Page 1

Valtek Logix 1400

Digital Positioner

GENERAL INFORMATION

The following instructions are designed to assist in

unpacking, installing and performing maintenance as

required on Valtek® Logix™ 1400 digital positioners.

Series 1000 is the term used for all the positioners herein;

however, specific numbers indicate features specific to

a model (i.e. Logix 1400 digital positioner indicates that

the positioner uses FOUNDATION™ fieldbus protocol). Prod-

uct users and maintenance personnel should thoroughly

review this bulletin prior to installing, operating, or performing any maintenance on the valve.

More detailed operation instructions are included in other

manuals in the owner’s manual binder; refer to them

when more information is needed.

Separate Flowserve Installation, Operation, Maintenance

instructions cover the valve (IOM 1 or IOM 27) and

actuator (IOM 2 or IOM 31) portions of the system and

other accessories. Refer to

Installation & Reference Guide

implementation. Refer to the appropriate instructions

when this information is needed.

To avoid possible injury to personnel or damage

to valve parts, users must strictly adhere to

WARNING and CAUTION notes. Modifying this

product, substituting non-factory or inferior parts,

or using maintenance procedures other than

outlined could drastically affect performance or

be hazardous to personnel and equipment and

may void existing warranties.

Logix 1400 Digital Positioner

for details on fieldbus

WARNING: Standard industry safety practices must

be adhered to when working on this or any other

process control product. Specifically, personal

protective and lifting devices must be used as

warranted.

Unpacking

1. While unpacking the Logix 1400 positioner, check

the packing list against the materials received. Lists

describing the system and accessories are included

in each shipping container.

2. When lifting the system from the shipping container,

position lifting straps in a way that avoids damaging

mounted accessories. Systems with valves up to

six inches may be lifted by actuator lifting ring. On

larger systems, lift unit using lifting straps or hooks

through the yoke legs and outer end of body.

WARNING: When lifting a valve/actuator assembly with lifting straps, be aware the center of

gravity may be above the lifting point. Therefore,

support must be given to prevent the valve/

actuator from rotating. Failure to do so can cause

serious injury to personnel or damage to nearby

equipment.

3. In the event of shipping damage, contact the shipper

immediately.

4. Should any problem arise, contact a Flowserve

representative.

Valtek Part No. 164713 46-1

Page 2

Table of Contents

General Information .................................................... 1

Unpacking .................................................................. 1

Logix 1400 Digital Positioner Overview ...................... 2

Specifications ............................................................. 3

Positioner Operation ................................................... 3

Tubing Positioner to Actuator ..................................... 4

Wiring and Grounding Guidelines ................................ 4

Driver Module Assembly ............................................. 5

Spool Valve Cover ...................................................... 6

Regulator .................................................................... 7

Internal Coalescing Filter ............................................ 7

Main PCB Assembly .................................................. 7

Collector Board ........................................................... 7

Field Terminations ...................................................... 8

Stem Position Sensor................................................. 8

LED Indicators ............................................................ 9

Re-Cal Button ............................................................. 9

Checking or Setting Internal Regulator Pressure ...... 10

Checking or Setting the Driver Module

Minimum Pressure ............................................... 10

Linear Mark I Valve Mounting................................... 11

Standard Rotary Mounting Procedure ....................... 12

Optional Rotary Mounting Procedure ........................ 13

Troubleshooting the Logix 1400 Digital Positioner .... 13

Theory of Operation.............................................. 13

Mounting and Installation ......................................... 15

Calibration ................................................................ 16

Control and Tuning ................................................... 16

Alarms ...................................................................... 18

Alerts ........................................................................ 19

Travel Accumulator .................................................. 20

Cycle Counter ........................................................... 20

Position Deviation ..................................................... 20

Advanced Features .................................................. 20

Glossary and Definitions ........................................... 23

Transducer Block Signature Parameters .................. 24

Exploded View of Positioner..................................... 27

Available Spare Parts Kits ....................................... 28

Troubleshooting Tables ............................................ 29

Positioner Mounting Kits........................................... 32

Logix 1400 Digital Positioner

Logix 1400 Digital Positioner Overview

The Logix 1400 digital positioner is a two-wire, FOUNDATION

fieldbus compliant, digital valve positioner. The Logix

1400 digital positioner also utilizes the fieldbus protocol

to allow two-way remote communications with the positioner. The Logix 1400 digital positioner can control both

double- and single-acting actuators with linear and rotary

mountings.

Since the positioner is insensitive to supply pressure

changes and can handle supply pressures from 35 to 150

psig, a supply regulator is usually not required; however,

an air filter is required due to the close clearances in the

spool assembly.

NOTE: The air supply should conform to ISA Standard

S7.3 (a dew point at least 18° Fahrenheit less than

ambient temperature, particle size below one micron, and

oil content not to exceed one part per million).

46-2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

Specifications

Electrical Specifications

ylppuSrewoPsubdleif,eriw-owT

ylppuS.B.FCDV0.23-0.9

wardtnerrucmumixaMAm22

snoitacinummoCFNOITADNUO subdleif

NI Configurator Software Specifications

retupmoCrossecorp68408muminiM

,TNro59swodniWgninnur

BM-23(yromemlatotBM-61

BM-02,)dednemmocer

evirdyppolfhcni-5.3

rotacinummocBF

drac

)snoitporofINtcatnoc(

Positioner Specifications

dnabdaeDelacslluf%1.0<

siseretsyHelacslluf%2.0<

ytilibataepeRelacslluf%5.0<

ytiraeniL,)yrator(%5.0<

tanoitpmusnoCriA

)grab4(gisp06

MFCS%3.0<

3

mN5.0(

)rh/

Physical Specifications

gnitarepO

egnaRerutarepmeT

gnisuoHdetniap-redwop,tsaC

thgieW)gk9.3(sdnuop5.8

o

04-

o

04-(

o

581+otF

F

o

58+otC

)C

leetssselniats,munimula

sdnuop5.02munimula

leetssselniats)gk3.9(

Hazardous Area Certifications

foorPnoisolpxE,1viD,1ssalCASC/MF

gnidnep,D,C,BspuorG

eno,ecapsksiddrahelbaliava

evidnecninoN,2viD,1ssalCASC/MF

gnidnep,D,C,B,AspuorG

rotarugifnocINhtiwdeilppuS

efaSyllacisnirtnI,1viD,1ssalCASC/MF

gnidnep,D,C,B,AspuorG

CE Mark Qualifications

evitceriDCME

CEE/633/98

22055NE

elacslluf)raenil(%8.0

evitceriDDVLelbacilppAtoN

04105VNE,2-4-00016NE

1-18005NE,4-4-00016NE

1-18005NE,2-28005NE

CDV57<;CAV05<sitinU

Positioner Operation

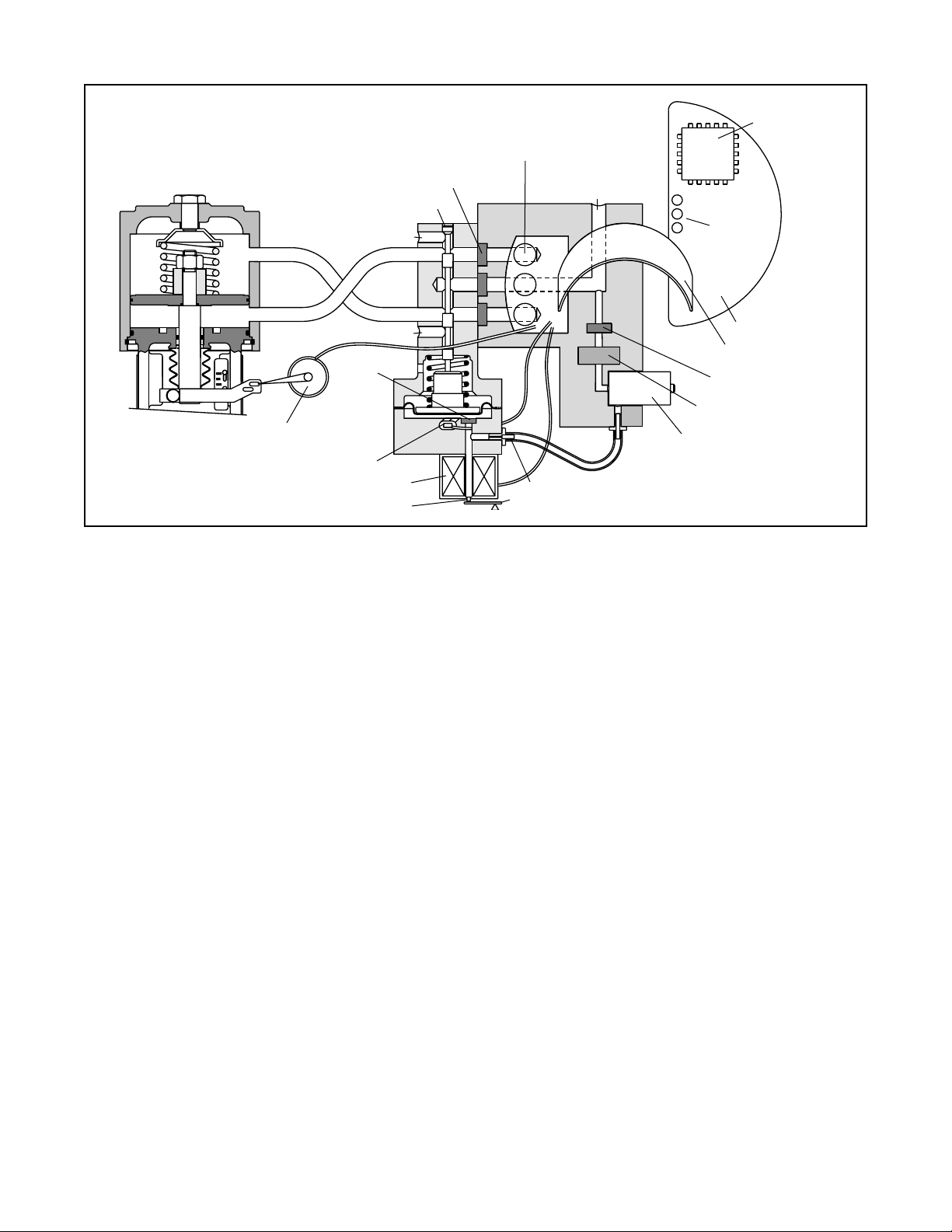

The Logix 1400 positioner is an electric feedback instrument. Figure 1 shows a Logix 1400 positioner installed on

a double-acting actuator for air-to-open action. Positioning is based on a balance of two signals: one proportional

to the command input signal and the other proportional to

the valve stem position.

The supply pressure for the positioner pressure modulator is tapped off the main supply and is filtered as it

passes through a field-replaceable, coalescing filter

element in the module. This air passes through an

internal pressure regulator that regulates it to approximately 22 psig. The air then passes through an orifice

that restricts the flow and air consumption.

The pressure modulator further controls the air from 6-12

psig, using a spring-diaphragm flapper that is attracted

by an electromagnet to a nozzle. A temperature compen-

sated hall effect sensor mounted on a circuit board

senses the spool valve position. The hall effect sensor

and circuitry create an inner feedback loop, which determines how much current to send to the electromagnet for

a desired spool valve position. The electromagnet in the

feedback loop varies the nozzle-flapper spacing, which

regulates the output pressure between 6 and 12 psig,

proportional to the digital positioning algorithm.

When the command and stem position signals are equal,

the system will be in equilibrium and the valve stem will

be in the position called for by the command signal. If

these opposing signals are not equal, the spool valve will

move up (or down) and, by means of the pressure

modulator, change the output pressures and flow rate.

This will cause the actuator piston to move until the

signal of the position sensor equalizes with the

command signal.

46-3Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 4

Air-to-Open

Configuration

Flame Arrestors

Spool Valve

Exhaust

OUTPUT 1

Collector Board

Pressure Sensor

Air Supply

Digital Position

Algorithm

LED

Dis-

play

OUTPUT 2

Exhaust

OO

Stem Position Sensor

Hall Effect Sensor

Electromagnetic Coil

Nozzle

Flame

Arrestor

Figure 1: Logix 1000 Digital Positioner Schematic

Detailed Sequence of Positioner Operations

The positioner operates on a pressure equilibrium principle with a spool valve apportioning supply to the

actuator. An increase in the command signal causes the

modulator pressure to increase, pushing the spool assembly upward from its equilibrium position. This opens

the spool valve ports, supplying air to output 1 and

exhausting air from output 2. This causes the actuator

piston to move upward.

The upward motion of the piston is transmitted back to

the positioner through the stem-position feedback linkage. The piston continues to stroke upward until the

stem-position signal of the sensor increases sufficiently

to counter the command signal being sent to the control

algorithm. At this point, the spool is at its equilibrium

position as the pressures in the cylinder stabilize and the

air flow to the actuator decreases. The computer will then

make small adjustments to fine-tune the desired position

and compensate for changes in dynamic loading.

A decrease in the command signal reverses the

described actions, causing a proportional downward

movement of the actuator piston and stem.

Tubing Positioner to Actuator

Proper tubing orientation is critical for the positioner to

function correctly and have the proper failure mode.

Referring to Figure 1 note that for air-to-open valves, the

output 1 port of the positioner manifold is tubed to the

bottom side of the actuator. The output 2 port of the

Main PCB Tray

Ribbon Cable

Flame Arrestor

Filter

Regulator

Orifice

Flapper

positioner manifold is tubed to the top side of the

actuator. For air-to-close valves the above configuration

is reversed.

Wiring and Grounding Guidelines

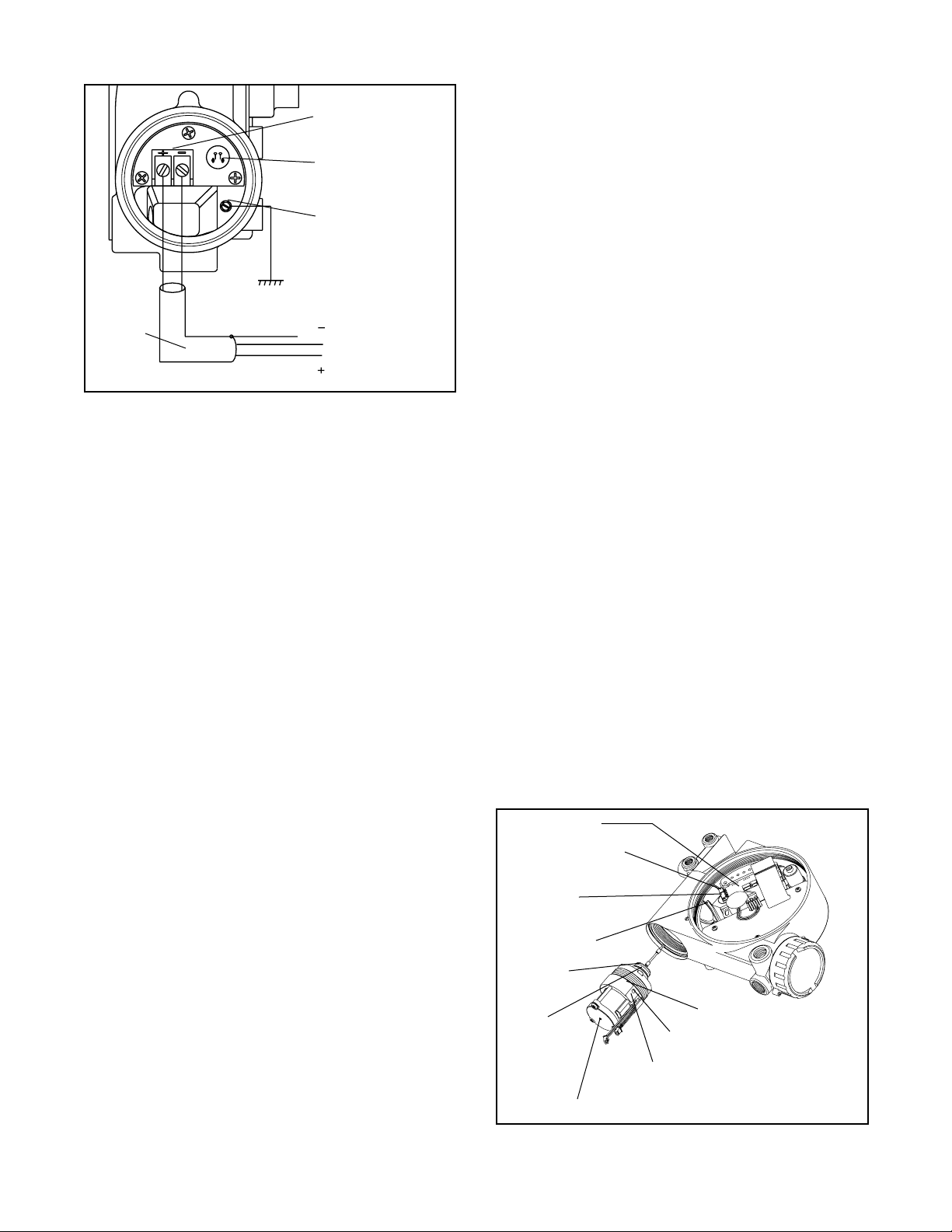

Input Cable Shielding (Figure 2)

The fieldbus signal to the Logix 1400 digital positioner

should be in shielded cable. Shields must be tied to a

ground at only one end of the cable to provide a place for

environmental electrical noise to be removed from the

cable. In general, shield wire should be connected at the

source.

Cable Requirements

The Logix 1400 digital positioner utilizes the fieldbus

communication protocol. Refer to Fieldbus Foundation

document AG-140, Wiring and Installation 31.25 kbit/s,

Voltage Mode, Wire Medium Application Guide for full

information on wiring and building fieldbus networks.

Grounding Screw

The green grounding screw, located inside the termination cap, should be used to provide the unit with an

adequate and reliable earth ground reference.

This ground should be tied to the same ground as the

electrical conduit. Additionally, the electrical conduit

should be earth grounded at both ends of its run. The

green grounding screw must not be used to terminate

signal shield wires.

46-4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

Field Terminations

FB Connection

Terminals

Housing EARTH

Terminal

Shielded

Cable

Ground

Fieldbus

connection

Figure 2: Field Termination

Driver Module Assembly

The driver module assembly moves the spool valve by

means of differential pressures on its diaphragm. Air is

routed to the module from the interface plate through a

hose that connects to the assembly through a hose barb

with an integral orifice. Wires from the module connect

the hall effect sensor and the pressure modulator coil to

the collector board.

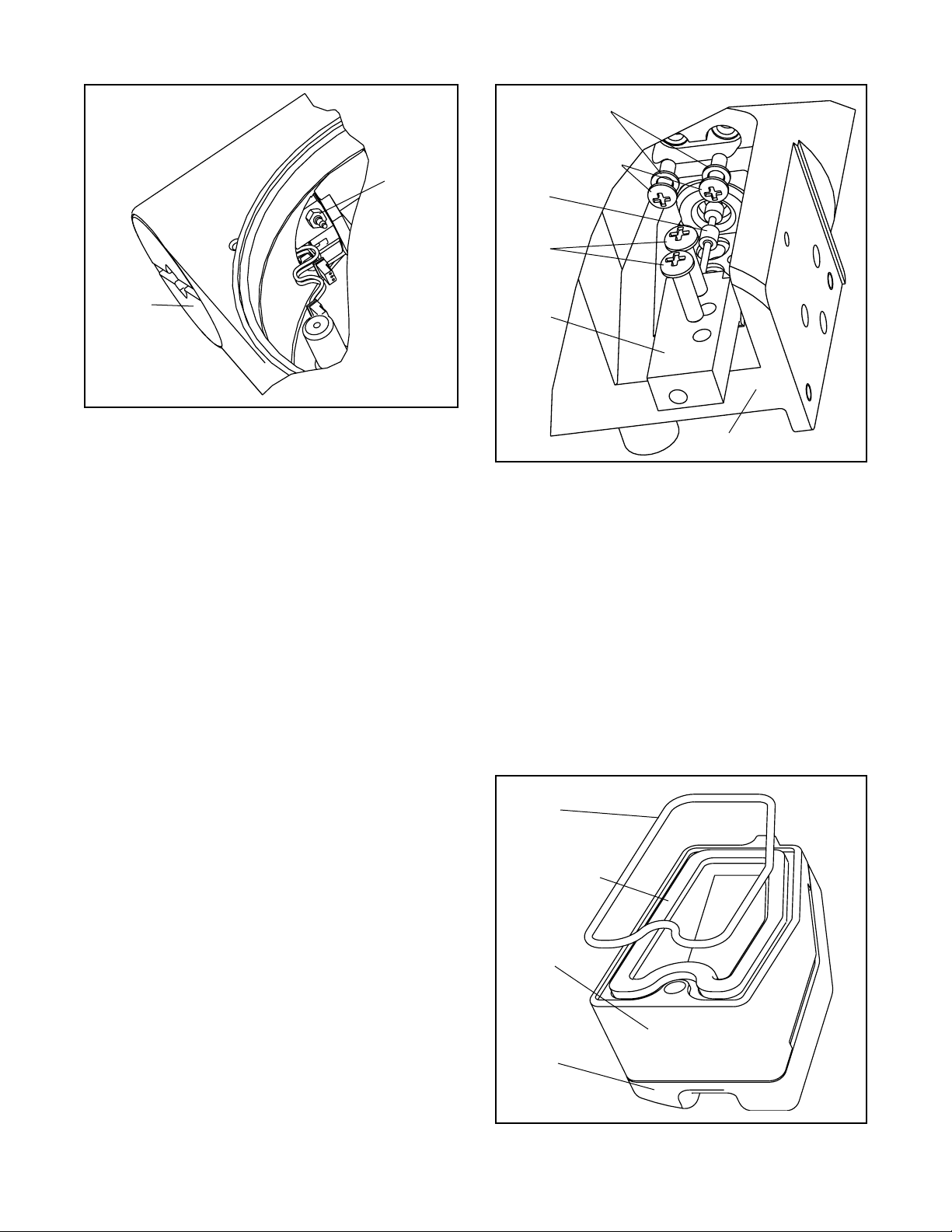

Driver Module Assembly Replacement

To replace the driver module assembly, refer to Figures

3 - 5, 7 and 19 then proceed as outlined below. The

following tools are required:

1

/4-inch open-end wrench

1

/2-inch hex wrench

Phillips screwdriver

Driver Module removal tool

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the driver module cover, using a

wrench (Figure 4). Do not force the cover. If undue

resistance is encountered, use the slots to loosen

cover.

4. Remove the spool valve cover by removing the

screw and sliding the cover assembly backwards

until the tab is clear of the slot. It is not necessary

to remove the sheet metal cap from this assembly

(Figure 7).

5. Being careful not to lose the nylon washers, remove

the two phillips-head screws that attach the driver

module to the main housing (Figure 5).

6. Remove the spool valve block by removing the two

phillips-head screws and carefully sliding the block

off the spool (Figure 5).

1

/2-inch hex

CAUTION: The spool (extending from the driver

assembly) is easily damaged. Use extreme caution when handling driver assembly.

7. Remove the tubing from the orifice in the driver

module assembly. Using a

1

/4-inch open-end wrench,

remove the orifice from the driver module (Figure 4).

8. Remove the two wiring connections that link the

driver module assembly to the collector board.

(Figure 4).

9. Feed the wires back through the housing so they

extend backward toward the driver module opening.

This will allow the driver module to thread out without

tangling the wires.

10. Grasp the driver module cap with the driver module

removal tool and rotate the entire driver module

counter clockwise to remove. After it is threaded out,

carefully retract the driver module from the housing

to avoid damaging the spool.

11. Take the new driver module and verify that the O-ring

and boot are in place. Lay the wires back along the

modulators as shown in Figure 3 and hold in place.

12. Gently direct the driver module into the housing bore,

making sure the spool does not hit the housing. Turn

driver module clockwise to thread it into the housing.

Continue rotating the module until it bottoms out.

13. Once the threads are fully engaged, rotate the driver

module counter clockwise until the flat on the driver

module and the flat on the housing are aligned. This

will align the screw holes for the next step (Figure 3).

14. Verify that nylon gaskets are in the counter bores in

the driver module retaining screw holes as shown in

Figure 5.

15. Insert two driver-to-housing screws into the driver

housing through the counter-bored holes in the

positioner main housing. Tighten evenly with a phillips

screwdriver.

Collector Board

Pressure Modulator

Connection

Hall Sensor

Connection

Flat in Housing

Protective

Boot

O-ring

Orient this flat parallel

to flat in housing

Minimum Pressure Set Screw (factory calibrated)

Driver Module Assembly

Install orifice after driver

module is in housing

Figure 3: Driver Module Assembly

46-5Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 6

Orifice

Nylon Gaskets

Driver to

Housing Screws

Spool

Spool

Valve

Screws

Driver

Module

Cover

Figure 4: Driver Module Orifice

16. Feed the driver module wires into the main chamber

of the housing and connect them to collector board.

17. Verify that the three O-rings are in the counter-bores

on the machined platform where the spool valve

block is to be placed (Figure 19)

18. Carefully slide the block over the spool, using the

machined surface of the housing base as a register

(Figure 5). Slide the block toward the driver module

until the two retaining holes line up with the threaded

holes in the base.

19. Install two spool-valve screws and tighten securely

with a phillips screwdriver.

20. Insert the orifice into the threaded hole in the driver

module assembly. Tighten with a 1/4-inch open-end

wrench (Figure 4). Attach the flexible tubing from the

interface plate to this fitting.

21. Set the minimum pressure as described on page 10.

22. Thread driver module cover into driver module bore

in the main housing.

Spool

Valve

Block

Housing

Figure 5: Spool and Block

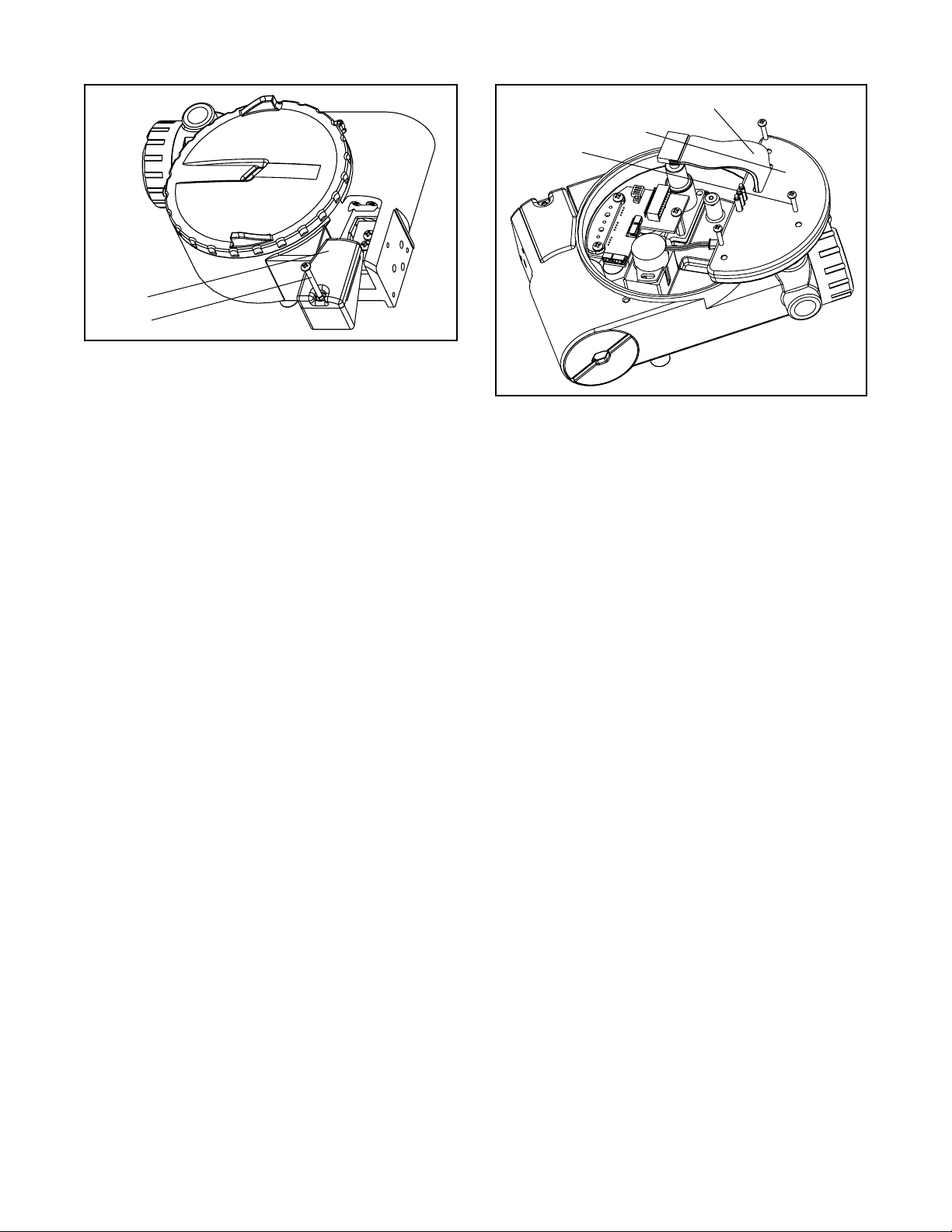

5. Remove the molded filter element by pulling it

straight out of chamber cover vent piece.

6. Install O-ring into base of chamber cover vent piece

as shown in Figure 6.

7. Place new molded filter element into the chamber

cover vent piece. This element provides part of the

track to secure the O-ring installed in the last step.

8. Place spool valve shroud onto spool valve cover.

9. Place the spool valve cover assembly in place by

setting it on the ramp and sliding it until the tab seats

in the slot (Figure 7) and secure with No. 8-32 screw.

O-ring

Spool Valve Cover

The spool valve cover incorporates a coalescing filter

element in a two-piece cover. This protects the spool

valve chamber from moisture and provides a low back

pressure vent for exhaust air from the spool valve.

Replacing Filter in Spool Valve Cover

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the spool cover by removing the screw and

sliding the cover assembly backward until the tab is

clear of the slot. The sheet metal cover may be

removed and cleaned with a brush or by blowing out

with compressed air (Figure 7).

4. Remove the O-ring from around hydrophobic filter

element and set aside (Figure 6).

46-6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Hydrophobic

Filter

Spool

Valve

Cover

Spool

Valve

Shroud

Figure 6: Spool Valve Cover Assembly

Page 7

Spool Valve

Cover

Screw

Figure 7: Spool Valve Cover Assembly

Ribbon Cable

Main PCB Assembly

Screws (3)

Regulator

The regulator reduces the pressure of the incoming

supply air to a level that the driver module can use.

Replacing Regulator

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and unscrew the regulator

from the interface plate, exercising caution not to

damage the collector board (Figure 19).

4. Verify that the O-rings are in place on the base of the

new regulator

5. Replace the regulator by threading into the port on

the interface plate.

6. Check regulating pressure to ensure that it is set at

22 psi.

Internal Coalescing Filter

The internal coalescing filter ensures that supply air is

clean and dry before it gets to the regulator. Because the

air has already been filtered before this point, the element

should not require extended maintenance.

Replacing Input Filter Element (Figure 19)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and remove collector board

by disconnecting the wiring and removing three

screws that attach it to the housing. Each cable has

its own unique connector to prevent improper

connections.

4. Remove the four No. 6-32 hex screws from the filter

housing and remove filter housing.

5. Remove the old coalescing filter from the bore in the

interface plate.

Figure 8: Main PCB Assembly

6. Insert new coalescing filter into the bore on interface

plate.

7. Verify that the O-ring is in place in filter housing.

8. Set filter housing over coalescing filter and secure

with four No. 6-32 screws.

9. Replace collector board and reconnect wiring.

Main PCB Assembly

The main PCB assembly contains the circuit boards and

processor that perform the control functions of the

positioner. The boards are conformal-coated with a

protective silicon coating. This module can be easily

replaced if positioner upgrades are desired. None of the

components are user-serviceable. This module is to be

replaced as an entire unit.

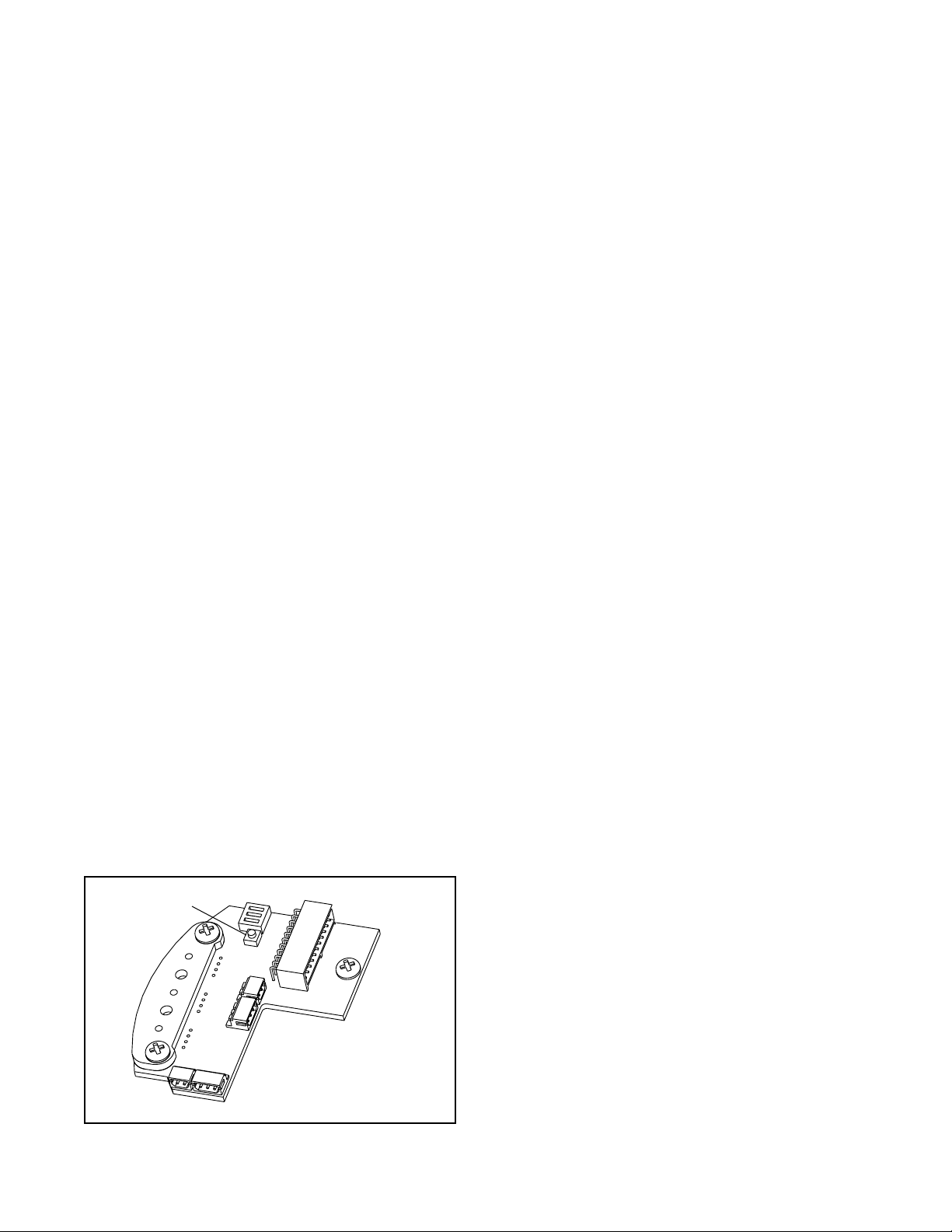

Replacing Main PCB Assembly (Figure 8)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and disconnect the ribbon

cable from the collector board.

CAUTION: To avoid damaging any components,

exercise caution by gently raising the locking tab

to release the ribbon cable.

4. Remove the PCB assembly by removing the three

No. 6-32 screws and lifting out of housing.

5. Place the new PCB assembly on bosses inside the

positioner housing.

6. Insert three No. 6-32 screws through the boards, with

the nylon washers on the bottom into the threaded

bosses and tighten evenly, using a phillips screwdriver. Do not overtighten.

7. Reconnect the ribbon cable to the collector board.

46-7Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 8

Collector Board

The collector board assembly provides a central routing

for all electronic connections in the positioner, linking the

pressure modulator coil, hall effect sensor and field

inputs to the main electronics. The collector board

assembly also serves as a mounting for the pressure

sensors used on the advanced model of the positioner.

Removing Collector Board (Figure 19)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and disconnect the wiring to

the collector board. Each cable has its own unique

connector to prevent mistakes in reconnecting.

4. Remove the three No. 8-32 screws holding the

collector board to the housing.

5. Remove the collector board.

Replacing/Upgrading Collector Board

1. For the advanced collector board (Logix 1x1x),

check that pressures sensors are in place on back

of collector board. For the standard model (Logix

1x0x), make sure the adapter block is securely

fastened to the collector board.

2. Make sure the O-rings are in place in the counterbores

of the pressure ports.

3. Set collector board assembly in place.

4. Insert three No. 8-32 screws through collector boards

into the threaded holes on sensor shelf and standoff.

5. Tighten all three screws.

6. Connect the main ribbon from electronics tray.

7. Reconnect wiring to the collector board.

Field Terminations

The field terminations board provides a connection point

inside the explosion-proof housing for all hookups to the

positioner. While the board is not likely to experience a

failure, it can easily be replaced to upgrade the positioner.

Replacing Field Terminations Board

(Figure 19)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and disconnect the field

termination cable from collector board.

4. Remove the field terminations cover and the three

No. 8-32 screws.

5. Remove field terminations board, carefully pulling

wiring through bore.

6. Verify that the O-ring is in place in the counter bore

in the positioner housing.

7. Feed wiring through passageway into main chamber

of housing.

8. Set the circuit board in place and secure with three

No. 8-32 screws.

9. Connect field termination cable to collector board.

Stem Position Sensor

The position feedback assembly transmits valve position information to the processor by means of a rotary

position sensor that connects to the valve stem through

a feedback linkage. The follower arm is biased against

one side of the slot with a rotary spring to provide

accurate tracking of the pin in the slot. This spring also

automatically moves the position feedback assembly to

its limit in the unlikely event of failure of any component

in the linkage.

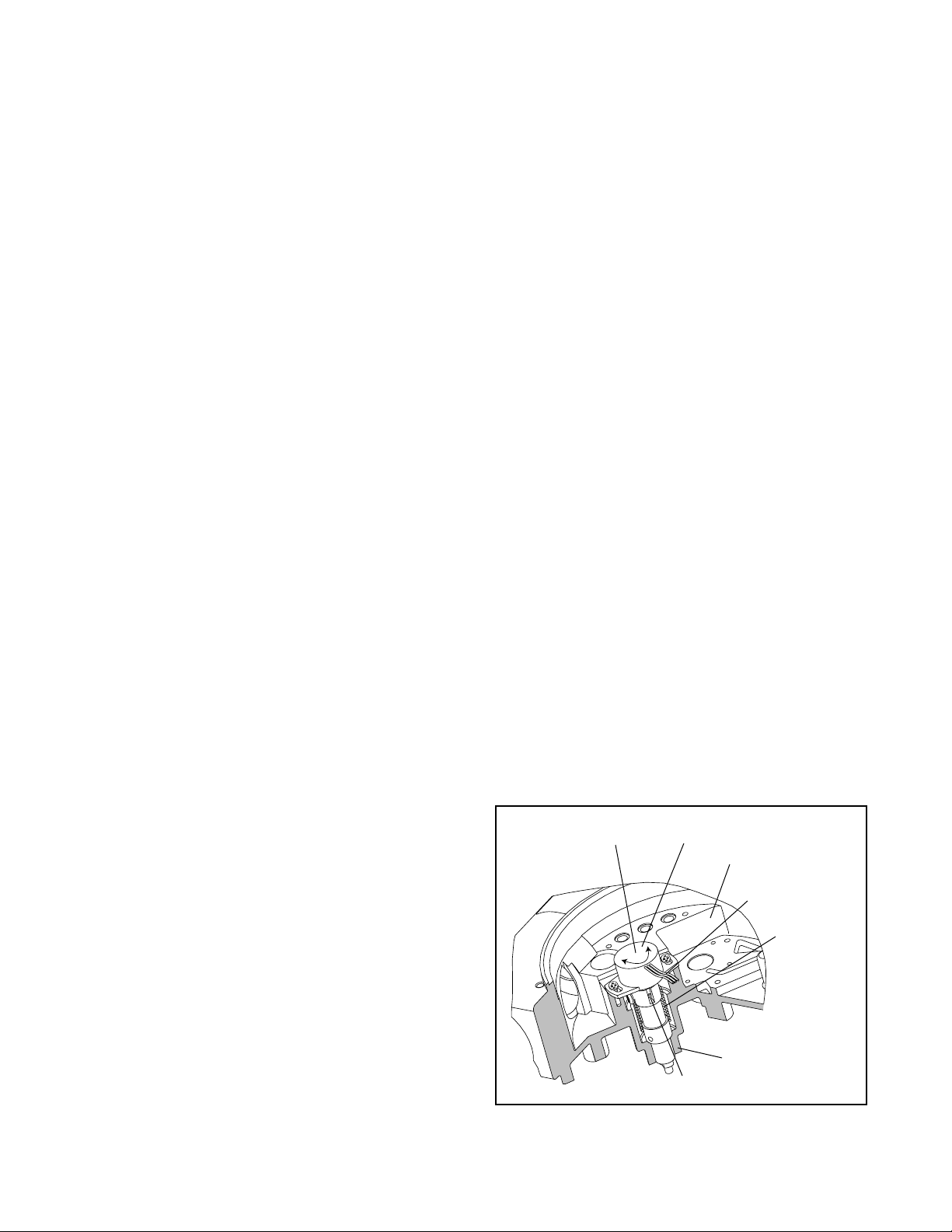

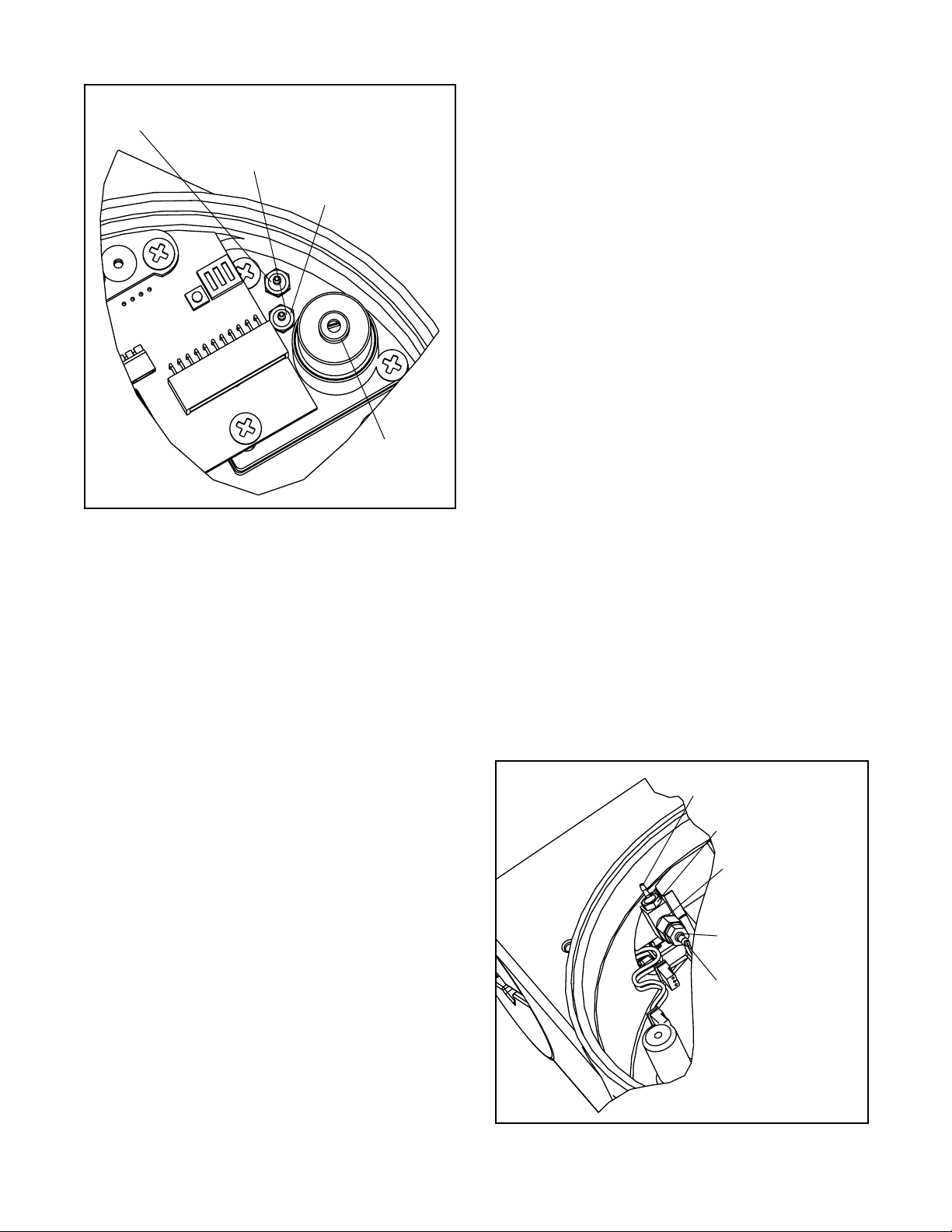

Stem Position Sensor Replacement

(Figure 9)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and disconnect rotary position sensor wires from collector board.

4. Remove the two screws from the rotary position

sensor, taking care not to lose the washers, and

remove the sensor from the housing.

5. Turn position sensor shaft until the dot on the slot is

aligned with the wires on the pot (Figure 9).

6. Insert the position sensor into the shaft with the

wires pointing toward the main PCB assembly. Turn

position sensor clockwise until the bolting slots align

with the housing screw holes and the wires on the

sensor protrude over the main PCB assembly tray.

7. Carefully center the position sensor on the shaft

bore, insert and tighten the screws.

Do not over

tighten.

8. Route wires along the position sensor and reconnect

to collector board.

Rotate Stem Position

Sensor

slowly

Stem Position Sensor

Housing

Sensor Cable

Feedback

Shaft

Bearing

Stem Position Sensor Dot

Figure 9:

Stem Position Sensor Orientation

46-8 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 9

LED Indicators

The Logix 1400 digital positioner has three LED indicators that are visible through a window in the main cover.

Only one LED will blink at any given time. Each LED has

a different color to convey basic information about the

positioner status. Green indicates that the positioner is

operating normally. Yellow indicates that a ‘customer

defined limit’ or ‘alert’ has been reached. Red indicates

that an error condition exists. A fieldbus configurator

must be used to determine the specific reason for a

yellow or red LED status.

During stroke and actuator calibration, no LED will blink.

After calibration is complete, the green LED indicates

that the calibration was completed successfully. If the

yellow or red LED blinks after a calibration process, a

warning or error was detected and the configurator must

be used to identify the specific calibration error.

NOTE: If the LED indicator changes from green to yellow

after a calibration process, the user may have set a

warning limit (position alert, cycle counter alert, etc.).

Use a fieldbus configurator to monitor status.

Re-Cal Button

If the fieldbus configurator is not available, Logix 1400

digital positioner has a Re-Cal feature that performs a

stroke calibration and allows basic operation of the positioner.

NOTE:The Re-Cal operation retains all previously configured information. All settings remain unchanged except

stroke calibration parameters. If the device is being

installed for the first time, factory default parameters are

used. The FB Configurator must be used the first time to

configure the Logix 1400 digital positioner. The trans-

ducer block must be out of service for Re-cal to work.

The Re-Cal button is located on the collector board inside

the main housing chamber as shown in Figure 10.

Warning: Accessing this function requires removal

of the main cover. The user must take all necessary

precautions if this operation is performed in explosion-proof areas.

Re-Cal Button

NOTE: DIP switches not

used on Logix 1400

positioner

Figure 10: Re-Cal Button

Make the appropriate configuration settings, using FB

Configurator and CONTROL_FLAGS variable. ATO/ATC

selects air-to-open or air-to-close (this is determined by

the mechanical tubing of the actuator). The Actuator

Style check box allows the user to select linear or rotary

feedback linkage. If

activates custom characterization.

Press Re-Cal button and hold for five seconds. If the button

is released before five seconds have elapsed, no action

will be taken. After five seconds, the positioner will begin

a stroke calibration. Release the Re-Cal button once

calibration has started. The positioner will automatically

stroke the valve. No LED will blink during this process.

Upon completion of calibration:

•A blinking green LED indicates the valve is in control

mode and calibration was successful.

•A blinking yellow LED immediately after a stroke

calibration usually indicates that the valve did not

stroke. Check the air supply and cable connections.

• The red LED will blink if a calibration error occurred.

The cause of a red LED is generally a stem position

linkage/feedback sensor alignment problem. For

linear linkage, the active electrical feedback angle is

65 degrees. For rotary linkage, the active electrical

feedback angle is 95 degrees. The red LED indicates

that the mechanical travel is not centered within the

electrical sensor travel. If a red LED is blinking after

a stroke calibration, loosen the feedback sensor

mounting screws as shown in Figure 9. Turn the stem

position sensor slowly while watching the LED indicators. Try small movements, both clockwise and counterclockwise. If the yellow LED begins to blink, the

feedback sensor has been correctly moved into range.

Tighten the feedback sensor mounting screws and

repeat the Re-Cal procedure. If the LED remains red

even after moving the full length of the sensor slot,

verify the following items:

under the CONTROL_FLAGS parameter ‘Actuator

Style’ (checked is rotary, unchecked is linear), stem

clamp and take-off arm height.

Custom

is selected, the positioner

Rotary

check box setting

NOTE:If the stroke stops in the closed position, the error

occurred when the position sensor/linkage was at closed

position. If the stroke stops in the open position, the error

occurred when position sensor/linkage was at the open

position. No calibration parameters are saved if an error

occurs. If the power to the positioner is removed, the unit

will power-up with the previous configuration parameters.

A successful calibration will save parameters.

If the valve does not stroke after pressing the Re-Cal

button, this may be an indication that the internal regulator pressure and/or the driver module minimum pressure is low. Refer to the following instructions to check

and set the internal regulator and minimum pressure

settings.

Note that the tools and equipment used in the next two

procedures are from indicated vendors.

46-9Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 10

This port is Internal Regulator Output. This

should be tubed to orifice on Driver Module.

Check pressure through

No. 10-32 x

1

/16 Barb fitting

Regulator Pressure

Test Port

Internal

Regulator

Set Screw

Figure 11: Internal Regulator

Checking or Setting Internal Regulator

Pressure

1. Disconnect the air supply from the positioner.

2. Remove the main cover. The regulator pressure set

port is factory plugged with a No. 10-32 hex plug

(Figure 11). Replace hex plug with a No. 10-32 x

1

/16-inch barb fitting.

3. Attach a 0 to 30 psi pressure gauge (with some

1

/16-inch flexible tubing) to the barb fitting shown in

Figure 11.

4. Reconnect the air supply to the positioner and read

the internal regulator pressure on the 0 to 30 gauge

(the internal regulator should be set to 22.0 psi).

Adjust the regulator pressure by turning the set

screw with a small flat screwdriver.

5. Once the regulator pressure is set, remove the air

supply to the positioner, and replace the No. 10-32 x

1

/16-inch barb fitting with the No. 10-32 hex plug.

Checking or Setting the Driver Module

Minimum Pressure

Once the internal regulator pressure is set to 22.0 psi, the

driver module minimum pressure can be checked. To do

this, refer to Figure 12, and proceed as follows:

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect power from the positioner.

3. Remove the main cover and remove the

flexible tubing from the orifice.

1

/16-inch

4. Obtain a No. 10-32 x swivel elbow (Pneumadyne part

No. SFL-10 or equivalent).

5. Remove No. 10-32 x .016 orifice (Figure 4) from the

driver module, and screw in No. 10-32 x swivel elbow.

6. Direct the swivel elbow so the minimum pressure

test port is accessible.

7. Screw a No. 10-32 x

1

/16-inch barb fitting into the test

port, and screw the No. 10-32 x .016 orifice into the

end of the elbow as shown.

8. Connect the tubing from the internal regulator output

port to the orifice.

9. Using some

1

/16-inch flexible tubing, connect a 0 to

30 gauge to the minimum pressure set port.

10. Once the gauge is connected, reapply the positioner

air supply. The minimum pressure should now be

registering on the gauge and must be 3.8 to 4.2 psi.

If the minimum pressure is not correct, use a

9

/64-inch Allen wrench to turn the minimum pressure

set screw located at the bottom of the driver module

(Figure 3) until the pressure is in the range indicated.

Cycle the positioner air supply several times and

recheck the minimum pressure and readjust, if

necessary, to ensure that the pressure has settled

within the range specified.

11. When the pressure is set, remove the air supply.

12. Remove the No. 10-32 x

1

/16-inch barb and orifice from

the swivel elbow and then remove the swivel elbow.

13. Replace the orifice as shown in Figure 4 and

reconnect the

1

/16-inch tubing from the internal regulator output port to the orifice. Reconnect the positioner air supply and power. The positioner should

now be ready to calibrate.

Minimum Pressure

Test Port

No.10-32 x

1

/16-inch

barb

No.10-32 x Swivel

ELL Pneumadyne

Part No. SFL-10

No.10-32 x .016

Orifice

Pressure from

Internal Regulator

to be tubed to this

orifice

Figure 12: Driver Module

46-10 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 11

Logix 1400 Positioner

Locknut

Washer

Follower

Arm

Nut

Lock Washer

Nut

Follower Pin

Take-off Arm

Bracket Bolts

Bracket

Positioner

Bolts

Nut

Stem Clamp

Bolts

Figure 13: Linear Mark I Control Valve Mounting

Linear Mark I Valve Mounting (Figure 13)

The tools required for the following procedure are:

9

/16-inch open-end wrench

7

/16-inch box wrench

3

/8-inch open-end wrench

1. Remove washer and first nut from follower pin

assembly. Insert pin into the appropriate hole in the

follower arm, based on stroke length. The stroke

lengths are stamped next to their corresponding

holes in the follower arms. Make sure the unthreaded

end of the pin is on the stamped side of the arm.

Reinsert lock washer and tighten nut to complete

follower arm assembly.

2. Slide the double-D slot in the follower arm assembly

over the flats on the position feedback shaft in the

back of the positioner. Make sure the arm is pointing

toward the field terminations side of the positioner.

Slide lock washer over the threads on the shaft and

tighten down the nut.

3. Align the bracket with the three outer mounting holes

on the positioner. Fasten with 1/4-inch bolts.

Metal

Washers

4. Screw mounting bolt into the hole on the yoke

mounting pad nearest the cylinder. Stop when the

bolt is approximately 3/16-inch from being flush with

mounting pad.

5. Slip the large end of the teardrop-shaped mounting

hole in the back of the positioner/bracket assembly

over the mounting bolt. Slide the small end of the

teardrop under the mounting bolt and align the lower

mounting holes.

6. Insert lower mounting bolt and tighten the bolting.

7. Slide the appropriate pin slot on the take-off arm,

based on stroke length, over the follower arm pin.

The appropriate stroke lengths are stamped near

each pin slot.

8. Position the take-off arm mounting slot against the

stem clamp mounting pad and insert take off arm

bolting.

9. Center the take-off arm on the rolling sleeve of the

follower pin.

10. Align take-off arm with top plane of the stem clamp

and tighten bolting.

46-11Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 12

Positioner Bolts 1/4-20 (4)*

Bracket Bolts 5/16-18 (2)

Follower Arm,

Rotary

Lock Washer (2)

Bolt No.10-32

Nut No.10-32

Self Tapping

Screws (2)

Spline Lever

Adapter

Figure 14: Standard Rotary Mounting

Standard Rotary Mounting Procedure

(Figure 14)

The standard rotary mounting applies to valve/actuator

assemblies that do not have mounted volume tanks or

handwheels. The standard mounting uses a linkage

directly coupled to the valve shaft. This linkage is not

affected by misalignment between the positioner and the

actuator.

The tools required for the following procedure are:

two5/16-inch open-end wrenches

3

/16-inch box-end wrench

1

/2-inch end wrench phillips driver

1. Fasten spline lever adapter to splined lever using two

No. 6 x 1/2-inch long self tapping screws.

2. Slide take-off arm assembly onto spline lever adapter

shaft and tighten nut with 5/16-inch end wrenches so

arm is snug on shaft but still able to rotate. This will

Nut No.10-32

Lock Washer

* Located in appropriate

Follower Arm

hole pattern as indicated on

bracket. (25, 50, 100/200)

Logix 1400 Positioner

be tightened after the linkage is correctly oriented.

3. Attach follower arm to positioner feedback shaft

using the star washer and No. 10-32 nut.

4. Using four 1/4-20 x .50 L. bolts and 7/16-inch box

wrench, fasten positioner to universal bracket using

appropriate hole pattern (stamped on bracket).

5. Using a 1/2-inch box wrench and two 5/16 -18 x .50 L.

bolts, attach bracket to actuator transfer case pad,

noting that the take-off arm pin must slide into slot on

follower arm. Leave these bolts slightly loose until

final adjustments are made.

6. Adjust bracket position noting the engagement of the

take-off arm pin and the follower arm slot. The pin

should extend approximately 3/16-inch past follower

arm. When properly adjusted, securely tighten the

bracket bolting.

46-12 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 13

Orient the Take-off Arm for Final Lock Down

Tube positioner to valve in the following manner:

1. Output 1 port of the manifold to bottom side of actuator.

2. Output 2 port of the manifold to the top side of the

actuator.

3. Connect the fieldbus to the field termination screws

under cover.

4. Connect regulated (70 psi) air supply to appropriate

port in manifold.

5. If setup was successful the green LED will blink and

the valve will be in control mode.

Use the NI Configurator to complete and monitor the

following steps:

1. Start the configurator.

2. Monitor the FVPTB block

3. In the transducer block, variable AD_RAW_FB

number is the digital representation of shaft position.

NOTE: To update the AD_RAW_FB variable, the

‘Enable Diagnostic Variable Access’ selection must

be enabled in TEST_MODE of the transducer block.

4. With supply pressure cut, rotate follower arm in the

same direction the shaft would rotate upon a loss of

supply pressure. When the mechanical stop of follower

arm is reached, tighten bolt on the take-off arm.

NOTE: The nut should be snug enough to hold the

follower arm in place but allow movement when

pushed.

The AD_RAW_FB number should now read 3600 or

500 (± 50).

5. Back the follower arm away from the mechanical

stop, watching the AD_RAW_FB number, until the

number changes 50-150 counts.

6. Tighten the nut on the take-off arm.

socket head bolt on the take-off arm needs to be as

tight as possible. If the take-off arm slips the positioner

will need to be re-calibrated.

7. Recalibrate using the Re-Cal button.

8. Set the FINAL_VALUE to 100. Using a screwdriver

press down on the follower arm’s pin so the pin

touches the other side of the slot. The AD_RAW_FB

number should change about 20 counts and the

valve should move a small amount. If no change in

the AD_RAW_FB number or movement in the valve

occurs repeat steps 4-8 but limit the change in

AD_RAW_FB in step 5 to 30-75 counts.

WARNING: Failure to follow this procedure will

result in positioner and/or linkage damage. Check

air-action and stroke carefully before lockdown

of take-off arm to spline lever adapter.

NOTE: The

Optional Rotary Mounting Procedure

(Figure 15)

The optional rotary mounting applies to valve/actuator

assemblies that are equipped with mounted volume

tanks or handwheels. The optional mounting uses a fourbar linkage coupled to the valve shaft. The following tools

are required:

3

/8-inch box wrench

7

/16-inch box wrench

1

/2-inch box wrench

1. Using a 1/2-inch box end wrench and two 5/16-18 x .50

L. bolts, attach bracket to actuator transfer case

pads. Leave bracket loose to allow for adjustment.

2. Using four 1/4-20 x .50 L. bolts and a 1/16-inch box

wrench, fasten positioner to universal bracket, using

the four-hole pattern that locates the positioner the

farthest from the valve. Rotate positioner 90 degrees

from normal so gauges are facing upward.

3. Attach follower arm to positioner feedback shaft,

using the star washer and No. 10-32 nut.

4. Attach tripper and tripper clamp to shaft, using two

1

/4-20 L. bolts and two 1/4-20 locknuts. Leave tripper

loose on shaft until final adjustment.

5. Thread ball joint linkage end to tripper and tighten

(Thread locking compound such as Loctite is recommended to prevent back threading). Adjust length of

tie rod so follower arm and tripper rotate parallel to

each other (the rod must be cut to the desired

length). Connect other ball joint end to follower arm

using a star washer and a No. 10-32 nut.

6. Tighten bracket and tripper bolting.

7. Check for proper operation, note direction of rotation.

WARNING: Rotating in the wrong direction will

result in serious damage to the positioner and/or

linkage. Check air action and stroke direction

carefully.

Third-party Actuator Mounting

Contact the factory for information on mounting the Logix

1400 digital positioner on actuators not manufactured by

Flowserve.

Troubleshooting the Logix 1400 Digital

Positioner

This section provides troubleshooting information for the

two-wire, FOUNDATION fieldbus communication based, Logix

14xx series digital positioner. In addition, pointers on

operation and configuration will also be covered.

Theory of Operation

Figure 16 shows the basic positioning block diagram for

the Logix 1400 digital positioner.

46-13Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 14

Bolts (2)

Locknuts (2)

Tripper

Tripper Clamp

* Tie Rod must be cut to desired length

*Tie Rod

Nut No. 10-32

Lock Washer

Mounting Bolts

1

/4-20 (4)

Bracket Bolts 5/16-18 (2)

Ball Joint Ends

Follower Arm

Rotate Positioner 90°

Figure 15: Optional Rotary Mounting

NOTE: Variable names in Figure 16 are for internal posi-

tioner use and are not directly accessible via fieldbus.

The Logix 1400 digital positioner receives power from the

two-wire, fieldbus input signal. A digital signal, sent via

fieldbus, is used as the command source.

Zero percent is always defined as the valve closed

position and 100 percent is always defined as the valve

open position.

Next, the command value is passed through a characterization/limits algorithm. The positioner no longer

uses CAMs or other mechanical means to characterize the output of the positioner. This function is done

in software, which allows for in-the-field customer

adjustment. The positioner has two basic modes:

linear

and

custom

characterization. In linear mode, the

command signal is passed straight through to the control

algorithm in a 1:1 transfer. In addition the user-defined

46-14 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

features, Soft Limits, FINAL_VALUE_CUTOFF_HI,

and FINAL_VALUE_CUTOFF_LO may affect the final

command signal. The actual command being used to

position the stem is called CMD_USED. The

CMD_USED is the actual positioning command after any

characterization or user limits have been evaluated.

The Logix 1400 digital positioner uses a two-stage stem

positioning algorithm. The two stages are comprised of

an inner-loop, spool control and an outer-loop, stem

position control. Referring again to Figure 16, a stem

position sensor provides a measurement of the stem

movement. The FINAL_VALUE command is compared

against the FINAL_VALUE_POSITION. If any deviation

exists, the control algorithm sends a signal to the innerloop control to move the spool, up or down, depending

upon the deviation. The inner-loop then quickly adjusts

the spool position. The actuator pressures change and

Page 15

the stem begins to move. The stem movement reduces

the deviation between control command and stem position. This process continues until the deviation goes to

zero. The control algorithm is both proportional and

integral. This algorithm will be further explained later in

this document.

A more detailed example to explain the control function

follows. The following configuration exists.

• Unit will receive its command from the FB.

• Custom characterization is disabled (therefore characterization is linear).

• Soft limits or FINAL_VALUE_CUTOFF are disabled.

• Valve has zero deviation with a present input command of 50 percent.

Actuator is tubed Air-to-Open

Given these conditions, 50 percent represents a command of 50 percent. Custom characterization is disabled

so the command is passed 1:1 to the CMD_USED. Since

zero deviation exists, the stem position is also at 50

percent. With the stem at the desired position, the spool

valve will be at a position in which no air flow is allowed

to either side of the actuator. This is commonly called the

nullorbalanced

mand from 50 percent to 75 percent. The positioner sees

this as a FINAL_VALUE command of 75 percent. With

linear characterization, the CMD_USED becomes 75

percent. Deviation is the difference between the control

command (CMD_USED) and Stem Position: Deviation =

75 percent - 50 percent = +25 percent, where 50 percent

is the present stem position. With positive deviation, the

control algorithm sends a signal to move the spool up

from its present position. As the spool moves up, the

supply air is applied to the bottom of the actuator and air

is exhausted from the top of the actuator. This new

pressure differential causes the stem to start moving

towards the desired position of 75 percent. As the stem

moves, the deviation begins to decrease. The control

algorithm begins to reduce the spool opening. This

process continues until the deviation goes to zero. At

this point, the spool will be back in its

position. Stem movement will stop. Desired stem position has now been achieved.

One important parameter should now be discussed point:

Inner-loop offset. A number called inner-loop offset

(IL_OFFSET) is added to the output of the control

algorithm. (Refer to Figure 16.) For the spool to remain in

its

null

or

output a non-zero spool command. This is the purpose of

the inner-loop offset. The value of this number is equivalent to the signal that must be sent to spool position

control to bring it to a

deviation. This parameter is important for proper control

and will be discussed further in the

section.

spool position. Now, change the com-

null

balanced

position, the control algorithm must

null

position with zero stem

Control and Tuning

or

balanced

Mounting and Installation

Electrical Wiring

Verify polarity when making field termination connection.

With a fieldbus power supply connected, verify that an

LED is blinking to determine if the electronics are

running. Only one LED will blink at any given time.

Compatibility with DCSs using 24VDC

FB specifies a 9-32V operation range. A fieldbus compatible power supply with terminators should be used to

power a Logix 14xx digital positioner with a DCS using

9 - 32 VDC.

Reverse polarity protection

The Logix 14xx digital positioner is reverse polarity

protected. Inadvertent reversing of the voltage supply

across the Logix 1400 digital positioner should not

damage the device, if current is limited.

Air Action

Air-to-open and air-to-close are determined by the actuator tubing, not the software. When air action selection is

made during configuration, the selection is telling the

control which way the actuator is tubed. Verify that tubing

is correct prior to a stroke calibration. The top output port

on the positioner is called

the increase open side of the actuator. That is, for an airto-open actuator,

actuator.

output 1

output 1

should go to the bottom of the

. It should be tubed to

Linear vs. Rotary

The positioner has two configuration settings: Linear and

rotary. To achieve better resolution, stem position sensor gains are adjusted based on the angle of rotation of

the linkage. The linear setting allows for linkage rotation

up to 65 degrees. The rotary setting allows for linkage

rotation up to 95 degrees. These settings only determine

the angle of sensor rotation and do not affect control

parameters. If a positioner is set to linear linkage and a

red LED blinks after calibration, the most common cause

is that the sensor movement was greater than 65 degrees. This can occur if the roller pin was placed in the

wrong hole on the follower arm or the stem clamp is

placed too high. The take-off arm should always be level

with the stem clamp on linear mountings.

The Logix 14xx positioner has an electrical measurement range of 95 degrees. That is, the electronics will

sense stem position over a 100 degrees range of travel

of the follower arm. On a rotary valve, the typical rotation

is 90 degrees. When installing a Logix 14xx positioner on

a rotary valve, it is important that the 90 degrees valve

rotation is centered within the 95 degrees electrical

range. If mechanical movement falls outside the electrical measurement range, the positioner can have a deadband at one end of travel in which valve movement

cannot be sensed.

46-15Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 16

Centering the rotary linkage

To determine whether the rotary linkage is centered in the

100 degrees range move the valve to the fully closed

position. The slot in the take-off arm has enough clearance around the roller pin to move the follower arm

slightly. At this position, move the follower arm within the

slot clearance. If the valve does not respond, linkage

adjustment is necessary. Repeat this test at the fully

open position.

To adjust the stem position linkage, use the AD_RAW_FB

variable. With the valve in its mechanical fail position

(i.e. no pressure applied), slightly move the follower arm

while watching the A/D feedback. If the number does not

change, the arm is not centered in the electrical range.

(The number will bounce 1 or 2 counts due to noise at a

fixed position and should not be considered a change, it

should move greater than 10 to 20 counts if the linkage

is centered correctly). Rotate the take-off arm, if necessary, to bring the linkage in range. This procedure is only

necessary on a rotary mounting. For linear mountings,

the red LED will blink if you exceed 65 degrees travel.

Refer to the

stroke calibration errors.

To view the feedback variable use the FB configurator of

view the AD_RAW_FB in the transducer function block.

NOTE:To update the AD_RAW_FB variable, the ‘Enable

Diagnostic Variable Access’ selection must be enabled in

TEST_MODE of the transducer block.

Calibration

section for further information on

Calibration

Re-Cal

Re-Cal is a method by which the valve can be stroke

calibrated without using the fieldbus configurator.

NOTE:The transducer function block must be in OOS (out

of service) mode for the Re-Cal button to be operational.

Re-Cal only affects position calibration. Any previous

configuration or stored information is not affected.

Position 0% Calibration Flag in

CALIBRATE_FLAGS

Position 100% Calibration Flag in

CALIBRATE_FLAGS

During stroke calibration, the Logix 1400 digital positioner checks to see if the linkage is placing the stem

position sensor in range. If the valve stroke causes stem

position measurement to go out of range in the open

position, a

valve stem will stop in the open position and the red LED

will blink. Linkage must be adjusted to bring the sensor

in range.

range, the LEDs can be used as an adjustment guide. The

LED will change from a red to yellow when the linkage is

brought into range.

Position 100% Flag

Special LED indication: If the linkage is out of

will be generated. The

Position Span Flag in

CALIBRATE_FLAGS

Position span is a check during stroke calibration to

verify that the valve stem moved. The algorithm waits to

see if no movement is detected when the valve is

automatically stroked open. Anything which could prevent the valve from stroking will generate a

error (no supply pressure, malfunctioning spool valve).

Position Span

Control and Tuning

Setting P + I Parameters

Using the configurator, you can set individual tuning

parameters. A few key points are mentioned below. (See

Figure 17.)

GAIN_UPPER, GAIN_LOWER, and GAIN_MULT: These

three parameters are related by the following formula.

Proportional Gain =

Maximum Gain - Ideviation| x Gain Multiplier

If Proportional Gain < Minimum Gain,

then Proportional Gain = Minimum Gain

This algorithm allows for quicker response to smaller

steps yet stable control for large steps. Setting the gain

multiplier to zero and max gain = min gain results in a

typical fixed proportional gain.

The higher the gain multiplier, the larger the required

deviation before the gain increases. Default values

upon initiating a RESET to factory defaults (under

During stroke calibration, the Logix 1400 digital positioner checks to see if the linkage is placing the stem

position sensor in range. If the valve stroke causes stem

position measurement to go out of range in the closed

position, a

stem will stop in the closed position and the red LED will

blink. Linkage must be adjusted to bring the sensor in

range.

range, the LEDs can be used as an adjustment guide. The

LED will change from a red to yellow when the linkage is

brought into range.

46-16 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Position 0% Flag

Special LED indication: If the linkage is out of

will be generated. The valve

Figure 16: Gain Effect Diagram

Page 17

Air Supply

Tubed ATO

Control

Algorithm

P

max

P

min

G

mult

(GAIN_MULTI)

Integration Summer

Inner Loop Offset

XDAO

Linear Mode

Characterization

Soft Limits

MPC

Control

Command

(CMD_USED)

+

Deviation

Position

Figure 17: Logix 1400 Digital Positioner Block Diagram

LOAD_EE_DEFAULTS) are maximum gain = 2.0, minimum gain= 1.0, and gain multiplier= 0.05. These values

will allow stable control on all Valtek control product

actuator sizes.

Integral Gain (IGAIN): The integral gain is primarily for

deviations due to temperature drift within the inner loop

spool control. The factory default value is 10. Although

higher numbers can speed the time it takes to reach zero

deviation, it can add overshoot if too large. It is recommended that maximum and minimum gains be adjusted

while leaving integral gain fixed at 10. Integration is

disabled below a stem position of 3 percent and above a

stem position of 97 percent. This is to prevent integration

windup from calibration shifts due to lower pressure or a

damaged seat which may prevent fully closing the valve.

Integration Summer: The integral summer within the

Logix 1400 digital positioner is clamped at +20 percent

and -20 percent. If the integration summer is fixed at +20

percent or -20 percent, it usually indicates a control

problem. Some reasons for a clamped integration summer are listed below:

• Stroke calibration incorrect.

• Any failure which prevents stem position movement:

stuck spool, handwheel override, low pressure.

• Incorrect inner loop offset.

• Loss of air supply on a fail in place actuator.

Writing a zero to integral gain (IGAIN) will clear the

integral summer. The integral gain can then be returned

to its original value.

Inner loop offset (IL_OFFSET): Three control numbers

are summed to drive the inner loop spool position control:

proportional gain, integral summer, and inner-loop offset.

Inner-loop offset is the parameter which holds the spool

in the ‘null’ or ‘balance’ position with a control deviation

of zero. This value is written by the positioner during

Sensor

Modulator

Coil Current

Inner Loop

Spool Control

Stem

Position

Sensor

(GAIN_UPPER)

(GAIN_LOWER)

(IL_OFFSET)

(HALL_SENSOR)

D/A Output

Percentage

Inner-Loop

Hall Sensor

Output

stroke calibration and is a function of the mechanical and

electrical spool sensing tolerances. However, if it becomes necessary to replace the driver module assembly

or the software RESET calibration constants has been

performed, it may be necessary to adjust this value. The

method below should be used to adjust inner-loop offset.

Or simply perform a new stroke calibration.

From the fieldbus configurator:

• Send a 50 percent command.

• Set integral to zero.

• Locate the DAC_PERCENT

• Write this percentage value to IL_OFFSET

• Write original value to Integral

These tuning sets can be used to obtain initial values for

Flowserve products and comparable actuator sizes. The

user may need to adjust this tuning to achieve optimal

performance for a particular application.

Table I: Factory Tuning Sets

.gfM

ketlaVA_yrotcaFV0.10.250.00152

remmaK84repoorT4.05.050.05213

xamotuA1R3.05.050.0015ot3

gninuT

teS

B_yrotcaFV0.15.250.00105

C_yrotcaFV0.20.350.001001

D_yrotcaFV0.40.550.001002

E_yrotcaFV0.40.750.001003

84repoorT4.05.050.05213

94repoorT0.30.450.0015.77

94repoorT0.30.450.0015.77

2R0.15.150.00121ot9

3R3.10.250.00191ot61

4R0.25.250.00173ot72

5R5.26.350.00157ot84

6R0.40.550.001901

_NIAG

_NIAG

_NIAG

REWOL

REPPU

niagl

TLUM

elbarapmoC

).ni.qs(eziS

46-17Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 18

Spool Valve

The spool valve is a four-way directional valve with

precision features to provide optimal control and low air

consumption. To help prevent spool valve malfunction,

the positioner supply air must conform to ISA Standard

S7.3 (a dew point at least 18 degrees below ambient

temperature, particle size below 1 microns, oil content

not to exceed 1 part per million). Flowserve’s standard

coalescing filter is highly recommended to help meet

these requirements.

Small particles, oil that has varnished, corrosion, ice,

burrs and extreme wear could cause the spool valve to

act abnormally. If the spool valve is suspected of

sticking, it can be inspected by performing the following.

1. Make sure the valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the spool valve cover by removing the

screw and sliding the cover assembly backwards

until the tab is clear of the slot.

4. Inspect the coalescing filter element in the spool

valve cover for signs of oil, water and debris that may

have come from the air supply. A clean filter is white.

5. Remove the two phillips-head screws holding the

spool valve to the housing. Inspect the free movement of the spool by carefully sliding the block up

and down on the spool about 1/4 inch. The block

should slide on the spool with no resistance. Carefully remove the block ensuring it is removed concentric with the spool.

6. Inspect the block and spool for oil, water, debris and

wear. If oil, water and/or debris are found, the spool

and block can be cleaned with a non-residue cleaner,

lint free cloth and soft bristle brush. If wear is found,

replace the driver module assembly as instructed in

this document.

7. Before reassembly, verify that the three O-rings are

in the counter-bores on the machined platform where

the spool valve block is to be placed.

8. Carefully slide the block over the spool, using the

machined surface of the housing base as a register.

Slide the block toward the driver module until the two

retaining holes line up with the threaded holes in the

base. If resistance is still encountered re-clean both

parts or replace the driver module assembly. Refer

to the

Spare Part Kits

section.

Alarms

The Logix 1400 digital positioner has several internal

alarms which monitor electronics operation. An internal

alarm causes the red LED to blink. Alarms differ from

alerts because the action of the positioner may be erratic

during the alarm conditions. Alert warns operations that

a predefined, user configured, condition has occurred

that may require service in the near future. Alarms cause

the red LED to blink, while alerts cause the yellow LED

to blink. Refer to the FOUNDATION fieldbus documentation

for the handling of FB alerts and alarms.

12-bit A/D Reference Alarm

The Logix 1400 digital positioner utilizes a 12-bit analogto-digital converter to acquire stem position readings. If

the precision reference used by the A/D drifts outside

rated tolerances, the 12-bit A/D reference alarm will

become active. A reference error will cause change in

calibration and control readings. If a continuous 12-bit

A/D reference alarm exists, the main PCB assembly

must be replaced. Refer to the

Spare Part Kits

section.

1.23 V Reference Alarm

The 1.23 V reference is used by the inner-loop spool

position control. If it drifts outside normal tolerances, the

1.23 V reference alarm will become active. If a continuous 1.23 V reference alarm exists, the main PCB

assembly must be replaced. Refer to the

section.

Spare Part Kits

12-bit D/A Alarm

The Logix 1400 digital positioner utilizes a 12-bit digitalto-analog converter to send a control signal from the

microcontroller to the inner loop spool positioning circuit.

The output of the D/A converter is independently measured to verify correct operation. A 12-bit D/A alarm

indicates that the D/A may be malfunctioning. If a

continuous 12-bit D/A Alarm exists, the main PCB

assembly must be replaced. Refer to the

section.

Spare Part Kits

Temperature Alarm

The main PCB assembly contains an ambient temperature sensor. If the ambient temperature readings goes

outside the operating range, -40° F to +185° F (-40° C to

+85° C), the temperature alarm will become active. The

red LED will also blink. If this alarm is present and the

ambient temperature reading is incorrect, the main PCB

assembly must be replaced. Refer to the

section.

Spare Part Kits

Hall Sensor Alarm

The Logix 1400 digital positioner uses an inner-loop,

spool-positioning stage. A hall sensor is used for spool

control. If the electronics senses a problem with the

sensor, the hall sensor alarm will activate. Some common reasons for a hall sensor alarm are loose or missing

cable connection to the collector board assembly or a

broken wire. In the event that the actual hall sensor is

defective, the driver module assembly must be replaced.

Refer to the

Spare Part Kits

section.

46-18 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 19

Modulator Current Alarm

The pressure modulator is an electro-pnuematic device

which takes a current signal from the electronics control

and generates a pressure which moves the spool. The

Logix 1400 digital positioner is a FB powered device

which must run on very low power. During operation, the

pressure modulator current is monitored. If the current

draw exceeds 0.9mA under normal control, the modulator current alarm will become active and the red LED will

blink. Sometimes, the current level may be right at the

threshold of 0.9mA causing the LED to alternate between

red and green. Listed below are some reasons for a

modulator current alarm. The magnitude of modulator

coil current can be viewed from the configurator.

• Modulator minimum pressure too low

• Clogged or restricted orifice

• Bad or missing cable connection to collector board

assembly

• Stuck or sticky spool

• Internal air leaks: tubing, orifice gasket, pressure

modulator

EEPROM Checksum Alarm

Configuration data is stored in EEPROM. When power is

lost, configuration information is retrieved from EEPROM

and operation resumes. A check is done by the microcontroller after a power-up to make sure data saved in

EEPROM has not been corrupted. The checksum is a

number which is calculated based on configuration data.

It is also saved in EEPROM every time data is stored. If

after a power-up, this number does not match the data in

memory, an EEPROM checksum alarm is generated and

the red LED will blink. If this occurs, try powering the

Logix 1400 digital positioner off and then back on. If the

error does not clear, try saving configuration data again

using FB Configurator. If previous configuration has not

been saved, you must reset the device and re-configure.

If these steps still do not clear the error, the main PCB

assembly must be replaced. Refer to the

section.

Spare Part Kits

Pressure Alarms

Note: Pressure alarms are only available on models with

advanced diagnostics (Logix 141x).

Advanced diagnostic models add ouput port 1, output port

2 and supply pressure sensors. These sensor readings

and alarms are only accessible from the communicator

when the configuration has been set to advanced.

Loss of Pressure: The loss of pressure alarm becomes

active when the supply pressure is near the minimum

positioner operating pressure of 30 psig. If the LEDs

alternate between red and green, the supply pressure

may be at the limit threshold. This alarm is meant to alert

the user to low supply pressure as well as complete loss

of pressure.

Output Port 1 Sensor, Output Port 2 Sensor, Supply

Sensor: Each sensor is checked during actuator calibra-

tion. If a calibration reading appears to be out of range,

the appropriate alarm will become active. The pressure

sensors are located on the collector board assembly.

Alerts

FINAL_VALUE_CUTOFF

The FINAL_VALUE_CUTOFF or tight shutoff feature

of the Logix 1400 digital positioner allows the user to

control the level at which the command signal causes

full actuator saturation in the closed or open position.

This feature can be used to guarantee actuator saturation in the closed or open position or prevent throttling

around the seat at small command signal levels. To

enable, use configuration to apply the desired

FINAL_VALUE_CUTOFF threshold.

Note: The positioner automatically adds a 1 percent

hysteresis value to the FINAL_VALUE_CUTOFF_LO

setting to prevent jumping in and out of saturation when

the command is close to the setting.

Effects of FINAL_VALUE_CUTOFF on Operation

With the FINAL_VALUE_CUTOFF_LO set at 5 percent

the positioner will operate as follows:

Assume that the present command signal is at 50

percent. If the command signal is decreased, the positioner will follow the command until it reaches 5 percent.

At 5 percent, full actuator saturation will occur. The

actuator will maintain full saturation below 5 percent

command signal. Now, as the command increases, the

positioner will remain saturated until the command

reaches 6 percent (remember the 1 percent hysteresis

value added by the positioner). At this point, the stem

position will follow the command signal.

If the FINAL_VALUE_CUTOFF_LO is set to 3 percent

but the valve will not go below 10 percent,

SOFTSTOP_LOW may be enabled. The lower soft

limit must be less than or equal to 0 percent in order

for the FINAL_VALUE_CUTOFF_LO to become active. If soft stops are active (ie: SOFTSTOP_LOW =

0 or SOFTSTOP_HIGH = 100) FINAL_VALUE_CUTOFF

is disabled.

Soft Limits

Unlike position alerts, soft limits prevent the stem position from going below or above the configured limits. If

the command signal is trying to drive the position past

one of the limits, the yellow LED will blink but the stem

position will remain at the set limit.

Travel Accumulator

The travel accumulator is equivalent to a car odometer

and sums the total valve movement. Using the user

defined stroke length and travel dead-band, the Logix

46-19Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 20

1400 digital positioner keeps a running total of valve

movement. When the positioner first powers up, high and

low dead-band limits are calculated around the present

position. When the stem position exceeds the travel

dead-band, the movement from the center of the deadband region to the new position is calculated and added

to the travel accumulator. From this new position, deadband high and low limits are again calculated.

Example: The Logix 1400 digital positioner has a default

dead-band configuration of 20 percent. The valve has a

4 inch linear stroke. When the valve first powers up, the

command signal is 50 percent. The unit will calculate a

high travel threshold of 70 percent (50 percent present

position plus 20 percent dead-band) and a low travel

threshold of 30 percent (50 percent present position

minus 20 percent dead-band). As long as the stem

position remains greater than 30 percent and less than 70

percent, no additions are made to the travel accumulator.

Now, assume the stem position moves to 80 percent

which is outside the present dead-band. The Logix 1400

digital positioner calculates the stem movement and

adds this number to the travel accumulator.

80 percent (present position) - 50 percent (previous) =

30 percent movement x 4-inch stroke = 1.2 inches

So, 1.2 inches is added to the travel accumulator. New

dead-band thresholds of 100 percent (80 percent present

position plus 20 percent dead-band) and 60 percent (80

percent present position minus 20 percent dead-band)

are calculated. This process continues as the stem

position moves throughout its stroke range.

Cycle Counter

The cycle counter is another means of monitoring valve