User Instructions LinedFlow - KMENIM3202-02 01/12

®

USER INSTRUCTIONS

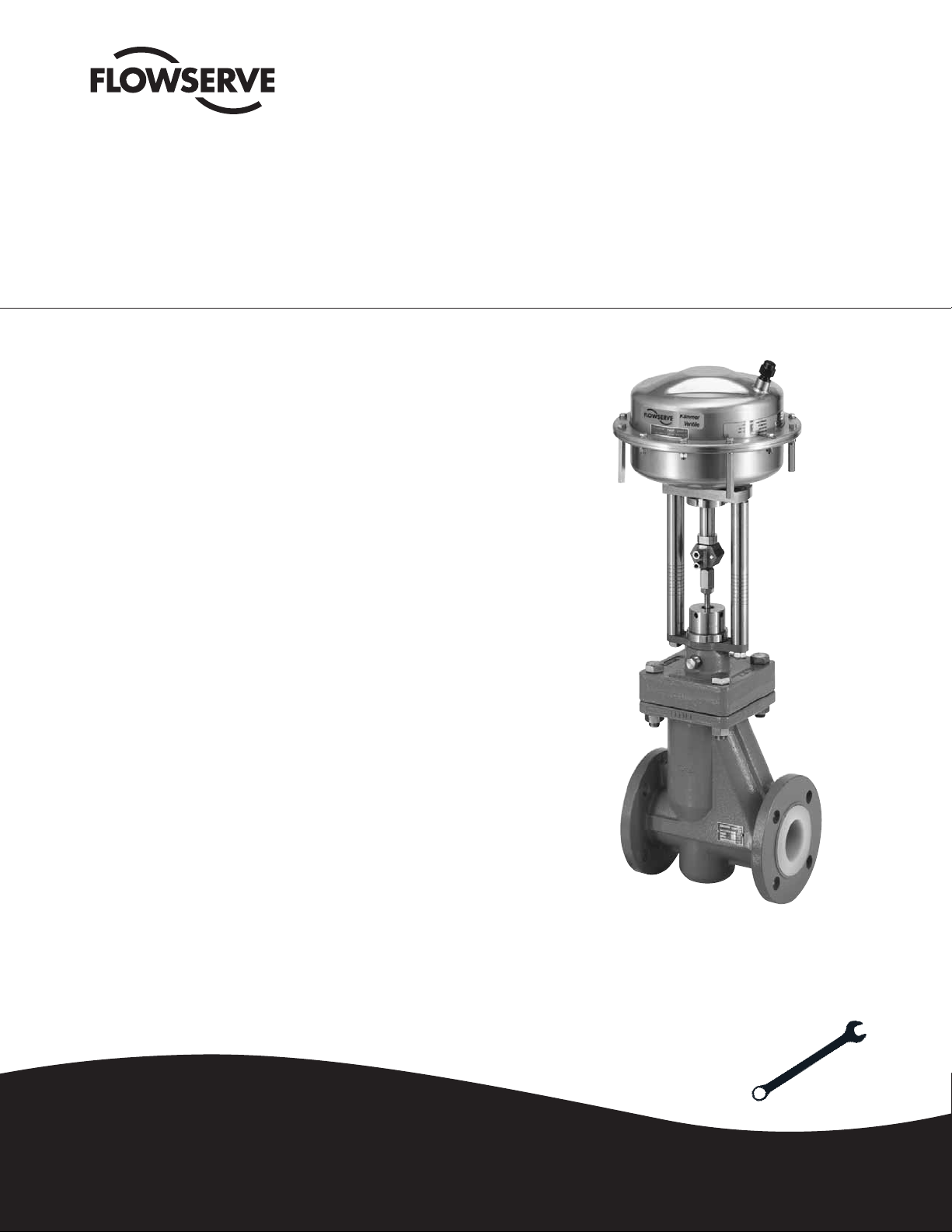

Kämmer ® LinedFlow™ - 132000

Valves for Corrosive Applications

FCD KMENIM3202-02 01/12

Installation

Operation

Maintenance

Experience In Motion

1

User Instructions LinedFlow - KMENIM3202-02 01/12

STOP!

STOP!

STOP!

STOP!

STOP!

®

INDEX

1 Using FLOWSERVE valves and actuators

and accessories correctly

2 Transport and storage

3 Installation

4 Intended use

5 Installation

6 Pressure test pipe section

7 Normal operation and maintenance

8 Trouble-shooting

9 Product description

10 Bonnet

11 Plug and seat

12 Bellows seal

1 3 Stem

14 Packing

15 Test connection

16 Quick check

17 Maintenance

18 Remove actuator from valve

19 Install actuator on valve

20 Disassemble and assemble valve

21 Trouble-shooting chart

1

USING KÄMMER VALVES AND ACTUATORS CORRECTLY

1.1 Use

FLOWSERVE control valves and actuators are intended

exclusively for control of mediums in an approved pressure

and temperature range after installation in a piping system

and connection of the actuator to the control system.

The permissible pressure and temperature limits are defined

in the operating instructions for the individual valve series.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAUTION and NOTE

are used in these instructions to highlight particular dangers

and/or to provide additional information on aspects that

may not be readily apparent.

DANGER: indicates that death, severe personal injury and/

or substantial property damage will occur if proper precautions are not taken.

WARNING: indicates that death, severe personal injury and/

or substantial property damage can occur if proper precautions are not taken.

CAUTION: indicates that minor personal injury and/or pro-

perty damage can occur if proper precautions are not taken.

NOTE: indicates and provides additional technical infor-

mation, which may not be very obvious even to qualified

personnel. Compliance with other, not particularly emphasised notes, with regard to transport, assembly, operation and

maintenance and with regard to technical documentation

(e.g. in the operating instruction, product documentation or

on the product itself) is essential, in order to avoid faults,

which in themselves might directly or indirectly cause

severe personal injury or property damage.

2

1.3 Safety Notes for Operator

The manufacturer is not responsible for the following and it

is therefore necessary to ensure the following when using

FLOWSERVE control valves:

1.3.1 ...use valve as intended (Section 1)

DANGER: Never operate a control valve whose approved

pressure/temperature range according to the applicable

documentation for the valve series is not sufficient for the

operating conditions. Moreover, it must be ensured that the

valve is approved for the operating medium:

WARNING: Protection against incorrect use of control valve:

In particular, it is necessary to ensure that the selected

coating on the valve parts in contact with the medium are

suitable for the mediums, pressures and temperatures encountered. The manufacturer is not responsible for damage

to the valve resulting from corrosive mediums. Failure to

observe these precautions can pose a danger for the use

and cause damage to the piping system.

1.3.2 ...the piping system and control system must be installed

properly and checked regularly. The wall thicknesses of the

FLOWSERVE control valves correspond to the standards

and regulations for the pressure stage requirements of the

piping system in question.

1.3.3 ...the valves must be connected properly to this system.

1.3.4 ...the usual flow rates in continuous operation are not

exceeded in this piping system and abnormal operating

conditions such as vibration, water hammer, cavitation and

excessive quantities of solids in the medium – particularly

abrasive solids – must be clarified with the manufacturer.

WARNING: At temperatures > +50 °C and < -20 °C, it is

necessary to provide for protection against skin contact

including the piping connections.

1.4 Particular dangers

DANGER: The valve stem is sealed with a packing gland.

Before loosening or unscrewing the packing nut , ensure

that the pressure in the pipeline is completely relieved so

that the medium cannot escape through the packing.

Observe the usual safety precautions for hazardous medium

– particularly the use of protective clothing – when working

on the valves.

DANGER: On valves with a bellows seal also ensure that the

bellows does not leak by using a test connection, if present,

before removing the packing gland nut.

DANGER: Before removing the valve from the pipeline, en-

sure that the pressure in the pipeline is completely relieved

so that the medium does not escape uncontrolled from the

line.

WARNING: If it is necessary to remove a valve from the

pipeline, medium can escape from the line or from the valves. In the case of mediums which pose a health danger or

other danger, ensure that the pipeline is completely purged

before removing the valve.

User Instructions LinedFlow - KMENIM3202-02 01/12

STOP!

STOP!

STOP!

STOP!

STOP!

STOP!

STOP!

®

Observe caution with residues flowing out of the line or

remaining in the dead chambers of the valves. In the case of

dangerous mediums, observe the usual safety precautions

– particularly protective clothing.

WARNING: Disconnect or loosen the fastners – particularly

between bonnet and housing – only after the valve has been

removed. When reinstalling, tighten the bolts as specified in

these maintenance instructions using a torque wrench.

2 TRANSPORT AND STORAGE

Handle, transport and store FLOWSERVE control valves

carefully.

2.1 Store the valve in its protective packaging and/or with the

protective caps on the connection ends. Valves heavier

than approx. 10 kg should be stored and transported on a

pallet (or similarly supported, where applicable also on the

installation site).

WARNING: Do not place unpackaged valves on dirty

surfaces with the flange sealing surfaces. Hard and/or sharp

particles can damage the plastic lining.

2.2 During storage before installation, the valves should be

stored in a closed room as a rule and protected against

damaging influences such as dirt or moisture.

2.3 Large valves can be picked up using hoisting belts on

the yoke stems / eyes or - if present – on the supporting

shackles provided for this purpose. If hoisting belts are

used for unpacking, connect them so that the outer piping

and attached parts are not damaged.

WARNING: If hoisting belts are used, the center of gravity

of the valve can be higher than the connection point. In

such cases, secure the valve against turning or support it to

prevent injury or property damage.

In the event of transport damage, please contact your

FLOWSERVE representative immediately.

3 INSTALLATION

3.1 General

The same instructions apply for installing FLOWSER-

VE control valves in a pipeline as for connecting pipes

and similar piping elements with plastic liner materials. For control valves, the following instructions

apply in addition. Observe Section 3 for transport at

the installation site.

WARNING: Handle valves with particular care and observe

instructions for flange connections.

NOTE: As a rule, additional flange seals are not required.

The counterflanges must have smooth sealing surfaces in

all cases, e.g. Form C, Form D or Form E according to Standard DIN 2526 or Form B1 or B2 according to EN 1092-1

or stock finish according to ANSI B16.5. Other flange forms

must be coordinated with the manufacturer.

In addition, observe the following for actuators:

WARNING: Never subject actuators to external loads; this

can damage the valve – actuators are not step ladders -

WARNING: Heavy actuators must be supported in a suita-

ble manner if it is possible that their installation situation

would exert an impermissible bending force on the valve.

4 INTENDED USE

The series 132000 valves from Flowserve Essen GmbH

can be installed in all areas endangered by gas explosion,

because they do not have any potential ignition sources.

The valves can be used for shutting off the flow of noncombustible gaseous mediums and combustible gaseous

and fluid mediums far below the maximum explosion limit.

Inside the valve the atmospheric range is not reached under the conditions (see table below); here Directive 95/9/EC

is not applicable. Please note that certain (non-conductive)

mediums at certain flow rates can result in a potential

(static charge), which is subject to the operating conditions

and therefore is the responsibility of the operator.

Version Packing Seat Ring

Standard PTFE Compound PTFE Compound

4.1 Description of Unit

The valve is a lined control valve. The housing consists

of cast iron and the lining and gaskets are of elastomer

material.

The compatibility of the materials used with the surroun-

ding mediums must be observed in particular by the

operator.

4.2 Evaluation

Conformance with EN 13463, Parts 1 through 8 (non-

electrical explosion protection)

The fittings fulfill the following requirements.

4.2.1 All exposed parts were subjected to the impact and envi-

ronmental stress tests in conformance with

EN 13463-1 by the manufacturer and satisfy the require-

ments.

4.2.2 The valve body for the valves consists of cast iron. Formation of sparks resulting from the effect of exterior impact is

excluded under normal conditions.

5 INSTALLATION

WARNING: Plastic liners on the valves require particular

protection before/during installation; therefore:

CAUTION: Transport valve to installation site in protective

package if available. If flange covers are present, remove

them only immediately before installation.

5.1 Check valve for transport damage. Do not install damaged

valves.

Ensure that only valves are installed whose pressure class,

type of connection and connection dimensions satisfy the

installation conditions. See Markings and Valve specifications.

3

User Instructions LinedFlow - KMENIM3202-02 01/12

STOP!

®

DANGER: Do not install valves whose approved pressure

and temperature range is not sufficient for the operating

conditions. The limits for use are marked on the valves.

Moreover, use only valves suitable for the operating medium

in question.

Failure to observe these precautions can pose a danger for

the user and cause damage to the piping system.

5.2 The actuator must correspond to the intended connections

and control data.

5.3 The connection flanges must be inline with the valve

connections and parallel. Connection flanges which are not

parallel can damage the plastic liner during installation!

5.4 Before installing, thoroughly clean the valve and the pipeline

to remove any contamination, particularly hard foreign particles.

5.5 In particular, it is necessary to ensure that the sealing surfaces on the flange connection are free of all contamination

when installing.

5.6 When inserting the valve into a pipeline already installed, the

distance between the ends of the pipeline must be sufficient

to prevent damage to any of the sealing surfaces.

WARNING: Tighten all flange connections to the torques

specified in Tables 1a or 1b. When using torque wrenches,

ensure that these torques are reached, however not exceeded.

The values in the table apply for flanges according to

EN1092, PN10/16 for a maximum operating pressure of

10 bar. Values for other flanges can be obtained from the

manufacturer.

5.7 Valves are to be installed in the appropriate flow direction.

The flow direction is indicated by an arrow on the valve.

5.8 Observe the appropriate instructions for connecting the

actuator to the valve. Control valves are equipped with a

positioner. The connections for air supply and signals are

marked clearly (see also applicable operating instructions for

the positioner). The maximum air supply is specified on the

name plate. If the air supply exceeds the pressure specified

on the rating plate, a pressure reduction station is required.

If no instrument air is available, install an air filter in the air

supply line if required.

5.9 After completion of installation, perform a function test with

the control signals: The valve should open and close properly

corresponding to the control commands. Always eliminate

any recognizable malfunctions before startup. See also

applicable sections in maintenance regulations for this valve

series.

DANGER: Improperly executed control commands can pose

a danger for life and limb and damage to the piping system

and/or the valve.

6 PRESSURE TESTING PIPING SECTION

The valve has already been pressure-tested by the manuf-

acturer. When pressure testing a section of the pipeline with

valves installed, observe the following:

6.1 First thoroughly flush newly installed piping systems to

remove all foreign objects.

6.2 Valve opened: The test pressure should not exceed the

value of 1.5 x PN (according to nameplate):

6.3 Valve closed: The test pressure should not exceed the value

1.1 x PN (according to nameplate).

If a leak occurs on the valve, observe Section 8 “Trouble-

shooting”.

CAUTION: If the flange connection with plastic liner leaks:

First retighten flange connection to torque specified in Table

1a or 1b in Section 5.6 (installation).

If the flange connection is still leaks:

Loosen flange connection. Check the flange connection to

ensure that it is smooth and parallel.

Check the sealing surfaces on both flanges: When the inner

lining is damaged, replace valve and/or counterflange.

Table 1a: Tightening Torques for Flange Connections, Flanges EN1092 (DIN)

DN [mm] 15 20 25 40 50 80 100 150

M

[Nm] 10 18 25 50 65 65 65 140

A

Table 1b: Tightening Torques for Flange Connections, Flanges EN1759 (ANSI)

NW [inch] ½" ¾" 1" 1½" 2" 3" 4" 6"

M

[Nm] 8 11 15 26 60 100 76 100

A

4

®

7 NORMAL OPERATION AND MAINTENANCE

These installation, operating and maintenance instructions

cannot contain all detailed information on all possible

versions for reasons of clarity and, in particular, cannot take

into consideration all imaginable cases for setup, operation

and maintenance. Therefore, only primarily instructions

are contained, which are required for the intended use in

industrial applications. If anything is not clear, particularly if

any detailed information on the specific product is missing,

clarify as required with the responsible FLOWSERVE representative.

8 TROUBLESHOOTING

When troubleshooting or during general maintenance,

always observe Section 1 “Safety precautions”.

DANGER: If a valve contaminated with dangerous sub-

stances has to be removed from the system or pipeline,

decontaminate it properly before performing further maintenance work.

9 PODUCT DESCRIPTION

9.1 Housing

The body material is made of GGG40.3 (standard), other

body materials are also available from the manufacturer on

request. For valve bodies with plastic liners: See Table 2b

for coating materials.

The liner thickness is at least 5 mm for DN25 and higher

and 3.5 mm for DN15 and DN20.

10 BONNET

The bonnet is connected with a form fit to the valve body

providing, on the one hand, a potential compensation

between the housing and bonnet and on the other a defined

compression force for the body seal and bellows. The bonnet is provided with a blowout safety system. This means

that the valve stem cannot be pulled or pressed upward out

of the bonnet.

User Instructions LinedFlow - KMENIM3202-02 01/12

Table 2a: Body Specifications

Body material 0.7043 (GGG40.3)

Pressure class PN16

End connections

(Flanged)

DIN PN 16

ANSI Class 150

Liner thickness 4 – 6 mm

Table 2b: Liner Materials

PFA Perfluoralkoxypolymer

(Standard)

PFA conductive Perfluoralkoxypolymer,

electrically conductive

PVDF Polyvinilidenfuoride

ETFE Ethylene Tetrafluorethylene–

Copolymer (Tefzel

FEP Tetrafluorethylene

Perffluorpropylene

PP Polypropylene

®

)

11 PLUG AND SEAT

The seat and plug are screwed, i.e. replacement is possible

at any time when the Kvs value changes or for repair. The

plug is screwed to the bellows and secured against loosening by a PTFE insert. For smaller Kvs values, a Hastelloy

insert can be provided in the plug as well as in the seat (see

Table 3).

The possible material combinations and available Kvs values

and curves are shown in Table 3.

12 BELLOWS

The bellows seal is manufactured from modified PTFE.

TF1620 for DN15, DN20 and DN25 and TFM1600 for sizes

DN40, DN50, DN80 and DN100. The bellows is designed

and tested on a standard basis for an operating pressure of

16 bars at 120 °C. The pressure/temperature limitations are

limited only by the lining material, not the bellows: Observe

the additional operating forces required by the bellows for

sizing your actuator.

5

User Instructions LinedFlow - KMENIM3202-02 01/12

®

Table 3: Kvs / Cv Values

Plug Valve Size

Kvs / Cv-Values Seat DN15/20 DN25 DN 40 DN 50 DN 80 DN 100 DN 150

K

C

vs

v

0.011 3 0.12

0.017 3 0.12

0.025 0.029 3 0.12

0.040 0.047 3 0.12

0.063 0.074 3 0.12

0.10 0.12 4.5 0.18

0.16 0.19 4.5 0.18

0.25 0.29 4.5 0.18

0.40 0.47 4.5 0.18

0.63 0.74 4.5 0.18

1.0 1.2 7 0.28

1.6 1.9 7 0.18

2.5 2.9 10 0.25

4.0 4.7 12 0.30

5.0 5.8 15 0.38

6.3 7.4 16 0.41

10 12 20 0.51

13 25 0.64

16 19 25 0.64

25 29 32 0.81

32 40 1.02

40 47 40 1.02

47 50 1.27

63 74 50 1.27

100 120 63 1.60

120 139 80 2.03

160 190 80 2.03

180 100 2.54

250 290 100 2.54

340 400 125 3.18

Seat ø 0.5"/0.75" 1" 1½" 2" 3" 4" 6"

mm in. Stroke (mm/inch)

10/0.39 10/0.39

10/0.39 10/0.39

10/0.39 10/0.39

10/0.39 10/0.39

10/0.39 10/0.39

10/0.39 20/0.79

10/0.39 20/0.79

10/0.39 20/0.79

10/0.39 20/0.79

10/0.39 20/0.79

10/0.39 20/0.79

10/0.39 20/0.79

10/0.39 20/0.79

20/0.79 20/0.79

10/0.39

20/0.79 20/0.79 20/0.79

20/0.79 20/0.79

20/0.79

20/0.79 20/0.79 40/1.57

20/0.79 40/1.57

20/0.79

40/1.57 40/1.57

20/0.79

40/1.57 40/1.57

40/1.57 40/1.57

40/1.57

40/1.57

40/1.57

40/1.57

40/1.57

Hastelloy Hastelloy TFM1600

Hastelloy TFM1600 TFM1600

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Tabelle 4: Bellows Seal

Size Seat/Plug Stroke (mm) Bellows Material Part No.

DN 15 TFM1600 10 HS22121 132538501 6,4

DN 20 TFM1600 10 HS22121 132538501 6,4

DN 25 TFM1600 10/20 HS22121 132538601 8,6

DN 40 TFM1600 20 HS22121 132538802 8,6

DN 50 TFM1600 20 HS22121 132538802 8,6

DN 80 TMF1600 40 HS22121 132538901 13,2

DN 100 TFM1600 40 HS22121 132538901 13,2

DN 150 TFM1600 40 HS22121 132539101 13,2

6

Effective area (cm2)

User Instructions LinedFlow - KMENIM3202-02 01/12

STOP!

STOP!

®

13 STEM

The valve stem is equipped with a blowout protection fea-

ture. This ensures that the valve stem cannot be removed

from the top of the valve. This is an important safety factor

when the actuator is removed from the valve, because there

would be otherwise no mechanical restriction.

Table 5: Valve stem materials

Valve stem 1.4571 (Standard)

14 PACKING

The 132000 valve series has a safety packing to back-up

the bellows seal and to prevent leakage to the outside in

the event of a bellows rupture.

15 TEST CONNECTION

WARNING: If the optional test connection (1/4” NPT) is

present, it must be sealed to prevent the medium from

exiting in the event of a bellows rupture.

16 Quick check

Before operating, check the valve as follows:

16.1 Open and close the valve and observe the movement of the

actuator stem. The movement should be smooth and linear.

16.2 Check the minimum stroke by changing the control signal

(for pneumatic position regulator 0.2 – 1.0 bar or corresponding “split range” values for IP position regulator 4-20

or 0-20 mA).

16.3 Check all air connections for leaks.

16.4 Check the packing nut (see Table 8).

CAUTION: An excessively tightened gland nut can cause

excessive packing wear and can hinder the free movement

of the plug stem.

16.5 Check fail-safe position. To do this, close supply pressure

and observe whether the valve opens or closes as defined.

16.6 After use under varying temperatures, retighten all threaded

connections and check for leaks.

17 MAINTENANCE

Check for proper function at regular intervals as follows.

These checks can be accomplished in the installed state

and, in many cases, without shutting down production. If

internal defects are suspected, see section “Disassembly

and assembly of valve”.

17.1 Check gaskets for leakage and retighten bolts if required

(see Fig. 1).

17.2 Check bellows seal, test connection and body drain screw –

if present – for leakage to the outside.

17.3 Check valve for damage resulting from corrosive process

residues or corrosive vapors.

17.4 Clean valves and repaint as required.

2.4819 (Hastelloy C276) (optional)

17.5 Check packing nut (see Table 8).

CAUTION: An excessively tightened gland nut can cause

excessive packing wear and can hinder the free movement

of the plug stem.

17.6 If possible, open and close valve and check for maximum

stroke and ensure that the plug stem moves without jerking.

Irregular motion of the plug stem can indicate an internal

defect

WARNING: ..Keep hands, hair, clothing, etc. away from all

moving parts. Failure to observe can lead to severe injuries.

17.7 Ensure that all accessory parts are seated tightly.

17.9 Connect air supply and check safety position.

Check air filter, if present, and replace element as necessary.

17.10

7

User Instructions LinedFlow - KMENIM3202-02 01/12

®

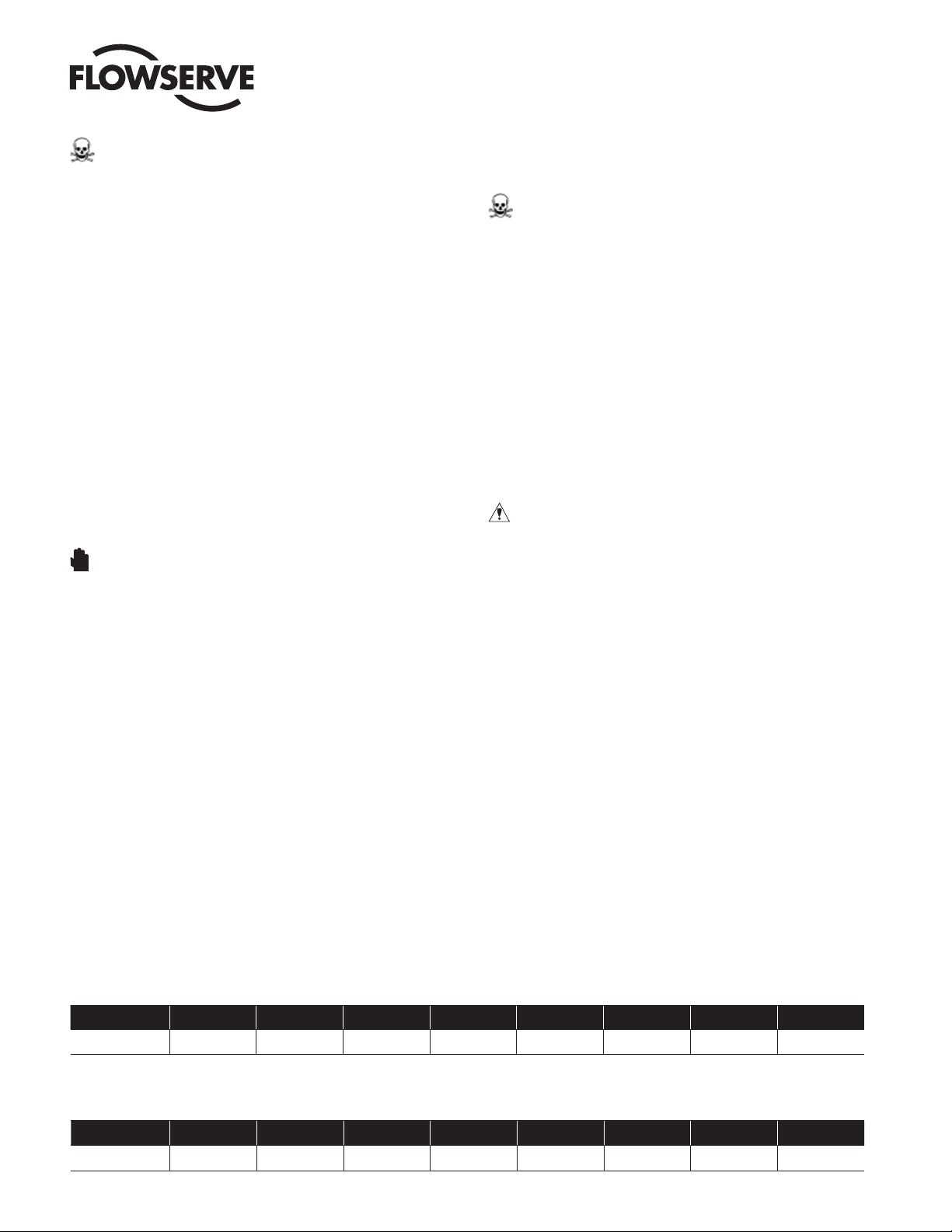

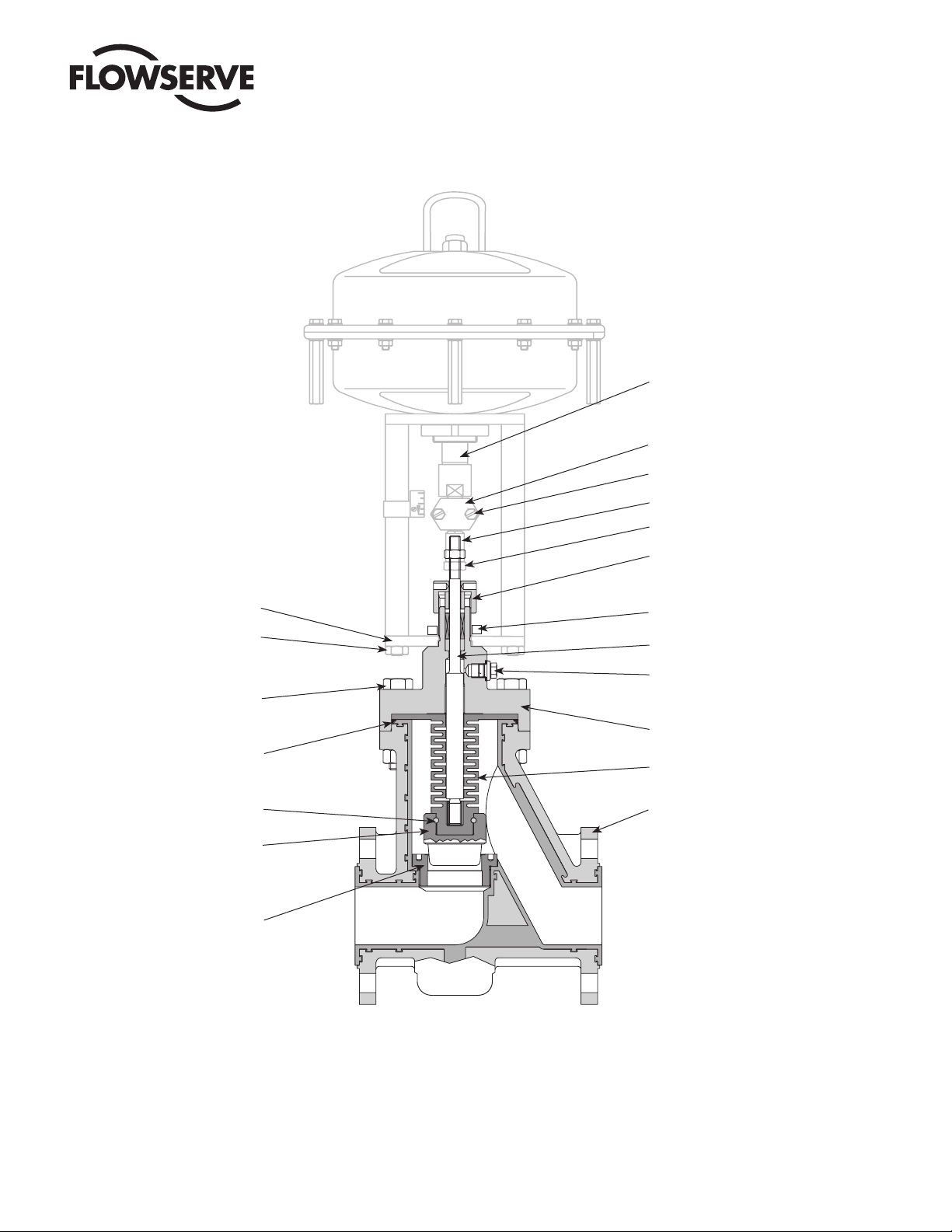

Actuator stem

Coupling

Coupling screw

Coupling insert

Locknut

Yoke plate

Yoke rod nut

Bonnet bolt

O-Ring (body/bonnet)

Insert, thread lock

Plug

Seat

Packing nut

Slotted nut

Plug stem

Test connection

(drawn rotated 90°)

Bonnet

Bellows seal

Body

Fig. 1: Typical Valve Series 132000 with Series 2 Actuator

8

®

18 REMOVING ACTUATOR FROM VALVE

(See Fig. 1)

18.1 Shut off air supply.

DANGER: Ensure that actuator is not under pressure and

drain process medium before performing maintenance

work. Failure to observe can lead to serious injuries.

18.2 Remove piping if required.

18.3 Remove 2 coupling bolts and remove coupling.

18.4 Loosen yoke stem nuts and remove. Carefully remove actuator from valve.

18.5 After loosening counternut, unscrew coupling insert (caution: hold plug with wrench on coupling insert to prevent

turning).

19 ATTACHING ACTUATOR TO VALVE

(see Fig. 1)

The actuator stem must be fully extended:

Actuators with air-to-open action must be fully vented.

Actuators with air-to-close action apply supply pressure.

Manually depress the plug stem to ensure the plug is fully

seated.

The valve plug must make contact in the valve seat, i.e.

press valve stem in all the way by hand.

19.1 Screw coupling insert locknut and coupling insert as far as

possible onto plug stem.

19.2 Place the actuator assembly on the valve engaging the

yoke rod threads in the lower yoke plate and ensuring the

actuator faces in the correct direction.

19.3 Unscrew the coupling insert until the yoke rods are raised

from the lower yoke plate by around 2 mm.

NOTE: Ensure that the plug assembly is not rotated with

the plug seated. This may cause irreparable damage to the

seating faces.

19.4 Refit the coupling, ensuring that the arrows, embossed on

the coupling halves, point upward towards the actuator,

and secure with 2 retaining screws.

User Instructions LinedFlow - KMENIM3202-02 01/12

9.5 Apply supply pressure resp. vent actuator to half stroke

and refit and tighten yoke rod retaining nuts.

19.6 Reconnect all tubing.

9

18

User Instructions LinedFlow - KMENIM3202-02 01/12

®

17

16

15

14

13

12

11

1 Bellows seal

2 O-Ring

3 Plug

4 Insert, thread lock

5 Seat

6 Body

1

7 nut

8 Plug

9 Seal (G¼

only with adapter)

10 Bushing

11 Bonnet

2

12 Screw

13 Slotted nut

3

14 Stem

15 Packing

16 Packing follower

17 Packing nut

4

9

8

5

18 Nut

10

10

7

Fig. 2: Individual Parts for Series 132 000

(also see spare parts lists)

Table 6: Tightening Torque for Seat (Nm)

DN 15 DN 20 DN 25 DN 40 DN 50 DN 80

6 6 6 25 25 35

Table 7: Tightening Torque for Bonnet Fastners (Nm)

DN 15 DN 20 DN 25 DN 40 DN 50 DN 80 DN1 100 DN 150

60 60 60 145 145 145

6

1DN 1002

55

280

DN 150

70

250

10

User Instructions LinedFlow - KMENIM3202-02 01/12

STOP!

STOP!

®

20 DISASSEMBLE AND ASSEMBLE VALVE

20.1 DISASSEMBLE VALVE

(see Fig. 2)

DANGER: As toxic or hazardous substances could be

present, release all pressure in the system and drain all

process substances. If necessary, decontaminate valve.

Keep hands, hair and clothing away from moving parts.

Wear face and eye protection. Failure to observe can lead to

severe injuries.

20.1.1 Carefully loosen test connection and check whether medium has collected in bellows cap (bellows defective).

20.1.2 Remove bolts/nuts from bonnet and remove bonnet.

Note: Due to packing friction the bellows/plug is usually

pulled out when the bonnet is removed. In such cases, hold

the bellows/plug so that it cannot fall and be damaged.

20.1.3 If the bellows remains in the housing, it can be pried out

carefully with two screwdrivers.

20.1.4 Without stretching the bellows, remove the plug/bellows

assembly from the bonnet. Press guides, packing and

spacer out of packing chamber from below with a punch

(the punch diameter should be slightly larger than the plug

stem).

20.1.5 If required, pull out thread lock insert with a pair of pliers

and unscrew plug from bellows.

WARNING: When the plug is loosened, medium residues

can be released which have leaked through the thread.

20.1.7 Unscrew seat ring with seat ring wrench.

20.1.8 Check sealing edges on seat ring and plug for damage. The

sealing surfaces must be clean and free of damage.

WARNING: To avoid damage to the seat, plug or plug stem,

observe the preceding instructions exactly.

20.2 ASSEMBLE VALVE

(see Fig. 2)

20.2.1 Replace all worn or damaged parts. Use only genuine

FLOWSERVE parts. Parts to be reused must be clean.

Always replace parts subject to wear such as gaskets,

packings and O-rings.

20.2.2 Insert seat ring and tighten (see Table 6 for torque).

20.2.3 Screw plug onto bellows hand-tight and insert a new thread

lock insert. Cut off thread lock insert so that approx. 3 mm

extends from the hole.

20.2.4 Carefully insert plug stem with bellows into bonnet.

20.2.5 Position new O-ring on inclined surface on top of housing.

20.2.6 Position bonnet slowly and absolutely upright on body, to

avoid damage to seat/plug.

20.2.7 Insert bonnet mounting bolts and tighten hand-tight in

crisscross pattern.

20.2.10 Tighten all bolts to specified torques in crisscross pattern

with torque wrench (see Table 7).

20.2.11 Replace packing by inserting packing rings one at a time

tapping each one down with a suitable bushing.

NOTE: ensure that the gaps in the packing rings are distri-

buted evenly around the circumference in the packing box

(gaps not in line).

Different packings and fitting sequencess are shown in the

spare parts list.

Insert packing follower and tighten packing nut (see Table 8).

20.2.12

20.2.13 During the subsequent pressure test, ensure that the pressure does not exceed the maximum permissible pressure

for the bellows (PN16). After checking the test connection

for leakage – if present – plug with a plug or appropriate

pressure gauge.

Table 8: Tightening Torque for Packing Nut (Nm)

Thread

M20 x 1,5 1

M30 x 1,5 6

M38 x 1,5 15

M45 x 1,5 17

PTFE

11

®

22 TROUBLE-SHOOTING CHART

Fault Possible Cause Remedy

1.

Stem motion

impeded

Excessive

leakage

Inadiquate flow 1.

Plug slams 1.

1.

Packing excessively tightened

2.

Operating temperature too high for selected

trim

Supply pressure inadiquate

3.

Positioner defective

4.

Bonnet loose

1.

Worn or damaged seat ring/plug

2.

Gaskets damaged

3.

Inadiquate actuator thrust

4.

Plug incorrectly adjusted

5.

Incorrect direction of flow

6.

Handwheel incorrectly adjusted

7.

(acts like end stop)

Plug incorrectly adjusted (short stroke)

Positioner defective

2.

Operating requirements too high

3.

Plug adjustment incorrect

Inadiquate supply pressure

2.

Trim too large for flow rate

3.

Tighten gland nut

2.

Note operating data and contact dealer

3.

Check system for leaks in the supply pressure or signal lines. Retighten the connections, if necessary replace leaky lines

See operating instructions for positioner

4.

See step 20.2.7 for correct tightening of bonnet

1.

Re-machine or replace seat ring/plug

2.

Replace gaskets

3.

Check air feed. If air feed is OK, contact dealer.

4.

Correctly adjust plug according to step

5.

Check specification. Contact dealer

6.

Adjust handwheel

7.

Correctly adjust plug

1.

See operating instructions for positioner

2.

Check operating data. Contact dealer

3.

Correctly adjust plug

1.

Check supply pressure, seal leaks, remove blockage

2.

Replace trim

3.

User Instructions LinedFlow - KMENIM3202-02 01/12

Germany

Flowserve Essen GmbH

Schederhofstr. 71

45145 Essen

Deutschland

Tel.: +49 (0)201 8919 5

Fax: +49 (0)201 8919 662

Your Contact:

All data subject to change without notice

© 07.2003 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

USA

Flowserve Corporation

1300 Parkway View Drive

Pittsburgh, PA 15205

USA

Tel.: +1 412 787 8803

Fax: +1 412 787 1944

Singapore

Flowserve Pte Ltd

12 Tuas Avenue 20

Singapore, 638824

Singapore

Tel.: +65 6879 8989

Fax: +65 6862 4940

12

flowserve.com

Loading...

Loading...