Page 1

USER INSTRUCTIONS

IPS Wireless™ 103 Smart Multi-Port

Installation

Operation

Maintenance

Multiple Sensor Input and Wireless Transmitting Unit

PCN = 26999976 11-13 (E). Original Instructions

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

701-3001-01^

Page 2

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

CONTENTS

1 INTRODUCTION AND SAFETY .......................... 3

1.1 GENERAL ......................................................... 3

1.2 CE MARKING AND APPROVALS .......................... 3

1.3 DISCLAIMER ..................................................... 3

1.4 COPYRIGHT ...................................................... 3

1.5 DUTY CONDITIONS ............................................ 3

1.6 SAFETY ............................................................ 4

1.7 SPECIFIC MACHINE PERFORMANCE .................... 4

1.8 SPECIFICATIONS ............................................... 4

2 TRANSPORT AND STORAGE ............................ 5

2.1 CONSIGNMENT RECEIPT AND UNPACKING ............ 5

2.2 HANDLING ......................................................... 5

2.3 STORAGE .......................................................... 5

2.4 RECYCLING AND END OF PRODUCT LIFE .............. 5

2.5 DISPOSAL INSTRUCTIONS ................................... 6

3 DESCRIPTION ..................................................... 6

3.1 OPTIONS AND MODEL NUMBERS ......................... 7

3.2 DEFAULT CONFIGURATION ................................ 7

3.3 PERFORMANCE AND OPERATION LIMITS .............. 8

3.4 VB-103-TAM OPTIONAL ACCESSORY ............... 8

3.5 VISUAL ALERT OPTIONAL ACCESSORY ............... 8

4 MAINTENANCE ................................................... 9

4.1 TOOLS REQUIRED ............................................. 9

4.2 TURNING UNIT ON/OFF ...................................... 9

4.3 BATTERY REPLACEMENT ................................... 9

5 CUSTOM CONFIGURATION

PROGRAMMING ................................................ 10

6 INSTALLATION .................................................. 10

6.1 TOOLS REQUIRED ........................................... 10

6.2 UNPACKING ...................................................... 5

6.3 PRELIMINARY OPERATIONAL CHECK ................. 11

6.4 MOUNTING ..................................................... 11

6.5 CONNECTING SENSORS AND POWER-UP ......... 12

6.6 CONNECTING 103 TAKE AWAY MEMORY .......... 12

6.7 CONNECTING 103 VISUAL ALERT ..................... 12

7 PARTS LIST AND DRAWINGS ......................... 12

7.1 SPARE PARTS ................................................ 12

7.2 DRAWING ....................................................... 12

8 CERTIFICATIONS ............................................. 14

9 TROUBLE-SHOOTING GUIDE ......................... 14

9.1 LOSS OF COMMUNICATIONS ............................ 14

9.2 INACCURATE OR MISSING DATA ....................... 15

9.3 NO DATA RECORDED ON VB-103-TAM ........... 15

9.4 NO LIGHTS ON VB-103-VIS ............................ 15

10 DECLARATION OF CONFORMITY

(TYPICAL)........................................................... 16

Page 2 of 20 flowserve.com

Page 3

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques, and

safety requirements.

Flowserve is committed to continuous quality

improvement and being at your service for any

further information about the product in its

installation and operation or about its support

products, repair and diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted

use. Operating the product in compliance with

these instructions is important to help ensure

reliability in service and avoid risks. The

instructions may not take into account local

regulations; ensure such regulations are observed

by all, including those installing the product.

Always coordinate repair activity with operations

personnel, and follow all plant safety requirements

and applicable safety and health laws/regulations.

These instructions must be read prior to

stalling, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety, noted in the

instructions, have been met. Failure to follow

and apply the present user instructions is

considered to be misuse. Personal injury,

product damage, delay or failure caused by

misuse are not covered by the Flowserve

warranty.

1.2 CE Marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic

Compatibility (EMC), Pressure Equipment Directive

(PED) and Equipment for Potentially Explosive

Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory

provision of technical documents and safety

instructions. Where applicable this document

incorporates information relevant to these Directives

and Approvals.

To confirm the Approvals applying and if the product

is CE marked, check the serial number plate

markings and the Certification. (See Section 8)

1.3 Disclaimer

Information in these User Instructions is believed

to be complete and reliable. However, in spite of

all of the efforts of Flowserve Corporation to

provide comprehensive instructions, good

engineering and safety practice should always be

used.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality Assurance

organizations. Genuine parts and accessories have

been designed, tested and incorporated into the

products to help ensure their continued product

quality and performance in use. As Flowserve cannot

test parts and accessories sourced from other

vendors the incorrect incorporation of such parts and

accessories may adversely affect the performance

and safety features of the products. The failure to

properly select, install or use authorized Flowserve

parts and accessories is considered to be misuse.

Damage or failure caused by misuse is not covered

by the Flowserve warranty. In addition, any

modification of Flowserve products or removal of

original components may impair the safety of these

products in their use.

1.4 Copyright

All rights reserved. No part of these instructions

may be reproduced, stored in a retrieval system or

transmitted in any form or by any means without

prior permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchase order. The

acknowledgement of these conditions has been

sent separately to the Purchaser. A copy should be

kept with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

Page 3 of 20 flowserve.com

Page 4

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice.

If the conditions of service on your purchase order are

going to be changed (for example: liquid pumped,

temperature or duty) it is requested that the user

seeks the written agreement of Flowserve before start

up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction

would cause hazards. The specific safety markings

are:

This symbol indicates electrical safety

instructions where non-compliance will involve a

high risk to personal safety or the loss of life.

This symbol indicates safety instructions

where non-compliance would affect personal safety

and could result in loss of life.

This symbol indicates “hazardous and toxic

fluid” safety instructions where non-compliance

would affect personal safety and could result in loss

of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in

safety instructions where non-compliance in the

hazardous area would cause the risk of an

explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the

hazardous area would cause the risk of an

explosion.

This sign is not a safety symbol but

indicates an important instruction in the assembly

process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the

manufacturer/supplier to provide applicable

training.

Always coordinate repair activity with operations

and health and safety personnel, and follow all

plant safety requirements and applicable safety

and health laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For

products used in potentially explosive

atmospheres section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

(Lock out.)

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and

equipment is required when handling these

components. To lift heavy pieces above 25 kg (55

lb.) use a crane appropriate for the mass and in

accordance with current local regulations.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

Avoid excess temperature

Prevent buildup of explosive mixtures

Prevent the generation of sparks

1.7 Specific machine performance

For performance parameters see section 1.5 Duty

conditions. Where performance data has been

supplied separately to the purchaser these should be

obtained and retained with these User Instructions if

required.

1.8 Specifications

1.8.1 SELD-103 Unit Specifications

Operating frequency: 868 MHz or 900 MHz

Channels: (External) 4-GP, 1-Gas, 2-Inst,

2-DI, 1-RS-485

Channels: (Internal) 1-Battery Voltage,

1-Onboard Temperature

Ports: 5-Sensor ports / 1-Diagnostics port (RS-

485)

Page 4 of 20 flowserve.com

Page 5

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Transmission rates: 5 seconds or higher

Operating temperature: -20°C to +60°C (-40°F to

+185°F)

Humidity: 0-95% noncondensing

Power requirement: 3.6 VDC Battery Pack

(S1-1043)

Base: 316LSS

Base Mounting: Magnetic base, unistrut mount

Sensor Cable Connection: 6 pin amphenol style

1.8.2 Optional add-on sensor specifications

RTD: 1000 or 100 Ohm (Platinum, 2 wire)

Thermocouple: Type: J, K, N, T, etc. (+ Cold

Reference and Polynomial)

Pressure: Vacuum to 10Kpsi (Specific sensor for

each range)

Vibration (Velocity): Single Axis or Tri Axis 0-25

mm/sec (0-1 ips)

Vibration: (Acceleration): 0 - 10G Peak

Discrete: Dry Contact Only

Gas: See test sheet for details

2 TRANSPORT AND STORAGE

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the

current local regulations at all times.

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must

be checked against the delivery/shipping

documents for its completeness and that there has

been no damage in transportation. Any shortage

and/or damage must be reported immediately to

Flowserve and must be received in writing within

ten days of receipt of the equipment. Later claims

cannot be accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as

well as when ordering spare parts or further

accessories.

2.1.1 Unpacking

Carefully open package received from

factory and remove protective wrapping from

SELD-103 units and accessories. Inspect all

hardware for damage. Report any damage to

shipping carrier immediately.

Ensure you have received the correct sensors and

mounting accessories for your application. Crosscheck hardware received versus packing slip and

purchase order.

Record unit serial numbers for future reference.

2.1.2 Electrostatic Discharge (ESD) Handling

Procedure

The SELD-103 contains sensitive electronic

components that may be damaged by static

electricity present in work environments. The

following precautions are recommended to reduce

the risk of damage due to electrostatic discharge:

Only wipe exterior of unit with a damp cloth

Use of a grounding wrist strap when removing

outer plastic cover is recommended

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their

size and construction.

2.3 Storage

Store the equipment in a clean, dry

location. The SELD-103 unit should be powereddown prior to storage (see section 4

MAINTENANCE for how to power down unit) to

preserve battery life.

2.3.1 Storage and packaging

All SELD-103 units must be carefully packaged for

transport. Each unit should be boxed individually

with protective packaging (foam, bubble wrap, etc.)

in the box surrounding the unit.

After unpacking, protection will be the responsibility

of the user.

2.4 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and in accordance with local

regulations. If the product contains substances

that are harmful to the environment, these should

be removed and disposed of in accordance with

current local regulations.

Page 5 of 20 flowserve.com

Page 6

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Sensor Input

Connection Ports

Diagnostics

Connection

Port

2.5 Disposal Instructions

At the end of the product’s life, do not

dispose of any electronic component or instrument

in the domestic waste. Disposal should be done in

accordance with applicable regulations, which vary

from state to state and country to country.

Battery Disposal Instructions: Disposal should

be done in accordance with applicable regulations,

which vary from country to country. Batteries

should not be incinerated, unless suitable

procedures are followed and qualified handlers

have taken appropriate precautions. Exposure of

these cells to high temperatures or fire can cause

the cells to vent and/or rupture. These cells do not

contain dangerous substances. The reaction

products are inorganic and do not represent

environmental hazards, once the decomposition or

neutralization process has terminated.

Disposal in Europe

Batteries for disposal should not be transported by

air. For road transport of dangerous goods ADR

special provision 636 and packing instruction 903a

apply.

Disposal in US

Hazardous waste of spent batteries can be disposed

after they are first neutralized through an approved

secondary treatment prior to disposal. Disposal of

spent batteries should be performed by authorized,

professional disposal company, which has the

knowledge in the requirements of the Federal, the

State and the Local authorities regarding hazardous

materials, transportation and waste disposal. In

any case it is recommended to contact the local

EPA office.

Proper Shipping Name: Waste lithium Batteries

UN Number: 3090

Label requirements: Miscellaneous, Hazardous

Waste

Disposal Code: D003

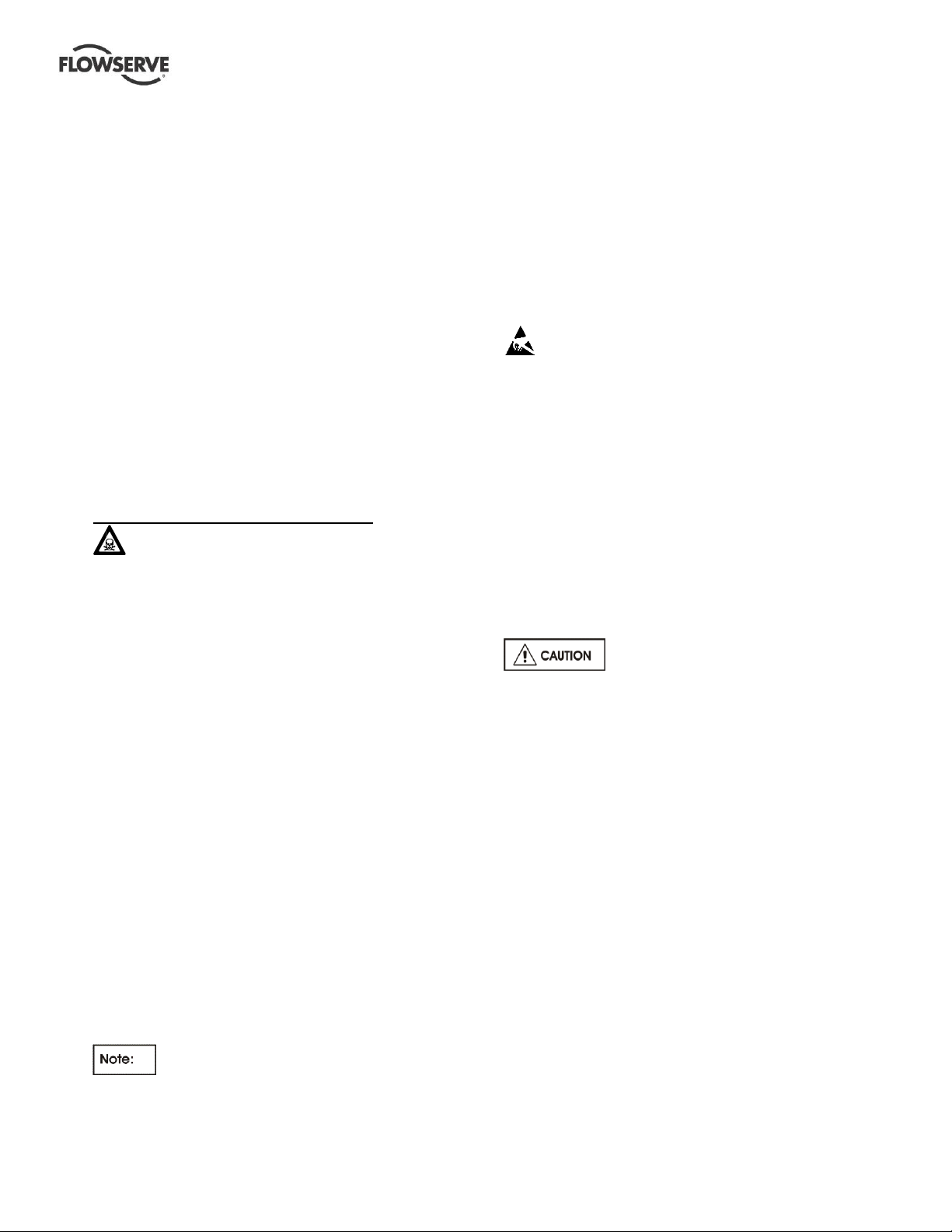

3 DESCRIPTION

The SELD-103-X (where “X” designates a specific

hardware or software configuration custom per the

order) model is a wireless transmitting unit

designed to monitor multiple sensor inputs and

wirelessly transmit the data to a receiver. It has the

option of enabling wireless transmission (to

become part of an IPS Wireless system) or

disabling wireless functionality (to perform as a

local alert or data-logging unit).

Figure 1: Sample SELD-103 unit

The SELD-103 is a self-powered unit that has 5

communication ports to measure up to 7 different

sensor inputs (utilizing combination sensors) per

unit (configuration limitations are detailed in section

3.1 Options and model numbers). Each unit also

has a single diagnostics port (on the back of the

base) for programming and troubleshooting the unit

as well as logging data with the VB-103-TAM

accessory (where collected data is stored).

Programming the unit requires a programming

cable and special software utility (PSP).

Figure 2: SELD-103 unit connection ports

The SELD-103 model has a built-in Omnidirectional wireless antenna, allowing for reliable

signal transmission. Data transmittal can occur at

a customizable time interval, ranging from every 5

seconds to once a day (this time interval is usually

pre-configured at the factory). Transmission rates

can also be varied according to sensor signal

values (see section 5 CUSTOM

CONFIGURATION PROGRAMMING), thereby

prolonging battery life. The SELD-103 unit has a

Page 6 of 20 flowserve.com

Page 7

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Part Number

Description

M1-0045

Magnetic Mounting Base,

Two-pole, 70 lbs (31.75 kg)

High Temp.

M1-0081

Unistrut Mounting Bracket

for SELD-103 unit, SS

casting base

M1-0085

SS cap for SELD-103

connection ports (single)

301-4024

Programming cable for

SELD-103 Unit: 5’ length,

Serial Port- RS-485

connection

PSP

SELD-103 Unit

Configuration Software

Utility

VB-103-TAM

Take-Away Memory Module

VB-101-DOCK

IPS Dock for communication

with VB-103-TAM TakeAway Memory Module

TAM103

VB-103-TAM data download

and configuration software

VB-103-VIS

Visual Light Alert Module

Parameter

Name

Parameter

Description

Default

Value

Normal

Measurement

Interval

How often data is

read from each of

the sensors by the

5 minutes

maximum data transmittal range of ¾ mile (1.2km)

under ideal conditions, but its effective

transmission range can be extended using a

network of repeaters.

Each SELD-103 can be part of a larger wireless

monitoring network. As such, each unit comes with

a calibration sheet from the factory which contains

unit-specific configuration information describing

the sensors and wireless network the unit is

configured for (parameters such as the wireless

system number, unit transmitter number, data

transmittal/check-in interval, scale factor and offset

to use with specific sensors). As long as your

specific application has been communicated to the

factory, the SELD-103 unit should come preconfigured for your specific use.

3.1 Options and model numbers

The SELD-103 can either have wireless data

transmission enabled or disabled. In both settings,

it is compatible with all SELD-103 accessories.

SELD-103 units with wireless transmission

disabled (designated as SELD-103-VB) are

intended for use as local data collectors with either

the take away memory (VB-103-TAM) or visual

light alert modules (VB-103-VIS).

The SELD-103 is available with the following

sensors as options to connect to each port on the

unit:

1. Vibration & Temperature (RTD) Combination

Sensor

2. Vibration Sensor

3. Temperature Sensor (RTD)

4. Temperature Sensor (Thermocouple)

5. 4-20mA Analog Input Sensor

6. General Pulse Input Sensor

7. Tachometer (TTL)

8. Pressure & Temperature (RTD) Combination

Sensor

9. Discrete Sensor

10. Oil/Water Sensor

11. Vibration Sensor with FFT analysis output

12. Serial Port RS-485 Interface

13. Gas Sensor

Additionally the SELD-103 has the following

options available:

Table 1: Optional parts for SELD-103 unit

Figure 3: Magnetic mount option for SELD-103

unit

The exact configuration of different sensors

attached to each SELD-103 unit is limited to certain

combinations. Contact the factory for a complete

list of the different configurations available for the

SELD-103.

3.2 Default Configuration

The SELD-103 is configured to the following

parameters by default, unless otherwise specified.

Table 2: Parameter default configuration values

for SELD-103 unit

Page 7 of 20 flowserve.com

Page 8

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

SELD-103 unit

Measurement Interval

Estimated Battery Life

5 seconds

4 months

10 seconds

8 months

30 seconds

2 years

1 minute

4 years

2 minutes

8 years

5 minutes

8 years

10 minutes

8 years

Measurement Interval

Data

Points

5 s

10 s

30 s

1

min 2 min 5 min

10

min

1

50

day

100

day

10

mo

1.6

yrs

3.3

yrs

4 yrs

4 yrs 2 25

day

50

day 5 mo

10

mo

1.6

yrs

4 yrs

4 yrs 3 16

day

33

day

3.3

mo

6.6

mo

1.1

yrs

2.7

yrs

4 yrs 4 12

day

25

day

2.5

mo 5 mo

10

mo

2 yrs

4 yrs 5 10

day

20

day 2 mo 4 mo 8 mo

1.6

yrs

3.3

yrs

6

8

day

16

day

50

day

100

day

6.6

mo

16.6

mo

2.7

yrs

7

7

day

14

day

42

day

2.8

mo

5.7

mo

14.2

mo

28.5

mo

LED

State

Description

GREEN

Flash every

5 seconds

Normal operation – all sensors are within

acceptable limits

3.3 Performance and operation limits

This product has been selected to meet the

specification of your purchase order.

The following data is included as additional

information to help with your installation. This is

typical information and if required, a definitive

statement for your application can be obtained from

Flowserve.

SELD-103 material compatibility is

the responsibility of the end user.

3.3.1 Sensor specifications

Refer to section 1.8 Specifications for available

sensor specifications.

3.3.2 Battery

Power is provided by a user-

replaceable lithium battery pack S1-1043, located

in the inner portion of the transmitter housing.

Battery life is dependent upon data transmittal

intervals. Battery voltage should normally be

between 2.8 and 3.6 VDC. If it is lower than this,

the battery will need to be replaced. The battery

voltage can be read at the receiver or through the

PSP software when connected directly to the

SELD-103 unit (refer to PSP software user

instructions for details on how to do this). See

table below for approximate battery life times for

the SELD-103.

Table 3: SELD-103 approximate battery life at

various measurement intervals under ideal

conditions

3.4 VB-103-TAM Optional Accessory

The VB-103-TAM is an optional Take Away

Memory module for the SELD-103 unit. When

connected to an SELD-103, it automatically logs

data from all sensors at the preconfigured log

interval. Data from the VB-103-TAM and the log

interval can be reviewed utilizing an IPS Dock

connected to a PC. The VB-103-TAM is set to a

default log interval (how often current data from the

SELD-103 is logged to the VB-103-TAM device) of

5 minutes (300 seconds), unless otherwise

specified. This is independent of the normal

measurement interval of the SELD-103 which

governs how often sensors are read.

The VB-103-TAM has a separate battery

that governs the lifetime of this unit. The expected

life of this battery is 6 years at the default 5 minute

log interval. The battery in the VB-103-TAM is not

replaceable and requires replacing the VB-103TAM unit when it is depleted.

The VB-103-TAM also has a finite amount of data

storage available. Dependent on the amount of

data points being measured and the measurement

interval, this storage capacity is defined as listed in

the table below.

Table 4: VB-103-TAM data storage capacity at

various measurement intervals and numbers of

data parameters

3.5 Visual Alert Optional Accessory

The Visual Alert is an optional accessory for the

SELD-103 unit. When connected to an SELD-103,

it automatically provides a visual light indication if

any sensors on the SELD-103 unit is or have been

in alarm status. To define the alarm limits for each

sensor, refer to Section 5 CUSTOM

CONFIGURATION PROGRAMMING.

The table below describes each of the different

types of indications offered by the Visual Alert

accessory.

Table 5: Visual Alert description

Page 8 of 20 flowserve.com

Page 9

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

RED

Flash every

5 seconds

Current alarm – one of the sensor

measurements has exceeded its alarm

limit and has not returned within the

acceptable range

RED &

GREEN

Flash every

5 seconds

Alarm – one of the sensor measurements

previously exceeded its alarm limit, but has

now returned within the acceptable range

Magnetic set

screw for powering

unit on/off

WARNING STATIC HAZARD: Wipe only with

a damp cloth due to electrostatic discharge hazard.

4 MAINTENANCE

The only field maintenance required on the SELD103 unit is replacement of the battery. The SELD103 can also be turned off when not in use for

extended periods of time to conserve battery life.

4.1 Tools required

Allen Wrenches (1/8” and 3/16”)

Tools required to install the various mounting

configurations are conditional based on the

type of mounting and location

Phillips head torque screw driver

4.2 Turning unit on/off

To power off the SELD-103 unit remove the

magnetic set screw at the bottom of the base. This

will stop sensor readings and data transmission.

To power up the SELD-103 unit again, simply

install the magnetic set screw at the bottom of the

base. This will activate sensor readings and data

transmission at the pre-configured intervals.

The substitution of components may

impair intrinsic safety.

Power is provided by a lithium battery pack (S1-

1043), located in the inner portion of the transmitter

housing. Battery life is dependent upon data

transmittal intervals. Battery voltage should

normally be between 2.8 and 3.6 VDC. If it is lower

than this, the battery will need to be replaced. The

battery voltage can be read at the receiver or

through the PSP software when connected directly

to the SELD-103 unit (refer to PSP software user

instructions for details on how to do this).

The battery pack is NOT re-chargeable and

shall only be replaced by contacting your local

Flowserve representative (battery pack part

number S1-1043).

Perform the following steps to replace the battery:

1. Power down unit by removing the magnetic set

screw located at the bottom of the base.

2. Remove sensor cable(s) and any installed

accessories.

3. Take SELD-103 to non-classified area before

performing next step.

4. Loosen the set screw in the side of the tube

and gently unscrew the external housing (tube)

from the transmitter assembly.

Figure 4: Magnetic Set Screw at Bottom of

SELD-103

4.3 Battery Replacement

EXPLOSION HAZARD: The unit must be

powered OFF during the battery installation & must

be in a General Purpose Classified Area to prevent

the possible ignition of a hazardous atmosphere.

Page 9 of 20 flowserve.com

Figure 5: Set screw on side of tube keeping

external housing on SELD-103 unit

Page 10

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Nuts holding

battery bracket

Battery bracket

Battery wires

5. The battery pack should be visible on the lower

end of the transmitter assembly. Carefully

disconnect the battery pack connector.

Remove the nuts holding the battery bracket in

place and remove the bracket. Remove the

battery pack.

Figure 6: SELD-103 unit battery with external

housing removed

5 CUSTOM CONFIGURATION

PROGRAMMING

This section is optional. As long as your

specific application was communicated to the

factory prior to shipment, the SELD-103 unit is preconfigured for your specific use.

Errors in programming

configuration can render the SELD-103 unit

inoperable, proceed with caution. Flowserve is

not liable for any damage caused by user

configuration errors.

For instructions on how to change software

configuration options on the SELD-103 unit, refer to

the PSP software user instructions. The list below

provides an overview of the functions that can be

performed using this software utility:

- Reading & saving SELD-103 configuration

- View & modify SELD-103 transmission

intervals

- Setting the time on the SELD-103

- Calibration of individual sensors on SELD103 unit

- Read live data from sensors on the SELD103 unit

- Turn specific SELD-103 sensor channels

on or off

Figure 7: SELD-103 unit with battery bracket

removed and battery pack partially removed

6. Install new battery pack (part number S1-

1043). Reinstall battery bracket and nuts,

reconnect battery pack connector.

7. Install tube back onto unit and tighten set

screw to no more than 0.9 Nm (8 lb.-in US).

8. Reinstall SELD-103 unit in the field.

9. Reconnect sensor cable(s).

10. Install magnetic set screw into the base of the

unit.

11. Install any applicable accessories on the

SELD-103 unit.

12. Dispose of battery pack in accordance with

instructions in section 2.5 Disposal Instructions.

For instructions on how to perform software options

on the VB-103-TAM unit, refer to the IPS Dock user

instructions. The list below provides an overview of

the functions that can be performed using the IPS

Dock and appropriate software utility:

- Reading & saving VB-103-TAM log data

- Clearing the log from the VB-103-TAM

- Setting the time on the VB-103-TAM

- Changing the data logging interval on the

VB-103-TAM

6 INSTALLATION

Always wear appropriate personal

protective equipment during the installation of

SELD-103 units.

6.1 Tools required

Allen Wrenches (1/8” and 3/16”)

Tools required to install the various

mounting configurations are conditional

based on the type of mounting and location

Phillips head torque screw driver

Page 10 of 20 flowserve.com

Page 11

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Magnetic mount set

screw installation

location

6.2 Preliminary operational check

After unpacking and before field installation,

perform the following operational check on the unit:

1. Ensure the magnetic set screw (at the bottom

of the base) is removed. This keeps the unit

powered down during the installation process.

2. Place SELD-103 unit in vertical position with a

clear line of sight to and close to (<10ft) the

receiver. If only using the VB-103-TAM or VB103-VIS accessories, install the appropriate

accessory on the SELD-103 unit (VB-103-TAM

on port 6 and VB-103-VIS on port 5).

3. Insert sensor cable(s) into the proper port(s).

4. Install the magnetic set screw (in the bottom of

the base) to power up the unit.

5. Ensure the receiver is receiving data from the

unit. Let the VB-103-TAM log data for a few

minutes and confirm appropriate light operation

of the VB-103-VIS unit as applicable.

6. If applicable, disconnect VB-103-TAM and use

IPS Dock to confirm accurate data has been

logged (refer to IPS Dock user instructions for

how to do this).

7. Remove magnetic set screw (bottom of base)

to power down unit.

8. Disconnect sensor cable(s) from SELD-103

port(s).

Lastly, attach the other end of the mounting

adapter to the pole (using a U-bolt) or unistrut

(using bolting).

Figure 8: Pole or unistrut mounting options

6.3.2 Magnetic Mount Option

Insert set screw into bottom of SELD-103 unit and

tighten.

In case of issues with powering up the unit, refer to

section 9 Trouble-Shooting Guide.

6.3 Mounting

Each unit should be clear of physical obstructions

to the receiver and/or repeater(s) in order to

maintain consistent communications.

The SELD-103 is designed to be mounted in a

vertical position and should only be mounted in a

horizontal position with approval from the factory.

Ensure the SELD-103 is not subjected to excessive

vibration unless a routine maintenance program

includes verification of associated connections.

The SELD-103 unit should be installed near but not

on process equipment being monitored.

Mount the SELD-103 unit before connecting any of

the sensor cables.

6.3.1 Pole or Unistrut-Mounted Option

With this option the SELD-103 unit can be mounted

to either a vertical or horizontal pole or unistrut.

Start by bolting the SELD-103 unit to the mounting

bracket and then bolt the bracket to the appropriate

holes on the mounting adapter (see figure below).

Figure 9: Magnetic mounting option set screw

location

Next, take magnetic mounting base and thread

onto the exposed set screw from the bottom of the

SELD-103 unit. The magnetic mounting base (with

the SELD-103 unit attached) can now be attached

to any metal structure in a vertical position.

Figure 10: Sample SELD-103 unit with

magnetic mount option installed on unistrut

Page 11 of 20 flowserve.com

Page 12

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Part

Number

Description

Recommend

Quantity for

2-Year Operational

Spares

S1-1043

Replacement Lithium

Battery Pack

1 (dependent on

transmit interval

selected)

M1-0083

Replacement Outer

Tube. 4” UV Protected

PVC Cap, Red, dwg#

100-2012

0

M1-0085

SS cap for SELD-103

connection ports (single)

6

G0-0047

Viton cap sealing gasket

1

G0-PACK

Desiccant pack

2

6.4 Connecting Sensors and Power-Up

Install all sensors on equipment to be monitored.

Ensure sensor cable connections and SELD-103

sensor ports are free from dust and debris (use

compressed moisture-free air to blow out any

contamination if needed). Then insert the sensor

cable(s) into the proper port(s) on the SELD-103

unit (reference the label on the connector side of

each sensor cable to determine which port it

attaches to). SELD-103 port numbers are labeled

on the stainless steel base and the unit serial

number is printed below the bar code on top of the

red cap. Lastly, install the magnetic set screw (in

the bottom of the base) to power up the SELD-103

unit.

Figure 11: Sample SELD-103 unit with one

sensor connected and port caps (optional item)

on remaining ports

6.5 Connecting 103 Take Away Memory

Install the VB-103-TAM into port 6 (single

amphenol-style connection on the back) of the

SELD-103 unit. The VB-103-TAM will

automatically start logging data from the SELD-103

unit at its preconfigured log interval.

To change the logging interval or download data

from the VB-103-TAM, refer to the IPS Dock User

Instructions.

6.6 Connecting 103 Visual Alert

Disconnect sensor (if any) installed on port 5 of the

SELD-103 unit. Install the VB-103-VIS into port 5

of the SELD-103 unit. Reinstall sensor (if any) on

port 5 of the SELD-103 unit. If no sensor is to be

used on port 5, be sure to install a port cover on

the sensor connection of the VB-103-VIS.

The VB-103-VIS will automatically review all

sensors on the SELD-103 unit for alarm conditions

and respond accordingly.

7 PARTS LIST AND DRAWINGS

7.1 Spare Parts

Available spare parts for the SELD-103 unit are

shown below. No spare parts are needed during

start-up. Recommended quantities of 2-year

operational spares are listed below.

Table 6: SELD-103 Spare Parts

7.2 Drawing

Page 12 of 20 flowserve.com

Page 13

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Figure 12: SELD-103 drawing

Page 13 of 20 flowserve.com

Page 14

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

0518

II 1 GD

Ex ia

CSA 2010 2273150

IECEx SIR.10.0006

Cl I, Zn 0 A/Ex ia IIC T6

I.S. for Cl I, Div 1 Grps A, B,

C, D;

Cl II, Div 1, Grps E, F, G;

Cl III, Div 1, and provides I.S.

circuits with Entity

Parameters per Install

Manual 701-2000 and 7013000

Tem. Code T6

-20°C ≤ Ta ≤ +60°C

Sira 10ATEX2013

Ex ia IIC T6 Ga

Ex iaD IIIC T85°C DA

8 CERTIFICATION

The following certifications are applicable to the

SELD-103:

Table 7: Model SELD-103 certifications

9 TROUBLE-SHOOTING GUIDE

EXPLOSION HAZARD: The unit must be

powered OFF during the battery installation & must

be in a General Purpose Classified Area before

removing outer plastic tube to prevent the possible

ignition of a hazardous atmosphere.

9.1 Loss of Communications

Loss of communications with SELD-103 unit may

occur for several reasons:

Unit not powered up

Unit not configured correctly

Unit out of range of receiver

Receiver not configured correctly

4. Remove sensor cable(s) and configuration

cable.

5. Ensure SELD-103 is in a non-classified area

before performing next step.

6. Loosen the set screw in the side of the tube

and gently unscrew the external housing (tube)

from the transmitter assembly.

7. The battery pack should be visible on the lower

end of the transmitter assembly. Carefully

disconnect the battery pack.

8. Use a voltmeter to read battery voltage across

pins with red and black wires on connector to

battery pack. If the voltage level is below 2.8V,

replace the battery according to instructions in

section 4 MAINTENANCE.

Figure 13: Measuring battery level on SELD-103

unit (external housing removed) using a

voltmeter

See solutions below to each of the possible

causes:

9.1.1 Unit Not Powered Up

Verify set screw is installed at base of SELD-103

unit (see section 4 MAINTENANCE on how to turn

on unit).

1. Connect diagnostics RS-485 cable to port 6 of

SELD-103 and other end to a PC.

2. Read battery level using PSP software. If the

battery level is above 2.8V, skip to step 8. If

you are able to successfully read the battery

voltage on this screen but the level is below

2.8V, replace the battery according to

instructions in section 4 MAINTENANCE.

3. If communications are still not successful,

power down unit by removing the magnetic set

screw located at the bottom of the base.

Page 14 of 20 flowserve.com

Figure 14: Detail view of voltmeter connection

to battery pack cables.

9.1.2 Unit Not configured Correctly

To perform the diagnostic steps for this issue, the

SELD-103 unit will need all sensors connected to it.

Refer to PSP software instructions to reload the

original configuration into the SELD-103 unit.

9.1.3 Unit Out of Range of Receiver

If communications from the SELD-103 unit to the

receiver are still not successful, physically move

the SELD-103 unit next to and with a clear line of

sight to the receiver.

Page 15

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

If data is being read from this location, then ensure

that the repeater network is appropriately located

and functional.

9.1.4 Receiver Not Configured Correctly

Check receiver configuration to ensure it is set up

to receive data from this particular SELD-103 unit

(refer to receiver user instructions).

If none of the above solutions are successful in

getting data reception at the receiver, contact the

factory for additional support.

9.2 Inaccurate or Missing Data

If the data being read from the SELD-103 unit is

either inaccurate or missing, this could have

several causes:

Loose cable connections

Unit configuration incorrect

Inaccurate sensor calibration

Incorrect receiver configuration

9.2.1 Loose Cable Connections

Ensure the sensor cables to and sensors ports on

the SELD-103 unit are free from dust and debris.

Use compressed moisture free air to blow out any

debris if needed.

Reconnect all sensor cables to the SELD-103 unit

to ensure tight connections.

9.2.2 Unit Configuration Incorrect

If the inaccurate/missing data problem is across all

sensors, reload the original configuration for the

SELD-103 unit (see PSP user instructions).

9.2.3 Inaccurate Sensor Calibration

If the data received on certain channels/sensors is

not accurate, recalibrate those sensors (see PSP

user instructions).

9.2.4 Incorrect Receiver Configuration

Refer to receiver instructions to confirm correct

configuration. If necessary, contact factory to

reload receiver configuration settings.

9.3 No Data Recorded on VB-103-TAM

If no data is being stored to the VB-103-TAM unit,

this could have several causes:

Loose sensor cable connections

Loose VB-103-TAM connection

Low battery on VB-103-TAM

Incorrect VB-103-TAM log interval

configuration

9.3.1 Loose Sensor Cable Connections

Ensure the sensor cables to and sensors ports on

the SELD-103 unit are free from dust and debris.

Use compressed moisture free air to blow out any

debris if needed.

Reconnect all sensor cables to the SELD-103 unit

to ensure tight connections.

9.3.2 Loose VB-103-TAM Connection

Ensure the VB-103-TAM and SELD-103 ports are

free from dust and debris. Use compressed

moisture free air to blow out any debris if needed.

Disconnect and reconnect the VB-103-TAM from

the SELD-103 unit. Ensure that VB-103-TAM is

completely and fully threaded onto the SELD-103.

9.3.3 Low Battery on VB-103-TAM

Check to see if VB-103-TAM unit can be read on

an IPS Dock. If not, replace VB-103-TAM unit (the

VB-103-TAM battery is not user replaceable).

9.3.4 Incorrect VB-103-TAM Log Interval

Configuration

Connect the VB-103-TAM to the IPS Dock and

ensure the log interval is set to the expected value

(see IPS Dock user instructions for additional

details on how to perform this task).

9.4 No Lights on VB-103-VIS

If no lights are flashing on the VB-103-VIS, this

could have several causes:

Loose VB-103-VIS connection

9.4.1 Loose VB-103-VIS Connection

Ensure the VB-103-VIS and SELD-103 ports are

free from dust and debris. Use compressed

moisture free air to blow out any debris if needed.

Disconnect and reconnect the VB-103-VIS from the

SELD-103 unit. Ensure that VB-103-VIS is

completely and fully threaded onto the 103.

If none of the above solutions are successful in

resolving the issue, contact the factory for

additional support.

Page 15 of 20 flowserve.com

Page 16

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

EN 61326-1

2006

Electrical equipment for measurement, control and laboratory use EMC requirements - Part 1: General Requirements

EN 55011

2009

Industrial, scientific and medical equipment. Radio-frequency

disturbance characteristics. Limits and methods of measurement

Class A, Group 1

EN 61000-3-2,

EN 61000-3-3,

EN 61000-4-2,

EN 61000-4-3,

EN 61000-4-4,

EN 61000-4-5,

EN 61000-4-6,

EN 61000-4-8,

EN 61000-4-11

Series, Electromagnetic compatibility (EMC).

EN 61010-1

2002

Safety requirements for electrical equipment for measurement, control

and laboratory use. Part 1 General requirements

10 DECLARATION OF CONFORMITY (TYPICAL)

We, Flowserve Corporation

10920 West Sam Houston Parkway North

Suite 950

Houston, Texas 77064

USA

Declare in sole responsibility that the equipment:

ELD-102-X Single Point Transmitters

SELD-103-X Smart Point Transmitters

ELD-FA-403-Receiver, AO/DO and Serial Modbus

S-EGI-NB-4/20-AC/SP, Smart RTU

ELD-FA-525-AC/SP, Intelligent Repeater

Including all options and versions of the base model numbers to which this Declaration refers are in compliance

with the Directives and Norms specified herein.

1.1 EMC Directive 2004/108/EC

Basis for compliance:

The equipment has been assessed using the following standards and is supported by the following

technical documents:

Under these environmental and use conditions:

Industrial Applications, Pollution Degree 2

Technical File Reference Number: 701-5000

Installation and use of this equipment shall comply with the relevant installation and use instructions.

1.2 Low Voltage Directive 2006/95/EC

Basis for compliance:

The Single point transmitters are fully-enclosed, intrinsically-safe apparatus and are considered to meet

the requirements as set forth in the standard below without further consideration:

Under these environmental and use conditions: Industrial Applications, Pollution Degree 2

Page 16 of 20 flowserve.com

Page 17

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

EN 60079-0

2006

(+ corr. 1)

Electrical apparatus for explosive gas atmospheres Part 0

General requirements

EN 60079-11

EN 60079-26

2007

2007

Explosive atmospheres Part 11 Equip protection by intrinsic

safety i

Explosive Atmospheres- Part 26: Equipment with equipment

protection level (ELP) Ga

EN 61241-0

2006

Elec App for use in presence of combustible dust Part 0 Gen

requirements

EN 61241-1

2004

(+ Corr. 1

& 2)

Elec app for use in presence of combustible dust Part1

Protection by enclosures tD

EN 61241-11

2005

Elec app for use in presence of combustible dust Part11

Protection by intrinsic safety iD

Declaration of Conformity

1.3 ATEX Directive 94/9/EC + all amendments

Basis for compliance:

The equipment has been assessed using the following standards and is supported by the following

technical documents:

Certificate Number: Sira 10ATEX2013

Notified Body: Sira Certification Services, 0518

Report Number: R20441A

Markings:

Notified Body: CSA International

Report Number: 1005105

Markings:

Page 17 of 20 flowserve.com

Page 18

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

The technical documentation required to demonstrate that the product meets the requirements of the Directives

has been compiled by the signatory below and is available for inspection by the relevant enforcement authorities.

Signed: _____________________________________________ Date: _________________________

Authorized Person, Rick Lawson

General Manager

Page 18 of 20 flowserve.com

Page 19

Notes:

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Page 19 of 20

flowserve.com

Page 20

IPS WIRELESS SELD-103 ENGLISH 26999976 11-13

Your Flowserve factory contacts:

Flowserve Corporation

10920 W Sam Houston Parkway N, Suite 950

Houston, TX 77064 USA

Phone: +1 832 375 0807

Your Flowserve sales contact:

Go To: www.flowserve.com

Equipment Monitoring and Control Products

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

Pump

5215 North O’Connor Blvd.,

Suite 2300

Irving, Texas 75039-5421 USA

Telephone 1 972 443 6500

Fax 1 972 443 6800

Europe, Middle East, Africa

Flowserve FSG – Italy

Worthington S.r.l.

Via Rossini 90/92

20033 Desio (Milan), Italy

Telephone +39 0362 6121

Fax +39 0362 303 396

Latin America and Caribbean

Flowserve Corporation

6840 Wynnwood Lane

Houston, Texas 77008 USA

Telephone 1 713 803 4434

Fax 1 713 803 4497

Asia Pacific

Flowserve Pte. Ltd

10 Tuas Loop

Singapore 637345

Telephone 65 6771 1600

Fax 65 6862 2329

Loading...

Loading...