories for firm seating.

2.8 If possible, close supply pressure and check the failsafe position.

2.9 Check stem boot for wear.

2.10 Check actuator for leaks. To do this, spray housing,

air connections and plug stem guide with leak spray

and note any bubble formation.

2.11 Clean plug stem.

2.12 Check air filter, if present, and if necessary replace

insert.

3.2 Assemble valve

Attention: All worn or damaged parts must be re-

placed. Reusable parts must be clean. All consumable items such as seals, O-Rings and gaskets must

always be renewed.

3.2.1 Carefully enter the plug into the bonnet.

3.2.2 Replace body/bonnet gasket.

3.2.3 Carefully place the bonnet/plug assembly vertically

onto the body ensuring the body/bonnet gasket is

correctly seated.

3.2.4 Insert the guide bush with O-Rings into the bonnet

using an assembly bushing (see Fig. 2) and tighten

down the packing follower.

3.2.5 Place the clamp around the body an tighten the wingnut.

3 DISASSEMBLE AND ASSEMBLE VALVE

General Information

We recommend separating the actuator from the

valve before commencing repair work.

However, many maintenance and adjusting operations can be carried out with the valve installed.

Attention: Never turn plug or perform any service

on the valve while the plug is in the seat ring. Doing so may cause irreparable damage to the trim

set. To ensure against this, always hold the plug

out of the seat while working on the valve assembly.

3.1 Disassemble valve

3.1.1 Disconnect actuator from valve body

3.1.2 Loosen and remove the clamp.

3.1.3 Carefully remove the bonnet complete with plug and

packing kit..

Assembly bushing

Fig. 2 Assembly bushing

3.1.4 Carefully remove the plug from the bonnet.

3.1.5 Unscrew the packing follower and extract the packing kit from the top of the bonnet. Check the wiper

ring and O-Rings for damage.

3.1.6 Remove the body/bonnet gasket.

3.1.7 Clean and inspect all parts.

311.00

Page 4

Flow Control Division

Kammer Control Valves

Germany

Tel.: (02 01 ) 89 19 5 • Fax: (02 01 ) 89 19 600

Flowserve Essen GmbH Flowserve Essen GmbH Flowserve Essen GmbH Flowserve Essen GmbH

Sales Office Hamburg Sales Office Niederrhein Sales Office West Sales Office Maintal

Hoher Weezer Weg 27a Büdericher Straße 8 Robert-Bosch-Strasse 11

D - 47574 Goch D - 47877 Willich D - 63477 Maintal

Tel.: (02 01) 89 19 665 Tel.: (0 28 23) 9 80 02 Tel.: (0 21 54) 20 20 71 Tel.: (0 61 81) 42 404 11

Fax: (02 01) 89 19 662 Fax: (0 28 23) 9 80 03 Fax: (0 21 54) 20 20 73 Fax: (0 61 81) 42 404 29

Flowserve Essen GmbH Flowserve Essen GmbH Flowserve Essen GmbH Flowserve Essen GmbH

Sales Office Frankfurt Sales Office Südwest Sales Office Augsburg Sales Office Ost

Steinweg 22 Am Mühlhübel 13 Staatsstraße 10 Oberhasel 18

D - 65824 Schwalbach a. Ts. D - 67686 Mackenbach D - 86450 Altenmünster D - 07407 Kirchhasel

Tel.: (06196) 85 203 Tel.: (06 374) 99 27 84 Tel.: (0 82 95) 9 00 03 Tel.: (0 36 72) 46 46 82

Fax: (06196) 84 462 Fax: (06 374) 99 27 85 Fax: (0 82 95) 9 00 04 Fax: (0 36 72) 46 46 89

FRANCE USA / CANADA SWITZERLAND

Flowserve S.A.S. Flowserve (FCD) Flowserve S.A.

SEREG KAMMER VALVES, INC. Kammer Vannes.

12, av. du Québec, BP645 1300 Parkway View Drive Allée du Quartz 1

F- 91965 Courtaboeuf Cedex Pittsburgh, Pa 15205 U.S.A. CH-2300 La Chaux-de-Fonds

Flowserve Essen GmbH

Kammer Ventile

Manderscheidtstrasse 19

D-45141 Essen

Tel.: +33 1 60 92 32 87 Tel.: +1 412 787 - 8803 Tel.: +41 (0) 32 925 9700

Fax : +33 1 60 92 32 99 Fax: +1 412 787 -1944 Fax: +41 (0) 32 926 5422

AUSTRALIA AUSTRIA DENMARK FINLAND

Flowserve Australia PTY LTD Flowtec Industrietechnik GmbH Scana Godtkjær & Armatur as KONTRAM OY

14 Dalmore Drive Weinitzstrasse 1 Kong Svends Vej 65 PO. Box 88

Scoresby VlCTORlA 3179 8045 Graz 2765 Smorum 02201 Espoo

AUSTRALIA AUSTRIA DENMARK FINLAND

Tel.: +61 3 9764 0060 Tel.: +43 (0) 316 69 70 69-0 Tel.: +45 44 20 00 00 Tel. +358 9 8866 4500

Fax: +61 3 9764 0013 Fax: +43 (0) 316 69 70 69-9 Fax: +45 44 20 00 01 Fax: +358 9 8866 4599

GREAT BRITAIN IRELAND ISRAEL ITALY

Flowserve Flexachem Manufacturing Ltd TECHNOMAD LTD EUROVALVE S.R.L.

Station Road, Pershore Donnybrook Commercial Centre 19 Hashikma Str. Via Camicie Rosse 11

Worcestershire, WR10 2BZ Douglas, Cork Azor 58009 20090 Opera (Ml)

ENGLAND IRELAND ISRAEL ITALY

Tel.: +441386 554 551 Tel.: +353 21 363742 Tel.: +972 3 5585550 Tel.: +390 2 57 6018 45

Fax: +441386 554 968 Fax: +353 21 891297 Fax: +972 3 5585090 Fax: +390 2 57 6017 00

JAPAN NETHERLANDS NORWAY R. O. C.

TOKO VALEX Co., Ltd Conovalve B.V. NOR Instruments A.S. Eagle Process Service Ud.

2-17, 4-chome, Matsushima Postbus 270 Jerikoveien 26 Suite 4, 5th Floor No. 312

Edogawa-Ku, Tokyo 3100 AG Schiedam 1067 Oslo Chung Hsiao E. Road, Sec. 4

JAPAN 132 NETHERLANDS NORWAY TAIWAN

Taipei, Taiwan, R. O. C.

Tel.: +81 3 3655 6769 Tel.: +31 10 4 71 53 33 Tel.: +47 2210 05 00 Tel.: +8862 2751 6197

Fax: +81 3 3655 5181 Fax: +31 10 4 70 44 82 Fax: +47 2210 0510 Fax: +8862 2781 4640

SINGAPORE SOUTH AFRICA SWEDEN

Valtek Asia Pacific Operations Valtek South Africa (Pty.) Ltd alnab

c/o Durco-Valtek Asia P. O. Box 9279 Ögärdesvägen

12, Tuas Avenue 20 Edenglen 1613 433 86 Partille

Singapore 2263

SINGAPORE SOUTH AFRICA SWEDEN

Tel.: +65 862 3332 Tel.: +2711 609 2094-96 Tel.: +46 31 44 94 50

Fax: +65 862 4940 Fax: +2711 609 3735 Fax: +46 31 44 94 55

4 11.00

©09.2000 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

All data subject to change without notice

Loading...

Loading...