Page 1

GAS RANGE

for residential use only

R

Models: OR30SDBMX

USERS OPERATING INSTRUCTIONS

IMPORTANT - PLEASE READ AND FOLLOW

• Before beginning, please read these instructions completely and carefully.

• Do not remove permanently affi xed labels, warnings, or plates from the product. This may

void the warranty.

• Please observe all local and national codes and ordinances.

• Please ensure that this product is properly grounded.

• The electrical plug should always be accessible.

• The installer should leave these instructions with the consumer who should retain

for local inspector’s use and for future reference.

Installation must conform with local codes or in the absence of codes, the National Fuel Gas

Code ANSI Z223.1/NFPA 54 - Iatest edition. Electrical installation must be in accordance with

the National Electrical Code, ANSI/NFPA70 - latest edition and/or local codes.

IN CANADA: Installation must be in accordance with the current CAN/CGA-B149.1 National

Gas Installation Code or CAN/CGA-B149.2, Propane Installation Code and/or local codes.

Electrical installation must be in accordance with the current CSA C22.1 Canadian Electrical

Codes Part 1 and/or local codes.

INSTALLATION IN MANUFACTURED (MOBILE) HOME: The installation must conform with

the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly

the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD (Part 280)]

or, when such standard is not applicable, the Standard for Manufactured Home Installations,

ANSI/NCSBCS A225.1, or with local codes where applicable.

INSTALLATION IN RECREATIONAL PARK TRAILERS: The installation must conform with

state or other codes or, in the absence of such codes, with the Standard for Recreational Park

Trailers, ANSI A1 19.5.

Installation of any gas-fi red equipment should be made by a licensed plumber . A manual shut-

off valve must be installed in an accessible location in the gas line external to the appliance

for the purpose of turning on or shutting off gas to the appliance (In Massachusetts such shutoff devices should be approved by the Board of State Examiners of Plumbers & Gas Fitters).

If an external electrical source is utilized, the appliance, when installed, must be electrically

grounded in accordance with local codes or, in the absence of local codes, with the national

Electrical Code, ANSI/NFPA 70.

Some models are supplied with a protective fi lm on steel and aluminium

parts. This fi lm must be removed before installing/using the appliance.

FOR INSTALLER ONLY

THIS RANGE IS FOR RESIDENTIAL USE ONLY

590599B 1104419-ß2 04.14

Page 2

2

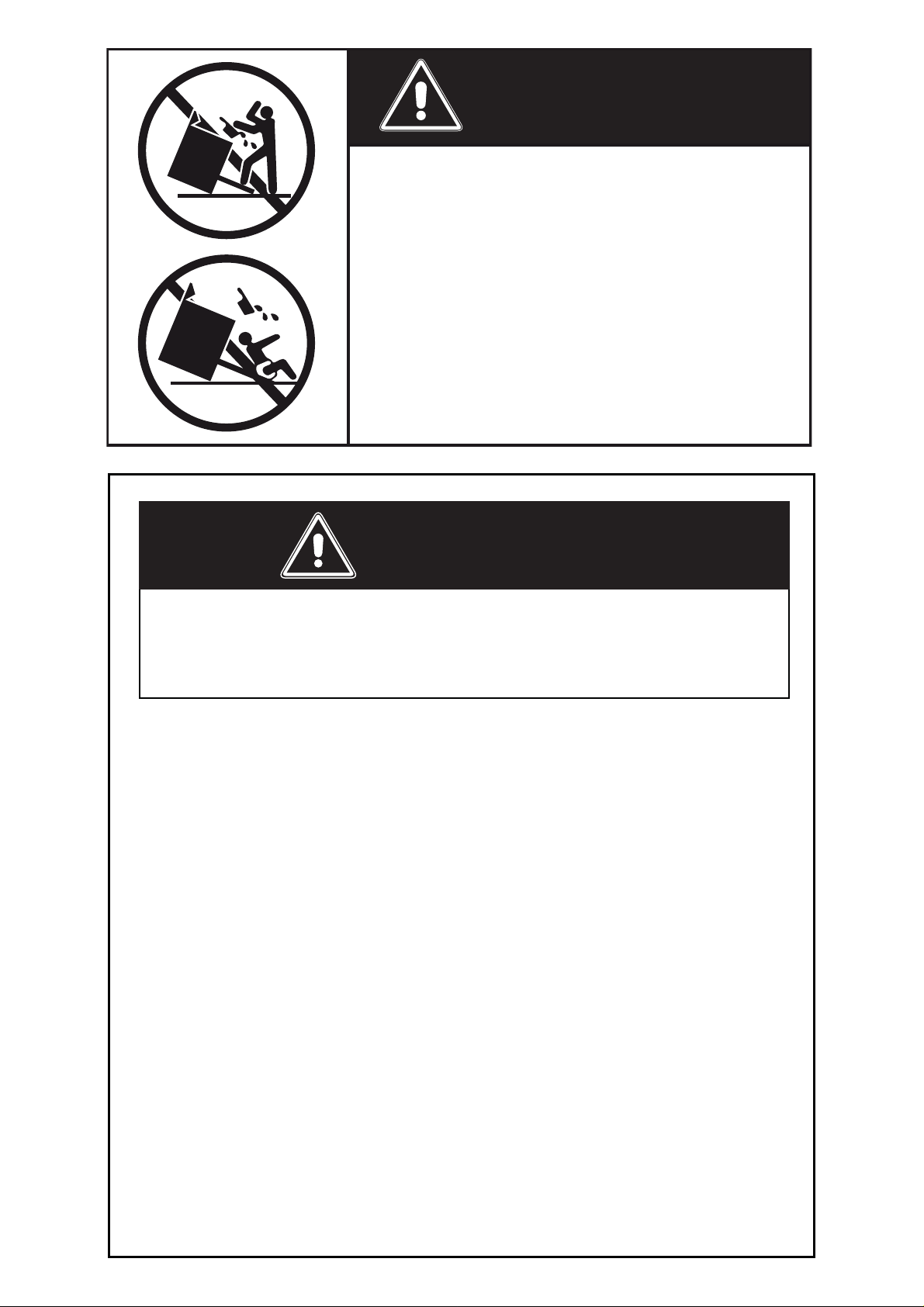

WARNING !

T o reduce the risk of tipping the appliance,

the appliance must be secured by properly

installed anti-tip device packed with the

appliance.

• ALL RANGES CAN TIP

• INJURY TO PERSONS COULD RESULT

• INSTALL ANTI-TIP DEVICE PACKED

WITH RANGE

• SEE INSTALLATION INSTRUCTIONS

WARNING !

If the information in this manual is not followed exactly,

a fi re or explosion may result causing property damage,

personal injury, or death.

– Do not store or use gasoline or other fl ammable vapors and

liquids in the vicinity of this or any other appliance.

– NEVER use this appliance as a space heater to heat or warm

the room. Doing so may result in carbon monoxide poisoning and overheating of the appliance.

– WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• lmmediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• lf you cannot reach your gas supplier, call the fi re de-

partment.

– Installation and service must be performed by a qualifi ed

installer, service agency, or the gas supplier.

2

Page 3

3

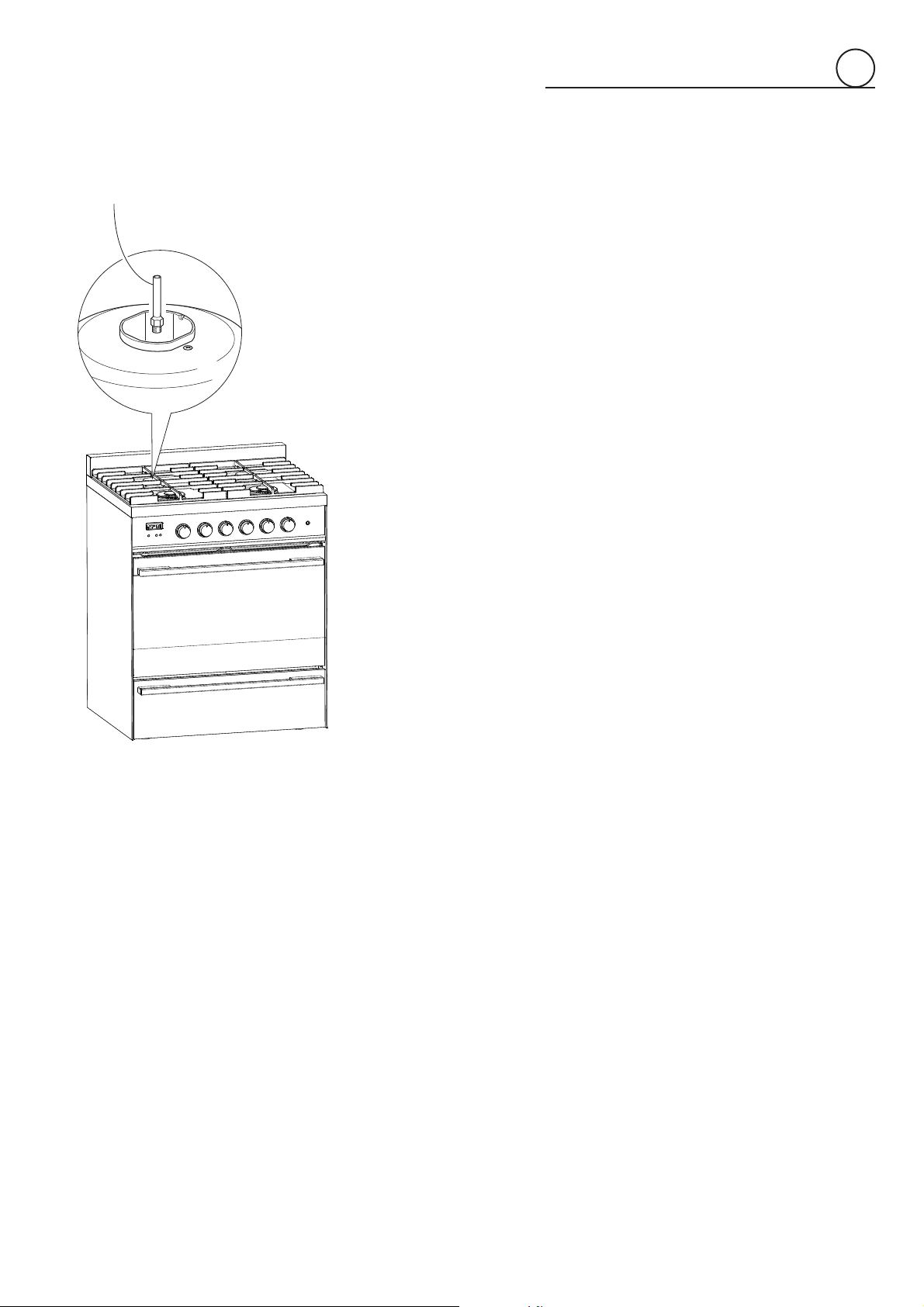

DATA PLATE

CONVERSION LABEL

The product data plate is

located on the outside of

the drawer on the left hand

side.

The Governor of California is required to publish a list of substances known to the state of California to cause cancer or reproductive harm and requires businesses to warn customers of potential

exposures to such substances.

WARNING!: Gas appliances contain or produce substances which can cause death or serious

illness and which are known to the State of California to cause cancer, birth defects or other reproductive harm. To reduce the risk from substances in fuel or from fuel combustion, make sure this

appliance is installed, operated, and maintained according to the manufacturer’s instructions.

This appliance is designed and manufactured solely for the cooking of domestic (household) food

and is not suitable for any non-domestic application and therefore should not be used in a commercial environment.

The appliance warranty will be void if the appliance is used within a non-domestic environment i.e.

a semi commercial, commercial or communal environment.

3

Page 4

4

INSTALLATION INSTRUCTIONS

WARNING!

THIS APPLIANCE MUST BE INSTALLED BY A QUALIFIED INSTALLER.

Improper installation, adjustment, alteration, services, or maintenance can cause injury or property damage. Consult a qualifi ed installer, service agent, or the gas supplier.

IMPORTANT: The use of suitable protective clothing/gloves is

recommended when handling, installing of this appliance.

TOOLS NEEDED FOR INSTALLATION (NOT SUPPLIED WITH THE APPLIANCE)

Screwdriver 2 - Wrench

Suitable protective

gloves

Hammer

T-handle

wrench

Adjustable

wrench

Adjustable

pliers

Tape

measurePencil

Drill

4

Page 5

5

GENERAL INFORMATION

1. Installation must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54

CGA-B149.2.

2. Installation in manufactured (mobile) home: installation must

conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 [formerly the

Federal Standard for Mobile Home Construction and Safety, Title 24, HUD (Part 280)] or, when such standard is

not applicable, the Standard for Manufactured Home Installations, ANSI/NCSBCS A225.1, or with local codes where

applicable.

- Latest Edition, CAN/CGA-B149.1 or CAN/

16. When installing or removing the range for service, a rolling lift

jack should be used. Do not push against any of the edges of

the range in an attempt to slide it into or out of the installation.

Pushing or pulling a range (rather than using a lift jack) also

increases the possibility of bending the leg spindles or the

internal coupling connectors.

WARNING!!

3. Installation in Recreational Park Trailers: installation must

conform with state or other codes or, in the absence of such

codes, with the Standard for Recreational Park Trailers,

ANSI A119.5.

4. To eliminate risk of burns or fi re by reaching over heated sur-

face units, cabinet storage located above the surface units

should be avoided.

5. Air curtain or other overhead range hoods, which operate by

blowing a downward air fl ow on to a range, shall not be used

in conjunction with gas ranges other than when the hood and

range have been designed, tested and listed by an independent test laboratory for use in combination.

6.

This appliance shall not be used for space heating. This

information is based on safety considerations.

7. AlI openings in the wall behind the appliance and in the fl oor

under the appliance shall be sealed.

8. Keep appliance area clear and free from combustible materials, gasoline, and other fl ammable vapors.

9. Do not obstruct the fl ow of combustion and ventilation air.

10. Disconnect the electrical supply to the appliance before servicing.

11. When removing appliance for cleaning and/or service;

A. Shut off gas at main supply.

B. Disconnect AC power supply.

C. Disconnect gas line to the inlet pipe.

D. Carefully remove the range by pulling outward.

CAUTION: Range is heavy; use care in handling.

WARNING!!

ELECTRICAL GROUNDING INSTRUCTIONS

The range must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA No. 70-latest edition, in Canada Canadian Electrical Code.

Installation should be made by a Iicensed electrician.

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PRO-

PERLY GROUNDED.

If an external electrical source is utilized, the installation must be

electrically grounded in accordance with local codes or, in the

absence of local codes, with the national Electrical Code, ANSI/

NFPA 70.

This appliance is equipped with a three-prong grounding plug

(NEMA 5-15P) for your protection against shock hazard and

should be plugged directly into a properly grounded socket.

Do not under any circumstances cut or remove the third

(ground) prong from the power plug.

REPLACEMENT PARTS

Only authorized replacement parts may be used in performing service on the range. Replacement parts are available from factory

authorized parts distributors. Contact the nearest parts distributor

in your area.

Electrical Requirement

12.

Electrical installation should comply with national and local

codes.

13.

Air Supply and Ventilation

The installer must refers to local/national codes.

14.

Gas Manifold Pressure

Natural gas - 4.0” W.C.P.

LP/Propane - 11.0” W.C.P.

15. The misuse of oven door (e.g. stepping, sitting, or leaning on

them) can result in potential hazards and/or injuries.

5

Page 6

6

1

3”

(76 mm)

MAX 36” 11/32 (923 mm)

MIN 35” 21/32 (905.5 mm)

24” 3/16

(615 mm)

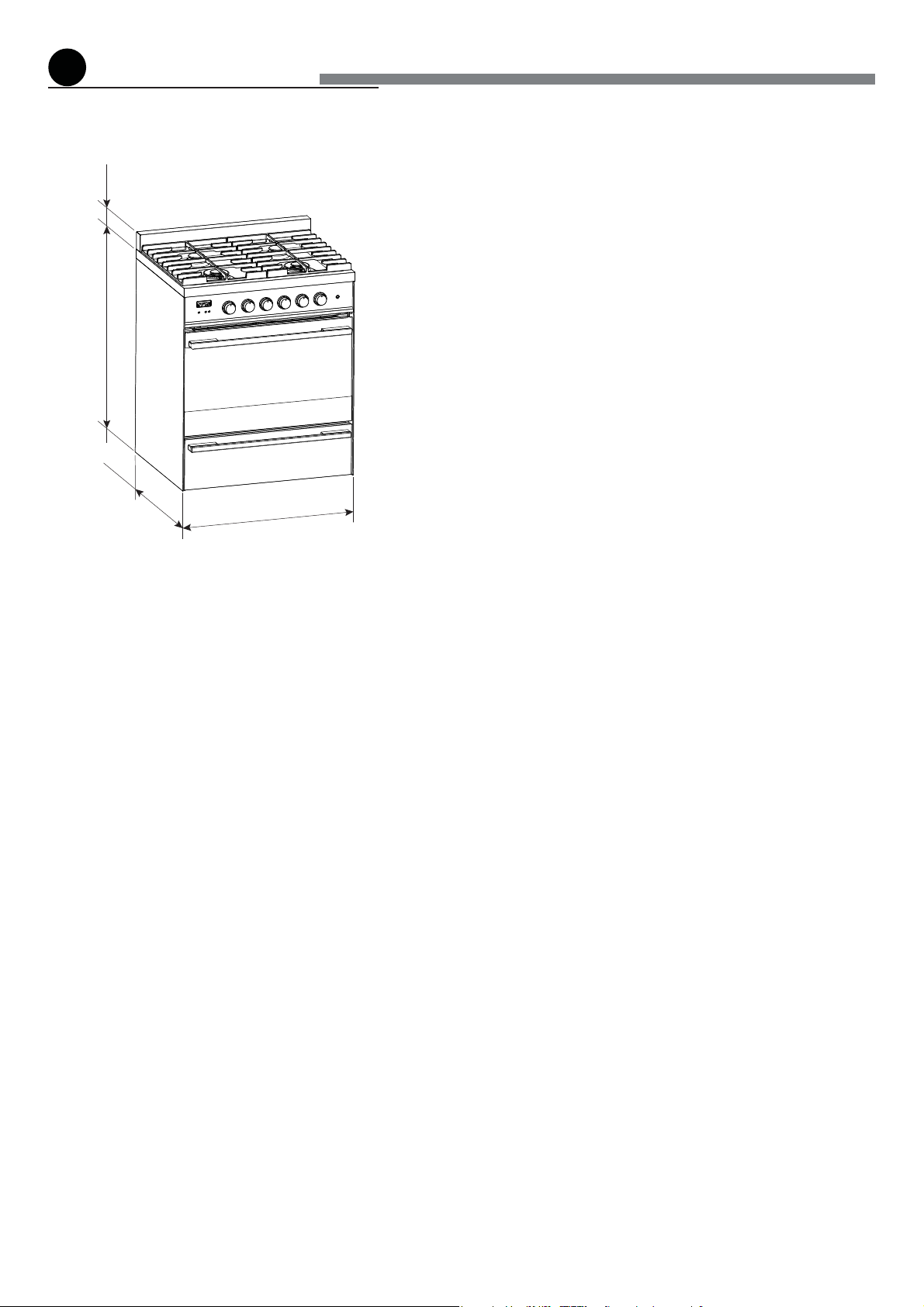

Fig. 1.1

29” 7/8

(759 mm)

installation

PROXIMITY TO SIDE CABINETS

1. This range may be installed directly adjacent to existing 36” (914 mm)

high base cabinets.

Range dimensions:

• width: 29” 7/8 (759 mm)

• depth: 24” 13/64 (614.9 mm)

• height (without backguard): MIN 35” 21/32 (905.5 mm) - MAX 36”

11/32 (923 mm)

• backguard (height): 3” (76 mm)

Gas line opening: Wall - 37/64” (14.5 mm) from the right side to centre

of range; from 5” 7/16 (138 mm) to 6” 1/8 (155.5 mm) [depending on feet

regulation] from the fl oor.

Grounded outlet: The electric cord with 3-prong ground plug (NEMA

5-15P) has a length of 72” (1830 mm). Grounded outlet should be located 37/64” (14.5 mm) from the left side to centre of range; from 5” 7/16

(138 mm) to 6” 1/8 (155.5 mm) [depending on feet regulation] from the

fl oor.

2. The range CANNOT be installed directly adjacent to sidewalls, tall cabinets, tall appliances, or other side vertical surfaces above 36” (914 mm)

high.

There must be a minimum of 1 1” 13/16 (300 mm) side clearance from the

range to such combustible surfaces TO THE LEFT or TO THE RIGHT

above the 36” (914 mm) high countertop.

IMPORTANT: One side (left or right) above the 36” (914 mm) high

countertop must always be kept clear.

Island installation: There must be a minimum of 12” (305 mm) clearan-

ce from the rear of the backguard to such combustible surface on the

back of the range above the 36” (914 mm) high countertop.

3. The maximum upper cabinet depth recommended is 13” (330 mm). Wall

cabinet above the range must be a minimum of 30” (762 mm) above the

countertop for a width of minimum 30” (762 mm): it has to be centered

with the range. Side wall cabinets above the range must be a minimum

of 18” (457 mm) above the countertop.

6

Page 7

7

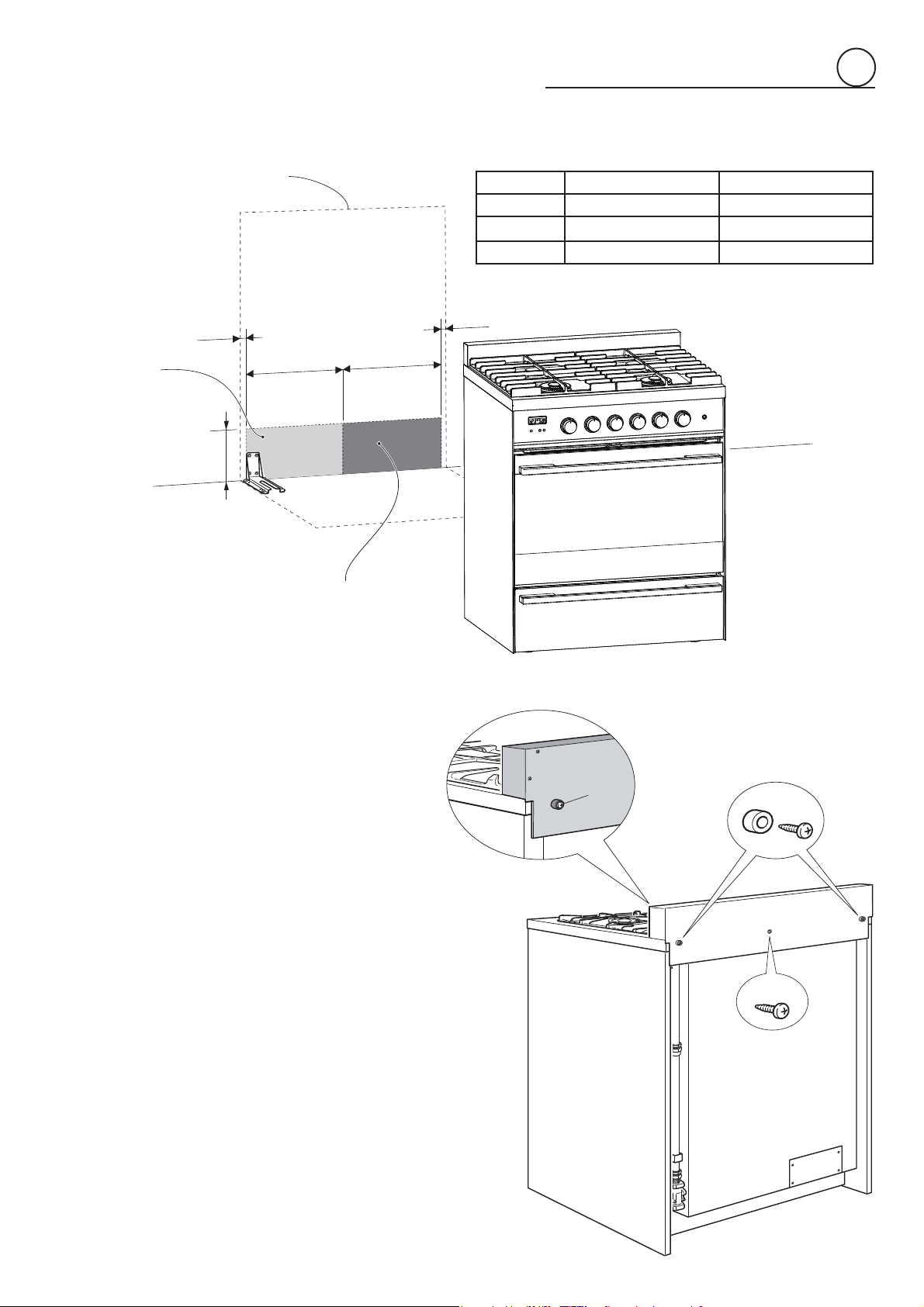

Dotted line showing the position

of the range when installed

1

GAS AND ELECTRIC CONNECTION

Ref. inch mm

A 5” 7/16 - 6” 1/8 (*) 138 - 155.5 (*)

B 14” 3/8 365

C 37/64” 14.5

(*) : Depending on feet regulation

Area for

ELECTRICAL

connection

C

B

A

Area for

GAS connection

B

C

Fig. 1.2

ASSEMBLING THE BACKGUARD

It is mandatory to install the backguard.

Assemble the backguard as shown in fi gure 1.3:

• Screw the 2 screws “A” interposing the spacers.

• Screw the central screw “B”.

A

A

B

Fig. 1.3

7

Page 8

8

1

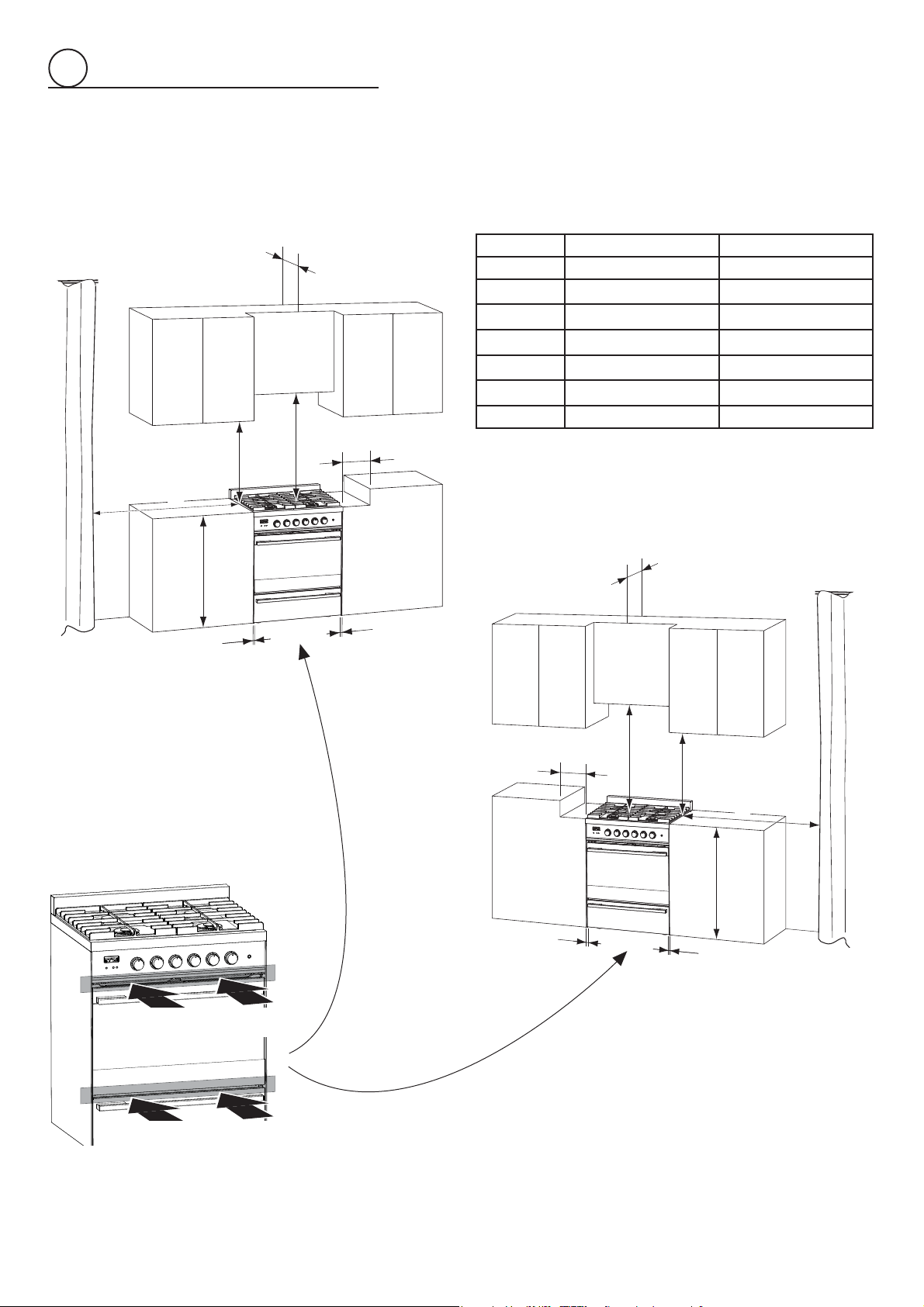

PROXIMITY TO SIDE CABINETS

STANDARD INSTALLATION

Fig. 1.4a

F

E

D

G

B

A

C

A

Ref. inch mm

A 0” 0

B 36” 914

C 11” 13/16 300

D 30” minimum 762 minimum

E 18” minimum 457 minimum

F 13” maximum 330 maximum

G 20” minimum 500 minimum

F

Fig. 1.4b

OVEN VENT

OVEN VENT

C

A

D

E

G

B

A

8

Page 9

9

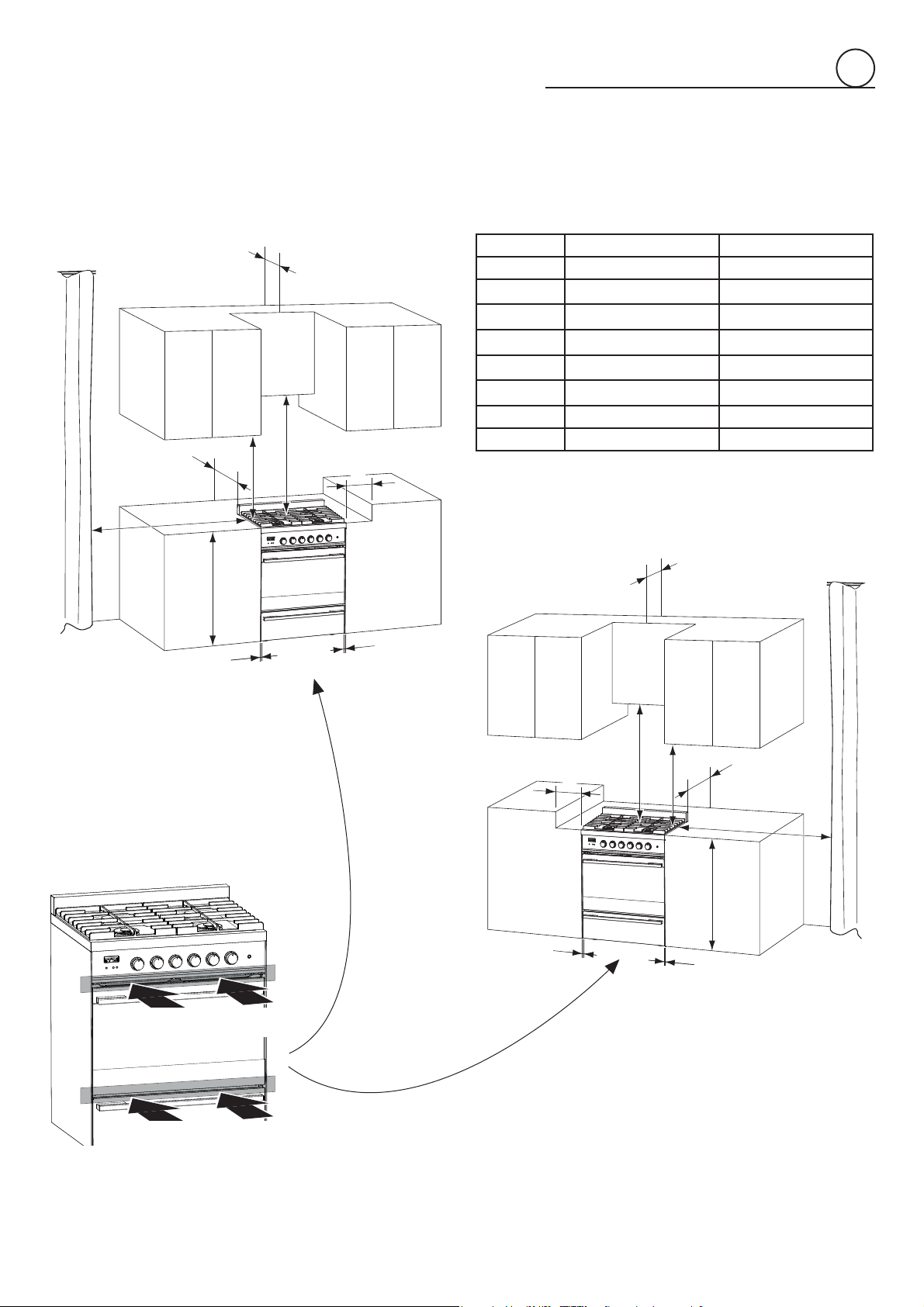

PROXIMITY TO SIDE CABINETS

ISLAND INSTALLATION

1

Fig. 1.5a

F

D

H

E

G

B

A

C

A

Ref. inch mm

A 0” 0

B 36” 914

C 11” 13/16 300

D 30” minimum 762 minimum

E 18” minimum 457 minimum

F 13” maximum 330 maximum

G 20” minimum 500 minimum

H 12” minimum 305 minimum

F

Fig. 1.5b

OVEN VENT

OVEN VENT

C

D

A

H

E

G

B

A

9

Page 10

10

1

Fig. 1.6

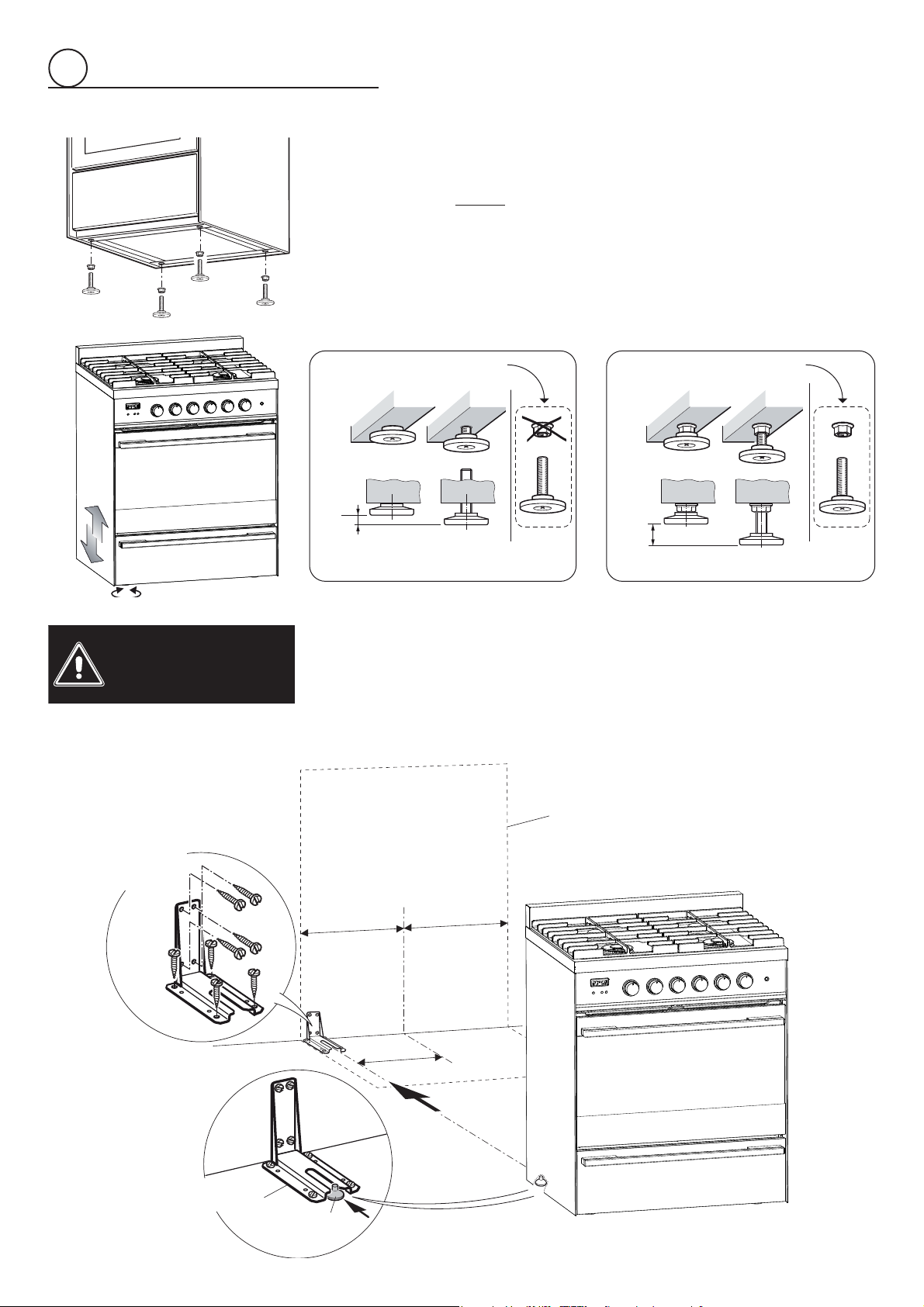

LEVELLING THE RANGE

The range is equipped with 4 LEVELLING FEET and may be levelled by screwing or

unscrewing the feet (fi gs. 1.6 - 1.7).

It is important to observe the directions in fi gures 1.6, 1.8a, 1.8b.

Fig. 1.7

YOU MUST USE STABILITY

ANTI TIP BRACKET TO

PREVENT UNIT FROM

TIPPING.

Supplied with the range

in a separate kit

0”

0 mm

+ 5/16”

+ 8 mm

Supplied with the range

in a separate kit

+ 5/16”

+ 8 mm

+ 11/16”

+ 17.5 mm

Fig. 1.8bFig. 1.8a

ANTI-TIP STABILITY DEVICE INSTALLATION INSTRUCTIONS

1. The anti-tip bracket has to be attached as shown on fi gure below (only rear left side),

it has to be fi xed on the fl oor OR on the rear wall by no. 4 (four) suitable screws (not

supplied). Alternatively the anti-tip bracket can also be fi xed on the fl oor AND on the

rear wall by no. 8 (eight) suitable screws (not supplied).

2. After fi xing the anti-tip bracket, slide range into place. Be sure the rear left foot slides

under the anti-tip bracket attached.

Dotted line showing the position

of the range when installed

ANTI-TIP STABILITY

DEVICE FIXING

10

Anti-tip stability

device

Rear left

feet of range

=

11”

11/16

(297 mm)

=

Fig. 1.9

Page 11

11

1

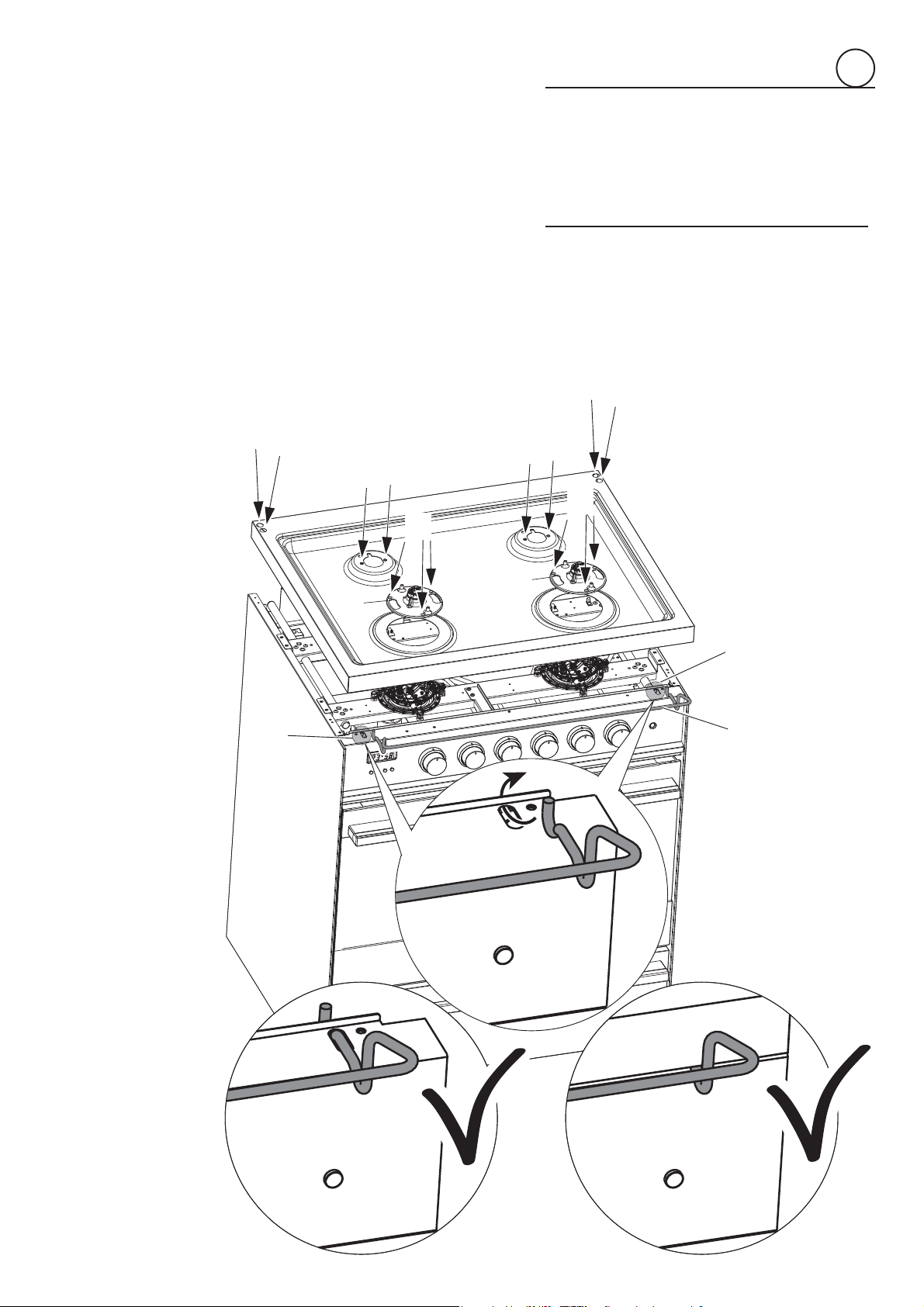

INSTALLING THE COOKTOP FRONT GUARD

To increase the clearance between the front edge of the cooktop and the burners it is possible to install the cooktop front guard supplied

with the appliance.

IMPORTANT: To install/remove the guard it is necessary to remove the cooktop.

Attempting to install/remove the guard without disassembling the cooktop will result in permanent damage to the appliance.

Install the front guard as shown in fi gure 1.10:

1. Remove the backguard.

2. Remove the pan supports, the burner caps and the fl ame spreaders.

3. Unscrew cooktop fi xing screws (“A” in fi gure below).

4. Remove the dual burner inner fl ame spreader (“B” in fi gure below).

5. Remove the cooktop (keep attention not to damage the gaskets fi tted above the burner cups - below the cooktop).

6. Install the front guard “C” by inserting the wire terminals into the proper holes above the control panel (“D” in fi gure below).

7. Reassemble the cooktop and the other components (steps from 5 to 1).

Pay special attention to the gaskets fi tted above the burner cups

(below the cooktop); if they are damaged they shall be replaced.

A

A

D

A

A

A

A

B

B

D

C

Fig. 1.10

11

Page 12

12

2

All gas connections must be made according to national and local codes. This gas supply

(service) line must be the same size or greater than the inlet line of the appliance. Sealant on all pipe joints must be resistant to the action of LP/Propane gas.

The range is equipped for the use with NA TURAL gas. It is design-certifi ed by CSA Inter-

national for NATURAL and L.P. gases with appropriate conversion.

The model/serial rating plate, located inside the bottom pivoting panel, has information

on the type of gas that can be used. If this information does not agree with the type of

gas available, check with the local gas supplier. See page from 16 to 23 for L.P. gas

conversion instructions.

gas connection

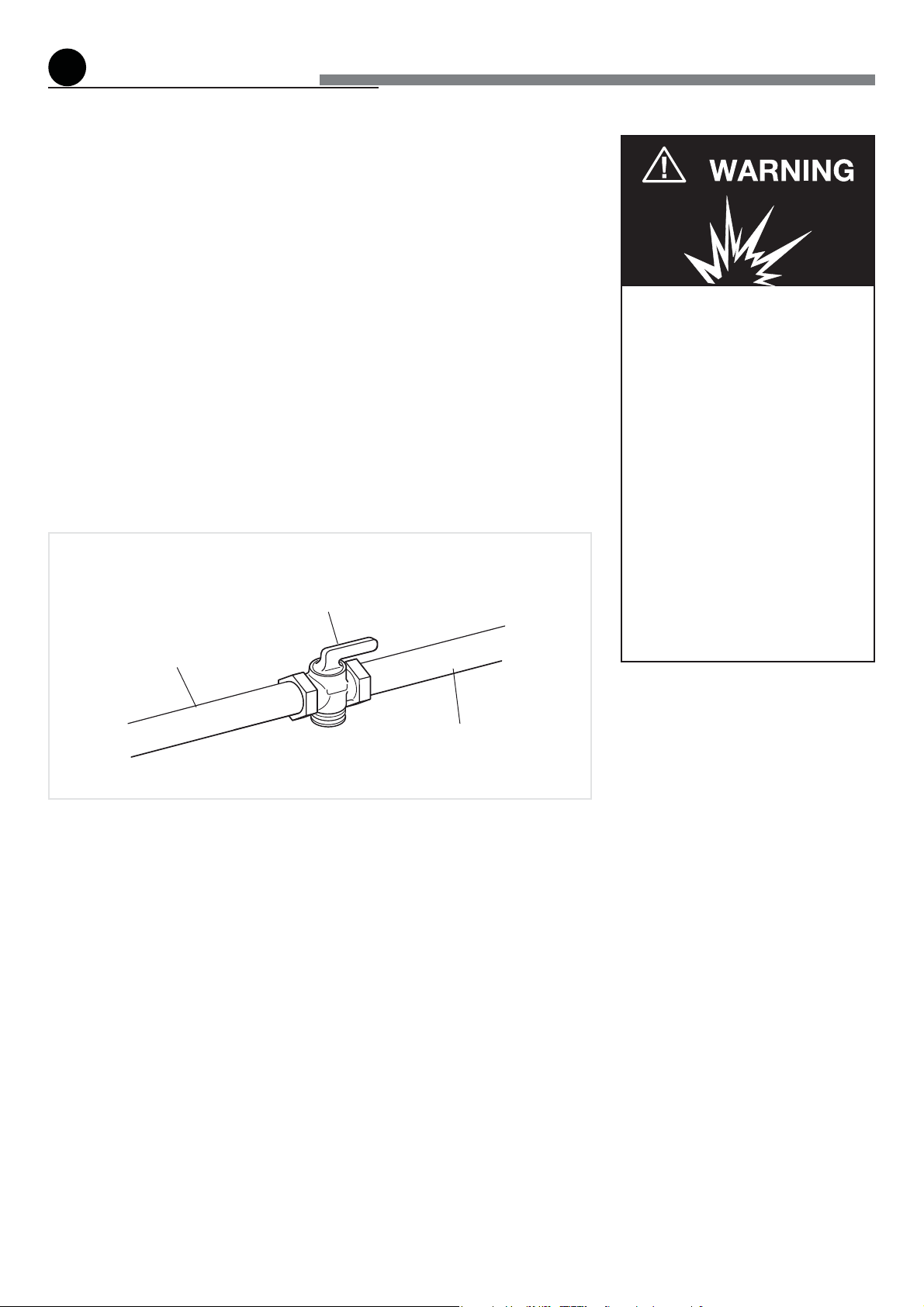

1. Manual Shut-off Valve (fi g: 2.1):

A manual shut-off valve must be installed in an accessible location in the gas line external

to the appliance for the purpose of turning on or shutting off gas to the appliance (In Massachusetts such shutoff devices should be approved by the Board of State Examiners of

Plumbers & Gas Fitters).

This valve should be located in the same room as the range and should be in a location

that allows ease of opening and closing (in a position where it can be reached quickly in

the event of an emergency).

Do not block access to the shutoff valve. The valve is for turning on or shutting off gas

to the appliance.

Shuto valve

“open” position

To range

Explosion Hazard

Use a new CSA or UL approved

gas supply line.

Install a shut-off valve.

Securely tighten all gas connec-

tions.

If connected to LP, have a quali-

fied person make sure gas pressure does not exceed 14" water

column.

Examples of a qualified person

include licensed heating personnel, authorized gas company personnel, and authorized

service personnel.

Failure to do so can result in

death, explosion, or fire.

Gas supply line

Fig. 2.1

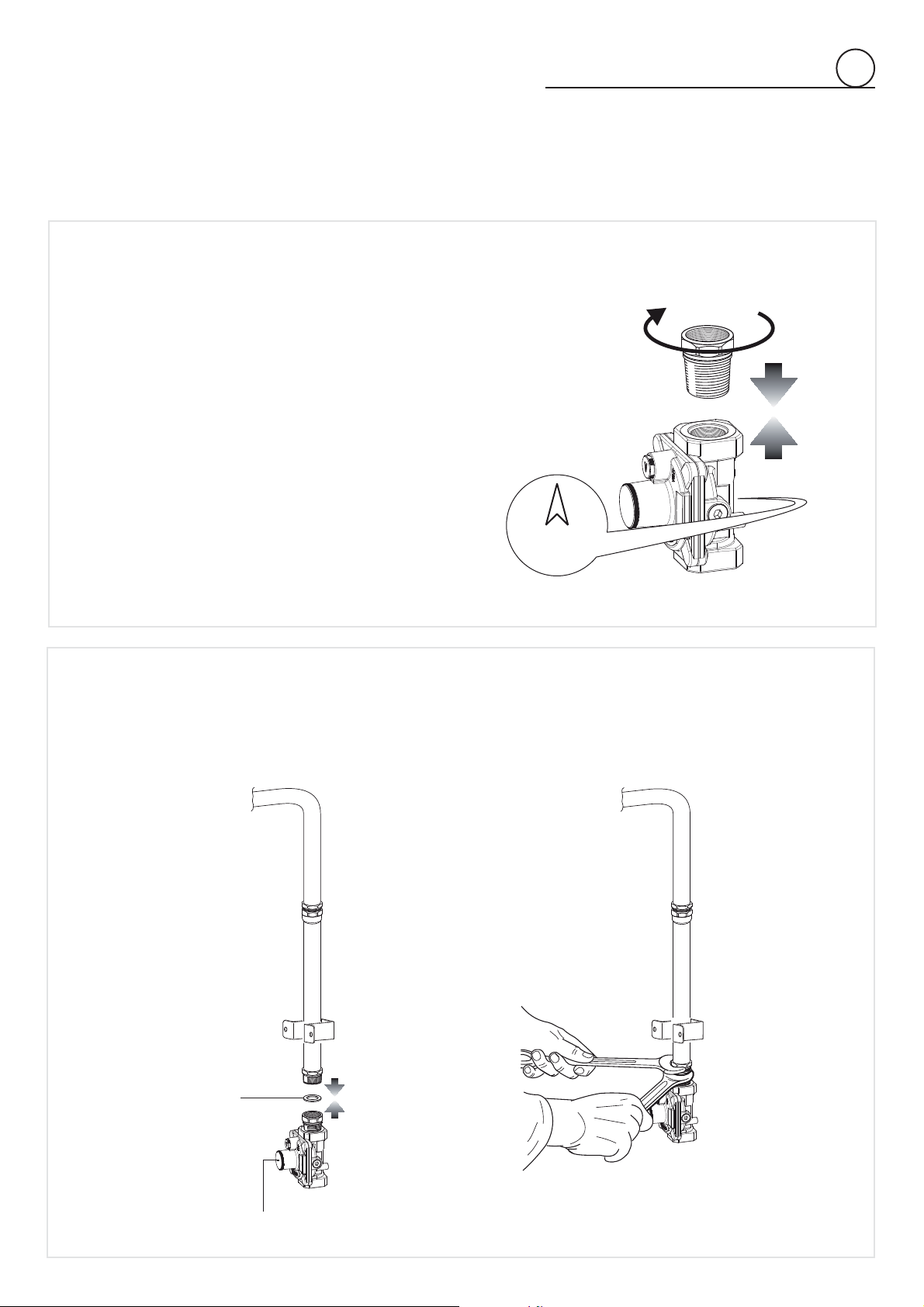

2. Pressure Regulator:

a. All heavy duty, commercial type cooking equipment must have a pressure regulator

on the incoming service line for safe and effi cient operation, since service pressure

may fl uctuate with local demand.

Before installing the regulator mount the 1/2” NPT (conical) male connector to the

regulator (see picture 2.2).

Gasket supplied has to be placed between 1/2” NPT (conical) connector/extension

pipe male pipe fi tting (see picture 2.3).

The regulator supplied with this range must be installed before any gas connections

are made.

Use supplied pressure regulator only.

12

Page 13

13

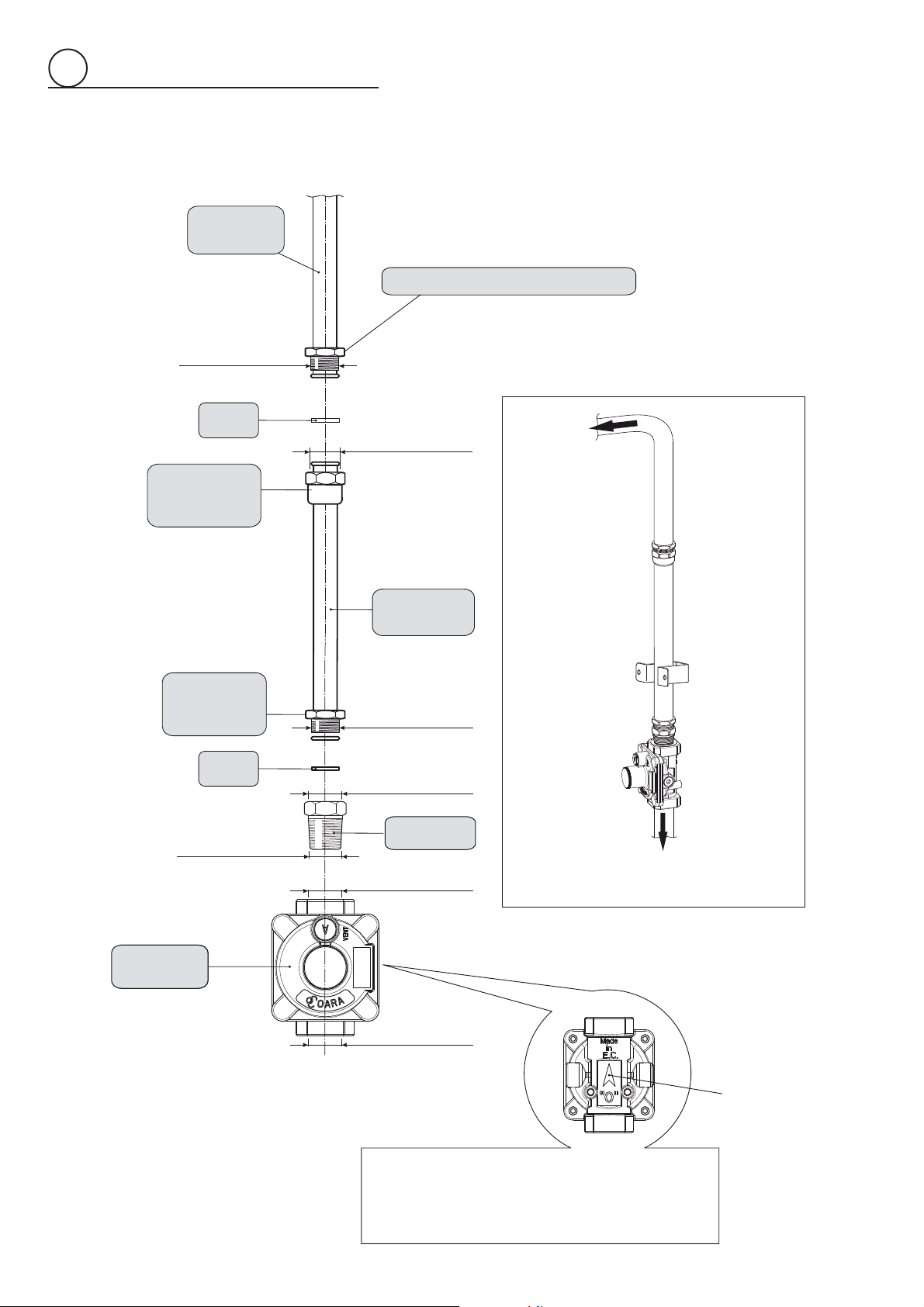

PRESSURE REGULATOR INSTALLATION

STEP 1

Mount the 1/2” NPT (conical) male connector to the pressure regulator and

tighten by using a wrench.

Do not over tighten the connector.

Over tightening may crack regulator.

2

LOCK

Arrow

STEP 2

Assemble the 1/2” NPT connector + pressure regulator group to the extension pipe interposing the gasket supplied.

The regulator cover must be oriented toward the front side of the range.

IMPORTANT: use two wrenches to tighten the connection.

Fig. 2.2

Gasket

Regulator cover

Fig. 2.3

13

Page 14

14

2

GAS CONNECTION SPECIFICATION

Range

manifold

Manifold male pipe fi tting

1/2” G cylindrical

(ISO 228-1) male

Gasket

Extension

pipe female

pipe fi tting

Extension

pipe male

pipe fi tting

Gasket

1/2” NPT (conical)

male

1/2” G cylindrical

(ISO 228-1) female

Extension

pipe

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) female

Connector

1/2” NPT

female

To range

To mains

connection

14

Pressure

regulator

Fig. 2.4

1/2” NPT

female

Arrow

WARNING: Check the correct positioning of the gas

regulator.

The arrow on the back of the gas regulator must be

oriented toward the connector.

Page 15

15

TEST POINT ADAPTER

The Test Point adapter is available from the

After-Sales Service.

2

b. Any conversion required must be performed by your dealer or a qualifi ed licen-

sed technician or gas service company. Please provide the service person with

this manual before work is started on the range. (Gas conversions are the responsibility of the dealer or end user.)

c. This range can be used with NATURAL or LP/PROPANE gas. It is shipped from

the factory adjusted for use with NATURAL gas.

d. Manifold pressure should be checked with a manometer and by operating as

below detailed:

• Remove the injector from the rear left (or rear right) burner and mount the

proper test point adapter which is available from the After-Sales Service

(see side fi gure and the “OPERATIONS TO BE PERFORMED WHEN SUB-

STITUTING THE INJECTORS OF THE COOKTOP BURNERS” chapter).

• Turn the rear left (or rear right) burner control knob to the maximum position.

• Press the knob and keeping it pressed check the manifold pressure with a

manometer; NA TURAL gas requires 4.0” W .C.P. and LP/PROPANE requires

11.0” W.C.P.

• Incoming line pressure upstream from the regulator must be 1” W.C.P. higher than the manifold pressure in order to check the regulator.

• The regulator used on this range can withstand a maximum input pressure

of 1/2 PSI (14.0” W.C.P). If the line pressure is in excess of that amount, a

stepdown regulator will be required.

e. The appliance, its individual shut-off valve, and pressure regulator must be di-

sconnected from the gas supply piping system during any pressure testing of

that system at pressures in excess of 1/2 PSI (3.5 kPa).

f. The appliance must be isolated from the gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the gas supply

piping system at test pressure equal to or less than 1/2 PSI (3.5 kPa).

Fig. 2.5

3. Flexible Connections:

If local codes permit, CSA or UL design-certifi ed, fl exible metal appliance connector

is recommended for connecting this range to the gas supply line. Do Not kink or damage the fl exible connector when moving the range. The pressure regulator has 1/2”

NPT female pipe threads.You will need to determine the fi ttings required, depending

on the size of your gas supply line, fl exible metal connector and shutoff valve.

4. Rigid Pipe Connections:

If rigid pipe is used as a gas supply line, a combination of pipe fi ttings must be used to

obtain an in-line connection to the range. All strains must be removed from the supply

and fuel lines so range will be level and in line.

• Use joint compounds and gaskets that are resistant to action of natural or propane gas on all male pipe threads.

• Do not over tighten gas fi tting when attaching to pressure regulator. Over tighte-

ning may crack regulator.

5. Leak Testing:

IMPORTANT: Leak testing of the appliance shall be conducted as follows:

• After fi nal gas connection is made, turn on manual gas valve and test all con-

nections in gas supply piping and appliance for gas leaks with a soapy water

solution. During this test all appliance gas valves have to be closed.

• In order to avoid property damage or serious personal injury, never use a Iighted

match. If a leak is present, tighten joint or unscrew, apply more joint compound,

tighten again and retest connection for leak.

15

Page 16

16

2

CONVERSION TO LP/PROPANE GAS (OR CONVERSION BACK TO THE

ORIGINAL GAS - NATURAL GAS)

Every range is provided with a set of orifi ces for the various types of gas.

Select the orifi ces to be replaced according to the “ORIFICES TABLE”.

The nozzle diameters, expressed in hundredths of a millimetre, are marked on the body of each orifi ce.

CAUTION: Save the orifi ces removed from the appliance for future use.

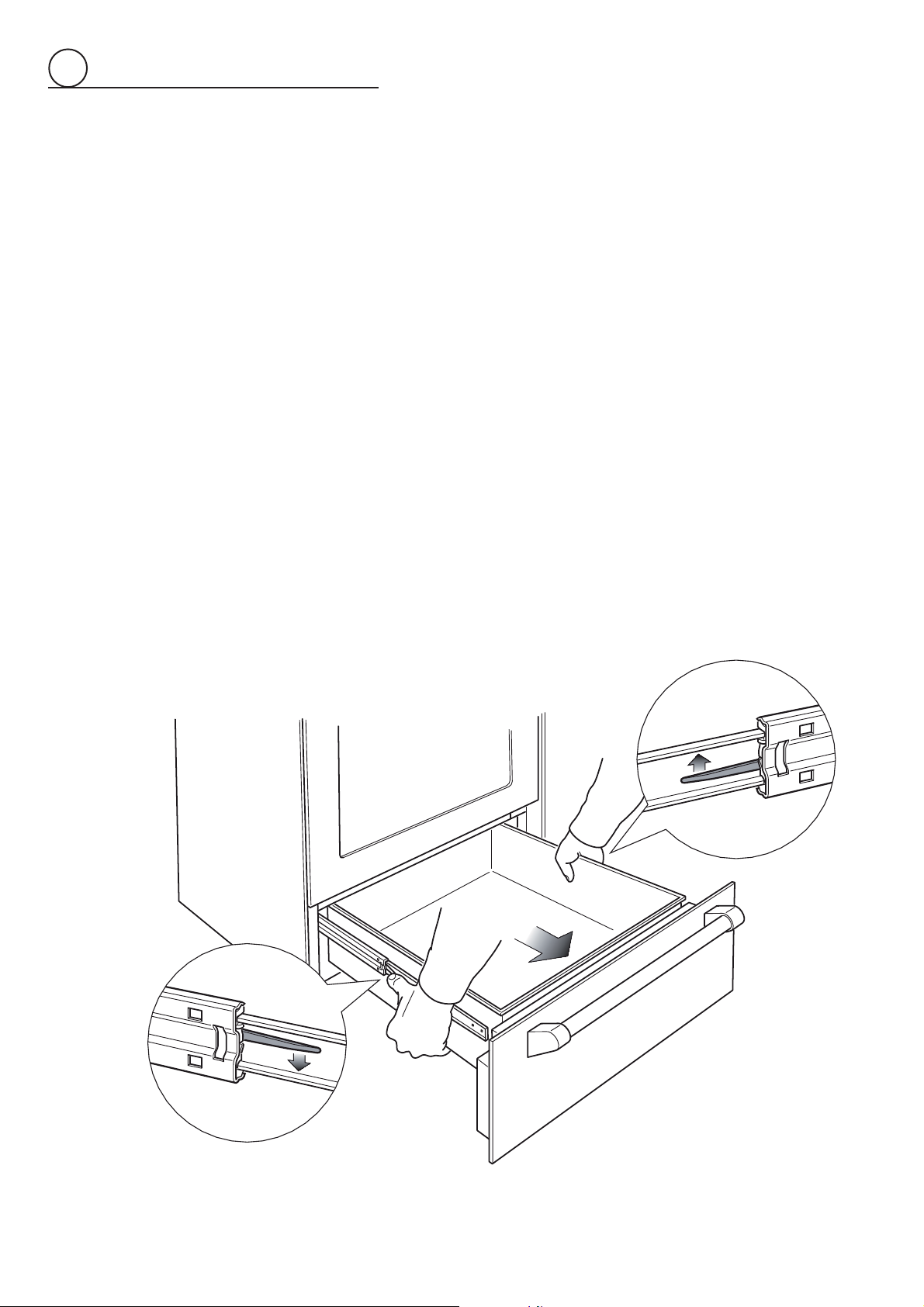

SETTING THE PRESSURE REGULATOR

The pressure regulator is accessible by removing the storage drawer; the pressure regulator is positioned

on the rear right side of the range (fi g. 2.9).

To remove the storage drawer:

1. Open the drawer completely (fi g. 2.6)

2. Move down the lever of left guide (fi g. 2.7) and up the lever of right guide (fi g. 2.8).

3. Remove the drawer holding the levers in the same position (fi g. 2.6).

Fig. 2.7

2

Fig. 2.8

3

2

Fig. 2.6

16

Page 17

17

Pressure

regulator

2

To set the pressure regulator (fi g. 2.9):

1. Unscrew the regulator cover.

2. Unscrew the “A” component, reverse and screw it according to the LP/PROPANE (or NATURAL GAS) regulation.

1

REGULATOR COVER

2

Fitting the storage drawer:

1. Insert the drawer guides into the range guides (fi g. 2.10).

2. Gently close the drawer completely; the safety catches will automatically hook into place.

Fig. 2.9

A

NATURAL GAS

REGULATION

LP/PROPANE

REGULATION

Fig. 2.10

17

Page 18

18

2

INJECTORS TABLE

NOMINAL

POWER

BURNERS BTU/hr BTU/hr

Semirapid (SR) 8000 1500 85 139

REDUCED

POWER

LP/PROPANE

11” W.C.P.

Ø injector

[1/100 mm]

NATURAL GAS

4” W.C.P.

Ø injector

[1/100 mm]

Dual (D)

Oven burner 14000 2400 109 190

Broil burner 11000 - 100 170

(*) inner crown (“J

(**) outer crown (“J

Inner crown 2100 1000

Inner & outer crown 17000 6500

” in fi gure 2.12)

2

” in fi gure 2.12)

3

42 (*)

115 (**)

70 (*)

200 (**)

18

Page 19

19

2

OPERA TIONS TO BE PERFORMED WHEN SUBSTITUTING THE

INJECTORS OF THE COOKTOP BURNERS

• Remove the pan supports, the burner caps and the fl ame spreaders.

• Dual burner only (fi g. 2.12): Unscrew the no.3 fi xing screws “A” and remove the inner

crown fl ame spreader “B”; then unscrew the no.2 fi xing screws “C” and remove the

cover plate “D”.

• Using a wrench substitute the nozzle injectors “J

those most suitable for the kind of gas for which it is to be used.

• Dual burner only (fi g. 2.12):

Refi t

the cover plate “D” and screw the no.2 fi xing screws

“C”; then refi t the inner crown fl ame spreader “B” and screw the no.3 fi xing screws “A”

• Refi t the fl ame spreaders, the burner caps and the pan supports.

The burners are conceived in such a way so as not to require the regulation of the

primary air.

”, “J2” and “J3” (fi gs. 2.11, 2.12) with

1

SEMI-RAPID BURNER

DUAL BURNER

A

A

A

J

1

Fig. 2.11

B

C

SECOND ORIFICE

DEUXIEME ORIFICE

C

D

J

3

J

2

Fig. 2.12

19

Page 20

20

2

SETTING THE BURNER MINIMUM OF THE COOKTOP BURNERS

When switching from one type of gas to another, the minimum fl ow rate must also be cor-

rect: the fl ame should not go out even when passing suddenly from maximum to minimum

fl ame.

To regulate the fl ame (fi g. 2.13) follow the instructions below:

Semirapid burner

• Light the burner.

• Set the gas valve to

• Remove the knob.

• With a thin screwdriver, turn the regulation screw “R

Inside crown of DUAL burner

• Light the DUAL burner.

• Set the gas valve to

• Remove the knob

• With a thin screwdriver, turn the regulation screw “R

Outside crown of DUAL burner

• Light the DUAL burner.

• Set the gas valve to

• Remove the knob.

• With a thin screwdriver, turn the regulation screw “R

position (minimum rate).

” until adjustment is correct.

1

position (minimum rate of inner crown).

” until adjustment is correct.

2

position (minimum rate of inner and outer crowns).

” until adjustment is correct.

3

For LP/PROPANE gas, tighten the adjustment screws completely.

Regulation screw (Semirapid burner)

R

1

Regulation screw (Inner crown of dual burner)

R

2

Regulation screw (Outer crown of dual burner)

R

3

R

3

20

R

2

R

1

Fig. 2.13

Page 21

21

2

OPERA TIONS TO BE EXECUTED FOR THE REPLACEMENT OF

THE INJECTOR OF THE OVEN BURNER

• Lift and remove the lower panel inside the oven.

• Gently unlock, from the burner, the safety valve probe “V” and the ignition electrode

“E” (as indicated in fi g. 2.14). Take care not to damage the probe and the ignition

electrode.

• Unscrew and remove the burner securing screws “A” (fi g. 2.14).

• Withdraw the burner as shown in fi gure 2.15.

• Using a 7 mm box spanner, unscrew the injector (indicated by the arrow in fi g. 2.15)

and replace it with a new one selected in accordance with the “Injectors table”.

• Then replace the burner and the other components repeating the above steps in

reverse order.

IMPORTANT: Pay special attention to replace correctly the safety valve probe

“V” and the ignition electrode “E” as per fi gure 2.14. Check the correct opera-

tion of the safety valve and the ignition electrode.

E

A

V

Anchorage

clip

E

Anchorage

clip

V

Fig. 2.14

Fig. 2.15

21

Page 22

22

2

OPERA TIONS TO BE EXECUTED FOR THE REPLACEMENT OF

THE INJECTOR OF THE BROIL BURNER

• Gently unlock, from the burner, the safety valve probe “V” and the ignition electrode

“E” (as indicated in fi g. 2.16). Take care not to damage the probe and the ignition

electrode.

• Unscrew and remove the burner securing screw “A” (fi g. 2.16).

• Withdraw the burner as shown in fi gure 2.17.

• Using a 7 mm box spanner, unscrew the injector (indicated by the arrow in fi g. 2.17)

and replace it with a new one selected in accordance with the “Injectors table”.

• Then replace the burner and the other components repeating the above steps in

reverse order.

IMPORTANT: Pay special attention to replace correctly the safety valve probe

“V” and the ignition electrode “E” as per fi gure 2.16. Check the correct opera-

tion of the safety valve and the ignition electrode.

Anchorage

V

clip

V

A

E

Fig. 2.16

Anchorage

E

clip

22

Fig. 2.17

Page 23

23

2

ADJUSTMENT OF THE OVEN BURNER MINIMUM

This needs to be done only for the oven burner (the broil is a fi xed capacity) by acting

on the thermostat in the following way:

• Turn on the burner by setting the thermostat knob on position “8” (maximum).

• Remove the knob and unscrew the by-pass screw “G” (fi g. 2.18) about three times by

passing a small fl at screwdriver (Ø 3 mm blade, 100 mm length) through the panel

opening.

• Re-mount the knob and let the oven heat up for about 10 minutes, then bring the knob

to position “1” (minimum) to operate the thermostat by-pass.

• After having removed the knob again and being very careful not to turn the tap rod,

slowly screw the by-pass screws “G” (fi g. 2.18) until you obtain a fl ame of 3-4 mm in

height. The fl ame should not go out even when passing suddenly from maximum to

minimum fl ame.

N.B. For LP/PROPANE gas the by-pass screw must be fi xed thoroughly.

Fig. 2.18

G

After regulation repeat the operations indicated in paragraph “2. PRESSURE REGULATOR” at page 12 and 15.

If the range has been disconnected and then connected again to the gas supply line repeat the operations indicated in paragraph “5. LEAK TESTING” at page 15.

IMPORTANT:

• After conversion to LP/PROPANE gas has been carried out affi x near the data plate

the conversion label supplied and also affi x a conversion label at page 3 of this in-

struction manual.

• After conversion back to the original gas (NATURAL GAS) has been carried out remove, near the data plate and at page 3 of this instruction manual, the LP/PROP ANE

conversion labels. Save the labels removed for future use.

23

Page 24

24

3

Electrical Shock Hazard

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can result in death, fi re, or

electrical shock.

electrical connection

If codes permit and a separate ground wire is used, it is recommended that a qualifi ed electrician determine that the ground path is adequate.

Check with a qualifi ed electrician if you are not sure whether the range is properly

grounded.

Do Not ground to a gas pipe.

A 120-volt, 60-Hz, AC-only, 15-ampere, fused electrical supply is required.

A time-delay fuse or circuit breaker is recommended.

It is recommended that a separate circuit serving only this appliance be provided.

The outlet must be checked by a qualifi ed electrician to see if it is wired with correct

polarity.

This appliance, when installed, must be electrically grounded in accordance with local

codes.

Recommended ground method

For your personal safety, this range must be grounded.

This range is equipped with a 3-prong ground plug.

To minimize possible shock hazard, the cord must be plugged into a mating 3-prong

ground-type outlet, grounded in accordance with the National Electrical Code ANSI/

NFPA 70 latest edition and local codes and ordinances.

If a mating outlet is not available, it is the personal responsibility and obligation of the customer to have a properly polarized and grounded, 3-prong outlet installed by a qualifi ed

electrician.

Before any operation of maintenance disconnect the appliance

from the electrical main supply.

3-prong

ground

plug

supply cord

3-prong polarized

ground-type outlet

Power

Ground prong

Fig. 3.1

24

Page 25

25

S1

3

WIRING DIAGRAM

A

MS

F1

N/7

EC

1

P1

L/8

2

MS

LF

P2

V

PA

CF

V MOTEUR DU VENTILATEUR DU FOUR

TL THERMOLIMITATEUR DE SÉCURITÉ

PA GROUPE D'INTERRUPTEURS D'ALLUMAGE (BRÛLEURS DE LA TABLE DE TRAVAIL)

A GÉNÉRATEUR D'ALLUMAGE

OS INTERRUPTEUR D'ALLUMAGE FOUR/GRIL

MU ÉLÉMENT MAGNÉTO THERMOCOUPLES FOUR/GRIL

T0 DISPOSITIF D'ALLUMAGE FOUR/GRIL

CF MOTEUR DU VENTILATEUR DE REFROIDISSEMENT

M BLOC DE RACCORDEMENT

AS

LÉGENDE DU SCHÉMA ÉLECTRIQUE

F1 INTERRUPTEUR

EC HORLOGE ÉLECTRONIQUE

MS MICROCONTACT DE SÉCURITÉ

LF LAMPE DU FOUR

AS INTERRUPTEUR FLUX DE DÉBIT D'AIR

S1 VOYANT DE DÉTRAQUEMENT DÉFAILLANCE DU VENTILATEUR DE REFROIDISSEMENT

T CONNEXION DE MISE À LA TERRE

T

TL

LN

MU

M

T

TC1

TC2

TC3

TC4

TC5

TC6

T0

T-Zero

L

N

Sw

Sw

L

N

OS

ELECTRIC DIAGRAM KEY

F1 SWITCH

EC ELECTRONIC CLOCK

MS SECURITY MICROSWITCH

S1 COOLING FAN FAILURE LAMP

LF OVEN LAMP

AS AIR FLOW SWITCH

V FAN MOTOR

TL THERMAL OVERLOAD

PA IGNITION SWITCHES GROUP (COOKTOP BURNERS)

A IGNITION COIL

OS OVEN/BROIL IGNITION SWITCH

MU MAGNET UNIT - OVEN/BROIL THERMOCOUPLES

T0 OVEN/BROIL IGNITION SYSTEM

CF COOLING FAN MOTOR

M TERMINAL BLOCK

T EARTH CONNECTION

25

Page 26

26

The manufacturer cannot be held responsible for possible inaccuracies due to printing or transcription errors

in the present booklet.

The manufacturer reserves the right to make all modifi cations to its products deemed necessary for manu-

facture or commercial reasons at any moment and without prior notice, without jeopardising the essential

functional and safety characteristics of the appliances.

26

Page 27

CUISINIÈRE À GAZ

Cet appareil est réservé à l’usage résidentiel uniquement.

Modèles: OR30SDBMX

R

MODE D’EMPLOI POUR LES UTILISATEURS

IMPORTANT - VEUILLEZ LIRE ET SUIVRE

• Avant de commencer, veuillez lire attentivement toutes les instructions.

• N’enlevez pas les étiquettes, plaques ou avertissements permanents de l’appareil. Cela

pourrait annuler la garantie.

• Veuillez respecter tous les codes et les règlements locaux et nationaux.

• Veuillez vous assurer que cet appareil est bien mis à la terre.

• La prise de courant devrait être toujours accessible.

• L’installateur doit confi er ces instructions au consommateur qui les conservera

pour l’usage de l’inspecteur local et pour s’y reporter ultérieurement.

L’installation doit être conforme aux codes locaux, ou en l’absence de ces codes, à la dernière édition du National Fuel Gas Code ANSI Z223.1/NFPA 54. L’installation électrique doit

être conforme à la dernière édition du Code national de l’électricité, ANSI/NFPA70 et/ou aux

codes locaux.

AU CANADA: L’installation doit être conforme au CAN/CGA-B149.1, Code d’installation du

gaz naturel ou au CAN/CGA-B149.2, Code d’installation du propane en vigueur et/ou aux codes locaux. L’installation électrique doit être conforme au Code canadien de l’électricité CSA

C22.1, partie 1, en vigueur et/ou aux codes locaux.

INSTALLATION DANS UNE MAISON PRÉFABRIQUÉE (MOBILE) : L’installation doit être

conforme au Manufactured Home Construction and Safety Standard, Titre 24 CFR, Partie

3280 [anciennement le Federal Standard for Mobile Home Construction and Safety, Titre 24,

HUD (Partie 280)] ou, lorsque cette norme n’est pas applicable, au Standard for Manufactured Home Installations, ANSI/NCSBCS A225.1, ou aux codes locaux, là où il y a lieu.

INSTALLATION DANS UNE CARAVANE DE PARC : L’installation doit être conforme aux

codes de l’État ou aux autres codes ou, en l’absence de tels codes, au Standard for Recreational Park Trailers, ANSI A1 19.5.

L’installation de tout appareil au gaz doit être ef fectuée par un technicien qualifi é. Par mesure

de sécurité et pour faciliter le service, un robinet d’arrêt de gaz manuel doit être installé dans

le tuyau d’alimentation en gaz, juste avant l’appareil.

Si vous utilisez une source d’alimentation électrique extérieure, cet appareil doit être, au

moment de son installation, mis à la terre conformément aux codes locaux en vigueur ou,

en l’absence de tels codes, conformément au Code national de l’électricité, ANSI/NFPA 70.

Certains modèles sont livrés avec une pellicule protectrice recouvrant les pièces

en acier et en aluminium.

Cette pellicule doit être enlevée avant l’installation ou l’utilisation de l’appareil.

À L’INTENTION DE L’INSTALLATEUR SEULEMENT

CETTE CUISINIÈRE EST RÉSERVÉE À L’USAGE

RÉSIDENTIEL UNIQUEMENT.

Page 28

28

Pour réduire le risque de basculer l’appareil, il doit être

fi xé correctement par le dispositif antibasculement

fourni avec l’appareil.

• TOUS LES TYPES DE CUISINIÈRE PEUVENT

BASCULER

• CELA PEUT PROVOQUER DES BLESSURES

• INSTALLEZ LE DISPOSITIF ANTIBASCULEMENT

FOURNI AVEC LA CUISINIÈRE

• CONSULTEZ LES INSTRUCTIONS D’INSTALLATION

MISE EN GARDE !

Le fait de ne pas suivre toutes les instructions de ce

manuel

peut provoquer un feu ou une explosion causant

des dommages matériels, des blessures ou la mort.

– Ne rangez et n’utilisez pas de l’essence ou d’autres liquides et vapeurs

infl ammables à proximité de cet appareil ou de tout autre appareil.

– N’utilisez JAMAIS cet appareil pour chauffer une pièce. Le non-respect

de cette consigne peut causer un empoisonnement au monoxyde de

carbone et une surchauffe de l’appareil.

–

QUE FAIRE SI VOUS DÉCELEZ UNE ODEUR DE GAZ:

•

Ne tentez d’allumer aucun appareil.

•

Ne touchez à aucun interrupteur électrique.

•

N’utilisez aucun téléphone dans l’édifi ce.

•

Appelez immédiatement votre fournisseur de gaz en utilisant le

téléphone d’un voisin. Suivez les consignes du fournisseur de gaz.

28

•

S’il vous est impossible de joindre votre fournisseur de gaz,

appelez le service d’incendie.

–

L’installation et l’entretien doivent être effectués par un installateur

ou un technicien qualifi é, ou par un employé de votre fournisseur de

gaz.

Page 29

29

PLAQUE SIGNALÉTIQUE

ÉTIQUETTE DE CONVERSION

La plaque signalétique du

produit est fi xée sur le côté

extérieur du tiroir, à gauche.

Le Gouverneur de la Californie est tenu de publier une liste de substances dont l’État sait qu’ils

accroissent les risques de cancer ou d’infertilité; les entreprises sont tenues d’aviser leur clientèle

des risques associés à de telles substances.

AVERTISSEMENT! : Les appareils au gaz contiennent ou produisent des substances qui peuvent

entraîner la mort ou des maladies graves, et dont l’État de la Californie reconnaît qu’ils augmentent

les risques de cancer, d’anomalies congénitales ou autres risques au système reproductif. Pour

réduire les risques causés par les substances contenues dans le carburant ou par la combustion

du carburant, s’assurer d’installer, d’entretenir et d’utiliser cet appareil selon les consignes du fabricant.

Cet appareil a été conçu et fabriqué uniquement pour la cuisson domestique des aliments et ne

convient pas à l’usage non ménager. Cet appareil ne devrait donc pas être utilisé dans un environnement commercial.

La garantie de l’appareil sera annulée s’il est utilisé dans un environnement non domestique, c’està-dire un environnement semi-commercial, commercial ou communautaire.

29

Page 30

30

INSTRUCTIONS D’INSTALLATION

AVERTISSEMENT!

CET APPAREIL DOIT ÊTRE INSTALLÉ PAR UN INSTALLATEUR QUALIFIÉ.

Une mauvaise installation, modifi cation, réparation ou un mauvais réglage ou entretien peuvent causer des blessures ou des

dommages matériels. Consultez un installateur qualifi é, un agent autorisé ou le fournisseur de gaz.

IMPORTANT: L’utilisation de vêtements et de

gants de protection est recommandée lors de la

manutention et l’installation de cet appareil.

OUTILS REQUIS POUR L’INSTALLATION (NON FOURNIS AVEC L’APPAREIL)

Tournevis 2 - Clef

Gants de protection

Marteau

Clef à

poignée en T

Clef à

molette

Crayon

Pince

multiprise

Mètre à

ruban

Perceuse

30

Page 31

31

RENSEIGNEMENTS GÉNÉRAUX

1. L’installation doit être conforme aux codes locaux ou, en

l’absence de ceux-ci, à la dernière édition du National Fuel

Gas Code, ANSI Z223.1/NFPA 54, au CAN/CGA-B149.1 ou

au CAN/CGA-B149.2.

2. Installation dans une maison préfabriquée (mobile): L’installation doit être conforme au Manufactured Home Con-

struction and Safety Standard, Titre 24 CFR, Partie 3280

[anciennement le Federal Standard for Mobile Home

Construction and Safety, Titre 24, HUD (Partie 280)] ou,

lorsque cette norme n’est pas applicable, au Standard for Manufactured Home Installations, ANSI/NCSBCS A 225.1, ou

aux codes locaux, là où il y a lieu.

3. Installation dans une caravane de parc: L’installation doit être

conforme aux codes de l’État ou aux autres codes ou, en

l’absence de tels codes, au Standard for Recreational Park

Trailers, ANSI A1 19.5.

4. Afi n d’éliminer les risques de brûlures ou d’incendie qui peu-

vent se produire lorsqu’on s’étire au-dessus d’appareils aux

surfaces chauffantes, évitez de placer des armoires de cuisine au-dessus de l’appareil.

5. Les rideaux d’air ou les hottes de cuisinières en hauteur, qui

projettent de l’air vers la cuisinière en contrebas, ne doivent

pas être utilisés avec des cuisinières à gaz, sauf si la hotte

et la cuisinière ont été conçues, testées et répertoriées par

un laboratoire d’essais indépendant pour pouvoir fonctionner

conjointment.

6.

Cet appareil ne doit pas être utilisé pour chauffer une

pièce. Ces renseignements sont basés sur des facteurs

de sécurité.

7. Toute ouverture dans le mur derrière l’appareil et dans le sol

au-dessous de l’appareil doit être obstruée.

8. Gardez l’appareil loin des matériaux combustibles, de l’essence ou de toute autre vapeur infl ammable.

9. N’obstruez pas le fl ux de l’air de combustion et de l’air de

ventilation.

10. Coupez l’alimentation électrique de l’appareil avant de

procéder à l’entretien.

1 1. Lors du déplacement de l’appareil pour le nettoyage et/ou une

réparation :

A. Fermez l’alimentation générale en gaz.

B. Coupez l’alimentation c.a.

C.

tuyau d’entrée.

D. Déplacez la cuisinière avec soin en la tirant en

dehors de l’installation.

ATTENTION : La cuisinière est lourde. Faites attention

12. Exigences électriques

L’installation électrique doit être conforme aux codes natio-

naux et locaux.

13. Alimentation d’air et ventilation

L’installateur doit consulter les codes locaux et nationaux.

14. Pression du collecteur d’alimentation en gaz

Gaz naturel - 4,0 po CE

Gaz propane/GPL - 11,0 po CE

15. L’utilisation inappropriée de la porte du four (par exemple,

AVERTISSEMENT!!

Débranchez le tuyau d’alimentation en gaz du

lorsque vous la manipulez.

marcher, s’asseoir ou s’appuyer dessus) peut présenter des

dangers possibles et/ou entraîner des blessures.

16. Lors de l’installation ou du déplacement de la cuisinière

pour une réparation, un timon rouleur devrait être utilisé. Ne

poussez pas en appuyant sur les rebords de la cuisinière en

tentant de la faire glisser dans ou en dehors de l’installation.

Pousser ou tirer une cuisinière (plutôt que d’utiliser un timon

rouleur) augmente également les risques de déformation des

tiges ou des connecteurs de couplage internes.

AVERTISSEMENT!!

INSTRUCTIONS DE MISE À LA TERRE

La cuisinière doit être mise à la terre conformément aux codes locaux ou, en l’absence de ceux-ci, à la dernière édition

du Code national de l’électricité, ANSI/NFPA n° 70 ou au Code

canadien de l’électricité au Canada.

L’installation doit être effectuée par un électricien qualifi é.

POUR VOTRE SÉCURITÉ, CET APPAREIL DOIT ÊTRE COR-

RECTEMENT MIS À LA TERRE.

Si vous utilisez une source d’alimentation électrique extérieure,

cet appareil doit être, au moment de son installation, mis à la terre

conformément aux codes locaux en vigueur ou, en l’absence de

ces codes, conformément au Code national de l’électricité, ANSI/

NFPA 70.

Pour diminuer les risques de choc électrique, cet appareil est muni

d’une fi che de mise à la terre à quatre broches (NEMA 14-50P)

et devrait être branché directement dans une prise correctement

mise à la terre.

Ne coupez et ne retirez en aucun cas la quatrième broche

(mise à la terre) de la fi che du cordon d’alimentation.

PIÈCES DE RECHANGE

Seules les pièces de rechange autorisées peuvent être utilisées

lors d’une réparation sur la cuisinière. Des pièces de rechange

sont disponibles chez les concessionnaires de pièces d’origine.

Veuillez communiquer avec le concessionnaire de pièces de votre

région.

31

Page 32

32

1

3 po

(76 mm)

36-11/32 po (923 mm) MAX.

35-21/32 po (905,5 mm) MIN.

24- 3/16 po

(615 mm)

Fig. 1.1

29-7/8 po

(759 mm)

installation

PROXIMITÉ DES ARMOIRES

1. Cette cuisinière peut être installée directement adjacente à des armoires

de base existantes de 36 po (914 mm) de hauteur.

Dimensions de la cuisinière :

• largeur : 29-7/8 po (759 mm)

• profondeur : 24-13/64 po (614,9 mm)

• hauteur (sans dosseret) : 35-21/32 po (905,5 mm) MIN. - 36-11/32 po

(923 mm) MAX.

• dosseret (hauteur) : 3 po (76 mm)

Ouverture du tuyau de gaz: Mur - 37/64 po (14,5 mm) du côté droit

vers le centre de la cuisinière; de 5-7/16 po (138 mm) à 6-1/8 po (155,5

mm) du sol, selon le réglage des pieds.

Prise mise à la terre: Le cordon d’alimentation électrique avec fi che

à 3 broches (mise à la terre) (NEMA 5-15P) a une longueur de 72 po

(1 830 mm). La prise mise à la terre doit être située à 37/64 po (14,5

mm) du côté gauche vers le centre de la cuisinière; de 5-7/16 po (138

mm) à 6-1/8 po (155,5 mm) du sol, selon le réglage des pieds.

2. La cuisinière NE PEUT PAS être installée directement adjacente à un

mur, à une armoire haute, à un électroménager haut ou à toute autre

surface latérale verticale de plus de 36 po (914 mm) de hauteur.

Un dégagement latéral minimal de 1 1-13/16 po (300 mm) est nécessaire

entre la cuisinière et toute surface combustible À DROITE ou À GAUCHE, au-dessus du comptoir de 36 po (914 mm) de hauteur.

IMPORTANT : Un côté (gauche ou droit) au-dessus du comptoir de

36 po (914 mm) de hauteur doit toujours être dégagé.

Installation en d’îlot: Un dégagement minimal de 12 po (305 mm) est

nécessaire entre l’arrière du dosseret et toute surface combustible derrière la cuisinière, au-dessus du comptoir de 36 po (914 mm) de hauteur.

3. La profondeur maximale recommandée de l’armoire supérieure est de

13 po (330 mm). L’armoire au-dessus de la cuisinière doit être située au

moins 30 po (762 mm) au-dessus du comptoir, avec une largeur minimale de 30 po (762 mm); elle doit être centrée avec la cuisinière. Les armoires latérales au-dessus de la cuisinière doivent être situées au moins 18

po (457 mm) au-dessus du comptoir.

32

Page 33

33

Ligne pointillée illustrant la position de la

cuisinière au moment de l’installation

1

RACCORDEMENTS ÉLECTRIQUE ET AU GAZ

Réf. pouces mm

A 5-7/16 po - 6-1/8 po (*) 138 - 155,5 (*)

B 14” - 3/8 po 365

C 37/64 po 14,5

(*) : En fonction du réglage des pieds

Zone pour le

raccordement

ÉLECTRIQUE

C

B

A

Zone pour le

raccordement au GAZ

C

B

Fig. 1.2

MONTAGE DU DOSSERET

L’installation du dosseret est obligatoire.

Montez le dosseret tel qu’indiqué à la fi gure 1.3 :

• Vissez les 2 vis “A” en interposant les butoirs.

• Vissez la vis centrale “B”.

A

A

B

Fig. 1.3

33

Page 34

34

1

PROXIMITÉ DES ARMOIRES

INSTALLATION STANDARD

Fig. 1.4a

F

E

D

G

B

A

C

A

Réf. pouces mm

A 0 po 0

B 36 po 914

C 11-13/16 po 300

D 30 po minimum 762 minimum

E 18 po minimum 457 minimum

F 13 po maximum 330 maximum

G 20 po minimum 500 minimum

F

Fig. 1.4b

ÉVENT DE FOUR

ÉVENT DE FOUR

C

A

D

E

G

B

A

34

Page 35

35

PROXIMITÉ DES ARMOIRES

INSTALLATION EN ÎLOT

1

Fig. 1.5a

F

D

H

E

G

B

A

C

A

Réf. pouces mm

A 0 po 0

B 36 po 914

C 11-13/16 po 300

D 30 po minimum 762 minimum

E 18 po minimum 457 minimum

F 13 po maximum 330 maximum

G 20 po minimum 500 minimum

H 12 po minimum 305 minimum

F

Fig. 1.5b

ÉVENT DE FOUR

ÉVENT DE FOUR

C

D

A

H

E

G

B

A

35

Page 36

36

1

Fig. 1.6

MISE À NIVEAU DE LA CUISINIÈRE

La cuisinière est munie de 4 PIEDS DE MISE À NIVEAU et peut être mise à niveau

en vissant ou en dévissant ces pieds (fi gs. 1.6, 1.7).

Il est important de respecter les instructions des fi gures 1.6, 1.8a, 1.8b.

Fig. 1.7

VOUS DEVEZ UTILISER LE

SUPPORT DE STABILITÉ

ANTIBASCULEMENT POUR

ÉVITER QUE L’APPAREIL

BASCULE.

INSTALLATION DU

DISPOSITIF DE STABILITÉ

ANTIBASCULEMENT

Fournis avec la cuisinière

dans une trousse séparée

0 po

0 mm

+ 5/16 po

+ 8 mm

Fournis avec la cuisinière

dans une trousse séparée

+ 5/16 po

+ 8 mm

+ 11/16 po

+ 17,5 mm

Fig. 1.8bFig. 1.8a

INSTRUCTIONS D’INSTALLATION DU DISPOSITIF DE STABILITÉ

ANTIBASCULEMENT

1. Le support antibasculement doit être fi xé tel qu’indiqué dans l’illustration ci-dessous (seu-

lement le côté arrière gauche). Il doit être fi xé au sol OU au mur arrière avec des vis n°

4 (quatre) appropriées (non fournies). Alternativement, le support antibasculement peut

être fi xé aussi au sol ET au mur arrière avec des vis n° 8 (huit) appropriées (non fournies).

2. Après avoir fi xé le support antibasculement, glissez la cuisinière en place. Assurez-vous

que le pied arrière gauche glisse sous le support antibasculement fi xé.

Ligne pointillée illustrant la position de la cuisinière au moment

de l’installation

36

Dispositif de stabilité

antibasculement

=

11 11/16 po

(297 mm)

Pied arrière gauche

de la cuisinière

=

Fig. 1.9

Page 37

37

1

INSTALLATION DE LA PROTECTION ANTÉRIEURE POUR LA SURFACE DE CUISSON

Pour augmenter la distance entre le bord avant de la surface de cuisson et les brûleurs, il est possible d’installer une protection

antérieure (fournie avec l’appareil).

IMPORTANT: Puor installer/démonter cette protection, il est nécessaire d’enlever la surface de cuisson. Essayer d’installer/

démonter la protection sans avoir enlevé la surface de cuisson, causera des dommages permanents à l’appareil.

Installez la protection antérieure comme indiqué sur la fi gure 1.10:

1. Enlevez le dosseret.

2. Enlevez les grilles, les couvercles des brûleurs et les diffuseurs de fl ammes.

3. Dévissez les vis de fi xation de la surface de cuisson (“A” sur la fi gure ci-dessous).

4. Enlevez

5. Enlevez la surface de cuisson (en faisant attention à ne pas endommager les joints installés au-dessus des coupes des brûleurs

- dessous de la surface de cuisson).

6. Installez la protection antérieure “C”, en accrochant les deux extrémités dans les trous appropriés au-dessus du tableau de bord

(“D” sur la fi gure ci-dessous).

7. Remontez la surface de cuisson et les autres composants (étape de 5 à 1).

Faites beaucoup d’attention aux joints installés au-dessus des coupes des brûleurs (dessous de la surface de cuisson); s’ils sont

endommagés, ils doivent être remplacés.

le répartiteur de fl ammes intérieur des brûleurs doubles

(“B” sur la fi gure ci-dessous).

A

A

D

A

A

A

A

B

B

D

C

Fig. 1.10

37

Page 38

38

2

Tous les raccordements au gaz doivent être effectués conformément aux codes nationaux et locaux. Ce tuyau d’alimentation en gaz doit être du même format ou plus grand

que la conduite de l’appareil. Le produit d’étanchéité sur tous les joints de tuyau doit être

résistant à l’action du gaz propane/GPL.

Cet appareil est muni d’un équipement pour l’utilisation avec du gaz NATUREL. La conception a été certifi ée par CSA International pour le gaz NATUREL et le GPL, avec

conversion appropriée.

La plaque signalétique de modèle/série, située à l’intérieur du panneau pivotant, contient

des renseignements sur le type de gaz pouvant être utilisé. Si cette information ne correspond pas au type de gaz disponible, consultez le fournisseur de gaz de votre région.

Consultez les pages 42 à 49 pour les instructions de conversion au GPL.

raccordement au gaz

1. Robinet d’arrêt manuel (fi g. 2.1):

Le tuyau d’alimentation doit être muni d’un robinet d’arrêt approuvé. Ce robinet doit être

situé dans la même pièce que la cuisinière et à un endroit permettant la mise en service

et l’arrêt faciles (dans une position rapidement accessible en cas d’urgence).

Ne bloquez pas l’accès au robinet d’arrêt. Le robinet sert à mettre en service ou à fermer

l’alimentation en gaz à l’appareil.

Robinet d’arrêt en

position « ouvert »

Vers la cuisinière

Tu yau d’alimentation

en gaz

Risque d’explosion

Utilisez un nouveau tuyau

d’alimentation en gaz homologué CSA ou cUL.

Installez un robinet d’arrêt.

Serrez bien tous les raccorde-

ments au gaz.

Dans le cas d’un raccordement

au GPL, faites vérifier par une

personne qualifiée que la

pression de gaz ne dépasse pas

14 po de colonne d’eau.

Les personnes qualifiées

comprennent le technicien en

chauffage agréé, le personnel

autorisé de la société gazière et

le technicien autorisé.

Le non-respect de ces consignes peut entraîner la mort,

provoquer une explosion ou un

incendie.

Fig. 2.1

2. Régulateur de pression :

a. Tout appareil de cuisson à usage industriel ou commercial doit être muni d’un régu-

lateur de pression sur le tuyau d’alimentation pour un fonctionnement sécuritaire

et effi cace, étant donné que la pression de service peut varier en fonction de la

demande de la région.

Avant d’installer le régulateur, montez le connecteur mâle (conique) NPT de 1/2 po

au régulateur (fi g. 2.2). Le joint fourni doit être placé entre le connecteur (conique)

NPT de 1/2 po et le raccord mâle du tuyau de prolongation (fi g. 2.3).

Le régulateur fourni avec cette cuisinière doit être installé avant d’effectuer tout rac-

cordement au gaz.

Utilisez uniquement le régulateur de pression fourni.

38

Page 39

39

INSTALLATION DU RÉGULATEUR DE PRESSION

ÉTAPE 1

Montez le connecteur mâle (conique) NPT de 1/2 po sur le régulateur de

pression et serrez avec une clef.

Ne serrez pas le connecteur outre mesure.

Trop serrer pourrait entraîner une fi ssure dans le régulateur.

FERMER

LOCK

2

Flèche

Arrow

Fig. 2.2

ÉTAPE 2

Montez le connecteur NPT de 1/2 po et l’ensemble du régulateur de pression sur le tuyau de prolongation en interposant le joint

fourni. Le couvercle du régulateur doit être orienté vers l’avant de la cuisinière.

IMPORTANT : Utilisez deux clefs pour serrer le raccord.

Joint

Couvercle du régulateur

Fig. 2.3

39

Page 40

40

2

SPÉCIFICATION DU RACCORDEMENT AU GAZ

Collecteur de

la cuisinière

Raccord mâle du tuyau du collecteur

Mâle G cylindrique

(ISO 228-1) de 1/2 po

Joint

Raccord femelle

du tuyau de

prolongation

Raccord m

du tuyau de

prolongation

Mâle NPT (conique)

âle

Joint

de 1/2 po

Femelle G cylindrique

(ISO 228-1) de 1/2 po

Tuyau de

prolongation

Mâle G cylindrique

(ISO 228-1) de 1/2 po

Femelle G cylindrique

(ISO 228-1) de 1/2 po

Connecteur

Femelle NPT

de 1/2 po

Vers

la cuisinière

Vers le raccord

principal

40

Régulateur

de pression

Fig. 2.4

Femelle NPT

de 1/2 po

Flèche

A VERTISSEMENT : Vérifi ez que le régulateur de gaz

est bien positionné.

La fl èche située à l’arrière du régulateur de gaz doit

être orientée vers le connecteur.

Page 41

41

ADAPTATEUR DU POINT D’ÉPREUVE

L’adaptateur du point d’épreuve est disponible

auprès du Service après-vente.

2

b. Toute conversion requise doit être effectuée soit par votre détaillant, soit par un

technicien agréé qualifi é ou par la société gazière. Veuillez remettre le présent

manuel au technicien avant de commencer l’entretien de la cuisinière (Les conversions de gaz sont la responsabilité du détaillant ou de l’utilisateur fi nal).

c. Cette cuisinière fonctionne au gaz NATUREL ou au gaz PROPANE/GPL. Elle

est livrée avec le gaz NATUREL comme réglage par défaut.

d. La pression d’admission doit être vérifi ée avec un manomètre et en suivant les

indications ci-dessous :

• Enlevez l’injecteur du brûleur arrière gauche (ou arrière droite) et montez

l’adaptateur du point d’épreuve approprié, disponible auprès du Service après-vente (consultez la fi gure ci-contre ainsi que le chapitre intitulé

“

OPÉRATIONS À EFFECTUER POUR REMPLACER LES INJECTEURS

DES BRÛLEURS DE LA TABLE”).

• Tournez le bouton de commande du brûleur arrière gauche (ou arrière droite) à la position maximale.

• Appuyez sur le bouton et en le maintenant enfoncé, vérifi ez la pression

d’admission avec un manomètre. Le gaz NA TUREL nécessite une pression

de 4,0 po CE et le gaz PROPANE/GPL, une pression de 11,0 po CE.

• La pression du tuyau d’alimentation en amont du régulateur doit être de 1 po

CE plus élevée que celle de la pression d’admission afi n de pouvoir vérifi er

le régulateur.

• Le régulateur utilisé avec cette cuisinière peut résister à une pression d’entrée maximale de 1/2 lb/po

cette valeur, vous aurez besoin d’un régulateur abaisseur.

e. Lorsque vous utilisez des pressions de plus de 1/2 lb/po2 (3,5 kPa) pour faire un

essai de pression sur le système d’alimentation en gaz, débranchez l’appareil,

le robinet d’arrêt individuel de la tuyauterie d’alimentation en gaz et le régulateur

de pression.

f. Lorsque vous utilisez des pressions de 1/2 lb/po2 (3,5 kPa) ou moins pour faire

un essai de pression sur le système d’alimentation en gaz, isolez l’apareil du

système d’alimentation en gaz en fermant le robinet d’arrêt individuel.

2

(14,0 po CE). Si la pression du tuyau excède

Fig. 2.5

3. Raccords fl exibles :

Si les codes locaux le permettent, l’utilisation d’un raccord fl exible métallique pour

électroménager, certifi é par CSA International ou UL, est recommandée pour raccor-

der cette cuisinière au tuyau d’alimentation en gaz. Assurez-vous de ne pas plier ni

d’endommager le raccord fl exible lorsque vous déplacez la cuisinière. Le régulateur

de pression possède un fi letage femelle NPT de 1/2 po. Vous devrez déterminer les

raccords requis en fonction du format du tuyau d’alimentation en gaz, du raccord de

métal fl exible et du robinet d’arrêt.

4. Raccords de tuyaux rigides

Si vous utilisez un tuyau rigide comme tuyau d’alimentation en gaz, vous devrez vous

servir d’une combinaison de raccords de tuyauterie pour obtenir un raccordement en

ligne à la cuisinière. Vous devez éliminer toute tension mécanique des tuyaux d’alimentation et de carburant afi n que la cuisinière soit de niveau et en ligne.

• Utilisez de la pâte à joints et des joints qui résistent à l’action du gaz naturel ou

du propane sur tout fi letage mâle.

• Ne serrez pas le raccord de gaz outre mesure lors de la fi xation du régulateur de

pression. Trop serrer pourrait entraîner une fi ssure dans le régulateur.

5. Vérifi cation de l’absence de fuite :

IMPORTANT : La vérifi cation de l’absence de fuite doit être effectuée comme suit :

• Après avoir effectué le dernier raccordement au gaz, ouvrez le robinet de gaz

manuel et testez chaque raccord de la tuyauterie d’alimentation en gaz ainsi que

l’appareil pour vérifi er l’absence de fuite de gaz, en utilisant une solution d’eau

savonneuse. Lors de cette vérifi cation, tous les robinets de gaz de l’appareil

doivent être fermés.

• Pour réduire les risques de dommages matériels ou de blessures corporelles

graves, n’utilisez jamais la fl amme d’une allumette. S’il y a une fuite, serrez le

joint ou dévissez-le, appliquez-y de la pâte à joints supplémentaire, resserrez-le

et vérifi ez à nouveau l’absence de fuite.

41

Page 42

42

2

CONVERSION AU GAZ PROPANE/GPL (OU CONVERSION POUR RETOURNER AU GAZ ORIGINEL - GAZ NATUREL)

Chaque cuisinière est fournie avec un ensemble d’injecteurs pour les divers types de gaz.

Choisissez les injecteurs à être remplacés selon le “TABLEAU DES INJECTEURS”.

Le diamètre de la busette, exprimé en centièmes de millimètre, est indiqué sur le corps de chaque injecteur.

REMARQUE : Conservez les embouts que vous avez enlevés de l’appareil pour un usage ultérieur.

RÉGLAGE DU RÉGULATEUR DE PRESSION

Vous pouvez accéder au régulateur de pression en retirant le tiroir. Le régulateur de pression est situé sur

le côté droit arrière de la cuisinière (fi g. 2.9).

Pour retirer le tiroir :

1. Ouvrez le tiroir complètement (fi g. 2.6).

2. Abaissez le levier de la glissière gauche (fi g. 2.7) et levez le levier de la glissière droite (fi g. 2.8).

3. Retirez le tiroir; les leviers ne doivent pas bouger (fi g. 2.6).

Fig. 2.7

2

Fig. 2.8

3

2

Fig. 2.6

42

Page 43

43

Régulateur

de pression

2

Pour régler le régulateur de pression (fi g. 2.9):

1. Dévissez le couvercle du régulateur.

2. Dévissez le composant “A”, inversez-le et vissez-le selon le

réglage PROPANE/GPL (ou GAZ NATUREL).

1

COUVERCLE DU

RÉGULATEUR

2

Installation du tiroir:

1. Insérez les glissières du tiroir dans les glissières de la cuisinière (fi g. 2.10).

2. Refermez le tiroir complètement avec précaution; les dispositifs de sécurité s’accrocheront

automatiquement.

Fig. 2.9

A

RÉGLAGE

GAZ NATUREL

RÉGLAGE

PROPANE/GPL

Fig. 2.10

43

Page 44

44

2

TABLEAU DES INJECTEURS

PUISSANCE

NOMINALE

BRÛLEURS

Semi-rapide (SR) 8000 1500 85 139

BTU/hr BTU/hr

PUISSANCE

RÉDUITE

PROPANE/GPL

Pression de 11 po CE

Injecteur Ø

[1/100 mm]

GAZ NATUREL

Pression de 4 po CE

Injecteur Ø

[1/100 mm]

Couronne intérieure 2100 1000

Double (D)

Brûleur du four 14000 2400 109 190

Brûleur du gril 11000 - 100 170

(*) couronne intérieure (“J

(**) couronne extérieure (“J

Couronne extérieure et

intérieure

” dans la fi gure 2.12)

2

” dans la fi gure 2.12)

3

17000 6500

42 (*)

115 (**)

70 (*)

200 (**)

44

Page 45

45

2

OPÉRATIONS À EFFECTUER POUR REMPLACER LES

INJECTEURS DES BRÛLEURS DE LA TABLE

• Enlevez les grilles, les couvercles des brûleurs et les diffuseurs de fl ammes.

• Seulement pour le brûleur double (fi g. 2.12): Dévissez les trois vis “A” et enlevez le

diffuseur de fl ammes intérieures “B”; ensuite dévissez les deux vis “C” et enlevez la

plaquette de recouvrement “D”.

• En vous servant d’une clef, remplacez les busettes “J

avec celles les plus appropriées pour le type de gaz à utiliser.

• Seulement pour le brûleur double (fi g. 2.12): Remontez la plaquette de recouvrement

“D” et vissez les deux vis “C”; ensuite remontez le diffuseur de fl ammes intérieures

“B” et vissez les trois vis “A”.

• Remontez les diffuseurs de fl ammes, les couvercles des brûleurs et les grilles.

Les brûleurs ont été conçus de façon telle qu’ils ne nécessitent pas de réglage de

l’air primaire.

”, “J2” et “J3” (fi g. 2.11, 2.12)

1

BRÛLEUR

SEMI-RAPIDE

BRÛLEUR DOUBLE

A

A

A

J

1

Fig. 2.11

B

C

SECOND ORIFICE

DEUXIEME ORIFICE

C

D

J

3

J

2

Fig. 2.12

45

Page 46

46

2

RÉGLAGE MINIMUM DES BRÛLEURS DE LA TABLE

Lorsque vous passez d’un type de gaz à un autre, le débit minimal doit aussi être

correct: les fl ammes ne devraient pas s’éteindre même lors du passage brusque des

fl ammes maximales aux fl ammes minimales.

Pour régler les fl ammes (fi g. 2.13), suivez les instructions ci-dessous:

Brûleur semi-rapide

• Allumez le brûleur.

• Réglez le robinet de gaz à la position “LO” (ouverture minimale).

• Enlevez le bouton.

• En vous servant d’un tournevis fi n, tournez la vis de réglage “R

réglage soit correct.

Couronne intérieure du brûleur DOUBLE

• Allumez le brûleur DOUBLE.

• Réglez le robinet de gaz à la position “

” (ouverture minimale de la couronne

intérieure).

• Enlevez le bouton.

• En vous servant d’un tournevis fi n, tournez la vis de réglage “R

réglage soit correct.

Couronnes extérieures du brûleur DOUBLE

• Allumez le brûleur DOUBLE.

• Réglez le robinet de gaz à la position “

” (ouverture minimale des couronnes

intérieure et extérieure).

• Enlevez le bouton.

• En vous servant d’un tournevis fi n, tournez la vis de réglage “R

réglage soit correct.

” jusqu’à ce que le

1

” jusqu’à ce que le

2

” jusqu’à ce que le

3

Pour le gaz PROPANE/GPL, serrez complètement les vis de réglage.

Vis de réglage (Brûleur semi-rapide)

R

1

Vis de réglage (Couronne intérieure brûleur double)

R

2

Vis de réglage (Couronne extérieure brûleur double)

R

3

R

3

R

2

46

R

1

Fig. 2.13

Page 47

47

2

OPÉRATIONS À EFFECTUER POUR LA SUBSTITUTION DE

L’INJECTEUR DE BRÛLEUR DU FOUR

• Soulever et enlever le panneau inférieur à l’intérieur du four.

• Déverrouiller délicatement la sonde de la soupape de sécurité “V” et l’électrode d’allumage “E” (comme indiqué sur la fi g. 2.14). Veiller à ne pas endommager la sonde

et l’électrode d’allumage.

• Dévisser et enlever les vis “A” qui bloquent le brûleur (fi g. 2.14).

• Enlever le brûleur comme le montre la fi gure 2.15.

• Avec une clé tube de 7 remplacer l’injecteur (indiqué par la fl èche - fi g. 2.15) con-

formément au “Tableau des injecteurs”.

• Remonter le brûleur et les composants en effectuant les opérations en sens inverse.

IMPORTANT: Veiller spécialement à remettre correctement en place la sonde

de la soupape de sécurité “V” et l’électrode d’allumage “E”, comme indiqué à

la fi gure 2.11. Vérifi er le bon fonctionnement de la soupape de sécurité et de

l’électrode d’allumage.

E

A

V

Patte

d’ancrage

E

Patte

d’ancrage

V

Fig. 2.14

Fig. 2.15

47

Page 48

48

2

OPÉRATIONS À EFFECTUER POUR LA SUBSTITUTION DE

L’INJECTEUR DE BRÛLEUR DU GRIL

• Déverrouiller délicatement la sonde de la soupape de sécurité “V” et l’électrode d’allumage “E” (comme indiqué sur la fi g. 2.16). Veiller à ne pas endommager la sonde

et l’électrode d’allumage.

• Dévisser et enlever la vis “A” qui bloque le brûleur (fi g. 2.16).

• Enlever le brûleur comme le montre la fi gure 2.17.

• Avec une clé tube de 7 remplacer l’injecteur (indiqué par la fl èche - fi g. 2.17) con-

formément au “Tableau des injecteurs”.

• Remonter le brûleur et les composants en effectuant les opérations en sens inverse.

IMPORTANT: Veiller spécialement à remettre correctement en place la sonde

de la soupape de sécurité “V” et l’électrode d’allumage “E”, comme indiqué à

la fi gure 2.16. Vérifi er le bon fonctionnement de la soupape de sécurité et de

l’électrode d’allumage.

V

Patte

d’ancrage

V

A

E

Fig. 2.16

Patte

E

d’ancrage

48

Fig. 2.17

Page 49

49

2

RÉGLAGE MINIMUM DU BRÛLEUR DU FOUR

Cela doit être fait seulement pour le brûleur du four (pour le brûleur du gril, la capacité

est fi xe) en effectuant les opérations suivantes sur le thermostat :

• Allumez le brûleur en réglant le bouton du thermostat à la position “8” (maximale).

• Enlevez le bouton et dévissez la vis de dérivation “G” (fi g. 2.18) environ trois fois

en passant un petit tournevis plat (lame de Ø 3 mm, longueur de 100 mm) à travers

l’ouverture du panneau.

• Replacez le bouton et faites chauffer le four pendant une dizaine de minutes, puis

réglez le bouton à la position “1” (minimale) pour faire fonctionner la dérivation du

thermostat.

• Après avoir enlevé à nouveau le bouton et en faisant attention de ne pas tourner la

tige du robinet, vissez lentement les vis de dérivation “G” (fi g. 2.18) jusqu’à l’obtention

d’une fl amme d’une hauteur de 3 à 4 mm. L

même lors du passage brusque des fl ammes maximales aux fl ammes minimales.

N.B. Pour le gaz PROP ANE/GPL, la vis de dérivation doit être complètement serrée.

es fl ammes ne devraient pas s’éteindre

Fig. 2.18

G

Après le réglage, répétez les opérations indiquées au paragraphe “2. RÉGULATEUR DE

PRESSION” à la page 38 et 41.

Si la cuisinière a été débranchée, puis branchée à nouveau au tuyau d’alimentation en

gaz, répétez les opérations indiquées au paragraphe “5. VÉRIFICA TION DE L’ABSENCE

DE FUITE” à la page 41.

IMPORTANT :

• Une fois la conversion au gaz PROPANE/GPL complétée apposez, près de la plaque

signalétique, l’étiquette de conversion fournie et apposez également une étiquette de

conversion à la page 29 du présent manuel d’instructions.

• Une fois la conversion pour retourner au gaz originel (GAZ NATUREL) completée

enlever, près de la plaque signalétique et à la page 29 du présent manuel d’instructions, les étiquettes de conversions au PROPANE/GPL. Conservez les étiquettes

que vous avez enlevées de l’appareil pour un usage ultérieur.

49

Page 50

50

3

Risque de choc électrique

Branchez dans une prise à 3 alvéoles.

Ne retirez pas la broche de mise à la

terre.

N’utilisez pas d’adaptateur.

Le non-respect de ces instructions

peut entraîner la mort, provoquer un

incendie ou un choc électrique.

raccordement électrique

Si les codes le permettent et qu’un fi l de mise à la terre distinct est utilisé, il est

recommandé qu’un électricien qualifi é détermine que le trajet de mise à la terre

est approprié.

Si vous n’êtes pas certain que la cuisinière est bien mise à la terre, consultez un

électricien qualifi é.

Ne mettez pas à la terre à un tuyau de gaz.

Une alimentation électrique fusionnée, en c.a. uniquement, de 15 ampères, 120 volts, 60

Hz est nécessaire. Un fusible temporisé ou un disjoncteur est recommandé.

Il est recommandé qu’un circuit distinct, servant seulement à cet appareil, soit fourni.

La prise doit être vérifi ée par un électricien qualifi é pour s’assurer qu’elle est branchée

avec la polarité appropriée.

Cet appareil, lors de son installation, doit être mis à la terre conformément aux codes

locaux.

Méthode de mise à la terre recommandée

Pour votre sécurité, cette cuisinière doit être mise à la terre. Cette cuisinière est munie

d’une fi che à trois broches (mise à la terre). Pour diminuer les risques de choc, le cordon

doit être branché à une prise d’accouplement à 3 alvéoles mise à la terre conformément

à la dernière édition du Code national de l’électricité ANSI/NFPA 70 et aux codes et règlements locaux. Si une prise d’accouplement n’est pas disponible, le client a la responsabilité et l’obligation personnelle de faire installer, par un électricien qualifi é, une prise à trois

alvéoles correctement polarisée et mise à la terre.

Avant toute opération d’entretien,

déconnectez l’appareil de l’alimentation électrique.

Fiche à 3

broches

mise à la

terre

d’alimentation

Prise polarisée

à 3 alvéoles et

mise à la terre

Cordon

Broche de mise

à la terre

Fig. 3.1

50

Page 51

51