Page 1

USER INSTRUCTIONS

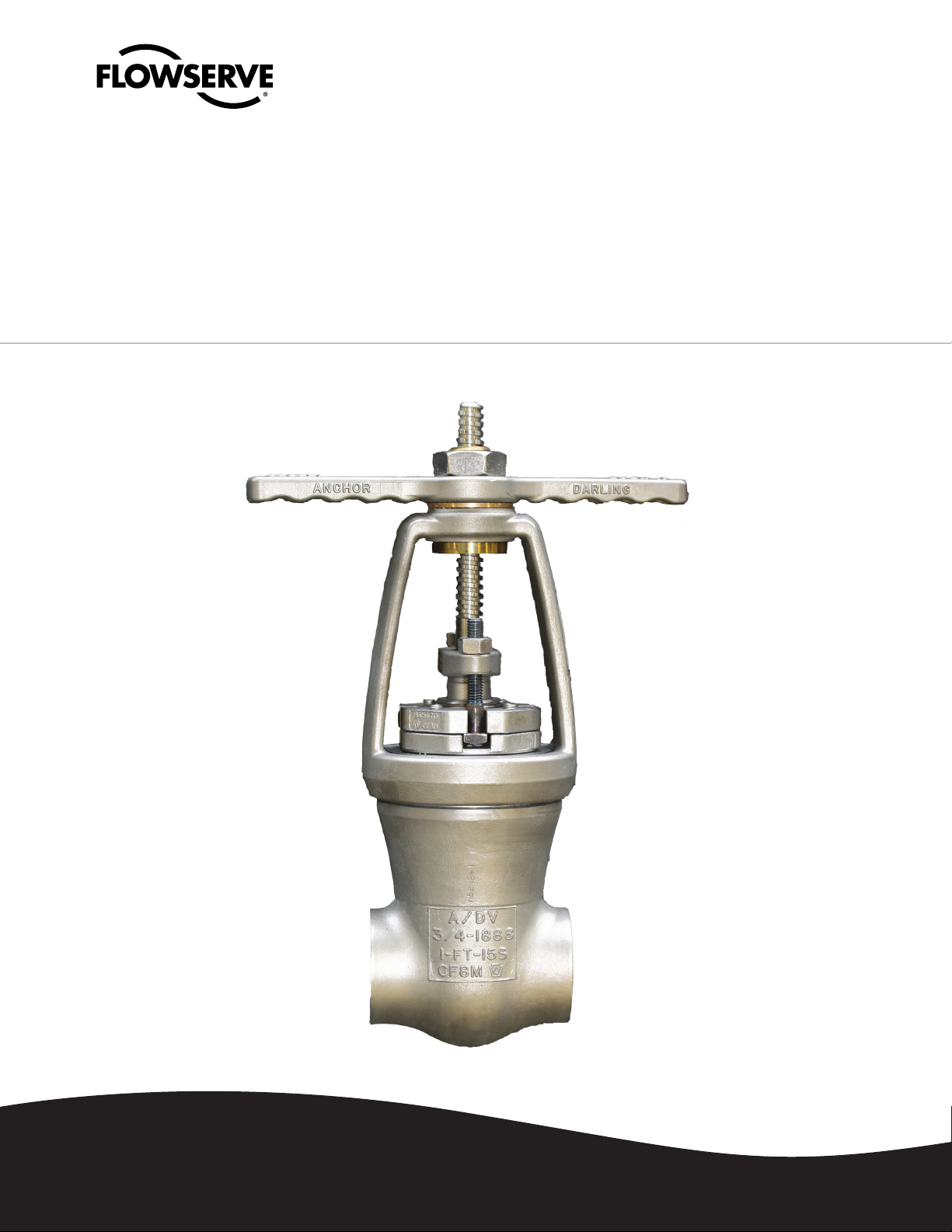

Anchor Darling 1888-lb. Double-Disc Gate Valve

½" through 2" Valves with 10" Manual Tee Handles

FCD ADENIM0001-00

Installation

Operation

Maintenance

Experience In Motion

Page 2

Table of Contents

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

1.0 Physical Description and Operation of Equipment

2.0 Design Conditions

3.0 Operating Conditions

4.0 Test Conditions

5.0 Operating Precautions and Limitations

6.0 Installation Instructions

7.0 Maintenance Requirements

8.0 Periodic In-Service Testing Recommendations

and Procedures

9.0 Maintenance Instructions

10.0 Storage Requirements

11.0 Bolting Torque Values

12.0 Reference Drawings

13.0 Customer-Certified Assembly Drawing(s)

2

Page 3

Revision Sheet

Revision Date Changes Description

- 02/03/2004 Original Issue

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

3

Page 4

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

1.0 PHYSICAL DESCRIPTION AND OPERATION OF EQUIPMENT

1.1 Double-Disc Gate Valves

The double-disc design is unique in that there are two independent discs. During each

closing stroke, immediately prior to the disc seating, each disc rotates a few degrees in

the plane of the seats. This rotating feature allows the disc to seat in a different position

on each closing stroke, providing for equal wear and preventing small imperfections from

being agitated into major leakage problems.

The wedge assembly is designed to impart sufficient thrust to each disc to maintain

acceptable low-pressure seat leakage. As the differential pressure across the disc

increases, the seating load also increases, thus maintaining acceptable leakage through

the entire range of operating differential pressures. Since the discs are completely

independent of each other and the design is essentially symmetrical, zero leakage can

be maintained in either direction, depending only on the direction of flow. This feature

eliminates the necessity of installing a check valve to stop reverse flow.

To operate these manual valves, turn the tee handle in a clockwise direction for closure

and counterclockwise for opening.

4

Page 5

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

2.0 DESIGN CONDITIONS

Refer to the applicable drawing(s) in Section 13 of this manual.

5

Page 6

3.0 OPERATING CONDITIONS

Refer to the applicable drawing(s) in Section 13 of this manual.

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

6

Page 7

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

4.0 TEST CONDITIONS

4.1 Each valve covered by this manual has received the following hydrostatic tests with no measurable leakage

4.1.1 A shell hydrostatic test at 1.5 times the 100°F pressure rating.

4.1.2 A seat leakage and disc closure test at 110% of the 100°F pressure rating.

4.1.3 A backseat leakage test at 110% of the 100°F pressure rating.

4.1.4 A packing test at 110% of the 100°F pressure rating.

7

Page 8

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

5.0 OPERATING PRECAUTIONS AND LIMITATIONS

5.1 Maximum hydrostatic test pressure shall not exceed the values imposed by the ASME Code, Section III.

8

Page 9

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

6.0 INSTALLATION INSTRUCTIONS

6.1 Lifting and Handling Requirements and Limitations

6.1.1 Good judgment should be exercised in selecting a lifting device that will safely support the unit’s weight.

6.2 Assembly Instructions

6.2.1 The valves have been shipped in a clean condition. Examine the lines and the valve ports for foreign matter

prior to installation and clean them thoroughly if they have been exposed to the elements; (BEFORE

CLEANING IN THIS FASHION, CHECK AT THE SITE TO SEE IF A SPECIFIC CLEANING PROCEDURE

SHOULD BE FOLLOWED.) Open the valves fully and flush them out with water, if possible; otherwise, blow

them out with air or steam.

In performing this cleaning procedure, the ports should be vertical and the stem horizontal to assure

complete removal of all matter that might have accumulated during storage.

6.2.2 Ensure that there is no line sag at the point of installation. Eliminate any pipeline deviation by the proper

use of pipeline hangers or a similar device.

6.2.3 Where possible, install the valves with the stem vertical. When other orientations are used, take care when

disassembling the valve to avoid any internal damage.

6.2.4 Remove the end protectors and clean the socket weld ends or, in the case of butt weld end valves, clean

with a solvent such as acetone in preparation for welding the valve into the line. The valves should then be

blocked or slung into position with an apparatus that is sufficient to hold the valve assembly weight while

the valve is being welded into the line. WELDING MUST TAKE PLACE WITH THE DISC IN THE

OPEN POSITION.

6.3 Pre-Operational Checks

6.3.1 After installation, the operation of manual valves should be verified by closing the valve. The valve should

seat tightly with less than 80 Ibs. of push/pull combined force on the tee handle. If the valve does not close

tightly, do not apply extra leverage; instead, refer to Paragraph 9.4 A and B.

9

Page 10

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

7.0 MAINTENANCE REQUIREMENTS

7.1 Preventive Maintenance

7.1.1 Check all nuts and bolts periodically to ensure tightness and to forestall possible leaks. Recommended

torque values are presented in Section 11.0.

7.1.2 Keep valve stem clean and properly lubricated.

7.1.3 Check conditions of packing and replace as necessary.

7.2 Recommended Spare Parts

7.2.1 Recommended spare parts are packing and pressure seal gaskets. The recommended quantity is one (1)

set of packing and one (1) pressure seal gasket for every two (2) valves of a particular type. However, not

less than one (1) set of the above for each type.

7.3 Lubrication

7.3.1 Apply a light coating of lubricant (Dow Corning Molykote 111 Compound, Dow Coming Molykote P37 paste

or equal) to the threaded area of the stem when necessary.

7.3.2 The bearing area in the yoke bushing can be lubricated via the grease fitting (340) with the

above-mentioned lubricants.

10

Page 11

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

8.0 PERIODIC IN-SERVICE TESTING RECOMMENDATIONS

AND PROCEDURES

8.1 It is recommended that the valve be operated from full open to full close at least once every six months.

11

Page 12

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

9.0 MAINTENANCE INSTRUCTIONS

9.1 The following instructions cover the disassembly and reassembly of a Series 1888 double-disc gate valve.

Typical valve configuration is shown in Figure 1 (see Section 12).

CAUTION

CHECK ONE PRESSURE: IF LINE IS STILL UNDER PRESSURE, VENT

BEFORE VALVE DISASSEMBLY IS STARTED

9.1.1 Disassembly

Extreme care should be taken to avoid possible damage to the valve’s moving parts. It is recommended

that valves be placed in a vertical position for disassembly, if possible. For valves inline, take special care

not to drop or damage any of the internals.

Ensure that the stem and disc pack do not separate when removed. They are removed as one unit until

both are adequately supported. Failure to remove as one unit could cause damage to the discs.

After removal from the valve, care should be taken to protect the seating surface of the discs from damage.

The discs should be placed in a clean area until ready to replace in the valve. THE SLIGHTEST NICK OR

SCRATCH ON A SEATING SURFACE COULD PREVENT COMPLETE SHUT-OFF AND NECESSITATE

EXTENSIVE REWORK OR REPLACEMENT.

(a) Place the valve in the closed position without wedging the discs into position by closing the valve

and then opening about one-half of a revolution of the tee handle.

(b) Remove the handwheel nut (240) from the yoke sleeve (017). Remove the tee handle (175) and

thrust washer (147) from the yoke sleeve (017) by sliding it up and over the yoke sleeve.

(c) Remove the tee handle (175) and thrust washer (147) from the yoke sleeve (017) by sliding it up

and over the yoke sleeve.

(d) Remove the yoke clamp nut (233), allowing removal of the yoke capscrew (217).

(e) Rotate the yoke (011) in a counterclockwise direction to remove from the body (001) and slide it

up and over the yoke sleeve.

12

(f) Turn the yoke sleeve (017) off the stem (025).

Page 13

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

9.0 MAINTENANCE INSTRUCTIONS (Continued)

9.1.1 Disassembly (Continued)

(g) Remove the gland bolt nuts (234), allowing removal of the gland bolts (210).

(h) Lift the flange gland (133) upward and remove the packing (110, 112) from the stuffing box. Removal of

the packing is best accomplished with a packing hook or similar device.

(i) Loosen the gland retainer setscrews (220) until they do not make contact with the gasket retainer (033).

Then turn the gland retainer (131) counterclockwise off the bonnet (002). Turn the gasket retainer (033)

out of the body (001). If the bonnet (002) drops and turns with the gland retainer (131), grasp the stem

(025) and lift to hold the bonnet, thus preventing it from rotating.

(j) Remove the pressure seal gasket (030) by carefully lifting the bonnet (002). It is imperative that the

bonnet be lifted over the stem as straight as possible to eliminate the possible scoring of the stem. If the

bonnet is wedged into position, carefully lift up on the stem until the gasket and bonnet come free.

(k) The stem (025), wedge and disc assembly (069, 071, 269, 004) can now be lifted from the valve body. As

the discs (004) rise above the guides in the valve body, they should be retained to reduce the possibility

of them falling from the wedges (069, 071) and becoming damaged by falling on the lapped surfaces

(refer to Figure 2).

(I) Remove the discs (004) from the upper wedge (069) and place them where they will not become damaged

or scratched.

(m) The stem (025) can be removed from the upper wedge (069) by sliding it from the “T” slot. Be careful that

the wedges do not separate and the wedge spring (269) is lost.

(n) At this time, the discs and seat rings may be lapped, if required. The seating surfaces should be inspected

to determine if scratches or minor imperfections can be corrected by lapping and/or replacement parts are

necessary. (Refer to Paragraph 9.3 for lapping instructions.)

13

Page 14

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

9.0 MAINTENANCE INSTRUCTIONS (Continued)

9.1.2 Assembly

Assembly of the valves is simply the reverse of disassembly. Prior to reassembly, read the following

special instructions.

(a) All dirt, scale and foreign matter should be removed from inside the valve body and bonnet.

(b) Check the seating surfaces to determine that scratches or minor imperfections do not exist on

the discs or seat rings. If any are evident, lap these surfaces until none are visible.

(Reference Paragraph 9.3.)

(c) Insert the stem (025) into the “T” slot in the upper wedge (069). The lower wedge (071), wedge

spring (269) and discs (004) can now be positioned on the upper wedge. As the stem and disc

pack are lowered into the valve body, they should be contained to reduce the possibility of falling

and becoming damaged.

(d) Once the stem/disc pack assembly is positioned in place, the bonnet (002) can be lowered

into the body neck. Care must be taken in lowering the bonnet onto the stem to prevent

possible scoring.

(e) With the bonnet resting inside the body neck, a new pressure seal gasket (030) can be inserted.

Because tolerances are close and the gasket may cock, it must be inserted with care.

(f) Thread the gasket retainer (033) into the body, tighten to the bottom of the threads and back

out enough to align the packing gland bolts on the valve body. With the gasket retainer in the

proper position, the gland retainer (131) can be lowered over the stem and threaded onto the

bonnet (002). The bonnet will be raised squarely until it is firmly in contact with the pressure

seal gasket.

(g) Note that it is not necessary to torque the gland retainer. The bonnet is truly sealed by pressure.

The only function of the retainer is to hold the bonnet in contact with the gasket until it is

deformed by pressure, locking the joint together and ensuring a tight seal. Since the bonnet is

sealed by pressure, constant cycling will compress the gasket and necessitate tightening of the

gland retainer setscrews.

(h) Once the bonnet is in the proper position, the gland retainer may require backing off to align the

slots for the gland bolts. Once this has been accomplished, the gland retainer setscrews (220)

should be installed and tightened (see Section 11.0 for recommended torque values).

14

Page 15

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

9.0 MAINTENANCE INSTRUCTIONS (Continued)

9.1.2 Assembly (Continued)

(i) Install the packing into the bonnet in accordance with Section 9.2.

(j) Place the gland bolts (210) into the slots and through the flange gland (133) and tighten the gland stud

nuts (234) (see Section 11.0).

(k) Replacement of the yoke (011), yoke sleeve (017), thrust washer (147), tee handle (175) and

handwheel nut (240) can be accomplished by reversing the procedure specified in Paragraph 9.1.1 (a), (b),

(c), (d), (e) and (f).

9.2 RepIacement of Packing (Reference Figure 1)

If the valve is in service, backseat it. If the valve is not backseated, be sure that line is depressurized.

(Refer to Figure 1 for referenced part designations.)

(a) Remove the two (2) gland stud nuts (234) and raise the flange gland (133), allowing the gland bolts (210)

to be removed.

(b) Lift the flange gland (133) upward and away from the stuffing box area.

(c) Use a packing hook or similar device to remove the old packing.

d) Install the packing (110, 112) a few rings at a time, carefully placing the joint of each ring approximately

180° from the preceding piece to prevent a leakage path. It might be necessary to slightly flatten each

packing ring prior to installation to allow easy insertion within the stuffing box. The flange gland (133) can

be used to seat the packing in position once a ring has been slipped within the box.

(e) Upon completely filling the stuffing box, replace the nuts and bolts. Very carefully draw the packing to

assure that the flange gland is even and that the bore of the flange gland is concentric with the valve stem.

(If the flange gland (133) is drawn unevenly, scoring of the stem may result; or the gland might be tilted,

which could cause binding.) Recommended torque values can be found in Section 11.0.

(f) Check the packing periodically (six-month intervals), replacing as needed.

15

Page 16

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

9.0 MAINTENANCE INSTRUCTIONS (Continued)

9.3 Lapping Procedure

After the valve has been disassembled, a visual inspection of the seating surfaces of the discs (004) and seat rings

(013) can be made to determine if lapping is necessary to remove any minor scratches on these parts prior to

assembling the valve. Abide by the following procedure:

(a) The disc should be lapped on a flat, grooved lapping plate or, if available, a lapping machine can be used.

A “medium” grade lapping compound should be used for the first and successive applications and a “fine”

grade compound similar to “Clover A Grit No. 280” should be used for the final lapping process.

(b) If it is necessary to lap the face of the seat ring, a standard lapping plate can be used of approximately the

same diameter as the disc.

9.4 Troubleshooting

A. EXCESSIVE TEE HANDLE (175) EFFORT OR BINDING

Excessive tee handle effort or binding indicates that the stem (025) either needs to be lubricated or

the flange gland (133) is too tight as a result of the gland nuts being tightened unevenly. Lubrication

(Paragraph 7.3) should be checked at regular intervals of six months. To evenly tighten the gland nuts,they

should be loosened and retightened in an alternating fashion.

B. LEAKAGE BETWEEN THE DISC (004) AND SEAT RING (013)

Leakage between the disc (004) and seat ring (013) could be an indication that foreign matter is on

the seating surfaces, in which case the valve should be opened and closed ONE TIME in an attempt

to dislodge any matter that might have inadvertently lodged there. DO NOT OPEN AND CLOSE THE VALVE

MORE THAN ONCE, SINCE THIS COULD CAUSE PERMANENT DAMAGE TO THE SEATING SURFACES

IF THE FOREIGN MATTER IS SECURELY LODGED IN PLACE. Instead, disassemble the valve and remove

the sources of the trouble. If no foreign matter is found, inspect the seating surfaces of the valve for signs

of a scarred or damaged seat—in which case the seating surfaces of the disc (004) and seat ring (013)

should be lapped until no visible defects remain. (Refer to Paragraph 9.3.)

C. LEAKAGE AROUND STEM (025) AND THROUGH THE STUFFING BOX

Worn packing (110, 112). Replace the packing following the instructions set forth in Paragraph 9.2

in this section.

16

Page 17

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

10.0 STORAGE REQUIREMENTS

The valves have been shipped in the closed position. Upon receipt of the valves at destination, the crates should be examined

thoroughly for signs of mishandling or damage during shipment. With the valves strapped to the shipping skids, all yoke cap

and gland bolting should be checked to ensure that the joints are secure. On occasion, bolting could become loosened during

shipment and handling.

The valves should be stored in a sheltered area to protect them from the elements, dirt and foreign material. They should not be

exposed to the atmosphere, uncrated or removed from the shipping skids, except in a clean area just prior to installation.

If the valves are not to be installed within a short period of time after receipt and will require long-term storage, the following

should be adhered to:

(a) The valves should be stored in an upright position, stem vertical, and where there is minimal temperature variation

and the temperature does not drop below 50°F.

(b) In their storage condition, the valves should be wrapped in polyethylene to prevent accumulation of dust or

foreign matter.

(c) A check-off tag should be affixed to each unit and should be dated and signed off by the inspector witnessing the

inspection, which is recommended at six-month intervals.

(d) The shelf life for grafoil and graphite filament packing and spiral-wound gaskets is indefinite when stored under the

proper conditions.

17

Page 18

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

Flowserve gate valves are supplied with a crowned sealing surface on the seat in order to provide precise seat width and tight sealing.

Lapping of the seat will cause the sealing band width to be significantly increased. After all seat refinishing operation, the seat width must

be checked against the dimensions supplied below and reduced if necessary. Failure to do so could create leakage problems, particularly

at lower pressures.

F

SEAT RING

VALVE SIZE

1/2"

3/4" .062

1"

1-1/4" .062

1-1/2" .062

1-3/4"

2"

F

1888#

.062

.062

.062

.062

18

Page 19

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

11.0 BOLTING TORQUE VALUES

At intervals of not more than six (6) months, check the tightness of all bolting. The recommended torque values for all bolting

are shown below:

TORQUE ft-lb.

PART # DESCRIPTION NOMINAL MAXIMUM

210 Gland Bolts 10 15

217 Yoke Capscrew 20 25

220 Gland Retainer Setscrews 9 10

240 Handwheel Nut 20 25

19

Page 20

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

SECTION 12.0

REFERENCE DRAWINGS

20

Page 21

Figure 1

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

21

Page 22

Figure 2

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

22

Page 23

1888-lb. Double-Disc Gate Valve FCD ADENIM0001-00

SECTION 13.0

CUSTOMER-CERTIFIED ASSEMBLY DRAWING(S)

23

Page 24

FCD ADENIM0001-00Printed in USA.

To find your local Flowserve representative:

United States

Flowserve Corporation

Flow Control Division

1900 S. Saunders Street

Raleigh, NC 27603

Phone: (919) 832-0525

Fax: (919) 831-3369

For more information about Flowserve Corporation,

visit www.flowserve.com or call USA 1 800 225 6989

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to

perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in

numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific

data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation,

operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with

the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered

certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding

any matter with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information

contained herein are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at

any one of its worldwide operations or offices.

© 2008 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Loading...

Loading...