Page 1

Instruction Manual

September 2015

Types N551 and N851

Types N551 and N851 Snappy Joe™ Emergency

Shutoff Valves

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or re

causing property damage and personal injury

or death.

Fisher® equipment must be installed,

operated and maintained in accordance

with federal, state and local codes

and Emerson Process Management

Regulator Technologies, Inc. (Emerson™)

instructions. The installation in most

states must also comply with NFPA No. 58

or ANSI K61.1 standards.

Only personnel trained in the proper

procedures, codes, standards and

regulations of the LPG or anhydrous

ammonia (NH3) industries should install and

service this equipment.

Figure 1. Type N551 in Closed Position

Introduction

Scope of the Manual

This manual provides installation and maintenance

instruction for the Types N551 and N851 Emergency Shutoff

Valves and Accessories.

Description

Type N551 Snappy Joe (Figure 1) emergency shutoff valve is

UL® Listed for service in Propane or Anhydrous Ammonia (NH3).

Type N851 emergency shutoff valve is intended for all other

compressed gas service. Reference to Type N551 also refers to

Type N851 unless otherwise specied.

UL® is a mark owned by Underwriters Laboratories.

www.fisherregulators.com

The valves may be installed on both ends of transfer hoses

where the hose connects the bulk plant piping to the bobtail,

transport or tank car. They provide a quick way of shutting

off gas ow in the event of a hose rupture and meet the

requirements for such service when correctly installed with

a remote release and proper piping support. The Type N551

valve is lever operated, latch-open and quick closing valve. A

fusible element in the latch melts if the temperature reaches

212°F / 100°C, allowing the valve to close.

The following accessories are also covered:

Type P164B – Cable Release Assembly

Type P327D – Remote Pneumatic Release Assembly

D450343T012

Page 2

Types N551 and N851

Specifications

The Specifications table lists specifications for the Types N551 and N851 valve which is designed for butane, propane

or NH

service at ambient temperatures. Contact your local Sales Office if the valve is to be used on any other service,

3

fluid, compressed gas or temperature condition.

TYPE BODY SIZES, NPS*

N551-10, N851-10, N851K-10

N551-16, N851-16, N851K-16

N551-24, N851-24, N851K-24

Maximum Inlet Pressure: 400 psig / 27.6 bar

1. FFKM (Kalrez®) gasket and seals.

2. The pressure limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

* Nominal Pipe Size.

Operation

(1)

(1)

(1)

CAUTION

1-1/4 FNPT 150 / 568

2 FNPT 295 / 1117

3 FNPT 850 / 3127

(2)

Temperature Capabilities: -20 to 160°F / -29 to 71°C

Installation

Shutoff Direction

The valves shall be installed in the fixed piping between a

The Type N551 handle and shaft may break if

the valve is forced open against the gas ow

and before pressure is equalized on each

side of the main valve disc.

storage tank and the transfer hose connection at the truck or

tank car loading/unloading area. They can be placed in a line

used either for filling or withdrawing from the storage tank

(or both). The valve shall be installed to shutoff flow from the

tank towards the hose, enabling the valve to control product

To Open a Closed Valve:

loss in case of a hose break.

Close a shutoff valve downstream of the Type N551. Pull

the Type N551 handle counterclockwise. There will be an

opening as inlet pressure helps hold the valve disc closed

against the seat. The initial opening force on the handle

opens a pilot valve in the main valve disc, permitting

pressure to build-up downstream. When differential pressure

across the main disc has been reduced, the Type N551 can

be opened without further difficulty by continuing to lift the

handle to the open position. When the handle is fully open

(handle perpendicular to the pipe) the latch engages to hold

the valve open.

The Type N551 valve is a spring closed (aided

by pressure) and shutoff ow in one direction

only. THE NAMEPLATE FLOW ARROW SHOWS

FLOW DIRECTION FOR VALVE SHUTOFF (see

Figure 6). The arrow shall point to the hose

connection. Improper ow direction will not

shutoff ow through the line.

When installed in horizontal piping, install with the nameplate

up. The valve can be installed in vertical piping with the flow

CAUTION

arrow pointing to the desired flow direction for valve shutoff.

In some cases the normal flow through the valve may be

Because the valve is spring closed (aided by

opposite the shutoff direction (like a back check valve).

pressure), the handle can snap down with

considerable force when closing. Keep hands

and ngers away from the handle as it closes.

To Close an Open Valve:

Pushing the handle down (handle parallel to the pipe) will

close the valve.

From a remote location, pulling on the remote cable or

exhausting pneumatic pressure from the Type P327D will retract

the plunger allowing the Type N551 to close. If emergency

conditions cause the fusible element to reach a temperature

of 212°F / 100°C, the element, which attaches the handle to

the shaft, pulls apart and allows the valve to close.

Bulkhead Protection

The valve should be installed near the hose connection, but

shall be positioned so that any undue strain resulting from a

hose pull cannot shear the valve or its inlet piping from the

storage area piping. The piping shall always be firmly supported

and anchored to be sure of meeting the requirement.

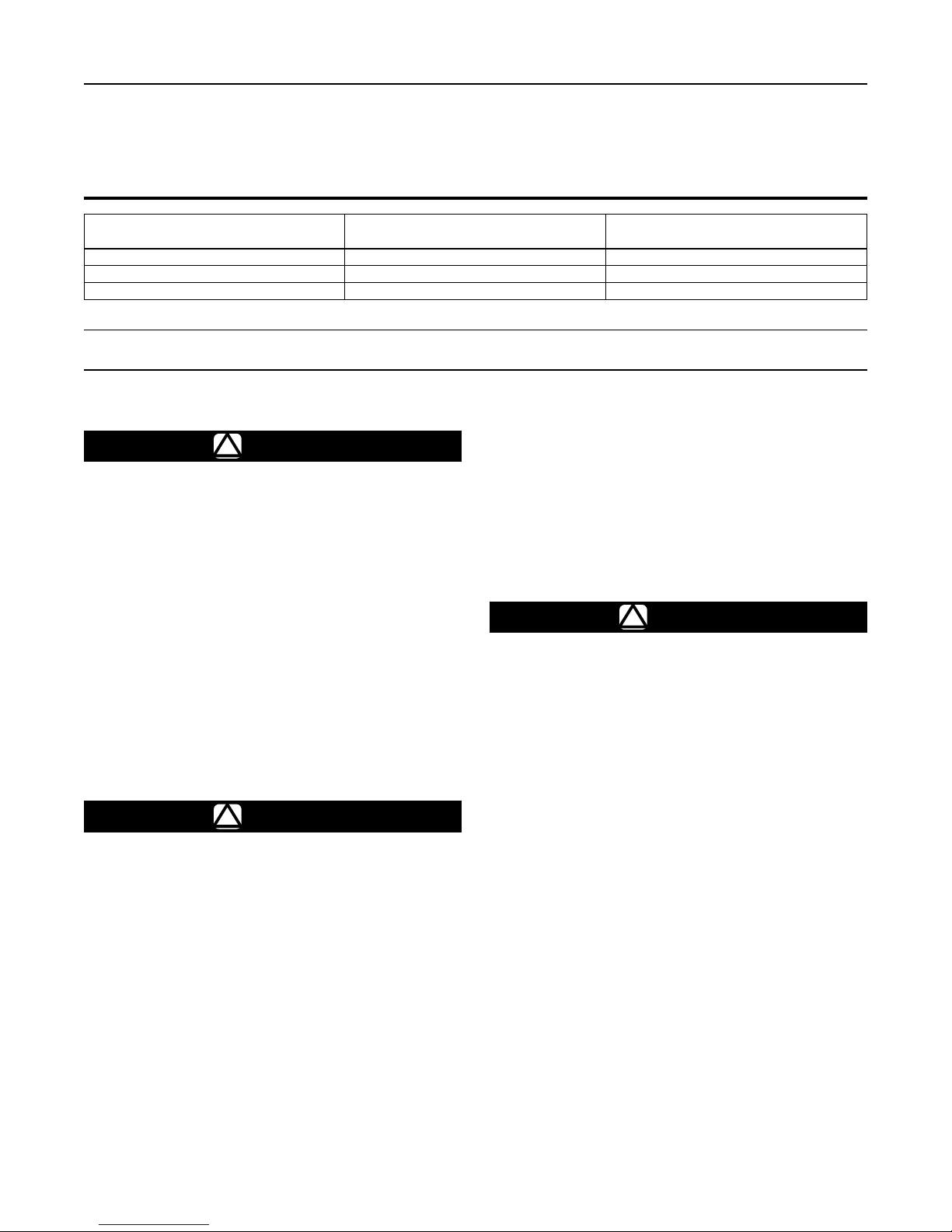

One preferred method of installation is shown in Figure 2

where the pipe connection to the valve and to the hose

coupling is securely anchored in a solid bulkhead.

A bobtail truck can provide enough pull on the hose

connection to cause a break in the system. That break must

not occur between the Type N551 and the storage tank.

PROPANE FLOW AT 2 psi / 0.14 bar

DIFFERENTIAL, GPM / l/min

WARNING

!

®

Kalrez

is a mark owned by E.I. Du Pont de Nemours and Co..

2

Page 3

HOSE CONNECTION

Types N551 and N851

12 / 305

OR MORE

HOSE CONNECTION

T20874

Figure 2. Typical Installation of Type N551 Using Remote Cable Release

Fusible Element Location

A fusible element that will close the Type N551 shall be located

within five feet of the hose connection. If the Type N551 is placed

within five feet of the hose connection, this requirement is met.

If not, an additional fusible element must be provided near the

hose coupling which will activate a remote release.

Remote Release Installation

In all installations a remote release shall be connected to the

latch on all emergency valves at the bulkhead. The remote

release has to extend to a place where it can be easily reached

to close the Type N551 valve(s) in the event that an emergency

makes the valve(s) inaccessible. The remote release shall

shutdown all emergency valves when activated. Remote

release activation may be by cable or pneumatic hook-up.

Cable Hook-Ups

WARNING

!

Remote release cables shall be installed so

that they will close the Type N551 valve(s)

when pulled from the farthest remote location.

Cable shall operate smoothly, over pulleys

and/or through conduit. Do not kink cable or

run cable around sharp corners. If installed

in conduit, keep water out of conduit. Frozen

water, dirt or dried mud in the conduit will

render the remote release inoperable.

Remote releases used on Type N551 valve

shall not:

(a) be made from plastic or ber rope;

(b) have any kind of fusible link which could

melt and prevent the cable from pulling

the Type N551 latch.

NAMEPLATE UP

EMERGENCY SHUTOFF

VALVE TYPE N551

REMOTE CABLE TO

SAFE LOCATION

FIXED PIPING

In. / mm

To provide a remote release, aircraft cable can be connected

to the short looped cable on the valve and run to the remote

release point over pulleys or through conduit. Adjust the cable

so that minimal pull is required to close the emergency valves.

Type P164B Cable Installation

To connect a Type P164B remote release assembly, which is

supplied with 50 ft. / 15 m of cable:

1. Run the inner cable and housing assembly to the

remote release point. Leave enough slack on each end

for a smooth, flowing path, without sharp bends in the

cable, between the Type N551 latch block and remote

release handle.

2. If it is necessary to cut the cable to a shorter length,

pull about one foot of inner cable from the Type N551

latch block cable end (end with the 3/16 x 1/2 in. / 4.8

x 13 mm long cylindrical cast fitting, see Figure 3) from

the housing.

At the remote release end (other end of inner

cablehousing assembly), cut the housing and inner

cable at desired length. Push the excess inner cable

back through the housing so that the bare cable extends

from the remote release end.

3. Close the Type N551 valve. Handle parallel to pipe.

4. If necessary for additional working space, remove the long

end of the external spring from under the latch block. DO

NOT REMOVE SPRING FROM HANDLE.

5. Loosen the slotted screw, Figure 3, on the Type N551

valve’s latch block until the plunger can be pulled from

the latch block.

6. Disconnect the short looped cable and remove it.

7. Insert the Type P164B inner cable end cylindrical cast

fitting through the latch block rear conical hole and connect

the cylindrical cast fitting into the side slot in the plunger.

3

Page 4

Types N551 and N851

REMOTE RELEASE END

CLAMP

CLAMP

3/16 x 1/2 / 4.8 x 13

CYLINDRICAL

CAST FITTING

TYPE N551

LATCH

BLOCK END

CABLE

HOUSING NUT

Figure 3. Type P164B Cable Release Installation Schematic

PLUNGER

SLOTTED PLUNGER SCREW

8. Replace the plunger in the latch block, oriented so the

screw will enter the plunger slot. Tighten the screw.

9. The end of the cable housing and cable housing nut fit

into the conical end of the latch block. Pulling the excess

inner cable through the housing from the remote release

end will hold the housing in the latch block.

10. Mount the remote release cylinder assembly to a

suitable support at the remote release location (7/16 in. /

11 mm diameter mounting hole) but do not tighten the

mounting nut.

11. At the remote release end, strip about 3/4 in. / 19 mm of

vinyl cover from the cable housing end.

12. Insert the inner cable completely through the release

cylinder. Screw the bare cable housing end into the

remote release cylinder by rotating the cylinder. Tighten

the mounting nut.

13. Pull any slack from the inner cable, just tight enough so

that the latch is not activated, and cut the inner cable

off 1 in.

14. Insert the 1 in.

/ 25 mm

past the remote release cylinder end.

/ 25 mm

bare inner cable into the remote

release handle shaft. Push the remote release handle

completely into the remote release cylinder. Tighten

the handle set screw to secure the handle to the

inner cable.

CAUTION

Possible hand and nger pinch point

between closing Type N551 handle and

latch block. Handle closes quickly and with

extreme force. Keep hands and ngers away

from handle as it closes.

1 / 25

HANDLE

SET

SCREW

REMOTE RELEASE CYLINDER

MOUNTING NUT

In. / mm

15. Test the remote release and Type N551 operation

from the most remote location. Rotate handle

counterclockwise to open valve. Valve must stay

open. HANDLE AND VALVE MUST QUICKLY “SNAP”

CLOSED when (a) the remote release cable is pulled and

(b) handle is pushed closed from the open position.

WARNING

!

All open Type N551 emergency valve(s)

attached to the remote release must properly

close when the release cable is pulled.

Pneumatic Hook-Up

Type P327D Pneumatic Release

Block Installation

If several valves are installed at the same location, remote

release may be accomplished with the Type P327D pneumatic

release block which replaces the cable latch block installed on

the Type N551 valve.

To install the Type P327D, see Figure 4:

1. Close the Type N551 valve. Handle is parallel to

the pipe.

2. Remove the long end of the external spring from

under the latch block. DO NOT REMOVE SPRING

FROM HANDLE.

3. Remove latch bolt(s). Older valves will have 2 bolts.

DISCARD CABLE LATCH BLOCK.

4

Page 5

Types N551 and N851

T40337

5/32 / 4 ALLEN HEAD

WRENCH REQUIRED

Figure 4. Type P327D Pneumatic Cylinder Installation

TO HOSE

5/32 / 4 ALLEN HEAD

WRENCH REQUIRED

AIR SOURCE – 1/8 NPT

NAMEPLATE

TO TANK

In. / mm

4. Use a 5/32 in. / 4 mm Allen head wrench to screw

1/4 in. / 6.4 mm long bolt into bottom hole.

5. Tighten until bolt head seats firmly on body.

6. Place latch block on body with lower blind hole over bolt

in body.

7. Install 3/4 in. / 19 mm long bolt through second hole and

firmly tighten with 5/32 in. / 4 mm Allen head wrench.

8. Refasten long end of spring under latch block by

ROTATING 180 DEGREES CLOCKWISE.

9. Attach the remote air source to the cylinder end with

appropriate supply tubing and valving. A regulated

air supply of 30 to 70 psig / 2.1 to 4.8 bar to the

Type P327D pneumatic release cylinder is required for

proper operation.

CAUTION

Possible hand and nger pinch point

between closing Type N551 handle and

latch block. Handle closes quickly and with

extreme force. Keep hands and ngers away

from handle as it closes.

10. Test the remote release and Type N551 operation.

Rotate handle counter clockwise to open valve. Valve

must stay open. HANDLE AND VALVE MUST QUICKLY

“SNAP” CLOSED when (a) air pressure is exhausted

from Type P327D pneumatic remote release and (b) the

handle is pushed closed from the open position.

WARNING

!

All open Type N551 Emergency Valve(s)

attached to the remote pneumatic release

system must properly close when air

pressure is exhausted from the system.

Remote release controls must quickly

exhaust pressure from the supply line to

close emergency valves.

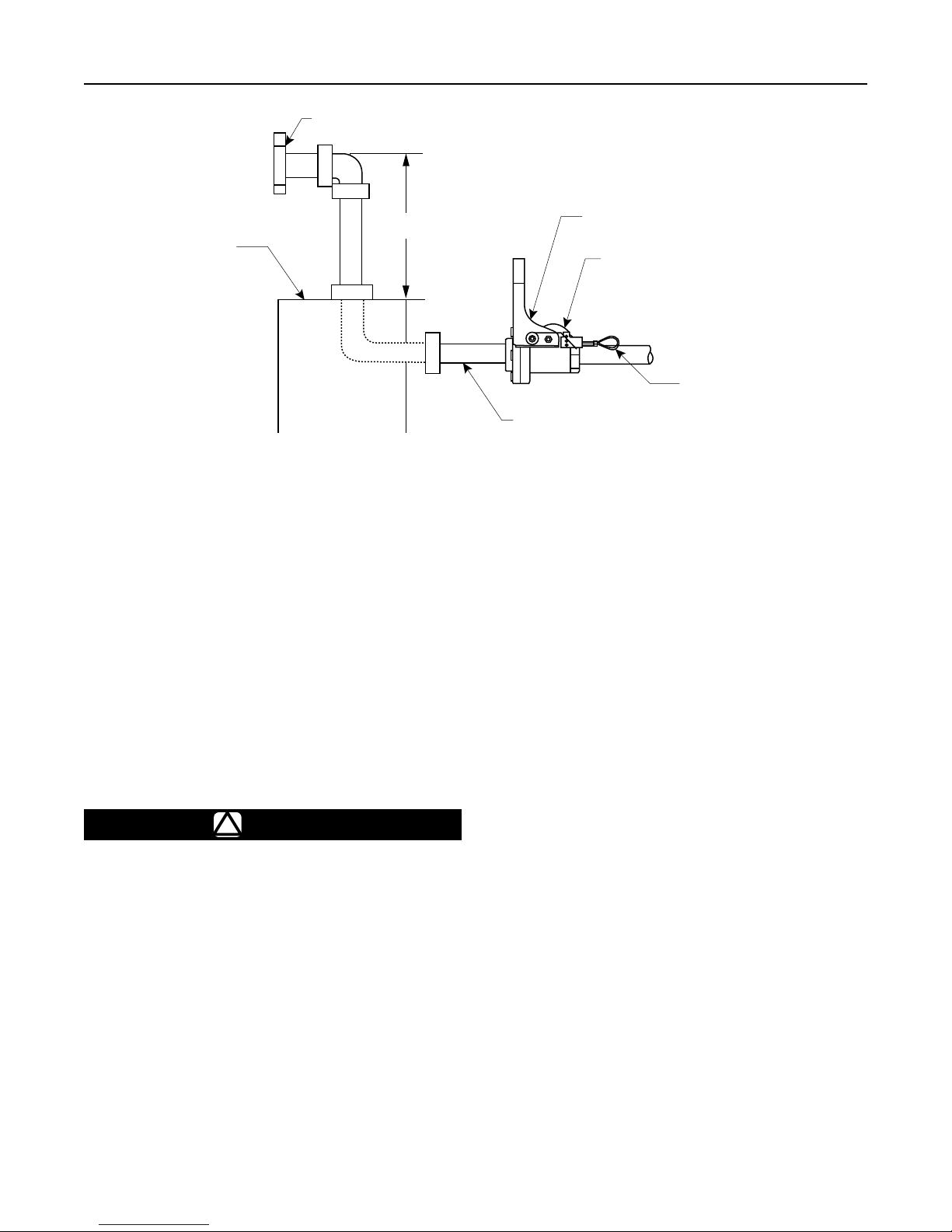

Optional Motion Release Cable

With either the cable or pneumatic remote release hookups, it is possible to connect an additional cable from the

Type N551’s operating handle to the truck along the transfer

hose(s). This cable would close the valve if the hose(s) is

stretched (driver does not disconnect) beyond a preselected

limit. The hook-up does not affect the normal operation of

the valve.

Motion Release Cable Installation

1. Connect a suitable release cable such as stainless steel

aircraft cable to a standard “S” hook. Attach the “S” hook

to the Type N551 handle as shown in Figure 5.

2. The cable should run through the bulkhead just below

and to the side of the pipe. The cable should be in line

with the operating lever, refer to Figure 5.

5

Page 6

Types N551 and N851

HOSE CONNECTION

12 / 305

OR MORE

T20995

BULKHEAD

TO TRUCK

Figure 5. Motion Release Cable Installation (Optional)

3. Leave enough slack in the cable to allow the Type N551

lever to move freely but not close during normal hose

movement or hook-up.

4. Run the cable along the hose. Tape or secure it to

the hose. Fasten the cable securely to the “truck” end

hose connection.

When the hose stretches more than the amount of slack left

in the cable, the tightening cable will pull the lever down and

close the Type N551 valve.

FIXED PIPING

NAMEPLATE UP

EMERGENCY SHUTOFF

VALVE TYPE N551

REMOTE ACTIVATION METHOD,

CABLE OR PNEUMATIC,

ATTACHMENT LOCATION

CABLE

1 / 25

“S” HOOK

slowly, packing replacement (refer to Type N551

Packing Removal/Replacement Instruction Manual,

D450355T012) may be required.

2. Make sure that the lever, latch and release are

working smoothly. The latch parts and lever are easily

accessible for replacement or repair by removing the

securing bolts.

3. Check for packing and joint leakage.

Replacing Internal Parts

IN. / mm

Maintenance

WARNING

!

Only qualied service personnel should

attempt to repair these valves. Before starting

any type of repair, close off the upstream

valves and remove all pressure from both the

inlet and outlet of the Type N551 Emergency

Shutoff Valve.

At least once a month, inspect and check the

following things:

1. See that the remote release is properly connected,

works freely and is not worn. Operate the release to

make certain it closes the valve. If the valve closes

6

Verify that the Emergency Shutoff Valve is Type N551 and

not the previous version Type N550 by confirming that it is

marked with “1” as shown in Figure 7.

Type N551 can be repaired in the field. However, due to the

special fire resistant seals and assembly techniques, repairs

should be done only by trained personnel. If repair should

become necessary, contact your local LPG Equipment

Distributor for information and assistance.

Only parts manufactured by Emerson™ should be used for the

repair of Fisher® Type N551 Valve. Be sure to give the complete

type number of the Type N551 when corresponding with your

local distributor.

Type N551 valve that have been disassembled for repair

must be tested for proper operation before being returned

to service.

Page 7

Types N551 and N851

39

WITH ITEM 46 (NUT)

NOT SHOWN

41

TORQUE:

36

37

63

64

38

21

20

35

34

9

33

32

22

3 TO 4 FT-LBS /

4.1 TO 5.4 N•m

L2

TORQUE:

19

10 TO 15 FT-LBS /

13.6 TO 20.3 N•m

TORQUE:

L1

6 TO 7 FT-LBS /

8.1 TO 9.5 N•m

61

S1

23

62

43

TORQUE:

8 TO 9 FT-LBS /

10.8 TO 12.2 N•m

24

15

16

25

27

28 29

L2

ERAA06717_AC

APPLY LUBRICANT (L) OR SEALANT (S)

L1 = High Temperature Anti-Seize and Extreme Pressure Nickel Lubricant

L2 = Multi-Purpose Polytetrauoroethylene (PTFE) Lubricant

S1 = Medium Strength Threadlocker

1. Lubricants and sealants must be selected such that they meet the temperature requirements.

30 65

L2

L2

(1)

31

18

L2

:

TYPE N551-10 ONLY

47

45

TORQUE:

3 TO 4 FT-LBS /

4.1 TO 5.4 N•m

40

41

L1

8

17

42

L2

TORQUE:

40 TO 55 FT-LBS / 54.2 TO 74.6 N•m FOR TYPE N551-10

50 TO 60 FT-LBS / 67.8 TO 81.3 N•m FOR TYPE N551-16

1

5

4

7

6

L2

2

3 L1

Figure 6. Type N551 Shutoff Valve Assemblies

Figure 7. Type N551 body marked with “1”

7

Page 8

Types N551 and N851

Parts List

Key Description Part Number

Packing Assembly Kit RCN551T0012

Includes packing stack (key 30), O-ring (key 65)

and two washers (key 29).

1 Body, Ductile iron

Type N551-10 (NPS 1-1/4 FNPT) ERSA05033A0

Type N551-16 (NPS 2 FNPT) ERSA05031A0

Type N551-24 (NPS 3 FNPT) ERSA05032A0

2 Flange, Ductile iron

Type N551-10 (NPS 1-1/4 FNPT) ERAA00718A0

Type N551-16 (NPS 2 FNPT) T12783T0YW2

Type N551-24 (NPS 3 FNPT) T20699T0YW2

3 Cap Screw

Type N551-10 (NPS 1-1/4 FNPT) (4 Required) T12864T0012

Type N551-16 (NPS 2 FNPT) (4 Required) 1E760432992

Type N551-24 (NPS 3 FNPT) (8 Required) 1E760432992

4* Seat Ring, Stainless steel

Type N551-10 (NPS 1-1/4 FNPT) T12857T0012

Type N551-16 (NPS 2 FNPT) T12548T0012

Type N551-24 (NPS 3 FNPT) T12887T0012

5* Sealing Ring, Nitrile (NBR)

Type N551-10 (NPS 1-1/4 FNPT) T12858T0012

Type N551-16 (NPS 2 FNPT) T12547T0012

Type N551-24 (NPS 3 FNPT) T12891T0012

6* O-ring, Nitrile (NBR)

Type N551-10 (NPS 1-1/4 FNPT) 10A3800X032

Type N551-16 (NPS 2 FNPT) 1H8762X0022

Type N551-24 (NPS 3 FNPT) T12759T0012

7* Gasket, Graphite

Type N551-10 (NPS 1-1/4 FNPT) T12863T0012

Type N551-16 (NPS 2 FNPT) T12839T0012

Type N551-24 (NPS 3 FNPT) T12890T0012

8 Poppet Sub-Assembly

Type N551-10 (NPS 1-1/4 FNPT) T12964T0012

Type N551-16 (NPS 2 FNPT) T12965T0012

Type N551-24 (NPS 3 FNPT) T12966T0012

9 Pipe Plug T13718T0012

15 Shaft, Stainless steel

Type N551-10 (NPS 1-1/4 FNPT) ERSA05039A0

Type N551-16 (NPS 2 FNPT) ERSA05038A0

Type N551-24 (NPS 3 FNPT) ERSA05040A0

*Recommended spare part.

1. Applicable for Type N551-10 (NPS 1-1/4 FNPT) only.

Key Description Part Number

16 Sleeve, Nylon (PA)

Type N551-10 (NPS 1-1/4 FNPT) T12842T0012

Type N551-16 (NPS 2 FNPT) T12842T0012

Type N551-24 (NPS 3 FNPT) T12893T0012

17 Nameplate - - - - - - - - - - 18 Handle, Aluminum T20677T0012

19 Shoulder bolt, Alloy steel-plate T12853T0012

20 Nut, Carbon steel T1166228982

21 Roller, Nylon (PA) T12847T0012

22 Fuse link, Brass T13500T0012

23 Bolt, Zinc-plated steel 1B290524052

24 Retainer, Zinc-plated steel T12843T0012

25 Spring, 302 Stainless steel

Type N551-10 (NPS 1-1/4 FNPT) T12844T0012

Type N551-16 (NPS 2 FNPT) T12844T0012

Type N551-24 (NPT 3 FNPT) T13005T0012

27 Gland, 303/416 Stainless steel

Type N551-10 (NPS 1-1/4 FNPT) ERSA05036A0

Type N551-16 (NPS 2 FNPT) ERSA05036A0

Type N551-24 (NPS 3 FNPT) ERSA05037A0

28* Spring, 302 Stainless steel T12851T0012

29* Washer, Carbon steel (2 Required) T1207524082

30* Packing Stack T12854T0012

31* Follower, 174 Stainless steel T12841T0012

32 Retainer, Steel ERSA05035A0

33 Bolt, Stainless steel (2 Required) T12499T0012

34 Bushing T12551T0012

35 Washer, Nylon (PA) T12781T0012

36 Latch Block, Aluminum T13800T0012

37 Spring, 302 Stainless steel T13877T0012

38 Plunger, Polyester T12846T0012

39 Cable T12849T0012

40 Screw, Carbon steel 1E175828982

41 Bolt T12980T0012

42 Drive Screw, 18-8 Stainless steel (2 Required) 1A368228982

(1)

Adaptor Plate, Zinc-plated steel T12878T0012

43

(1)

Cap Screw 1D617032992

45

(1)

Nut (Not Shown) T1022724122

46

47 Handgrip T12928T0012

61 Spring, Mandrel T13826T0012

62 Spring, Torsion T20973T0012

63 Bolt, Alloy steel T13803T0012

64 Cap Screw, Carbon steel GE25968X012

65* O-ring, Nitrile (NBR) T1224006562

LPG Equipment

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S.: +1 972 548 3574

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc,. 2014, 2015; All Rights Reserved

Loading...

Loading...