Fisher & Paykel OR90SCG6X1, OR90SCG1X1, OR90SCG6B1, OR90SCG4X1, OR90SCG6R1 Installation Guide

...Page 1

FREESTANDING RANGE

OR90 Dual Fuel

models

INSTALLATION GUIDE

NZ AU

Page 2

Page 3

1SAFETY AND WARNINGS

WARNING!

Electrical shock hazard

Before carrying out any work on the electrical section of the appliance,

it must be disconnected from the mains electricity supply.

Connection to a good ground wiring system is absolutely essential

and mandatory.

Alterations to the domestic wiring system must only be made by a

qualified electrician

Failure to follow this advice may result in electrical shock or death.

WARNING!

Cut Hazard

Take care – some edges are sharp.

Failure to use caution could result in injury or cuts.

WARNING!

To reduce the risk of tipping the appliance, the appliance must

be secured by properly installed anti-tip device packed with

the appliance.

●

A child or adult can tip the range and be killed.

●

Install the anti-tip device to the structure by fastening

the supplied bracket to the floor and wall following the

instructions for installing the anti-tip device.

●

Engage the anti-tip device.

●

Re-engage the anti-tip device if the range is moved.

Failure to do so can result in death or serious burns to children

of adults.

IMPORTANT SAFETY INSTRUCTIONS!

●

To avoid hazard, follow these instructions carefully before installing or using this appliance.

●

Please make this information available to the person installing the appliance - doing so could

reduce your installation costs.

●

This appliance must be installed according to AS/NZS 5601.1 (latest edition).

●

This appliance must be installed in accordance with these installation instructions.

●

This appliance shall only be serviced by authorized personnel.

●

This appliance is to be installed only by an authorised person in compliance with the current

electrical regulations gas codes and in observation of the instructions supplied by the

manufacturer. Failure to comply with this condition will render the guarantee invalid.

●

In the room where the range is installed, there must be enough air to allow the gas to burn

correctly, according to the current local regulations.

●

This appliance must only be installed in a permanently ventilated room in compliance with

the applicable regulations.

●

Isolating switch: make sure this range is connected to a circuit which incorporates an

isolating switch providing full disconnection from the power supply in accordance with the

wiring rules.

●

The range must be earthed.

●

Do not use adaptors, reducers or branching devices to connect the range to the mains

electricity supply, as they can cause overheating and burning.

●

Check for damage after unpacking and that the range door closes correctly.

●

The manufacturer accepts no responsibility for the incorrect installation of appliances.

Incorrect installation may result in personal injury, damage to property and may invalidate

any warranty or liability claims.

●

Do not modify this appliance.

●

Some models are supplied with a protective film on steel and aluminum parts.

●

This film must be removed before installing/using the appliance.

●

Packing elements (eg plastic bags, polystyrene foam, staples, packing straps etc) and tools

should not be left around during and after installation, especially if they are within easy

reach of children, as these may cause serious injuries.

●

Make sure you recycle the packaging material where possible.

●

Before disposing of any appliance, make sure that it can no longer be used and that all

hazardous parts are removed or made harmless, so that children playing with the old

appliance cannot harm themselves.

●

The various components of the appliance are recyclable. Dispose of them in accordance with

the regulations in force in your country. If the appliance is to be scrapped, remove the power

cord.

●

Be sure that the unit being installed is set up for the kind of gas being used. The gas range

is shipped from the factory set and adjusted for Natural Gas. It can be converted for use with

ULPG following the instructions in this manual.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country,

please go to our website fisherpaykel.com or contact your local Fisher & Paykel dealer.

3

Page 4

2GENERAL INSTALLATION INFORMATION

Cleaning and servicing

●

Service should only be performed by an authorised technician.

●

When removing appliance for cleaning and/or service:

●

Shut off gas at main supply.

●

Disconnect AC power supply.

●

Disconnect gas line to the inlet pipe.

●

Carefully remove the range by pulling outward.

●

CAUTION: Range is heavy; use care in handling.

●

The misuse of oven door (eg stepping, sitting, or leaning on them) can result

in potential hazards and/or injuries.

●

When installing or removing the range for service, a rolling lift jack should be used.

Do not push against any of the edges of the range in an attempt to slide it into or

out of the installation. Pushing or pulling a range (rather than using a lift jack) also increases

the possibility of bending the leg spindles or the internal coupling connectors.

IMPORTANT!

●

Range is heavy, use care in handling.

●

Do not lift the range by the oven door handle or hob rail, or by lifting the cooktop trim as

this may damage the appliance.

Replacement parts

Only authorised replacement parts may be used in performing service on the range.

Replacement parts are available from factory authorised parts distributors.

Contact the nearest parts distributor in your area.

PRODUCT LABEL

4

Page 5

3PARTS SUPPLIED FOR INSTALLATION

Anti-tip bracket

and lock pin (1)

Screws and plastic

sleeve anchors (2)

Pressure regulator (1) Test point adapter (1) brass conical adapter

4TOOLS NEEDED FOR INSTALLATION (NOT SUPPLIED WITH THE APPLIANCE)

IMPORTANT!

THIS APPLIANCE MUST BE INSTALLED BY A QUALIFIED INSTALLER.

●

Improper installation, adjustment, alteration, services, or maintenance can cause injury or property damage.

Consult a qualified installer, service agent, or the gas supplier.

●

The use of suitable protective clothing/gloves is recommended when handling or installing this appliance.

and gasket (1)

Screwdriver 2 – Wrench T-handle

wrench

Pencil Tape measure Suitable

protective gloves

Hammer Adjustable

wrench

Adjustable

pliers

Drill

5

Page 6

Model features may vary

OR90 MODELS

OR90SCG1

OR90SCG2

OR90SCG4

OR90SCG6

OR90SDG6

5MODEL IDENTIFICATION

6PRIOR TO INSTALLATION

Unpacking and handling

●

Inspect the range to verify that there is no shipping damage. If any damage is detected, call the shipper and initiate a damage claim. Fisher & Paykel is not responsible for shipping damage.

●

DO NOT discard any packing material until the range has been inspected.

●

Remove the outer carton and any packing material from range. Some models are supplied with a protective film on steel and aluminum parts.

This film must be removed before installing or using the appliance.

6

Page 7

7PRODUCT DIMENSIONS

NOTE: Model features may vary

Optional kickstrip is available (purchased separately)

A

FRONT

E

F

G

C

SIDE

D

C

B

TOP

PRODUCT DIMENSIONS

Overall height of range

A

(from floor to top of cooktop, excluding grates and optional backguard)

Overall width of range

B

Overall depth of range

C

(from front of range to rear of backguard, excluding handles and dials)

Height of optional backguard from top of cooktop

D

(supplied with some models only)

Height of chassis (excluding adjustable feet)

E

F

Adjustable feet height

G

Depth of open door to front of range

OR90 DUAL FUEL

mm

min. 898

max 946

897

600

60

813

min. 85

max. 133

451

7

Page 8

8CLEARANCE DIMENSIONS

A

F

ISO

CLEARANCE DIMENSIONS

Minimum vertical distance between benchtop and cabinet extending above counter 450

A

Minimum clearance from left and right edge of cooker to nearest vertical combustible surface*

B

Minimum clearance from cooking surface to:

C

– Overhead cabinet centered above the cooktop (combustible/unprotected)*

– Overhead cabinet centered above the cooktop (non-combustible/protected)*

– Ventilation hood centered above the cooking surface

Width of cabinetry opening 900

D

Maximum height of cabinetry immediately adjacent to the range (from floor to countertop)**

E

Maximum depth from wall to cabinetry face

F

* Installation clearances and protection of combustible surfaces shall comply with the current local regulations eg. AS/NZS5601.1 (latest edition)

Gas Installations code. The standards above specify that where required protection shall ensure that the surface temperature of the combustible

surface does not exceed 65°C above room temperature.

** Depending on the height of the feet adjustment. The cooking surface must sit flush or above countertop level.

COOKING SURFACE

E

Electrical & Gas

(see diagrams following)

D

FRONT

OR90 DUAL FUEL

C

mm

200

650

450

750

946

600

Note

Overhead Clearances

●

In no case shall the clearances between

the highest part of the cooker be less

than 650mm or for an overhead exhaust

fan 750 mm. All other downward facing

combustible surfaces less than 650

mm above the cooker surface shall

BB

be protected for the full width of the

cooking surface in accordance with the

standards noted above. In no case shall

the clearance be less than 450 mm.

Rear and Side Clearances

●

Where the dimensions from the

periphery of the nearest burner to any

vertical combustible surface is less than

200 mm the surface shall be protected

in accordance with the standards to a

height of not less than 150 mm above

the cooking surface for the full width or

depth of the cooking surface.

●

Where the dimensions from the

periphery of the nearest burner to any

horizontal combustible surface is less

than 200 mm, the horizontal surface

shall be greater than 10 mm below the

surface of the hob, or the horizontal

surface requirement above.

●

Do not install the range near flammable

materials such as curtains.

Installing the range on a plinth

●

The range can be installed on a plinth

without the adjustable feet fitted.

●

Ensure the range is secure and provide

safety measures to keep it in place.

●

Cabinetry dimensions can be adjusted

to suit the plinth height, see product

dimensions for chassis height.

8

Page 9

9FITTING THE OPTIONAL BACKGUARD

Backguard (supplied with some models only)

●

Remove the screws and spacers on the rear of the cooktop.

●

Assemble the backguard as shown and fix onto the back of the range using the

same screws and spacers.

●

Fix the backguard onto the range using the screws provided.

!0LOCATION OF ELECTRICAL SUPPLY

C

B

A

f

Left side

of cavity

Final position of cooker against wall

C

Gas

E

Electricity and Gas

Floor

D

BAA

SUPPLY AREA DIMENSIONS mm

Distance from either edge of Range to supply area 19

A

Width of electrical area 860

B

Width of gas only supply area 79

C

Height of electrical supply area* 210-260

D

Height of gas supply area* 700-750

E

Depth of supply area (

f

ie maximum protrusion of gas and electrical connection from wall)

* Depending on adjustment of feet

74

9

Page 10

!1VENTILATION REQUIREMENTS

A suitable ventilation hood may be installed above the range.

Fisher & Paykel has a choice of ventilation hoods designed to match the rest of our kitchen appliance family. See fisherpaykel.com or your local dealer for more details.

Hood (inc. combustible) Hood (inc. combustible)

750mm 750mm

Wall Installation

Island Installation

IMPORTANT

●

Consult local building codes and/or local agencies, before starting, to ensure that hood and duct installation will meet local requirements.

●

Hood blower speeds should be variable to reduce noise and loss of heated or air conditioned household air when maximum ventilation is not required.

Normally, the maximum blower speed is only required when using the grill or the self-cleaning cycle.

10

Page 11

!2FITTING THE ADJUSTABLE FEET

Fitting the adjustable feet

The adjustable feet must be fitted to the base of the range before use.

Rest the rear of the range on a piece of the polystyrene packaging exposing

the base for the fitting of the feet.

IMPORTANT

Take care not to damage the range during this operation.

Fit the four legs by screwing them tight into the support base as shown.

Fitting the adjustable feet covers (optional)

If using the adjustable feet covers fit these while the range is tipped over.

1 Tip range onto its back and fix

brackets to mounting holes.

2 Assemble the feet covers by slotting

the inner cover inside the outer cover.

Levelling the range

●

The range may be levelled by screwing the lower ends of the feet IN or OUT.

●

Small adjustments may be made to the range in the upright position, however it

may be necessary to tip the range again to make larger adjustments.

3 Gently bend the edges of the

inner cover to adjust the tension

between the two parts if needed.

Stand range back upright. 6 Adjust the inner panels of the foot

5

4

Secure covers to brackets using

the provided screws

covers to suit height of range feet.

11

Page 12

IMPORTANT!

●

When raising range to upright position always ensure two people

carry out this manoeuvre to prevent damage to the adjustable

feet.

●

Be careful: do not lift the range by the oven door handle, the

hob rail or by lifting the cooktop trim as this may damage the

appliance.

●

When moving range to its final position DO NOT DRAG.

Lift feet clear of floor.

!3MOVING THE RANGE

12

Page 13

IMPORTANT!

●

To restrain the range and prevent it tipping accidentally secure the

range to the wall using the supplied anti-tip bracket. Make sure

you also fit the supplied lock pin to the anti-tip bracket.

●

If installing the range above a plinth (without fitting the

adjustable feet) revise the installation dimensions for the anti-tip

bracket accordingly, considering that the feet have the following

measurements: min 85mm - max 133mm.

●

Before drilling and holes or inserting any screws into the floor or

wall check that you will not damage any wiring or pipes.

!4INSTALLING THE ANTI-TIP BRACKET

Dotted line showing the position

of the range when installed

To fit the anti-tip bracket

1 Loosely fix the anti-tip bracket to the wall using the supplied screws.

●

Drill two 8mm diameter holes in the wall and insert the supplied

plastic sleeve anchors before inserting the screws.

2 Slide the range into place and adjust the height of the bracket so that

it will align with the slot on the back of the range.

3 Tighten the screws to fix the anti-tilt bracket in place.

4 Push the range back into place so that the bracket is fully inserted

into the slot on the back of the range.

40mm

min. 167mm

max. 217mm

anti-tip bracket

bracket slot at back

of the range

13

Page 14

!4INSTALLING THE ANTI-TIP BRACKET

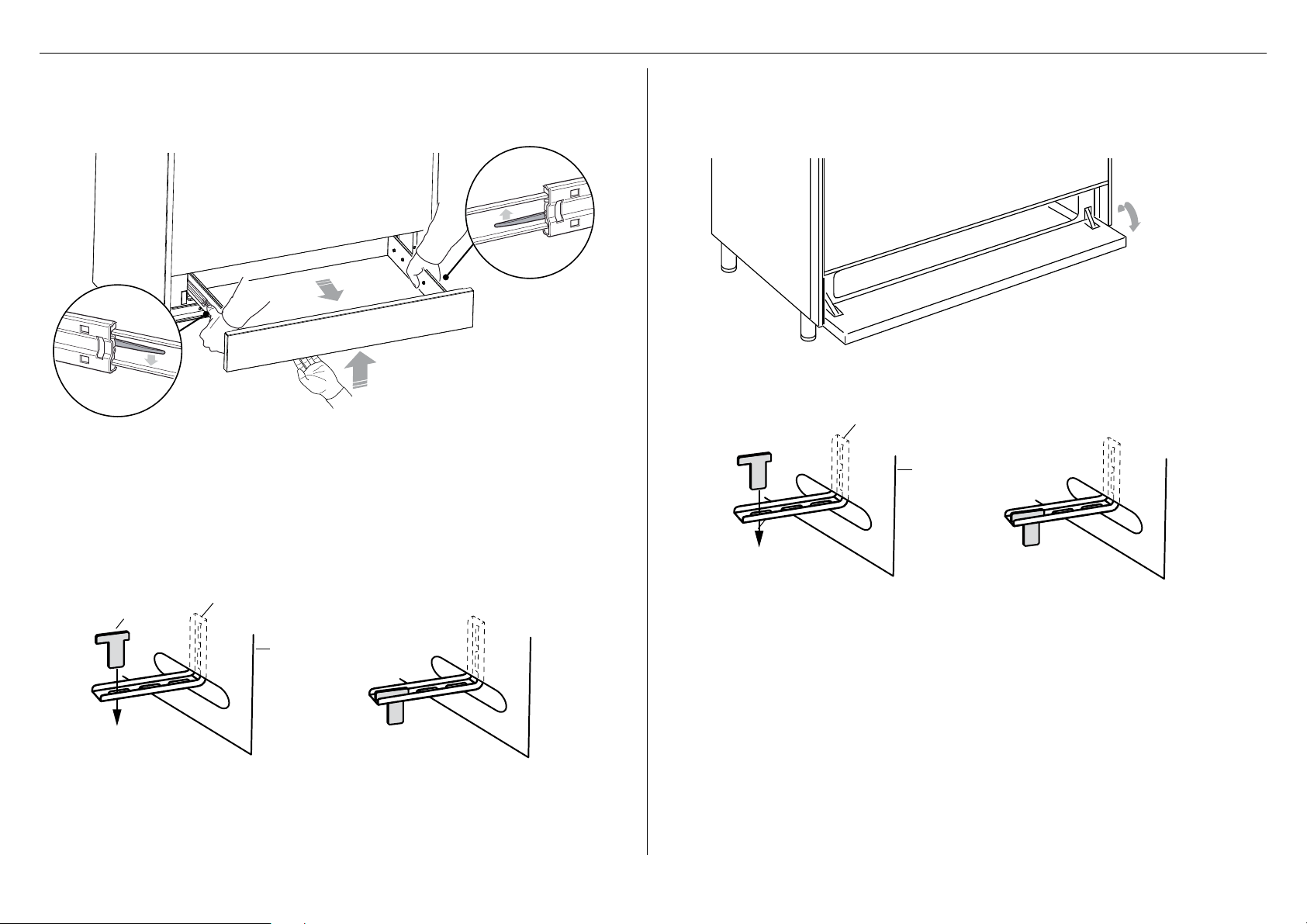

Fitting the lock pin (models with a storage/warming drawer)

The anti-tip bracket is accessible by removing the storage/warmer drawer, and is

positioned on the rear right side of the range.

A

To remove the storage/warming drawer

1 Open the storage/warming drawer completely.

2 Move down the lever of left guide A and up the lever of right guide B.

3 Remove the drawer holding the levers in the same position.

IMPORTANT

●

Do not remove storage/warming drawer while hot or during operation.

●

Be sure storage/warming drawer is empty before removing.

●

Always position your hand below the front panel to open/close the drawer.

bracket mounted

lock pin

to rear wall

range

back

B

Fitting the lock pin (models with a storage compartment)

The anti-tip bracket is accessible by opening the storage compartment door., and is

positioned on the rear right side of the range.

1 Open the storage compartment door.

bracket mounted

lock pin

to rear wall

range

back

2 Fit the lock pin through the bracket as shown.

3 Close the storage compartment door.

6 Fit the lock pin through the bracket as shown

7 Insert the drawer guides onto the sliding runners on either side of the range interior.

●

Make sure they are correctly lined up on both sides of the drawer.

8 Gently close the drawer completely. The safety catches will automatically lock into place.

14

Page 15

!5ELECTRICAL CONNECTION

IMPORTANT!

●

This range must be connected to the mains power supply only by a suitably qualified person.

●

This range must be earthed.

●

If the installation requires alterations to the domestic electrical system, call a qualified electrician. The electrician should also check that the

electrical system is suitable for the electricity drawn by the cooker.

●

The appliance must be connected to the mains electricity supply, checking that the voltage corresponds to the value given in the rating plate and

that the electrical cable sections can withstand the load specified on the plate.

●

A suitable disconnection switch must be incorporated in the permanent wiring, mounted and positioned to comply with the local wiring rules

and regulations. The switch must be of an approved type installed in the fixed wiring and provide a 3mm air gap contact separation in all poles in

accordance with the local wiring rules.

●

A switch of the approved type with a 3mm air gap must be installed in the active (phase) conductor of the fixed wiring.

●

The switch must always be accessible.

●

The power supply cable must not touch any hot parts and must be positioned so that it does not exceed 75oC at any point.

●

This cooker must be connected to a suitable double pole control unit adjacent to the cooker. No diversity can be applied to this control unit.

●

This appliance must be connected to the electrical supply using a cable fitted with an appropriately rated plug. The plug must be compatible with

the socket-outlet fitted to the final subcircuit in the fixed wiring that is intended to supply the appliance.

Replacing the power cord

●

Replacements should only be made by a qualified electrician.

●

Use a cable according to the applicable local regulations.

MODEL CODE MAX POWER (W) HZ VOLTAGE (V) AMPS (A)

OR90SCG1 3210 50 Hz 220 - 240 V~ 13.95

OR90SCG2 4950 50 Hz 220 - 240 V~ 21.54

OR90SCG4 4950 50 Hz 220 - 240 V~ 21.54

OR90SCG6 5200 50 Hz 220 - 240 V~ 22.60

OR90SDG6 5200 50 Hz 220 - 240 V~ 22.60

Location of

nameplate

15

Page 16

!6CONNECTION OF THE POWER SUPPLY CABLE

PE

L

N

1

2

3

4

5

PE

L

N

IMPORTANT!

●

The power supply cable must be connected by an authorised service person

●

DO NOT unscrew the screws fixing the cover plate behind the terminal block

OR90SG6 MODELS ONLY

1 Unhook the terminal board cover by inserting a

screwdriver into the two hooks at the base of the

block.

Feeder cable section

Use a type of cable according to the applicable local regulations.

220-240V AC

cable clamp

2 Unscrew the screw to open the cable clamp.

For OR90SCG6 and OR90SDG6 models, connect the

U bolts onto the terminal.

220-240V AC

cable clamp

3 Connect the phase, neutral and earth wires to the

terminal board as shown. Strain the feeder cable and

block it with cable clamp. Screw clamp shut before

closing the main cover.

MODEL CODE CABLE SPECIFICATIONS

OR90SCG1 220-240 V 50Hz 3210 W (13.95 A) 3 x 1,5 mm **

OR90SCG2 220-240 V 50Hz 4950 W (21.54 A) 3 x 2,5 mm *

OR90SCG4 220-240 V 50Hz 4950 W (21.54 A) 3 x 2,5 mm *

OR90SCG6 220-240 V 50Hz 5200 W (22.60 A) 3 x 2,5 mm *

OR90SDG6 220-240 V 50Hz 5200 W (22.60 A) 3 x 2,5 mm *

* Connection with wall box connection.

** Connection possible with plug and outlet or with wall box connection.

16

Page 17

!7GAS CONNECTION

Gas supply

●

The connection must be performed by an authorised person according to the relevant

standards.

●

This appliance is suitable for use with Natural Gas or ULPG. The gas range

●

is shipped from the factory set and adjusted for Natural Gas. It can be converted for use

with ULPG following the instructions in this manual.

●

The connection must be made at the rear of appliance. Ensure the pipe does not cross the

cooker.

●

The inlet not used must be closed off with the cap and sealing gasket supplied.

Installation with a flexible hose assembly

●

If this appliance has to be installed with a hose assembly, the installer shall refer to the

network operator or gas supplier for confirmation of the gas type, if in doubt.

●

When used with a flexible hose, the connector on the wall should be between 450mm to

500mm from the floor and 200 mm to 300 mm from the left-hand side of the appliance as

viewed from the front. The hose connection on the appliance shall face downwards.

●

It is important that the hose does not come in contact with the metal of the appliance

and is secured as per appropriate gas installation codes. A chain 80% of the length of

the flexible gas hose must be used to prevent stress being applied to the hose. The chain

should be attached securely to the product where shown, and on the wall.

●

Flexible hose assemblies should be AS/NZS 1869 Class B or Class D certified. The thread

connection shall be Rp ½” (ISO 7-1) male.

●

The hose assembly shall be as short as practicable and comply with relevant AS5601 /

NZS5261 requirements.

IMPORTANT!

●

After connection the installer must check that the hose is not kinked, subjected to

abrasion or permanently deformed. The installer must check also that the hose is not

near (or in contact) with any hot surfaces.

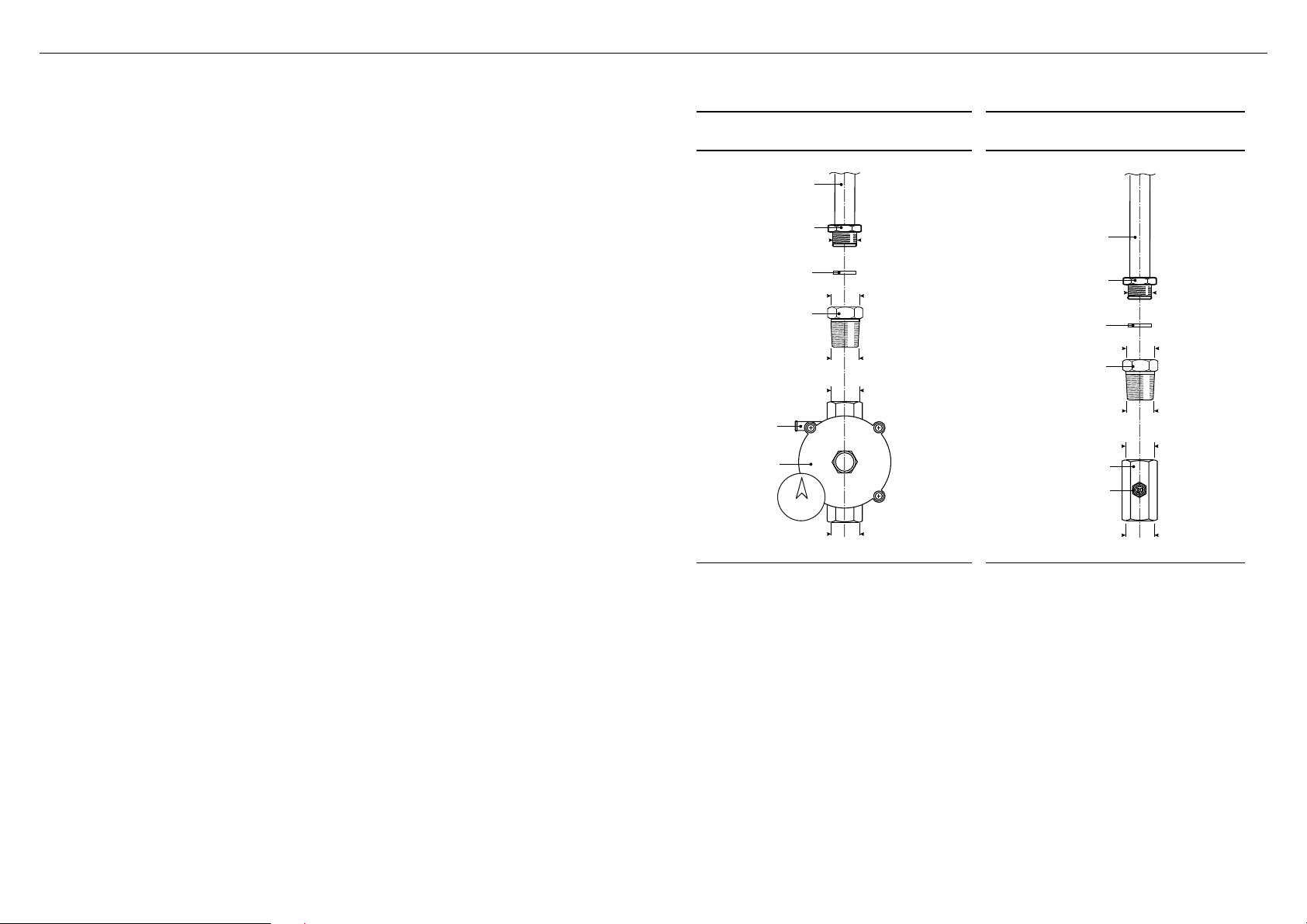

Gas connection specification

NG ULPG

Gas inlet pipe

Nipple

Gasket

Brass conical

adapter

Test point

Gas regulator

Gas inlet pipe

Nipple

Gasket

Brass conical

adapter

Test point

adapter

Test point

Arrow

IMPORTANT!

●

Check the correct positioning of the gas regulator. The arrow on the back of the gas

regulator must be oriented toward the connector.

17

Page 18

IMPORTANT!

The connection must be performed by an authorised person

according to the relevant standards.

Natural Gas

ULPG

!7GAS CONNECTION

1 Before connecting the appliance to the gas main,

mount the brass conical adaptor onto the gas inlet

pipe, ensuring the supplied gasket is positioned

between.

Natural Gas

Connect gas supply to the pressure regulator and

adjust the regulator to obtain a test point pressure of

1 kPa with the two semi-rapid (SR) burners operating

at maximum.

LP/Propane

Connect gas supply to the test point adaptor and

ensure that the supply pressure is regulated to

2.75 kPa

18

2 Tighten connection 3 The connection must be made at the rear of

appliance as shown above.

IMPORTANT!

Use two wrenches to tighten the connection.

Do not over tighten the connector.

Over tightening may crack regulator.

The pipe should not cross the back of the

range

IMPORTANT!

The inlet not used must be closed off with

the cap and sealing gasket supplied.

Page 19

!8FLAME TESTING

●

The operation of the appliance must be tested when installation is completed.

●

Turn on the appliance gas controls and light each burner individually and in combination. Check for a well defined blue

flame without any yellow tipping. If any abnormality is evident then check that the burner cap is located properly and the

injector nipple is aligned correctly.

●

Check the minimum burner setting by quickly rotating the gas control knob from the maximum to the minimum position.

The flame must not go out. If adjustment is required see section “Adjusting the minimum burner setting”

If correct burner operation cannot be achieved, the installer shall check the installation and contact the local gas supply

authority to ensure there are no gas supply problems. If correct operation still cannot be achieved contact Customer

Service.

Lifting off

Yellow tip

Good flame

!9LEAK TESTING

●

Make sure all oven and burner knobs are set to OFF before connecting range to gas supply.

●

After final gas connection is made, turn gas supply on and test all connections in gas supply piping for gas leaks with

a soapy water solution.

●

In order to avoid property damage or serious personal injury, never use a Iighted match or open flame.

If a leak is present, tighten joint or unscrew, apply more joint compound, tighten again and retest connection for leak.

ON

ON

GAS

GAS

19

Page 20

@0GAS CONVERSION

Conversion to ULPG

●

This range can be used with Natural Gas or ULPG. It is shipped from the factory adjusted

for use with Natural gas.

●

Any conversion required must be performed by an authorised person or service agent.

●

The range is supplied with a set of injectors required for converting the range burners.

●

Refer to the following table to select the appropriate size injector. The nozzle diameters

(hundredths of a millimetre) are marked on the body of each injector.

IMPORTANT!

●

After converting the range repeat flame testing.

●

If the range has been disconnected and re-connected to the gas supply line repeat leak

testing.

●

After conversion to ULPG gas affix the supplied conversion label near the data plate on

the product, as well as at the beginning of this manual.

●

If the range is being converted for use ULPG, before connecting to the gas mains remove

the appliance gas regulator and replace with test point adaptor.

Injectors table

NATURAL GAS

1 kPa

BURNERS

Ø INJECTOR

CONSUMPTION

MM

Auxiliary (A) 0.92 3.90 0.56 3.90

Semirapid (SR) 1.17 6.5 0.70 6.3

GAS

MJ/HR

ULPG 2.75 kPa

Ø INJECTOR

MM

CONSUMPTION

GAS

MJ/HR

Replacing the cooktop burner injectors

1 Remove the pan supports, the burner caps and the flame spreaders.

2 Using a wrench substitute the nozzle injectors with those most suitable for the kind of gas

for which it is to be used.

3 Adjust the minimum burner setting (see “Adjusting the minimum burner setting”)

4 Refit the flame spreaders, the burner caps and the pan supports.

5 Fix the warning label (supplied with the conversion kit) stating that the cooker has been

converted for use with ULPG to the rear of the range. Ensure it is in close proximity to to

the gas inlet connection.

The burners are designed so that no regulation of the primary air is required.

Injector

Injector

Rapid (R) 1.54 11.75 0.98 11.75

Triple Ring (TR) 1.75 14.40 1.07 14.40

Inner crown

injector

0.76

Dual (D)

Outer crown

injector (x2)

1 Power calculated with inner and outer crown operating

1.23 0.71

16.20

1

0.48

16.20

20

Auxiliary, Semi-rapid and

Triple ring burners

Rapid burners

1

Inner crown

Injector

Injector for

inner crown

J

Injectors for

Dual burner

outer crown

Outer crown

J

Injectors

Page 21

@1ADJUSTING THE MINIMUM BURNER SETTINGS

B

C

A

Adjusting the cooktop burner minimums

Check whether the flame spreads to all burner ports when the burner is lit with the gas tap

set to the minimum position.

●

If some ports do not light, increase the minimum gas rate setting.

●

Check whether the burner remains lit even when the gas tap is turned quickly from the

maximum to the minimum position.

●

If the burner does not remain lit, increase the minimum gas rate setting.

To regulate the flame follow these instructions:

Auxilliary, Rapid, Semi-rapid, Triple-ring and Single Wok burners (A)

●

Light the burner

●

Set the gas valve to position (minimum rate)

●

Remove the knob.

●

With a thin screwdriver, turn the regulation screw inside the tap rod

until adjustment is correct

Inner crown Dual Wok burner (B)

(OR90SG2, OR90SG4, OR90SDG6 and OR90SG6 models only)

●

Light the dual wok burner

●

Set the gas valve to position (minimum rate of inner crown)

●

Remove the knob

●

With a thin screwdriver, turn the regulation screw until adjustment is correct.

●

The screw is accessible via a hole in the microswitch.

Outer crown Dual Wok burner (C)

(OR90SG2, OR90SG4, OR90SDG6 and OR90SG6 models only)

●

Light the dual wok burner

●

Set the gas valve to position

(minimum rate of outer crown and maximum rate of inner crown).

●

Remove the knob

●

With a thin screwdriver, turn the regulation screw inside the tap rod

until adjustment is correct

For ULPG, tighten the adjustment screws completely.

Lubrication of the gas valves

If a gas valve becomes stiff, it is necessary to dismantle it carefully and clean it with

petroleum spirit.

Specialist high temperature resistant grease should be used to lubricate the valve before

replacing.

This must be carried out by an authorised person or service agent.

Regulation

screws

Regulation

screws

A Regulation screw (Auxilliary, Rapid, Semi-rapid, Triple-ring and Single Wok burners)

B Regulation screw (Inner crown Dual Wok burner)

C Regulation screw (Outer crown Dual Wok burner)

21

Page 22

@2 FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

GENERAL

F Placement of unit.

F Specified clearance maintained to cabinet surfaces.

F Unit Level – front to back, side to side.

F All packaging material and tie straps removed.

F Island trim or optional backguard correctly attached.

F The anti-tip bracket is correctly installed.

ELECTRICAL

F Adequate ground connection.

GAS SUPPLY

F Site gas supply is compatible with range model, and sufficient pressure is available

(see section ‘Gas connection’).

F The pressure regulator (Natural Gas) or the test point adapter (ULPG) are connected

and correctly set for the type of gas.

F Unit tested and free of gas leaks.

OPERATION

F All internal packing materials removed. Check below the cooktop grates and inside

the oven.

F If converted for use with ULPG, confirm that the test point adapter and cooktop

burner injectors have been correctly set for use with ULPG.

F Dials turn correctly and freely.

F Each burner lights satisfactorily, both individually and with other burners operating

at the same time.

F The oven display is functioning correctly and the oven is heating when turned on.

F Oven door hinges seated and door opens and closes properly.

F Cooktop grates are correctly positioned, level, and do not rock.

F Cooktop burner flame correct.

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

22

Page 23

23

Page 24

FISHERPAYKEL.COM

© Fisher & Paykel Appliances 2017. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

NZ AU

591516A / 1105505-ß0 12.17

Loading...

Loading...